Gregory TTMA-100 Assembly Manual

TTMA-100

Assembly Manual

4100 13th Street, SW • Canton, Ohio 44710 • Phone 330-477-4800

i

Gregory Industries, Inc.

www.gregorycorp.com

June 2010

FOREWORD

Thank you for your purchase of the Trailer Truck Mounted Attenuator, Model 100, from

Gregory Industries, Inc. (herein referred to as the TTMA-100). The TTMA-100 is a Test Level 3

(TL-3) crash cushion designed for use with a support truck in both stationary and moving work

zones. We are committed to providing our customers with highway safety products that have the

best performance and value for your money, as well as the highest level of customer service. The

TTMA-100 is one of the most innovative TMA’s in the market, offering a higher level of

performance with heavy tow vehicles and requiring no modification of the tow vehicle. It has

successfully passed all required and optional crash tests set forth in NCHRP Report 350 and is

fully approved for use on the National Highway System by the Federal Highway Administration.

This manual provides step-by-step instructions on the assembly of the TTMA-100 and applies to

both initial assembly and repair and replacement of damaged components. Please read and

understand the recommendations contained in this manual thoroughly before actual assembly,

and keep it handy for future reference. If you have any questions or comments regarding the

operation and maintenance of this product, please contact us by telephone 330-477-4800 or by

mail at Gregory Industries, Inc. 4100 13th Street, SW, Canton, Ohio 44710. Technical issues

can be emailed to TTMATechnicalSupport@gregorycorp.com

This manual is divided into four sections:

• TTMA Design and Major Components. An overview of the Trailer TMA design and

major components are presented in this section, including the product specifications and

parts list.

• General Instructions. Some general information regarding assembly of the TTMA-100,

such as shipping package, recommended tool list, bolt torque specifications, pintle hook,

and removal of excess zinc.

• Assembly Instructions. Step-by-step instructions on the assembly of the TTMA-100 are

outlined and illustrated in this section.

• Repair of Damaged Trailer. Discussions of impacts by an errant vehicle and the

associated repair and replacement of trailer parts are presented in this section.

ii

CUSTOMER SERVICE CONTACTS

Gregory Industries, Inc. is committed to providing the best service and care to our customers.

You are automatically registered with your purchase and you will be notified of any future

changes or upgrades to the TTMA-100. If you have any comments or questions regarding this

product, please contact Gregory Industries via telephone, e-mail or conventional mail:

Telephone (330)-477-4800; Monday to Friday, 9:00 a.m. to 5:00 p.m. Eastern Standard Time.

Email: TTMATechnicalSupport@gregorycorp.com

Web Site: http://www.gregorycorp.com

Mail: Gregory Industries, Inc.

4100 13th Street, SW

Canton, Ohio 44710

iii

TABLE OF CONTENTS

Page

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

CUSTOMER SERVICE CONTACTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

TTMA-100 DESIGN AND MAJOR COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

