GREER Company MICROGUARD 434 Troubleshooting Manual

MICROGUARD® 434

RATED CAPACITY LIMITER

SYSTEM

TROUBLESHOOTING

MANUAL

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

1

The Greer Company

The Greer Company is dedicated to the design and

manufacture of electronic parts created to aid in crane

operation and in the protection of crane operators and

associated personnel. The following manual has been

developed to assist in helping Service Personnel to

understand, locate, and identify problems that may

®

arise during the operation of the MicroGuard

434

Rated Capacity Limiter System. Persons using this

Manual must be familiar with this System and

with Electrical Servicing. Use of calibration routines

without consultation with the Greer Company

invalidates the warranty.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

2

TABLE OF CONTENTS

MicroGuard ®434

Rated Capacity Limiter System

TROUBLESHOOTING MANUAL

Introduction

SERVICE DEDICATION..................................................................INSIDE FRONT COVER

WHERE TO GO FOR HELP.............................................................................................

SYSTEM DIAGRAM...........................................................................

INSIDE BACK COVER

4

Section I

PREPARATION ................................................................................................................ 5

Section ll

PROBLEM FINDER TABLES ........................................................................................... 7

Section III

SYSTEM INSTALLATIONS ..............................................................................................23

Section IV

SYSTEM COMPONENTS AND ASSOCIATED FUNCTIONS........................................ 27

Section V

FAULT CODES............................................................................................................... 66

SECTION VI

SYSTEM DIAGRAMS..................................................................................................... 73

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

3

WHERE TO GO FOR HELP

When field repairs cannot be made without replacement of a part,

when troubleshooting advice is needed, or when corrections to

memory chips are reported, one of the following support numbers

should be called:

Link-Belt Construction Equipment Company

Product Support: Lexington, KY

Telephone:(606) 263-0241

FAX: (606) 263-5260

Greer Company

Service: Santa Ana, CA

Telephone:(714) 259-9702

FAX: (714) 259-7626

Information provided to support personnel must be accurate and

complete. Please follow the Troubleshooting Table guidelines.

Have your crane Model Number and Serial Number ready.

Carefully describe the problem, noting any unusual System

responses that may help us to quickly and effectively

solve your problem.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

4

SECTION I

PREPARATION

This Troubleshooting Manual for the MicroGuard®434 Rated Capacity Limiter System,

manufactured by the Greer Company and installed on Link-Belt Construction Equipment Company

(LBCE) cranes, provides information and methods for isolating problems that may arise during

operation of the System. Some of these problems can be corrected in the field. Other problems may

require replacement of parts or a return of a part to the factory for servicing. Persons servicing this

System should have prior training and experience in the procedure for operation and setu p of this

System.

Please refer to the MicroGuard

the MicroGuard

®

434 Calibration Manual regarding questions relating to the operation or calibration

®

434 Operating Instructions in the LBCE Operator’s Manual and/or

of this System. Accurate methods must be used to locate a problem. We recommend using the

PROBLEM FINDER TABLES in Section II to help locate and define a problem.

The procedures in this manual, where possible, are based on crane operation and function. A basic

tool kit consisting of wrenches and screwdrivers (flat and Phillips’ blades) will be required to remove

covers and units for inspection. A digital multimeter (DMM) may be required. The DMM must be

capable of measuring DC voltage with a range of 0 volts to ± 50 volts and resolution of 0.1 volts.

Resistance range is 0 Ohms to 2 Megohms. Low cost analog meters are not appropriate si nce the

input impedance of these meters can give false readings.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

