GREER Company MICROGUARD 424 Calibration Manual

GREER

GREER COMPANY

GREERGREER

COMPANY

COMPANYCOMPANY

MODELS USING M414371A & M414380C PROGRAMS

MODELS USING M414371A & M414380C PROGRAMS

MODELS USING M414371A & M414380C PROGRAMSMODELS USING M414371A & M414380C PROGRAMS

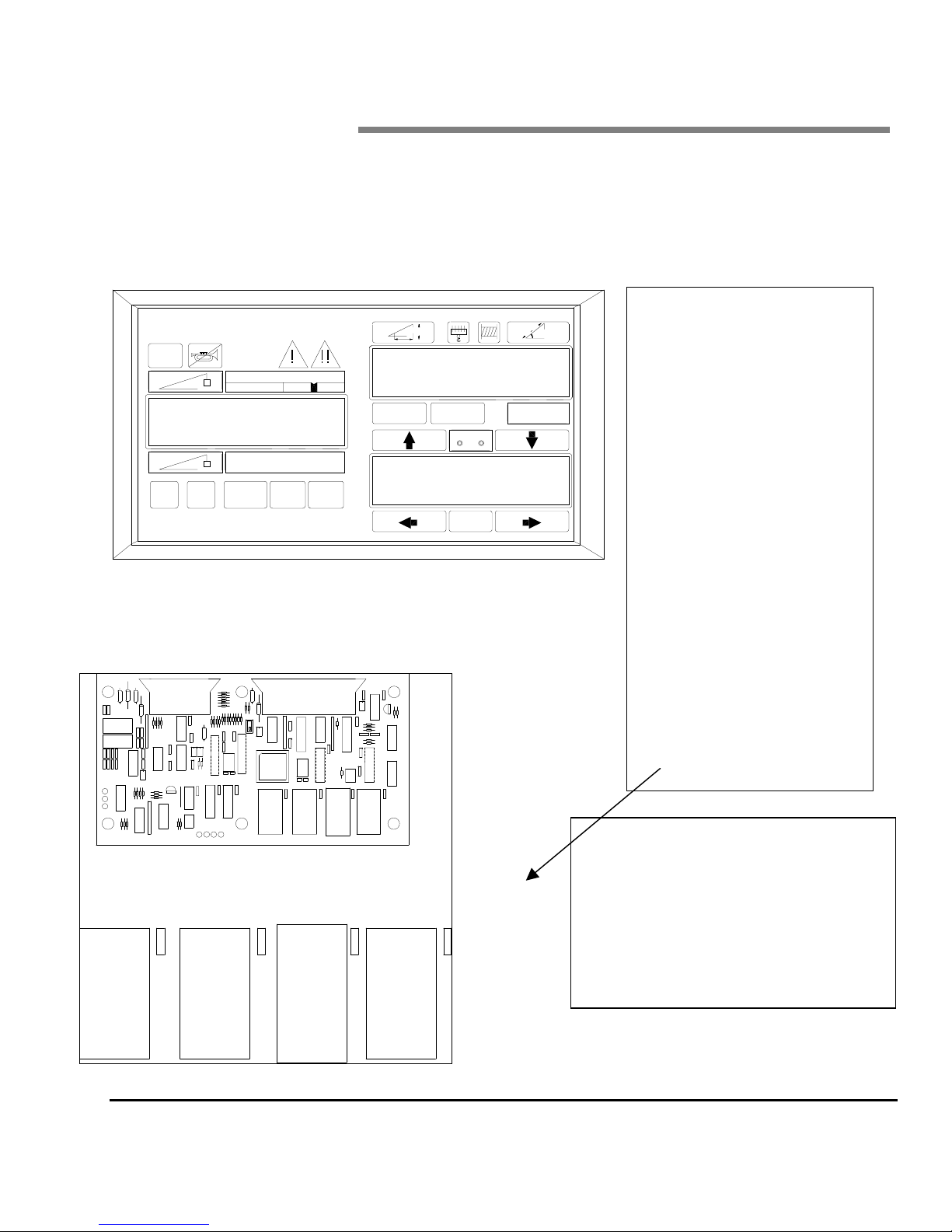

MicroGuard 424

TEST

W

MAX

5.82

3.46

ATB ALARM

Crane Systems

MICROGUARD

MICROGUARD

MICROGUARDMICROGUARD

for

GENERIC

GENERIC

GENERICGENERIC

57.2

100%

O/R FULEXT 360

CRANE

SET UP

60%

8

STOWED

DEDUCT

DEDUCT

ERECTED STOWED

424

F 49.1

WORKING

o

AREA

W

INFORMATION

Lifting point

MAIN BOOM

VIEW

OPERATOR ALARMS

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

SET

DOWNCLEAR UP

CONTRAST

SELECT

CALIBRATION PROCEDURE

CALIBRATION PROCEDURE

CALIBRATION PROCEDURECALIBRATION PROCEDURE

1 of 44

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

424 SYSTEM

MicroGuard

MicroGuard

MicroGuardMicroGuard

GENERIC CALIBRATION MANUAL

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

GENERAL INFORMATION .................................................................................................................................... 3

CALIBRATION PROCEDURES ............................................................................................................................. 4

COMMAND 00 RUN............................................................................................................................................5

COMMAND 01 PERSONALITY ..........................................................................................................................5

ENTRY TO CALIBRATION ROUTINES ................................................................................................................6

COMMAND 01/2 INITIALIZE..................................................................................................................................6

COMMAND 01/0 SAVE..........................................................................................................................................7

COMMAND 02 TEST/FAULT..............................................................................................................................7

FAULT CODES................................................................................................................................................8

NUMBER ENTRY .......................................................................................................................................9-10

COMMAND 03 ZERO.................................................................................................................................11

424 SYSTEM

424 SYSTEM424 SYSTEM

ZERO PRESSURE TRANSDUCERS ................................................................................................11-12

ZERO EXTENSION SENSOR ................................................................................................................13

ZERO BOOM ANGLE SENSOR ............................................................................................................. 14

COMMAND 04 SPAN........................................................................................................................................15

BOOM ANGLE SENSOR ..............................................................................................................................15

EXTENSION SENSOR.................................................................................................................................. 16

COMMAND 05 SWING ................................................................................................................................17-18

CONFIGURATION SELECTION.....................................................................................................................19-20

COMMAND 06 PRESSURE..............................................................................................................................21

COMMAND 07 RADIUS/MOMENT MAIN BOOM (MODE A) ......................................................................22-24

COMMAND 07 RADIUS/MOMENT MANUAL (MODE B) ............................................................................25-27

COMMAND 08 BOOM DEFLECTION CORRECTION .....................................................................................28

COMMAND 09 ANNULAR GAIN ......................................................................................................................29

COMMAND 12 WINCHES ................................................................................................................................30

COMMAND 13 ATTACHMENTS ......................................................................................................................30

COMMAND 15 ALARM LIMITS ...................................................................................................................31-33

COMMAND 16 ROPE DATA.............................................................................................................................34

COMMAND 17 AMPLIFIER GAIN.....................................................................................................................35

COMMAND 01/0,3, 4 SAVE/BACKUP/RESTORE.........................................................................................36-37

COMMAND 19 DIGITAL INPUTS .....................................................................................................................38

GLOSSARY.....................................................................................................................................................39-44