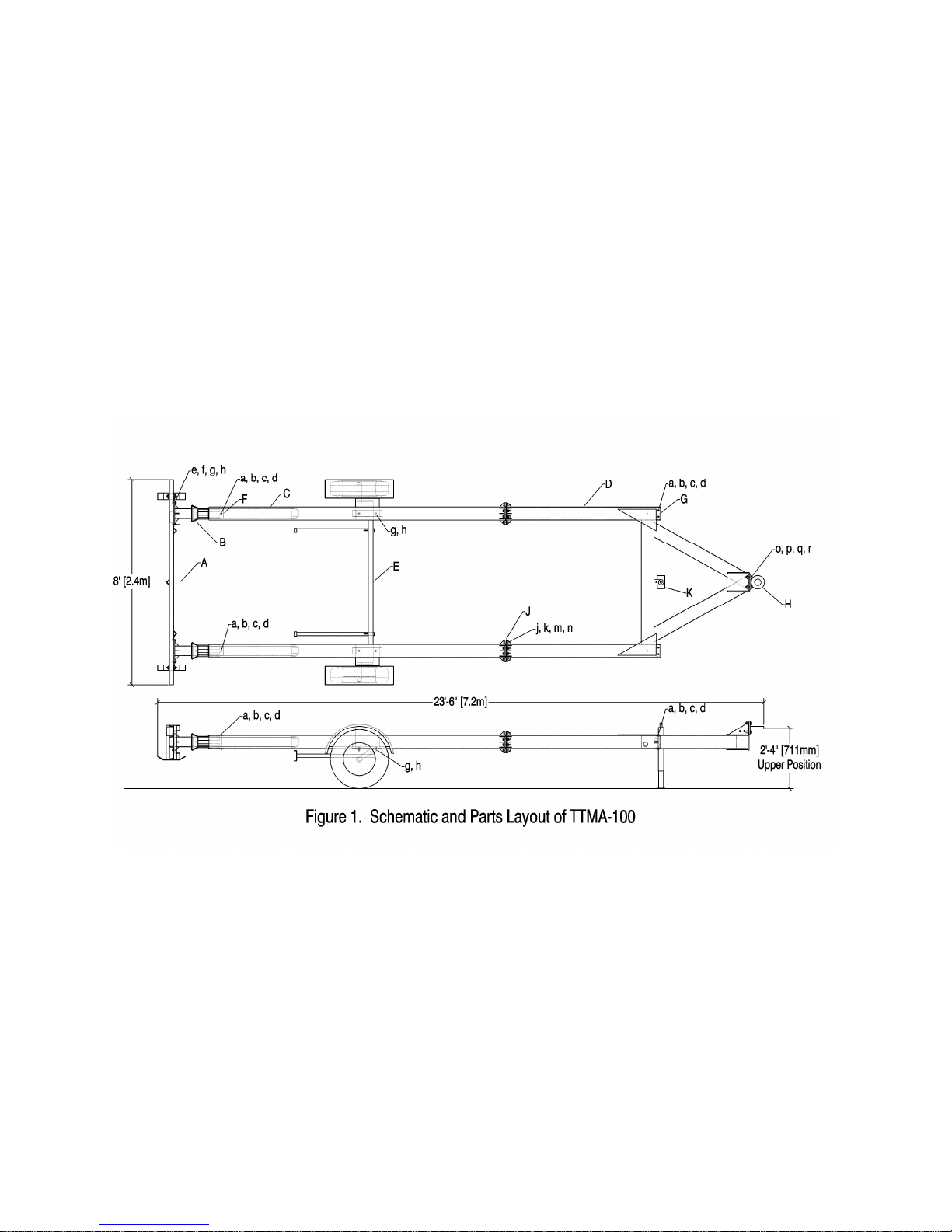

Figure 1. Schematic and Parts Layout of TTMA-100 . . . . . . . . . . . . . . . . . . 2

Table 1. General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 2. Trailer Component and Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . 4

