Page 1

blocstop™ BSO

Dispositif antichute pour plateformes suspendues pour levage de personnens et matériel (PSLP & PSLM)

Fangvorrichtung für hochziehbare Personen- und Materialaufnahmemittel (PAM & MAM)

Opvangvoorziening voor omhoog trekbare personen- en materiaalhefmiddelen (PAM & MAM)

Fall arrest device for suspended material-lifting and rigging installations

OUVRIR

OPEN

AUF

ZU

OUVRIR

OPEN

AUF

ZU

ZU

CLOSE

CLOSE

FERMER

OUVRIR

OPEN

AUF

ZU

CLOSE

FERMER

FERMER

CLOSE

FERMER

Model series / Typenreihe /

Série / Serie

blocstop™ BSO 500

Model series /

Typenreihe /

Série / Serie

blocstop™ BSO 1000

Original Operation and

Installation Manual

Original-Montage- und

Betriebsanleitung

00327/0

Model series / Typenreihe / Série / Serie

blocstop™ BSO 2050/2360

Manuel d´installation et de

manutention original

Originele montage- en

bedieningshandleiding

Page 2

blocstop™ BSO

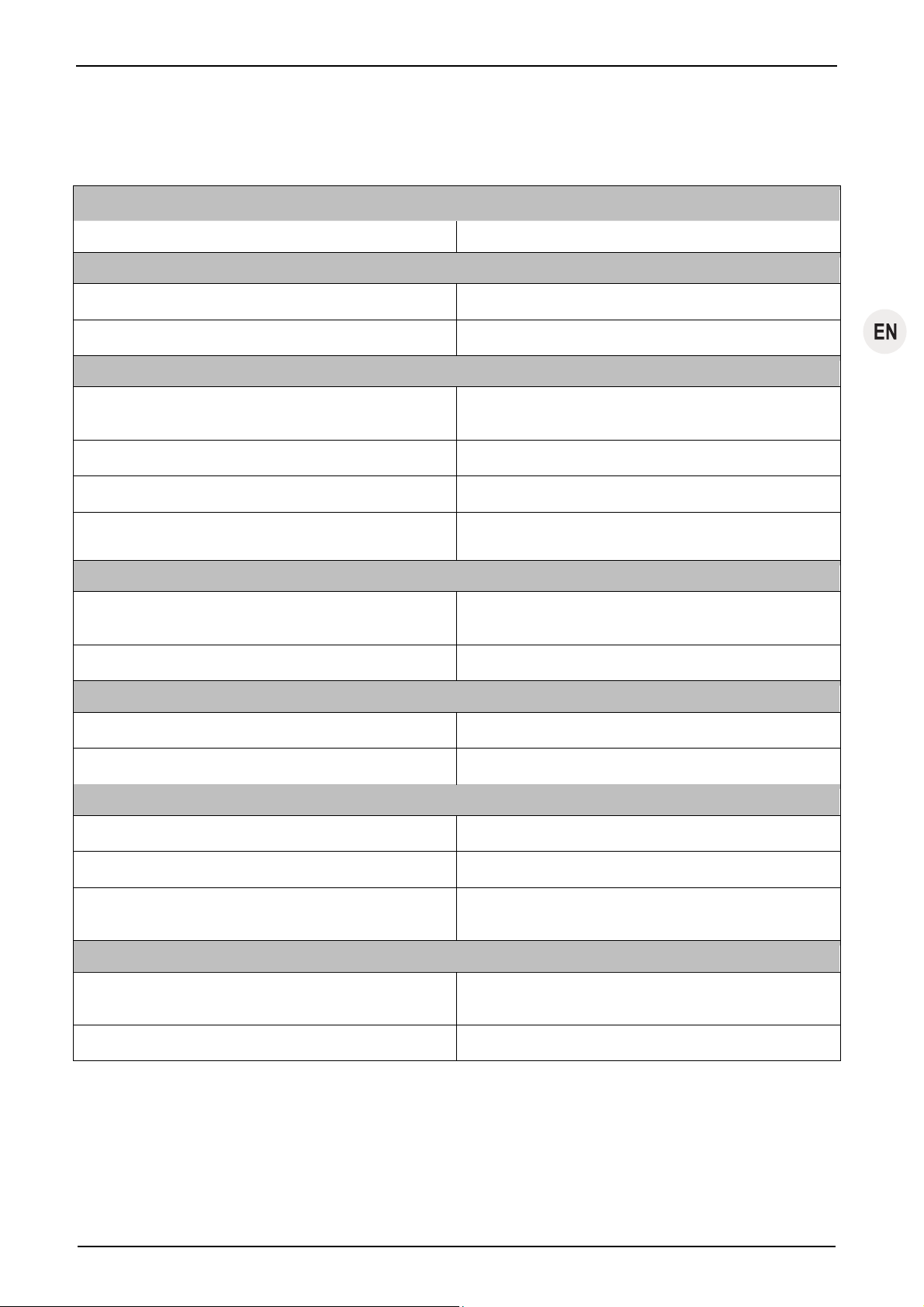

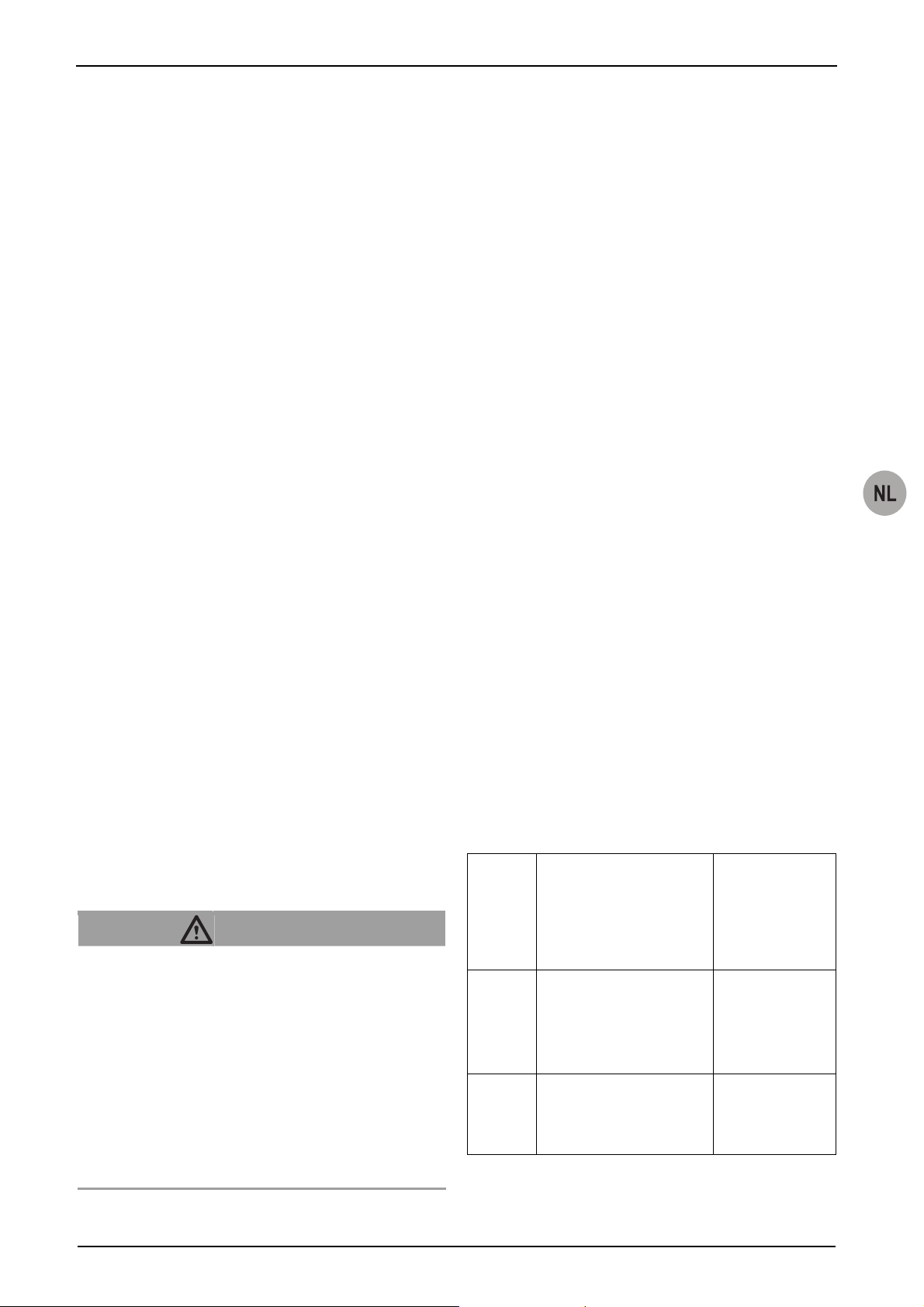

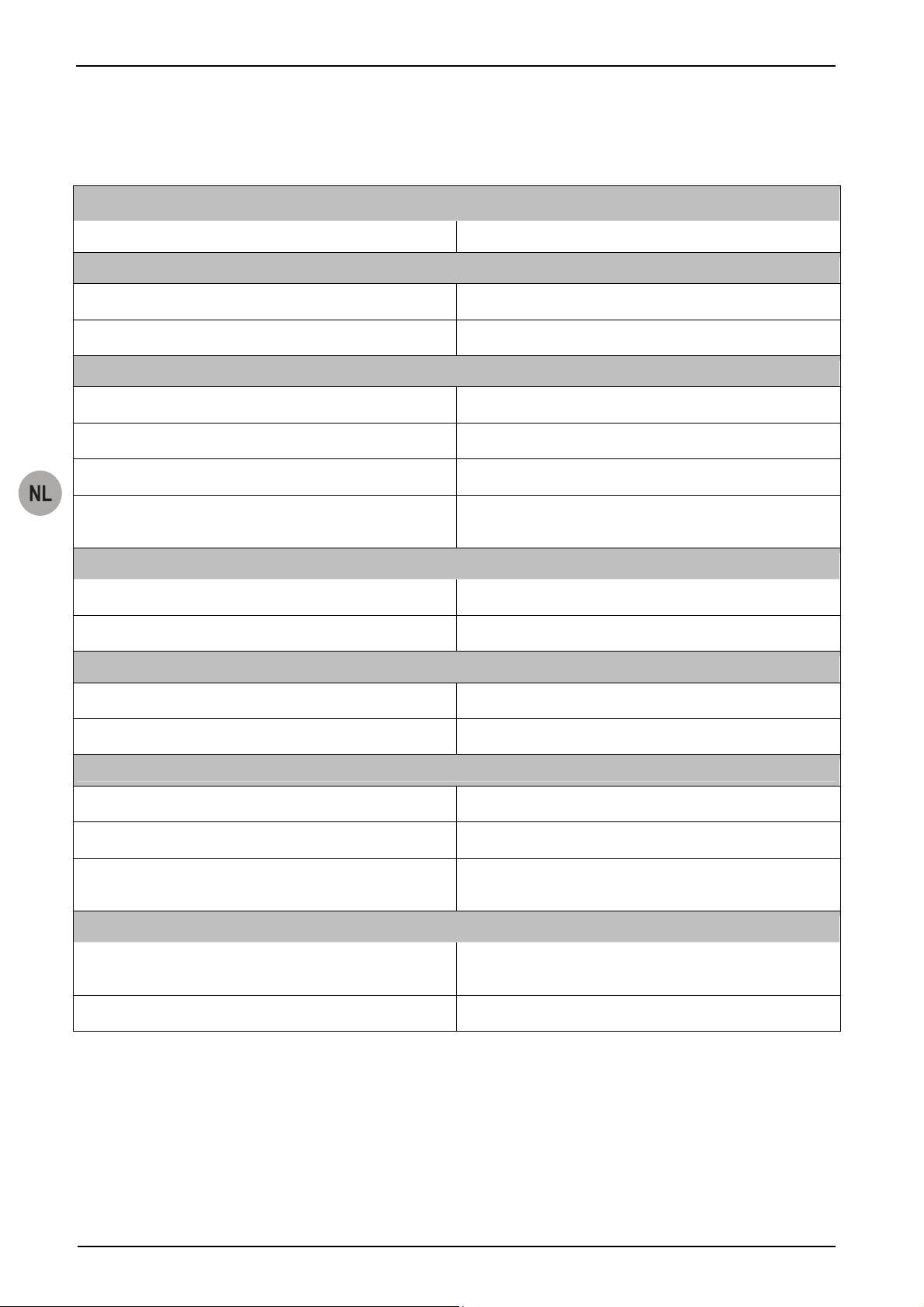

Technical Data / Technische Daten / Données techniques / Technische gegevens

3) 4) 5)

Type

Typ

Type

Type

3) 4) 5)

3) 4) 5)

3) 4) 5)

Capacity in t

Tragfähigkeit in t

Capacité in t

Draagvermogen in t

Wire rope specification

Seilspezifikation

Spécification du câble

Kabelspecificatie

Bolt-Ø in mm2)

Bolzen-Ø in mm2)

Diamètre des axes2)

Bout-Ø in mm2)

