Gregson-Clark

3213 Lehigh Street

Caledonia, NY 14423

www.GregsonClark.com

V-Series Sprayers and

Modular Systems

Operator’s Manual

Do not hesitate to call your dealer or Gregson-Clark directly with any questions or concerns.

We welcome your comments and suggestions on how we can continue to improve this product.

There are separate manuals for the hose reel, pump, and engine included with the sprayer.

Toll free: 800 . 706 . 9530 Fax: 585 . 538 . 9577

Phone: 585 . 538 . 9570 E-mail: Sales@GregsonClark.com

VSS 10-12

2

TABLE OF CONTENTS

Safety Precautions ............................................................................................................. 2

Set-Up and Assembly ......................................................................................................... 3

Start-up and Testing ........................................................................................................... 6

Overview of Operation ........................................................................................................ 8

Component Descriptions .................................................................................................... 9

Maintenance ....................................................................................................................... 13

Specifications ..................................................................................................................... 13

Troubleshooting ................................ ................................................................ .................. 14

About Diaphragm Pumps .................................................................................................... 15

Pump Service Guide ........................................................................................................... 16

Winter Storage .................................................................................................................... 18

Accessories ........................................................................................................................ 19

Warranty ............................................................................................................................. 21

SAFETY PRECAUTIONS

Pesticides can cause personal injury and harm the environment when used improperly. Be

sure to follow label recommendations concerning safety and disposal. Observe all safety

precautions including wearing protective clothing and equipment.

Calibrate and test using clean water.

Check before each use for leaks or damage.

Read and follow the label instructions of the products used.

NOTE:

V-Series skid sprayers and modular systems are available with many different component

options. The photos and information shown herein are intended to be general guidelines.

Please refer to the additional manuals provided for information regarding the specific

components of your sprayer or call us at 1-800-706-9530.

VSS 10-12

3

SET-UP AND ASSEMBLY

Check for apparent signs of shipping damage and that the order is complete. Carefully

uncrate the sprayer and report any freight damage or shortages. Claims must be within

five days of delivery. The sprayer was completely assembled and tested prior to

shipping. Some disassembly may have been required for shipping. Re-attach the reel

to the frame in the desired location. Mount the reel on the end opposite the pump for

use in pick-up trucks or under the pump when used in enclosed trailers or vans. (See

