Operating Manual SL1

English

Operating Manual

SL1

Greiner Vibrograf AG

Mittelstrasse 2

CH-4900 Langenthal

Schweiz / Switzerland

Tel : +41 (0)62 916 60 80

Fax : +41 (0)62 916 60 81

e-mail: info@greinervibrograf.ch

www.greinervibrograf.ch

Operating Manual SL1

1. Contents

2. Introduction

3. Scope of supply

4. Safety instructions

5. Warning and safety stickers

5.1 Information on the device

5.2 Information in the

Operating Manual

6. Technical data

6.1 Technical data list

6.2 Speed table, stepless adjustment

6.3 Device overview

7. Before putting into service

8. Operation

8.1 Fitting the adaptor

8.2 Changing the belt

8.3 Control panel

8.4 Drive motor

8.5 Speed indicator

8.6 Emergency stop button

9. Disposal

10. EC – Declaration of conformity

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7 - 8

Page 9

Page 10 - 17

Page 18

Page 19

Page 2

1. Contents

Operating Manual SL1

Our SL1 grinding machine with polishing disc is a further development with various

technical refinements distinguish it substantially from other similar devices.

This device was developed as a logical continuation of the following thought:

EFFICIENCY THANKS TO SOLID, COMPACT EQUIPMENT DESIGN.

With the SL1, all grinding and polishing jobs are possible under professional

conditions and, as usual, we guarantee performance, reliability and a long service

life. We congratulate you on your purchase of this high-performance device.

Please take the time to read this Operating Manual. It includes important

information about the use and application of the device.

Please make yourself and the personnel who will be working with the unit familiar

with the SL1and make sure all comply with the safety instructions given below.

Carry out the necessary maintenance and cleaning work at regular intervals, as this

is the only way that safe and effective operation can be guaranteed.

Please keep the Operating Manual close to the device and accessible at all times.

We would also ask you to kindly keep the original packaging.

Please read and comply with all safety instructions ! They should simplify

appropriate operation of the device and help to prevent any misunderstandings, as

well as material or immaterial damage.

All illustrations, instructions and technical specifications in this Operating Manual

are based on the current state-of-the-art machine construction. As the product is

being continually further developed, we reserve the right to make modifications to it.

Greiner Vibrograf AG

Mittelstrasse 2

CH–4900 Langenthal

Tel.: +41 (0) 62 916 60 80

Fax: +41 (0) 62 916 60 81

info@greinervibrograf.ch

www.greinervibrograf.ch

Page 3

2. Introduction

Operating Manual SL1

Page 4

Belt grinding machine with SL1 polishing disc Ready to plug in

1 x Operating Manual

1 x Quick unpacking instructions

1 x Original packaging Packaging set + pallet

3. Scope of supply

3. Scope of supply

Operating Manual SL1

This device is built according to state-of-the-art, recognised safety regulations. However, when in use

dangers can arise to the life and limb of those operating it or third parties, and/or adverse effects to

the device and other property.

For this reason, we would ask you to please comply with the safety instructions below:

(1) The device must only be used in technically perfect condition in accordance with its designated use and

the instructions set out in the operating manual, and only by safety-conscious persons who are fully

aware of the risks involved in operating the unit. No claims under guarantee can be entertained in the

event of operator error or lack of maintenance.

(2) Before putting into service, check the information on the type plate on the rear of the device. The device

is designed for a 115 or 230 V power supply and may only be connected to mains sockets of this type.

(3) In the event of any faults that could also have a detrimental impact on safety, have them repaired by the

manufacturer immediately, as the unit will otherwise not be covered by any guarantee or liability for

defects.

(4) The device is intended exclusively for grinding, milling, scratching and polishing with approved tools. Any

other use or use above and beyond the specifications will be regarded as improper use. The

manufacturer cannot accept any liability for damage resulting from such improper use.

The risk will be borne entirely by the user.

(5) As an additional security equipment the polishing machine is inclusive an emergency stop button.

(6) Always keep the Operating Manual carefully to hand at the location where the device is used.

(7) Supplementary to the Operating Manual, all generally valid statutory and other binding regulations

relating to accident prevention and environmental protection must be observed and communicated to

others.

(8) Personnel entrusted with the operation of the device must, before starting work, have read the Operating

Manual and in particular the Safety instructions chapter.

This is especially important in the case of personnel who only work with the device occasionally.

(9) DO NOT WEAR any jewellery, ties or loose clothing. Loose clothing can get caught up in rotating

parts and cause severe injuries. Use appropriate protection if you have long hair.

(10) Protect the mains cable from heat and sharp objects and install it in such a way that it cannot be

damaged. When not in use, before maintenance, tool changing or repairs, DISCONNECT THE

MAINS PLUG. When disconnecting the mains plug, be sure not to pull by the cable, but by the plug.