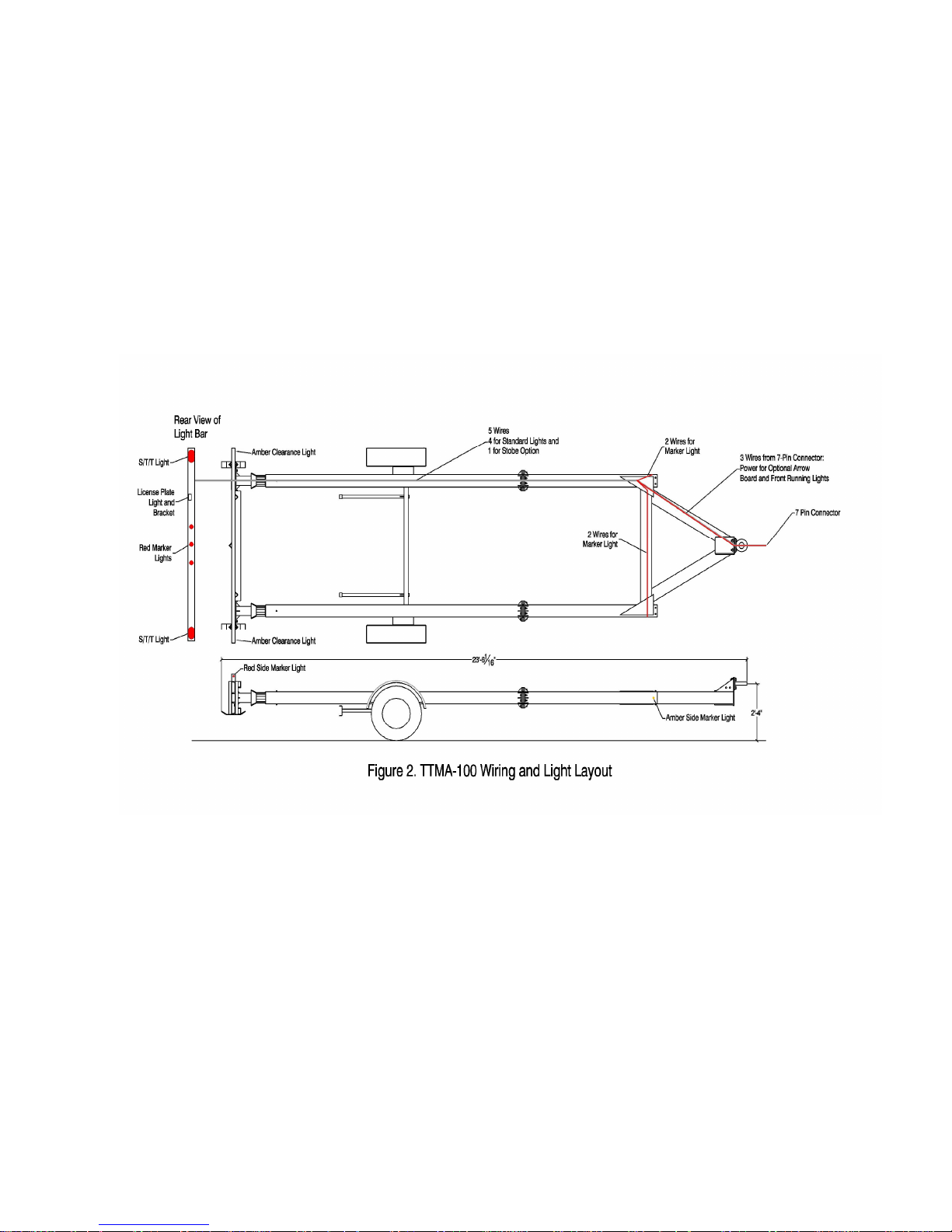

Figure 2. TTMA-100 Wiring and Light Layout . . . . . . . . . . . . . . . . . . . . . . 5

GENERAL INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Shipping Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Recommended Tool List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bolt Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pintle Hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Layout of Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connect Energy Absorbing Tubes to A-Frame. . . . . . . . . . . . . . . . . . . . . . . . . 10

Insert Connecting Block for Axle and Fender Assembly . . . . . . . . . . . . . . . . . 12

Install Mandrels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Attach Impact Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Align and Tighten Connections between Energy Absorbing Tubes

and A-Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Assemble Axle, Fenders, and Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . 14

Install Light Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install Accessories on A-Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Install Chevron Panels and Conspicuity Tapes . . . . . . . . . . . . . . . . . . . . . . . . 10

REPAIR INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Impact by Errant Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TTMA-100 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Damage Assessment and Repair Parts Packages . . . . . . . . . . . . . . . . . . . . . . . 19

No Apparent Damage to Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Axle Assembly Not Detached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Axle Assembly Detached, but No Damage to Trailer A-Frame . . . . . . . . 21

Bursting Reaches Trailer A-Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Repair Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

iv

TTMA-100 DESIGN AND MAJOR COMPONENTS

GENERAL

A schematic of the TTMA-100 is shown in Figure 1. The major components of the TTMA-100,

as shown in Figure 1, are as follows:

Component

A Impact Head

B Bursting Mandrel

C First Energy Absorbing Tube

D Trailer Frame

E Axle Assembly

F Plastic Guide Plates

K Jack Assembly

Table 1 presents the general specifications for the Trailer TMA, including:

• Overall dimensions, i.e., length, width and maximum height to the top of the impact head

and the top of the light bar

• Weight of the trailer with no optional equipment and the tongue weight. Note the small

tongue weight of the trailer, which would not affect the load carrying capacity of the tow

vehicle.

• The capacity and mounting height of the pintle hook.

• Information on the axle assembly, i.e., load rating, wheel and tire sizes, and cold inflation

pressure.

Table 2 provides a list of parts with legends and part numbers. Please refer to these part numbers

and legends for ordering of spare parts. Note that this is not a complete parts list. Please inquire

about the complete parts list and pricing from the manufacturer, distributor, or reseller of the

Trailer TMA.

Figure 2 shows the schematic of the wiring details of the Trailer TMA. Also, detailed

instructions on the wiring of the trailer TMA are provided in a separate Wiring Manual and will

not be repeated herein.

Description

G End Caps

H Hitch Assembly

J Spacer

1

2

TABLE 1. GENERAL SPECIFICATIONS

Overall Dimensions:

Length 23 ft 6 in.

Width 8 ft 0 in.

Maximum Height (to top of impact head) 31 in.

Maximum Height (to top of light bar) 37 in.

Ground Clearance (to bottom of impact head) 13 in.

Weight:

Basic Trailer Weight with No Optional Equipment 1,450 lb

Approximate Tongue Weight 190 lb

Pintle Hook:

Capacity Rating (Minimum) 8 tons

Mounting Height 19.5-32.0 in.

Breakaway Axle:

Rating 1,750 lb

Tire Size 205/75D15

Rim Size 15x5JJ

Cold Tire Inflation Pressure 30 psi

3

TABLE 2. TRAILER COMPONENT AND PARTS LIST

TRAILER COMPONENTS

ITEM PART # QUANTITY DESCRIPTION

A T100A 1 Impact Head

B T100B 2 Bursting Mandrel

C T100C 2 First Stage Energy Absorber

D T100D 1 Trailer A-Frame

E T100E 1 Axle Assembly

F T100F 4 Plastic Guide Plates

G T100G 2 End Caps

H T100H 1 Hitch Assembly

J T100J 8 Spacer

K T100K 1 Jack Assembly

HARDWARE ITEMS

ITEM PART# QUANTITY DESCRIPTION

a B0516070A 6 5/16” x 7” Grade 5 Hex Bolt

b W0516 6 5/16” Washer

c LW0516A 6 5/16” Heavy Lock Washer

d N0516A 6 5/16” Grade 5 Hex Nut

e B0816020A 8 1/2” x 2” Grade 5 Hex Bolt

f W0816 8 1/2” Washer

g LW0816A 12 1/2” Heavy Lock Washer

h N0816A 12 1/2” Grade 5 Hex Nut

j B0916030A 16 9/16” x 3” Grade 5 Hex Bolt

k W0916S 16 9/16” SAE Washer

m LW0916A 16 9/16” Heavy Lock Washer

n N0916A 16 9/16” Grade 5 Hex Nut

o B1016025A 4 5/8” x 2 1/2” Grade 5 Hex Bolt

p W1016 4 5/8” Washer

q LW1016A 4 5/8” Heavy Lock Washer

r N1016A 4 5/8” Grade 5 Hex Nut

4

5

GENERAL INSTRUCTIONS

SHIPPING PACKAGE

This manual is intended for the assembly of the TTMA-100. Note that the unit may be shipped in

different stages of assembly, depending on the order. Similarly, when repairing a damaged

trailer, the extent of disassembly and re-assembly would vary depending on the nature and extent

of repair and the parts that need to be replaced. Thus, the instructions cover the entire assembly

process, with the exception of wiring, even though only part of the instructions may be

applicable in any given situation.