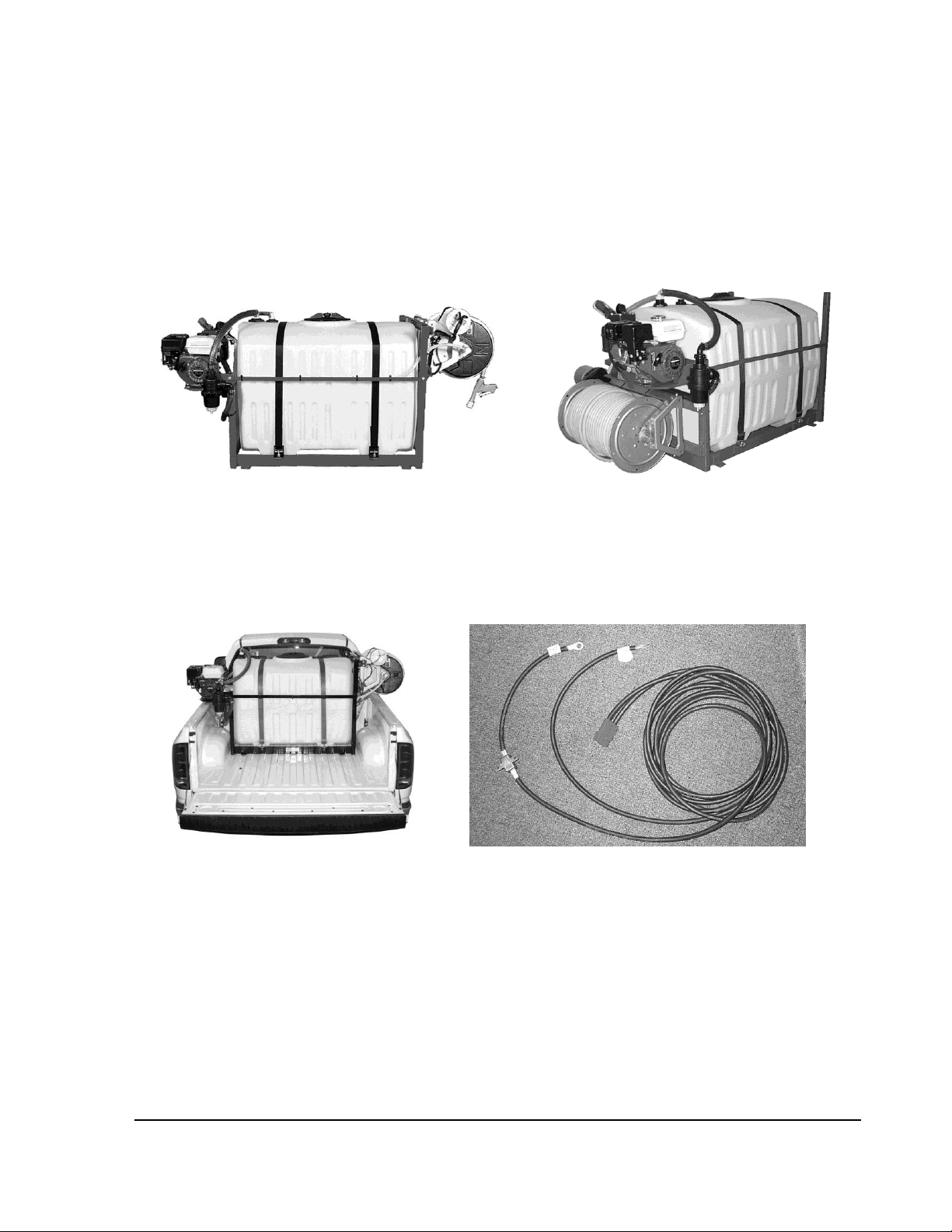

photos 1 & 2)

Photo 1 Reel mounted opposite pump. Photo 2 Reel mounted under pump

In a pick-up truck, the sprayer typically is mounted in the forward-most position against the

front wall of the truck bed. Secure the frame by bolting through the truck bed or by using a

ratchet strap if suitable anchoring locations are available. (See photo 3) Note that your skid

must be secured in compliance with your local Department of Transportation regulations.

Photo 3 Sprayer mounted in truck Photo 4 Wiring Harness

Do not exceed weight limitations of vehicle. The weight should be balanced left-to-right and

positioned for-and-aft to distribute the weight in accordance with the capacities of the

vehicle’s axles.

If the sprayer is equipped with an electric hose reel, install the quick-disconnect wiring

harness provided. (See photo 4) Once installed, the shorter section will stay with the sprayer

and the longer section will remain with the truck. When removing the sprayer from the truck,

simply pull the modular connectors apart. Refer to Diagram 1 (See page 4) and connect

according to the labels on the terminals at the ends of the harness cables.

VSS 10-12

4

When connecting the ground wire to the truck frame, be sure to clean the contact area down

Pushbutton

Reel Switch

30 Amp Circuit Breaker

Auto Reset

14–16 Gauge Wire

Solenoid

Reel Motor

Positive

Modular

Connectors

Truck Battery

6 Gauge Wire

Batt.

Aux.

Circuit Breaker

Modular Connectors

Ground to Reel

Ground to Frame

Vehicle Ground

6 Gauge Wire

Diagram 1 Electrical Connections

Ground to

Reel Frame

to bare metal to ensure a good contact. When a reel will not rewind, it is often due to a faulty

ground connection. Use extra care in protecting the wires from the exhaust system and any

moving parts. Avoid any sharp edges that could cut through the wire insulation.

VSS 10-12

5

Set-Up and Assembly – Cont.

