GREINER PneumoLash LCV Operating Instructions And Spare Parts List

P

P

n

n

e

e

u

u

m

m

o

o

L

L

a

a

s

s

h

h

pneumatic tensioner for

cord and composite strap

up to 50 mm

LCV Stock no. 089192

Operating Instructions

and Spare Parts List

FIRST

read these

instructions

Do not destroy these operating instructions! The customer is obliged to make

these operating instructions available to

all operators and service personnel and to

ascertain that these persons understand

the contents.

Adhere to safety instructions and warnings! Erroneous operation may cause serious injuries!

4

Use safety glasses with lateral guards and protective gloves

during cutting operations while working with strapping

tools for cord and composite strap.

Do not put your hand or any other parts of your body

between the strap and the piece to be packaged while

operating the strapping tool.

The strap may tear while tensioning! Do not stand within the flight of the strap.

Hold the upper part in your hand while you cut the

strap, and place yourself outside this range.

Caution:

The lower strap end will spring up; Use safety

strap shears!

Use only original central spare parts.

Original

Field of Application for the PneumoLash

The PneumoLash central strapping tool is suitable exclusively for strapping all kinds

of goods to be packaged, for securing cargo load units respectively using conven-

tional cord and composite strap.

Warning and Safety Recommendations

5

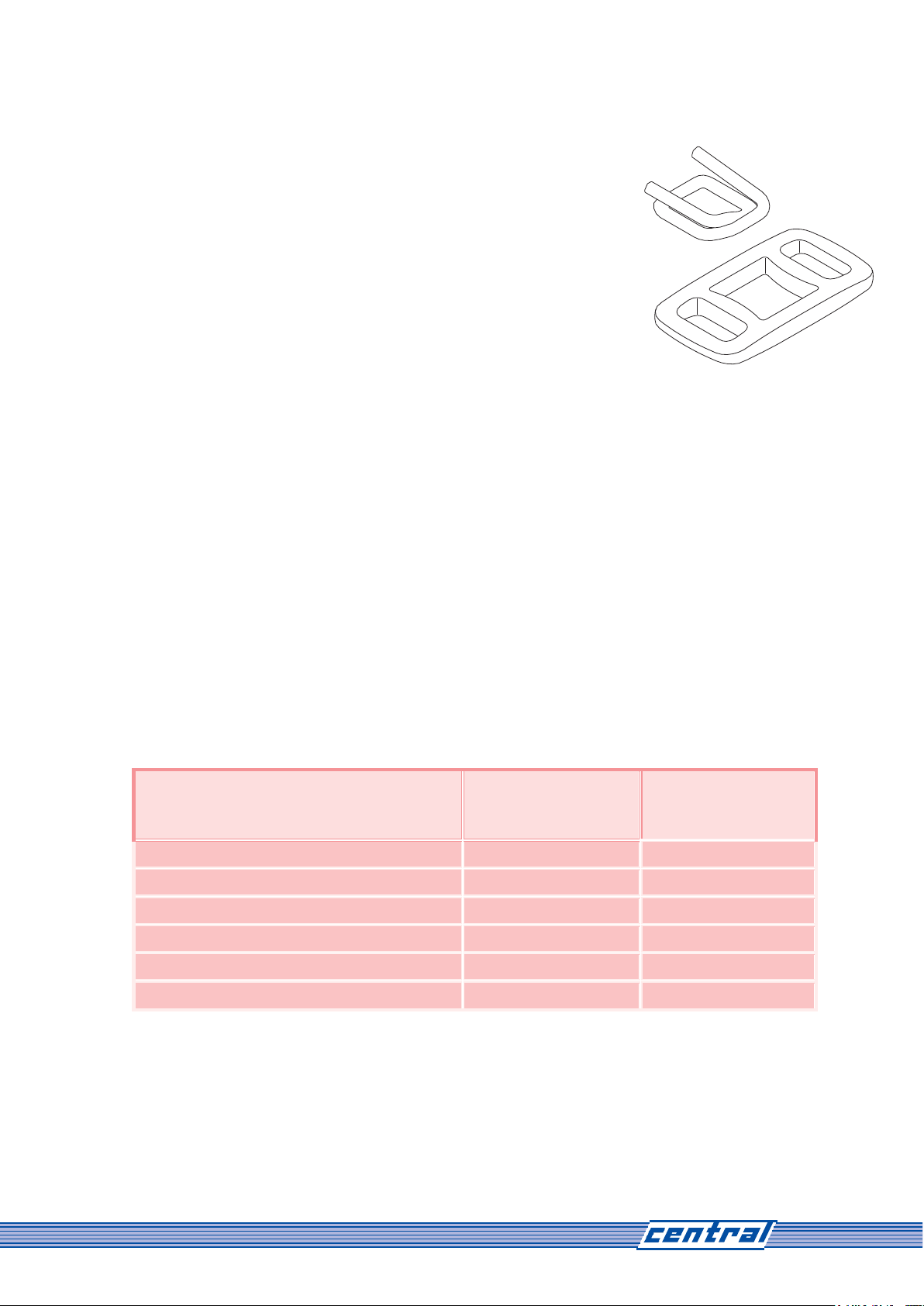

Suitable Cord and Composite Strap and Buckles

Use commercial size

textile and composite strap

0.5 to 2.4

mm thick and 50 mm (2") max. wide exclusively.

Use commercial type

locking buckles

of suitable size only.

The buckles must be used together with the proper textile or com-

posite strap as released by the strap producer.

Compressed Air Supply Requirements

However, the maximum air pressure of 700 kPa / 7.0 bar (100 psi) must not be

exceeded in any case. For trouble-free operation the compressed air supply should

deliver 700 l/

min

minimum.

Safe and reliable operation is ensured by installing an air filter and oiler into the feed

