Page 1

Operating manual

G 1910-02

Compact CO2 monitor with alarm

EN

Page 2

Table of contents

2 / 30

B-H90.0.01.DB2-2.1

Table of contents

1 About this documentation .......................................................................................................................... 4

1.1 Foreword .......................................................................................................................................................... 4

1.2 Purpose of the document ............................................................................................................................... 4

1.3 Legal notices .................................................................................................................................................... 4

1.4 Correctness of content ................................................................................................................................... 4

1.5 Layout of this document ................................................................................................................................. 4

1.6 Further information .......................................................................................................................................... 5

2 Safety ............................................................................................................................................................... 6

2.1 Explanation of safety symbols ....................................................................................................................... 6

2.2 Foreseeable misuse ....................................................................................................................................... 6

2.3 Safety instructions ........................................................................................................................................... 7

2.4 Intended use .................................................................................................................................................... 8

2.5 Qualified personnel ......................................................................................................................................... 8

3 Description ..................................................................................................................................................... 9

3.1 Scope of delivery ............................................................................................................................................. 9

3.2 Functional description..................................................................................................................................... 9

4 The product at a glance ............................................................................................................................. 10

4.1 The G 1910-02 .............................................................................................................................................. 10

4.2 Display elements ........................................................................................................................................... 10

4.3 Operating elements....................................................................................................................................... 10

4.4 Connections ................................................................................................................................................... 11

5 Operation ...................................................................................................................................................... 12

5.1 Commissioning .............................................................................................................................................. 12

5.1.1 Explanation ......................................................................................................................................... 12

5.2 Configuration.................................................................................................................................................. 12

5.2.1 Explanation ......................................................................................................................................... 12

5.2.2 Opening the configuration menu .................................................................................................... 12

5.2.3 Configuring parameters of the configuration menu ..................................................................... 13

5.2.4 Call-up of the expanded settings menu .......................................................................................... 15

5.2.5 Configure parameters of the expanded settings menu ................................................................ 16

6 Measurement Basics .................................................................................................................................. 18

6.1 NDIR CO2 sensor .......................................................................................................................................... 18

6.1.1 Explanation ......................................................................................................................................... 18

6.1.2 Design.................................................................................................................................................. 18

7 Operation and maintenance ..................................................................................................................... 19

7.1 Operating and maintenance notices .......................................................................................................... 19

7.2 Battery ............................................................................................................................................................. 19

7.2.1 Charge status display ........................................................................................................................ 19

7.2.2 Charging the batteries ....................................................................................................................... 19

7.2.3 Rechargeable battery replacement .................................................................................................. 20

7.3 CO2 adjustment ............................................................................................................................................. 21

8 Error and system messages .................................................................................................................... 24

9 Disposal ......................................................................................................................................................... 26

10 Technical data .............................................................................................................................................. 27

11 Spare parts and accessories ................................................................................................................... 28

Page 3

Table of contents

B-H90.0.01.DB2-2.1

3 / 30

12 Service ........................................................................................................................................................... 29

12.1 Manufacturer .................................................................................................................................................. 29

12.2 Repairs processing ........................................................................................................................................ 29

12.3 Sales offices ................................................................................................................................................... 29

Page 4

1 | About this documentation

G 1910-02

4 / 30

B-H90.0.01.DB2-2.1

1 About this documentation

1.1 Foreword

Read this document carefully and familiarise yourself with the operation of the product

before you use it. Keep this document ready to hand and in the immediate vicinity of

the product so that it is available to the personnel/user for reference at all times in

case of doubt.

The product was developed according to the state of the art and fulfils the requirements of the applicable European and national Directives. All corresponding documents are available from the manufacturer.

Only technically qualified persons are permitted to carry out commissioning, operation,

maintenance and decommissioning. The qualified personnel must have carefully read

and understood the operating manual before beginning any work.

1.2 Purpose of the document

– It provides important information for operating safely and efficiently with the prod-

uct.

– In addition to the quick reference guide with all relevant legal and safety content in

hard copy, this document is a detailed reference option for the product.

1.3 Legal notices

The liability and warranty of the manufacturer for damages and consequential damages are voided with misuse, disregarding this document, disregarding safety notices,

assignment of inadequately qualified technical personnel and arbitrary modifications of

the product.

Only carry out the maintenance and service tasks on this product that are described in

this documentation. In the process, adhere to the specified steps. For your own safety,

only use original spare parts and accessories of the manufacturer. We assume no liability for the use of other products and resulting damage.

This document is entrusted to the recipient for personal use only. Any impermissible

transfer, duplication, translation into other languages or excerpts from this operating

manual are prohibited.

The manufacturer assumes no liability for print errors.

1.4 Correctness of content

The contents of this document were checked for corrected and are subject to a continuous correction and updating process. This does not rule out potential errors. In the

event that errors are discovered or in case of suggestions for improvement, please

inform us immediately via the indicated contact information in order to help us make

this document even more user-friendly.

1.5 Layout of this document

Description

Each chapter is explained at the beginning in the description.

Page 5

G 1910-02

About this documentation | 1

B-H90.0.01.DB2-2.1

5 / 30

Prerequisite

All mandatory prerequisites are then listed for each step.