5

THIS PAGE SHOULD BE BLANK.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

6

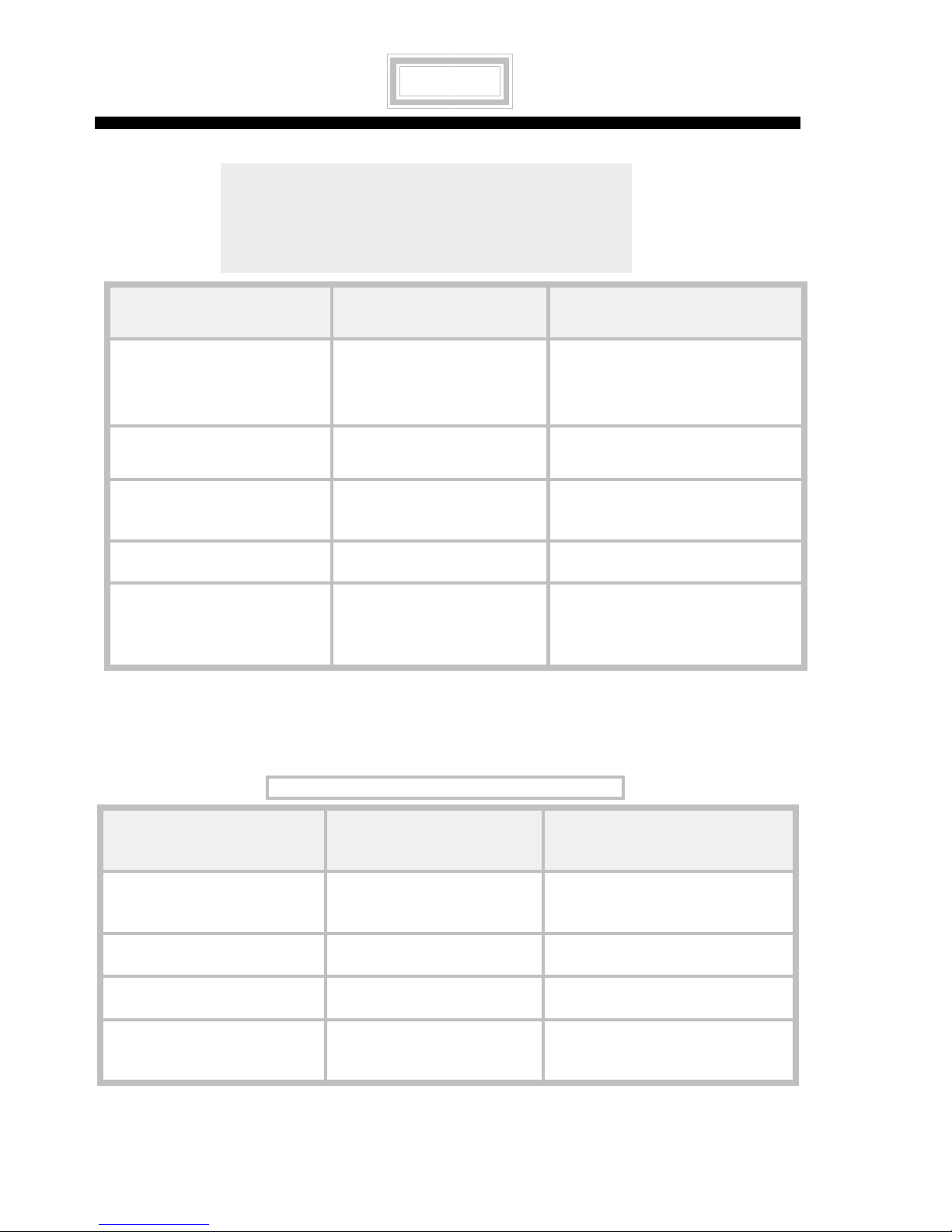

SECTION II

PROBLEM FINDER TABLES

These Problem Finder Tables are designed to aid in determining the location and type of

problem experienced. It is important to review these Tables carefully before contacting us.

SYSTEM SELF-TEST.................................................................................................................8

COMPUTER/DISPLAY COMMUNICATION ......................................................................9-12

DISPLAY OF FAULT CODES ....................................................................................... 13

CRANE MOTIONS ARE DISABLED.............................................................................

ANTI-TWO BLOCK CIRCUIT........................................................................................

SWING POT SENSOR..................................................................................................

BOOM EXTENSION SENSOR......................................................................................

BOOM ANGLE SENSOR ..............................................................................................

PRESSURE TRANSDUCERS...................................................................................

19-20

REMOTE BAR GRAPH.................................................................................................

14

15

16

17

18

21

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

7

SYSTEM SELF-TEST

The Computer and Operator’s Display Console do a Self-Test when the power is turned on or

during operation when the ”TEST” button is pressed. The Self-Test verifies that the Computer,

Display Console, cables, and all remote sensors are working properly.

TEST SEQUENCE FOR DISPLAY CONSOLE:

1. Push TEST BUTTON (T). BLACK BAR GRAPH (B) spans entire window . All lights and all

7 SEGMENT DISPLAYS turn on and the ALARM sounds. Graphic Display (GD) reads:

“This is a Test.”

FIGURE 2.0

LIQUID

CRYSTAL

DISPLAYS

GD

B

2. If no Fault (problem) is found, the System will start displaying Load, Radius, Angle, etc.

3. Faults discovered during Self-Test will cause the red and yellow lights to turn on. The

Graphics Display (GD) will read: “OUT OF SERVICE.”

4. The Operator then presses and holds the TEST button causing the Fault to be identified

with a FAULT CODE NUMBER (See Section V) in the Graphics Display.

T

CAUSES FOR COMMUNICATION FAILURE:

A) Bad connections between the Display Console and the Computer.

B) Incorrect voltage from the Computer to the Display Console.

C) Failure of the serial Transmit/Receive IC in either the Computer, Display Console, or

Remote Bar Graph Unit.

D) Failure of the Reset IC in either the Computer or Display Console.

E) The Computer is locked up and not working.