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

2 of 44

GREER COMPANY

A

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

GENERAL INFORMATION

GENERAL INFORMATION

GENERAL INFORMATIONGENERAL INFORMATION

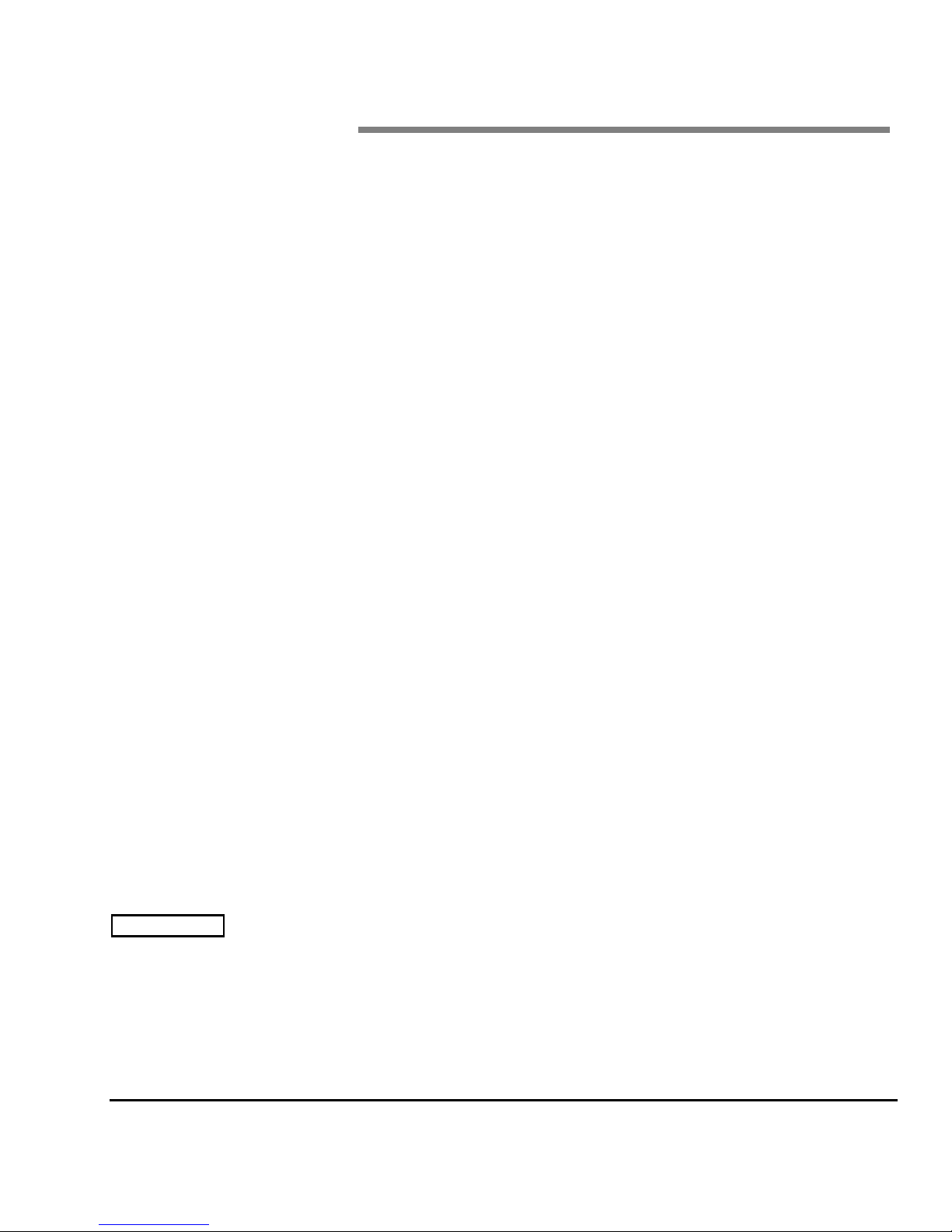

After satisfactory installation of the complete system, ensure that it is correctly wired in accordance with the Wiring

Diagram, which is issued with the duty chip.

Before carrying out any crane operations ensure that the crane is on firm and level ground and that the outrigger

beams are fully extended and jacks are correctly extended to level the carrier.

CAUTION: Do not exceed any

MicroGuard

TEST

W

MAX

W

VIEW SET CLEAR DOWN UP

414

100%

INFORMATION

CONTRASTOPERATOR ALARMS

CRANE

SET UP

STOWED

DEDUCT

ERECTED STOWED

SELECT

WORKING

AREADEDUCT

structural or stability limits

throughout this procedure.

For cranes using executive

programs labeled

M414370,M414371 or

M414380: Attachments can

remain on as long as they are

correctly selected in the

computer.

For cranes using other

programs:

Remove all

attachments which can be

optionally stowed or erected on

the boom during normal

operation (e.g. aux.head flys or

jibs The computer must be fitted

with the appropriate program

and duty chips. They are found

on the main computer board as

shown below.

PROGRAM

CHIP

DUTY

CHIP

IC2 IC3 IC7

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

PERSONALITY

CHIP

3 of 44

WARNING: WHEN THE SYSTEM IS IN

THE CALIBRATION MODE, THE AUDIBLE

ALARM AND FUNCTION KICK-OUTS ARE

INHIBITED AND THERE IS NO

PROTECTION FROM TWO-BLOCK OR

OVERLOAD. ALL CRANE OPERATIONS

RE AT THE SOLE DISCRETION OF THE

OPERATOR.