RECOMMENDED TOOL LIST

The following is the recommended tool list for assembling the TTMA-100:

• Socket wrenches: ½”, ¾”, 13/16”, 15/16”

• Open end wrenches: ½”, ¾”, 13/16”, 15/16”

• Pneumatic wrench

• Drift pin

• Wire crimper

• Round and flat metal files

• Electric drill and bits

• 4-ft level

• Measuring tape

Optional:

• Fork lift/crane for parts manipulation. Note that some parts are very heavy and care

should be taken in assembling and disassembling the unit.

BOLT TORQUE SPECIFICATIONS

All bolts should be tightened to the specified torque prior to use of the Trailer TMA. The

following are the recommended torques to the bolts according to the bolt size:

Bolt Size (in) 5/16” 1/2” 9/16” 5/8”

Torque (ft-lb) 15 60 85 115

Torque (N-m) 20 81 115 156

6

PINTLE HOOK ASSEMBLY

The pintle hook should have a minimum capacity rating of 8 tons. Due to the wide variations in

the frame structures of different tow vehicles, there is not a single standard means of mounting

the pintle hook assembly to the frame of the tow vehicle. The major considerations in mounting

of the pintle hook are the strength of the attachment and the mounting height.

The pintle hook assembly may be welded or bolted to the frame of the tow vehicle. Regardless of

the method of mounting or attachment to the tow vehicle, it is critical to ensure that the strength

of the attachment exceeds the rated capacity of the pintle hook with a wide margin of safety. It is

the obligation of the users to ensure that their particular pintle hook attachment system

meets these strength requirements.

