Greifzug Tirak X 1020, Tirak X 1530, Tirak T 1020, Tirak X 3050, Tirak X 300 Operation And Installation Manual

...Page 1

tirak™

Electrically driven rope traction hoists for wire ropes for material transportation

Elektrisch angetriebene Seildurchlaufwinden für Drahtseile zur Materialbeförderung

Treuils électriques à défilement continu pour câbles métalliques pour le transport de matériaux

Elektrisch aangedreven kabeldoorlooplieren voor draadkabels voor het materiaaltransport

Model series / Typenreihe /

Série / Serie

T 1000

T 1020

Model series / Typenreihe /

Série / Serie

X 300

X 400

X 500

X 800

X 1020

X 1530

Model series / Typenreihe /

Série / Serie

X 3050

Original Operation and Installation Manual

Traduction du manuel d´installation et de

manutention original

Übersetzung der Original-Montage- und

Betriebsanleitung

Vertaling van de originele montage- en

bedieningshandleiding

English

Deutsch

Français

Nederlands

Page 2

tirak™

EN-DE-FR-NL–II G932.1 - 06/2010

DE

FR

NL

ENEN

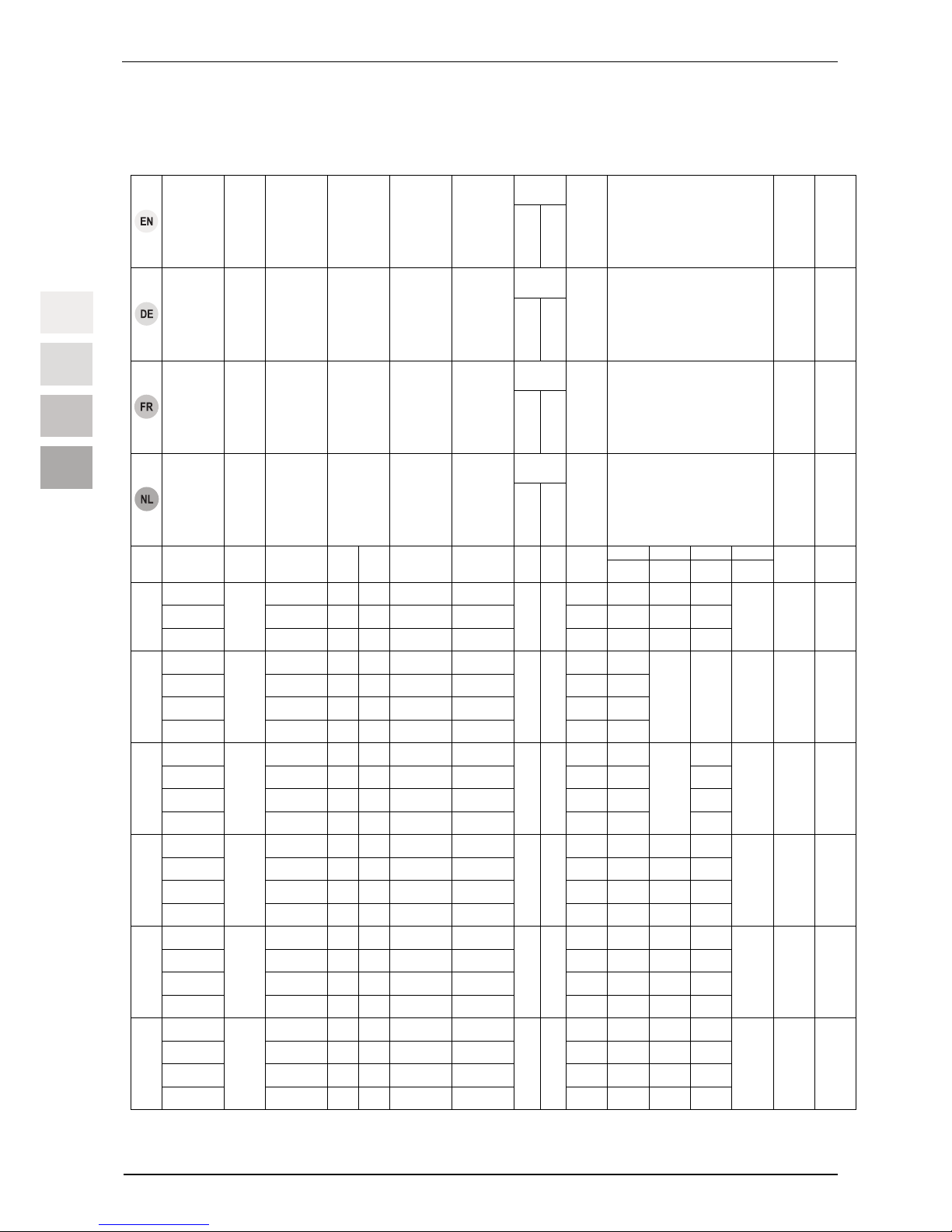

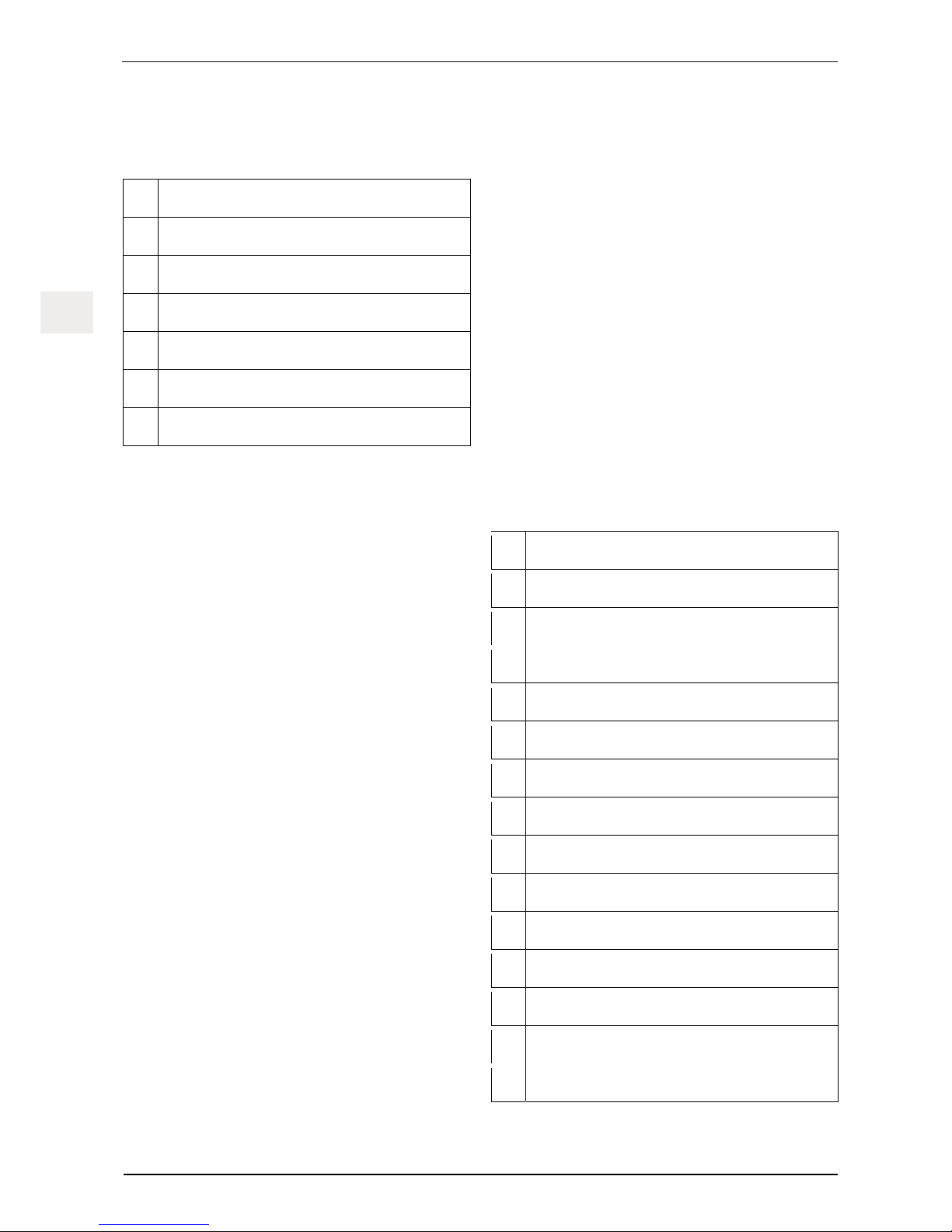

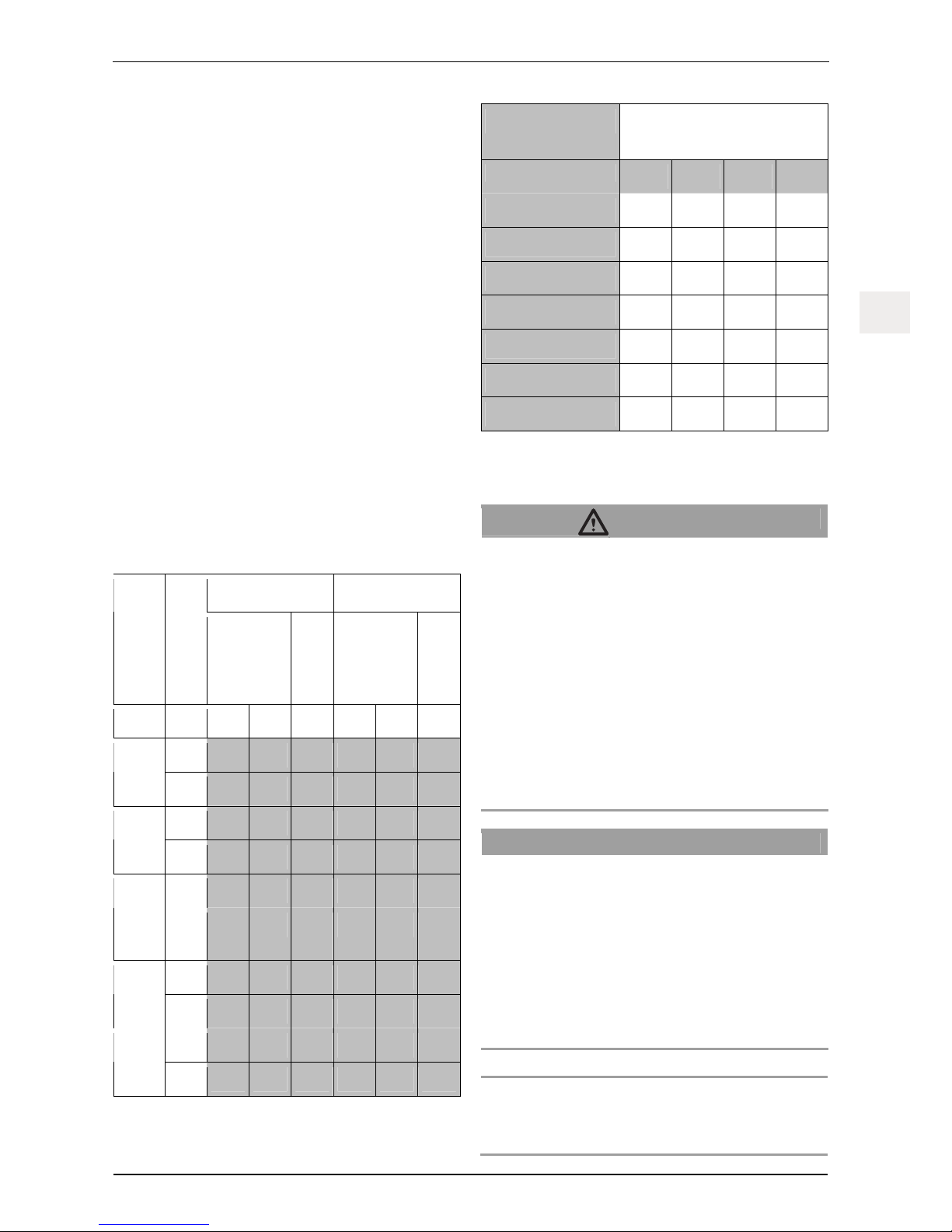

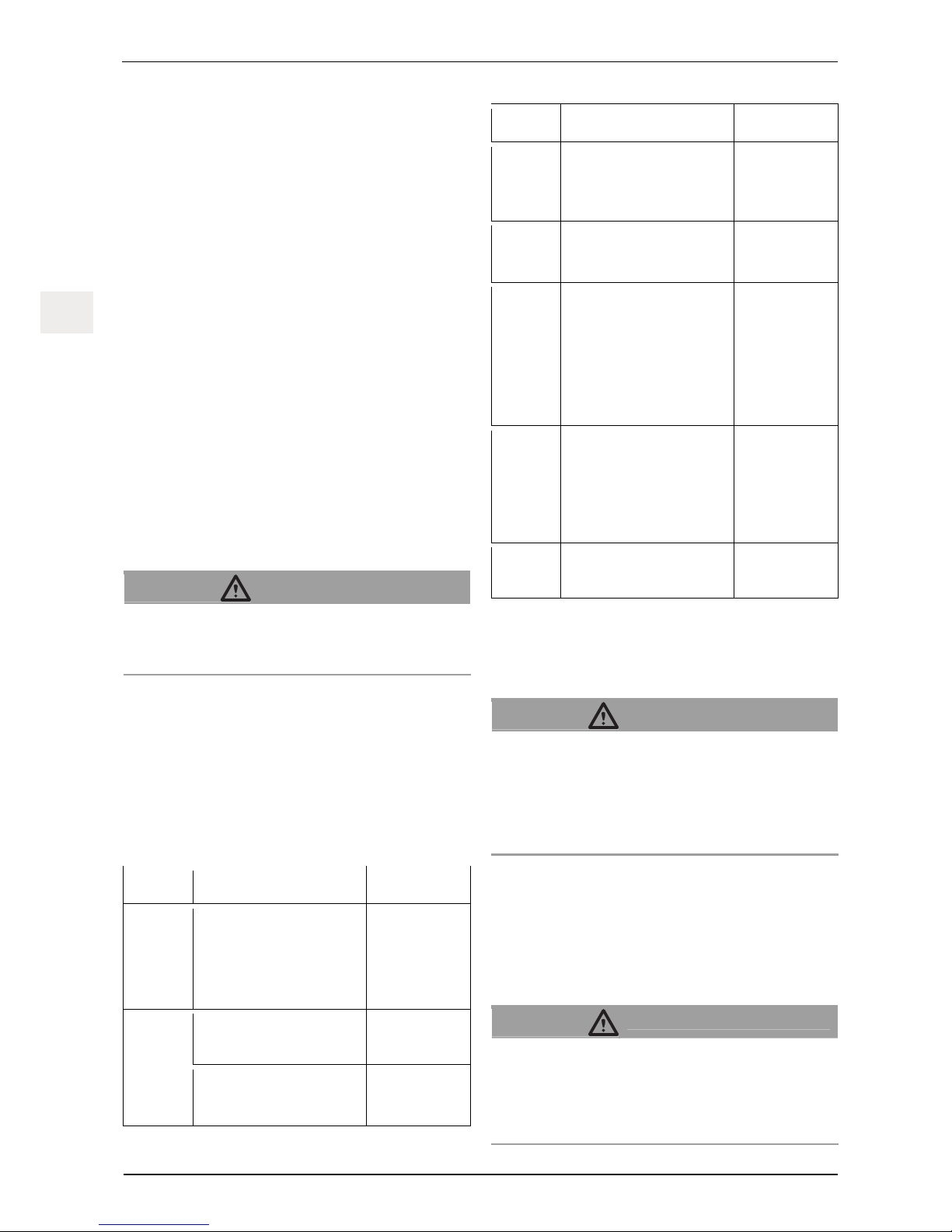

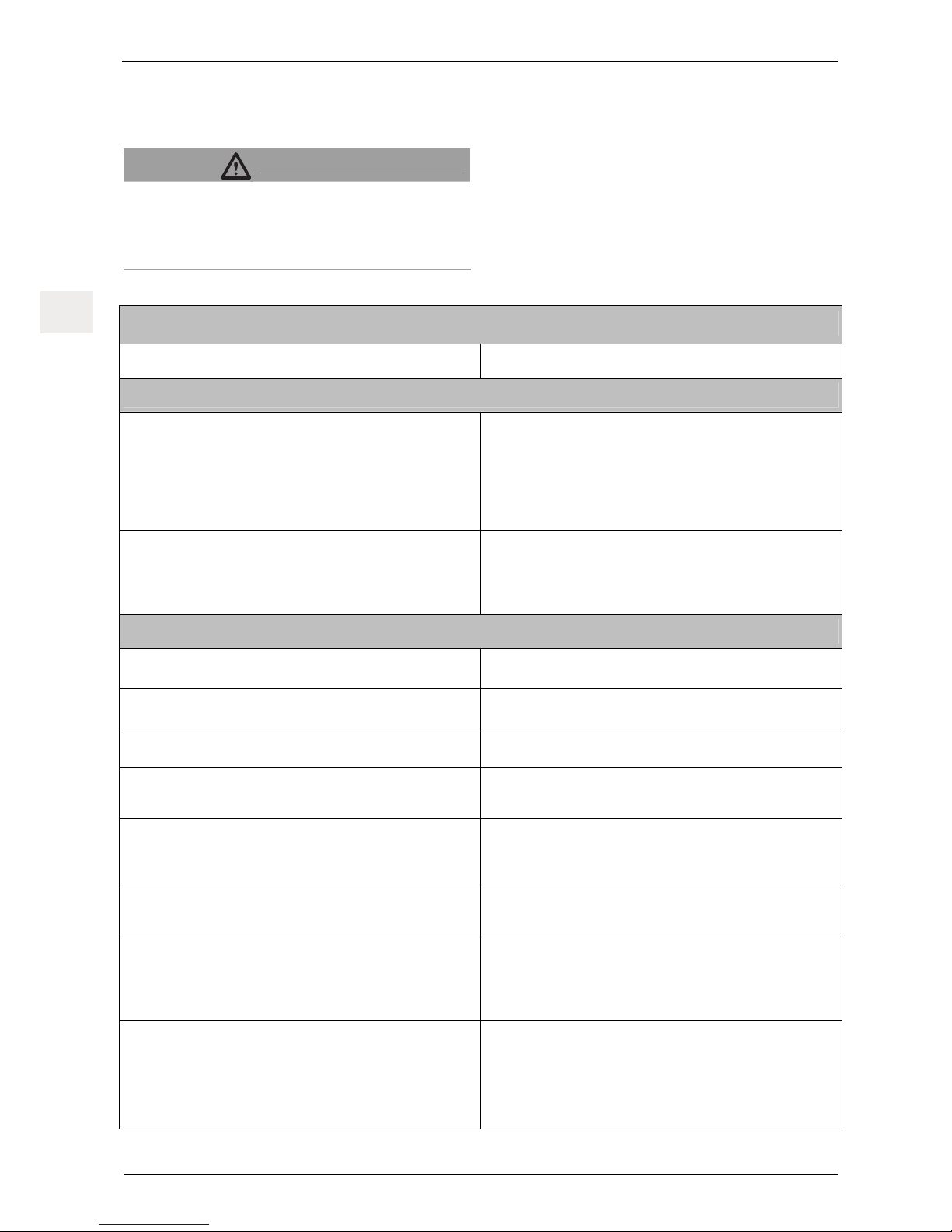

Technical Data / Technische Daten / Données techniques / Technische

gegevens

tirak

TM

rope

Hoist

Load-carrying

capacity

4)

Wire rope speed

6)

Connection

Power

Nominal

current

Diameter

Minimum

breaking load

5)

Weight

Dimensions / unit size

(see Fig. 2 and 3)

Temperature

range

3)

Noise

2)

tirak

TM

Seil

Winde

Tragfähigkeit

4)

Seilgeschwind-

igkeit

6)

Anschluss

Leistung

Nennstrom

Durchmesser

Mindest-

bruchkraft

5)

Gewicht

Abmessungen /

Einbaumaße

(siehe Abb. 2 und 3)

Temperatur-

bereich

3)

Geräuschent-

wicklung

2)

tirak

TM

câble

Treuil

Capacité de

charge

4)

Vitesse du câble

6)

Branchement

Puissance

Courant

nominal

Diamètre

Effort de rupture

minimal

5)

Poids

Dimensions /

Cotes de montage

(cf. Fig. 2 et 3)

Plage de tempé-

rature

3)

Emission so-

nore

2)

tirak

TM

kabel

Lier

Draagvermogen

4)

Kabelsnelheid

6)

Aansluiting

Vermogen

Nominale

stroom

Diameter

Min.

breukkracht

5)

Gewicht

Afmetingen/inbouwmaten

(zie Afb. 2 en 3)

Temperatuur-

bereik

3)

Geluidsont-

wikkeling

2)

a b c x/y

kg m/min

230 V

50 Hz

400 V

50 Hz

kW A

mm

kN

kg

mm mm mm mm