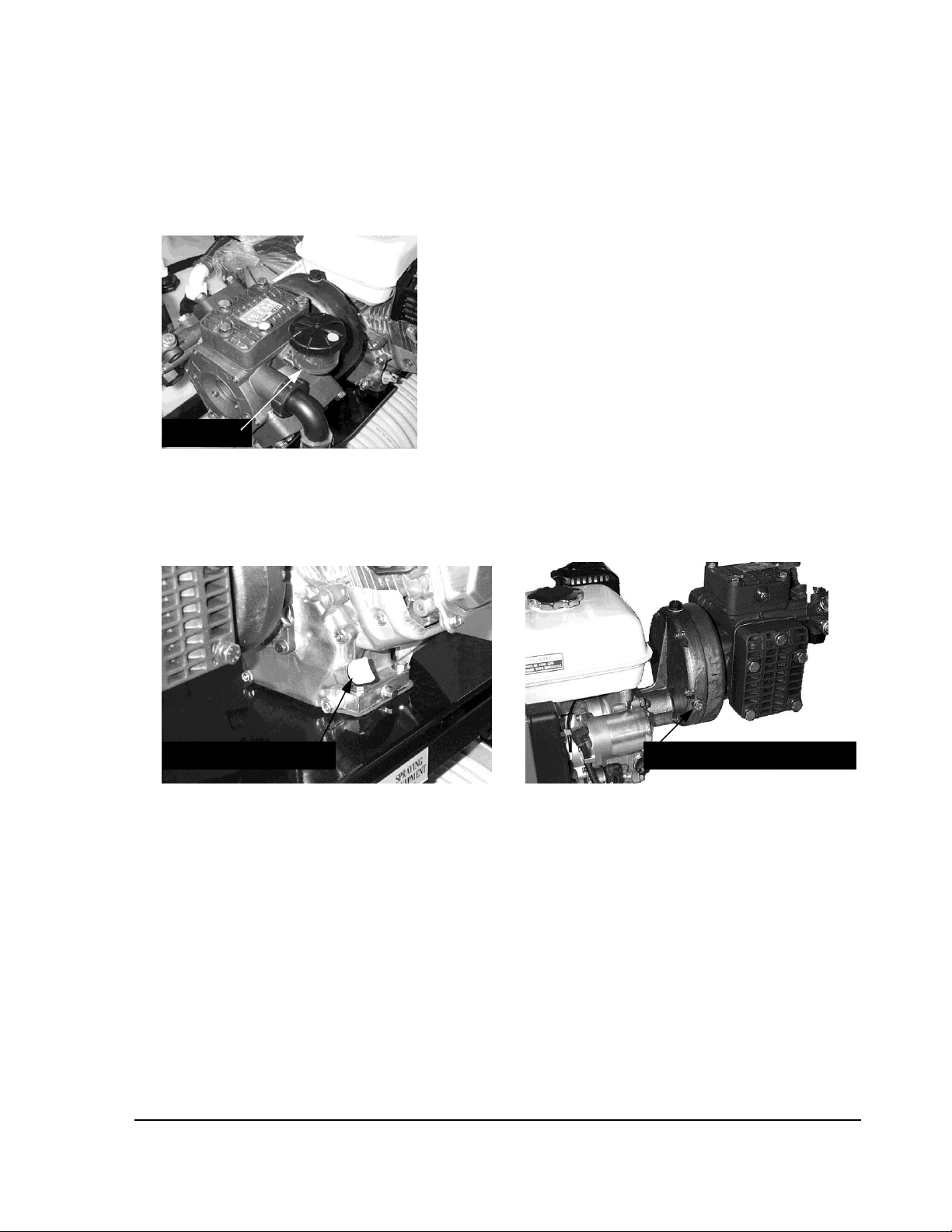

Oil Bowl

Engine Oil Dipstick

Pump Gearbox Side Plug

The engine oil, (SAE 10W30) gearbox oil, (SAE 80/90W) and pump oil (30W or 40W nondetergent) were added at the factory. The oil levels are as follows:

• Pump Crankcase – On the Kappa 43, 55 and Kappa 75 pump, the oil level is visible

in the oil bowl. (See photo 5) Other pump models may be slightly different.

Photo 5 Kappa 43, 55 & 75 Pumps

• Engine– The oil level should be up to the edge of the filler hole or at least to the tip

of the dipstick when inserted without screwing it into the filler neck. (See photo 6)

See the Honda Engine Owner’s Manual.

Photo 6 Engine Oil Dipstick Photo 7 Pump Gearbox Side Plug

• Pump Gearbox– The oil level should be up to the lower edge of the side-plug hole.

Do not overfill. (See photo 7)