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

CALIBRATION PROCEDURES

CALIBRATION PROCEDURES

CALIBRATION PROCEDURESCALIBRATION PROCEDURES

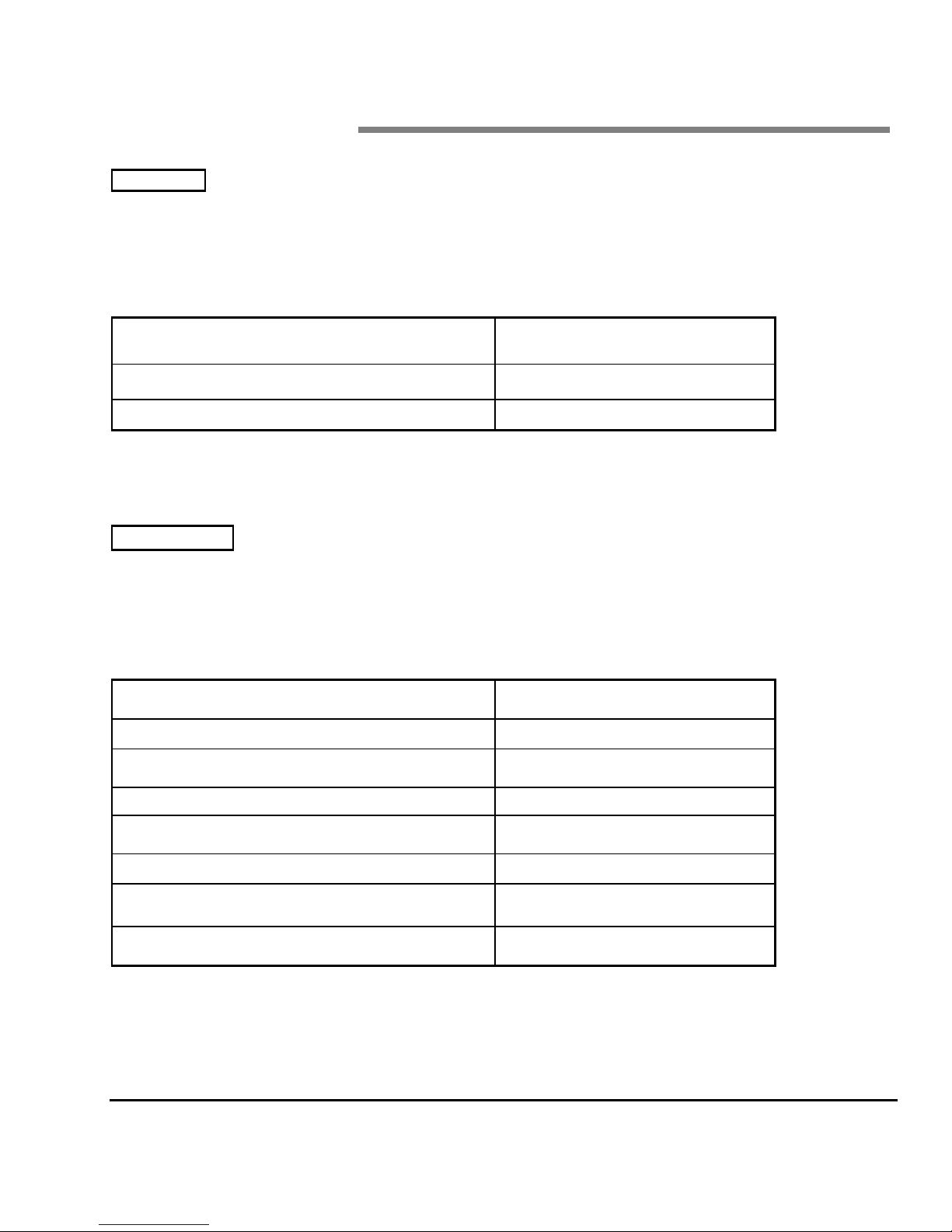

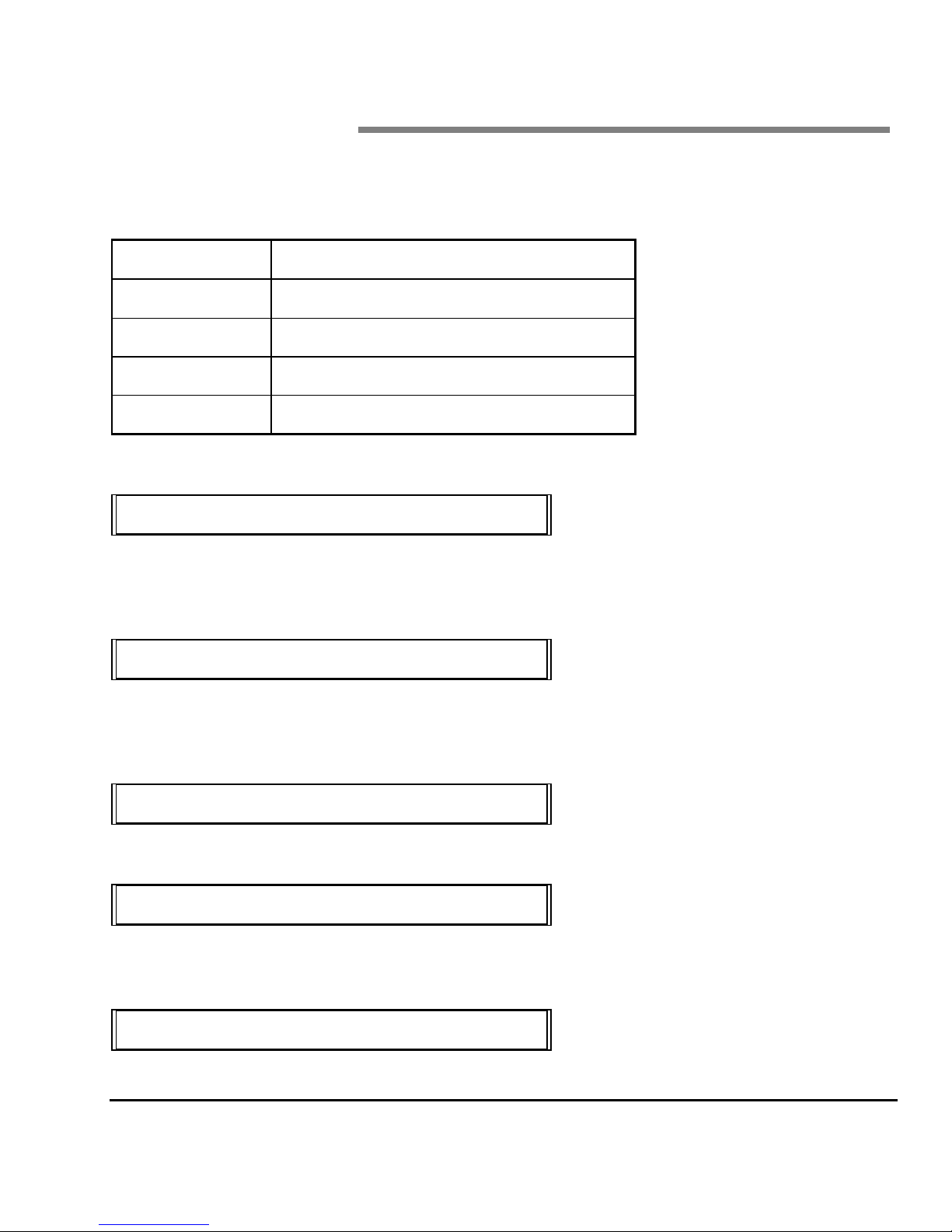

The Display Unit provides the interface between the user and the calibration program. By pressing the various

keypads on the Display, the user communicates with the program and executes the calibration. Information and

data stored in the Display Unit are activated via on-screen prompts.

The six keypads are shown below with a description of their basic function.

Calibration routines are initiated by simultaneously pressing and holding the

approximately 2 seconds. The display will then request entry of the Calibration Security Code.

To enter the Calibration Security Code, press the following keys IN THE SEQUENCE SHOWN BELOW.

If the wrong sequence is used or if the entry is not completed within 5 seconds, the calibration entry will be aborted

and must be restarted.

Calibration procedures will only work with the

CAL switch in the computer set to the CAL

position. To gain access to the CAL switch it is

necessary to remove the cover from the

computer assembly. The switch is located near

the center of the computer board between and

below the ribbon cable connectors.

UP ARROW INCREASES A NUMBER

××××

ØØØØ

ÕÕÕÕ

DOWN ARROW DECREASES A NUMBER

LEFT ARROW CHANGES A CATEGORY OR SENSOR

ÖÖÖÖ RIGHT ARROW CHANGES A CATEGORY AND/OR EXITS

SELECT

TEST

SELECT KEY SELECTS AND CALIBRATE

TEST KEY STARTS THE CALIBRATION

and

TEST

×××× ØØØØ ÕÕÕÕ ÖÖÖÖ

SELECT

SELECT

keys for

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

CAL SWITCH

4 of 44

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

COMMAND 00 RUN

COMMAND 00 RUN

COMMAND 00 RUNCOMMAND 00 RUN

Following correct entry of the calibration code, the System will be in the MONITOR mode and will be at

Command 00 Run. Execution of this Command will cause the System to carry out a System Self-TEST followed

by a return to the working screen.

COMMAND 01 PERSONALITY

COMMAND 01 PERSONALITY

COMMAND 01 PERSONALITYCOMMAND 01 PERSONALITY

Command 01 Personality is used to manipulate the crane calibration data.

The System has storage space for two sets of data in the EEPROM IC7.

used by the main program. Back-up Personality is used to keep a protected copy of the calibration data.

For convenience the sets of personality data are called:

"A" = the Active Personality in IC7

"B".= the Backup Personality in IC7

Command 01 provides the following functions:

Displays the status of the personality sets.

♦

Moves data between the two sets

♦

Deletes data from the active personality.

♦

Copies data to a back-up chip

♦

Retrieves data from a back-up chip.