If the cable has to be extended, make sure it is in perfect condition and, before use, ensure correct

current carrying capacity.

(11) Never use the device in a humid environment or close to combustible liquids or gases.

(12) The device must NOT be used for wet grinding jobs.

(13) Do not overload the device and clean thoroughly after use.

(14) In the event of damage to the polisher, disconnect the mains plug immediately. It may not be used

again until it has been repaired. Faulty mains cables must be replaced immediately.

(15) Always wear safety goggles with shatter-proof clear lenses.

(16) Spare parts must comply with the technical requirements specified by the manufacturer. This can

only be guaranteed in the case of original spare parts from Helmut Klein company.

(17) Work on/with the device may only be carried out by qualified, appropriately trained and assigned

personnel.

Be sure to observe the legally permitted minimum age !

(18) Store the Operating Manual carefully.

Page 5

4. Safety instructions

Operating Manual SL1

Page 6

5. Warning instructions and safety stickers

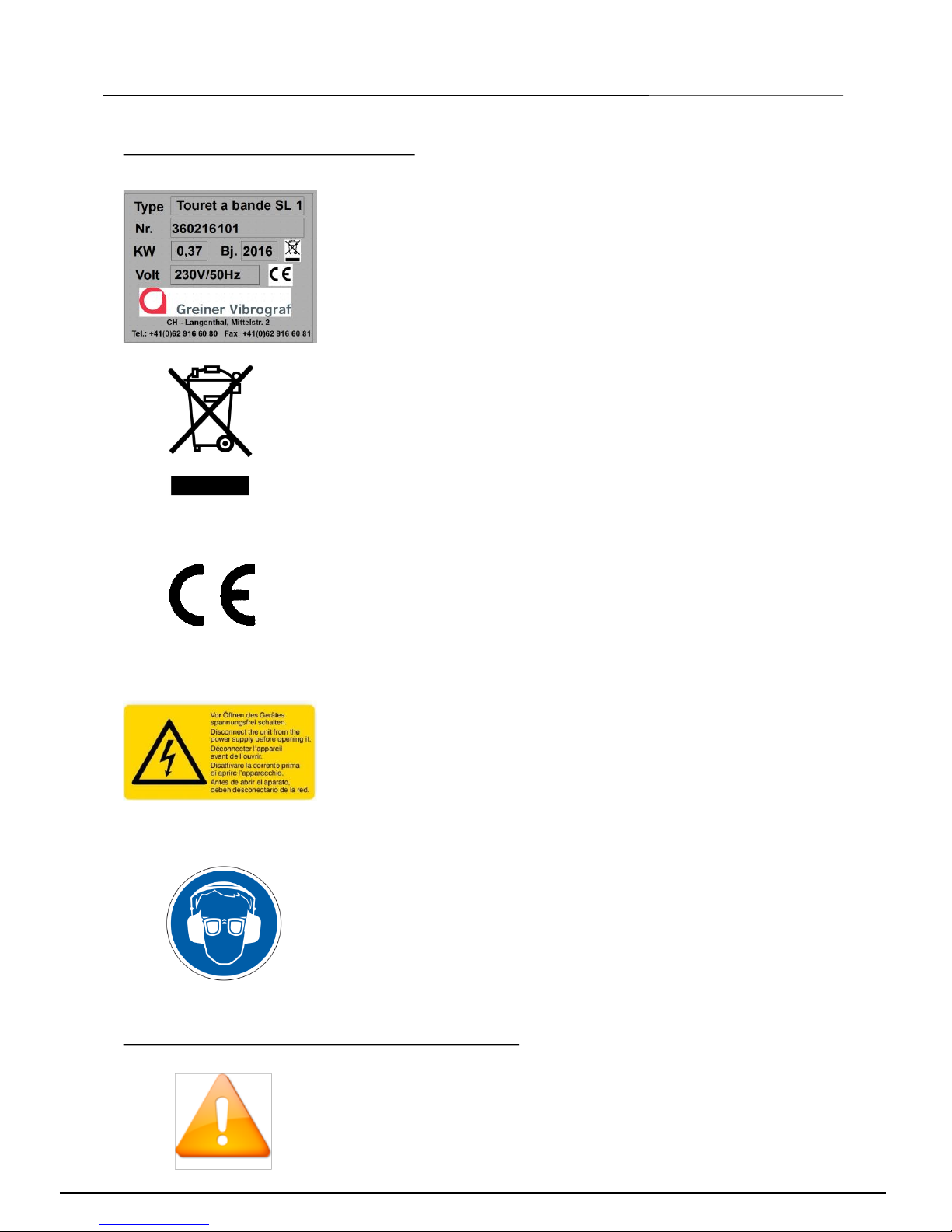

5.1 Information on the device

“Type plate”

This sticker includes the device description, serial

number, year of construction and most important

technical data. This sticker is located at the back, next to

the mains socket.