VSS 10-12

6

START-UP AND TESTING

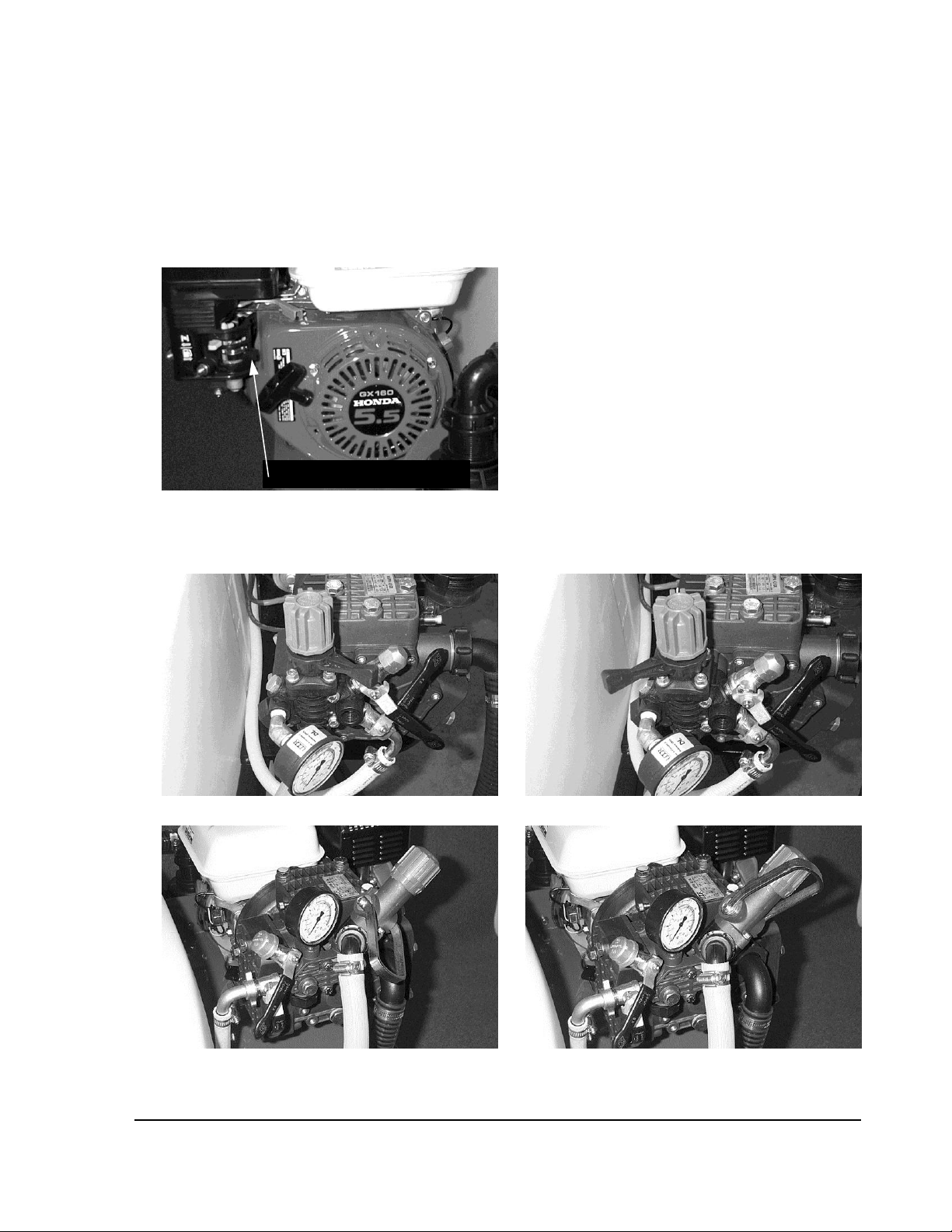

Fuel Shut-off Valve lever

1. Re-attach the hoses to any modular tanks that were disconnected for shipping.

Note: The hoses may be longer than necessary; trim to length as required.

2. Ensure that suction strainer bowl is on tight.

3. Fill the spray tank 1/4 full of clean water.

4. Put gas in engine gas tank.

5. Turn on fuel shut-off valve lever on the carburetor. (See photo 8)

Photo 8 Fuel Shut-off

6. Recheck the engine oil level and check the oil in the pump and gearbox.

7. Put regulator lever in the Bypass position. (See photos 9 and 11)

Photo 9 Kappa 43 Pressure Regulator Bypass Position Photo 10 Kappa 43 Pressure Regulator Spray Position

Photo 11 Kappa 40/55/75 Pressure Regulator Photo 12 Kappa 40/55/75 Pressure Regulator

VSS 10-12

Bypass Position Spray Position

7

START-UP AND TESTING - CONT.

8. Turn engine switch on.

9. Choke engine.

10. Start engine and adjust throttle. Once engine is running and warmed up, un-choke the

engine.

11. Liquid should be visible after a few seconds as it moves through the suction hose. Liquid

agitation in the tank should also be visible. Run the engine at full throttle until there is no

air in the suction lines. Lower the engine speed to about 1/2 throttle.

12. Turn the regulator pressure-adjustment knob counter-clockwise until there is no longer

any resistance. Rotate the black plastic lever clockwise to the spray position.

