Page 1

H60.0.71.6C-01

GMH Messtechnik GmbH • Standort Greisinger

as of version 1.8 BaleCheck 200 with GMH 38

Operating Manual Appendix

Hay and straw humidity measuring device

WEEE-Reg.-Nr. DE 93889386

Page 2

H60.0.71.6C-01 Operating Manual Appendix BaleCheck 200 with GMH 38 page 2 of 4

_____________________________________________________ _____________________________________________________________________________

1 General Note

Read this document carefully and get used to the operation of the device before you use it.

Keep this document within easy reach near the device for consulting in case of doubt.

Mounting, start-up, operating, maintenance and removing from operation must be done by qualified, specially trained

staff that have carefully read and understood this manual before starting any work.

The manufacturer will assume no liability or warranty in case of usage for other purpose than the intended one, ignoring this manual, operating by unqualified staff as well as unauthorized modifications to the device.

The manufacturer is not liable for any costs or damages incurred at the user or third parties because of the usage or

application of this device, in particular in case of improper use of the device, misuse or malfunction of the connection

or of the device.

The manufacturer is not liable for misprints.

2 Intended Use

The BaleCheck 200 is a complete set for material moisture measuring including an handheld instrument (GMH 3830) with moisture display and rating.

The slim and robust measuring probe (GSF 40 TF) makes the set a first-class tool for humidity

measurements of pressed straw or hay (bales) and grain.

The measuring probe included to the set is connected to the device by a BNC-plug and Thermocouple plug.

Depending on the application either the material moisture u (based on dry matter) or the water content w (based on wet total mass) can be displayed.

Please consider the information “Measuring precision” in chapter 5.4

3 Product Specification

3.1 Scope of supply

The set includes:

Measuring probe GSF 40 TF

Handheld meter GMH 3830 incl. 9V battery and Operating Manual

Protection bag ST-KR

Operating Manual Appendix BaleCheck 200

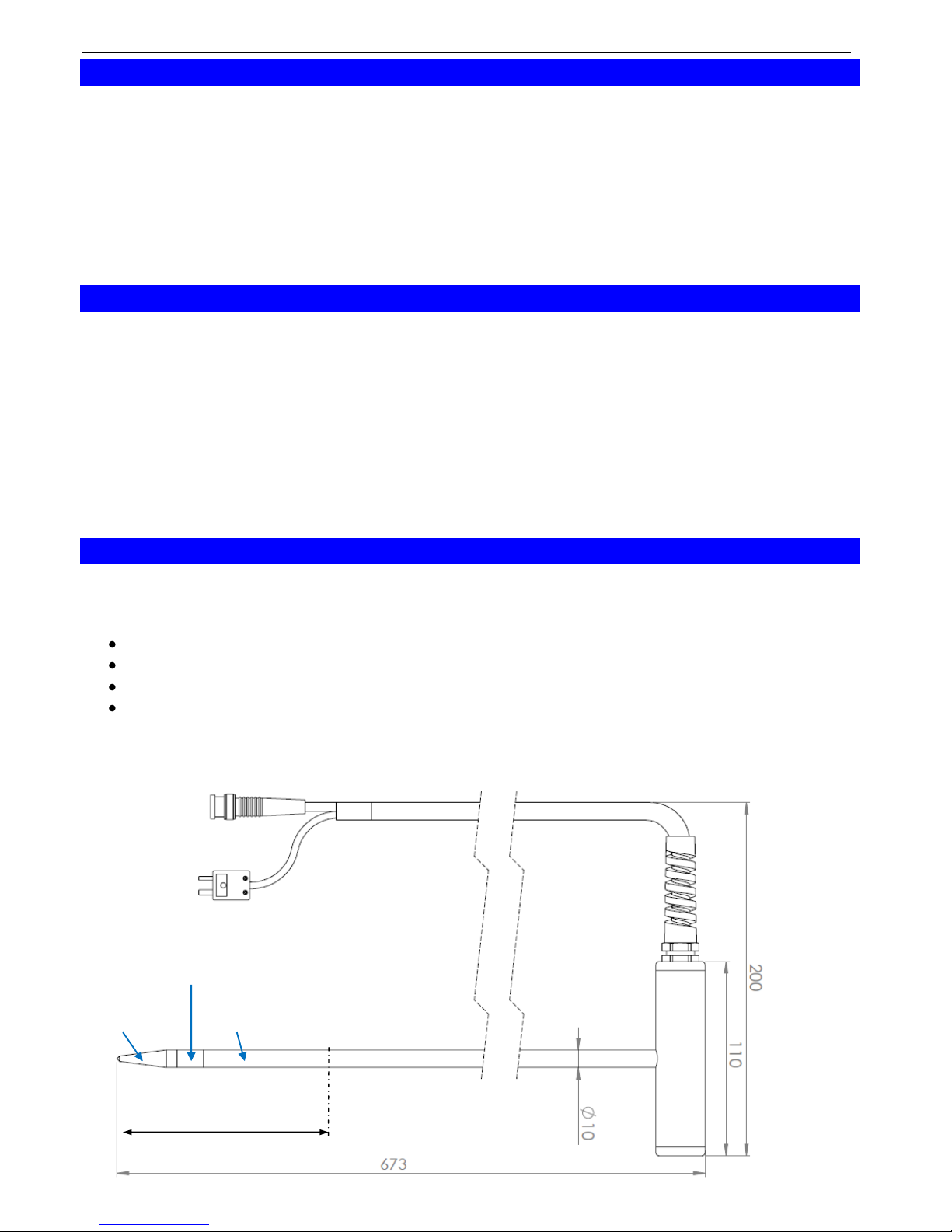

3.2 The measuring probe GSF 40 TF

isolator

probe tip with

temp. sensor probe tube

100

minimum immersion

Page 3

H60.0.71.6C-01 Operating Manual Appendix BaleCheck 200 with GMH 38 page 3 of 4

_____________________________________________________ _____________________________________________________________________________

4 Handling

4.1 Start of operation

Switch the device on with the on/off key. After segment test the device is ready for measuring.

4.2 Selection of the characteristic curve

Selection of characteristic curve: by pressing

the characteristic curve can be selected.

The use of inappropriate characteristics can cause faulty measurements!

Selectable material characteristics: (via “Sort”-function preselected, please refer to operating manual GMH 38xx)

4.3 Temperature Measurement

The Temperature value will be displayed temporarily when key is pressed.

Let the Probe adjust to the material for at least 20 seconds to achieve good measuring precision

5 Principles of the measurements

5.1 Moisture rating ( WET - MEDIUM - DRY )

In addition to the measuring value there is a moisture rating via bar graph.

This rating can only be a first approximate value, because factors like the application

field of the measured material have to be taken into account for the final rating.

Experience and knowledge can only be supported by this instrument, not replaced!

5.2 Moisture u and water content w

Either moisture u or water content w is needed according to the application. The BaleCheck 100 is

supposed to be used the unit moisture u (relating to oven-dry mass). In some cases, like rating of

combustibles, the water content w may be more suitable.

The instrument can be configured to both of the values, please refer to GMH 38xx manual.

Moisture u (relating to oven-dry mass) – recommended setting

The unit is %u (also common: % atro, weight percent)

Example: 1 kg wet hay that contains 500 g water has a moisture u of 100%

Water content w (= moisture relating to wet total mass, please refer to operating manual GMH 38xx)

5.3 Temperature compensation

The temperature compensation is important for a reliable moisture-measuring.

There for the device features a temperature measuring at the Tip of the injection probe.

According to the selected material characteristic curve the device will use the associated temperature compensation.

Display Characteristic curve

By means of additional equipment (not within scope of

supply) wood and building materials of many kinds can

be measured – therefore the user has to add the referring characteristic curves to the Sort- Preselection, or

deactivate it complete.

R E F

Reference characteristic

h.462

Wheat

h.463

Barley

h.464

Hay

h.465

Straw

moisture u[%] = ( (mass

wet

- mass

dry

) / mass

dry

) *100

o

r: m

oisture u[%] = (mass

/ mass ) *100

Page 4

H60.0.71.6C-01 Operating Manual Appendix BaleCheck 200 with GMH 38 page 4 of 4

_____________________________________________________ _____________________________________________________________________________

5.4 Measuring Practice

The measuring values

For storability and evaluation of quality and purpose the BaleCheck measuring is a valuable decision support – Beside other criteria like smell (mouldy?)– consistency (dust…) and look (color,

dirt…).

For freshly harvested material like straw, hay and grain the following can be recommended:

below 16 % u Material is sufficiently dry and storable

16 - 20 % u Material contains significant moisture, eventually dry it before storage

above 20 % u Material contains excess moisture, stop harvesting if possible!

Irregular moisture distributions

Please consider: depending on storage and harvesting procedure, there can be irregular distributions of moisture within the bales or grain heaps/stores.

Measuring precision

The BaleCheck 200 is designed for approximate determination of material moisture in hay, straw

and grain. Depending on state and sort of material there may be deviations. The strength of the

measuring system lies within the ability, due to the construction and usability, to gather fast and

comfortably many measurements spread over the bale/store (deep inside, at the floor, at critical

weathered places..) – in practical use this often is much more valuable than single precision measurements and also is a valuable supplement to single precision measurements!

Minimum immersion / minimum amount of material

For best measuring results, the black isolator at the probe tip has to be completely immersed into

the material plus at least 5 cm of the stainless steel shaft has to be in good contact to the material.

When measuring grain, try to use at least ~ 500ml of grain, covering the probe tip and ensure to

have enough contact/compressed grain around the probe – In heaps/stores higher than 30 cm and

minimum immersions of 20 cm no additional measures have to be taken; otherwise the measurement values may be too low.

Keep probe clean!

Especially when measuring in wet hay, the probe may be soiled very strong, this may produce to

low measuring displays.

Soilded probe -> wrong measuring!

In hard cases we suggest fine grinding fleece o rat least suitable household sponges for cleaning.

Do not use steel wool!

Display values at air

If the probe is not correctly in contact to material, the instrument may display any value!

This is caused by the design and measurement method.

At values above 25% u the measurement precision decreases!

But decision making in this range is: Wet is wet, no matter how wet!

Loading...

Loading...