F) The Display is locked up and not working.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

8

A

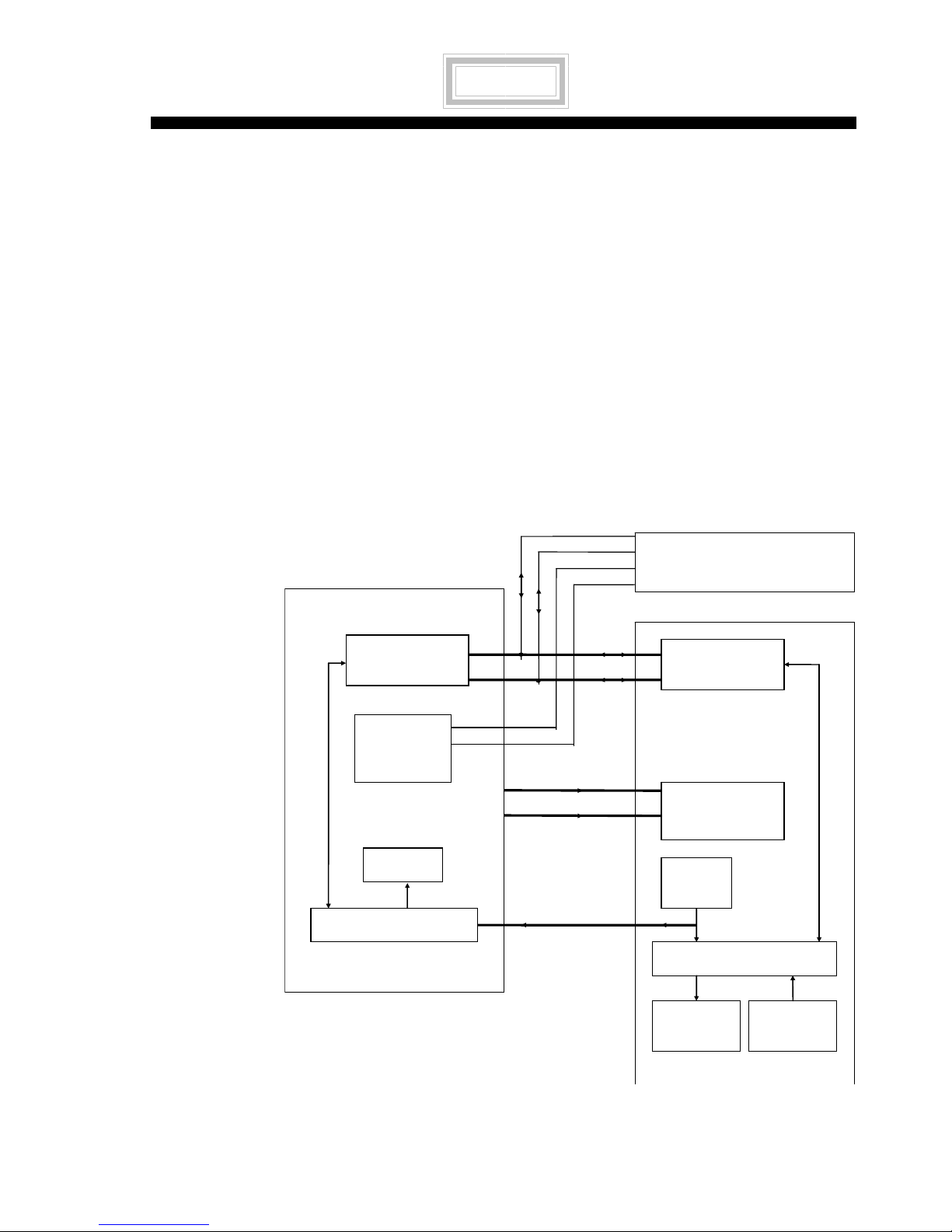

COMPUTER/DISPLAY COMMUNICATION

Communication problems are difficult to isolate because of the interaction between the Display

Console and the Computer. Failure of either unit causes malfunction of the Display Console. Such

problems need resolution before using the Problem Finding Tables.

Six wires, identified below and shown in the following diagram, connect the Computer to the

Display Console. (See Figure 4.8, page 40.)

DA Differential serial communication line

DB Differential serial communication line

RES Reset line from the display to the

computer

COMPUTER

TRANSCEIVER

IC6

5 VOLT

POWER

SUPPLY

+VP Power to Operator’s Display

Console

0V Common return

0V Common return

DA

DB

+5V

0V

D

DB

+VP

0V

REMOTE BAR GRAPH

DISPLAY CONSOLE

TRANSCEIVER

IC5

5 VOLT

REGULATOR

FIGURE 2.1

COMMUNICATION

BLOCK DIAGRAM

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

RELAYS

CPU

“TEST”

Button

RESET

CPU

DISPLAYS BUTTONS

9

COMPUTER/DISPLAY COMMUNICATION CONTINUED

NORMAL OCCURRENCES

WHEN SYSTEM IS TURNED ON

OR

WHEN “TEST” BUTTON IS PUSHED.

OPERATOR’S DISPLAY

COMPUTER REMOTE BAR GRAPH

CONSOLE

READS:

”This is a SELF-TEST.”

After Self-Test, the relays

turn on and allow crane

motions.

All lights turn on during Self-Test

and then return to normal.

Lamps on during Self-Test.

Audio alarm sounds during

Self-Test.

Bar Graph spans full window.

TEST button resets both

Listen for the relay “Click.”

Computer and Display

Console.

The following tables describe the reactions of the Operator’s Display Console, Computer, and

Remote Bar Graph when 1 of the 6 wires has a simulated failure. The wires were disconnected one

at a time and the results recorded. These tables are intended to help identify a faulty wire or circuit.