Instruction

Tasks to be carried out by the personnel / user are represented as numbered instructions. Adhere to the sequence of the specified instructions.

Representation

Shows an illustrative instruction or a configuration of the product.

Formula

Some instructions include a formula for a general understanding of a configuration,

programming or a setting of the product.

Outcome of an action

Result, consequence or effect of an instruction.

Emphases

In order to simplify legibility and provide a clearer overview, various sections / information are emphasised.

– 1234 Display elements

– Mechanical controls

– Product functions

– Product labels

– Cross-reference [ 4]

– Foot notes

1.6 Further information

Software version of the product:

– V1.6 or later

Page 6

2 | Safety

G 1910-02

6 / 30

B-H90.0.01.DB2-2.1

2 Safety

2.1 Explanation of safety symbols

DANGER

This symbol warns of imminent danger, which can result in death, severe bodily injury,

or severe property damage in case of non-observance.

CAUTION

This symbol warns of potential dangers or harmful situations, which can cause damage to the device or to the environment in case of non-observance.

NOTE

This symbol indicates processes, which can have a direct influence on operation or

can trigger an unforeseen reaction in case of non-observance.

2.2 Foreseeable misuse

The fault-free function and operational safety of the product can only be guaranteed if

applicable safety precautions and the device-specific safety instructions for this document are observed.

If these notices are disregarded, personal injury or death, as well as property damage

can occur.

DANGER

Incorrect area of application!

In order to prevent erratic behaviour of the product, personal injury or property damage, the product must be used exclusively as described in the chapter Description

[ 9] in the operating manual.

– Do not use in safety / Emergency Stop devices!

– The product is not suitable for use in explosion-prone areas!

– The product must not be used for diagnostic or other medical purposes on pa-

tients!

– The product is not intended to come into direct contact with food!

– Not suitable for use with requirements on functional safety, e.g. SIL!