Persons

Personen

Personnes

Personen

Material

Material

Materiel

Materiaal

Ø in mm

Ø in mm

Ø du câble en mm

Ø in mm

Minimum tensile strength in kN

Mindestbruchkraft in kN

Force minimal de rupture en kN

Minimum breukkracht in kN

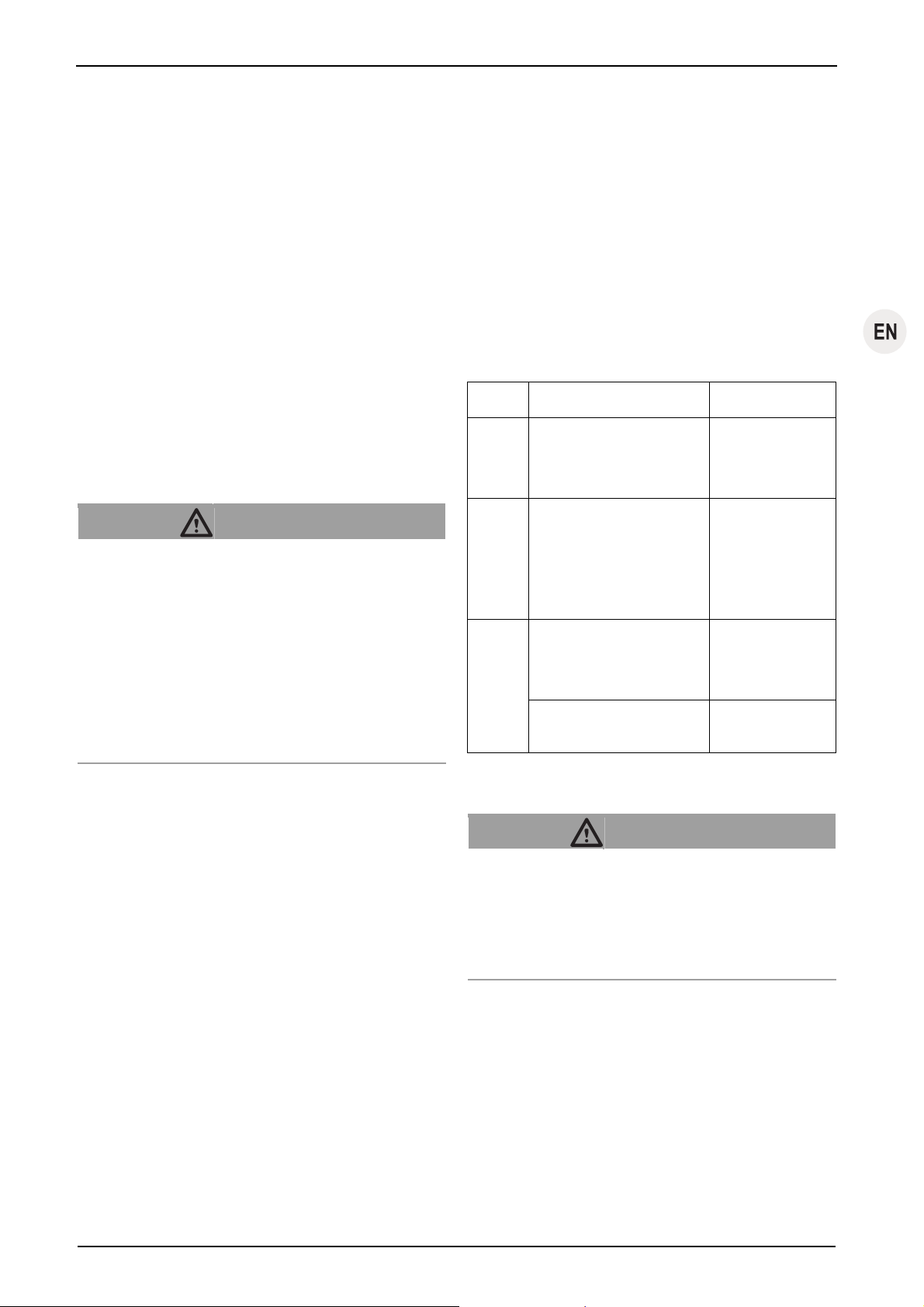

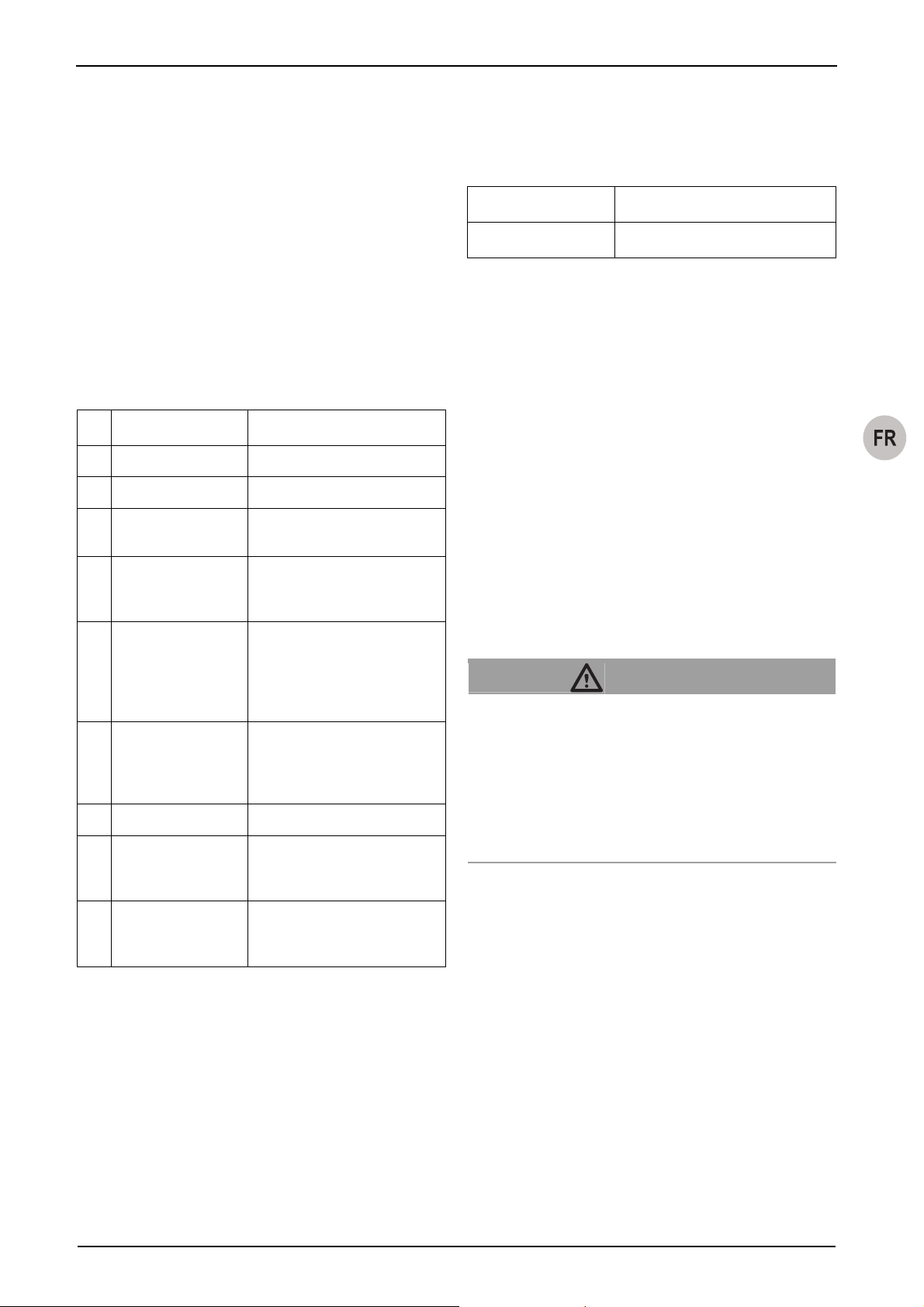

BSO 510 — 0,35 6 13,7

BSO 500 0,5 0,5 8 39,2

BSO 520 0,5 0,5 9 39,2

BSO 1000 0,5 0,5 8 39,2

BSO 1020 0,8 0,8 9 62,8

BSO 1030 1,0 1,0 10 78,5

BSO 1040 1,0 1,0 11,5 78,5

BSO 2050 2,0 2,6 14 157,0

BSO 2360 2,3 3,0 16 180,5

Table/Tabelle/Tableau/Tabel 1

1b)

1a)

1a)

1a)

1a)

1a)

1a)

1a)

1a)

12

22

1)

Calculation of the required minimum breaking load Fo of the rope (does not correspond to the actual, manufacturer-specific minimum breaking load!)

Fo = Zp x S

a) Fo = 8 x S [kg] x 9,81 [N/mm²]

b) Fo = 4 x S [kg] x 9,81 [N/mm²]

2)

Strength of the bolt material: 800 N/mm2 ≅ 800 MPa. Do not use high-strength galvanised screws (10.9 or 12.9).

3)

For hoists with a speed of up to 18 m/min

4)

optionally with limit switch: Identification E (e. g. BSO 500 E)

5)

Temperature range: -25 – +70 °C, depending on the ambient conditions (ambient temperature, sunrays, etc.) as well as the possible thermal discharge (dirt,

accumulated heat, etc.) / relative humidity < 75 %

: smallest guaranteed breaking load of the wire rope

F

o

: = 8 (4): Expansion coefficient of the wire rope

Z

p

S: maximum static load on the wire rope (maximum working load of the hoist)

1)

Berechnung der erforderlichen Mindestbruchkraft Fo des Seiles (entspricht nicht der tatsächlichen, herstellerspezifischen Mindestbruchkraft!)

= Zp x S

F

o

a) Fo = 8 x S [kg] x 9,81 [N/mm²]

b) Fo = 4 x S [kg] x 9,81 [N/mm²]

2)

Festigkeit des Bolzenwerkstoffes: 800 N/mm2 ≅ 800 MPa. Keine hochfesten verzinkten Schrauben (10.9 oder 12.9) verwenden.

3)

Für Winden mit Geschwindigkeit bis 18 m/min

4)

optional mit Endschalter: Kennzeichnung E (z. B. BSO 500 E)

5)

Temperaturbereich: -25 – +70 °C, abhängig von den Umgebungsbedingungen (Umgebungstemperatur, Sonneneinstrahlung, etc.) sowie der möglichen

Wärmeabfuhr (Schmutz, Stauwärme, etc.) / rel. Luftfeuchtigkeit < 75 %

: kleinste garantierte Bruchlast des Drahtseils

F

o

: = 8 (4): Ausnutzungskoeffizient des Drahtseils

Z

p

S: maximale statische Zuglast im Drahtseil (maximale Betriebslast der Winde)

1)

Calcul de l’effort de rupture mininal requis Fo du câble (ne correspond pas à l’effort de rupture minimal effectif et spécifique du fabricant!) :

= Zp x S

F

o

a) Fo = 8 x S [kg] x 9,81 [N/mm²]

b) Fo = 4 x S [kg] x 9,81 [N/mm²]

: Charge de rupture minimale garantie du câble métallique

F

o

: = 8 (4): Coefficient d’utilisation du câble métallique

Z

p

S: Charge statique maximale du câble métallique (capacité de charge maximale de

fonctionnement du treuil)

2)

Résistance du matériau de boulon : 800 N/mm2 ≅ 800 MPa. Ne pas utiliser de boulons galvanisés haute résistance (10.9 ou 12.9).

EN-DE-FR-NL-II G905.5 - 02/2011

Page 3

blocstop™ BSO

3)

Pour les treuils d'une vitesse jusqu'à 18 m/min

4)

en option avec fins de course : Marquage E (par exemple BSO 500 E)

5)

Plage de température: -25 – +70 °C, en fonction des conditions ambiantes (température ambiante, exposition à la lumière du soleil, etc.) et de l'évacuation de la

chaleur possible sur le site (saleté, accumulation de chaleur, etc.) / Humidité relative de l'air < 75

1)

Berekening van de minimum breukkracht Fo van de kabel (komt niet overeen met de daadwerkelijke fabrikantspecifieke min. breukkracht!)

= Zp x S

F

o

a) Fo = 8 x S [kg] x 9,81 [N/mm²]

b) Fo = 4 x S [kg] x 9,81 [N/mm²]

2)

Sterkte van het boutenmateriaal: 800 N/mm2 ≅ 800 MPa. Gebruik geen extra sterke verzinkte bouten (10.9 of 12.9).

3)

Voor lieren met een snelheid tot 18 m/min

4)

optioneel met eindschakelaar: Markering E (bijv. BSO 500 E)

5)

Temperatuurbereik: -25 – +70 °C, afhankelijk van de omgevingsfactoren (omgevingstemperatuur, zonnestraling etc.) en van de mogelijke warmteafvoer (vuil,

warmtestuwing etc.). / rel. luchtvochtigheid < 75 %

: kleinste gegarandeerde breuklast van de draadkabel

F

o

: = 8 (4): Belastingscoëfficiënt van de draadkabel

Z

p

S: maximale statische treklast in draadkabel (maximale bedrijfslast van de lier)