Do not dispose of electrical waste with household waste!

Directive 2002/96/EC on waste electrical and electronic

equipment, see also Page 16

This symbol can be found on the type plate.

This CE symbol indicates the product responsibility of the

manufacturer. With the CE symbol they are declaring that

their product satisfies all currently-valid EU-wide

harmonised standards (as per EU Regulation 765/2008)

This symbol can be found on the type plate.

This yellow safety symbol is a combination of warning

symbol and warning text. Please be especially careful, as

these devices are permanently energised.

This sticker can be found on the left-hand side of the unit.

“Wear hearing and eye protection!”

This sticker indicates that, when working with the device,

you must wear hearing protectors and protective

glasses/goggles with splinterproof, clear lenses.

This sticker is located at the front on the abrasive belt

safety cover.

This symbol identifies safety measures and information of

equal importance, as well as useful instructions on use.

This symbol can be found in the Operating Manual.

5.2 Information in the Operating Manual

Operating Manual SL1

Page 7

6. Technical data

Belt grinding machine with SL1 polishing disc

Article No.: 36000

Power supply: 230 V~/50 Hz or 115 V~/60 Hz

Motor output: 0.37 kW (0.5 HP)

Current consumption: 1.9A (230~V) or 3.8A (115~V)

Typical speed: 500 - 1400 rpm

Belt speed: 1.870 m/sec. - 5.237 m/sec.

Dimensions of abrasive belt: 1,000 x 50 mm

Diameter of polishing disc: 180 mm

Dimensions: W 630 / D 330 / H 600 mm

Weight: 32 kg net (minus packaging)

49 kg gross (incl. packaging)

6.1 Technical data

6.2 Adjusting the speed of the belt grinding machine with SL1 polishing disc

Stepless speed adjustment from typically 500 to 1400 rpm is carried out

using the speed adjusting knob and scale on the control panel

Setting: Speed:

Start = Min. 500 1/min.

Max. 1,400 1/min.

Operating Manual SL1

(5)

(6)

(9)

(10)

(7)

(2)

(3) (4)

(11)

(1)

(8)

6. Technical data

(1) Abrasive belt

(2) Abrasive belt safety cover

(3) Belt grinding arm

(4) Emergency stop button

(5) Drive motor

(6) Polishing disc

(7) Guide rod for sleeve

(8) Baseplate

(9) Control panel

(10) Workbench,

height-adjustable and to the

right tilt setting as per scale

(11) Belt adjusting screw

6.3 Overview of device

Page 8

Operating Manual SL1

7. Before putting into service

Before unpacking, check the packaging for any signs of external damage. Lift up the

cardboard carton and remove the cardboard sections from top to bottom and pull the

transport sleeve off. Remove the Operating Manual and the mains cable.

Carefully lift the machine out and remove the polystyrene foam packaging. Please

keep all the original packaging, including the device protection, for any return

shipments.

The belt grinding machine with its polishing disc is basically to be transported in an

upright position.

Check the device and packaging for any damage or shortcomings. If damage has

occurred during transportation, we would ask for documentation of the damaged

packaging and notification of any defects to the transport company, as well as

immediate contact with the supplier, otherwise claims for replacement due to

damage cannot be considered.

During assembly and equipment or modification of the

device, we would ask you to make sure the mains plug is

disconnected and green rocker switch 1 (see Chapter 6,

Control panel) is in the “Zero position”.

Remove the protective film from the workbench (10) and baseplate (8), see Chapter

5.3. Any residues of adhesive film are easily removed with suitable alcohol-based

cleaning agents.

Connect the mains cable at the rear of the device and make sure that the mains

voltage indicated on the type plate matches the mains voltage where you are

working. Only then should you plug the mains cable into the socket.

Protect the connecting cable from heat and sharp edges

and lay it in such a way that it cannot become damaged.

In the event of cable extensions, make sure in perfect

condition and check current carrying capacity before use.

The machine is now ready to use!

Page 9

Operating Manual SL1

Page 10

8. Operation

Configuration of belt grinder on delivery:

8.1 Fitting the adaptor

The adaptor must be fitted firstly to operate with a grinding belt:

Unscrew mounting angle with

knurled-head screw…

View of grinding arm

with mounting angle but

without adaptor.

Operating Manual SL1

Page 11

8. Operation

…and screw onto the adaptor

using the two countersunk

screws.

Then screw the mounting angle

with the adaptor attached back

onto the grinding arm.

The grinding belt can now be

operated with the adaptor

mounted on the belt grinding

machine.

Operating Manual SL1

Page 12

8. Operation

When changing the belt, as well as during maintenance and repair work, effective

disconnection of the power supply must be guaranteed (pull the mains plug out!)