♦

When Command 01 is first selected and after copying data, both "A" and "B" sets are checked for correct

check-sum. This is indicated by "good" or "bad" beside the respective reference in the lower display. Set "A" is

also checked against set "B". If the data is identical, this is indicated by "same;" if not the same, by "diff." Moving

data is by accomplished by means of the sub-commands selected and a special [CAL] sequence. This requires

the entry of a Code that is the same as the one used to enter the calibration routines and provides adequate

opportunity to abort the procedure. This is necessary because some of the sub-commands cause previously

entered data to be irretrievably lost.

Active Personality

is the data actually

SUB-COMMAND 0 SAVE Saves "A" into "B". (B data is lost)

SUB-COMMAND 1 XCHG Exchanges "A" with "B" (data is not lost)

SUB-COMMAND 2 INIT Initializes "A" prior to new calibration (A data is lost).

SUB-COMMAND 3 BACK Copies the active calibration to a back-up chip (data is not lost).

SUB-COMMAND 4 RETR Retrieves the calibration from a back-up chip.

WARNING

POWER TO THE SYSTEM SHOULD BE SWITCHED OFF BEFORE INSERTING OR REMOVING ANY

INTEGRATED CIRCUITS. FAILURE TO OBSERVE THIS PRECAUTION MAY CAUSE PERMANENT DAMAGE

TO THE SYSTEM OR ITS COMPONENTS AND RESULT IN THE LOSS OF CALIBRATION DATA.

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

5 of 44

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

WARNING

If the System has been previously calibrated and the intention is only to access data or change only a portion of

the previous calibration,DO NOT perform the initialization process that follows or the entire previous calibration

data will be lost.

ENTRY TO CALIBRATION ROUTINES

ENTRY TO CALIBRATION ROUTINES

ENTRY TO CALIBRATION ROUTINESENTRY TO CALIBRATION ROUTINES

OR

OR

AND

ØØØØ

ØØØØ

TEST

START THE ROUTINE BY PRESSING AND

HOLDING FOR APPROXIMATELY 2 SECONDS

FOLLOW THE CAL ENTRY SEQUENCE

CONFIRM THE CALIBRATION (or abort with Ö)

If the wrong sequence is used or if the entry is not completed within 5 seconds, the calibration entry will be aborted

and must be restarted. Before the first calibration of a new system, prepare the Personality Memory by following

the sequence below.

CAUTION

CAUTION

CAUTIONCAUTION

THIS PROCEDURE TRANSFERS PRE-CALIBRATED DATA TO THE PERSONALITY CHIP. IF THIS HAS ALREADY BEEN

CARRIED OUT AND THE INTENTION IS TO ONLY PARTIALLY CALIBRATE OR TO MODIFY CALIBRATION OR DATA IN

AN ALREADY CALIBRATED SYSTEM,

CALIBRATION.

COMMAND 01/2 INITIALIZE

COMMAND 01/2 INITIALIZE

COMMAND 01/2 INITIALIZECOMMAND 01/2 INITIALIZE

SCROLL TO 01 PERSONALITY BY PRESSING

START THE COMMAND BY PRESSING

SCROLL TO 01/2 INITIALIZE BY PRESSING

DO NOT

CARRY OUT THE INITIALIZE ROUTINE. PROCEED DIRECTLY WITH THE

SELECT

×××× ØØØØ ÕÕÕÕ ÖÖÖÖ

SELECT

××××

SELECT

××××

START THE COMMAND BY PRESSING

FOLLOW THE CAL ENTRY SEQUENCE

CONTINUE THE INITIALIZATION BY PRESSING

CONFIRM THE CALIBRATION (or abort with Ö)

SEE NOTE

AFTER THE MESSAGE CALIBRATING, EXIT BY

PRESSING

NOTE: The System will return to the MONITOR MODE but will remain in the CALIBRATION ROUTINE.

This procedure completely erases all previous data from the A personality. There is an opportunity to ABORT the

procedure at this point by first pressing

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

SELECT

×××× ØØØØ ÕÕÕÕ ÖÖÖÖ

SELECT

SELECT

ÖÖÖÖ

. Follow by pressing SELECT to erase the memory.

ÖÖÖÖ

6 of 44

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

COMMAND 01/0 SAVE

COMMAND 01/0 SAVE

COMMAND 01/0 SAVECOMMAND 01/0 SAVE

Upon completion of a calibration, it is necessary to carry out Command 01/0 SAVE. Refer to at the end of this

manual. There is no reason, however, why this command should not be used at any time during the intermediate

stages of a calibration, for example at the end of a period of work or if desired after each section of a calibration

has been completed. The use of this command will ensure that a copy of the calibration, up to the point of carrying

out "save", will be contained in the back-up memory.

SCROLL TO 01 PERSONALITY BY PRESSING

××××

OR

ØØØØ

START THE COMMAND BY PRESSING

SCROLL TO 01/0 SAVE BY PRESSING

SELECT

××××

START THE COMMAND BY PRESSING

FOLLOW THE CAL ENTRY SEQUENCE

SELECT

×××× ØØØØ ÕÕÕÕ ÖÖÖÖ

CONTINUE THE SAVE BY PRESSING SELECT

CONFIRM THE CALIBRATION (or abort with Ö)

SEE NOTE

AFTER THE MESSAGE "CALIBRATING," THE

DISPLAY WILL READ "A" GOOD "B" GOOD SAME

EXIT BY PRESSING

NOTE:

NOTE: This procedure completely erases all previous data from the B personality. There is an opportunity to

NOTE:NOTE:

ABORT

COMMAND 02 TEST/FAULT

COMMAND 02 TEST/FAULT

COMMAND 02 TEST/FAULTCOMMAND 02 TEST/FAULT

COMMAND 02 IS USED TO ACTIVATE A SYSTEM SELF-TEST WHICH WILL DETECT AND DISPLAY ANY ERRORS

PRESENT IN THE SYSTEM. THESE ERRORS ARE SHOWN BY MEANS OF AN ERROR CODE.