(See photos 10 and 12) Slowly turn the adjustment knob clockwise. Note the increasing

pressure on the gauge. Adjust to the desired pressure for your application. (See photos

13 and 14)

Although the pump and engine can safely operate at full throttle, reducing the engine

speed to the minimum required for your application will ensure fuel savings and reduce

wear of the pump.

Photo 13 Kappa 43 Pressure Adjustment Photo 14 Kappa 40/55/75 Pressure Adjustment

13. Shut off the engine and clean the filter. There may be small plastic particles remaining

from the manufacturing process. See the Maintenance section (page 13) for instructions.

VSS 10-12

8

OVERVIEW OF OPERATION

Liquid is drawn from the tank and through the suction strainer by a positive displacement

diaphragm pump. Excess flow returns to the tank through a pressure regulator. The

returning flow provides agitation in the tank.

When the lever is in the bypass position, (See photos 9 and 11) the fluid returns to the tank

under no restriction, therefore the system is at very low pressure. Move the lever to the

bypass position when starting and shutting down the engine, when priming the pump, and

when maximum agitation is desired. All spraying is done when the lever is in the spray

position. (See photos 10 and 12)

Operating pressure is adjusted by turning the plastic knob on the regulator clockwise to

increase pressure and counter-clockwise to decrease pressure. Pressure is only achieved

when the lever on the regulator is in the spray position. (See photos 10 and 12)

It is important that all fittings on the suction side of the pump, particularly the suction

strainer, remain tight. Otherwise, the pump can draw air into the system and that will affect

performance. The pump fittings are sealed with O-rings and should not be over-tightened.

VSS 10-12

9

COMPONENT DESCRIPTIONS

Suction Tube

Assembly

Agitator Tube

Assembly

Tank Fitting

Assembly, Suction

Barb Elbow,

Suction

V-50 & 50B-SA

STA-20

AGIT-14, 14” Lg.

TF125

HB125-90

V-100 & 100B-SA

STA-20

AGIT-20, 20” Lg.

TF125

HB125-90

V-150 & 150B-SA

STA-26

AGIT-20, 20” Lg.

TF125

HB125-90

V-200 & 200B-SA

STA-35

AGIT-29, 29” Lg.

TF125

HB125-90

V-300 & 300B-SA

STA-37

AGIT-29, 29” Lg.

TF125

HB125-90

Tank Fitting

Assembly, Return

Barb Elbow,

Return

Elbow,

Agitator

Agitator

V-50 & 50B-SA

TF075

HB075-90

SE34

500262

V-100 & 100B-SA

TF075

HB075-90

SE34

500262

V-150 & 150B-SA

TF075

HB075-90

SE34

500262

V-200 & 200B-SA

TF075

HB075-90

SE34

500262

V-300 & 300B-SA

TF075

HB075-90

SE34

500262

Suction Tube

Assembly

Tank Fitting,

Suction

Barb Elbow,

Suction

Tank Fitting,

Return

Barb Elbow,

Return

Agitator Tube

Assembly

Agitator

Elbow

Tank Wall

Tank Connections

Part Numbers

Photo 15 Tank Connection Fittings

VSS 10-12

10

COMPONENT DESCRIPTIONS, CON’T.

Strainer Body

Only

(No Checkvalve)

Strainer Element

O-ring

Strainer

Element

Strainer Cup

Plug O-ring

Strainer Plug

3142060.010

314300.060

314001.030

3142400.020

462300.230

3142400.060

Fly Nut (x 2)

Hose Barb

O-ring (x 2)

Hose Barb

(x 2)

Cup O-ring

Strainer Nut

2002060

G10061

116633

314000.050

314000.040

Strainer Body

Strainer Element

Strainer Element

O-ring

Strainer Cup

Plug

Cup O-ring

Plug O-ring

Fly Nut (x 2)

Hose Barb (x 2)

Hose Barb O-ring (x 2)

Strainer Nut

Strainer Assembly with Barbs - P/N 3142561-A

Strainer Assembly without Barbs - P/N 3142561

Part Numbers

Photo 16 Strainer Parts

VSS 10-12

11

COMPONENT DESCRIPTIONS, CON’T.