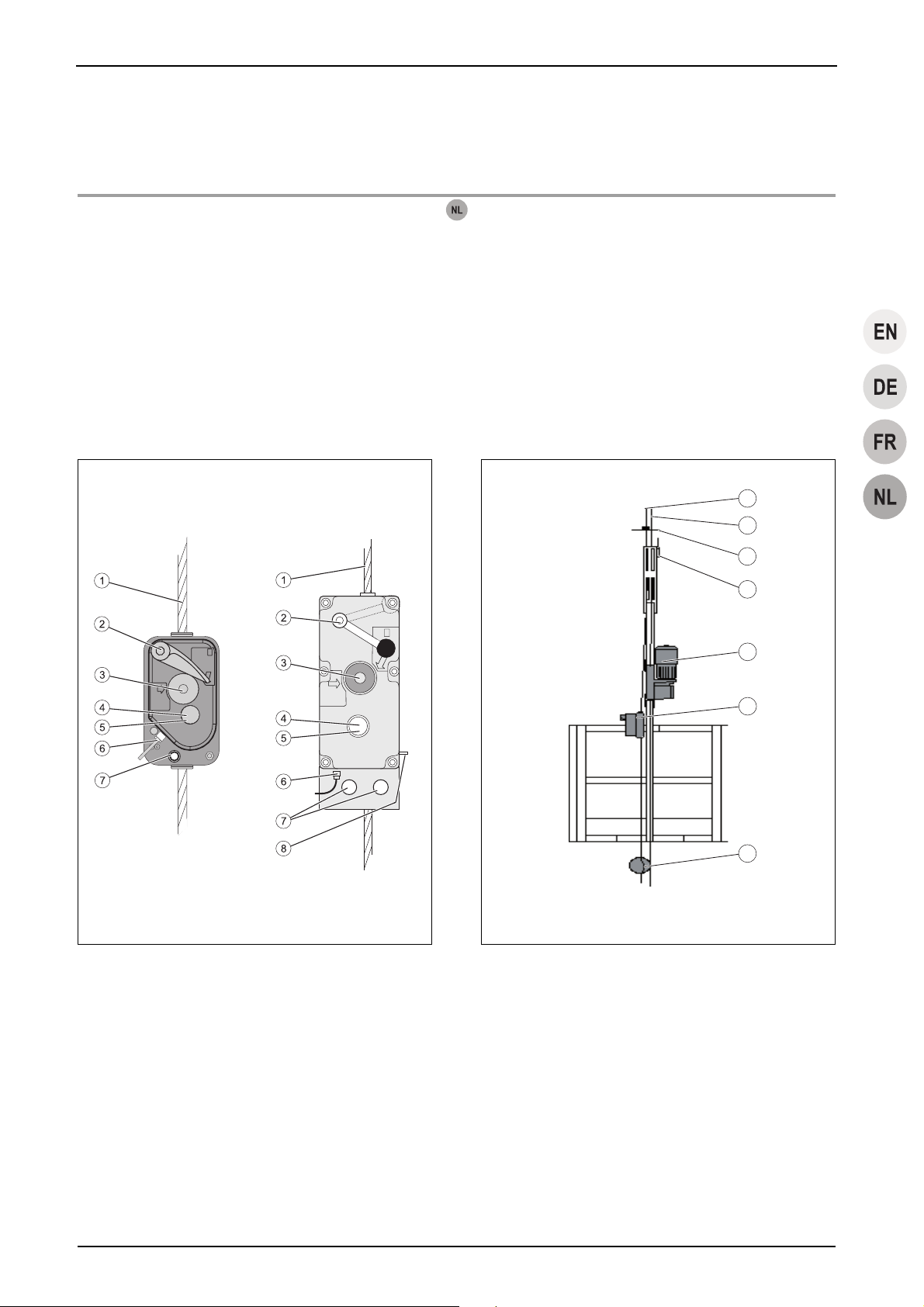

Components / Bestandteile / Composants / Bestanddelen

BSO 500–520

BSO 1000–1040

OUVRIR

OPEN

AUF

ZU

ZU

CLOSE

CLOSE

FERMER

FERMER

BSO 2050–2360

OUVRIR

OPEN

AUF

ZU

CLOSE

FERMER

1

2

3

4

5

6

7

Fig./Abb./Fig./Afb. 1

00322/0

Fig./Abb./Fig./Afb. 2

00323/0

G905.5 - 02/2011 EN-DE-FR-NL-III

Page 4

blocstop™ BSO

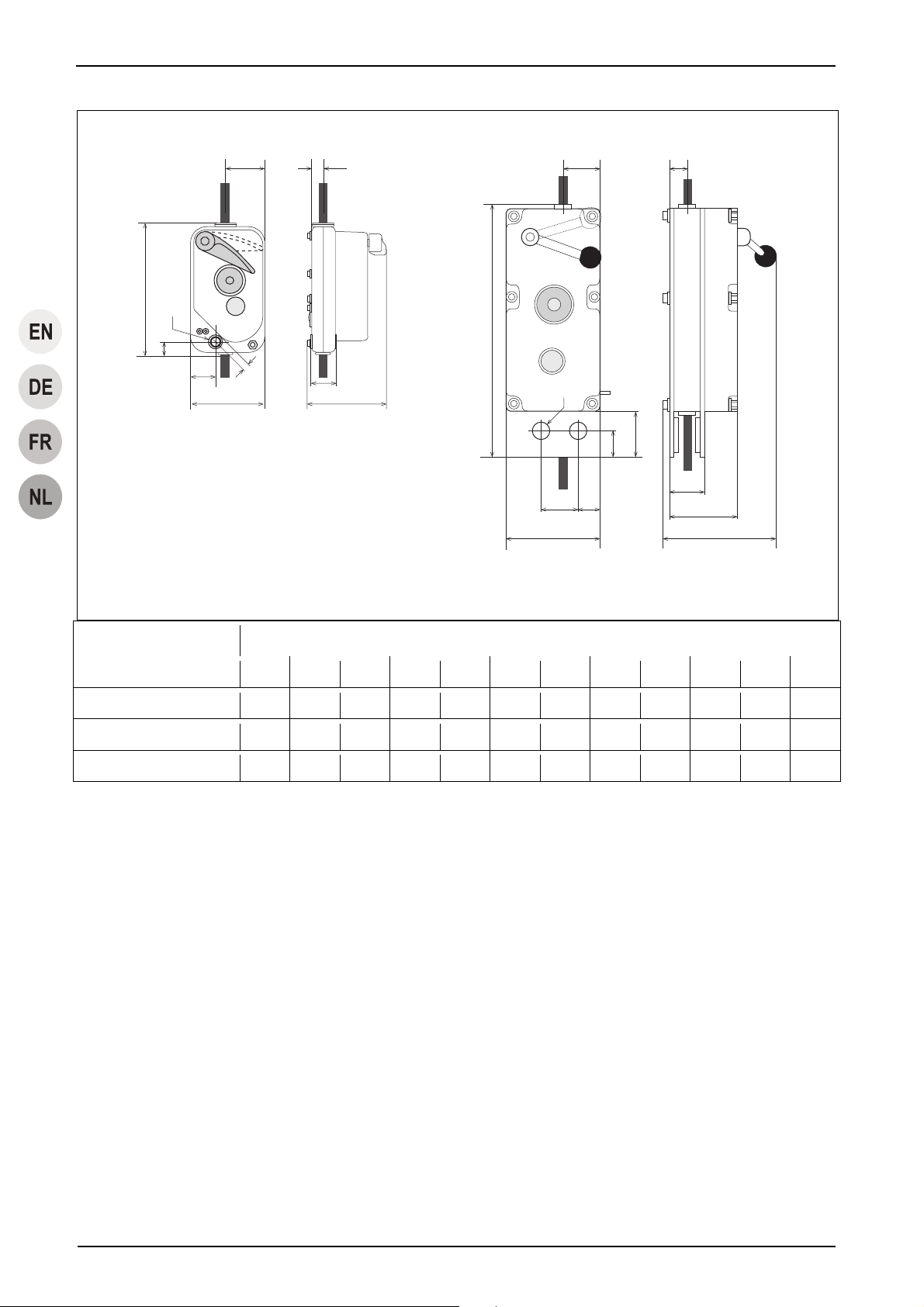

d

1

d

2

d

1

d

2

a

Ø h

a

g

e

f

b

c

2

c

1

Ø h

b

a

1

g

c

3

ef

c

2

c

1

00324/0

Fig./Abb./Fig./Afb. 3

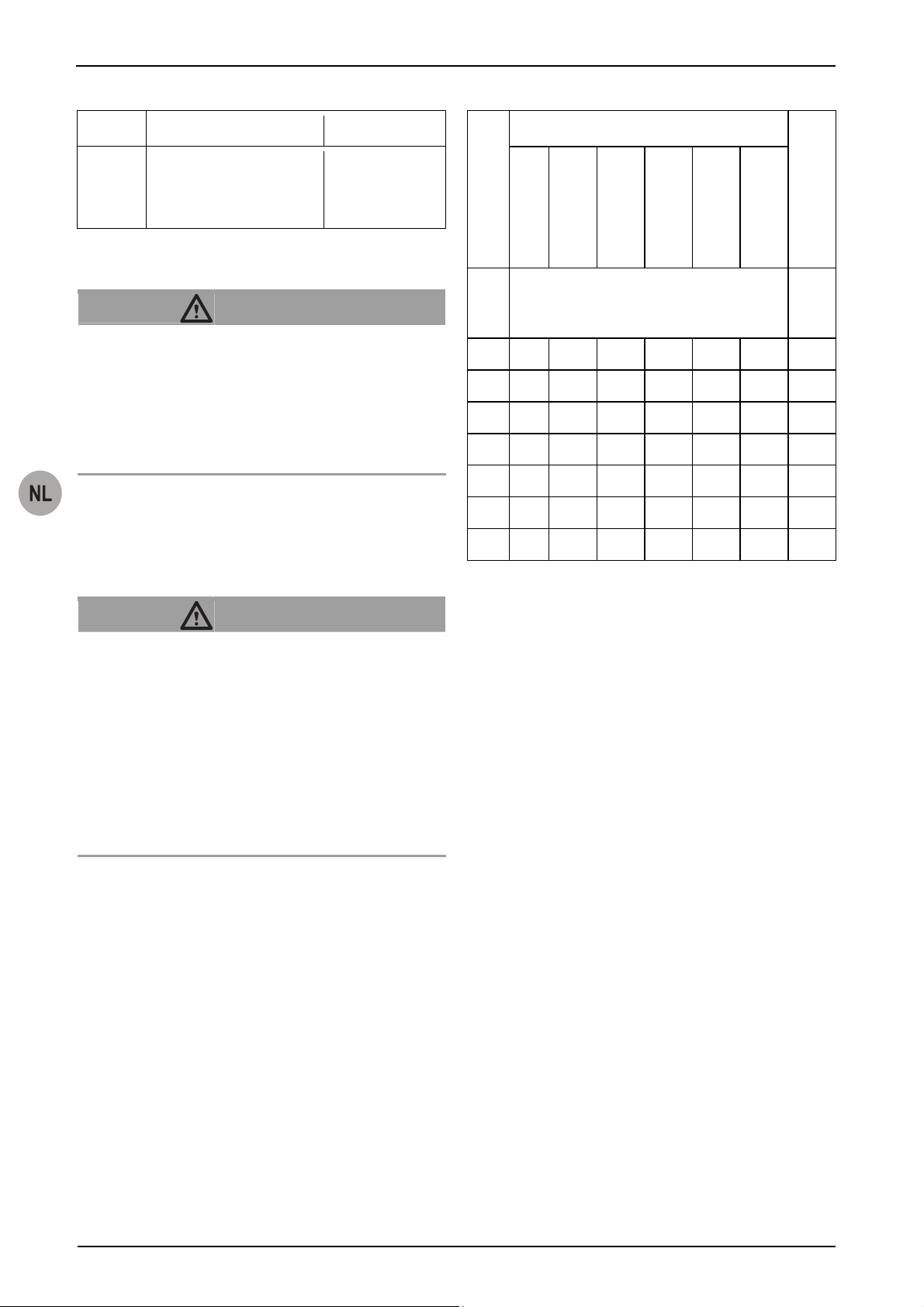

Measure in mm / Maß in mm / Mesure en mm / Maat in mm

a a1 b c1 c2 c3 d1 d2 e f g Ø h

BSO 500/510/520 214 — 121 131 40 — 64 20 40 12,5 21,5 12,2

BSO 1000/1020/1030/1040 251 — 140 131 40 — 65 20 56 12,5 21,5 12,2

BSO 2050/2360 409 70 150 183 110 55 60 27,5 35 60 36 22,2

Table/Tabelle/Tableau/Tabel 2

EN-DE-FR-NL-IV G905.5 - 02/2011

Page 5

blocstop™ BSO

V

2

OUVRIR

OPEN

AUF

ZU

ZU

CLOSE

CLOSE

FERMER

FERMER

Fig./Abb./Fig./Afb. 4

blocstop

Fangvorrichtung

Fall arrest device

TM

Typ (e): BSO

Original Tractel -®Se

il/

rope Ø:

Fabr.Nr./Serial No

Bauj./Year of man

201

Bei Rückfragen/Ersatzteilbestellungen

bitte Typ und Fabr.Nr. angeben!

In case of queries / spare part o rders

please mention type and serial number!