Page 7

G 1910-02

Safety | 2

B-H90.0.01.DB2-2.1

7 / 30

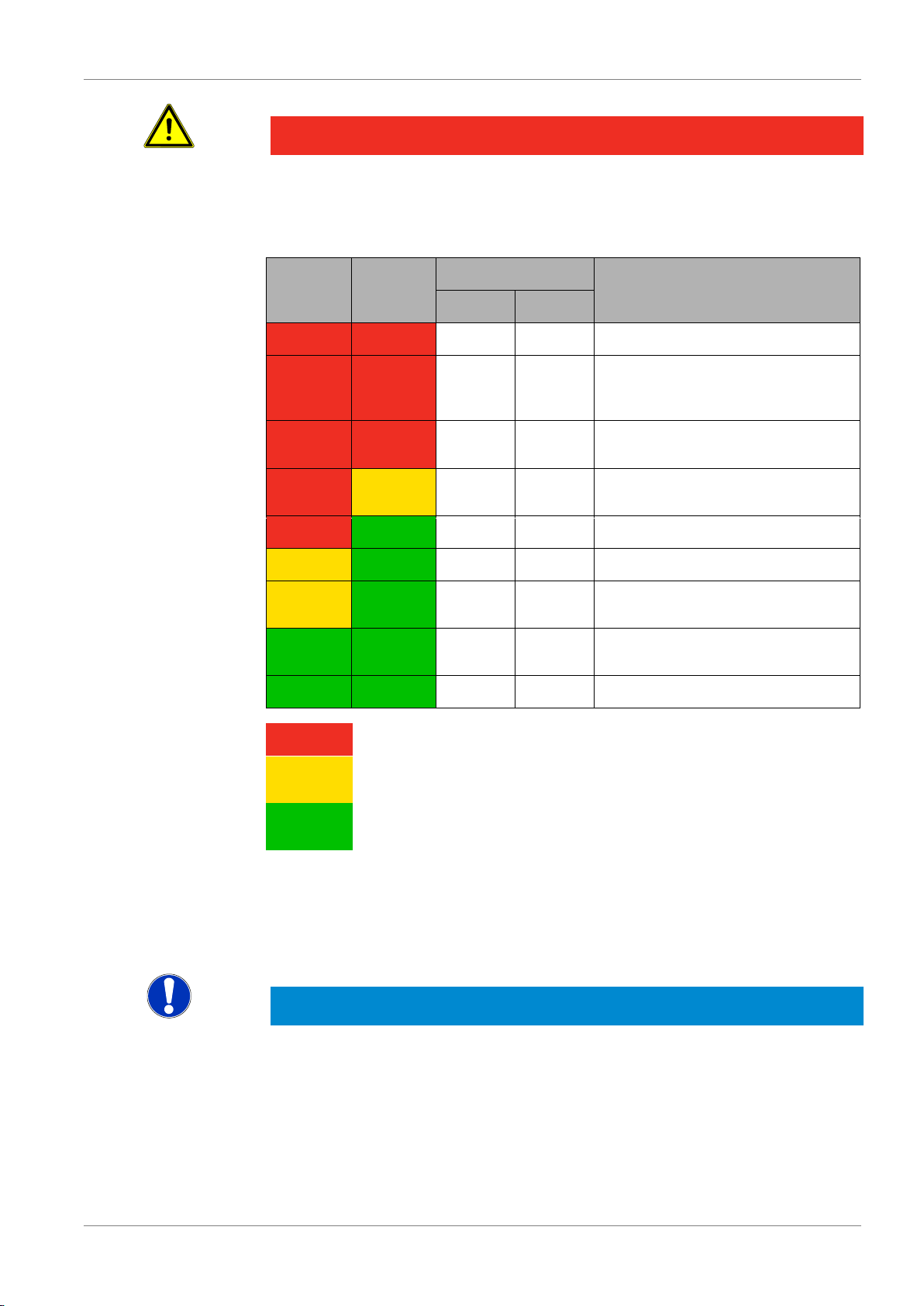

DANGER

Danger due to elevated CO2 concentration

The product is not suitable for use as personal protective equipment with elevated

CO2 levels. However, it can indicate an elevated CO2 value. The measured value appears in the display as a % or ppm value.

G 1910-02

G 1910-20

CO2 concentration

Effect

%

ppm

20 Death within a few seconds

10 Loss of consciousness, death, dizziness, vomiting, headaches, reduced

blood flow to brain

4.0 IDLH - immediate danger to life and

health

3.0 Normal exhalation concentration, elevated breathing and pulse rate

2,0

20,000

1.0

10,000

Possible shortness of breath

0.5

5000

TWA – Maximum for working conditions

0.1 .. 0.2

1000 ..

2000

Recommended maximum value in

public areas

0.04

400

Fresh air

Product is not permitted for the area

Expanded measuring range. The product can be

used conditionally

Area of application of the product with specified

accuracy

The values are guideline values. Depending on the health condition and duration of

exposure, problems can also occur below the indicated concentrations under certain

circumstances.

2.3 Safety instructions

NOTE

This product does not belong in children's hands!

Page 8

2 | Safety

G 1910-02

8 / 30

B-H90.0.01.DB2-2.1

2.4 Intended use

The product is designed exclusively for measurements in ambient air and environments with slightly elevated CO2 concentrations in areas that are not harmful to the

health. It is designed to be carried on the body for mobile use. The user can be

warned optically and acoustically of elevated CO2 concentrations based on variable

alarm limits. Example applications for this are:

– Use as a monitor for recording of the mean value weighted over 8 hours (TWA) or

15 minutes (STEL).

– Monitoring of air quality.

2.5 Qualified personnel

For commissioning, operation and maintenance, the relevant personnel must have

adequate knowledge of the measuring process and the significance of the measurements. This document makes a valuable contribution to this. The instructions in this

document must be understood, observed and followed.

In order to avoid any risks arising from interpretation of the measurements in the concrete application, the user must have additional expertise. The user is solely liable for

damages/danger resulting from misinterpretation due to inadequate expertise.

Page 9

G 1910-02

Description | 3

B-H90.0.01.DB2-2.1

9 / 30

3 Description

3.1 Scope of delivery

Please check to ensure the completeness of the product after opening the package.

You should find the following components:

– Quick reference guide

– Handheld measuring device, ready for operation, including rechargeable batteries

– Micro USB to USB type A connection cable

3.2 Functional description

The product offers precision, speed and reliability in a compact, ergonomic housing. It

is distinguished by an illuminated 3-line display. The product can be switched on,

switched off and configured and the measurements and parameters can be adjusted

and held with the operating elements. The product is equipped with an integrated optical carbon dioxide sensor. In addition to display of the currently measured CO2 value,

the mean value weighted over 8 hours (TWA) or 15 minutes (STEL) can be output.

An integrated two-stage alarm also issues an optical signal and an acoustic signal as

a warning when the adjusted limits are exceeded.

– A pre-alarm issues a text warning or the backlight flashes with a brief horn when

the limit is exceeded depending on the setting.

– A pre-alarm issues a text warning or the backlight flashes rapidly with a continu-

ous horn when the limit is exceeded depending on the setting.

Page 10

10 / 30

B-H90.0.01.DB2-2.1

4 | The product at a glance

G 1910-02

4 The product at a glance

4.1 The G 1910-02

LCD Display

Front view

Sensor openings

Micro USB socket

4.2 Display elements

Display

Charge status display

Evaluation of the charge status

Unit display

Display of units or type of mode, min/max/hold

Main display

Measurement of the current CO2 value

Auxiliary display

Display of the mean value

Bar graph

Visualisation of the CO2 value

4.3 Operating elements

On / Off button

Press briefly

Switch on the product

Activate / deactivate lighting

Long press

Switch off the product

Reject changes in a menu

Up / Down button

Press briefly

Display of the min/max value

Change value of the selected parameter

Long press

Reset the min/max value of the current measurement

Both simultaneously

Rotate display, overhead display

Page 11

G 1910-02

The product at a glance | 4

B-H90.0.01.DB2-2.1

11 / 30

Function key

Press briefly

Freeze measurement (Hold)

Return to measurement display

Call up next parameter

Long press, 2s

Start menu configuration, (ONF appears in the display

4.4 Connections

Micro USB socket

Charging the batteries

Page 12

12 / 30

B-H90.0.01.DB2-2.1

5 | Operation

G 1910-02

5 Operation

5.1 Commissioning

5.1.1 Explanation

The product is switched on with the On/Off button. It may be necessary to configure

the product after switching on. See Configuration [ 12].