Bypass Hose, *

3/4"

Hose Clamp,

Bypass

Suction Hose, *

1-1/4”

Hose Clamp,

Suction

Hose to Reel, *

1/2"

Hose Clamp,

Hose to Reel

A-1628-3/4

20J

K-125

20J

A-1661-1/2X1

10J

Hose Barb,

Bypass,

3/4"

O-ring,

Bypass

Nut,

Bypass

Hose Barb, 1/2"

Hose to Reel,

Includes Nut

and Gasket

Gasket,

Hose to Reel

Hose Barb,

Suction,

1-1/4”

O-ring,

Suction

Nut,

Suction

0254.04

1101.12

0604.26

163.604.6

0605.05

0202.52

1101.41

0604.18

Bypass Hose

Hose Barb, Hose to Reel

Suction Hose

Hose Barb, Suction

Hose Clamp x2

Hose Clamp x 2

Hose Clamp x 2

Hose Barb, Bypass

Hose to Reel

Pump Connections

Photo 17 Pump Connections

Part Numbers

* Hose lengths may vary

Photo 18 Connection Fittings

VSS 10-12

12

COMPONENT DESCRIPTIONS, CON’T.

Kit

Strap (2)

Clamp (4)

Hex Bolt (4)

Hex Nut (4)

Washer (4)

TDK-50

TS198 x 9.4, 64” Lg

TD-200

0115110

1137185

1133859

TDK-100

TS198 x 12.9, 77” Lg

TD-200

0115110

1137185

1133859

TDK-150

TS198 x 12.0, 80” Lg

TD-200

0115110

1137185

1133859

TDK-200

TS198 x 16.8, 98” Lg

TD-200

0115110

1137185

1133859

TDK-300

TS198 x 16.8, 98” Lg

TD-200

0115110

1137185

1133859

Tank

Size

Lid, Vented

50 Gallon PCO Style

8”

10525

100 Gallon PCO Style

8”

10525

150 Gallon PCO Style

12”

10527

200 Gallon PCO Style

12”

10527

300 Gallon PCO Style

16”

10528

8” Lid

12” Lid

16” Lid

Tank Strap Kits

Photo 19 Tank Strap

Part Numbers

Tank Lids

Part Numbers

Photo 20 Tank Lids

VSS 10-12

13

MAINTENANCE

Check and tighten all hose clamps.

Check for worn hoses. (rubbing, cracking)

Check Engine air filter, clean every 50 hours; change every year or 300 hours.

Check Engine oil with each use, change after 20 hours and every 100 hours thereafter.

Check Pump oil with each use, change every year or 500 hours.

Check Pump Gearbox oil with each use, change after 20 hours and every 100 hours

thereafter.

Clean Suction Strainer. (See photos 21 and 22)

SPECIFICATIONS

Engine Crankcase Oil ......................................................... 10W30 (SJ or SL)

Engine Fuel Recommendation ............................................ 86 Octane (Min) unleaded

Pump Crankcase Oil ........................................................... 30 Wt. or 40 Wt. Non-detergent

Pump Gearbox Oil .............................................................. 80W90 Gear Oil

Photo 21 Suction Strainer Photo 22 Center Post

The suction strainer is equipped with an internal shut-off valve that closes when the

cup is removed. It prevents the suction line from emptying when the strainer is

dissembled for cleaning.

IMPORTANT!

When re-assembling the strainer, ensure that the center post in the cup engages the

steel pin in the strainer head. (See photo 22) Otherwise, the valve will remain closed

and damage to the pump may result.

VSS 10-12

14

TROUBLESHOOTING

Problem

Possible cause

Solution

Low or no pressure or

Valve in suction strainer closed

Verify cup alignment with valve stem

Pump does not prime

See page 12

Plugged strainer

Clean screen

Plugged suction hose

Clear obstruction

- Check top of strainer for debris

Faulty or missing o-rings in Strainer

Replace o-rings

Assembly or pump Inlet Elbow Barb

Air leak in pump suction hose

Check hoses and fittings for leaks

Stuck or worn pressure relief valve on

Repair or replace relief valve

regulator

Low liquid level in tank

Refill tank

Improperly seated check valve(s) in

Clean or replace check valve

pump head

Fluctuating pressure

Pulsation dampener pressure incorrect

Adjust pulsation dampener pressure

(Excessive pulsation

-Should be at 20% of operating pressure

of Hoses)

Pump not purged of air

Run pump with regulator in the bypass

position to purge air

Defective regulator

Repair or replace regulator

Diaphragm Pumps

Pump oil has milky color

Ruptured diaphragm(s) in pump

Repair as necessary

Pump oil level low

VSS 10-12

Table 1

15

ABOUT DIAPHRAGM PUMPS

How the pump works

The diaphragm is what separates the pump oil from the spray solution. Each piston

down-stroke lowers the piston-attached diaphragm, drawing spray solution into the

pump head. As the piston passes below the cylinder sleeve side openings, oil is pulled

into the lower diaphragm cavity. During each piston up-stroke, the cushion of oil

between the piston and the diaphragm hydraulically pushes and cushions the

diaphragm as the piston tops out. This discharges the solution from the pump head.