Carry out the Command using the following sequence:-

the procedure at this point by use of the right arrow

SCROLL TO 02 TEST/FAULT BY PRESSING

SELECT

ÖÖÖÖ

ÖÖÖÖ

××××

START THE COMMAND BY PRESSING

SELECT

ØØØØ

OR

Continuing with SELECT will erase the memory

ØØØØ

OR

THE SYSTEM WILL EXECUTE A SELF-TEST AND

DISPLAY FAULT CODES

EXIT FROM THE ROUTINE BY PRESSING

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

ÖÖÖÖ

7 of 44

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

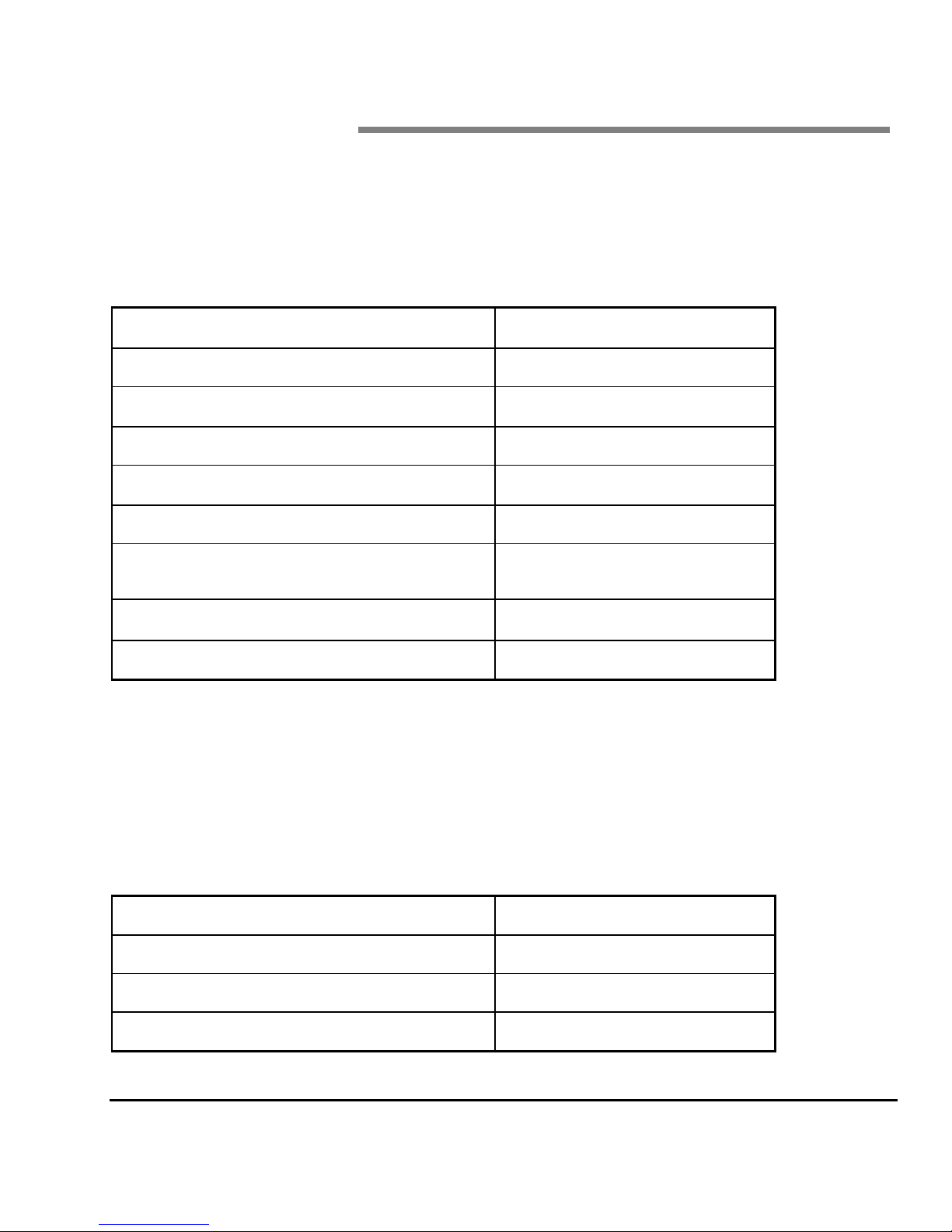

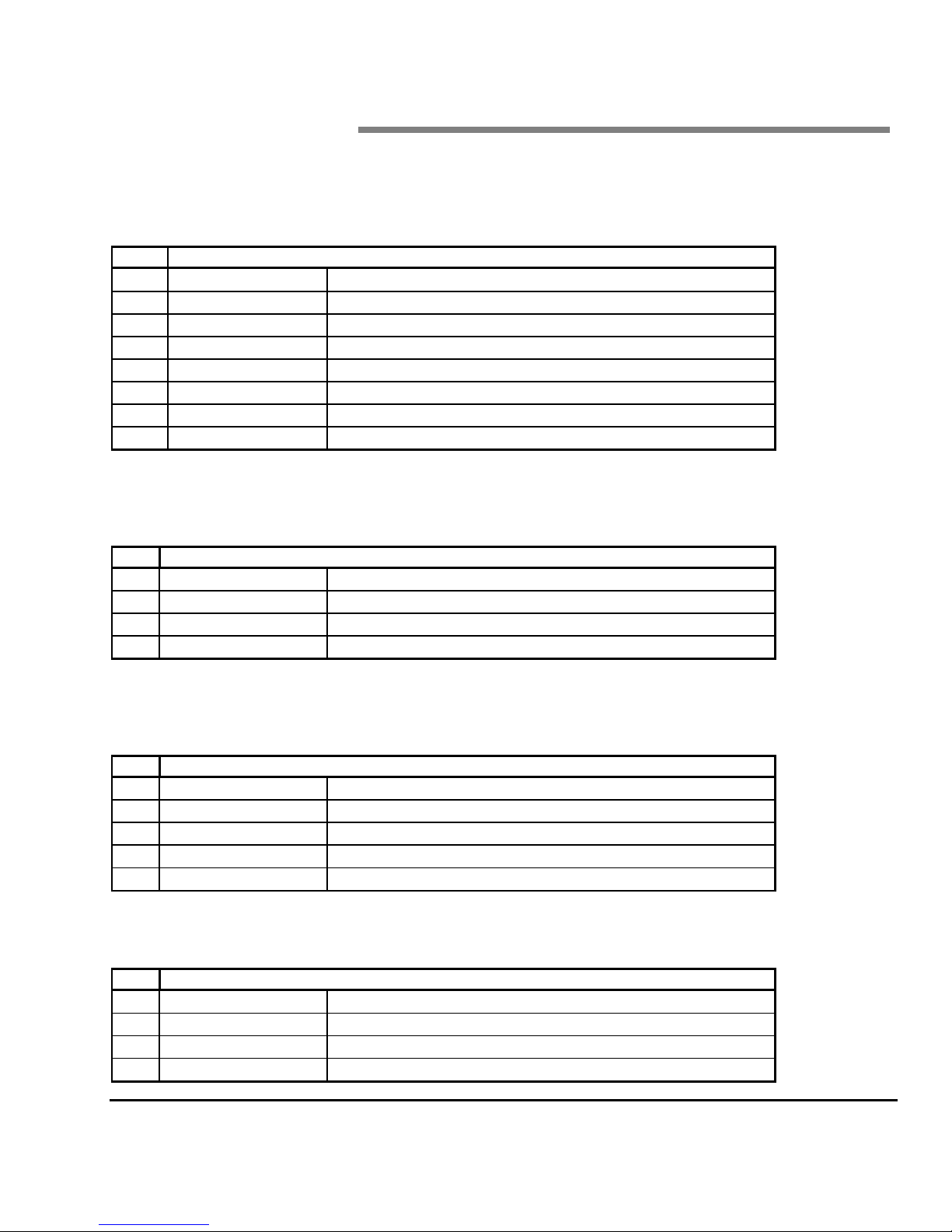

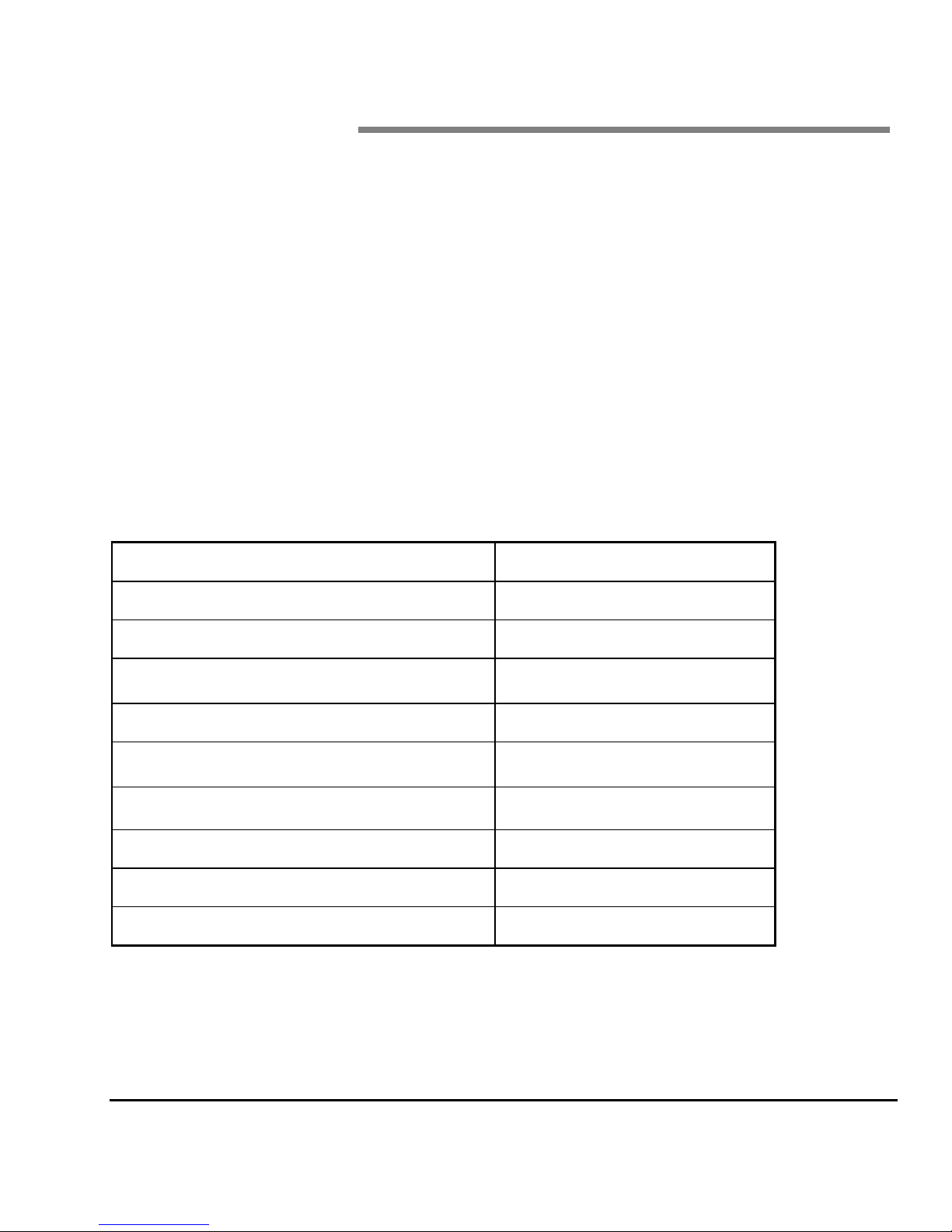

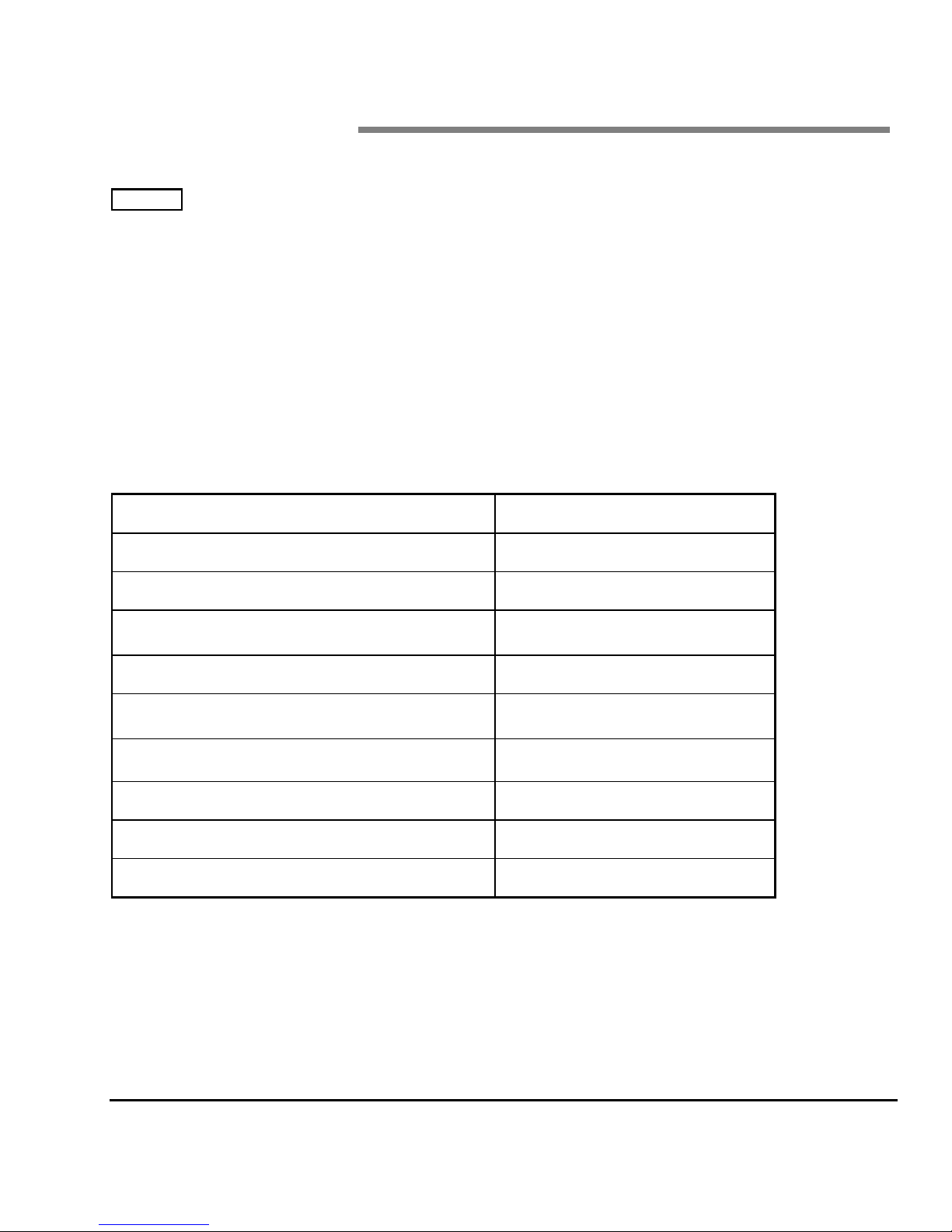

FAULT CODES

FAULT CODES

FAULT CODESFAULT CODES

GROUP "A" ANALOG SENSORS

GROUP "A" ANALOG SENSORS

GROUP "A" ANALOG SENSORSGROUP "A" ANALOG SENSORS

CODE

AAA

000

001

002

004

008

016

032

064

GROUP "B" INPUTS AND OUTPUTS

GROUP "B" INPUTS AND OUTPUTS

GROUP "B" INPUTS AND OUTPUTSGROUP "B" INPUTS AND OUTPUTS

CODE

BB

00

01

02

04

GROUP "C" MEMORY

GROUP "C" MEMORY

GROUP "C" MEMORYGROUP "C" MEMORY

CODE

CC

00

01

02

04

08

GROUP "D" GENERAL

GROUP "D" GENERAL

GROUP "D" GENERALGROUP "D" GENERAL

CODE

DD

00

01

02

04

NO FAULTS

SENSOR 0 PISTON PRESSURE TRANSDUCER

SENSOR 1 ROD SIDE PRESSURE TRANSDUCER

SENSOR 2 EXTENSION SENSOR

SENSOR 3 BOOM ANGLE SENSOR

SENSOR 4 UPPERSTRUCTURE ANGLE SENSOR

SENSOR 5 SWING POTENTIOMETER "A"

SENSOR 6 SWING POTENTIOMETER "B"