A self-test is conducted after switching on. The following increasing CO2 values 1000,

2000, 4000 and 8000 are shown in the display. TEST is shown in the secondary display.

If an alarm is active and is in one of these relevant areas, it is triggered.

If ---- appears in the display after the self-test, the sensor is not ready for measure-

ment.

If batteries are drained and the product is not used for an extended time, it can take up

to 30 seconds until the measurement starts. If no measurement is received by the

sensor within 30 seconds, the product issues an alarm.

– The rechargeable batteries have been charged via the micro USB socket.

– Press the On/Off button.

Information about the configuration of the product appears in the display.

TEST

Self-test

An automatic self-test is carried out during system

start-up. The bar indicator for the threshold value is

displayed and the alarm is tested if it has been activated.

POFF

Automatic shutoff

Automatic shut-off activated. The product is

switched off if no buttons have been pressed after

the adjusted time

– The product is now ready for measurement.

5.2 Configuration

5.2.1 Explanation

The following steps describe how to adapt the product for your purposes.

NOTE

There are various configuration parameters available depending on the product version and configuration. These can vary depending on the product version and configuration.

5.2.2 Opening the configuration menu

In order to configure the product, you must first open the Configuration menu. The

menu is opened as shown in the illustration.

1. Press the Function key for 2 seconds to open the Configuration menu.

2. (ONF appears in the display. Release the function key.

Description

Prerequisite

Instruction

Outcome of an action

Description

Prerequisite

Instruction

Page 13

G 1910-02

Operation | 5

B-H90.0.01.DB2-2.1

13 / 30

3. By briefly pressing the Function key, you can scroll through the parameters. Select

the parameter you would like to configure.

4. When you have selected the desired parameter, change the parameter to the de-

sired value with the Up button and the Down button.

5. The changes are saved after running through the entire Configuration menu. STOR

appears in the display. The Configuration menu can be exited from any arbitrary

parameter by pressing and holding the Function key for 2 seconds. The changes

made up that point are saved.

Call up menu

Next parameter

Change value

Save changes

Discard

changes

2s Press: Single

step

Hold: Fast

change

2s

2s

Product is

switched off

The Configuration menu is closed after the last parameter.

NOTE

If the product is switched off without saving the configuration, the last save value is

reproduced on the next start-up of the product.

5.2.3 Configuring parameters of the configuration

menu

The following representation shows the available parameters and various configuration options.

– The Configuration menu is open. See Opening the configuration menu [ 12].

1. Select the desired parameter you would like to configure.

2. Adjust the desired configuration in the selected parameter with the Up button and

Down button.

3. The available configuration options are listed for each parameter in the following

representation.

The changed value is saved and the Configuration menu is closed. STOR appears in

the display. If necessary, the product is restarted automatically in order to adopt the

changed values.

NOTE

The configuration is closed if no button is pressed for 2 minutes. Any changes made

up to that point are not saved. C.END appears in the display.

Parameter

Values

Meaning

Representation

Outcome of an action

Description

Prerequisite

Instruction

Outcome of an action

Representation

Page 14

14 / 30

B-H90.0.01.DB2-2.1

5 | Operation

G 1910-02

Input

INP

%

CO2 measurement in %

PPm

CO2 measurement in ppm

Alarms

AL.

OFF

No active alarm

ON

Alarm alerting via text display, acoustic signal and

flashing of the backlighting

BEEP

Alarm alerting via text display and acoustic signal

L,TE

Alarm alerting via text display and flashing of the

backlighting

AL.1 Depending on the setting of the parameter value INP

0.000 .. AL.2

0 .. AL2

Min. alarm limit in % or ppm; a pre-alarm is triggered when the value is exceeded

When the pre-alarm is triggered, it can be muted for

5 minutes. To do this, press any key. The display

shows (LR AL.1.

AL.2 Depending on the setting of the parameter value INP

AL.1 .. 1.000

AL1 .. 10000

Max. alarm limit in % or ppm; the main alarm is triggered when the value is exceeded

Mean value

LCD.2

8 H

Time weighted over 8 hours, mean value TWA

STEL

Time weighted over 15 minutes, mean value STEL

OFF

Mean value determination deactivated

Shut-off time

POFF

OFF

No automatic shut-off

0:15 0:30 1:00 4:00

12:00

Automatic shut-off after a selected time in hours

and minutes, during which no buttons have been

pressed

Page 15

G 1910-02

Operation | 5

B-H90.0.01.DB2-2.1

15 / 30

Backlight

L,TE

OFF

Backlight deactivated

0:15 0:30 1:00 4:00

Automatic shut-off of the backlight after a selected

time in minutes and seconds, during which no buttons have been pressed

ON

No automatic shut off of the backlight

Factory settings

IN,T

NO

Use current configuration

YES

Reset product to factory settings. IN,T DONE appears

in the display

5.2.4 Call-up of the expanded settings menu

In order to configure the product, you must first open the Expanded settings menu.