The lower diaphragm cavity oil cushion also lubricates the diaphragm and pistons,

ensuring minimal mechanical wear.

Remember – low crankcase oil level causes excessive mechanical wear on

diaphragms and internal components. The transparent oil bowl makes checking the oil

easy. Keep the oil filled to the mark on the bowl.

Do not run the pump with a starved suction

The diaphragm pump will not suffer any damage if run dry due to an empty tank.

However, a starved suction due to a clogged suction strainer or a closed suction valve

will cause premature failure of the pump diaphragms.

Note – Only use filter screens that are between 16 and 20 mesh. Never use a fine filter

screen on a diaphragm pump.

Pulsation Dampeners

It is the nature of diaphragm pumps to have some pulsation. It is caused by the

sudden changes in the piston direction. The pulsation dampener reduces pulsation by

providing a cushion of air for the piston to bump against. The UDOR pulsation

dampener uses a rubber bladder to separate the air cushion from the solution being

pumped.

Pulsation Dampener Setting

The basic rule is to inflate the pulsation dampener to 20% of the systems’ working

pressure. For example, if the spraying pressure is set at 100 psi, the pulsation

dampener should be inflated to 20 psi.

Always shut down the pump before adding air to the pulsation dampener or checking

its pressure. Air pressure can be supplied from a compressor or a manual air pump.

The diaphragm dome contains a very small volume of air. Take care when checking

the air pressure that a minimum amount of air leaks out when the pressure gauge is

applied to the air valve. It is possible to lose 5–10 psi when checking the pulsation

dampener air pressure.

Note: Two-cylinder diaphragm pumps may require more air pressure than 20% of the

operating pressure. The minimum pulsation dampener air pressure is 20 psi.

DO NOT run two-cylinder pumps with less than 20 psi in the pulsation dampener.

VSS 10-12

16

SERVICE GUIDE FOR REPLACING PUMP DIAPHRAGMS

1. Drain Crankcase Oil – drain pump crankcase by removing the oil drain plug located

at the bottom of the pump, also remove the oil fill cap or plug.

Note: On older pump models that do not have the oil drain plug, oil will need to be

drained after the head diaphragm and piston sleeve have been removed.

Note: When re-installing piston sleeves, the oil holes must always be aligned

parallel with the pump crankshaft.

2. External Manifold Removal – if your pump has external manifolds, they must be

removed prior to head removal.

3. Head Removal – remove the head bolts, then, remove the pump heads, which may

require some “light” prying.

4. Diaphragm Removal – turn the crankshaft to bring the piston up to the top of its

stroke, remove the diaphragm bolt and washer, and remove the diaphragm.

5. Crankcase Cleaning – to properly clean the crankcase, remove the piston sleeves

and wash the crankcase with a parts-washing solution or equivalent. Before reinstalling the piston sleeves, apply a light coating of oil to the pistons and sleeves.

Note: Make sure the oil holes in the piston sleeve are aligned parallel to the pump

crankshaft.

6. Installing New Diaphragms – install the diaphragm bolt and washer into the new

diaphragm. Install this assembly to the piston with the flat side of the diaphragm

down. Use blue thread locker or equivalent on the diaphragm bolt. Tighten the

bolts to the recommended torque specs. Rotate the crankshaft to bring the piston

and diaphragm to the bottom of its stroke and then seat the outside edge of the

diaphragm into the pump body.

7. Installing Head – it is very important to ensure that the check valves are installed

correctly when reinstalling the pump head. There are two valves for each cylinder;

one valve lets the solution into the head, the other valve lets the solution out of the

head. Tighten the pump head bolts to the recommended torque specs.

8. Installing Pulsation Dampener Diaphragm – bleed off the air in the chamber and

remove the cover bolts, cover, and diaphragm. Install the new diaphragm with the

dome down. Reinstall the cover and tighten the bolts to recommended torque

specs. Recharge the pulsation dampener with compressed air to 20% of the

pumps operating pressure.

9. Refilling Pump Crankcase – check the oil drain plug, making sure that it is installed

in the crankcase. Fill the pump with UDOR LUBE premium pump oil or SAE 30 or

40-weight non-detergent oil to the recommended mark on the oil sight glass/gauge,

about halfway on the oil sight glass/gauge. Rotate the crankshaft while filing to

eliminate air pockets.