EITHER DA OR DB IS OPEN TO THE DISPLAY

OPERATOR’S DISPLAY

CONSOLE

Shows everything remaining

after Self-Test.

Lamps remain on. Relays click with every reset.

Audio alarm remains OFF.

TEST button resets both the

Computer and the Display.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

10

COMPUTER REMOTE BA R GRAPH

Resets every 5 seconds. All lights on.

TEST button clicks the

relays.

COMPUTER/DISPLAY COMMUNICATION CONTINUED

DA AND DB ARE OPEN TO THE DISPLAY

OPERATOR’S

COMPUTER REMOTE BAR GRAPH

DISPLAY CONSOLE

Graphics Display

Reset repeats every 5 seconds. All lights on.

READS:

“Serial comms. Failure”

Lamps are on. Relays click with every reset.

Audio alarm on.

TEST button resets both

Computer & Display in

TEST button clicks the relays. Resets when the TEST button is

pressed.

about 14 seconds.

Wires DA and DB going to the Display unit can be checked with an Ohm meter. Unplug Connector

7 at the Computer and connect a meter to pins A and E on the cable. It should read between 210

and 230 ohms.

RESET IS OPEN TO THE COMPUTER

OPERATOR’S

COMPUTER REMOTE BAR GRAPH

DISPLAY CONSOLE

Operator’s Display

Console is normal

after Self-Test.

Graphics Display

remains blank when

TEST button is pushed.

The reset line comes from the Display Console and connects to the Computer through Connector

7, Pin D, and then connects to TB6-14 RES on the Termination Board.

pushed this line goes Hi (about 4.5v) and resets the computer. In normal operation the reset line is

Low (about 0v).

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

Relays turn on and allow crane

motions.

Relay clicks

when TEST button is pushed.

Normal.

Resets

when TEST button is pushed.

When the “TEST” button is

11

COMPUTER/DISPLAY COMMUNICATION CONTINUED

+VP (RED WIRE) IS OPEN

DISPLAY COMPUTER REMOTE BAR

GRAPH

Entire Operator’s Display Console

does not respond.

Relay clicks when TEST button is

Relays turn on and allow crane

motions.

pushed.

Normal.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

12

DISPLAY OF FAULT CODES

When the System detects a problem, it is identified in the System as a Fault and given a Fault

Code Number. At the same time a warning is activated. Fault Codes are displayed by holding

down the TEST button. See SECTION V for a complete description of FAULTS.

If a warning sounds or is exhibited on the Operator’s Display Console, and a FAULT does not

register, check the OPERATOR’S SETTABLE ALARMS button.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