The menu is opened as shown in the illustration.

– The product is switched off.

1. Press and hold the Down button.

2. Press the On/Off button to switch on the product.

3. Release the On/Off button after 1 second and then the Down button in order to call

up the Expanded settings menu. The display shows the first parameter.

4. By briefly pressing the Function key, you can scroll through the parameters. Select

the parameter you would like to configure.

5. When you have selected the desired parameter, change the parameter to the de-

sired value with the Up key and the Down key.

6. In order to save the new parameter value, press and hold the Function key for

longer than 2 seconds.

Call up menu

Hold

1s

Release

Release

The Expanded settings menu is closed after the last parameter.

Description

Prerequisite

Instruction

Representation

Outcome of an action

Page 16

16 / 30

B-H90.0.01.DB2-2.1

5 | Operation

G 1910-02

NOTE

If the Expanded settings menu is processed completely, the changes are saved automatically. STOR appears in the display. However, it can be exited at any time by press-

ing the Function key for 2 seconds. The changes made up that point are also saved.

If the product is switched off without saving the configuration, the last save value is

reproduced on the next start-up of the product.

5.2.5 Configure parameters of the expanded settings

menu

The following representation shows the available parameters and various configuration options.

– The Expanded settings menu is called up. See Call-up of the expanded settings

menu [ 15].

1. Select the desired parameter you would like to configure.

2. Adjust the desired configuration in the selected parameter with the Up key and

Down key.

3. The available configuration options are listed for each parameter in the following

representation.

Parameter

Values

Meaning

Adjustment

[AL

OFF

No adjustment

2.PT

2-point adjustment

1.PT

1-point adjustment

KARD

Basic sensor adjustment

Only 0 ppm or 0.000 % can be selected as a set-

point value for the adjustment, such as, for example

on nitrogen or 400 ppm or 0.040 % for adjustment

on clean ambient air.

Gradient adjustment specification

[.SL

350 .. 10,000

0.035 .. 1.000

Setpoint value in ppm or in % for 1.PT or 2.PT adjustment

0 / 400

0.000 / 0.040

Setpoint value in % or in ppm for KARD adjustment

Description

Prerequisite

Instruction

Representation

Page 17

G 1910-02

Operation | 5

B-H90.0.01.DB2-2.1

17 / 30

NOTE

The setpoint value of 400 ppm or depending on selection 0.040 % can be used for a

simple adjustment in clean ambient air. Otherwise, use the expected value of the test

gas according to the analysis certificate or display value of the reference device.

The changed value is saved and the Expanded settings menu is closed. STOR appears

in the display.

NOTE

If the product is switched off without saving the configuration, the last save value is

reproduced on the next start-up of the product.

Outcome of an action

Page 18

6 | Measurement Basics

G 1910-02

18 / 30

B-H90.0.01.DB2-2.1

6 Measurement Basics

6.1 NDIR CO2 sensor

6.1.1 Explanation

The sensors are based on non-dispersive infrared sensor technology, NDIR. This is

the most widely used sensor technology for CO2 measurement.

The principle of the NDIR sensor is that an IR light source is focusses so that an optical beam is created, which passes through the existing gas, including CO2. After an

optical band pass filter is passed, an IR sensor measures the level of IR light, wherein

the CO2 values in the optical path are displayed.

6.1.2 Design

1. Gas inlet

2. Gas outlet

3. IR lamp

4. Optical filter

5. Thermopile detector

IR detectors

A sensor module with single-channel detectors is used for the product.

A micro light bulb is used as an IR radiation source. It emits a broadband spectrum.

The sensor is long-lasting and maintenance-free. In order to be able to maintain the

specified accuracy for many years to come, regular adjustment must be carried out

depending on the required accuracy.

IR radiation source

Page 19

B-H90.0.01.DB2-2.1

G 1910-02

19 / 30

Operation and maintenance | 7

7 Operation and maintenance

7.1 Operating and maintenance notices

CAUTION

Damage to the sensor

A sensitive optical sensor is installed in the product. The sensor parameters can

change due to impact or falling. This can result in incorrect measurements.

– Protect the product from impact and falling!

– The measurements must be checked after the product falls or is jarred. If the val-

ues deviate, a basic sensor adjustment must be carried out!

NOTE

The product must be handled with care and used in accordance with the technical

data. Do not throw or strike.

NOTE

If the product is stored at a temperature above 50 °C, or is not used for an extended

period of time, the batteries must be removed or recharged regularly. This prevents

leaks from the rechargeable batteries and increases the life of the rechargeable batteries.

7.2 Battery

7.2.1 Charge status display

If the battery status display blinks, the batteries are depleted and must be recharged.

However, the device will still operate for a certain length of time.

If the BAT display text appears in the main display, the rechargeable battery voltage is

no longer adequate for operation of the product. Now the rechargeable battery is fully

depleted.

7.2.2 Charging the batteries

– Charge via Micro USB socket with the accompanying cable.