NO FAULTS

FAULT 1 DIGITAL INPUT AND OUTPUT

FAULT 2 ANALOG INPUT AND OUTPUT

FAULT 4 DISPLAY UNIT

NO FAULTS

FAULT 1 EXECUTIVE ROM

FAULT 2 DUTY ROM

FAULT 4 SCRATCHPAD RAM

FAULT 8 PERSONALITY ROM

NO FAULTS

FAULT 1 NO DUTY FOUND

FAULT 2 CURRENT DUTY BAD

FAULT 4 CONFIGURATION NOT CALIBRATED

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

8 of 44

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

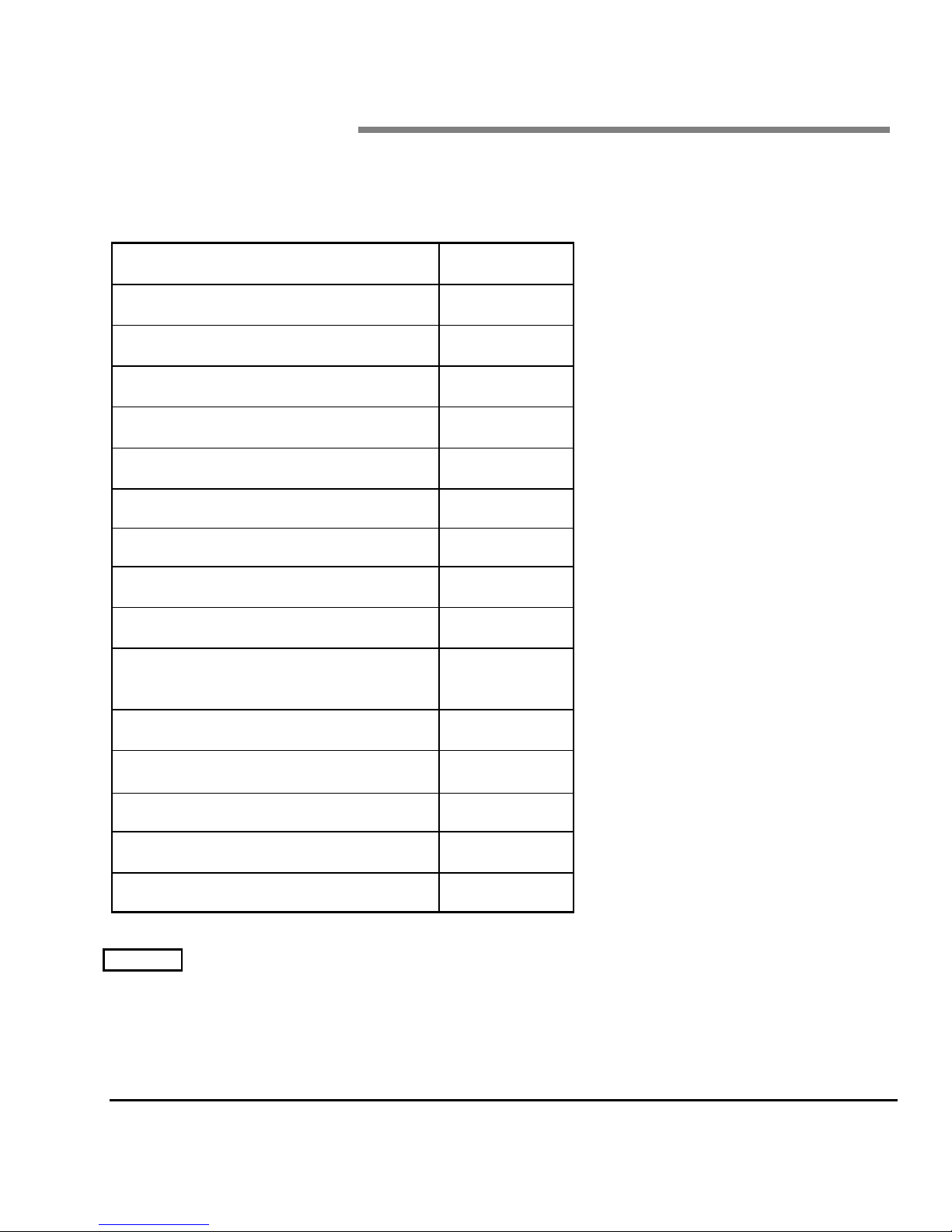

NUMBER ENTRY

NUMBER ENTRY

NUMBER ENTRYNUMBER ENTRY

The MicroGuard System does not have number entry keys. A special number entry procedure is used to allow

the simple entry of numbers. W hen numerical entry of data is required, the center display will change to allow the

entry of numbers. There are 5 categories in the display, as follows.

•

SELECTS A DECIMAL POINT

0

1. W

arrows pointing to the category.

• ÖÖÖÖ0ÕÕÕÕ ß C E

2. N

SELECT key. Successive numbers up to a total of five digits may be entered this way. If a number requires a

decimal point, the number is entered by moving the highlighted selection to the decimal point by means of

The decimal point then becomes highlighted.

ÖÖÖÖ

3. T

flashing cursor returns to the digits for the completion of the number entry. If a negative value is to be entered, the

number digit(s) must be entered first followed by the change sign command (enter the number and then move the

cursor to highlight the minus sign using

ß

C

E

hen the number entry is started, the display flashes on the number entry category that is highlighted by

umbers are changed using the

••••

ÕÕÕÕ 0

he decimal point is entered using the SELECT key. After the selection of a decimal point, the highlighted

SELECTS A DIGIT 0-9. THE

ARE USED TO CHANGE A NUMBER

CHANGE SIGN +/-

CLEARS A CURRENTLY DISPLAYED NUMBER

TERMINATES THE NUMBER AND COMPLETES

THE ENTRY PROCESS

and

××××

ß

C E

ÖÖÖÖ

keys. When selected, the required number is entered using the

ØØØØ

).

AND Ø KEYS

×

ÕÕÕÕ

.

ÕÕÕÕ C E

ÖÖÖÖ

ßßßß

.

•

0 ÖÖÖÖ

4. P

highlight the C using

•

5. P

correct number. After entry of all digits, decimal point and sign changes, move the cursor to E using

SELECT to terminate the sequence.

•

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

ress SELECT to change to a negative value. If an error is made in the entry of data, move the cursor to

0 ß ÖÖÖÖCÕÕÕÕ E

ress SELECT to delete the erroneous number, move the cursor back to the entry of digits and enter the

0 ß C ÖÖÖÖEÕÕÕÕ

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

9 of 44

and press

ÖÖÖÖ

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

NUMBER ENTRY

NUMBER ENTRY

NUMBER ENTRYNUMBER ENTRY

IN THE EXAMPLE THAT FOLLOWS, AN ARBITRARY NUMBER OF MINUS 123.45 HAS BEEN CHOSEN TO

ILLUSTRATE THE USE OF THE PROCEDURE.

SELECT THE FIRST DIGIT

BY PRESSING

WHEN AT

SELECT THE SECOND DIGIT

BY PRESSING

WHEN AT

SELECT THE THIRD DIGIT

BY PRESSING

WHEN AT

MOVE THE CURSOR TO THE DECIMAL

POINT

ENTER THE DECIMAL POINT BY

PRESSING

SELECT THE FIRST DECIMAL PLACE

Ö4Õ

WHEN AT

SELECT THE NEXT DECIMAL PLACE

BY PRESSING

Ö1Õ

Ö2Õ

Ö3Õ

BY PRESSING

ÖÕ

Ö4Õ

Õ

BY PRESSING

WHEN AT

MOVE THE CURSOR TO THE CHANGE

SIGN

ÖÖÖÖ

SELECT THE MINUS SIGN BY PRESSING

Ö5Õ

BY PRESSING

ÕÕÕÕ

ßßßß

(continued)

Ö1Õ

PRESS

Ö2Õ

PRESS

Ö3Õ

PRESS

PRESS

PRESS

Ö5

××××

OR

SELECT

××××

OR

SELECT

××××

OR

SELECT

ÕÕÕÕ

SELECT

××××

OR

SELECT

××××

OR

SELECT

ÖÖÖÖ

SELECT

ØØØØ

ØØØØ

ØØØØ

ØØØØ

ØØØØ

MOVE THE CURSOR TO

PRESSING ...............................SEE NOTE

TERMINATE THE ENTRY BY PRESSING

NOTE

AFTER THE ENTRY OF FIVE DIGITS, THE CURSOR WILL MOVE AUTOMATICALLY TO

IF LESS THAN FIVE DIGITS HAVE BEEN ENTERED, USE

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

ÖÖÖÖEÕÕÕÕ

BY

ÖÖÖÖ

SELECT

10 of 44

ÖÖÖÖ

TO MOVE THE CURSOR TO

E.