13

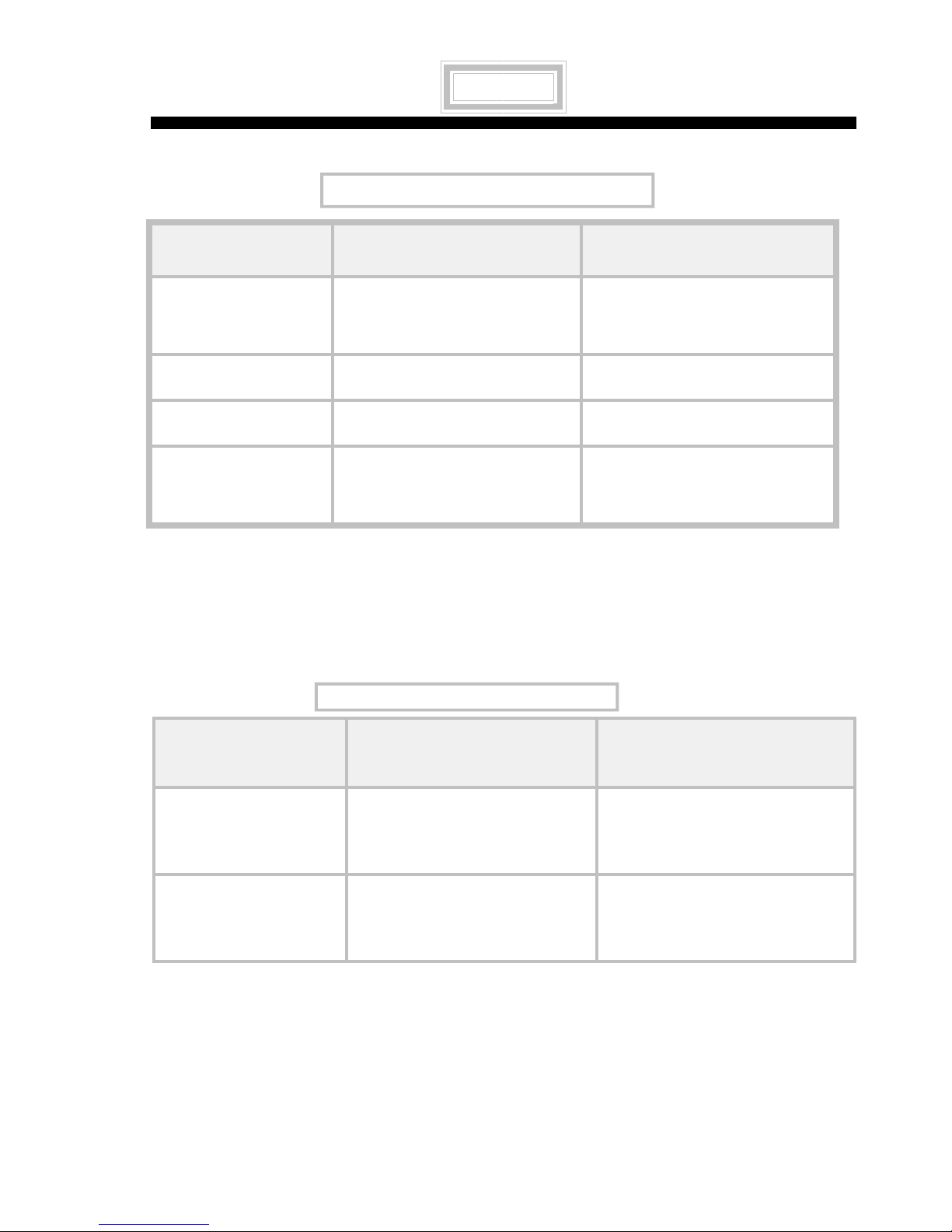

CRANE MOTIONS ARE DISABLED

Problem: Unable to boom down, extend boom, or hoist up.

Reason: The crane Motion Cut Solenoids aren’t powered.

Theory: The MicroGuard

and Motion Cut Solenoids of the crane. Refer to the MicroGuard

back cover of this Manual. Relay 1 cuts power when a Load Limit has been exceeded or a System

failure has been detected. Relay 2 cuts power when the Anti-two Block limit switch is opened.

ACTION RESULT DETAILED INFORMATION

®

434 System protection circuit has 2 relays, in series, between the Battery

®

434 System Diagram on the inside

Press and release the

TEST button on the

Press and Hold the TEST

button.

Press and Hold the

ALARM “OVERRIDE”

button for 5 seconds.

Measure the DC voltages

on Terminal Block 7 on the

Termination Board.

Measure the resistance

from Terminal Block 7 to

The System will perform a

Self-Test.

Fault codes will be

displayed until the button is

Relay 1 and Relay 2 will be

forced on by the computer

to provide power to the

Motion Cut Solenoids.

TB7-7 = 13.8V ( battery in )

TB7-8 = 13.8V ( jumper )

TB7-10 = 13.8V ( jumper )

TB7-7 to C8-B => 5 Ohms

TB7-11 to C8-E => 5 Ohms

Please refer to page 8.

Please refer to Fault Codes,

pages 66-72.

See the System Diagram the inside

back cover of this Manual to see the

voltage path from the battery through

the relays to the solenoids.

See the System Diagram on the inside

back cover of this Manual and the

Termination Board layout in Figure

4.24, page 63).

See Figure 4.21, page 60.

Check the wiring from the

computer to the Motion

Cable 8 supplies 13.8v to

the Motion Cut Solenoids.

Check the ATB Board

connections.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

14

All wires are making

contact.

See Figure 4.21, page 60.

ANTI-TWO-BLOCK CIRCUIT

The ANTI-TWO BLOCK switch is normally closed connecting ATBIN input to 0 volts. The

ANTI-TWO BLOCK WEIGHT holds the switch in this position. The switch is opened when the

weight is lifted. The ATBIN input has a 1 megohm pull up resistor that goes Hi when the switch

opens. The ATB board opens Relay 2 disabling crane motions. The ATB board also send s a signal

to the computer through DIN 13 allowing the computer to display an ATB alarm on the Operator’s

Display Console.

The ANTI-TWO BLOCK limit switch connects to the computer through a coax cable, slip rings

inside the Reeling Drum Assembly, and through cable 3. Please refer to EXTENSION REEL,

Section IV.

PROBLEM

There is an ATB ALARM

but there isn’t a TWO-

BLOCK condition on the

crane.

There is an ATB ALARM

but there isn’t a TWO

BLOCK problem on the

crane.

There is NO ATB ALARM

when the weight is lifted.

CRANE MOTION

REASON

DISABLED

The ANTI-TWO BLOCK circuit is open. Check

the connectors, cables, and slip rings for

continuity. The slip rings are inside the

Extension Reel. Check the position of the

“Selection Switch” mounted on the Anti-Two

Block Switch. It can be set at Main, Both, or

Jib and should be set to reflect the

configuration

of the crane.

CRANE MOTION OK The ATB board is not holding DIN 13 Hi.

Check the wire from the ATB board to the

Termination Board.

CRANE MOTION OK The ANTI-TWO BLOCK circuit is shorted to

ground. Unplug cable 3 to disconnect the ATB

switch. This generates an ATB ALARM. With

an Ohm meter, measure pins B and G of the

cable and lift the ATB WEIGHT. The

resistance is low during normal operation

and should switch to OPEN when the weight

is lifted.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

15

SWING POT SENSOR

FAULT CODE AAA 096

The Swing Pot Sensor is a 2.5k pot with two wiper arms separated at 90°. The System Diagram

on the inside back cover of this Manual shows the Swing Pot.