°C

dB

(A)

X 300 9 – x 0,5 1,6 27 437 262 265

X 301 9 x – 0,45 4,5 29 476 257 245

X 300

X 302

300

18 – x 0,9 2,6

8

14,7

27 437 262 265

∼ 250 /

250

-10

…

+50

1)

72

X 400 9 – x 0,75 2,8 29 437

X 401 9 x – 0,75 6,5 32 452

X 402 18 – x 1,5 5 31 496

X 400

X 403

400

9/18 – x 0,75/1,5 2,8/5,1

8

19,6

35 452

273 285

∼ 250 / 250

-15

…

+70

72

X 500 9 – x 0,9 2,8 40 489 265

X 501 9 x – 0,9 6,5 49 556 256

X 502 18 – x 1,8 5 43 504 265

X 500

X 503

500

9/18 – x 0,9/1,8 2,8/5,1

8

24,5

47 504

297

285

∼ 250 / 250

-10

…

+50

1)

70

X 800 9 – x 1,6 4,5 45 525 297 265

X 803 9/18 – x 1,75/3,5 4/8 49 550 297 285

X 805 4,5/9 – x 0,8/1,6 3/4,2 50 563 304 285

X 800

X 806

800

9/18 – x 0,8/3,2 3,6/9

8

39,2

71 603 328 315

∼ 250 / 250

-10

…

+50

1)

70

T 1000 9 – x 1,9 4,6 71 580 336 311

T 1003 9/18 – x 1,9/3,8 5,5/9,5 85 642 355 348

T 1005 4,5/9 – x 0,9/1,9 3,6/4,6 84 642 355 318

T 1000

T 1006

980

4,5/18 – x 0,9/3,8 4/9,7

8

48,1

94 679 386 348

∼ 250 / 250

-10

…

+50

1)

70

T 1020 9 – x 1,9 4,6 71 580 336 311

T 1023 9/18 – x 1,9/3,8 5,5/9,5 85 642 355 348

T 1025 4,5/9 – x 0,9/1,9 3,6/4,6 84 642 355 318

T 1020

T 1026

980

4,5/18 – x 0,9/3,8 4/9,7

9

48,1

94 679 386 348

∼ 250 / 250

-10

…

+50

1)

70

Page 3

tirak™

G932.1 - 06/2010 EN-DE-FR-NL–III

DE

FR

NL

ENEN

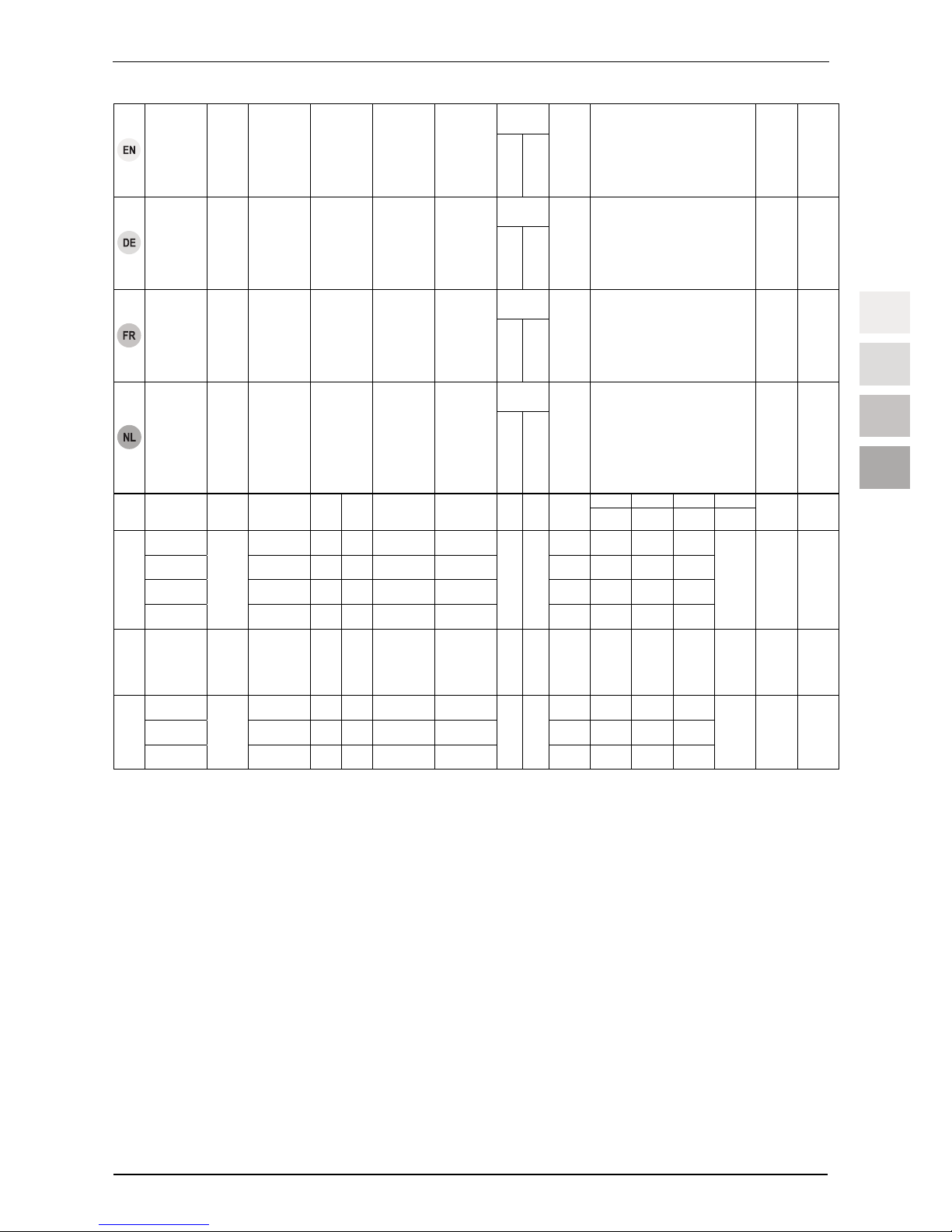

tirak

TM

rope

Hoist

Load-carrying

capacity

4)

Wire rope speed

6)

Connection

Power

Nominal

current

Diameter

Minimum

breaking load

5)

Weight

Dimensions / unit size

(see Fig. 2 and 3)

Temperature

range

3)

Noise

2)

tirak

TM

Seil

Winde

Tragfähigkeit

4)

Seilgeschwind-

igkeit

6)

Anschluss

Leistung

Nennstrom

Durchmesser

Mindest-

bruchkraft

5)

Gewicht

Abmessungen /

Einbaumaße

(siehe Abb. 2 und 3)

Temperatur-

bereich

3)

Geräuschent-

wicklung

2)

tirak

TM

câble

Treuil

Capacité de

charge

4)

Vitesse du câble

6)

Branchement

Puissance

Courant

nominal

Diamètre

Effort de rupture

minimal

5)

Poids

Dimensions /

Cotes de montage

(cf. Fig. 2 et 3)

Plage de tempé-

rature

3)

Emission so-

nore

2)

tirak

TM

kabel

Lier

Draagvermogen

4)

Kabelsnelheid

6)

Aansluiting

Vermogen

Nominale stroom

Diameter

Min. breukkracht

5)

Gewicht

Afmetingen/inbouwmaten

(zie Afb. 2 en 3)

Temperatuurbereik

3)

Geluidsont-

wikkeling

2)