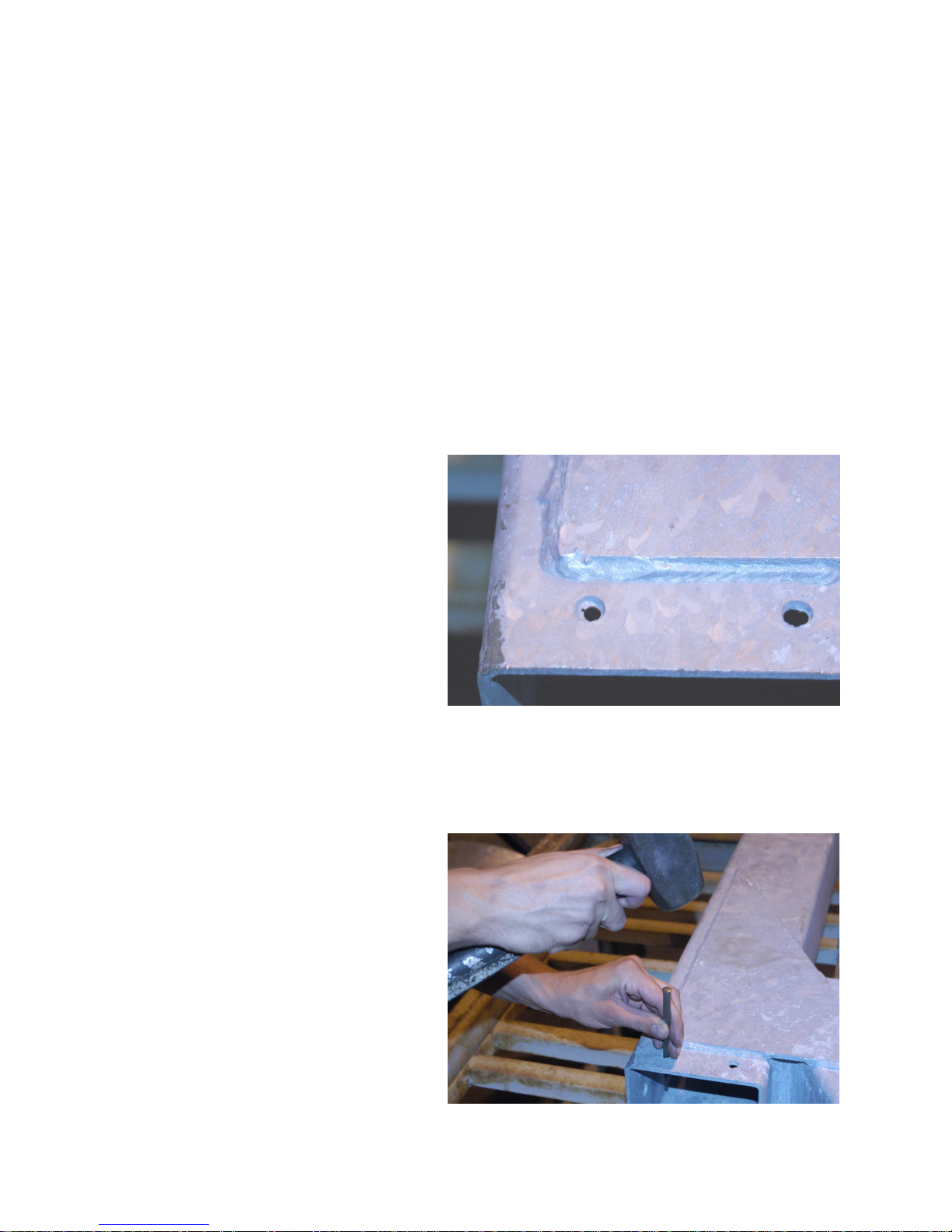

CLEARING OF EXCESS ZINC

• All the major components of the

TTMA-100 are galvanized to

protect the metal from the

weather elements. It is not

unusual for some of the holes to

have excess zinc as a result of the

hot-dip process, as shown in the

photograph.

The excess zinc would effectively reduce the size of the hole so that the bolt would not fit

through the hole. It is, therefore, necessary to remove excess zinc from the pre-drilled holes.

Depending on the excess amount of zinc, punching through the hole with a drift pin may be

sufficient; otherwise, an electric drill may be necessary, as shown in the following photographs.

• Use drift pin to remove excess

zinc.

7

• Use electric drill pin to remove

excess zinc.

8

INSTALLATION INSTRUCTIONS

The trailer can be assembled from scratch by two men in about 2 to 4 hours. Depending on the

shipping package, the trailer may already be partially assembled and certain steps in the

assembly process are, therefore, not applicable. However, all the steps of the assembly process

are shown for information purposes, in case the trailer has to be disassembled and reassembled.

Warning! Part D, the trailer frame, is too heavy for two men to move safely. It is

recommended that a lifting device be utilized to move the heavy parts.

Warning! Various parts of the trailer are heavy. Care in lifting should be exercised and

steel-toed boots are recommended.

Warning! The parts of trailer may have sharp asperities from the welding and

galvanizing processes. Use of appropriate gloves is recommended.

The major steps in the assembly of the trailer are as follows:

A. Arrange major components in approximate positions for assembly.

B. Connect energy absorbing tubes to A-frame.

C. Insert connecting block for axle and fender assembly.

D. Install mandrels.

E. Attach impact head.

F. Align and tighten connections between energy absorbing tubes and A-frame

G. Assemble axle, fenders, and wheels and tires.

H. Install light bar.

I. Install accessories.

J. Install chevron panels and conspicuity tapes.

More detailed descriptions of these major steps are presented in the following sections. A

separate section on wiring instructions is provided and will not be provided herein.