The Swing Pot can be checked with an Ohm meter. Disconnect cable 6 and measure from pin “C”

to “D” = 2.5k ± 20%.

Measure the wiper arms from pin “B” to “E” = 1.88k ± 20%.

If power going to the Swing Pot is cut, or if either wiper arm opens, the System will report a Fault.

Refer to Section IV, SWING SENSOR, page 64.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

16

BOOM EXTENSION SENSOR

FAULT CODE AAA 004

The Boom Extension Sensor sends a voltage to the computer. The voltage is sent through cable 3

to AIN2 on the Termination Board. The voltage on AIN2 is about .2v when the boom is retracted

and increases about .125v per drum revolution. If the voltage is missing or out of range, the

System will send forth an alarm. The Boom Extension Sensor is located inside the

Boom Extension Box.

PROBLEM ACTION RESULT

INDICATOR OUT OF

SERVICE Alarm.

AIN2 is not getting voltage

or is out of range.

Press and hold the TEST

button.

Measure AIN2 on the

Termination Board.

Fault Code AAA 004.

Retracted = ABOUT .2v.

The voltage increases as

the boom is extended.

The Extension Sensor is

not getting 5.25v from the

computer.

Measure the 5.25v on the

terminal strip inside the

Extension Reel. Check

.

cable 3.

NOTE: The computer may need to be re-calibrated when the Extension Sensor is replaced

or adjusted.

Please refer to the MicroGuard

®

434 System Diagram on the inside back cover of this manual. Also

review Section IV in this Manual for a detailed discussion of the Extension Sensor.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

17

BOOM ANGLE SENSOR

FAULT CODE AAA 008

The Boom Angle Sensor sends a voltage to the computer. The voltage is sent through cable 3 to

AIN 3 on the Termination Board. The voltage on AIN3 is about .437v when the Boom is at 0° and

4.375v at 90°. If the voltage is missing or out of this range, the System will display a Fault. The

Angle Sensor is located inside the Boom Extension box.

PROBLEM ACTION RESULT

System Overload

Alarm.

AIN3 is not getting

voltage or is out of

range.

Press and hold the

TEST button.

Measure AIN3 on the

Termination Board.

Fault Code AAA 008

Boom angle 0° = .437v

Boom angle 30° = 1.750v

Boom angle 60° = 3.062v

Boom angle 90° = 4.375v

The Angle Sensor is

not getting 5.25v from

the computer.

Measure the 5.25v on

the terminal strip

inside the Extension

Reel. Check cable 3.

NOTE: The computer may need to be re-calibrated when the angle sensor is replaced or adjusted.