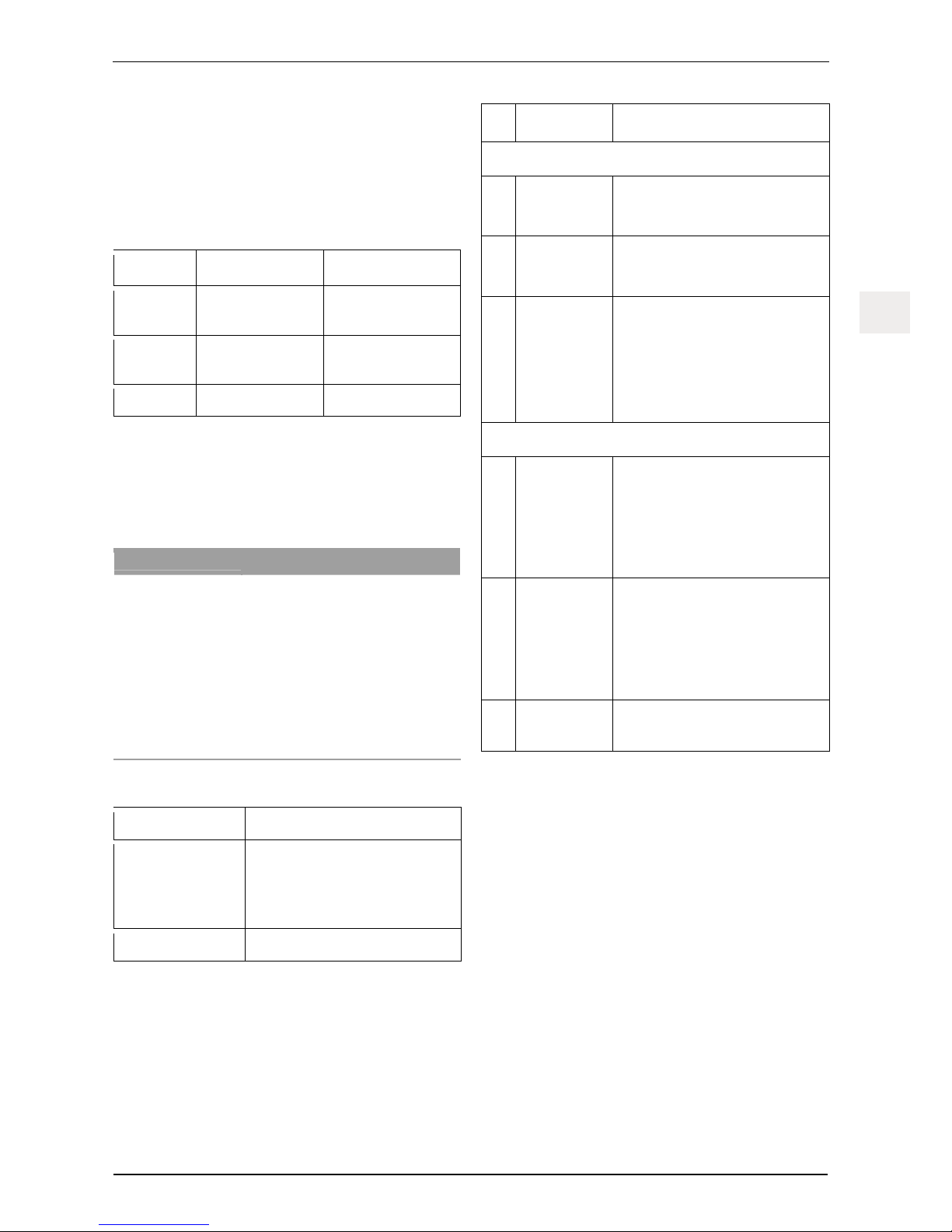

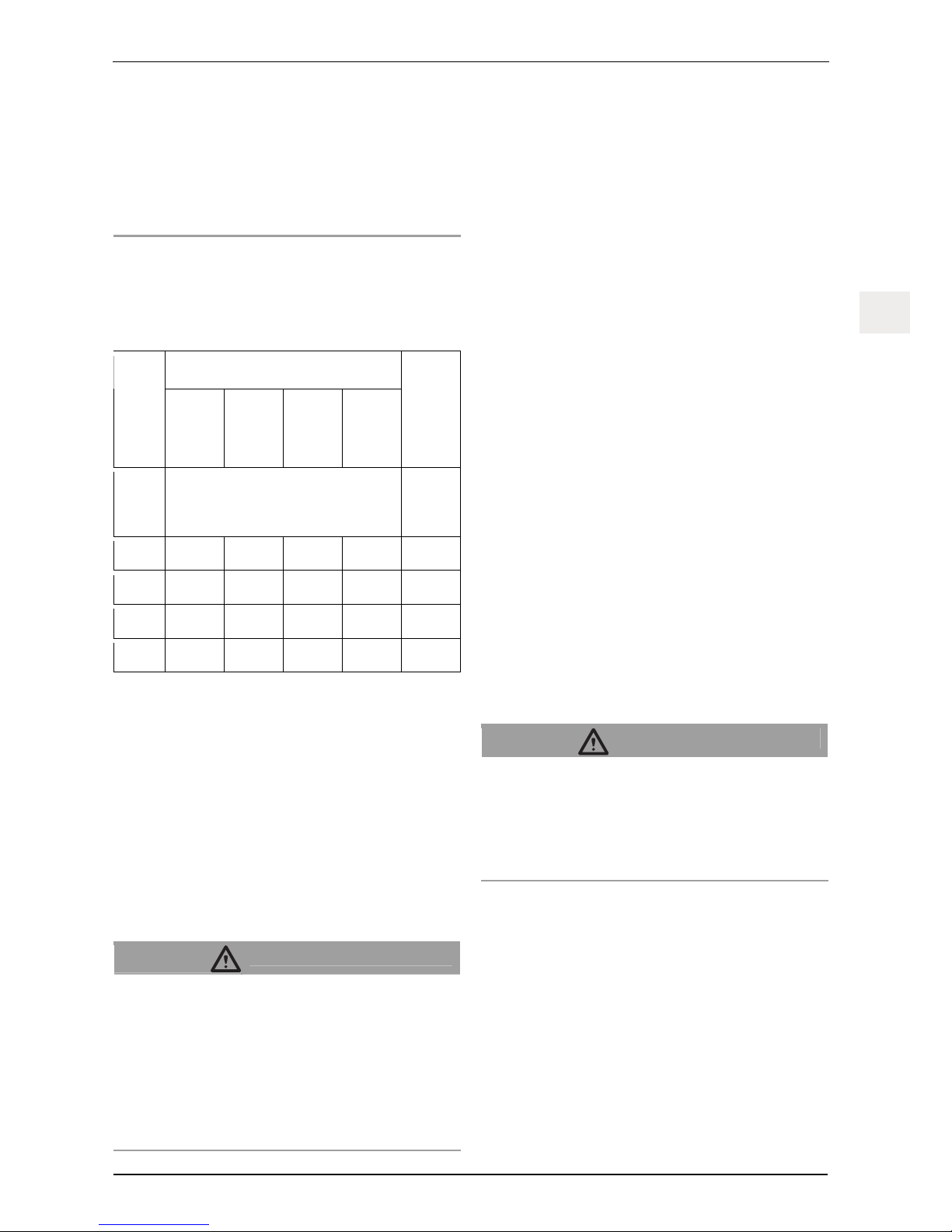

Table/Tabelle/Tableau/Tabel 1

4)

X-model series from 1000 kg load carrying capacity: with mechanical load limiting device; X-model series from

1000 kg load carrying capacity: mechanical or electric load limiting device can be supplied as an option. T

Model series: electric load limiting device can be supplied as an option.

X-Typenreihe ab 1000 kg Tragfähigkeit: mit mechanischer Hubkraftbegrenzung; X-Typenreihe bis 1000 kg

Tragfähigkeit: mechanische oder elektronische Hubkraftbegrenzung optional lieferbar. T-Typenreihen:

elektronische Hubkraftbegrenzung optional lieferbar.

Série X à partir d'une capacité de charge de 1000 kg : avec limitation mécanique de la force de levage; série X

jusqu'à une capacité de charge de 1000 kg : limitation mécanique ou électronique de la force de levage disponible en option. Séries T : limitation électronique de la force de levage disponible en option.

X-type serie vanaf 1000 kg draagvermogen: met mechanische hefkrachtbegrenzing; X-type serie tot 1000 kg

draagvermogen: mechanische of elektronische hefkrachtbegrenzing optioneel leverbaar. T-type series:

elektronische hefkrachtbegrenzing optioneel leverbaar.

1)

expanded temperature range on request / erweiterter

Temperaturbereich auf Anfrage / extension de la plage de

température sur demande / uitgebreid temperatuurbereik op

aanvraag

2)

at a distance of 1m / in 1 m Abstand / à 1m de distance / op 1 m

afstand

3)

Depending on the ambient conditions (ambient temperature,

sunrays, etc.) as well as the possible thermal discharge (dirt, accumulated heat, etc.)

Abhängig von den Umgebungsbedingungen (Umgebungstemperatur, Sonneneinstrahlung, etc.) sowie der möglichen Wärmeabfuhr (Schmutz, Stauwärme, etc.)

En fonction des conditions ambiantes (température ambiante,

rayonnement solaire etc.) et de l'éventuelle évacuation de la chaleur (saleté, accumulation de chaleur etc.)

Afhankelijk van de omgevingsvoorwaarden (omgevingstemperatuur, zonbestraling, etc.) en van de mogelijke

warmteafleiding (vuil, warmteopstopping, etc.)

a b c x/y

kg m/min

230 V

50 Hz

400 V

50 Hz

kW A

mm

kN

kg

mm mm mm mm

°C

dB

(A)

X 1020 9 – x 1,9 4,6

45

525 297 265

X 1023 9/18 – x 1,9/3,8 4,5/8,5

56

563 307 315

X 1025 4,5/9 – x 0,9/1,9 3,5/4,8

55

563 307 285

X 1020

X 1026

980

4,5/18 – x 0,9/3,8 4/9,6

9

48,1

71

605 332 315

∼ 250 / 250

-15

…

+70

70

X 1530

X 1530 1500 9 – x 2,8 7

10

73,6

49

522 297 285

∼ 250 / 250

-15

…

+70

70

X 3050 6 – x 3,8 9,9

105

669 400 372

X 3052 12

– x

7,5 17

117

681 403 372

X 3050

X 3053

3000

6/12 – x 3,8/7,5 9,9/19

14

147,2

156

786 428 442

∼ 250 / 250

-15

…

+70

78,5

Page 4

tirak™

EN-DE-FR-NL–IV G932.1 - 06/2010

DE

FR

NL

ENEN

5)

Calculation of the required minimum breaking load Fo of the rope

(does not correspond to the actual, manufacturer-specific

minimum breaking load!):

Berechnung der erforderlichen Mindestbruchkraft F

o

des Seiles

(entspricht nicht der tatsächlichen, herstellerspezifischen

Mindestbruchkraft!):

Calcul de l’effort de rupture mininal requis F

o

du câble (ne

correspond pas à l’effort de rupture minimal effectif et spécifique

du fabricant!) :

Berekening van de minimum breukkracht Fo van de kabel (komt

niet overeen met de daadwerkelijke fabrikantspecifieke min.

breukkracht!):

Fo = Zp x S

F

o

= 5 x S [kg] x 9,81 [N/mm²]

Fo: smallest guaranteed breaking load of the wire rope / kleinste garantierte

Bruchlast des Drahtseils / Charge de rupture minimale garantie du câble

métallique / kleinste gegarandeerde breuklast van de draadkabel

Z

p

: = 5: Expansion coefficient of the wire rope / Ausnutzungskoeffizient des

Drahtseils / Coefficient d’utilisation du câble métallique /

Belastingscoëfficiënt van de draadkabel

S: Maximum static load on the wire rope (load capacity of the hoist) / maximal

statische Zuglast im Drahtseil (Tragfähigkeit der Winde) / Charge statique

maximale du câble métallique (capacité de charge du treuil) / Maximale

statische treklast in draadkabel (draagvermogen van de lier)

6)

In accordance with DIN 15020 the devices correspond to drive group 1 Bm at rope speeds of up to 9

m/min, and to drive group 1 C

m

at a rope speed exceeding 9 m/min. The average operating time per

day with relation to a year (operating time class) depends on the actual load (load spectrum). /

Geräte entsprechen gemäß DIN 15020 bei Seilgeschwindigkeiten bis 9 m/min der Triebwerksgruppe

1 B

m

, über 9 m/min Seilgeschwindigkeit der Triebwerksgruppe 1 Cm. Die mittlere Laufzeit je Tag

bezogen auf ein Jahr (Laufzeitklasse) ist abhängig von der tatsächlich auftretenden Belastung

(Lastkollektiv). /

Appareils conformément à DIN 15020 pour les vitesses de défilement du câble jusqu'à 9 m/min dans

la catégorie de mécanismes de treuil 1 B

m

, vitesse de défilement du câble supérieure à 9 m/min dans

la catégorie de mécanismes de treuil 1 C

m

. La durée de vie moyenne par jour rapportée à un an

(classe de durée de vie) est fonction de la charge réelle sur le câble (spectre de charge). /

Apparaten voldoen volgens DIN 15020 bij kabelsnelheden tot 9 m/min aan de eisen van de

drijfwerkgroep 1 B

m

, boven 9 m/min kabelsnelheid aan de eisen van drijfwerkgroep 1 Cm. De

gemiddelde looptijd per dag gerelateerd aan een jaar (looptijdklasse) is afhankelijk van de

daadwerkelijk optredende belasting (collectieve belasting)