10. Initial Start Up – run the pump for five minutes under no load conditions. This will

evacuate any remaining air pockets in the crankcase. Turn the pump off and recheck oil level. Refill as necessary to proper oil level.

IMPORTANT During initial startup, monitor the oil color. If it turns milky white, the

diaphragms were not seated or installed correctly.

VSS 10-12

17

Torque Specifications for UDOR Diaphragm Pumps

All values are in Foot-Pounds unless otherwise noted.

Diaphragm

Bolts

(Use Blue

Loctite™

Head

Bolts

Valve

Caps

Inlet

Manifolds

and Inlet

Manifold

Covers

Discharge

Manifolds

(Brass/Aluminum)

Discharge

Manifolds

(Plastic)

Pulsation

Dampener

KAPPA

7, 15, 18

8

10 N/A N/A N/A

N/A 10

KAPPA

33, 35, 43,

55, 75, 100

18

28 N/A 6

(72 In/Lbs)

N/A

N/A 28

(KAPPA

100 = 20

Ft/Lbs)

KAPPA

30, 40, 50

18

28 N/A N/A N/A

N/A 28

KAPPA

120, 150

25

32 N/A 6

(72 In/Lbs)

N/A

N/A 20

RO Series

Pumps

25

28 N/A 5

(60 In/Lbs)

18

RO 106/121

Only

5

(60 In/Lbs)

18

IOTA – 17

8

15 4.2

(50 In/Lbs)

N/A N/A

N/A 15

ZETA

85, 100

18

28 N/A 5

(60 In/Lbs)

N/A

5

(60 In/Lbs)

18

Table 2

WARNING

Be sure to follow the above torque specifications when reassembling diaphragms.

Overtightening of the diaphragm bolts can strip the threads in the aluminum pistons. This will

require a complete new assembly or a replacement of the pump.

VSS 10-12

18

WINTER STORAGE

Clean the tank with soap and water. Pump some of the soap solution through the hose

and gun by spraying the gun into the tank through the top opening. Empty the tank and

partially refill with clean water. Flush out the hose and gun, and spray the exterior of

the tank and other components that were exposed to chemicals. Empty the tank

completely. Dispose of rinse fluids in accordance with all applicable regulations.

Add undiluted RV anti-freeze through the suction strainer. (See photo 20) Circulate the

anti-freeze solution through the pump regulator. Blow out the reel and hose with

compressed air or pump undiluted RV anti-freeze completely through the hose.

Empty the suction strainer.

For more information on winterizing your sprayer, refer to our Web site.

www.GregsonClark.com/resource_info.html

Photo 23 Add Anti-Freeze through Suction Strainer

VSS 10-12

19

ACCESSORIES

Eco-505 Injection Spraying System

The Eco-505 Injection System is an add-on

accessory for a turf spraying system that

injects pesticide into the fertilizer stream on

demand. The dual trigger spray gun and

coaxial hose provide a means of

minimizing unnecessary application and

eliminating the need for spot spraying in a

secondary operation.

Modular Tank Assemblies

Modular tank assemblies provide an

expandable, portable, versatile

solution to accommodate a wide

variety of needs.

High-Pressure Strainer

The high-pressure Strainer is mounted

between the reel and the pump. It is selfcleaning by means of an included flush

valve mounted on the bottom of the strainer

body.

The strainer eliminates the need for

repeated cleaning of your gun nozzle by

removing contaminates before they reach

the gun.

Strainer Bags

The Strainer Bag is ideal for mixing dry

fertilizers and chemicals in jet agitation

sprayers. The strainer bag can hold a full

bag of urea, saving mixing time and

preventing potential plugging of the suction

strainer or pump. The lid may be closed

while the bag is in place.

VSS 10-12

20

WARRANTY

Gregson-Clark Sprayers are warranted by the manufacturer to the original purchaser to be free

from defects in materials and workmanship for a period of one year. The pump elastomers and

hoses are considered normal wear items and carry a 90-day warranty against defects in

materials and workmanship.

Gregson-Clark’s liability shall be limited to replacement of defective components, FOB shipping

point. In no event shall Gregson-Clark be liable for any special, incidental, or consequential

damages including loss of profits.

Toll free: 800 . 706 . 9530 Fax: 585 . 538 . 9577

Phone: 585 . 538 . 9570 E-mail: Sales@GregsonClark.com

Web: www.GregsonClark.com

VSS 10-12

Loading...

Loading...