– Must be operated on a USB port or USB mains adapter with an output voltage of

4.75 V .. 5.25 V, which can deliver a current of 500 mA.

– The charging process is visualised in the charge status display.

– If the charging process has concluded BAT FVLL is shown in the display.

– Charging at room temperature in a range of 0 .. 40 °C is permitted.

– The device can heat up during charging. Max. up to 50 °C.

– Charging time approx. 8 hours.

– The charging time can take longer in ambient temperatures above 30 °C.

– The rechargeable battery temperature is monitored. At temperatures below 0 °C

and above 50 °C, the charging is interrupted.

Page 20

20 / 30

B-H90.0.01.DB2-2.1

7 | Operation and maintenance

G 1910-02

– In order to protect the batteries, the charging process is not started when the

charge cable is plugged in, if fully charged batteries are detected based on the

voltage monitor.

7.2.3 Rechargeable battery replacement

DANGER

Danger of explosion!

Using damaged or unsuitable rechargeable batteries can generate heat, which can

cause the rechargeable batteries to crack and possibly explode!

– Only use high-quality and suitable NiMH rechargeable batteries!

CAUTION

Damage!

If the rechargeable batteries have different charge levels, leaks and thus damage to

the product can occur.

– Use new, high-quality rechargeable batteries!

– Do not use different types of rechargeable batteries!

– Remove depleted rechargeable batteries and dispose of them at a suitable collec-

tion point!

NOTE

Read the following handling instructions before replacing rechargeable batteries and

follow them step by step. If disregarded, the product could be damaged or the protection from moisture could be diminished.

Proceed as follows to replace the rechargeable batteries.

– The product is switched off.

Fig. 1: Batteriewechsel

1. Unscrews the Phillips screws (A)and

remove the cover.

2. Carefully replace the two Mignon AA

batteries (B). Ensure that the polarity

is correct! It must be possible to insert

the batteries in the correct position

without using force.

3. The O-ring (C) must be undamaged,

clean and positioned at the intended

depth. In order to facilitate assembly

and avoid damage, a suitable grease

can be applied.

4. Fit the cover on evenly. The O-ring

must remain at the intended depth!

5. Tighten the Phillips screws (A).

The product is now ready for use again.

Description

Prerequisites

Instruction

Outcome of an action

Page 21

B-H90.0.01.DB2-2.1

G 1910-02

21 / 30

Operation and maintenance | 7

7.3 CO2 adjustment

In order to improve the accuracy, the carbon dioxide sensor can be adjusted. In order

to conduct a CO2 adjustment, proceed as follows.

1-point adjustment

Used for optimisation of the accuracy at the adjustment point. The best possible accu-

racy can be achieved even with elevated CO2 concentrations

2-point adjustment

Used for optimisation of the accuracy for extreme requirements over a wide measuring

range beginning from 0 ppm.

Basic sensor adjustment

Used to reset the sensor in case of deviations beyond the normally expected devia-

tions. The values of all prior adjustments are reset and cannot be restored. A plausibility check of the carbon dioxide concentrations does not take place. Depending on the

setting, adjustment to 0 ppm CO2 test gas or fresh outside air can take place. Ensure

that the setting of the gradient compensation setpoint [.SL was entered correctly in the

Expanded settings menu.

If reliable values can no longer be displayed, we recommend performing basic sensor

adjustment of the zero point at 0 ppm CO2 with nitrogen and a possibly necessary additional gradient compensation via 1-point adjustment.

If incorrect values are displayed after the adjustment, e.g. ERR.2 at 0 ppm CO2, the

adjsutment must be repeated.

NOTE

Adjustment can be carried out in clean ambient air or with test gases (optionally available gas extraction device recommended). 1-point adjustment at any arbitrary point

above 350 ppm and 2-point adjustment at 0 ppm and an arbitrary point above 350

ppm are both possible.

For automatic adjustment, open the Adjustment menu.

– The product is switched on.

– Clean ambient air or test gas for gradient correction

– Test gas 0 ppm CO2 for zero point adjustment for 2-point adjustment or basic sen-

sor adjustment at 0 ppm

– Gas extraction device, if applicable

Description

Prerequisite

Page 22

22 / 30

B-H90.0.01.DB2-2.1

7 | Operation and maintenance

G 1910-02

1. If you would like to perform a adjustment with test gas, connect the extraction de-

vice to the product first.

2. Press the Function key for 4 seconds to start the adjustment. [ONF appears in the

display first, then [AL.

3. 1-point, 2-point or basic sensor adjustment is started. This depends on what was

adjusted in the Expanded settings menu.

1-point adjustment

1. [.SL appears in the display for 1-point adjustment.

2. The product determines a stable value first. If the measured value is outside of the

value range integrated in the product, the display flashes briefly and an acoustic

signal is issued every 10 s.

3. If a stable correct value is reached, the display flashes briefly, an acoustic signal

sounds and the bar indicator blinks.

4. You can change the value of the gradient compensation with the up key and down

key. Otherwise, confirm the preadjusted value with the function key. The 1-point

adjustment is finished.

2-point adjustment

1. [.OF appears in the display for 2-point adjustment.