Page 5

tirak™

G932.1 - 06/2010 EN-DE-FR-NL–V

DE

FR

NL

ENEN

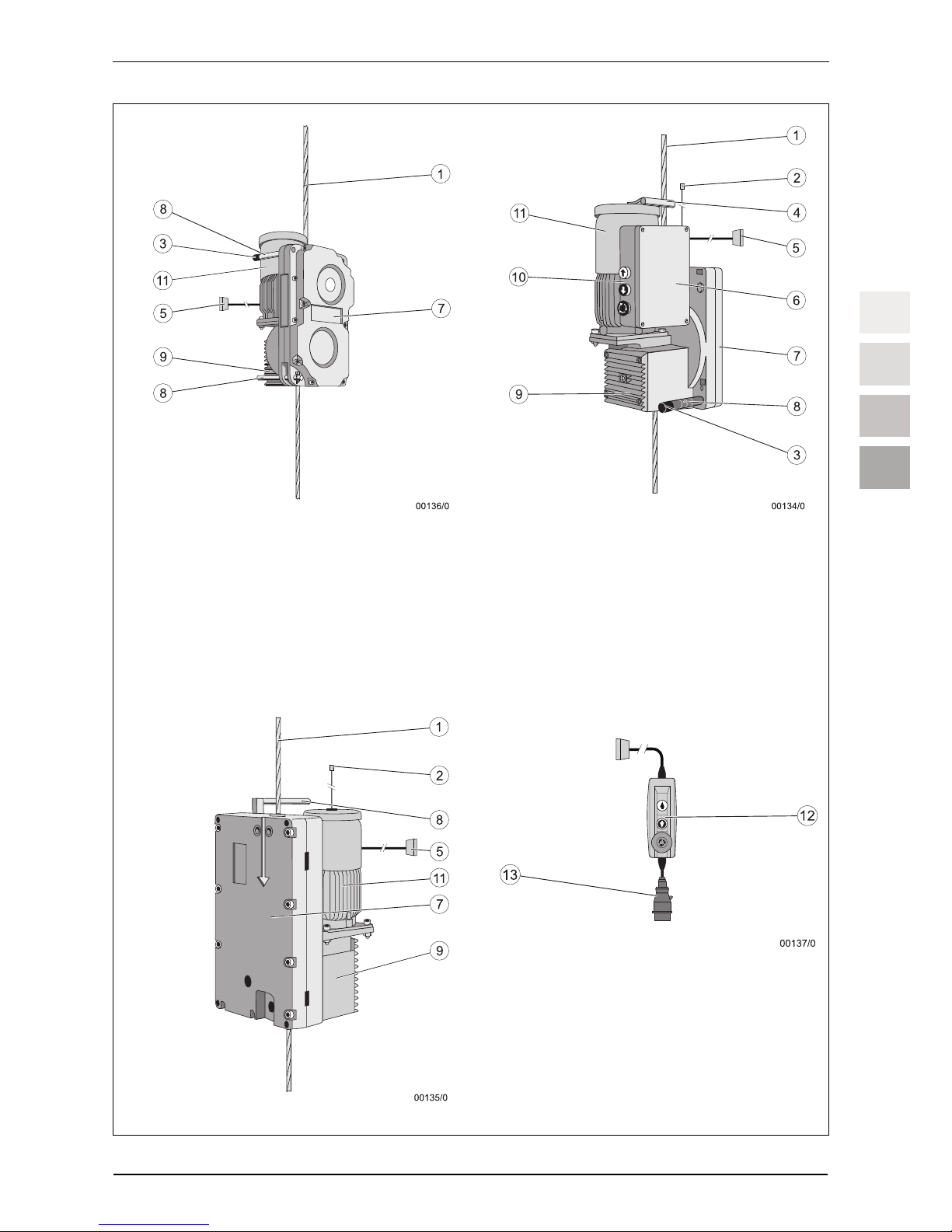

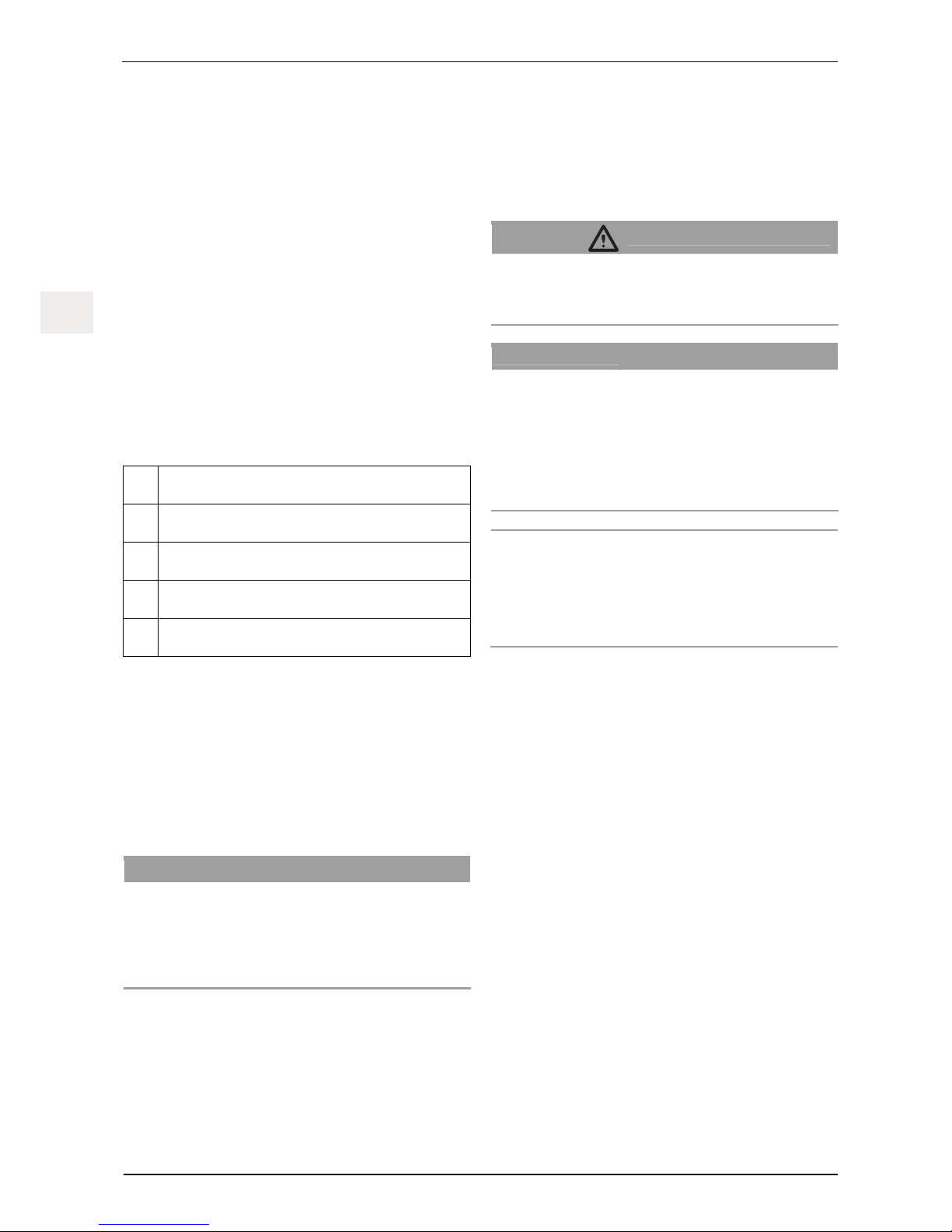

Model series / Typenreihe / Série / Serie

T 1000

T 1020

Model series / Typenreihe / Série / Serie

X 3050

Model series / Typenreihe / Série / Serie

X 300

X 400

X 500

X 800

X 1020

X 1530

Fig./Abb./Fig./Afb. 1

Page 6

tirak™

EN-DE-FR-NL–VI G932.1 - 06/2010

DE

FR

NL

ENEN

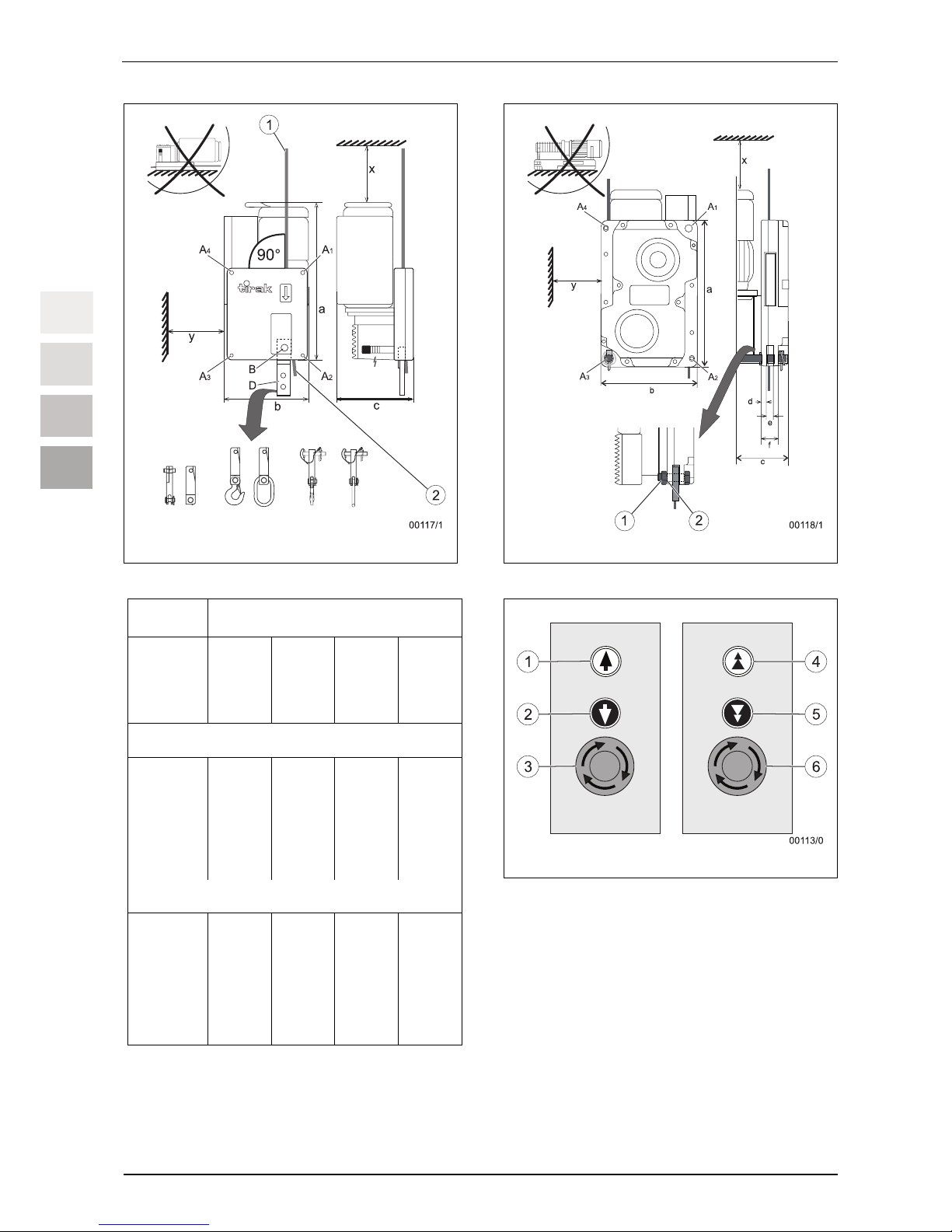

Fig./Abb./Fig./Afb. 2

Model series / Typenreihe / Série / Serie

X 300

X 400

X 500

X 800

X 1020

X 1530

T 1000

T 1020

X 3050

Distance / Abstand / Distance / Afstand [mm]

A1-A2

A2-A3

A1-A4

d

e

f

255

220

220

–

–

–

300

267

267

–

–

–

449

250

250

14

28

56

570

360

360

–

–

–

Screw / Schraube / Vis / Schroef

A

B

Adapter

Strength /

Festigkeit /

Résistance /

Sterkte

M10

–

M12

8.8

M10

M16

M12

8.8

M16

–

–

8.8

M16

M30

–

8.8

Table/Tabelle/Tableau/Tabel 2

Fig./Abb./Fig./Afb. 3

Fig./Abb./Fig./Afb. 4

Page 7

tirak™

G932.1 - 06/2010 EN-DE-FR-NL–VII

DE

FR

NL

ENEN

Fig./Abb./Fig./Afb. 5

Fig./Abb./Fig./Afb. 6

Fig./Abb./Fig./Afb. 7

Fig./Abb./Fig./Afb. 8

Fig./Abb./Fig./Afb. 9

Page 8

tirak™

EN-DE-FR-NL–VIII G932.1 - 06/2010

DE

FR

NL

ENEN

Fig./Abb./Fig./Afb. 10

Fig./Abb./Fig./Afb. 11

Fig./Abb./Fig./Afb. 12

Fig./Abb./Fig./Afb. 13

Page 9

tirak™

G932.1 - 06/2010 EN-DE-FR-NL–IX

DE

FR

NL

ENEN

Fig./Abb./Fig./Afb. 14

Fig./Abb./Fig./Afb. 15

Fig./Abb./Fig./Afb. 16

Fig./Abb./Fig./Afb. 17

Page 10

tirak™

EN-DE-FR-NL–X G932.1 - 06/2010

DE

FR

NL

ENEN

Fig./Abb./Fig./Afb. 18

Fig./Abb./Fig./Afb. 19

Page 11

Installation and operating manual

G932.1 - 06/2010 EN-1

ENEN

Contents

1 General ............................................................................... 2

1.1 Terms and abbreviations used in this manual .......... 2

1.2 Symbols used in this manual ....................................3

2 Safety.................................................................................. 3

2.1 General safety instructions ....................................... 3

2.2 Instructions for the operator...................................... 4

3 Overview............................................................................. 4

3.1 Delivery state ............................................................ 4

3.2 Scope of delivery ...................................................... 4

3.3 Equipment description .............................................. 4

4 Description......................................................................... 6

4.1 Functional description............................................... 6

4.2 Components / Modules............................................. 6

4.3 Technical Specifications ........................................... 7

4.4 Operating fluids......................................................... 7

4.5 Circuit diagram.......................................................... 7

4.6 Operating unit ........................................................... 7

4.7 Safety equipment...................................................... 7

4.8 Anchoring.................................................................. 8

4.9 Increasing the load bearing capacity ........................ 8

5 Ropes.................................................................................. 8

6 Optional accessories......................................................... 8

7 Options ............................................................................... 8

8 Necessary accessories ..................................................... 9

9 Installation and commissioning....................................... 9

9.1 Directives and standards .......................................... 9

9.2 Checks to be undertaken before starting the

installation................................................................. 9

9.3 Assembly ................................................................ 10

9.4 Commissioning ....................................................... 12

10 Operating / Operation...................................................... 13

10.1 Checks to be carried out before starting work ........ 13

10.2 Operation................................................................ 13

10.3 Emergency descent ................................................ 14

10.4 Switching off when overloaded ............................... 14

11 Foreseeable misuse ........................................................ 14

12 Dismantling ...................................................................... 14

13 Shutting down.................................................................. 15

13.1 Work breaks............................................................ 15

13.2 Temporary shutdown .............................................. 15

13.3 Permanently decommissioning............................... 15

14 Transport and storage .....................................................15

14.1 Hoists.......................................................................15

14.2 Rope........................................................................15

15 Maintenance work ............................................................15

15.1 Authorized maintenance personnel.........................15

15.2 Mandatory inspections.............................................15

15.3 Reading the running hours counter .........................16

15.4 Care and maintenance ............................................16

15.5 Adjustment...............................................................17

15.6 Ordering spare parts................................................19

16 Disposal and environmental protection.........................19

17 Troubleshooting...............................................................20

18 EU Declaration of Conformity (Extract)..........................23

DANGER!

Risk of injury caused by falling objects, malfunctions,

incorrect usage and incorrect operation!

Failure to follow these instructions:

can result in severe injuries or death,

can result in damage to the equipment.

– Read through this operating manual carefully before you

install and commission this machine.

– Follow the instructions and procedures specified in this

manual in order to ensure safe operation of the equipment.

Page 12

Installation and operating manual

EN-2 G932.1 - 06/2010

ENEN

1 General

Date of issue

June 2010

Copyright

The copyright of this instruction manual remains with Greifzug

Hebezeugbau GmbH.

This instruction manual is intended only for the operators of the

systems described here and their staff. This instruction manual

must be available to the operating personnel at all times. Additional copies can be obtained on request.

No part of this instruction manual may be reproduced, distributed

or otherwise communicated without the permission of Greifzug

Hebezeugbau GmbH.

Legal proceedings may be implemented in the case of any infringements.

Manufacturer's address

Sales and service office:

Greifzug Hebezeugbau GmbH

Scheidtbachstraße 19-21

51469 Bergisch Gladbach, Germany

Postfach 20 04 40

51434 Bergisch Gladbach, Germany

Tel: +49 (0) 22 02 / 10 04-0

Fax: +49 (0) 22 02 / 10 04-50 + 70

Greifzug Hebezeugbau GmbH reserves the right to make

changes to the product described in this instruction manual as

part of their ongoing product improvement programme.

Customers can obtain documentation about other TRACTEL

products by requesting the documentation from companies within

the TRACTEL Group or service organisations appointed by the

TRACTEL Group. Please visit our TRACTEL website at:

www.tractel.com for further details regarding the hoisting gear

and related accessories; stationary or mobile working platforms

for moving around on the inside and outside of buildings; rigging;

block stops for heavy loads; personal safety harnesses to prevent falls; traction and rope tension measuring equipment, etc.

The TRACTEL Group and its dealer network also provide additional customer and repair services upon request.

1.1 Terms and abbreviations used in

this manual

The terms used in this instruction manual have the following

meanings:

System / Machine

Pursuant to the Machine Directive 2006/42/EC lifting equipment,

hoisting gear and rigging for lifting are regarded as machines.

The term "system" or also "machine" describes the device in

which the unit described here will be fitted.

System manufacturer

The system manufacturer (system planner, system manufacturer,

installer) is the company marketing the system and all of the

required components. The system manufacturer is responsible

for the design, manufacturing, assembly and marketing.

Rigging

Rigging consists of equipment which does not belong to the

hoisting gear and which creates a connection between the carrying means and the load or the carrying means and the load lifting

equipment (e.g. rope loops, round slings, shackles, swivel hooks,

eye hooks, deflection rollers).

Anchoring point

Part of the on-site suspended construction to which the suspension rope, the safety rope, deflection rollers or the hoisting gear

is anchored.

Operating personnel

Personnel who have been trained by the operator to operate the

product and are authorised to operate it.

Operator

The operator is responsible for the correct operation of the system / equipment and also for adhering to the maintenance intervals and the undertaking of the service work.

Electrician

An electrician is someone who possesses sufficient knowledge

or has obtained the required qualification through training in

order to recognise the risks and avoid the dangers that can occur

when working with electricity.

Independent secondary brake

A device for stopping the load lifting equipment in the event of

the suspension rope snapping or a malfunction, e. g. drive malfunction.

Hoisting gear / machine for lifting loads

Device or equipment consisting of a device with load carrying

means for lifting or transporting loads (e.g. wire rope hoist or wire

rope hoist with rope and swivel hook).

Customer / end customer

The customer or end customer is the system manufacturer's

customer and can also be the operator.

Load lifting equipment (LAM)

A component or piece of equipment which does not belong to the

hoisting gear, which enables the load to be grasped and which is

attached between the machine and the load or to the load itself,

or is intended to be an integral component of the load. Rigging

and its components are also regarded as load lifting equipment.

Material lifting equipment (MAM)

Load lifting equipment for material.

Nominal load

The nominal load is the load bearing capacity of the hoist and is

the load that is applied to a certain position, e.g. on a deflection

roller. Simple reeving doubles the nominal load.

Page 13

Installation and operating manual

G932.1 - 06/2010 EN-3

ENEN

Specialist

An appointed person who has undergone the appropriate training

and who, due to his knowledge and practical experience, is able

to safely perform the required work when provided with the necessary instructions.

tirak™

tirak™ is used in the text as the abbreviation for the hoist.

Load bearing capacity

The load bearing capacity specifies the maximum load the hoist

is allowed to lift or pull. The load bearing capacity can be multiplied by reeving the rope.

Carrying means

The carrying means is equipment connected to the hoisting gear

for attaching load lifting equipment, rigging or loads (e.g. a hook

permanently attached to the suspension rope).

Maintenance personnel

A person appointed by and trained by Greifzug Hebezeugbau

GmbH with a valid certificate, who is capable of safely performing

the required maintenance, inspection and service work when

provided with the required instructions.

1.2 Symbols used in this manual

DANGER!

Type and source of danger

Result: e.g. death or severe injuries.

– Measures that must be taken to eliminate the danger.

ATTENTION!

Type and source of danger

Result: e.g. equipment or environmental damage.

– Measures that must be taken to eliminate any possible

damage.