FOR A MORE DETAILED DESCRIPTION, SEE SECTION IV, PAGE 53.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

18

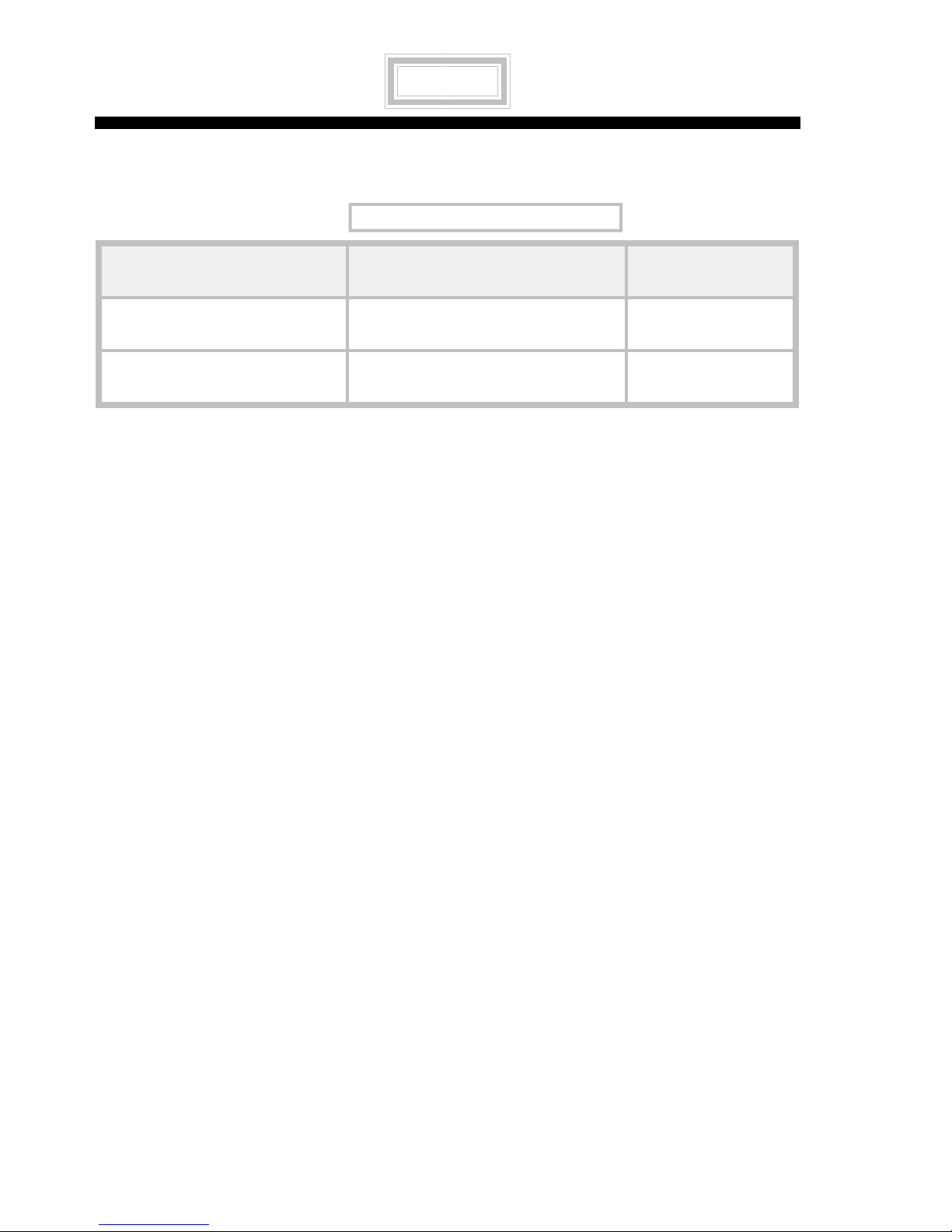

PRESSURE TRANSDUCERS

FAULT CODE AAA 001 OR 002

The Rod/Piston Pressure Transducers turn hydraulic pressure into voltages that can be used by the

computer. Each transducer has its own cable. They plug into connectors 1 and 2. Connector 1 goes

to Terminal Block 2, pins 1, 2, 3, + 4 and connector 2 uses pins 6, 7, 8, + 9 on the

Termination Board.

CONNECTOR 1 IS THE TXO CHANNEL ON THE INTERFACE BOARD

PROBLEM ACTION RESULTS

INDICATOR OUT OF

SERVICE Alarm.

Power from the computer to the

transducer is missing.

Input TXO + or - is missing or

incorrect.

The transducer or cable has

failed.

Connector to Terminal block

open.

Press and hold the TEST

button.

Measures the +5.25v supply

on the Termination Board.

Measures TXO inputs on the

Termination Board.

Unplug the cable and

measure the resistance.

Measure the connections

from terminal block 2 to

connector 1.

Fault Code AAA

001

Terminal block 2

Pin 1 (+DR) +5.25v

Terminal block 2

PIN 3 (TXO+) +2.625v

PIN 4 (TXO–) +2.625v

Pin C to D = 340 to 360 Ohm

Pin B to E = 340 to 360 Ohm

Pin B, C, D, & E open to the

shield.

Pin C to TB2 +DR = > 1 Ohm

Pin D to TB2 –DR = > 1 Ohm

Pin B to TB2 TXØ+ = > 1 Ohm

NOTE: The System will need to be re-calibrated if a new sensor is installed.

FOR A MORE DETAILED DESCRIPTION, SEE PRESSURE SENSOR SEC. IV, PAGE 54.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

Pin E to TB2 TXØ– = > 1 Ohm

19

PRESSURE TRANSDUCERS CONTINUED

CONNECTOR 2 IS THE TX1 CHANNEL ON THE INTERFACE BOARD

PROBLEM ACTION RESULTS

INDICATOR OUT OF

SERVICE Alarm.

Power from the computer to

the transducer is missing.

Input TX1 + or - is missing or

incorrect.

The transducer or cable has

failed.

Press and hold the TEST

button.

Measures the +5.25v

supply on the Termination

Board.

Measures TX1 inputs on

the interface board.

Unplug the cable and

measure the resistance.

Fault Code AAA

002

Terminal block 2

Pin 6 (+DR) +5.25v

Pin 7 (-DR) 0 volts

Terminal block 2

PIN 8 (TX1+) +2.625v

PIN 9 (TX1-) +2.625v

Pin C to D = 340 to 360 Ohm

Pin B to E = 340 to 360 Ohm

Pin B, C, D, & E open to the

shield.

Connector to Terminal block

open.

NOTE: The System will need to be re-calibrated if a new sensor is installed.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

20

Measure the connections

from terminal block 2 to

connector 2.