2. Allow the test gas to flow at about 0.5 l/min at 0 ppm of CO2. The product deter-

mines a stable value first. If the measured value is outside of the value range integrated in the product, the display flashes briefly and an acoustic signal is issued

every 10 s.

3. If a stable correct value is reached, the display flashes briefly, an acoustic signal

sounds and the bar indicator blinks. [.SL appears in the display.

4. Remove the test gas and connect a second test gas to the extraction device. The

product determines a stable value first. If the measured value is outside of the

value range integrated in the product, the display flashes briefly and an acoustic

signal is issued every 10 s.

Instruction

Page 23

B-H90.0.01.DB2-2.1

G 1910-02

23 / 30

Operation and maintenance | 7

5. If the display flashes briefly, an acoustic signal sounds and the bar display blinks,

a stable correct value has been achieved.

6. You can change the value of the gradient compensation with the up key and down

key. Otherwise, confirm the preadjusted value with the function key. Remove the

extraction device. The 2-point adjustment is finished

Basic sensor adjustment

1. KARD appears in the display for basic sensor adjustment.

2. Depending on the specification [.SL, let the test gas with 0 ppm CO2 flow in at ap-

prox. 0.5 l/Min or move the product into clean ambient are with 400 ppm CO2. The

product determines a stable value first. If the displayed measurement is outside of

the measuring range of the sensor, the product cannot perform stability recognition. It must be ensured that the carbon dioxide concentration at the sensor is stable before the adjustment is started.

3. If a stable correct value is reached, the display flashes briefly, an acoustic signal

sounds and the bar indicator blinks.

4. Remove the extraction device, if applicable.

NOTE

Current test gases normally have accuracies of ± 2 %. This tolerance must be taken

into consideration with the measurement uncertainty. The specifications on the analysis certificate must always be observed.

NOTE

For information about the available adjustment settings, refer to Configuring parameters of the configuration menu [ 13].

After the adjustment is finished [AL DONE is displayed.

Then, the current measurement is shown in the display again.

If the adjustment is not completed successfully an error message is displayed. [AL ERR.

appears in the display. See Error and system messages [ 24]. Confirm the error message pressing the Function key. The product restarts. The values of the last correctly

performed adjustment are restored.

Configure parameters of the expanded settings menu [ 16]

Outcome of an action

Page 24

24 / 30

B-H90.0.01.DB2-2.1

8 | Error and system messages

G 1910-02

8 Error and system messages

Display

Meaning

Possible causes

Remedy

----

No signal from the

sensor

Measurement far

outside of the measuring range

Sensor not ready

CO2 concentration

too high

Defective sensor ad-

justment

Sensor defect

Wait the start-up time of the

sensor

Place the product in clean

outdoor air

Perform sensor adjustment

Send in for repair

----

The display value

could not be determined

Sensor not ready

Sensor defect

Wait the start-up time of the

sensor

Send in for repair

No display,

unclear characters or no

response

when buttons are

pressed

Rechargeable battery depleted

System error

Product is defective

Rechargeable battery depleted

Error in the product

Product is defective

Charge battery

Replace rechargeable bat-

tery

Send in for repair

BAT LO

Rechargeable battery depleted

Rechargeable battery discharged

Rechargeable battery defect

Charge battery

Replace rechargeable bat-

tery

(AL ERR.1

Zero point adjustment defective

Incorrectly measured CO2 concentration for adjustment

Expose sensor to a test gas

with 0 ppm CO2

(AL ERR.2

(AL ERR.3

Defective gradient

compensation

Incorrectly measured CO2 concentration for adjustment

Incorrect CO2 concentration

Expose sensor to a test gas

with known CO2 concentration

Enter correct value

(AL ERR.5

Time for stability

recognition exceeded

Stability recognition

lasts longer than 10

minutes

Provide a consistent flow

with a constant CO2 concentration

ERR.1

Measuring range exceeded

Measurement too

high

Defective sensor adjustment

Sensor defect

Stay within allowable measurement range

Perform sensor adjustment

Send in for repair

ERR.2

Measuring range is

undercut

Defective sensor adjustment

Sensor defect

Perform sensor adjustment

Send in for repair

ERR.7

Sensor error

Defective sensor adjustment

Sensor defect

Perform sensor adjustment

Send in for repair

Page 25

B-H90.0.01.DB2-2.1

25 / 30

G 1910-02

Error and system messages | 8

ERR.T

Temperature error

Permissible temperature range during

charging exceeded

or undercut

Charging of battery only at 0

.. 40 °C

Bring product to room temperature and restart charging process

SYS ERR

System error

Error in the product

Sensor defect

Switch product on/off

Replace rechargeable bat-

teries

Send in for repair

STAB

No measurement

change within 2

minutes

Product in extremely

constant environment

Sensor defect

Place the product in clean

outdoor air

Perform sensor adjustment

Send in for repair

Page 26

9 | Disposal

G 1910-02

26 / 30

B-H90.0.01.DB2-2.1

9 Disposal

Separation by material and recycling of device components and packaging must take

place at the time of disposal. The valid regional statutory regulations and directives

applicable at the time must be observed.