Note:

This symbol is not used to indicate safety information but to

indicate information that will give you a better understanding o

f

the working procedures.

2 Safety

2.1 General safety instructions

DANGER!

Danger of severe injuries caused by malfunctions, incorrect use and incorrect operation!

– You must abide by the following instructions in order to

ensure safe operation and correct functioning of the

equipment!

– Please observe the special safety instructions for all of

the work to be performed as described in the individual

chapters in this manual.

– Faulty or damaged hoists, ropes, rigging or power supply

and control cables must never be used!

– The hoists may only be used with an original tirak™ wire

rope with the specified wire rope diameter.

– Rope, hoist and rigging must not be soiled by heavily soiling

building materials such as concrete, epoxy resin or other

adhesive materials. Protect the components against soiling!

Use the brush attachments to clean the rope when working

in an extremely dirty environment.

– Abide by the rope's withdrawal criteria, see ' 15.4 Care and

maintenance, Rope' on page 16.

– Cleaning the wire rope or the hoist with high pressure

cleaners is prohibited! Moisture results in malfunctions and

damage to the motor, brake and the electrical equipment.

– Dirt on the wire rope will result in premature wear or the

corrosion of the wire rope, rigging and hoist.

– Abide by the instructions concerning transport, storage and

cleaning listed on page 15.

– Always comply with the safety specification sheets provided

by the relevant manufacturers covering the lubricants to be

used.

– The anchoring devices must comply with the instructions

given in this manual or the applicable directives / standards.

– Never exceed the permitted load bearing capacity.

– Motors can become hot whilst working. Never touch the

motors.

– Operation without rubber plugs on the motor (Position 3, see

Fig. 15) is prohibited. Moisture can impair the effectiveness

of the brake. Risk of injury on the exposed motor shaft.

– Working outdoors during lightning or a storm is prohibited.

Danger of lightning strikes or the load being tipped over by

gusts of wind.

– Local climate and weather conditions must always be taken

into consideration during the planning stages: If in doubt,

you must request the weather and wind forecast from the

meteorological office before beginning work.

– Maintenance and repair work must only be undertaken by

authorised service personnel, see ' 15.1 Authorized mainte-

nance personnel' on page 15.

Page 14

Installation and operating manual

EN-4 G932.1 - 06/2010

ENEN

– Only qualified personnel who have been trained on the

system are permitted to install and operate it in compliance

with the instructions given in this instruction manual.

– Private users are obliged to obtain training in the assembly,

operation and maintenance of the unit by Greifzug Hebezeugbau GmbH.

– Only qualified electricians or trainees supervised by a quali-

fied electrician are permitted to undertake work on the electrical equipment in accordance with the electro technical

standards, rules and regulations.

– Never stand beneath suspended loads. Cordon off the

hazard zone whenever necessary.

– Never grasp the wire rope while the machine is operating.

– Never reach into the hoist's inlet or outlet whilst the machine

is operating. Risk of being pulled in and crushed.

– Hearing protection may be necessary, depending on how

the hoist is installed.

– If the load cannot be guided by on-site means then a low-

twist wire rope with a swivel hook or a rope swivel must be

used.

2.2 Instructions for the operator

– If more than one person is entrusted with the tasks men-

tioned above then the operator must appoint a supervisor

who is authorised to issue instructions.

– The operator is also responsible for preparing clear operat-

ing, maintenance, repair and other working instructions and

ensuring that the unit is operated correctly by instructing and

training the personnel in the correct and approved utilisation

methods.

– The operator is responsible for the correct operation of the

system as well as for adhering to the maintenance periods

and the undertaking of the service work.

– The operator is committed to maintaining the logbook sup-

plied with the system.

– You must always abide by the national accident prevention

regulations. EU Directive 89/391/EEC applies within the

European Union (in Germany Betriebssicherheitsverord-

nung (BetrSichV)). You must always abide by your country's

national accident prevention regulations.

– You must provide suitable protective equipment such as

safety gloves, hearing protectors and a fall prevention sys-

tem. Protection against extreme weather conditions (e.g.

sun protection, protection against cold) are also considered

to be part of the personal protective equipment.

– Always ensure that the workplace is sufficiently lit.

– A copy of these operating instructions must be provided and

readily available to the responsible personnel at all times.

– As Greifzug Hebezeugbau GmbH does not know the appli-

cations that the hoist described here will be used for in the

future, the system operator is therefore committed to inform-

ing their personnel about any new safety instructions as well

as any supplementary maintenance work.

– The system operator is responsible for selecting the anchor-

ing method and suitable rigging options.

– The anchoring devices must comply with the instructions

given in this manual or the applicable directives / standards.

– The use of non-original parts, in particular the use of other

than the prescribed original tirak™ wire ropes, will invalidate

the warranty of the manufacturer as well as the CE approval.

– Adhere to the permitted temperature range, see Table 1 on

page III.

3 Overview

3.1 Delivery state

The hoist is delivered completely assembled.

3.2 Scope of delivery

Hoist with control and connecting cable (wired fixed) in

accordance with the order specifications

tirak

TM

wire rope in accordance with the order specifications

Original Installation and operating manual

Circuit diagram

Logbook

Test certificate

CE Declaration of Conformity

Limit switch for switching off the lifting and pulling motions in

accordance with the order specifications.

Optional scope of delivery:

Button panel, pluggable

Central control unit, pluggable

Electronic or mechanical load limiting device

Deflection roller

Brush attachments for cleaning the ropes

The lengths of the control cable and the connecting cable are

determined when ordering. See also ' 6 Optional accessories' on

page 8, ' 7 Options' on page 8 and 'Electrical connection' on

page 10.

3.3 Equipment description

Approved use

The hoists are designed for raising and lowering as well as pulling and releasing or moving loads. Transporting personnel is

prohibited. The hoist is suitable for commercial as well as private

use. The precise intended use will be defined by the operator or

the system manufacturer.

Page 15

Installation and operating manual

G932.1 - 06/2010 EN-5

ENEN

Hooks, shackles and eyes or other optional carrying means

belonging to the device may only be used in combination with

this device.

X-Model series:

The rope infeed is on the motor side (observe the arrow on the

casing!). This corresponds to the load side of the hoist. The rope

outfeed is on the unloaded side of the hoist. The unloaded side

of the hoist may be loaded with a maximum of 100 kg (e.g. via

the rope pre-tensioning).

T-Model series:

The hoist can be pulled in both directions. Depending on the

running direction, the rope infeed is either on the motor side or

on the opposite side.

When pulling the rope pretension must not exceed 400 kg (see

Fig. 8 g/h).

The hoists may only be used with an original tirakTM wire rope

with the specified wire rope diameter.

If the load cannot be guided by on-site means then a low-twist

wire rope with a swivel hook or a rope swivel must be used.

Maintenance and repair work must only be undertaken by authorised service personnel, see ' 15.1 Authorized maintenance per-

sonnel' on page 15.

Greifzug Hebezeugbau GmbH declares that the machine described in this instruction manual complies with technological

safety standards that were applicable to the equipment in the

European Union when it was launched on the market by the

manufacturer.

Commissioning the machine is prohibited until the machine in

which this is installed complies as a whole with the regulations of

the 2006/42/EC Directive, the corresponding national legislation

for implementing the regulations in accordance with national law

and the corresponding declaration of conformity has been issued.

The operator or system manufacturer must perform a risk evaluation in accordance with Appendix I of the guideline 2006/42/EC

for machines for raising loads. EN 14492-1 must also be taken

into account when inspecting the equipment.

Any use other than that described here will be considered to be

unauthorised. Greifzug Hebezeugbau GmbH does not accept

any liability for damages resulting from unauthorised use. The

operator must assume sole responsibility in this case. Abiding by

all of the instructions given in this instruction manual, in particular

the installation and maintenance regulations, are also considered

part of authorised use.

Guarantee and liability exclusions

See ' 11 Foreseeable misuse' on page 14.

Application areas

The hoist is suitable for use under the following operating conditions:

For permanent or temporary installations

For short-term operation: Drive groups see Table1 on

page III.

At heights of up to 1,000 m above sea level (max)

Permitted temperature range see Table 1 on page III

DANGER!

Danger of severe accidents!

– 24-hour operation is prohibited.

– Use in areas where there is a risk of explosion is prohib-

ited.

– Use in a corrosive environment is prohibited.

1)

– Use in close proximity to open fire or in an extremely hot

environment is prohibited.

– Transport of persons is prohibited!

1)

Corrosion protection in accordance with order specifications

Installation example

See Fig. 8.

Structural requirements

Structural equipment for anchoring the hoist must possess a load

bearing capacity at least four times that of the hoist.

Please note that the load on the deflection roller, rigging and the

anchoring point increases depending on the arrangement of the

hoisting gear, deflection roller and load! See ' 4.9 Increasing the

load bearing capacity' on page 8.

The path of the hoist for lifting must be limited by one or multiple

limit switches, so that the upward and / or downward movement

is stopped. The operator or the system manufacturer must determine the design and the fitting position of the limit switches

when taking their risk assessment into account.

The operator or system manufacturer must install a limit switch

and, if necessary, an emergency limit switch and a floor limit

switch and connect them to the hoist. The limit switch must have

a positive opening. The clearance to the wire rope anchoring or

protruding components must be at least 1.5 m.

The wire rope must be long enough that the connection of the

rope end or the end of the rope cannot be called into the hoist

housing or the deflection roller.

If the load cannot be guided by on-site means then a low-twist

wire rope with a swivel hook or a rope swivel must be used.

It must be possible to position the operating equipment in such a

way that safe operation is always possible.

Rope, hoist and rigging must not be soiled by heavily soiling

building materials such as concrete, epoxy resin or other adhesive materials. The components must be protected against soiling.

Page 16

Installation and operating manual

EN-6 G932.1 - 06/2010

ENEN

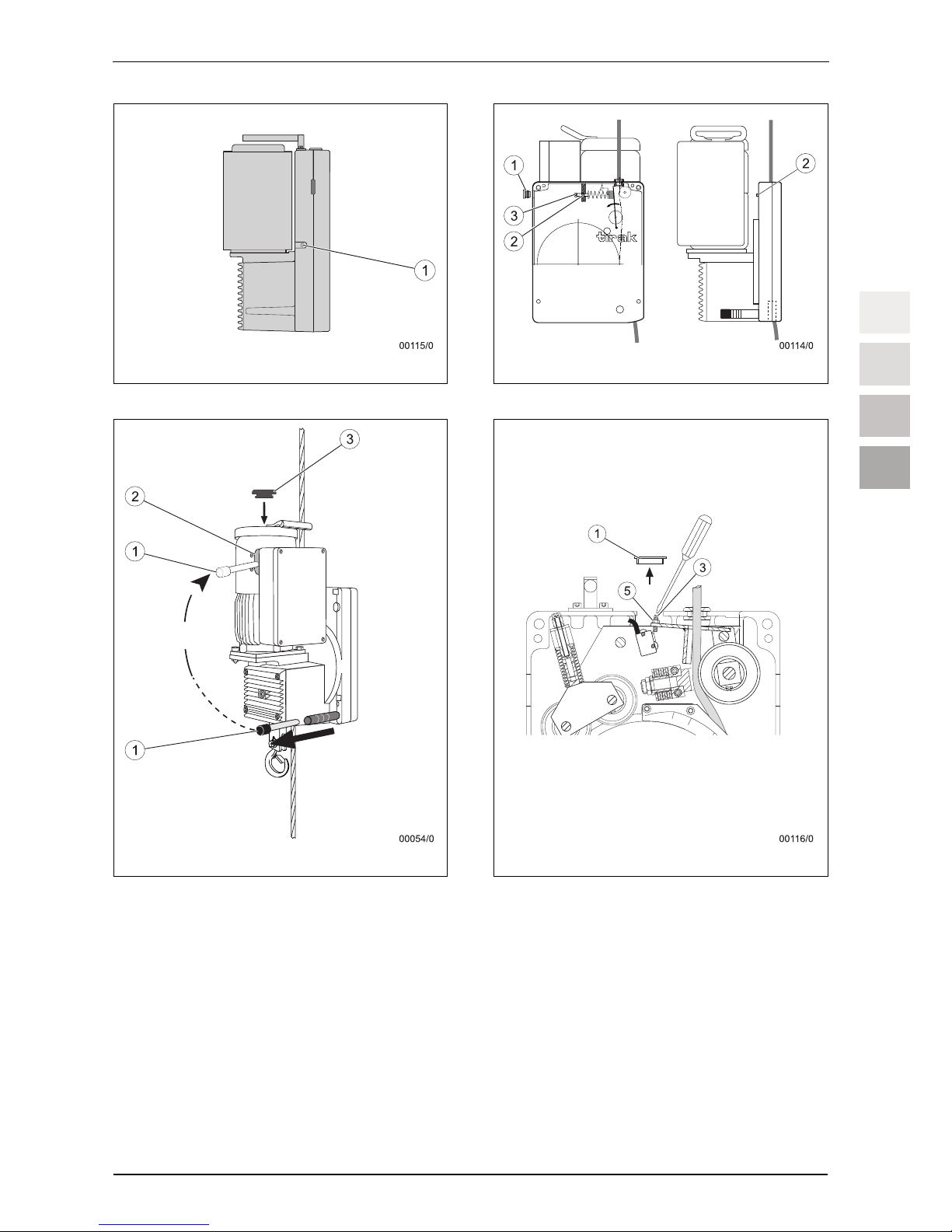

Nameplate and warning signs / application restrictions

See Fig. 10.

Item Name

1 Warning sign 'Wire rope diameter'

2 tirak™ nameplate

3 Brake nameplate

4 Electric motor nameplate

5 Emergency descend warning sign

6 Rope identification

The necessary information can be obtained from the nameplate.

Directives and standards

Applicable directives and standards: See ' 9.1 Directives and

standards' on page 9.

Product versions covered in the manual

The product versions described in this manual are listed in

Table 1 on page III.

Running hours counter

The running hours counter is located in the hoist's terminal box.

The running hours counter counts the time in which the hoist is in

operation as running hours (UPWARD or DOWNWARD movements). To read the running hours counter: See ' 15.3 Reading

the running hours counter' on page 16.

4 Description

4.1 Functional description

The tirakTM is a hoist for raising and lowering loads. The hoist is

operated with an electric motor.

The X-model series hoists can raise and lower as well as pull

and release in the pulling direction of the rope.

The T-model series hoists can pull in both directions and are

used, for example, for moving loads.

Operation is carried out via a button panel, control box or a central control unit.

The electromagnetic spring-applied brake automatically locks

when the operating control for travelling UP or DOWN is released

or when the power fails. A centrifugal brake prevents rope

speeds that are too high when lowering the load manually.

The load bearing capacity of the hoist can be multiplied according to the block and tackle principle by reeving the rope. See

' 4.9 Increasing the load bearing capacity' on page 8.

Press the EMERGENCY OFF button to stop the hoist immediately in an emergency situation.

X-Model series:

Hoists with a load bearing capacity of 1,000 kg or greater have a

mechanical load limiting device. Hoists with a load bearing capacity of 1,000 kg or greater can be optionally equipped with an

electrical or a mechanical load limiting device.

The load limiting device turns off the hoist at the latest once the

load reaches 1.25 times the load bearing capacity.

T-Model series:

Hoists of the T-model series can be optionally equipped with an

electrical load limiting device.

The load limiting device turns off the hoist at the latest once the

load reaches 1.25 times the load bearing capacity.

4.2 Components / Modules

See Fig. 1.

Item Name

1 Rope

2 Plug connector for the limit switch

3 Brake magnet lever

4 Handle

5 Plug connector for control unit1)

6 Terminal box (with optional running hours counter)

7 Rope drive

8 Carry handle

9 Gearbox

10 Operating unit1)

11 Motor

12 Controls (button panel)1)

13 Connecting plug

14 Limit switch (not shown)

1)

Optional scope of delivery, dependent on the hoist version and the

order specifications

Page 17

Installation and operating manual

G932.1 - 06/2010 EN-7

ENEN

4.3 Technical Specifications

The technical specifications are listed in Table 1 on page III.