Scheidtbachstraße 19-21

D-51469 Bergisch Gladbach

S248.1 12/09 102090

1

kg

kg

mm

00325/1

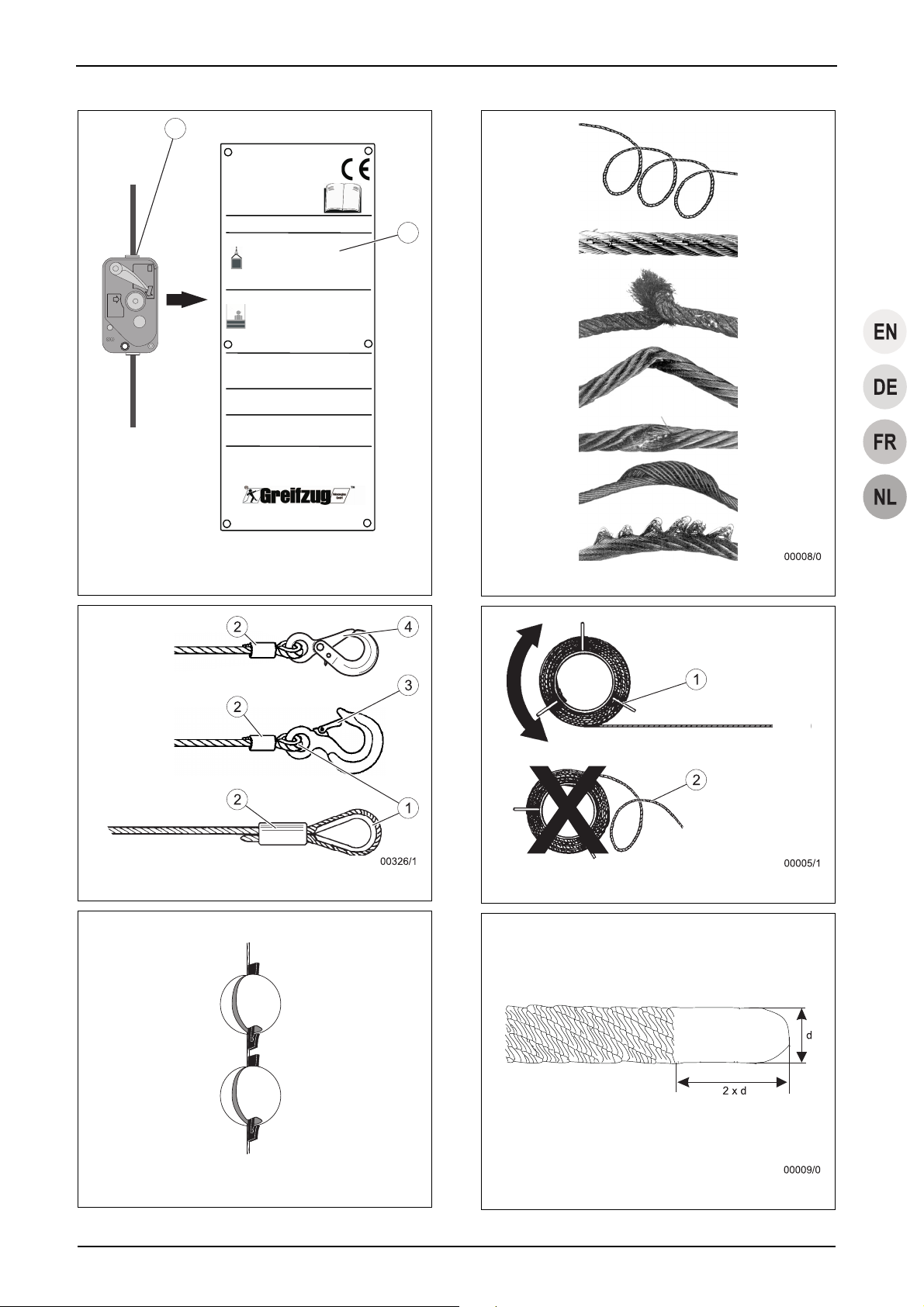

Fig./Abb./Fig./Afb. 7

Fig./Abb./Fig./Afb. 5

Fig./Abb./Fig./Afb. 8

00328/0

Fig./Abb./Fig./Afb. 6

Fig./Abb./Fig./Afb. 9

G905.5 - 02/2011 EN-DE-FR-NL-

Page 6

blocstop™ BSO

2

3

Fig./Abb./Fig./Afb. 10

CLOSE

CLOSE

FERMER

FERMER

OUVRIR

OPEN

AUF

ZU

ZU

1

00302/0

Fig./Abb./Fig./Afb. 12

Fig./Abb./Fig./Afb. 11

EN-DE-FR-NL-VI G905.5 - 02/2011

Page 7

Installation and operating manual

Contents

1 General ............................................................................... 2

1.1 Terms and abbreviations used in this manual .......... 2

1.2 Symbols used in this manual .................................... 3

2 Safety .................................................................................. 3

2.1 General safety instructions ....................................... 3

2.2 Instructions for the operator ...................................... 4

2.3 System manufacturer's responsibilities..................... 4

3 Overview............................................................................. 5

3.1 Delivery state ............................................................ 5

3.2 Scope of delivery ...................................................... 5

3.3 Equipment description .............................................. 5

4 Description ......................................................................... 6

4.1 Functional description ............................................... 6

4.2 Components / Modules ............................................. 7

4.3 Technical Specifications ........................................... 7

4.4 Operating fluids......................................................... 7

4.5 Circuit diagram.......................................................... 7

4.6 Safety equipment ...................................................... 7

4.7 Anchoring.................................................................. 7

5 Ropes.................................................................................. 8

6 Optional accessories......................................................... 8

13 Foreseeable misuse.........................................................14

14 Dismantling.......................................................................14

15 Transport and storage .....................................................14

15.1 Transport .................................................................14

15.2 Storage....................................................................15

16 Maintenance work ............................................................15

16.1 Authorized maintenance personnel.........................15

16.2 Mandatory inspections.............................................15

16.3 Care and maintenance ............................................15

16.4 Ordering spare parts................................................16

17 Disposal and environmental protection.........................16

18 Troubleshooting...............................................................17

19 EU Declaration of Conformity (Extract)..........................18

19.1 Independent secondary brake for

transport of persons.................................................18

19.2 Independent secondary brake for

transport of materials...............................................20

DANGER!

7 Options ............................................................................... 8

8 Model versions................................................................... 8

9 Necessary accessories ..................................................... 8

10 Installation and commissioning....................................... 8

10.1 Directives and standards .......................................... 8

10.2 Checks to be undertaken before starting

installation................................................................. 8

10.3 Assembly .................................................................. 9

10.4 Commissioning ....................................................... 10

11 Operating / Operation...................................................... 11

11.1 Checks to be carried out before starting work ........ 11

11.2 Operation with personnel lifting equipment............. 11

11.3 Operation with material lifting equipment................ 12

11.4 Manual EMERGENCY-STOP................................. 12

11.5 Securing the load.................................................... 12

12 Immediate measures to be taken after an emergency-

stop ................................................................................... 12

12.1 Emergency-stops for personnel lifting equipment... 12

12.2 Emergency-stops for material lifting equipment...... 13

12.3 Measures to be taken after a problem or an

emergency-stop ...................................................... 13

Risk of injury caused by falling objects, malfunctions,

incorrect usage and incorrect operation!

Failure to follow these instructions:

can result in severe injuries or death,

can result in damage to the equipment.

– Read through this operating manual carefully before you

install and commission this machine.

– Follow the instructions and procedures specified in this

manual in order to ensure safe operation of the equipment.

G905.5 - 02/2011 EN-1

Page 8

Installation and operating manual

1 General

Date of issue

02/2011

Copyright

The copyright of this instruction manual remains with Greifzug

Hebezeugbau GmbH.

This instruction manual is intended only for the operators of the

systems described here and their staff. This instruction manual

must be available to the operating personnel at all times. Additional copies can be obtained on request.

No part of this instruction manual may be reproduced, distributed

or otherwise communicated without the permission of Greifzug

Hebezeugbau GmbH.

Legal proceedings may be implemented in the case of any infringements.

Manufacturer's address

Sales and service office:

Greifzug Hebezeugbau GmbH

Scheidtbachstraße 19-21

51469 Bergisch Gladbach, Germany

Postfach 20 04 40

51434 Bergisch Gladbach, Germany

Tel: +49 (0) 22 02 / 10 04-0

Fax: +49 (0) 22 02 / 10 04-50 + 70

Greifzug Hebezeugbau GmbH reserves the right to make

changes to the product described in this instruction manual as

part of their ongoing product improvement programme.

Customers can obtain documentation about other TRACTEL

products by requesting the documentation from companies within

the TRACTEL Group or service organisations appointed by the

TRACTEL Group. Please visit our TRACTEL website at:

www.tractel.com for further details regarding the hoisting gear

and related accessories; stationary or mobile working platforms

for moving around on the inside and outside of buildings; rigging;

block stops for heavy loads; personal safety harnesses to prevent falls; traction and rope tension measuring equipment, etc.

The TRACTEL Group and its dealer network also provide additional customer and repair services upon request.

1.1 Terms and abbreviations used in

this manual

The terms used in this instruction manual have the following

meanings:

System / Machine

Pursuant to the Machine Directive 2006/42/EC lifting equipment,

hoisting gear, safety equipment and rigging for lifting are re-

garded as machines. The term "system" or "machine" also describes the device in which the unit described here will be fitted.

System manufacturer

The system manufacturer (system planner, system manufacturer,

installer) is the company marketing the system and all of the

required components. The system manufacturer is responsible

for the design, manufacturing, assembly and marketing.

Rigging

Rigging consists of equipment which does not belong to the

hoisting gear and which creates a connection between the carrying means and the load or the carrying means and the load lifting

equipment (e.g. rope loops, round slings, shackles, swivel hooks,

eye hooks, deflection rollers).

Anchoring point

Part of the on-site suspended construction to which the suspension rope, the safety rope, deflection rollers and the hoisting gear

are anchored separately from one another.

Actuation

The independent secondary brake is triggered (EMERGENCY

STOP situation) by manual actuation or uncontrolled actuation

resulting from vibrations.

Operating personnel

Personnel who have been trained by the operator to operate the

product and are authorised to operate it.

Operating personnel (PAM)

An appointed person who has undergone the appropriate advanced training for working at heights and who, due to his knowledge and practical experience, is in the position to perform the

required operating tasks when provided with the necessary

instructions.

Operator

The operator is responsible for the correct operation of the system / equipment and also for adhering to the maintenance intervals and the undertaking of the service work.

Running hours

The running hours are the effective operating times of a hoist's

motor.

BSO

BSO is used in the text as the abbreviation for the blocstop™

BSO model described here.

Electrician

An electrician is someone who possesses sufficient knowledge

or has obtained the required qualification through training in

order to recognise the risks and avoid the dangers that can occur

when working with electricity.

Emergency stop

The independent secondary brake is triggered (emergency stop

situation, e.g. overspeed) in the event of a suspension cable

rupture or a hoist malfunction.

Independent secondary brake

A device for stopping the load lifting equipment in the event of

the suspension rope snapping or a malfunction, e. g. drive malfunction.

EN-2 G905.5 - 02/2011

Page 9

f

g

Overall suspended load

The overall suspended load is the actual suspended static load,

which is made up of the payload, the load lifting equipment's own

weight, the additional fittings, the wire ropes and the control and

connection cables.

Hoisting gear / machine for lifting loads

Device or equipment consisting of a device with load carrying

means for lifting or transporting loads (e.g. wire rope hoist or wire

rope hoist with rope and swivel hook).

Customer / end customer

The customer or end customer is the system manufacturer's

customer and can also be the operator.

Load lifting equipment (LAM)

A component or piece of equipment which does not belong to the

hoisting gear, which enables the load to be grasped and which is

attached between the machine and the load or to the load itself,

or is intended to be an integral component of the load. Rigging

and its components are also regarded as load lifting equipment.

Material lifting equipment (MAM)

Load lifting equipment for material.

Nominal load

The nominal load is the load that the product bears. The maximum nominal load corresponds to the load bearing capacity.

Personnel lifting equipment (PAM)

Personnel lifting equipment. Combined material and personnel

lifting equipment also counts here.

Specialist

An appointed person who has undergone the appropriate training

and who, due to his knowledge and practical experience, is able

to safely perform the required work when provided with the necessary instructions.

Products in contact with the rope

Products in contact with the rope include hoists, deflection rollers,

independent secondary brakes and other products that the rope

runs through or is in contact with.

Load bearing capacity

The load bearing capacity specifies the maximum approved load

for the product.

Carrying means

The carrying means is equipment connected to the hoisting gear

for attaching load lifting equipment, rigging or loads (e.g. a hook

permanently attached to the suspension rope).

Maintenance personnel

A person appointed by and trained by Greifzug Hebezeugbau

GmbH with a valid certificate, who is capable of safely performing

the required maintenance, inspection and service work when

provided with the required instructions.

Installation and operating manual

1.2 Symbols used in this manual

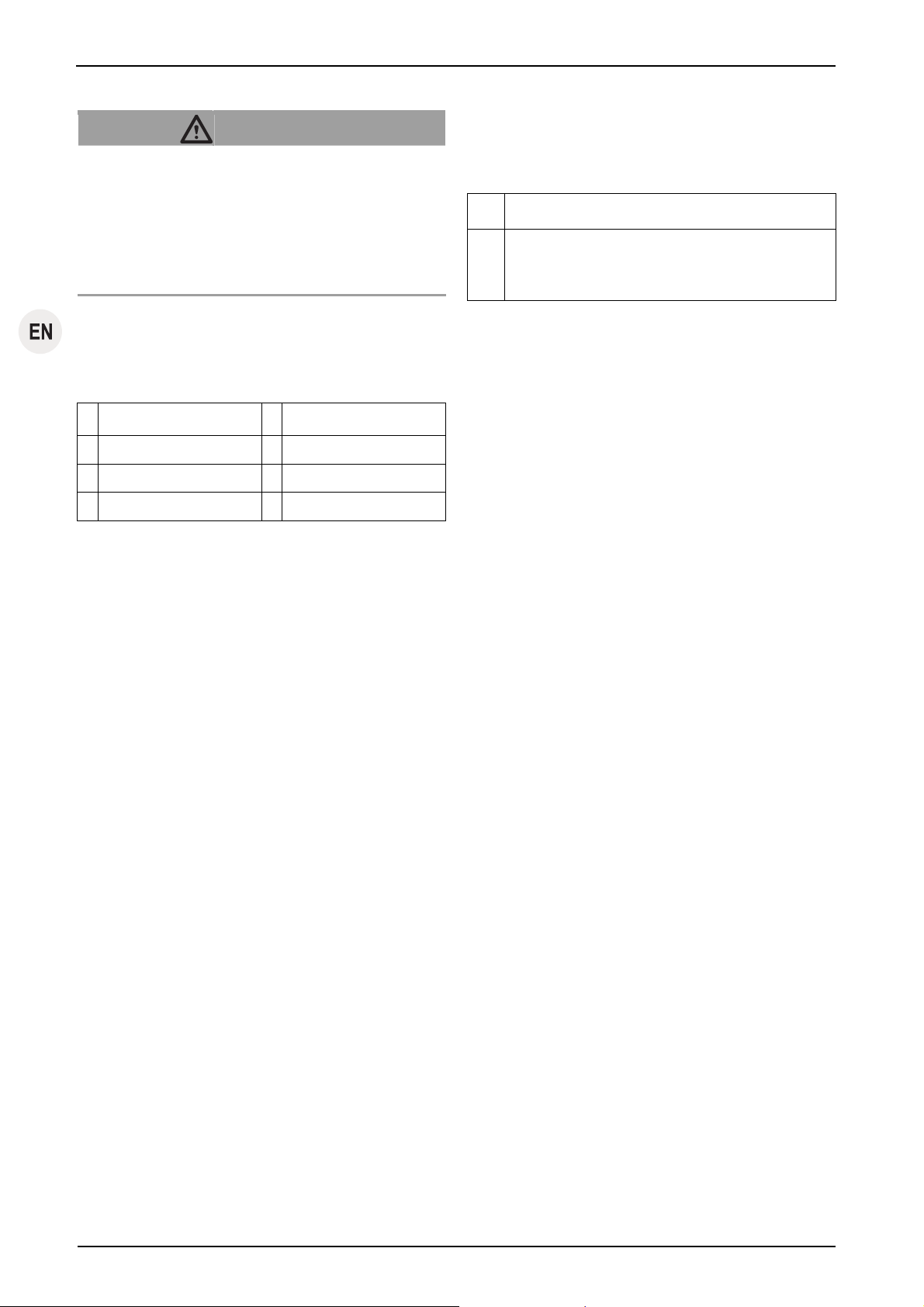

DANGER!

Type and source of danger

Result: e.g. death or severe injuries.

– Measures that must be taken to eliminate the danger.

ATTENTION!

Type and source of danger

Result: e.g. equipment or environmental damage.

– Measures that must be taken to eliminate any possible

damage.

Note:

This symbol is not used to indicate safety information but to

indicate information that will give you a better understanding of

the working procedures.

This symbol identifies devices for transport o

material.

This symbol identifies devices for transportin

people and materials.

2 Safety

2.1 General safety instructions

DANGER!

Danger of severe injuries caused by malfunctions, incorrect use and incorrect operation!

– You must abide by the following instructions in order to

ensure safe operation and correct functioning of the

equipment!

– Please observe the special safety instructions for all of

the work to be performed as described in the individual

chapters in this manual.

– Never use faulty or damaged independent secondary

brakes, rigging or ropes.