NOTE

The device must not be disposed of with household waste. Return it to us, freight prepaid. We will then arrange for the proper and environmentally-friendly disposal.

Private end users in Germany have the possibility of dropping off the product at the

municipal collection centre.

Please dispose of empty batteries at the collection points intended for this purpose.

NOTE

Fill in the return form available from the information base online at www.ghm-group.de

and sent it in with the product.

Page 27

G 1910-02

Technical data | 10

B-H90.0.01.DB2-2.1

27 / 30

10 Technical data

Measuring range (specified accuracy)

0 .. 2000 ppm

0.000 .. 0.200 %

Measuring range (not specified)

0.000 .. 1.000 %

Accuracy

± 70 ppm ± 3 % measurement

Measuring cycle

2 seconds

Display

3-line segment LCD, additional symbols, illuminated (adjustable white, permanent illumination)

Additional functions

Min/Max/Hold

TWA calculation / STEL

2-stage alarm (optical and acoustic)

Adjustment

1-point, 2-point and basic sensor adjustment

Housing

Break-proof ABS housing

Protection rating

IP30

Dimensions L*W*H

[mm] and weight

108 * 54 * 28 mm without measuring cell or kink protection

180 g, incl. battery and measuring cell

Operating conditions

0 to 50 °C; 0 to 85 % r.h. (non-condensing)

Storage temperature

-20 to 70 °C

Current supply

2*AA-NiMH batteries (included in delivery)

Current requirement/

Rechargeable battery

life

approx. 50 mA, approx. 60 mA with lighting

Life approx. 24 hours with NiMH batteries (without backlight)

charging time of about 8 hours

Battery indicator

4-stage charge status indicator,

Charge indicator for low charge level: "BAT LO"

Plug connector

Micro USB socket (not a data connection)

Auto-power-OFF function

The device switches off automatically if this is activated

Directives and standards

The devices conform to the following Directives of the Council

for the harmonisation of legal regulations of the Member

States:

2014/30/EU EMC Directive

2011/65/EU RoHS

Applied harmonised standards:

EN 61326-1:2013 Emission limits: Class B

Immunity according to Table 2

Additional errors: < 1 % FS

EN 50581:2012

The device is intended for mobile use and/or stationary operation in the scope of the specified operating conditions without

further limitations.

Page 28

11 | Spare parts and accessories

G 1910-02

28 / 30

B-H90.0.01.DB2-2.1

11 Spare parts and accessories

A selection of spare parts and accessories for this product is listed below.

Number

Name

Description

410355

NiMH rechargeable battery

NiMH replacement rechargeable battery

411907

GKK 1002

G1000 series case, 235 x 185 x 48 mm

476698

GZ-18

Gas cylinder with 12 l test gas: 5000 ppm CO2

476699

GZ-19

Adjustment set for G 1910: MiniFlo valve for 12 l gas

cylinders, quick-connect adapter 4 mm, closing screw,

gas-bezel

479767

GZ-20

Gas connection for G 1910: Quick-connect adapter 6

mm, spare closing screw, gas bezel

481885

G 1000 table

base and wall

suspension

Plastic holder with connection possibility for USB cable

A complete list of all accessories- and spare parts is available in our product catalogue

or on our home page. We can also provide further information by phone.

Internet:www.greisinger.de

Tel: +49 94029383-52

Article

Contact

Page 29

B-H90.0.01.DB2-2.1

29 / 30

G 1910-02

Service | 12

12 Service

12.1 Manufacturer

If you have any questions, please do not hesitate to contact us:

GHM Messtechnik GmbH

GHM GROUP - Greisinger

Hans-Sachs-Str. 26

93128 Regenstauf | GERMANY

Email: info@greisinger.de | www.greisinger.de

WEEE reg. no. DE 93889386

12.2 Repairs processing

Defective products are repaired professionally and quickly in our service centre.

Monday to Thursday from 8:00 to 16:00

Friday from 8:00 to 13:00

GHM Messtechnik GmbH

GHM GROUP - Greisinger

Hans-Sachs-Str.26

Service Centre

93128 Regenstauf | GERMANY

Tel: +49 94029383-39

Fax: +49 94029383-33

service@greisinger.de

NOTE

Fill in the return form available from the information base online at www.ghm-group.de

and sent it in with the product.

12.3 Sales offices

Post code:

00000 – 25999 | 27000 – 34999

37000 – 39999 | 98000 – 99999

Email:

vertrieb-nord@ghm-messtechnik.de

Tel:

+49 4067073-0

Fax:

+49 4067073-288

Contact

Open hours and contact

North Sales Office

Page 30

30 / 30

B-H90.0.01.DB2-2.1

12 | Service

G 1910-02

Post code:

26000 – 26999 | 35000 – 36999

40000 – 69999

Email:

vertrieb-west@ghm-messtechnik.de

Tel:

+49 2191 9672-0

Fax:

+49 2191 9672-40

Post code:

70000 – 97999

Email:

vertrieb-sued@ghm-messtechnik.de

Tel:

+49 9402 9383-52

Fax:

+49 9402 9383-33

West Sales Office

South Sales Office

Loading...

Loading...