9

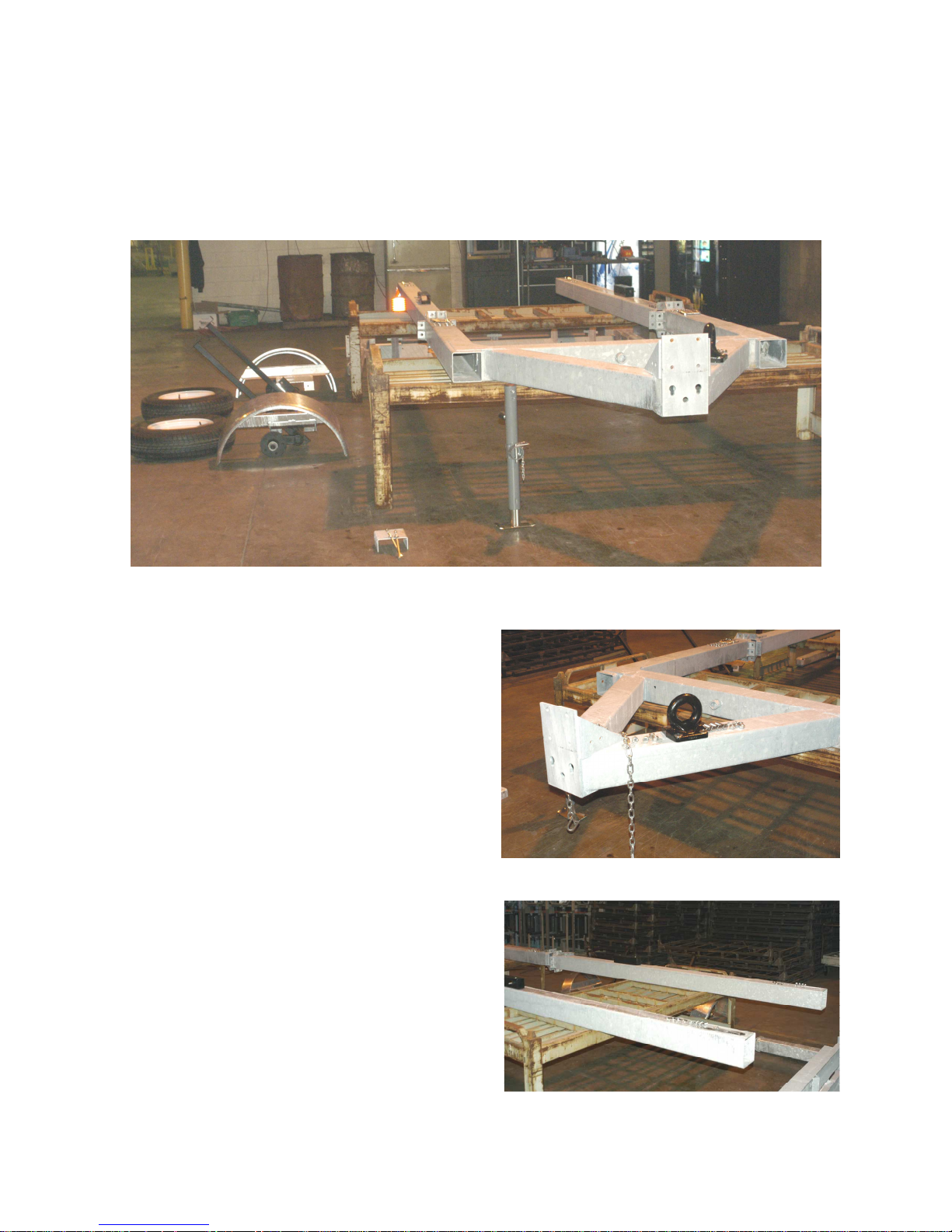

A. LAYOUT OF MAJOR COMPONENTS

Place the major components of the trailer in their approximate positions for assembly, as shown

in the following photograph. Note that the A-frame and the first energy absorbing tubes should

be placed on benches.

The following are close-up photographs of each major component:

• A-frame with lunette ring and safety

chains.

• Energy absorbing tubes.

10

• Connection between energy

absorbing tubes and A-frame.

• Axle assembly with push rods,

fenders, and wheels and tires.

• Impact head, mandrels and light

bar assembly.

11

Loading...

Loading...