– The devices must only be used with an original rope with the

rope diameter specified in this manual.

G905.5 - 02/2011 EN-3

Page 10

Installation and operating manual

– Rope, hoist, independent secondary brake and rigging must

not be soiled by any heavily soiling building materials such

as concrete, epoxy resin or other adhesive materials. Protect the components against soiling! Utilize brush attachments to clean the wire rope in an extremely dirty environment.

– Do not lubricate the rope using a lubricant that contains

disulfide (e. g. Molycote

®

).

– Abide by the rope's withdrawal criteria, see '16.3 Care and

maintenance, Rope' on page 15.

– Cleaning the rope or the independent secondary brake with

high pressure cleaners is prohibited! Penetrating moisture

causes malfunctions.

– Dirt on the wire rope results in premature wear or the de-

struction of the rope, rigging and independent secondary

brake.

– Abide by the instructions concerning transport, storage and

cleaning listed on page 14.

– Always comply with the safety specification sheets provided

by the relevant manufacturers covering the lubricants to be

used.

– The anchoring devices must comply with the instructions

given in this manual or the applicable directives / standards.

– Never exceed the permitted load bearing capacity.

– Maintenance and repair work must only be undertaken by

authorised service personnel, see '16.1 Authorized mainte-

nance personnel' on page 15.

– Self-locking nuts must never be reused and they must al-

ways be exchanged for new ones.

– Only qualified personnel who have been trained on the

system are permitted to install and operate it in compliance

with the instructions given in this instruction manual.

– The independent secondary brake must be secured in place

so that the rope runs vertically into the independent secon-

dary brake from above. The independent secondary brake

must be aligned so that it does not touch the rope. The rope

must be tensioned using a tensioning weight or a relevant

winding device.

– Only qualified electricians or trainees supervised by a quali-

fied electrician are permitted to undertake work on the elec-

trical equipment in accordance with the electro technical

standards, rules and regulations.

– Never stand beneath suspended loads. Cordon off the

hazard zone whenever necessary. Support and secure

caught or jammed loads.

– Never grasp the wire rope while the machine is operating.

– When performing welding work the national safety and

accident prevention regulations must be observed (e.g.

BGR 159 in Germany).

2.2 Instructions for the operator

– If more than one person is entrusted with the tasks men-

tioned above then the operator must appoint a supervisor

who is authorised to issue instructions.

– The operator is also responsible for preparing clear operat-

ing, maintenance, repair and other working instructions and

ensuring that the unit is operated correctly by instructing and

training the personnel in the correct and approved utilisation

methods.

– Attached warning signs and information signs must be

readable at all times. Missing or illegible warning signs and

information signs must be replaced immediately.

– The operator is responsible for the correct operation of the

system as well as for adhering to the maintenance periods

and the undertaking of the service work.

– The operator is committed to maintaining the logbook sup-

plied with the system.

– EU Directive 89/391/EEC applies within the European Union

(in Germany Betriebssicherheitsverordnung (BetrSichV)).

You must always abide by your country's national accident

prevention regulations.

– You must provide suitable protective equipment such as

safety gloves, hearing protectors and a fall prevention system. Protection against extreme weather conditions (e.g.

sun protection, protection against cold) are also considered

to be part of the personal protective equipment.

– Always ensure that the workplace is sufficiently lit.

– This instruction manual and the instruction manuals for all of

the accessory parts must be handed out to all of the author-

ised personnel. The documents must be available at all ti-

mes.

– As Greifzug Hebezeugbau GmbH does not know the appli-

cations that the product described here will be used for in

the future, the system operator is therefore committed to in-

forming their personnel about any new safety instructions as

well as any supplementary maintenance work.

– The system operator is responsible for selecting the anchor-

ing method and suitable rigging options.

– The anchoring devices must comply with the instructions

given in this manual or the applicable directives / standards.

– Safe operation is not guaranteed if non-original spare parts

are utilised. This applies, in particular, to the use of ropes

other than the specified original ropes approved for the ap-

plication. Guarantee claims against the manufacturer will be

invalidated and this will also invalidate the CE approval for

any product holding this approval.

– Adhere to the permitted temperature range, see Table 1 on

page II.

2.3 System manufacturer's responsibili-

ties

– The system manufacturer is responsible for the design,

manufacture, assembly and marketing as well as obtaining

the CE seal of approval and issuing the EU Declaration of

Conformity.

– The products contained in the package supplied by Greifzug

Hebezeugbau GmbH must be carefully selected by the sys-

tem manufacturer, be used in the approved manner and in-

EN-4 G905.5 - 02/2011

Page 11

stalled in compliance with the instructions given in this installation and operating manual.

– The screw connections for anchoring the independent sec-

ondary brake and the clamp must be fitted in compliance

with the structural version.

– The information and notes contained in this installation and

operating manual must be integrated into the system manufacturer's operating manuals and documentation and supplemented by the addition of system specific details (e.g.

blockages and malfunction procedures). Merely handing this

manual over to the operator is insufficient.

– Instructions regarding the maintenance of the product and

its accessories must be integrated in the system's maintenance manual.

3 Overview

3.1 Delivery state

The equipment is delivered fully assembled.

3.2 Scope of delivery

y Independent secondary brake blocstop™ BSO

y Tractel

y Original Installation and operating manual

y Logbook

y Test certificate

y CE Declaration of Conformity

Optional scope of delivery:

y Lanyards

3.3 Equipment description

Authorized utilization

The blocstop™ BSO fitted with an automatic sudden acceleration

controller is an independent secondary brake, which can be used

with any hoisting gear / load lifting equipment. The device has

not been designed for private use. The precise intended use will

be defined by the operator or the equipment manufacturer.

An independent secondary brake is a safety component in accordance with the Machine Directive 2006/42/EC, Appendix V.

Safety components are regarded as machines.

The independent secondary brake must only be used with an

original rope with the rope diameter specified in this manual (see

also nameplate).

With the execption of the blocstop™ BSO 510, all of the equipment described here can be used as an independent secondary

®

rope in accordance with the order specifications

Installation and operating manual

brake for material and personnel lifting equipment, see (table 1

on page II).

The BSO 510 independent secondary brake may only be used to

hold material.

Maintenance and repair work must only be undertaken by authorised service personnel, see '16.1 Authorized maintenance personnel' on page 15.

Greifzug Hebezeugbau GmbH declares that the machine described in this instruction manual complies with technological

safety standards that were applicable to the equipment in the

European Union when it was launched on the market by the

manufacturer.

Commissioning the machine is prohibited until the machine in

which this is installed complies as a whole with the regulations of

the 2006/42/EC Directive, the corresponding national legislation

for implementing the regulations in accordance with national law

and the corresponding declaration of conformity has been issued.

y The operator or system manufacturer must perform a risk

evaluation in accordance with Appendix I of the guideline

2006/42/EC for machines for raising loads. EN 14492-1

must also be taken into account when inspecting the equip-

ment.

y A conformity evaluation process must be run by the operator

or the system manufacturer on machines used for lifting

personnel or personnel and goods, which come under Ap-

pendix IV No. 17 of Directive 2006/42/EC, in accordance

with Article 12, Paragraphs 3 or 4 of Directive 2006/42/EC.

EN 14492-1 and EN 1808 must also be taken into account

when inspecting the equipment.

The independent secondary brake must never be integrated in

systems that must comply with Directive 95/16/EC (in Germany:

Lift Directive 12 GPSGV).

Guarantee and liability exclusions

See '13 Foreseeable misuse' on page 14.

Any use other than that described here will be considered to be

unauthorised. Greifzug Hebezeugbau GmbH does not accept

any liability for damages resulting from unauthorised use. The

operator must assume sole responsibility in this case. Abiding by

all of the instructions given in this instruction manual, in particular

the installation and maintenance regulations, are also considered

part of authorised use.

Application areas

The product is suitable for use under the following operating

conditions:

y For permanent or temporary installations

y For short-term operation

y At heights of up to 1,000 m above sea level (max)

y Permitted temperature range see Table 1 on page II

G905.5 - 02/2011 EN-5

Page 12

Installation and operating manual

DANGER!

Danger of severe accidents!

– 24-hour operation is prohibited.

– Use in areas where there is a risk of explosion is prohib-

ited.

– Use in a corrosive environment is prohibited.

1)

– Use in close proximity to open fire or in an extremely hot

environment is prohibited.

1)

Corrosion protection in accordance with order specifications

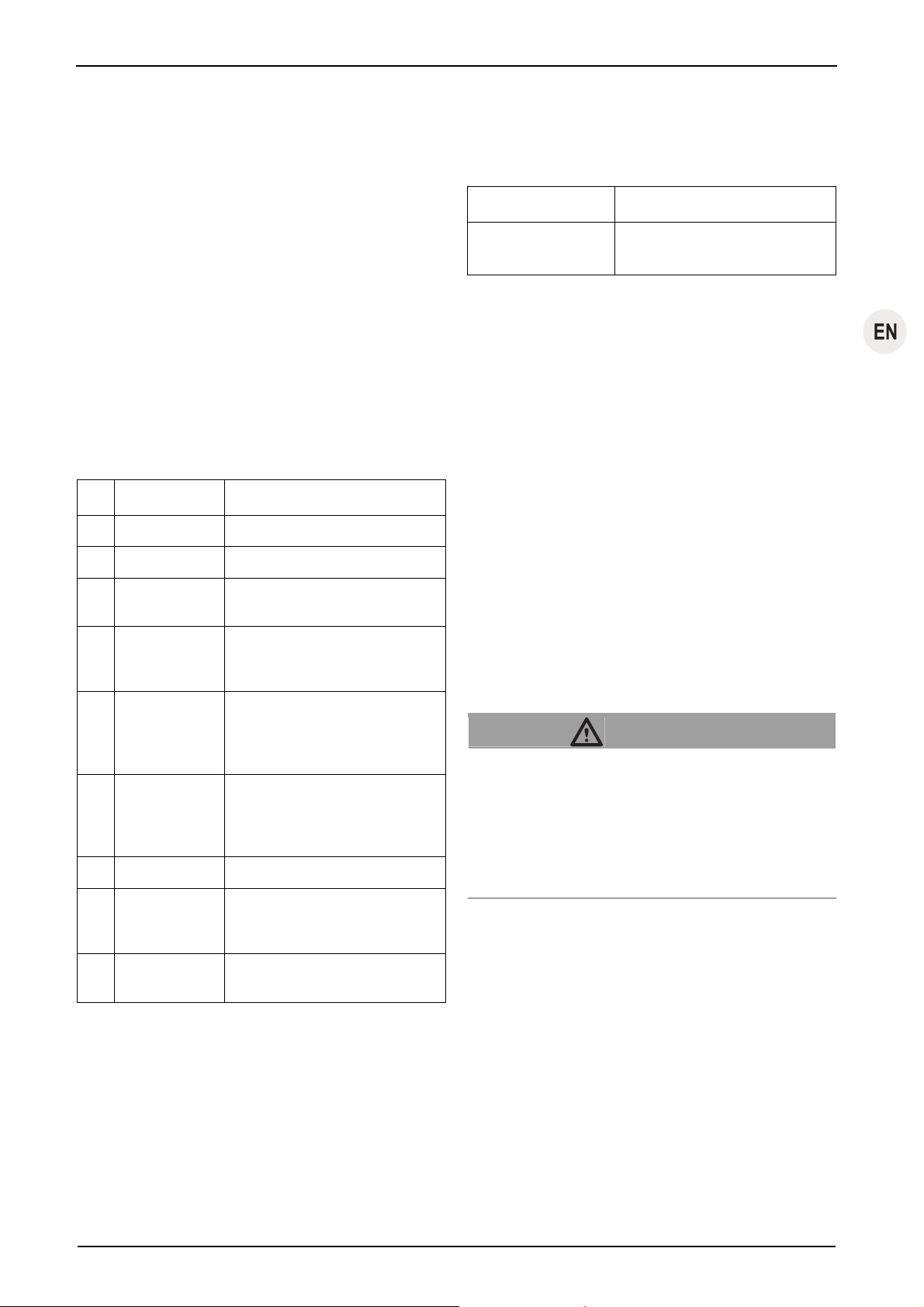

Installation example

See Fig. 2.

1 Safety rope 5 tirak™ hoist

2 Suspension rope 6 blocstop™ BSO

3 Limit switch actuator 7 Tension weight

4 "Lifting" limit switch

Nameplate and warning signs / application

restrictions

See Fig. 4.

Item Name

1 blocstop™ BSO nameplate

2 Rope diameter

The necessary information can be obtained from the nameplate.

Directives and standards

Applicable directives and standards: See '10.1 Directives and

standards' on page 8.

Product versions covered in the manual

The product versions described in this manual are listed in

Table 1 on page II.

Structural requirements

The maximum possible nominal load must be multiplied by the

operating coefficient in order to calculate the necessary load

bearing capacity.

The load bearing capacity of the structural equipment for anchoring the product, the rigging and the ropes must be at least the

nominal load bearing capacity multiplied by the operating coefficients:

Independent secondary brake: Operating coefficient = 5

The suspended assembly for the ropes and products must comply with the Directive 2006/42/EC and the applicable standards

(such as EN 1808).

The design must ensure that the impact factor remains below 3

(see EN 1808, 6.5.3.6) in the case of personnel lifting equipment

and securing to rigid assemblies. This is necessary in order to

ensure that the dynamic loading is adequate in the event of an

emergency stop.

The unit sizes of the different models can be found in Table 2 on

page IV.

Rope, products in contact with the rope and rigging must not be

soiled by heavily soiling building materials such as concrete,

epoxy resin or other adhesive materials. Protect the products

against soiling! Always use brush attachments to clean the wire

rope in an extremely dirty environment.

4 Description

4.1 Functional description

The independent secondary brake monitors the load lifting

equipment's speed. The independent secondary brake will stop

the downward movement of the load lifting equipment if the

speed is too high, using a friction actuated connection (clamps)

on the safety rope.

The independent secondary brake works automatically. The

speed of the safety rope is permanently monitored by a centrifugal force weight.

The centrifugal force balance weight will activate the clamping

jaws if a sudden acceleration occurs. The clamping jaws secure

the load to the safety rope. The clamping jaws are self clamping

jaws: The clamping jaws automatically shut tighter if the load

moves against the lifting direction. The greater the tractive force,

the tighter the clamping effect will be.