E

.

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

COMMAND 03 ZERO

COMMAND 03 ZERO

COMMAND 03 ZEROCOMMAND 03 ZERO

The Zero Command permits the calibration of the zero of most analog sensors. There are four sensors that can

be zeroed using Command 03. Each sensor is allocated a number that corresponds to the input to which it is

connected in the System.

These are as follows:

♦ Piston side pressure transducer Input Tx.0

♦ Rod side pressure transducer Input Tx.1

♦ Boom extension sensor Analog input 2

♦ Boom angle sensor Analog input 3

The swing sensor has its own routine and is calibrated using Command 05.

ZERO PRESSURE TRANSDUCERS

ZERO PRESSURE TRANSDUCERS

ZERO PRESSURE TRANSDUCERSZERO PRESSURE TRANSDUCERS

♦ Lower the boom onto its lower end stops (boom hoist cylinder fully retracted).

♦ Stop the hydraulic pump and reconnect electrical power to the System.

♦ With the boom hoist cylinder fully retracted, ensure that no pressure remains in the boom hoist cylinders by

de-pressurizing the hydraulic tank and opening the hydraulic lines to the pressure transducers.

♦ With the pressure transducers open to atmosphere, calibrate the zero of the piston and rod pressure

transducers using the sequence ON THE FOLLOWING PAGE.

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

11 of 44

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

SCROLL TO 03 ZERO BY PRESSING

START THE COMMAND BY PRESSING

××××

OR

SELECT

ØØØØ

SCROLL TO Tx.0 BY PRESSING

CONFIRM SELECTION OF THE SENSOR

BY PRESSING

THE DISPLAY WILL READ

START THE CALIBRATION OF Tx.0 BY PRESSING

CONFIRM THE CALIBRATION BY PRESSING

(or abort with

THE DISPLAY WILL READ

CHANGE SENSOR BY PRESSING

SCROLL TO Tx.1 BY PRESSING

CONFIRM SELECTION OF THE SENSOR

BY PRESSING

THE DISPLAY WILL READ

START THE CALIBRATION OF Tx.1 BY PRESSING

CONFIRM THE CALIBRATION BY PRESSING

(or abort with

THE DISPLAY WILL READ

Ö

Ö

)

)

××××

OR

ØØØØ

SELECT

Tx.0 = XXX (actual input)

SELECT

SELECT

Tx.0 = 0 (zeroed input)

ÕÕÕÕ

××××

SELECT

Tx.1 = XXX (actual input)

SELECT

SELECT

Tx.1 = 0 (zeroed input)

EXIT FROM THE ROUTINE BY PRESSING

ÖÖÖÖ

Reconnect all hydraulic lines before resuming crane operation.

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

12 of 44

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

ZERO EXTENSION SENSOR

ZERO EXTENSION SENSOR

ZERO EXTENSION SENSORZERO EXTENSION SENSOR

The Extension Sensor is fitted with 130 ft. of shielded 2-wire cable. The cable cannot be shortened to

accommodate varying boom lengths. The following method of pre-tensioning is recommended.

♦ Fully retract all the boom sections.

♦ Pre-tension the reel using the following procedure:

♦ With the boom fully retracted, remove the clamp on the reel cable and allow it to slowly rewind onto the

drum until there is no pre-tension. Continue to rewind the drum until the distance between the attachment

point and the end of the cable is approximately 12 ft. At this point, because of the clutch on the reel shaft

there will be no pre-tension. Now pull out the cable toward the attachment point and continue until the end

of the cable is 3 ft. beyond the anchor point. Secure the cable to the anchor point with at least 4 wraps,

ensuring that there is sufficient cable at the boom head to connect to the A.T.B. switch.

♦ When the boom is fully retracted, manually turn the large gear on the MicroGuard

counterclockwise. Then, advance the gear clockwise three clicks (approximately ¼ turn on the gear).

♦ Follow the sequence below to calibrate the zero of the sensor.

SCROLL TO 03 ZERO BY PRESSING

START THE COMMAND BY PRESSING

××××

OR

SELECT

ØØØØ

potentiometer fully

SCROLL TO SENSOR No. 2 BY PRESSING

CONFIRM SELECTION OF THE SENSOR

BY PRESSING

THE DISPLAY WILL READ

START THE CALIBRATION OF SENSOR No.2

BY PRESSING

TO CONFIRM THE CALIBRATION PRESS

(or abort with

THE DISPLAY WILL READ

EXIT THE ROUTINE BY PRESSING.

.

OR CHANGE SENSOR BY PRESSING

Ö

)

××××

OR

ØØØØ

SELECT

No.2 = XXX (actual input)

SELECT

SELECT

No.2 = 0 (zeroed input)

ÖÖÖÖ

ÕÕÕÕ

(Continue Next Page)

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

13 of 44

GREER COMPANY

GREER COMPANY

GREER COMPANYGREER COMPANY

Crane Systems

ZERO BOOM ANGLE SENSOR

ZERO BOOM ANGLE SENSOR

ZERO BOOM ANGLE SENSORZERO BOOM ANGLE SENSOR

NOTE

THE INCLINOMETER OR MEASURING DEVICE USED TO CALIBRATE THE ANGLE OF THE MAIN BOOM

MUST HAVE AN ACCURACY OF +/−−−− 0.25°. USE OF A LESS ACCURATE DEVICE MAY RESULT IN

CALIBRATION ERRORS.

USE GREAT CARE IN THE CALIBRATION OF THE BOOM ANGLE SENSOR. ALL SUBSEQUENT

CALCULATIONS ARE DEPENDENT ON THE ACCURACY OF THE CALIBRATION OF THIS SENSOR.

♦ Using an inclinometer, set the boom in a horizontal position.

♦ On all models the boom angle sensor is mounted inside the Extension sensor housing. Ensure that the

Extension Sensor is mounted perpendicular to the boom.

♦ Calibrate the zero of the boom angle sensor using the following sequence:

SCROLL TO 03 ZERO BY PRESSING

START THE COMMAND BY PRESSING

××××

OR

SELECT

ØØØØ

SCROLL TO SENSOR No.3 BY PRESSING

CONFIRM SELECTION OF THE SENSOR

BY PRESSING

THE DISPLAY WILL READ

START THE CALIBRATION OF SENSOR No.3

BY PRESSING

CONFIRM THE CALIBRATION BY PRESSING

(or abort with

THE DISPLAY WILL READ

EXIT FROM THE ROUTINE BY PRESSING

OR CHANGE SENSOR BY PRESSING

Ö

)

××××

OR

ØØØØ

SELECT

No.3 = XX.X (actual input)

SELECT

SELECT

No.3 = 0 (zeroed input)

ÖÖÖÖ

ÕÕÕÕ

GREER COMPANY 1918 EAST GLENWOOD PLACE SANTA ANA, CALIFORNIA 92705 TEL: 714)259-9702 FAX: 259-9702

MicroGuard 424 GENERIC Calibration Procedure for Programs M414371A & M414380C PN W424104- 11/23/99

14 of 44

Loading...

Loading...