4.4 Operating fluids

Transmission oil (hoist)

Mineral oil1) Synthetic oil2)

Temperature

range

-10…+50 °C -15…+70 °C

API specification

SAE85W-140 GL5 CLPPG or

PGLP ISO VG 460

Type Aral HYP85W-140 Klübersynth GH6 460

1)

Model series: X 300, X 500 to T 1020

(Identification: Oil drain plug with socket head screw)

2)

Model series: X 400, X 1020 to X 3050

(Identification: Oil drain plug with hexagon head screw)

In normal cases, it is not necessary to change the transmission

oil.

ATTENTION!

Incorrect transmission oil!

Damage to the gearbox due to insufficient lubrication.

– Use only the lubricants specified in the table.

Synthetic oil and mineral oil may not be mixed!

– Thoroughly flush the gearbox repeatedly with the new oil

type when changing the oil type.

– Change the oil drain plug to correspond with the new oil

type (socket head screw: mineral oil; hexagon head

screw: synthetic oil).

Lubricant

Application Lubricant

Traction sheave external

teeth (only model series

X 3050)

hebro-chemie VARILUB

or Klüber Grafloscon C-SG 0 Ultra

or Klüber C-SG 1000 Ultra

Quantity approx. 10 cm³ per lubrication

Rope Multipurpose oil/grease (without disulphide)

4.5 Circuit diagram

The circuit diagram is located in the terminal box of the motor.

4.6 Operating unit

Depending on the product version the hoist is controlled by a

button panel, control box or a central control unit, see Fig. 1 and

Fig. 4.

Item Name Function

Devices with one speed

1 UP button Move load upwards / pull rope:

– Press and hold the button

2 DOWN button Move load downwards / release rope:

– Press and hold the button

3 EMERGENCY

OFF button

Turn on the device:

– Turn to the right until the button

releases

Disconnecting power supply:

– Press the button in

Devices with two speeds

4 UP button Move load upwards /pull rope:

– Press the button halfway and hold:

slow

– Press the button completely and hold:

fast

5 DOWN button Move load downwards / release rope:

– Press the button halfway and hold:

slow

– Press the button completely and hold:

fast

6 EMERGENCY

OFF button

See Point 3.

4.7 Safety equipment

EMERGENCY OFF button

The hoist is stopped immediately in an emergency situation by

pressing the EMERGENCY OFF button.

Mechanical load limiting device

X-Model series:

y From 1,000 kg load bearing capacity

y Up to 1,000 kg load bearing capacity optional scope of

delivery

The load limiting device switches off automatically if overloading

occurs. When delivered, the load limiting device has been set in

such a way that it deactivates the hoist at the latest once the load

reaches 1.25 times the load bearing capacity.

Electric load limiting device (optional)

The electric load limiting device switches off automatically in

case of an overload. The load limiting device reacts to the power

consumption of the motor. Hoists with two speeds are equipped

Page 18

Installation and operating manual

EN-8 G932.1 - 06/2010

ENEN

with two electric load limiting devices. An overload is recognised

when lifting. When delivered, the load limiting device has been

set in such a way that it deactivates the hoist at the latest once

the load reaches 1.25 times the load bearing capacity.

Spring-applied brake

The electromagnetic spring-applied brake automatically locks

when the operating control for travelling UP or DOWN is released

or when the power fails.

Centrifugal brake

A centrifugal brake on the motor shaft of the hoist ensures that

the load is not lowered too fast when the spring-applied brake on

the hoist’s motor is released manually.

Limit Switch / emergency limit switch

The path of the hoist for lifting must be limited by one or multiple

limit switches, so that the upward and / or downward movement

is stopped. The operator or the system manufacturer must determine the design and the fitting position of the limit switches

when taking their risk assessment into account.

The operator or system manufacturer must install a limit switch

and, if necessary, an emergency limit switch and a floor limit

switch and connect them to the hoist. The limit switch must have

a positive opening.

EN 14492-1 must also be taken into account when inspecting the

equipment.

Running hours counter

The running hours can be read from the running hours counter,

in order to determine when the next hoist safety check must be

carried out.

Phase sequence relay (hoists without converter)

In control units operating by three-phase current, the phase

sequence relay shuts down the system in the case of an incorrect phase sequence and this prevents an UP / DOWN travel

direction mix-up, which could potentially disable the limit switches

and load limiting devices.

4.8 Anchoring

The hoist can be anchored with and without an adapter (see pos.

D in Fig. 2).

Anchoring without adapter: At least 2 screws with a minimum

strength class of 8.8 with self-locking nuts.

Anchoring with adapter: 2 screws with a minimum strength class

of 8.8 with self-locking nuts.

Bolts that have at least the same strength and a similar quality

for securing can be used instead of the screws.

See also ' 9.3 Assembly' on page 10.

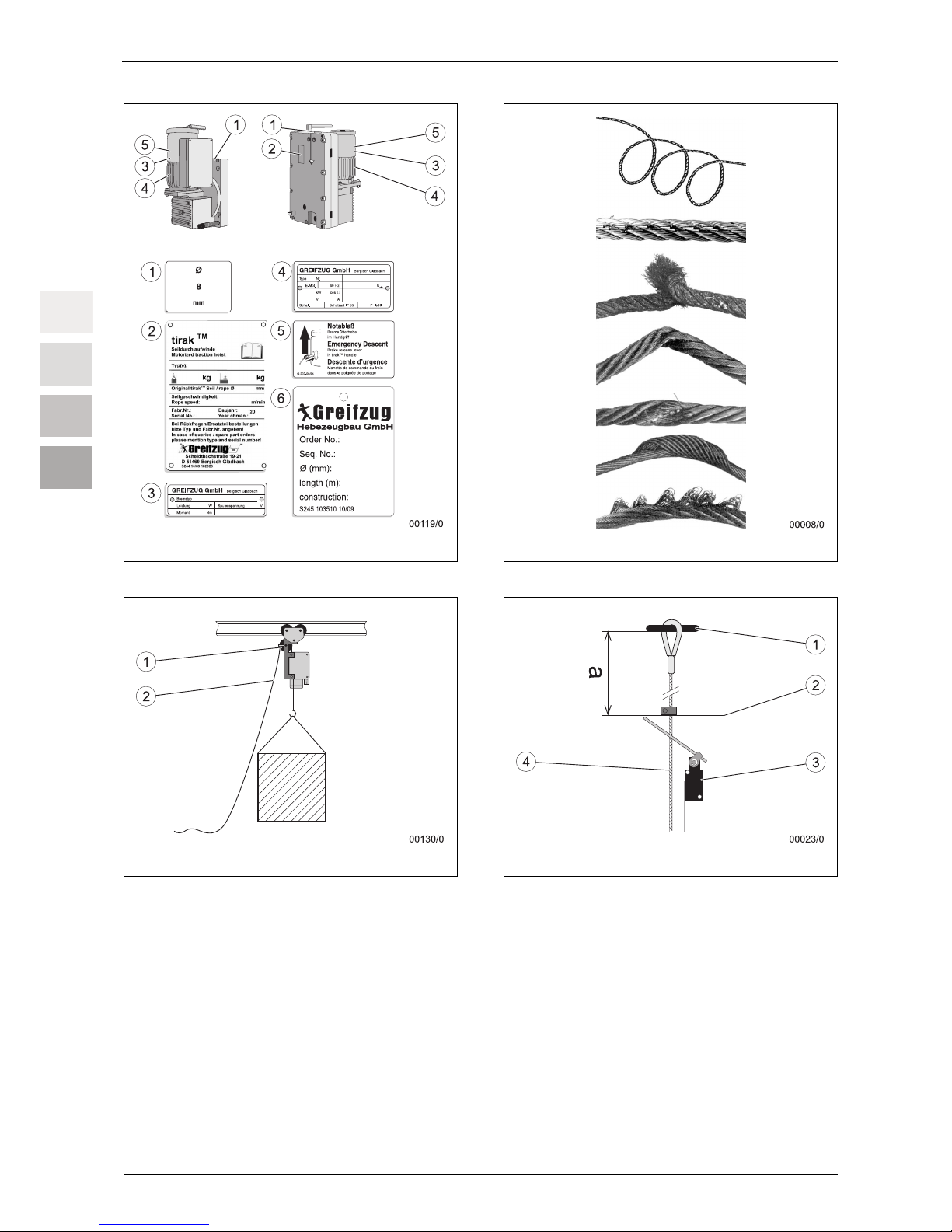

4.9 Increasing the load bearing capacity

DANGER!

Incorrect anchoring! Incorrect usage!

Risk of being injured by falling objects!

The load on the deflection roller, rigging and the anchoring

point increases depending on the arrangement of the hoisting

gear, deflection roller and load!

– The minimum breaking strength of the deflection roller,

the rigging and the anchoring point must be four times

greater than the nominal load of the hoist in the given installation situation (see Fig. 8).

The load bearing capacity of the hoist can be increased by reeving the rope, see Fig. 8 (F corresponds to the load bearing capacity of the hoist).

Note:

Reeving the rope reduces the hoist speed.

5 Ropes

DANGER!

Incorrect rope or rope with incorrect diameter!

Using an incorrect rope leads to a danger of falling or injury

through falling objects and the risk of malfunctions!

– In order to operate safely only use original ropes author-

ized by Greifzug Hebezeugbau GmbH with the correct

rope diameter and the required design.

– If the load cannot be guided by on-site means then a low-

twist wire rope with a swivel hook or a rope swivel must

be used.

– The required rope diameter is listed Table 1 on page III.

The design is listed Table 5 on page 17.

6 Optional accessories

The following accessories can also be purchased:

Deflection roller

Adapter, eye hook or master link

Please contact Greifzug Hebezeugbau GmbH directly.

7 Options

Please contact Greifzug Hebezeugbau GmbH directly.

Page 19

Installation and operating manual

G932.1 - 06/2010 EN-9

ENEN

8 Necessary accessories

The following accessories, which are not included in the scope of

delivery, are needed to be able to use the device:

Anchoring devices for the hoist (see ' 4.8 Anchoring' on

page 8).

Rigging equipment with a minimum breaking strength that

has four times the load bearing capacity of the hoist.

If the suspension rope is deflected or reeved: Deflection

rollers and rigging with a minimum breaking strength four

times greater than the nominal load of the hoist in the given

installation situation (see Fig. 8).

A longer connecting cable can be used if necessary, see

'Electrical connection' on page 10.

Other original Greifzug accessories: See ' 6 Optional accessories'

on page 8.

The operator or the manufacturer of the system is responsible for

selecting and using the accessories in accordance with the local

conditions. You must also abide by any other requirements of the

respectively applicable regulations and standards.

9 Installation and commissioning

9.1 Directives and standards

The machine fulfils the following directives and standards:

Machine Directive 2006/42/EC

DIN EN ISO 12100

Low voltage Directive 2006/95/EC

EN 60204

EN 14492; EN 14492-1/prA1:2009

The operator or the system manufacturer is responsible for ensuring that the machine is used within the limits specified in these

instructions. The operator or the system manufacturer must also

observe the directives and standards and EN ISO 14121 and

EN ISO 13849 for the machine in which the unit will be fitted.

9.2 Checks to be undertaken before

starting the installation

Check the rigging, deflection rollers and anchoring points

– Check to ensure that the deflection roller, the rigging and

the onsite anchoring point all have the necessary load bearing ratings and minimum breaking strength, see

' 4.9 Increasing the load bearing capacity' on page 8.

The maximum possible nominal load must be multiplied by 4

(operating coefficient) in order to calculate the necessary

load bearing capacity.

Inspecting the installation site

Check whether the hoist can be installed correctly without it

being obstructed by other system components. Observe the

required installation space in accordance with Fig. 2 and

Table 1 on page III. The installation space must not contain

any sharp or edged components.

Check that the mounting does not cover any nameplates

(see Fig. 10).

If necessary provide for notches.

Check whether the hoist can be mounted in such a way that

the rope feeds vertically into the hoist in the pulling direction

(Fig. 8).

Check whether a suitable connection for the power supply in

accordance with chapter 'Electrical connection' on page 10

is available on site.

Checking the hoists and the accessories

Hoists

– Check that the hoist and accessories are complete (see

' 3.2 Scope of delivery' on page 4 and ' 4.2 Components /

Modules' on page 6).

– Inspect the housing for signs of damage.

Rope

– Check whether the diameter and design of the rope match

the hoist, see Table 1 on page III.

If the load cannot be guided by on-site means then a low-

twist wire rope with a swivel hook or a rope swivel must be

used.

– Check that the length of the rope is sufficient:

It must be possible to safely move the load from the start to

the end position. The loose end of the rope must not reach

the hoist when lowering or releasing the load.

The rope end connection and the load bearing point or the

rope end must not be pulled into the the deflection roller.

– Inspect the entire length of the rope for any signs of damage,

see Fig. 12.

– Inspect the rope tip in accordance with Fig. 9 (see also

' 15.4 Care and maintenance, Rope' on page 16).

Anchoring devices

– Check whether the bolts/screws/rigging comply with the

specifications in ' 4.8 Anchoring' on page 8.

– Inspect the fishplates, load bolts and screw connections for

damage.

Connecting cable

– Check that the length is adequate.

– Check whether the cable diameter is sufficient for the

planned length (see Table 3 and 4 on page 11).

– Check the entire length of the cable for visible damage.

Page 20

Installation and operating manual

EN-10 G932.1 - 06/2010

ENEN

Control cable

– Check that the length is adequate.

– Check the entire length of the cable for visible damage.

9.3 Assembly

Requirements

Assembly may only be performed by trained personnel.

The workplace must have adequate lighting.

Anchor hoist

DANGER!

Incorrect anchoring!

Mortal danger of falling! Risk of being injured by falling objects!

– Only attach the hoist at the specified anchorage bore-

holes with the specified anchoring devices.

– The rope must run into the hoist vertically (see Fig. 2).

– If greater load bearing capacity is required: See the

specifications in ' 4.9 Increasing the load bearing capacity'

on page 8.

ATTENTION!

Incorrect installation position!

Damage to the equipment may occur!

The equipment will be damaged if incorrect or insufficient

lubricant is used!

– The hoist must not be mounted horizontally on the flat

side.

– Attach the hoist in such a way that the flat side only

points to the side or upward, see Fig. 2 and Fig. 3.

– Use screws with self-locking nuts to stop them from being

lost.

– Secure the bolts with a cotter pin or similar lock.

DANGER!

Cotter pins inserted incorrectly!

Risk of being injured by falling objects!

– Insert the cotter pin according to Fig. 6.

X-Model series

See Fig. 2 and Table 2 on page VI.

ATTENTION!

Incorrect anchoring!

Can result in damage to the device!

The unit can be damaged if fastened to the wrong anchorage

boreholes!

– Only attach the hoist at the specified anchorage bore-

holes with the specified anchoring devices.

– Securing to anchorage boreholes that are positioned

diagonally opposite one another is prohibited.

– Securing to the A3 + A4 anchorage boreholes in accor-

dance with Fig. 2 is prohibited.

Securing to anchorage points A:

– Secure the hoist to at least two anchorage points using

screws or bolts.

A1 + A2 or A2 + A3 or A1 + A4.

Securing to anchorage point B:

– Secure the hoist with screws or bolts.

T-Model series

See Fig. 3 and Table 2 on page VI.

ATTENTION!

Incorrect anchoring!

Can result in damage to the device!

The unit can be damaged if fastened to the wrong anchorage

boreholes!

– Only attach the hoist at the specified anchorage bore-

holes with the specified anchoring devices.