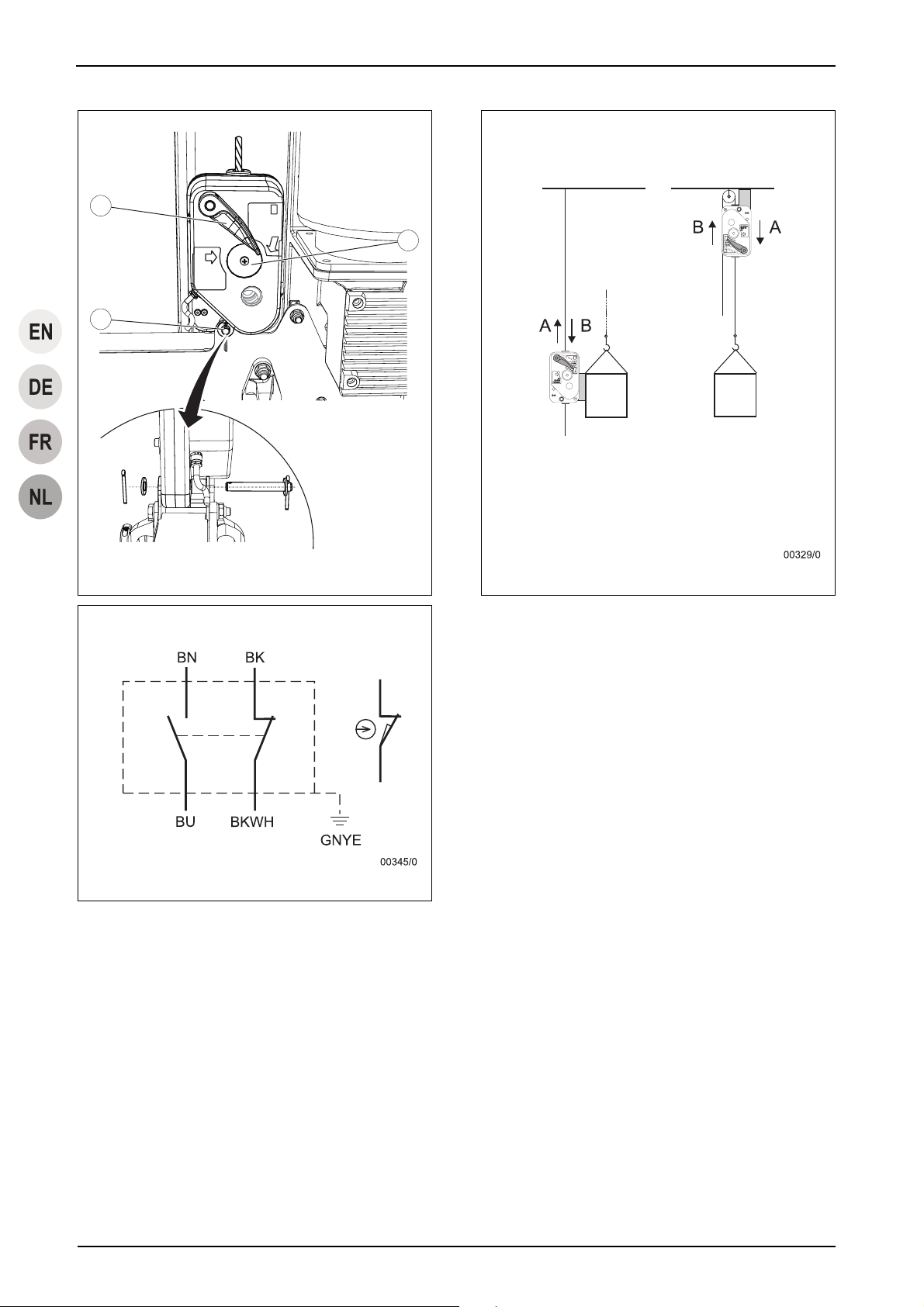

See Fig. 12.

When mounting the independent secondary brake the direction in

which the safety rope or the independent secondary brake accelerates in the event of the suspension rope snapping, for example,

so that the impulse to clamp the rope is triggered.

The braking direction (B) is the direction in which the independent secondary brake holds the end of the rope bearing the load.

The rope running direction (A) is the direction in which the rope

runs through the independent secondary brake regardless of

whether:

y the independent secondary brake is attached to a load

carrier or to a component and moves up and down a fixed

rope or

EN-6 G905.5 - 02/2011

Page 13

y the rope runs through a secondary brake mounted on-site,

for example.

The independent secondary brake must be mounted in such a

way that the direction (A) in which the rope runs through the

independent secondary brake at the time of the malfunction is

opposite to the braking direction (B).

This protects the hoisting gear / load lifting equipment against the

following damage:

y Suspension rope break

y Hoist malfunctions (broken gears)

Press the EMERGENCY-STOP button to manually trigger the

independent secondary brake in an emergency situation.

4.2 Components / Modules

See Fig. 1.

Item Name Function

1 Safety rope

2 Hand-lever Independent secondary brake release

3 EMERGENCY-

STOP button

Manually activates the independent

secondary brake

4 Inspection window Enables visual inspection of the function

of the centrifugal force mechanism during

operation

5 Centrifugal force

weight

Permanently monitors wire rope speed

during the run. The clamping jaw mechanism will be activated if the speed setting

is exceeded.

6 Clamping jaws Mechanical connection to the wire rope in

emergency-stop and activation situations.

The greater the tractive force, the tighter

the clamping effect will be.

7 Limit switches Optional

8 Securing holes Holds the bolts / screws used for securing

the independent secondary brake to the

anchoring devices

9 Control pin BSO 2050/2360 only: Visible when the

safety rope is running in correctly.

4.3 Technical Specifications

The technical specifications are listed in Table 1 on page II.

Installation and operating manual

4.4 Operating fluids

Lubricant

Application Lubricant

Rope Multipurpose oil/grease (without disul-

phide)

4.5 Circuit diagram

The hoist's circuit diagram is located in the terminal box of the

motor.

See '10.3 Assembly, Independent secondary brakes with limit

switch: Electrical connection' on page 10.

4.6 Safety equipment

Press the EMERGENCY-STOP button to manually trigger the

independent secondary brake in an emergency situation.

Optional for independent secondary brake with electrical deactivation:

The limit switch will ensure that the control voltage for the downward movement will be disconnected if an emergency-stop is

activated.

4.7 Anchoring

DANGER!

Danger of severe injuries caused by incorrect anchoring!

High-strength, galvanised bolts and screws can become brittle

and break. Risk of falling and of being injured by falling objects!

– High-strength galvanised bolts / screws (10.9 or 12.9)

may not be utilised for anchoring.

– Utilise bolts / screws with the specified strength.

Specifications detailing the strength of the bolts / screws are

listed in Table 1 on page II.

Observe the details in 'Structural requirements' on page 6.

The independent secondary brake must be secured in place so

that the rope runs vertically into the independent secondary

brake from above. The independent secondary brake must be

aligned so that it does not touch the rope. The rope must be

tensioned using a tensioning weight or a relevant winding device.

The required load bearing capability rating of the suspension and

securing modules depends on the independent secondary brake

model.

G905.5 - 02/2011 EN-7

Page 14

Installation and operating manual

5 Ropes

General

DANGER!

Incorrect rope or rope with incorrect diameter!

Using an incorrect rope leads to a danger of falling or injury

through falling objects and the risk of malfunctions!

– In order to operate safely only use original ropes author-

ized by Greifzug Hebezeugbau GmbH with the correct

rope diameter and the required design.

The required rope diameter is listed in Table 1 on page II.

The design is listed in Table 3 on page 16.

Alternative wire rope assemblies:

y End/thimble

y End/safety hook

6 Optional accessories

y Anchoring options e. g. fishplate sets

7 Options

10 Installation and commissioning

10.1 Directives and standards

The independent secondary brake fulfils the following directives

and standards:

y Machine Directive 2006/42/EC

y DIN EN ISO 12100

y Machines for lifting personnel or personnel and materials

(transport of persons):

EN 1808:1999 + A1:2010

The following are also applicable for independent secondary

brakes fitted with limit switches:

y The safety goals required by Directive 2006/95/EC have

been complied with in accordance with Appendix I No. 1.5 of

the Directive 2006/42/EC.

The operator or the system manufacturer is responsible for ensuring that the machine is used within the limits specified in these

instructions. The operator or the system manufacturer must also

observe the directives and standards and EN ISO 14121 and EN

ISO 13849 for the machine in which the unit will be fitted.

10.2 Checks to be undertaken before

starting installation

The independent secondary brake models described here are

can also be supplied with an optional limit switch fitted to them

(e.g. blocstop™ BSO 2030 E).

Please contact Greifzug Hebezeugbau GmbH directly.

8 Model versions

The standard stopping speed of the independent secondary

brakes described here is 30 m/min. Models with stopping speeds

of 20, 40, 60 and 70 m/min can also be supplied if requested.

9 Necessary accessories

The following accessories, which are not part of scope of delivery,

are necessary to use the product:

®

y Original Tractel

y Clamp (weights) for the rope, see Fig. 6

The operator or the manufacturer of the system is responsible for

selecting and using the accessories in accordance with the local

conditions. You must also abide by any other requirements of the

respectively applicable regulations and standards.

rope

Checking the suspended assembly

The suspended assembly for the ropes and products must comply with the Directive 2006/42/EC and the applicable standards

(such as EN 1808).

Observe the details in 'Structural requirements' on page 6.

Inspecting the installation site

– Check whether the device can be installed correctly without

it being obstructed by other components.

The installation space must not contain any sharp or edged

components.

– Check that the mounting does not cover any nameplates

(see Fig. 4).

– The independent secondary brake must be secured in place

so that the rope runs vertically into the independent secon-

dary brake from above. The independent secondary brake

must be aligned so that it does not touch the rope. The rope

must be tensioned using a tensioning weight or a relevant

winding device.

– The independent secondary brake must be mounted so that

the operator can trigger the EMERGENCY-STOP at any

time and can check the function via the inspection window.

Installation examples: When using personnel lifting equip-

ment e. g. on a working platform; when using material lifting

equipment e. g. at the operator's site.

EN-8 G905.5 - 02/2011

Page 15

See Fig. 12.

The independent secondary brake must be mounted in such a

way that the direction (A) in which the rope runs through the

independent secondary brake at the time of the malfunction is

opposite to the braking direction (B).

For independent secondary brakes equipped with a limit switch:

y Connection option available in the hoist's control box

Installation and operating manual

y Position of the securing module:

The gap between the securing module and the independent

secondary brake must be set up so that the rope runs verti-

cally into the inlet on the independent secondary brake.

Mounting the independent secondary brake

DANGER!

Checking the independent secondary brake

and the accessories

Independent secondary brake

– Inspect the housing for signs of damage.

Testing the EMERGENCY-STOP button:

– Trigger the independent secondary brake via the EMER-

GENCY-STOP button.

A clear audible click must be heard when it snaps shut.

Rope

– Check whether the diameter and design of the rope match

the product and the application, see Table 1 on page II,

Table 3 on page 16 and 'Nameplate and warning signs / application restrictions' on page 6.

– Check that the length of the rope is sufficient:

It must be possible to safely move the load from the start to

the end position.

The independent secondary brake requires a rope end of at

least 3 m.

– Check whether the thimble (1) and sealing cuffs (2) are

undamaged (see Fig. 5).

– Ropes with hooks:

Check that the hook and the safety catch (3) are intact, see

Fig. 5.

– Inspect the entire length of the rope for any signs of damage,

see Fig. 7.

– Inspect the rope tip in accordance with Fig. 9 (see also

'16.3 Care and maintenance, Rope' on page 15).

Anchoring devices

– Check whether the bolts/screws/rigging comply with the

specifications in '4.7 Anchoring' on page 7.

– Inspect the fishplates, load bolts and screw connections for

damage.

Danger of severe injuries caused by incorrect anchoring!

High-strength, galvanised bolts and screws can become brittle

and break. Risk of falling and of being injured by falling objects!

– High-strength galvanised bolts / screws (10.9 or 12.9)

may not be utilised for anchoring.

– Utilise bolts / screws with the specified strength.

Danger of severe injuries caused by incorrect anchoring!

Risk of falling and of being injured by falling objects!

– Both securing holes must be used to secure a blocstop™

BSO 2050 or 2360 to the securing module.

– The securing module must be fitted with two fishplates or

similar.

Depending on the application, observe the direction of the force

of the independent secondary brake (see also Fig. 12 and

'4.1 Functional description' on page 6).

– Attaching the independent secondary brake to the securing

module.

BSO 500 - BSO 1040: 1 bolt or 1 screw

BSO 2050 series, BSO 2360 series: 2 bolts or 2 screws

– Secure the bolts with a cotter pin or similar lock.

– Use screws with self-locking nuts to stop them from being

lost.

Installing the safety rope

DANGER!

Risk of injury through stabs and cuts!

Broken wires in the wire rope can result in protruding wires!

Protruding wires can cut or stab through safety gloves!

– Wear suitable leather protective gloves when working

with wire ropes.

– Never let the wire rope run through your hands!

10.3 Assembly

Requirements

y Assembly may only be performed by trained personnel.

y The workplace must have adequate lighting.

y The gap between the safety rope and the suspension rope

must be as small as possible.

Danger of severe injuries caused by incorrect anchoring!

There is a risk of malfunction if the independent secondary

brake cannot align with the rope.

– The independent secondary brake must be secured in

place so that the rope runs vertically into the independent

secondary brake from above.

– The independent secondary brake must be aligned so

that it does not touch the rope.

– The rope must be tensioned using a tensioning weight or

a relevant winding device.

G905.5 - 02/2011 EN-9

Page 16

Installation and operating manual

ATTENTION!

10.4 Commissioning

Incorrect assembly!

Damage to the rope may occur!

– The rope must never run over an edge!

– The loose rope end must hang free.

Note

Do not mix up the safety rope and the suspension rope: Observe

the correct rope diameter (see also Fig. 4).

– Roll-off the rope correctly so that no loops in the rope occur.

– Secure the rope to the suspended assembly. The rope must

hang free.

– Open the independent secondary brake by pressing down

on the manual lever.

– Feed the rope in from the top.

BSO 2050/2360: The control pin will spring out if the rope

has been fed in correctly.

– Manually pull the rope until it is taut.