Changing the belt is effected as described below:

8.2 Changing the belt

Rotate the belt adjusting screw to

the left until the head of the belt

adjuster is in the left-hand position

illustrated.

Operating Manual SL1

Page 13

8. Operation

When changing the belt be certain to pay attention to the

arrows on the inner side of the belt.

The arrows indicate the running direction of the belt.

Incorrect running direction will quickly lead to the

disintegration of the grinding belt..

In this position of the belt adjusting head, the

grinding belt can be removed and replaced.

Put the belt in place as shown in the picture,

then …

… press the upper belt cover together

with the roller downwards into the spring

system and push the belt onto the upper

roller in the middle position.

Operating Manual SL1

Page 14

8. Operation

Now rotate the belt adjusting screw

to the right until the adjusting head is

in line with the grinding arm.

Fine adjustment of the belt is carried

out with the belt motor running at its

slowest speed (500 rpm)

After changing the belt, carry out a 1-

minute trial run. If behaving

abnormally, switch the machine off

immediately!

Grinding belts must be

changed at regular

intervals!

Clean the belt grinder once every 20 hours of operation!

Operating Manual SL1

Page 15

8. Operation

Before putting into service, test the individual switches on the control panel and

make yourself familiar with the device.

Rocker switch1 Mains switch for turning on the supply voltage. If device

switched on, switch 1 lights up in green

This switch does not start up the motor.

Rocker switch 2 Start/Stop switch

To start the motor, check whether the mains switch (1) is

on setting 1 (= ON) and the emergency stop button has

not been pressed.

Then adjust the switch from 0 to 1.

This secures the restart protection of the machine, both in

the event of a power outage and if the emergency stop

button has been pressed and disengaged again.

The time between switching on the green mains switch (1)

and moving the motor swtiching knob (2) from 0 to 1 takes

at least 2 seconds for safety reasons. If the start button is

pressed only briefly, the motor will not start up.

Knob 3 Rotary knob for drive motor

This knob is used to adjust the speed of the motor from

500 to 1,400 rpm. The grinding belt and polishing disc

rotate simultaneously.

1

2

3

8.3 Control panel

Operating Manual SL1

Page 16

8. Operation

Important! Any defects or malfunctions must be remedied

by the manufacturer, Greiner Vibrograf AG. Noncompliance means that all warranty and liability

guarantees become null and void.

8.4 Drive motor

Your SL1 belt grinding machine with polishing disc is equipped with the most powerful

2-spindle electric motor in its class (0.5 HP). In spite of its power, this motor is

characterised by its extremely quiet running and optimal torque. The motor is

maintenance-free and based on our experience we can confirm it can be used for a

long time without any problems.

We would point out that, in the event of continuous use

over a long period, the motor can heat up to as much as

85°C. This is normal and does not influence either the

performance or durability of the motor.

The motor is started by turning the Start-Stop switch (2) from setting 0 to 1, (see Page

13, Chapter 6.1, Rocker switch 2)

You can adjust the speed at any time when the motor is running by rotating the knob.

You can see the selected speed on the speed setting knob scale.

Caution! The drive motor starts running

at the set speed immediately.

Operating Manual SL1

8.5 Emergency stop switch

Page 17

8. Operation

Regulation of the speed takes place steplessly

by rotating the speed setting knob in a clockwise

direction. The speed is indicated by the scale.

(See Chapter 6.1 Control panel, Page 8)

Once the emergency stop button has been

pressed, the grinding/polishing machine

continues running for up to 3 seconds!

8.5 Speed indicator

This is used to bring the motor of the device

quickly to a standstill in the event of danger or to

prevent a potential danger.

The motor can be stopped at any time during the

working process by pressing the emergency stop

button.

The motor can only be switched on again once

the emergency stop button has been unlocked.

To do this, reset the switch to its original position

by rotating in the direction of the arrow. The drive

motor can be set in motion again by turning the

Start/Stop switch from setting 0 to 1

(see also Chapter 6.1 Control panel, Page 11).

Operating Manual SL1

Page 18

9. Disposal

The German Electrical and Electronic Equipment Act (Elektrogesetz, ElektroG)

implements, amongst other things, the European WEEE

Directive 2002/96/EC in German law. It imposes on manufacturers of electrical and

electronic equipment the responsibility for an environmentally-friendly equipment

design and an obligation to accept returns of old equipment for correct disposal.

The manufacturer has been registered for many years and responsibly reports its

devices annually. We do everything possible to keep recycling costs to a minimum, in

order to pass the resulting benefits on to our customers and to society in general.

For this reason, we would also ask you, once you reach the point of having to dispose

of this device, not to put into the general waste, but to deliver it to the disposal centre

responsible for old electrical equipment.

Thank you !

WEEE Reg. No.: DE51617604

We hope you enjoy using your new device !

Operating Manual SL1

Page 19

10. EC - Declaration of conformity

Loading...

Loading...