– If the load should be pulled from direction A2, use an-

chorage point A1.

– If the load should be pulled from direction A4, use an-

chorage point A3.

– If the load should be pulled in both directions, use an-

chorage points A1 + A3.

Damage to the fixing fishplates is possible!

– Screw on the self-locking nuts (1) only as far as until they

lie flush on the fishplate (2).

– Fasten the hoist to anchorage points A1 or A3 or A1 + A3

using screws or bolts.

Electrical connection

DANGER!

Danger through unauthorised use!

The electrical connection on the operator's side must be

connected in such a way that the hoist can be secured against

unauthorised use! Suitable protective measures include:

– Lockable Emergency Off device

– Lockable main switch

– Key-switch

– Removable operating controls

The electric connection must be established in accordance with

EN 60204-32.

The equipment must be earthed via the power supply cable. The

earthing function must be tested (isolation inspection). Additional

measures, such as earthing the supporting cable, may be necessary.

Page 21

Installation and operating manual

G932.1 - 06/2010 EN-11

ENEN

If necessary, a generator with three times the specified power

rating of the hoist can be utilised (e.g.: 2 hoists x 2.2 kW x 3 =

13.2 kVA). The generator must be earthed by the operator. The

earthing function must be tested (isolation inspection).

The existing connection used must be equipped with a 30 mA

safety switch (FI or RCD) and overload protection (automatic

circuit breaker with K- feature) in accordance with the circuit

diagram and the order specifications. The starting current is three

times the nominal current of the hoist.

Three-phase current: 400 V (3P + N + PE), 50 Hz

Alternating current: 230 V (P + N + PE), 50 Hz

The longer the power supply cable, the larger the cable crosssection must be.

– Secure hanging cables with cable ties (1), see Fig. 7.

– Use heavy duty rubber lines with support elements.

Determining the required cable cross-section:

– Determine the code letter (e.g. 'C') using Table 3. On hoists

with two speeds the maximum rope speed is the determining factor.

– In Table 4 determine the cable cross-section required for the

code letter.

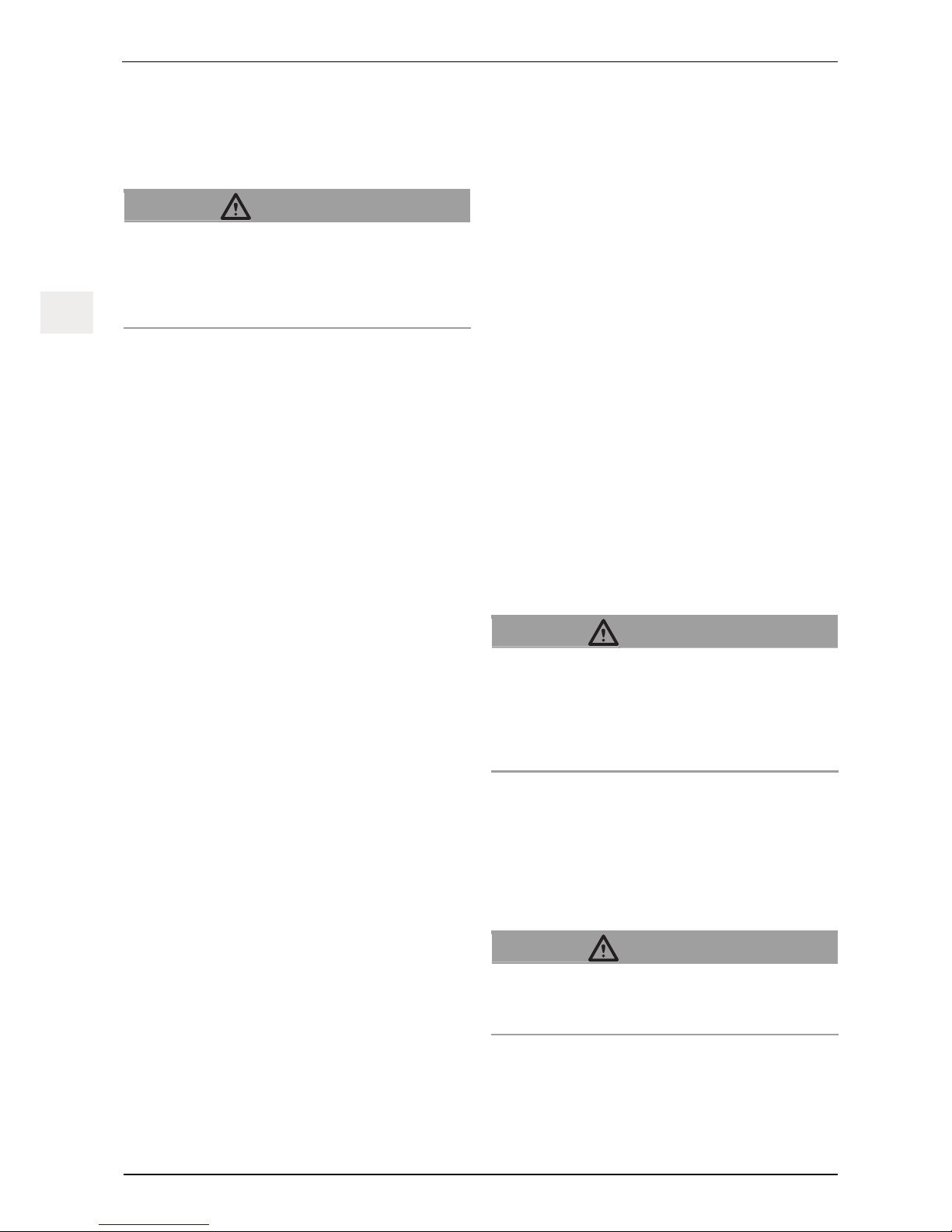

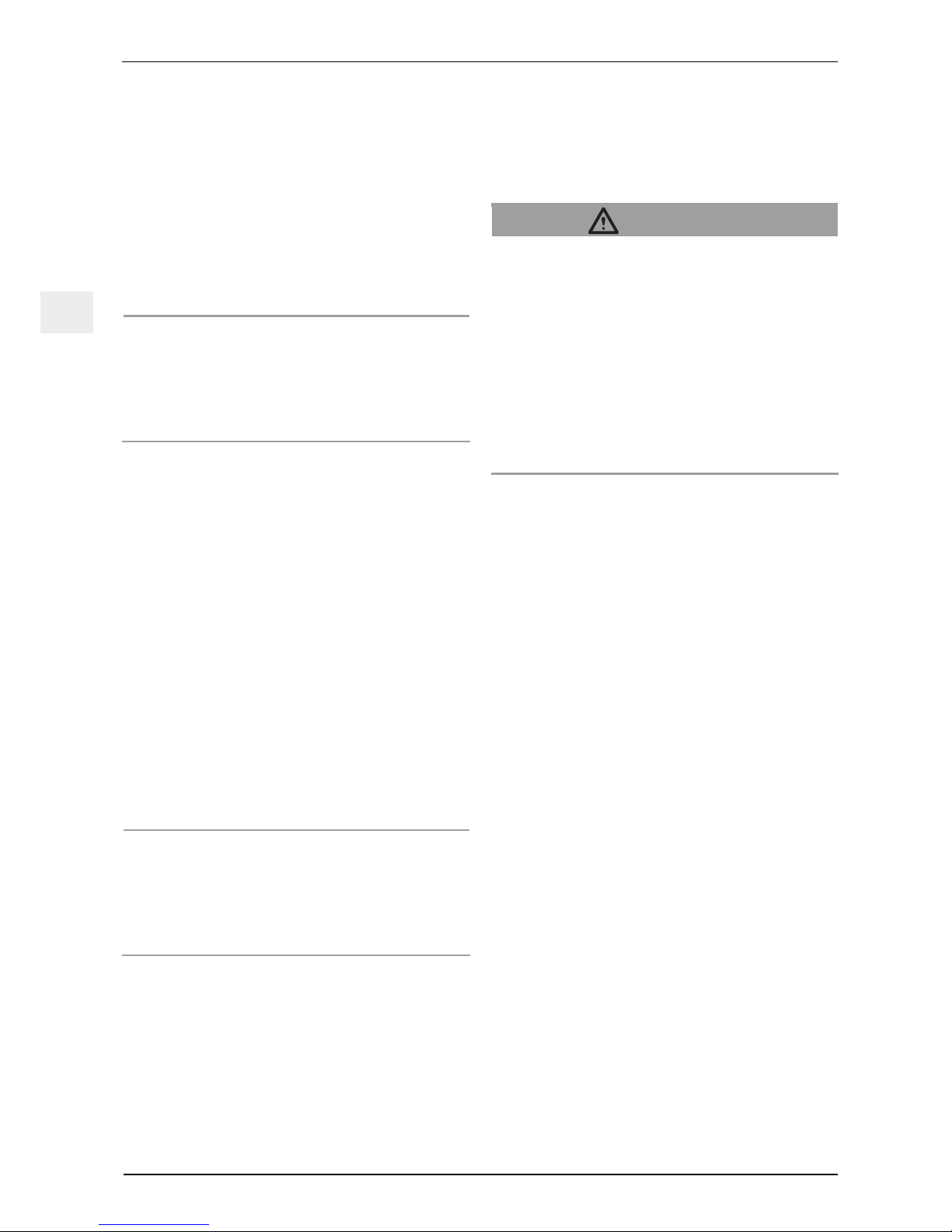

one hoist two hoists

Model series

max. rope speed

Three-phase

current

Alternating

current

Three-phase

current

Alternating

current

m/min 400 V 230 V 230 V 400 V 230 V 230 V

9 A B C A D E X 300

18 A C - B E -

9 A C E B E F X 400

X 500

18 B E - D G -

9 B E - D F - X 800

T 1000

T 1020

X 1020

18 C F - E G -

9 B E - D - - X 1530

18 C F - F - -

6 D F - F G - X 3050

12 E F - F G -

Table 3

Code letter Cable cross-section [mm²]

for cable lengths up to…

20 m 50 m 100 m 200 m

A 1.5 1.5 1.5 1.5

B 1.5 1.5 1.5 2.5

C 1.5 1.5 2.5 4

D 1.5 2.5 4 6

E 1.5 2.5 4 10

F 1.5 4 10 16

G 2.5 6 10 16

Table 4

Mount the rope

DANGER!

Risk of injury through stabs and cuts!

Broken wires in the wire rope can result in protruding wires!

Protruding wires can cut or stab through safety gloves!

– Wear suitable leather protective gloves when working

with wire ropes.

– Never let the wire rope run through your hands!

Danger of crushing or being pulled in!

When threading the rope in there is a risk of fingers or the

entire hand being pulled in with the rope or being crushed on

the pulleys and rope guides!

– Never touch the rope whilst the hoist is in operation! Do

not reach into the inlet or outlet of the hoist.

– Maintain a suitable distance from the rope.

– Watch out for rope loops.

ATTENTION!

Incorrect assembly!

Damage to the rope may occur!

– The rope must never run over an edge!

– The loose rope end must hang free.

Damage to the hoist possible (X-model series)!

– The unloaded side of the hoist may be loaded with a

maximum of 100 kg (e.g. via the rope pretensioning).

Damage to the hoist possible (T-model series)!

– When pulling the rope pretension must not exceed

400 kg (see Fig. 8 g/h).

Note:

If the anchoring point for the rope is located above the hoist the

rope must be fastened before it is fed into the hoist.

Page 22

Installation and operating manual

EN-12 G932.1 - 06/2010

ENEN

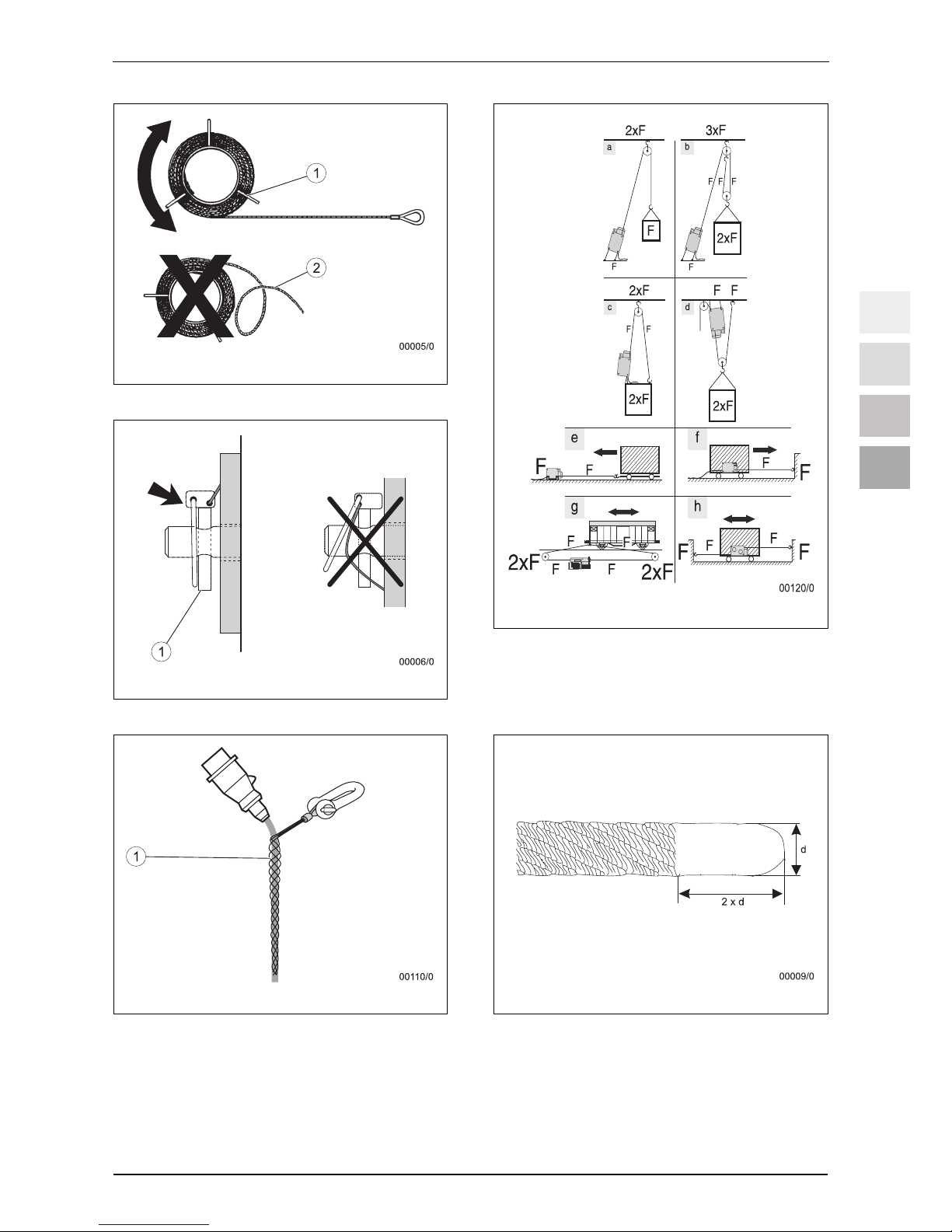

– Roll-off the rope correctly so that no loops in the rope occur.

– Insert the tip of the rope into the hoist as far as possible.

(X-Model series: Observe the direction of the arrow on the

casing.)

– Switch on the hoist in the pulling direction.

– Feed in the rope until the rope feeds automatically and

comes out of the opening on the other side.

– Make sure that the rope outlet is free to allow the loose end

to untwist.

– If necessary, guide the loose end of the rope over a pulley

or another suitable rope guide to prevent the rope from run-

ning over an edge that will result in the rope being damaged.

See Fig. 11.

– Place the loose end of the rope down correctly to prevent

any loops or knots from being created.

Mount and set limit switch

See Fig. 13.