– Clamp two tension weights (weighing approx. 11.5 kg) in

place about 20 cm above the ground (see Fig. 6).

– Place the loose end of the rope down correctly to prevent

any loops or knots from being created.

Independent secondary brakes with limit

switch: Electrical connection

The limit switch will ensure that the control voltage for the downward movement will be disconnected if an emergency-stop is

activated.

See Fig. 11.

Connection diagram for independent secondary brakes with limit

switch.

The switch must be connected as a break contact in order to

realise forced opening.

– Utilise the colours BK (black) and BKWH (black-white) for

the connection.

Limit switch cable with plug connection

– Connect the limit switch cable plug to the hoist's control box.

Hard-wired connection

Only a qualified electrician is permitted to undertake this work.

– Connect the limit switch cable inside the hoist's control box

as shown in the circuit diagram.

Determine operational readiness

– Check the rope anchoring.

– Inspect the connection between the independent secondary

brake and the load lifting equipment.

– Check whether the rope enters the independent secondary

brake vertically.

– Check whether the independent secondary brake can freely

align with the rope.

– Record the inspection results in the logbook.

Functional test

See Fig. 10 (example).

General function test:

– Inspect the housing for signs of damage.

– Press the EMERGENCY-STOP (1) button while moving

downward.

The independent secondary brake must close and hold the

rope.

Optional for independent secondary brakes equipped with a

limit switch:

The hoisting gear may not move downwards.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

Check the function of the centrifugal force weight:

– Check the inspection window (4) during every run to see

whether the centrifugal force weight is turning.

Check the activation of the independent secondary brake:

The function of the speed limitation can be checked using two

different tests. The testing method depends on how the independent secondary brake is installed.

y Method 1: The independent secondary brake is removed,

raised approx. 30 cm and allowed to fall on the (vertical)

rope. The falling path may not be obstructed by any on-site

components which could collide with the independent secondary brake.

y Method 2: The safety rope is abruptly jerked through the

independent secondary brake by hand.

Method 1 (Checking the speed limitation):

DANGER!

Danger of being injured by falling objects! Danger of

crushing and cutting!

When performing the following test there is a risk of being

crushed between and cut by the falling independent secondary brake and the on-site components.

– Do not reach into the falling path of the independent

secondary brake.

EN-10 G905.5 - 02/2011

Page 17

Installation and operating manual

DANGER!

Danger of being injured by falling objects! Danger of

crushing and cutting!

If the independent secondary brake fails to activate and the

falling path is not cordoned off by on-site equipment then the

independent secondary brake can fall unchecked and endanger other people!

– Use suitable measures to cordon off the falling path!

ATTENTION!

Danger of damage to the independent secondary brake

or other components!

When performing the following test the independent secondary brake can collide with other on-site equipment and be

damaged.

– Ensure that the independent secondary brake cannot

collide with on-site equipment.

– If a collision cannot be avoided than use the other

testing method.

– Remove the independent secondary brake anchoring (e.g.

via the bolts (3) in the installation example shown).

– Raise the independent secondary brake approx. 30 cm up

the rope.

– Let the independent secondary brake fall:

The independent secondary brake must close and clamp

onto the rope after a maximum of 8 cm.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Lower the independent secondary brake down the rope.

– Mount the independent secondary brake:

Secure the bolts with a new cotter pin.

Secure the screws with a new self-locking nut.

Method 2 (Checking the speed limitation):

See Fig. 12.

– Remove the tensioning weight from the safety rope or cre-

ate a rope loop at the rope outlet (the unloaded side of the

independent secondary brake).

– Abruptly jerk the rope in the direction 'A':

The independent secondary brake must close and hold the

rope.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Re-tighten the safety rope by hand, if necessary.

– Re-attach the tensioning weight to the safety rope, if neces-

sary.

11 Operating / Operation

Personnel must have been trained by the operator in operating

the unit and be authorised to use it.

11.1 Checks to be carried out before

starting work

– Check the rope for clinging dirt and clean if necessary.

– Check that everything is ready for working, see

'10.4 Commissioning, Determine operational readiness' on

Page 10.

– Run the function test, see '10.4 Commissioning, Functional

test' on page 10.

– Record the inspection results in the logbook.

11.2 Operation with personnel lifting

equipment

DANGER!

Danger of being injured by an emergency-stop due to

the drop being too long!

The safety rope will be pushed upwards when moving

upwards with the independent secondary brake shut and it

will no longer be tensioned between the suspension point

and the independent secondary brake!

– You must always ensure that the manual lever is set to

OPEN and latched in place before moving.

See Fig. 10 (example).

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Start the hoisting gear.

– Check the inspection window (4) during every run to see

whether the centrifugal force weight is turning.

Note:

Where possible perform this check when beginning to move and

before the load lifting equipment has reached a great height.

If the centrifugal force weight does not turn:

– Immediately stop the load lifting equipment.

– Observe the operator’s emergency plan.

– Remove the independent secondary brake and send it to

Greifzug Hebezeugbau GmbH or an authorised hoisting

gear workshop for inspection.

Safety rope is not tensioned

If the safety rope is not under tension when the independent

secondary brake is closed:

G905.5 - 02/2011 EN-11

Page 18

Installation and operating manual

– Stop the hoisting gear.

– Check whether the safety rope is hanging free.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Re-tighten the safety rope by hand, if necessary.

– Only continue with the original movement after the safety

rope has been re-tensioned.

11.3 Operation with material lifting

equipment

See Fig. 10 (example).

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Start the hoisting gear.

– Check the inspection window (4) during every run to see

whether the centrifugal force weight is turning.

If the centrifugal force weight does not turn:

– Immediately stop the load lifting equipment.

– Remove the independent secondary brake and send it to

Greifzug Hebezeugbau GmbH or an authorised hoisting

gear workshop for inspection.

See Fig. 10 (example).

Securing the load:

– Trigger the independent secondary brake via the EMER-

GENCY-STOP button.

Re-open the independent secondary brake:

– Move upwards slightly to reduce the strain on the rope.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Re-tighten the safety rope by hand, if necessary.

– Only continue with the original movement after the safety

rope has been re-tensioned.

12 Immediate measures to be

taken after an emergency-stop

An emergency-stop means that the independent secondary

brake was triggered by a hoist malfunction or suspension rope

breakage, for example.

12.1 Emergency-stops for personnel lift-

ing equipment

Safety rope is not tensioned

If the safety rope is not under tension when the independent

secondary brake is closed:

– Stop the hoisting gear.

– Check whether the safety rope is hanging free.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Re-tighten the safety rope by hand, if necessary.

– Only continue with the original movement after the safety

rope has been re-tensioned.

11.4 Manual EMERGENCY-STOP

Press the EMERGENCY-STOP button to manually trigger the

independent secondary brake in an emergency situation.

11.5 Securing the load

The independent secondary brake can be used to secure the

load during work breaks. This relieves the strain on the rope hoist

gearbox, for example.

Note:

– Please follow the operator's work instructions and safety

measures and the notes in the operating manuals for the

hoisting gear and load lifting equipment.

DANGER!

Danger of severe injuries caused by incorrect procedures!

– Keep calm.

– Check out the cause.

– Eliminate the problem.

If this was caused by a suspension rope snapping or a hoist

malfunction:

– Evacuate the team. See the personnel lifting equipment

documentation or, if available, the operators' emergency

rescue plan.

– Implement suitable measures to secure the personnel lifting

equipment in place so that the suspension rope or the hoisting gear can be replaced.

– Tension the safety rope on the ground.

If this was not caused by a suspension rope snapping or a hoist

malfunction:

– Try to move upwards.

If this is not possible:

– Evacuate the team and secure the personnel lifting equip-

ment in place (see above).

See Fig. 10.

If it is possible to move upwards then an independent secondary

brake malfunction has probably occurred.

EN-12 G905.5 - 02/2011

Page 19

– Move upwards slightly to reduce the strain on the rope.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Re-tighten the safety rope by hand, if necessary.

– Move downwards.

– Press the EMERGENCY-STOP (1) button while moving

downward.

Independent secondary brakes without limit switch:

– Lower the load until the independent secondary brake sup-

ports the load using the safety rope.

Independent secondary brakes with limit switch:

– Perform an emergency descent (see the documentation for

the hoist or the personnel lifting equipment) until the inde-

pendent secondary brake holds the load using the safety

rope.

If the load is not held:

– Evacuate the team and secure the personnel lifting equip-

ment in place (see above).

If the load is held:

– Move upwards slightly to reduce the strain on the rope.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Move the load lifting equipment carefully downwards and be

ready to press the EMERGENCY-STOP button on the inde-

pendent secondary brake at any time.

After every emergency-stop:

See '12.3 Measures to be taken after a problem or an emergency-stop' on page 13.

12.2 Emergency-stops for material lifting

equipment

DANGER!

Danger of being injured by falling loads!

– Never stand beneath the material lifting equipment.

– Check the cause of the problem.

– Eliminate the problem.

If this was caused by a suspension rope snapping or a hoist

malfunction:

– Implement suitable measures to secure the load lifting

equipment in place so that the suspension rope or the hoist-

ing gear can be replaced.

If this was not caused by a suspension rope snapping or a hoist

malfunction:

– Try to move upwards.

If this is not possible:

– Securing the load lifting equipment (see above).

Installation and operating manual

See Fig. 10.

If it is possible to move upwards then an independent secondary

brake malfunction has probably occurred.

– Move upwards slightly to reduce the strain on the rope.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Re-tighten the safety rope by hand, if necessary.

– Move downwards.

– Press the EMERGENCY-STOP (1) button while moving

downward.

If the load is not held:

– Take suitable measures to secure the load lifting equipment.

If the load is held:

– Move upwards slightly to reduce the strain on the rope.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

– Move the load lifting equipment carefully downwards and be

ready to press the EMERGENCY-STOP button on the inde-

pendent secondary brake at any time.

After every emergency-stop:

See '12.3 Measures to be taken after a problem or an emergency-stop' on page 13.

12.3 Measures to be taken after a prob-

lem or an emergency-stop

DANGER!

Danger of severe accidents!

In the event of an emergency-stop the entire construction is

subjected to sudden forces. Damage to the suspended assembly, the anchoring devices, the rope and the independent

secondary brake is possible.

– The independent secondary brake must be inspected by

Greifzug Hebezeugbau GmbH or an authorised hoisting

gear workshop.

– A qualified specialist must perform an on-site inspection.

– Remove the independent secondary brake and send it to

Greifzug Hebezeugbau GmbH or an authorised hoisting

gear workshop for inspection.

On-site inspection to be carried out by a specialist:

y Safety rope

y Safety rope anchoring point

y On-site anchoring point of the independent secondary brake

and anchoring point on the load lifting equipment

y All bolts and screw connections

An inspection is not needed after an activation.

G905.5 - 02/2011 EN-13

Page 20

Installation and operating manual

13 Foreseeable misuse

Guarantee and liability claims for personal injuries and equipment damage will be rejected if they can be traced back to one or

more of the following causes:

y Unauthorized use of the product, the accessories or the

carrying means belonging to the product

y BSO 510: Lifting personnel

y Operating with a soiled rope

y Use in potentially explosive or corrosive environments

y Not adhering to the stipulated maintenance periods

y Cleaning with a high-pressure cleaner

y Incorrect installation, commissioning, operation, mainte-

nance or repairs

y Working with an electrical connection that does not corre-

spond to the details stipulated in this manual

y Poor monitoring of the parts and the accessories, which has

resulted in wear occurring

y Carrying out incorrect and unauthorised repairs

y Use of non-original spare parts

y Alteration of safety device settings

y Ignoring measurements and checks that would detect early

signs of damage

y Product overloaded

y Manual lever jammed / wedged in place

y Accidents caused by foreign bodies or acts of God

y The manufacturer will not accept any liability for damages

resulting from modifications and conversions made to the

products or from the use of non-original parts that have not

been authorized by the manufacturer.

y Never use faulty or damaged products, accessories and,

rigging.

y The safety rope was anchored to the same anchoring point

as the suspension rope

y Load lifted when the safety rope was slack

y Use with personnel lifting equipment with a hoist that has a

rope speed exceeding 18 m/min

For transport of persons:

y The independent secondary brake was installed on the

suspension rope

14 Dismantling

DANGER!

Risk of injury through stabs and cuts!

Broken wires in the wire rope can result in protruding wires!

Protruding wires can cut or stab through safety gloves!

– Wear suitable leather protective gloves when working

with wire ropes.

– Never let the wire rope run through your hands!

– Disconnect the tension weight from the safety rope.

ATTENTION!

Increased wear or damage due to incorrectly opened

independent secondary brake!

– Always press the independent secondary brake lever

to the stop and hold until the rope has been pulled out.

– Open the independent secondary brake: Turn the manual

lever (2) clockwise until it latches into place.

Press the manual lever up to the stop and hold it there.

– Pull the safety rope upwards by hand.

– Dismantling the independent secondary brake: Unscrew the

screws and bolts.