air line within a distance of 10 m ahead of the motor. We also recommend to

integrate a pressure regulator into the compressed air conditioning unit. It keeps

the desired operating pressure constant and simultaneously serves for the perform-

ance regulation so that the motor performance is exactly adjusted to the strapping

requirements.

The maximum possible tension for the respective strapping operation should be

preset via the pressure control valve. The below table quotes reference values as to

the strap tension plus required compressed air feed with regard to the respective

operating pressure.

Operating pressure of applied

compressed air feed

SI ANSI

Maximum obtainable strap tension

Compressed air

consumption (appr.)

200 kPa / 2.0 bar

29 psi

2.5 kN

230 l/

min

300 kPa / 3.0 bar

43 psi

3.5 kN

280 l/

min

400 kPa / 4.0 bar

58 psi

5.0 kN

330 l/

min

500 kPa / 5.0 bar

72 psi

6.0 kN

380 l/

min

600 kPa / 6.0 bar

87 psi

6.4 kN

470 l/

min

700 kPa / 7.0 bar

100 psi

7.5 kN

610 l/

min

Table 1: Strap tension in dependence of pressure, compressed air consumption

The conditioning unit and compressed air feed line should be selected so as to

ensure sufficient flow cross-sections for a minimum pressure drop to ensure that

the motor will put out its full capacity.We recommend the use of the FESTO® Type

6

FRC-3/8-D-5M-MINI conditioning unit. For connecting the compressed air supply a

hose with 9 mm clear width should be used and connected to the unit using the

coupling 005-720, which comes with the set. For minimum pressure drop the air

feed hose must not be longer than 10 m.

Motor Lubrication

In order to guarantee optimal life and performance the air motor requires appr.

21

mm

3

/

min

oil. Insufficient lubrication leads to faster vane wear and reduced performance. For the required quantity of oil the mist oiler in the conditioning unit

must be set to deliver one drop of oil appr. every 45 seconds with continuous motor

operation (one drop of oil corresponds to appr. 15

mm

3

/

min

).

For long life and optimal performance with the corresponding operating tempera-

tures the oils used should fulfil the below listed requirements:

Ambient Temperature

Oil Type

Example

less than 5°C

ISO VG 46 / DIN 51502 DL 46

EA 60 S

5°C – 35°C

ISO VG 150 / DIN 51502 DL 150

Almo® 525

25°C – 60°C

ISO VG 32 / DIN 51502 PGL 32

Almo® 529

Table 2: Released oil types

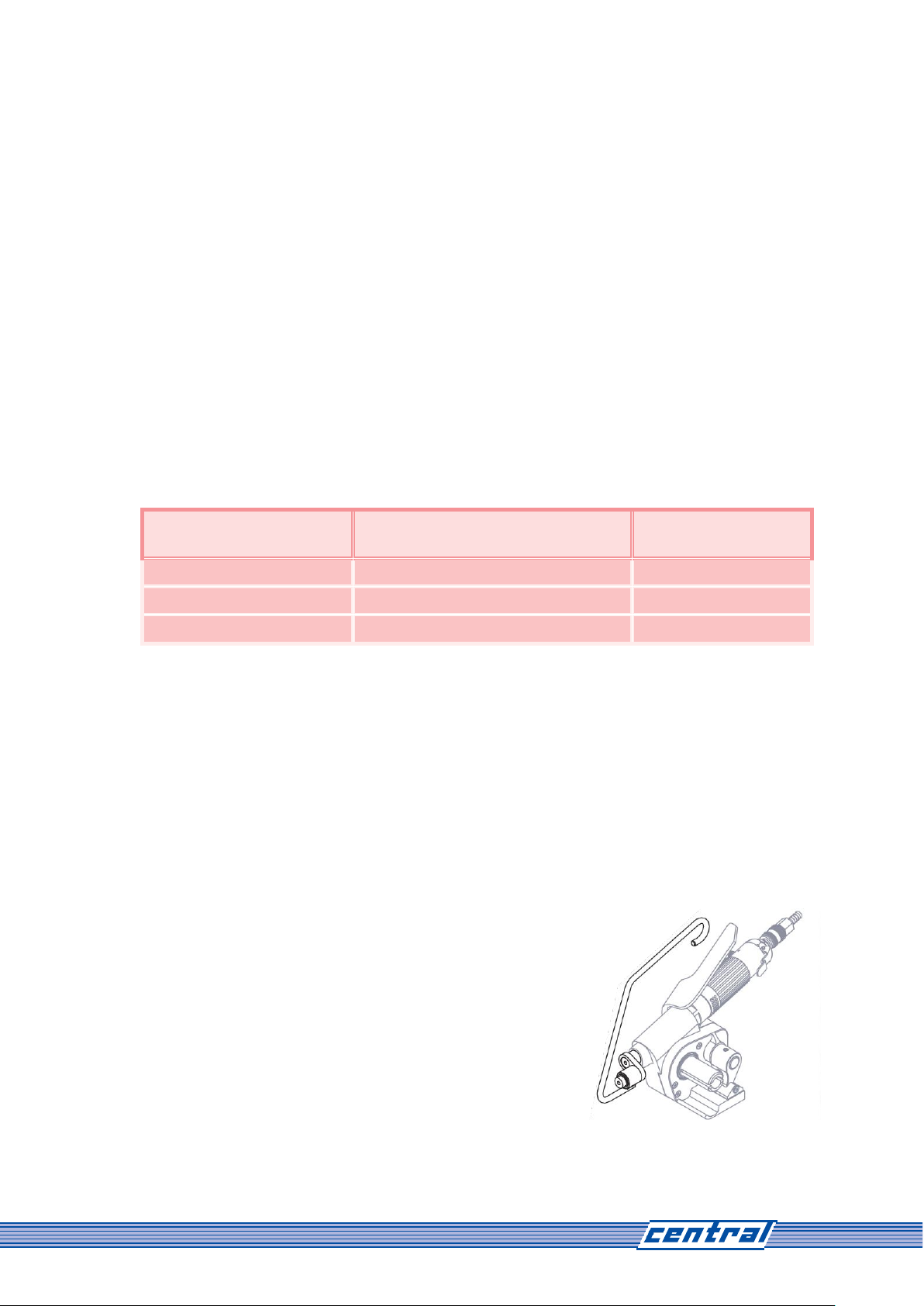

Accessories for PneumoLash

Your central dealer and service partner holds the below listed accessories in store

for you to usefully complete your PneumoCord strapping tool:

• Suspender (Stock no. 040-900)

The suspender (040-900) permits to hang up your PneumoLash

strapping tool on a balancer, giving the tool a stable bal-

ance in various orthogonal positions: PneumoLash in

horizontal position (refer to illustration) turned 90°

about the fixing point of the suspender; in vertical

position with motor pointing downward permitting

free turning of the unit within a range between 0

and 90° relative to the suspender.

Loading...

Loading...