Pin C to TB2 +DR = > 1 Ohm

Pin D to TB2 –DR = > 1 Ohm

Pin B to TB2 TX1+ = > 1

Ohm

Pin E to TB2 TX1– = > 1 Ohm

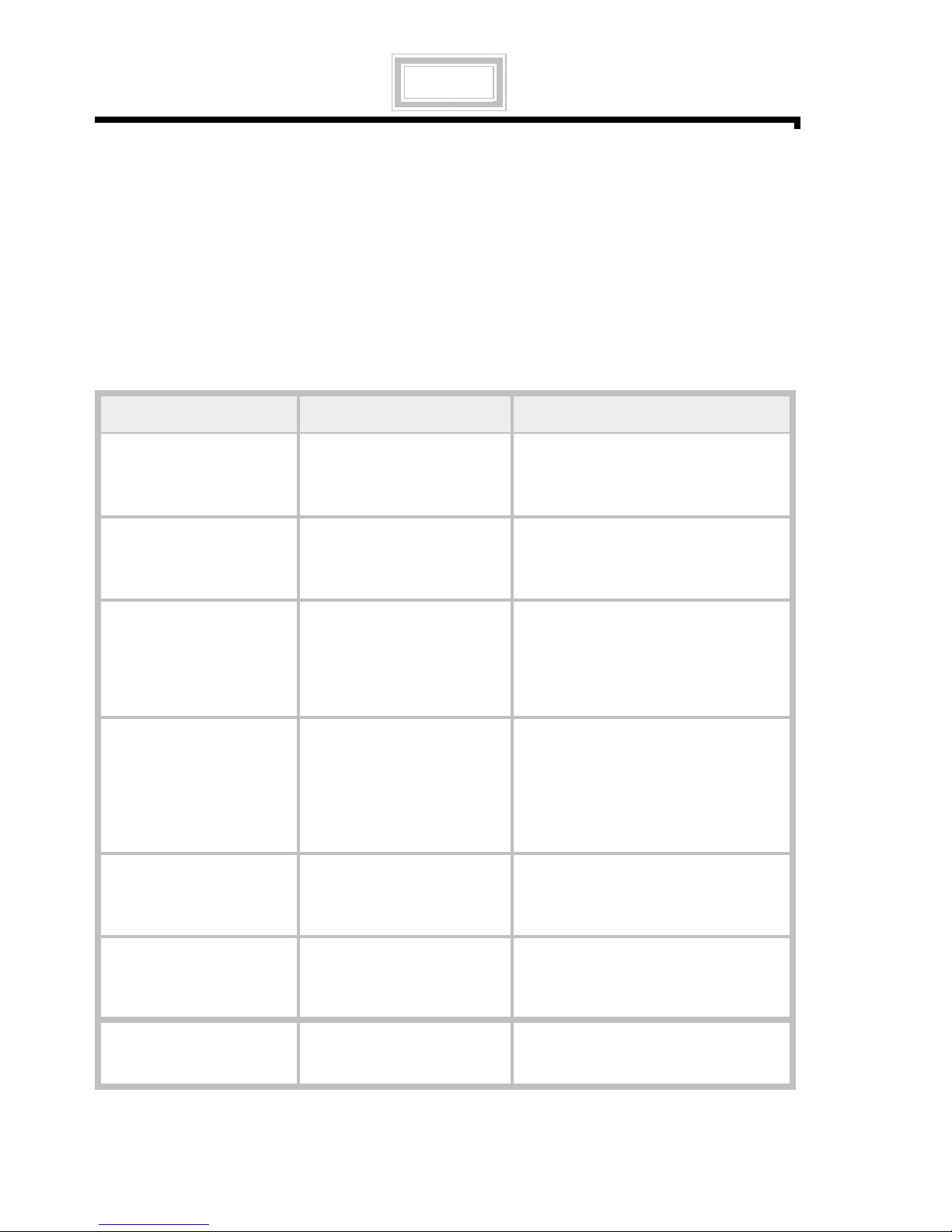

REMOTE BAR GRAPH

The Remote Bar Graph is connected to the computer with 4 wires.

DA Serial Communication Line

DB Serial Communication Line

+5v Power

Ground Power Return

PROBLEM ACTION RESULT

No lights.

(Not getting power.)

All lights remain on after

Self-Test. (No serial

communication.)

Lights pulsating.

(DA or DB is missing.)

Loose connection inside

the computer from

connector -5 to

terminal block 6.

Unplug cable 5. Measure

the 5 volt on connector 5 of

the computer.

Unplug cable 5 and

measure the resistance

from Pin D to Pin E on the

cable connector.

Unplug cable 5 and

measure the resistance

from Pin D to Pin E on the

cable connector.

Measure the resistance

from connector 5 to

terminal block 6 inside the

computer.

Pin A = + 5 volts.

Pin C = 0 volts

Pin D to E measures

between 210 and 230

ohms. If not, the cable is

open or shorted.

Pin D to E measures

between 210 and 230

ohms. If not, the cable is

open.

Pin C to TB9=>1 ohm

Pin A to TB10=>1 ohm

Pin D to TB12=>1 ohm

Pin E to TB13=>1 ohm

NOTE: The Remote Bar Graph unit must always be returned to the Service Center

for repair. Call your Service Representative.

SEE COMPUTER/DISPLAY COMMUNICATION BLOCK DIAGRAM PAGE 9

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

AND REMOTE BAR GRAPH, PAGE 43.

21

THIS PAGE SHOULD BE BLANK.

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

22

Section III

SYSTEM INSTALLATIONS....................................................................................23

SELECTING THE RIGHT SYSTEM INSTALLATION ILLUSTRATION.....................24

SYSTEM LAYOUTS WITH CORRESPONDING SERIAL NUMBER PREFIX..........25

1. SYSTEM INSTALLATION E1.......................................................................................25

2. SYSTEM INSTALLATION D3, E9, F1, F2, & F3...........................................................26

MicroGuard® 434 System — Troubleshooting Manual PN W434800 Rev D 09/19/06

23

Loading...

Loading...