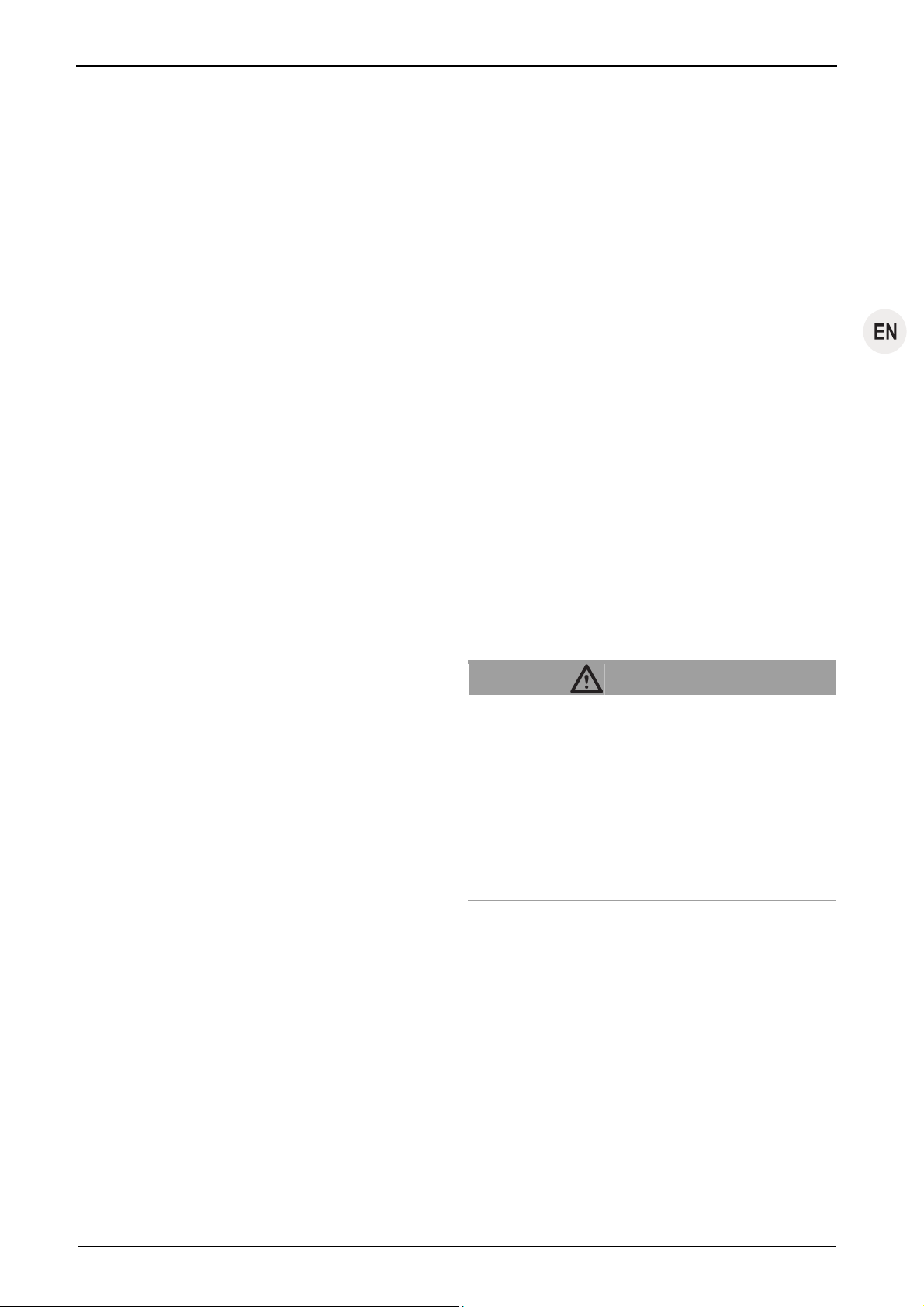

– Whilst lowering the ropes (1) you must wind them up in the

correct position or wind them onto a reel to ensure that there

are no loops (2), which would make the ropes unusable.,

see Fig. 8.

15 Transport and storage

15.1 Transport

General transporting instructions

Ensure that no damage occurs during the transporting.

Always use suitable transport equipment and get a second per-

son to help you with heavy components.

Rope

– Protect the ropes against direct sunlight, chemicals, soiling

and mechanical damage.

– Transport the ropes on the reels whenever possible.

– Rolled-up ropes without reels should be lifted and trans-

ported using a lifting strap.

– Minimise the load resulting from the dead weight as much

as possible.

EN-14 G905.5 - 02/2011

Page 21

15.2 Storage

General storage conditions

y Dry location (maximum of 75% relative humidity)

y Dust-free

y Even ambient temperature

Wire rope storage conditions:

y Lightly greased

y Avoid contact with chemicals (e.g. battery acid).

y Store without any mechanical crushing, pressure or tensile

stress.

Installation and operating manual

Contact Greifzug Hebezeugbau GmbH or your supplier with

regards to this test.

Exceptional tests

The independent secondary brake must be inspected by

Greifzug Hebezeugbau GmbH or an authorised hoisting gear

workshop.

See '12.3 Measures to be taken after a problem or an emergency-stop' on page 13.

16.3 Care and maintenance

Interval Work Implementation

16 Maintenance work

16.1 Authorized maintenance personnel

DANGER!

Risk of falling! Risk of being injured by falling objects!

Danger of death due to incorrectly carried out maintenance or

service work!

Maintenance and service work which requires the product to

be opened may only be performed by the following authorized

parties:

– The Greifzug Hebezeugbau GmbH

– Lifting equipment service companies authorized by

Greifzug Hebezeugbau GmbH

– Service personnel trained and certified by Greifzug He-

bezeugbau GmbH

16.2 Mandatory inspections

A written certificate is required for the annual safety inspection

and any exceptional tests. The inspections must be recorded in

the logbook included with delivery.

Prior to every use

Always check to ensure that the device is in an orderly working

condition before use, see '10.4 Commissioning' on page 10.

Annual safety inspection

The safety inspection must be carried out annually.

The safety inspection may only be undertaken by authorised

maintenance personnel, see '16.1 Authorized maintenance personnel' on page 15. Depending on the usage conditions (e.g.

operation in an extremely dirty environment), an intermediate

inspection may be necessary.

We recommend that the system is tested in our factory by

Greifzug Hebezeugbau GmbH.

Weekly

– Lubricate the safety rope

Operating personnel

– Clean the independent

secondary brake housing

1 x annually /

every 250

operating

hours of

– Inspect for clamping jaw

wear

– Check for pressure / drive

roller wear

Authorised maintenance personnel

the hoist

Whenever

necessary

– Replace the clamping jaws

– Replace the pressure / drive

Authorised maintenance personnel

rollers

– Replace the safety rope

Trained person nominated by the operator

Rope

DANGER!

Risk of injury through stabs and cuts!

Broken wires in the wire rope can result in protruding wires!

Protruding wires can cut or stab through safety gloves!

– Wear suitable leather protective gloves when working

with wire ropes.

– Never let the wire rope run through your hands!

Cleaning

Brush the dirt off soiled ropes when dry if necessary. Re-lubricate

as necessary.

G905.5 - 02/2011 EN-15

Page 22

Installation and operating manual

Lubrication

DANGER!

Danger of falling caused by a slippery safety rope!

May result in severe injuries or death!

– Never lubricate the safety rope using a lubricant that

®

contains disulfide (e.g. Molycote

).

– Use multi-purpose grease or oil.

– Cleaning the rope or the independent secondary brake

with high pressure cleaners is prohibited! Penetrating

moisture will result in malfunctions and damage.

– Dirt on the wire rope results in premature wear or the

destruction of the rope, rigging and independent secondary brake.

Replacement

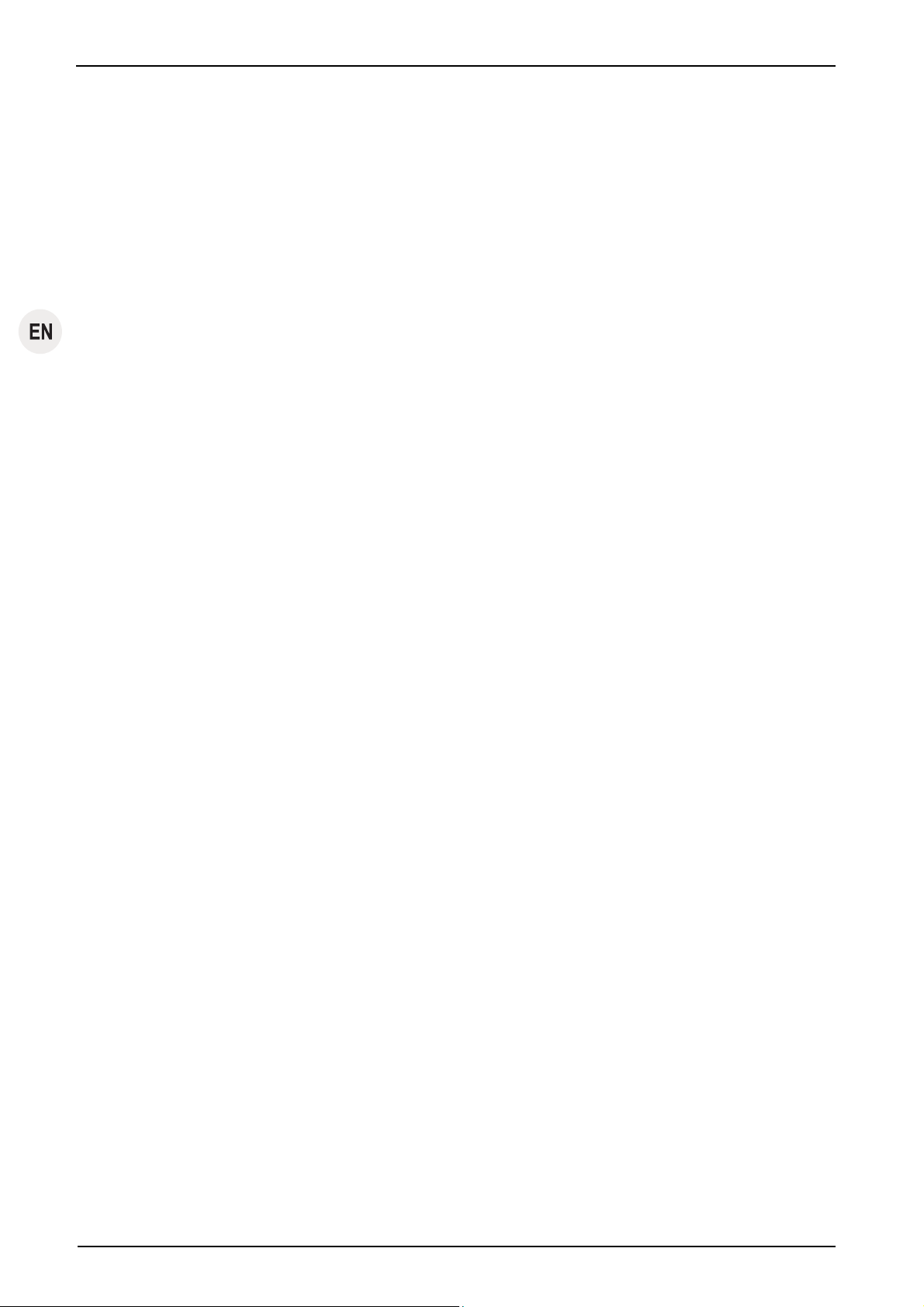

Replace the ropes immediately if the withdrawal criteria in accor-

dance with Table 3 have been reached (as per ISO 4309 and

DIN 15020, Sheet 2) or typical rope defects are present, see

Fig. 7.

Design of the rope

4 x 26

rope

Nominal diameter of the

Rotation-resistant

4 x 36 5 x 19 5 x 26 5 x 31

diameter

Minimum permitted rope

16.4 Ordering spare parts

Spare parts lists can be requested from your supplier or directly

from Greifzug Hebezeugbau GmbH.

The details needed to place the order are listed on the separate

component's nameplates, see 'Nameplate and warning signs /

application restrictions' on page 6.

The required information is e.g.:

Independent

Article no., model

secondary brake:

17 Disposal and environmental

protection

The equipment is made from recyclable materials. If the equipment is later scrapped, it must be disposed off correctly. The

national versions of the waste legislation directive 75/442/EEC

apply within the European Union (in Germany Kreislaufwirtschafts- und Abfallgesetz (KrWAbfG)).

The manufacturer is obliged to take back and dispose of specific

electrical and electronic components in accordance with Directive

2002/96/EC. The following symbol is used on the nameplate of

such components to identify them:

[mm] Number of visible broken wires in the outer strands

[mm]

over a length of 30 x rope's nominal diameter.

6

8 5,9

8 10 10 8 11 7,5

9 10 10 8

10 8

8,5

11 9,3

11,5 10 11 10,5

14 10 11 13,1

16 13 13 15,0

Table 3

Implementation: See '14 Dismantling' on page 14 and

'10.3 Assembly' on page 9.

Renewing rope tips

Send the rope to Greifzug Hebezeugbau GmbH or an lifting

equipment service company authorised by Greifzug Hebezeugbau GmbH and have the tip replaced.

EN-16 G905.5 - 02/2011

Page 23

18 Troubleshooting

Fault

Cause Elimination

The independent secondary brake cannot be opened

Installation and operating manual

The independent secondary brake holds the load on the safety rope.

Mechanical defect.

– Move the load upwards on the suspension rope.

– Replace the independent secondary brake and send in for repair.

Independent secondary brake activated by normal downwards travel

Emergency stop

Hoisting gear speed too fast.

Independent secondary brake triggering speed set incorrectly.

Speed difference between suspension rope and safety rope too great

– See '12 Immediate measures to be taken after an emergency-stop'

– Check the hoisting gear.

– Replace the independent secondary brake and send in for repair.

– No tensioning weight on safety rope. Attach tensioning weight.

when starting movement.

The centrifugal force weight does not turn.

Soiling or defect.

Ice buildup

– Replace the independent secondary brake and send in for cleaning

– Carefully use hot air to heat it up (70 °C max).

BSO 2050/2360: The control pin is not visible after the safety rope has been fed in.

The rope has not been fed in correctly.

– Pull the rope out and feed it back in correctly.

on page 12.

or repair.

Mechanical defect.

– Replace the independent secondary brake and send in for repair.

Independent secondary brakes with limit switch: The hoisting gear moves upwards but not downwards.

Limit switch connection with the hoist controller has failed.

Wire breakage

Limit switch defective.

– Plug in connector.

– Have an electrician replace the wire.

– Have it checked by an electrician and return the independent sec-

ondary brake for repair if necessary.

The rope cannot be fed in.

Rope tip faulty.

– Renewing rope tips, see '16.3 Care and maintenance, Rope' on

page 15.

Independent secondary brake is closed.

– Open (clamp) the independent secondary brake.

G905.5 - 02/2011 EN-17

Page 24

Installation and operating manual

19 EU Declaration of Conformity (Extract)

19.1 Independent secondary brake for transport of persons

The manufacturer hereby declares

Greifzug Hebezeugbau GmbH

Scheidtbachstraße 19–21 51469 Bergisch Gladbach

represented by

Dr. Ing. Uwe Schuht

Managing Director

DECLARATION OF CONFORMITY

that the machine described complies with technological safety standards that were applicable to the equipment in the EUROPEAN

UNION when it was launched on the market by the manufacturer.

APPLICABLE DIRECTIVES AND STANDARDS:

2006/42/EC;

EN 1808; EN ISO 12100-1; EN ISO 12100-2; EN ISO 14121-1

DESIGNATION

Independent secondary brake

APPLICATION

Transport of persons

MODEL