Item Name

1 Rope anchoring

2 Stop disc

3 Limit switch (similar to illustration)

4 Suspension wire rope

The path of the hoist must be limited by one or multiple limit

switches (3), so that the upward and/or downward movement is

stopped.

The stop disc (2) must be mounted below the rope anchoring (1)

on the suspension wire rope (4). The distance to the rope anchoring (1) or the protruding components must be at least 1.5 m

(dimension a).

9.4 Commissioning

ATTENTION!

Incorrect load anchoring!

Can result in damage to the device!

The load must not be directly attached to the towing rope.

– Use a wedge clamp and an anchorage rope to anchor

the load.

Determine operational readiness

– Check the rope anchoring.

– Check the anchoring of the hoist, deflector rollers and the

load.

– Check whether the rope enters the hoist vertically.

– Check that the rubber plugs on the motor (see Fig. 15,

Position 3) are sitting in the correct position.

– Record the inspection results in the logbook.

Functional test

DANGER!

Risk of being injured by falling objects!

– Never stand beneath suspended loads.

– Cordon off the hazard zone whenever necessary.

ATTENTION!

Incorrect rope lengths!

Can result in damage to the device!

The rope connection or the load bearing point or the rope end

must not be pulled into the hoist housing or into the deflection

roller!

– Monitor the rope during operation.

– Use a rope with adequate length.

Note (hoists without converter):

If the hoist fails to start then two poles in the power supply cable

may have been inverted. The built-in reverse polarity protection

locks out the control unit:

– Turn the phase reverser in the plug by 180°, see Fig. 19.

– Only load load lifting equipment with the permissible load.

– Run the hoist in the pulling direction until the rope is ten-

sioned (run hoists with two speeds at the lower speed).

– Run the hoist in the pulling direction until the load lifting

equipment is raised or pulled.

– Stop hoist:

The brake must hold the rope tightly.

– Let down or release load.

– Stop hoist:

The brake must hold the rope tightly.

– Let the hoist run in the pulling direction.

– Press the EMERGENCY OFF button. The power must be

shut-off. The brake must hold the rope tightly.

– Trigger the limit switch(es) manually or through movement

when raising the load: The power must be shut-off. The

brake must hold the rope tightly.

– If available, trigger the lower limit switch manually or through

movement: The hoist must stop. The brake must hold the

rope tightly.

– Record the inspection results in the logbook.

Page 23

Installation and operating manual

G932.1 - 06/2010 EN-13

ENEN

10 Operating / Operation

Personnel must have been trained by the operator in operating

the unit and be authorised to use it.

10.1 Checks to be carried out before

starting work

– Check the rope anchoring.

– Check the rope for clinging dirt and clean if necessary.

– Check the anchoring of the hoist, deflector rollers and the

load.

– Check that the rubber plugs on the motor (see Fig. 15,

Position 3) are sitting in the correct position.

– Run the function test, see ' 9.4 Commissioning, Functional

test' on page 12.

– Record the inspection results in the logbook.

10.2 Operation

DANGER!

Risk of being injured by falling objects!

The load or load lifting equipment may jam and fall!

– Constantly observe the load, the load lifting equipment

and rope.

– If necessary, work with a supervisor.

– Agree upon hand gestures before commencing use.

– If visual contact is not possible, use a mobile phone or

walkie-talkie for communicating.

– Never stand beneath suspended loads.

– Cordon off the hazard zone whenever necessary.

Risk of crushing! Risk of injury!

On the rope and wire rope hoist!

– Never touch the rope whilst the hoist is in operation! Do

not reach into the inlet or outlet of the hoist.

Risk of crushing! Risk of injury!

From the rotating motor shaft!

– Check that the rubber plugs on the motor (see Fig. 15,

Position 3) are sitting in the correct position.

Risk of being injured by falling objects!

Overloading can result in destruction of the hoist or the safety

devices! This can result in malfunctions!

– Observe the maximum permitted load when loading the

load lifting equipment.

– Do not release stuck or jammed loads by pulling with the

hoist.

– Do not pull loads with hoists for raising and lowering

diagonally.

– Avoid excessive inching/jogging (e.g. giving the motor

short impulses).

Risk of being injured by falling objects!

Moisture can impair the effectiveness of the brake!

– Check that the rubber plugs on the motor (see Fig. 15,

Position 3) are sitting in the correct position.

– Do not clean the rope and hoist with a high pressure

cleaner.

Risk of burns!

Motors can become hot during operation!

– Do not touch the motors.

ATTENTION!

Incorrect rope lengths!

Can result in damage to the device!

The rope connection or the load bearing point or the rope end

must not be pulled into the hoist housing or into the deflection

roller!

– Monitor the rope during operation.

– Use a rope with adequate length.

– Turn the EMERGENCY OFF button to the right until it re-

leases:

The control unit is switched on.

– Always abide by the maximum permitted load when loading

the load lifting equipment.

DANGER!

Risk of being injured by falling objects!

– Secure loads against falling.

– Secure loads against twisting.

– Run the hoist in the pulling direction until the rope is ten-

sioned (run hoists with two speeds at the lower speed).

– Run the hoist in the pulling direction until the load lifting

equipment is raised or pulled.

– Let down or release load.

– Observe the end of the rope when lowering or slackening.

– Stop immediately when damage, loops or knots are de-

tected.

– Stop: Release the operating control.

– Observe the operator’s emergency plan.

If the rope / hoist does not stop when letting go of the operating

control:

– Press the EMERGENCY OFF button.

– If the EMERGENCY OFF button fails, disconnect the hoist

power supply (e.g. by pulling out the plug)

– Have the hoist inspected and serviced by an electrician or

authorised service personnel (see ' 15.1 Authorized mainte-

nance personnel' on page 15).

Page 24

Installation and operating manual

EN-14 G932.1 - 06/2010

ENEN

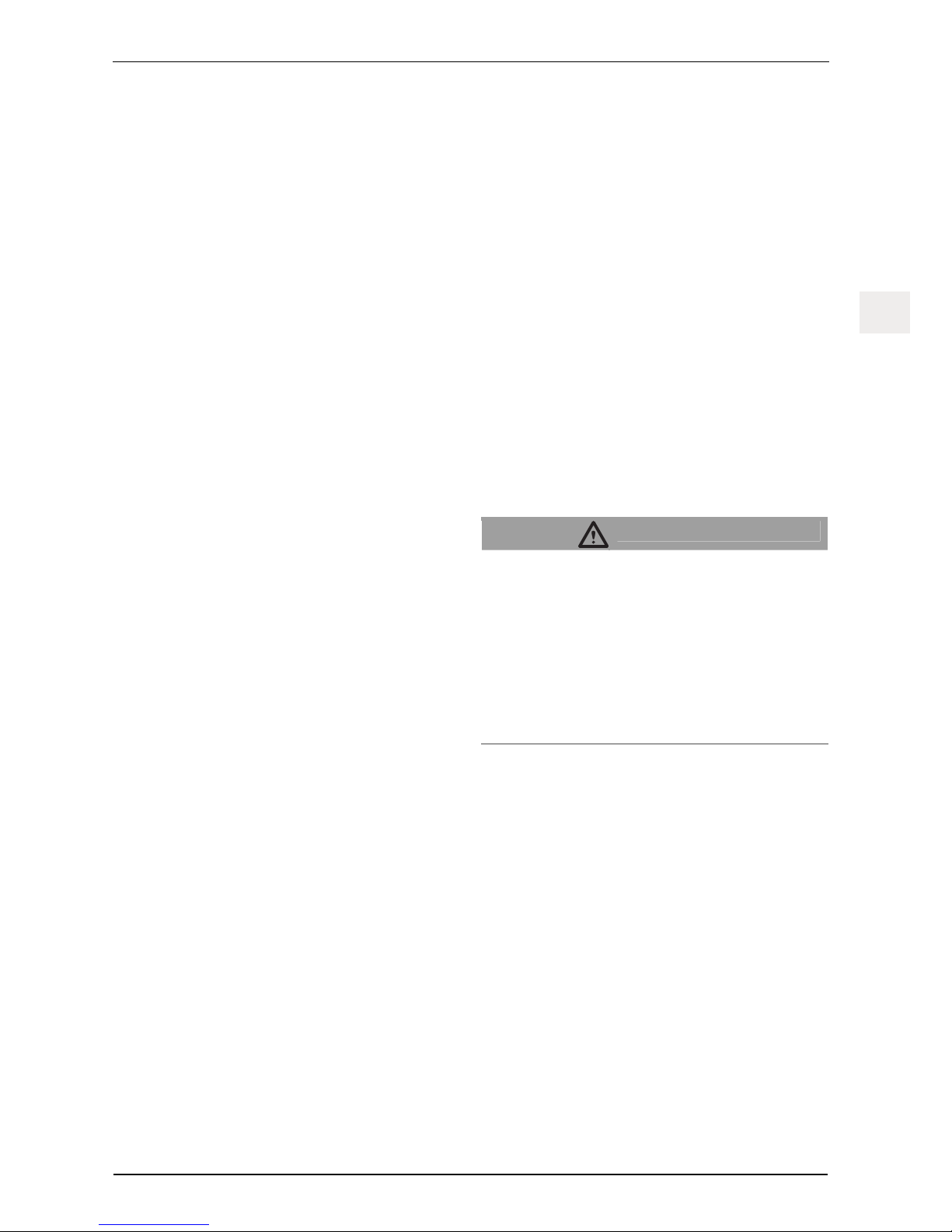

10.3 Emergency descent

The load lifting equipment can be lowered manually in the event

of a power failure.

DANGER!

Risk of being injured by falling objects!

The centrifugal brake might not brake the load in case of

overloading!

– In the event of overloading, never open the service brake

(spring-applied brake) manually.

See Fig. 15.

The centrifugal brake prevents rope speeds that are too high

when lowering manually.

For an emergency descent with low loads, increase the weight

using ballast and / or carefully pulling on the rope.

– Remove the lever (1) from the anchoring.

– Insert the lever (1) into the brake bracket through the slot in

the hood of the motor (2).

– Lift and hold the lever. The load is lowered.

– Let go of the lever to brake.

– Anchor the lever again after use.

10.4 Switching off when overloaded

Hoists with a mechanical or electrical load limiting device:

When delivered, the load limiting device has been set in such a

way that it deactivates the hoist at the latest once the load

reaches 1.25 times the load bearing capacity. A warning signal

sounds when deactivating.

Jamming of the load lifting equipment may also lead to deactivation.

When overloaded:

– Lower or release the hoist until the load has reached the

ground.

– Reduce the load until no overload is present.

When jammed:

– Lower or release the hoist until the load hangs freely again.

– Remove the obstacle before lifting the load again.

11 Foreseeable misuse

Guarantee and liability claims for personal injuries and equipment damage will be rejected if they can be traced back to one or

more of the following causes:

Unauthorized use of the device, the accessories or the

carrying means belonging to the device

Lifting personnel

Operating with a soiled rope

Operating without limit switch (hoist for lifting)

Not adhering to the stipulated maintenance periods

Cleaning with a high-pressure cleaner

Incorrect hoist installation, commissioning, operation, main-

tenance or repairs

Poor monitoring of the parts and the accessories, which has

resulted in wear occurring

Carrying out incorrect and unauthorised repairs

Use of non-original spare parts

Alteration of safety device settings

Ignoring measurements and checks that would detect early

signs of damage

Device overloaded

Load striking directly the towing rope or suspension cable

Accidents caused by foreign bodies or acts of God

The manufacturer will not accept any liability for damages

resulting from modifications and conversions made to the

devices, or from the use of non-original parts that have not

been authorised by the manufacturer. Faulty or damaged

hoists, ropes, rigging or power supply and control cables

must never be used!

12 Dismantling

DANGER!

Risk of injury through stabs and cuts!

Broken wires in the wire rope can result in protruding wires!

Protruding wires can cut or stab through safety gloves!

– Wear suitable leather protective gloves when working

with wire ropes.

– Never let the wire rope run through your hands!

– Lower the load lifting equipment and remove if necessary.

– X-Model series:

Press the DOWN button and pull the rope upwards out of

the hoist.

– T-Model series:

Press the UP or DOWN button and pull the rope out of the

hoist.

DANGER!

Danger of death due to electric shock!

– Disconnect the hoist from the power supply by pulling out

the plug.

– Pull out the power plug.

– Roll-up the rope correctly so that no loops in the rope occur

that make the rope unusable.

– Loosen the anchorage of the hoist.

– Dismantle the deflection rollers and load bearing points.

Page 25

Installation and operating manual

G932.1 - 06/2010 EN-15

ENEN

13 Shutting down

13.1 Work breaks

The hoist must be secured in the following way during work

breaks:

– Put the load lifting equipment on the ground or cordon off

the area beneath the suspended load.

– Interrupt the power supply and secure the hoist against

unauthorised use.

13.2 Temporary shutdown

If the hoist is not required for several days or weeks but should

remain mounted in the same position and location, the hoist must

be secured as follows:

– Put the load lifting equipment on the ground or cordon off

the area beneath the suspended load.

– Secure the load lifting equipment against oscillating move-

ments (e.g. tie to building).

– Pull up the rope without load to a position out of the reach of

people.

– Interrupt the power supply and secure the hoist against

unauthorised use.

13.3 Permanently decommissioning

– Dismantle the hoist and accessories, see ' 12 Dismantling'

on page 14.

– Clean the outside of the device and store.

14 Transport and storage

14.1 Hoists

Transport

Prevent the hoist from being damaged while it is being transported.

On-site, the hoist can be transported using the carrying handle,

see Fig. 1. If necessary transport with the help of a second person.

Heavy hoists can be transported using suitable transport equipment on the eye bolts or ring nuts.

Utilise the transport box when transporting with a vehicle. Secure

the hoist or the transport box with lashing straps.

Storage

Store in a dry, dust-free location that has a constant ambient

temperature.

14.2 Rope

Transport

– Protect the ropes against direct sunlight, chemicals, soiling

and mechanical damage.

– Transport the ropes on the reels whenever possible.

– Use suitable auxiliary equipment when transporting the reels.

– Rolled-up ropes without reels should be lifted and trans-

ported using a lifting strap.

– Minimise the load resulting from the dead weight as much

as possible.

Storage

– Store lightly oiled, free of dust and in a dry location.

– Avoid contact with chemicals (e.g. battery acid).

– Store without applying mechanical crushing, pressure or

tensile stress.

15 Maintenance work

15.1 Authorized maintenance personnel

DANGER!

Risk of falling! Risk of being injured by falling objects!

Mortal danger due to incorrectly performed maintenance and

service work!

Maintenance and service work which require the hoist to be

opened may only be performed by the following authorised

parties:

– Greifzug Hebezeugbau GmbH

– Lifting equipment service companies authorised by

Greifzug Hebezeugbau GmbH

– Service personnel trained and certified by Greifzug He-

bezeugbau GmbH

15.2 Mandatory inspections

A written certificate is required for the annual inspection and any

exceptional tests. The inspections must be recorded in the logbook included with delivery.

Prior to every use

Always check to ensure that the device is in an orderly working

condition before use, see ' 9.4 Commissioning' on page 12.

Annual safety inspection

The safety inspection must be carried out annually.

The safety inspection may only be undertaken by authorised

maintenance personnel, see ' 15.1 Authorized maintenance per-

Page 26

Installation and operating manual

EN-16 G932.1 - 06/2010

ENEN

sonnel' on page 15. Depending on the usage conditions (e.g.

operation in an extremely dirty environment), an intermediate

inspection may be necessary.

The general overhaul periods are, at the latest:

250 running hours for devices with 12 or 18 m/min rope

speeds,

500 running hours for devices with 6 or 9 m/min rope

speeds.

A general overhaul of the hoist must only to be undertaken by

Greifzug Hebezeugbau GmbH or a hoisting gear workshop that