2000PSI Pressure Washer

EPW-2000

Owner’s Manual

TOLL-FREE HELPLINE: 1-833-493-5483

www.greenworkselite.com

Read all safety rules and instructions carefully before operating this tool.

CONTENTS

Contents .............................................................................................................................. 2

Product Specications ......................................................................................................... 2

Important Safety Information ............................................................................................... 3

Symbols ............................................................................................................................... 6

Electrical .............................................................................................................................. 8

Know Your Pressure Washer ............................................................................................... 9

Assembly Instruction ......................................................................................................... 10

Operation Instruction ......................................................................................................... 16

Maintenance ...................................................................................................................... 22

Troubleshooting ................................................................................................................. 24

Limited Warranty ................................................................................................................ 25

Exploded View ................................................................................................................... 26

Parts List............................................................................................................................ 27

PRODUCT SPECIFICATIONS

HIGH PRESSURE WASHER

Model ..............................................................................................................EPW-2000

Universal Motor ..........................................................................120 V~ 60 Hz, 14 Amps

Max. Pounds Per Square Inch Pressure ........................................................... 2000 PSI

Rated Gallons Per Minute ................................................................................... 1.2 gpm

Maximum Inlet Water Temperature ..............................................................104°F (40°C)

Cleaning Units ................................................................................................ 2,400 C.U.

Weight..... ..............................................................................................30.9 lbs. ( 14 kg)

1

YEAR/ANS/AN

CHARGER WARRANTY

GARANTIE DE

INSTRUMENT

GARANTIE DU

CHARGEUR

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Read and understand all instructions. Failure to follow all instructions listed below may

result in electric shock, re, and/or serious personal injury.

WARNING

When using this product, basic precautions should always be followed.

READ ALL INSTRUCTIONS BEFORE USING THIS PRODUCT

• To reduce the risk of injury, close supervision is necessary when a product is used near

children.

• Be thoroughly familiar with controls. Know how to stop the product and release pressure

quickly.

• Stay alert and exercise control. Watch what you are doing and use common sense. Do not

operate the product when you are tired. Do not rush.

• Do not operate the product while under the inuence of drugs, alcohol, or any medication.

• Keep the area of operation clear of all people, particularly small children, and pets.

• Don’t overreach or stand on unstable support. Keep proper footing and balance at all times.

• Follow the maintenance instructions specied in this manual.

WARNING

Risk of injection or injury – Do not direct discharge stream at people or animals.

EXTENSION CORDS

• When using a power tool at a considerable distance from a power source, be sure to use

an extension cord that has the capacity to handle the current the product will draw. An

undersized cord will cause a drop in line voltage, possibly resulting in

of power, and/or damage to circuit breaker.

wire size required in an extension cord. Only round jacketed cords listed by Underwriter’s

Laboratories (UL) should be used. When working outdoors with a product, use an extension

cord that is designed for outside use. This type of cord is designated with “WA” or “W” on

the cord’s jacket. Before using any extension cord, inspect it for loose or exposed wires and

cut or worn insulation. It is possible to tie the extension cord and power cord in a knot to

prevent them from becoming disconnected during use. Make a knot, then connect the plug

end of the power cord into the receptacle end of the extension cord. This method can also

be used to tie two extension cords together.

Use the chart to determine the minimum

overheating, loss

WARNING

To reduce the risk of electrocution, keep all connections dry and off the ground. Do not touch

plug with wet hands.

WARNING

Check extension cords before each use. If damaged, replace immediately. Never use the product

with a damaged cord since touching the damaged area could cause electrical shock, resulting in

serious injury.

WARNING

Keep the extension cord clear of the working area. Position the cord so that it will not get caught

on lumber, tools, or other obstructions while you are working with a power tool. Failure to do so

can result in serious personal injury.

3

IMPORTANT SAFETY INSTRUCTIONS

• Know your product. Read the operator’s manual carefully. Learn the machine’s applications

and limitations, as well as the specic potential hazards related to this product.

• To reduce the risk of injury, keep children and visitors away. All visitors should wear safety

glasses and be kept a safe distance from the work area.

• Use the right product for the job. Don’t force the product or the attachments to do a job it was

not designed for. Don’t use it for a purpose not intended.

• Dress properly. Do not wear loose clothing, gloves, neckties, or jewelry. They can get caught

and draw you into moving parts. Rubber gloves and nonskid footwear are recommended

when working outdoors. Also wear protective hair covering to contain long hair.

• Do not operate the equipment while barefoot or when wearing sandals or similar lightweight

footwear. Wear protective footwear that will protect your feet and improve your footing on

slippery surfaces.

• Exercise caution to avoid slipping or falling.

• Always wear eye protection with side shields marked to comply with ANSI Z87.1. Following

this rule will reduce the risk of serious personal injury.

• Use only recommended accessories. The use of improper accessories may cause risk of

injury.

• Check damaged parts. Before further use of the product, all parts should be carefully checked

to determine that they will operate properly and perform their intended function. Check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other part that is damaged must be

properly repaired or replaced by an authorized service center to avoid risk of personal injury.

• Never leave product running unattended. Turn power off. Do not leave the product until it

comes to a complete stop.

• Keep the motor free of grass, leaves, or grease to reduce the chance of a re hazard.

• Follow manufacturer’s recommendations for safe loading, unloading, transport, and storage of

machine.

• Keep product dry, clean, and free from oil and grease. Always use a clean cloth when

cleaning. Never use brake fluids, gasoline, petroleum-based products, or any solvents to

clean product.

• Check the work area before each use. Remove all objects such as rocks, broken glass, nails,

wire, or string which can be thrown by the machine.

• Do not use product if switch does not turn it off. Have defective switches replaced by an

authorized service center.

• Avoid dangerous environment. Don’t expose to rain. Keep work area well lit.

• Do not abuse the cord. Never use the cord to carry the product or to disconnect the plug from

an outlet. Keep cord away from heat, oil, sharp edges, or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of electric shock.

• Never direct a water stream toward people or pets, or any electrical device.

• Before starting any cleaning operation, close doors and windows. Clear the area to be

cleaned of debris, toys, outdoor furniture, or other objects that could create a hazard.

• Do not use acids, alkalines, solvents, flammable material, bleaches, or industrial grade

solutions in this product. These products can cause physical injuries to the operator and

4

IMPORTANT SAFETY INSTRUCTIONS

irreversible damage to the machine.

WARNING

High pressure jets can be dangerous if subject to misuse.

people, animals, electrical devices, or the machine itself.

• Keep the motor away from ammables and other hazardous materials.

• Check bolts and nuts xing the pressure washer shell for looseness before each use. A loose

bolt or nut may cause serious motor problems.

• Before storing, allow the motor to cool.

• When servicing use only identical replacement parts. Use of any other parts may create a

hazard or cause product damage.

• ONLY use cold water.

• Make sure minimum clearance of 3 feet is maintained from combustible materials.

• Connect pressure washer only to an individual branch circuit.

• Hold the handle and wand securely with both hands. Expect the trigger handle to move when

the trigger is pulled due to reaction forces. Failure to do so could cause loss of control and

injury to yourself and others.

• Save these instructions. Refer to them frequently and use them to instruct other users. If you

loan someone this product, loan them these instructions also.

WARNING(PROPOSITION 65)

Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to the state of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry products,

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies depending on how often you do this type of work. To

reduce your exposure to these chemical: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to lter out microscopic

particles.

The jet must not be directed at

5

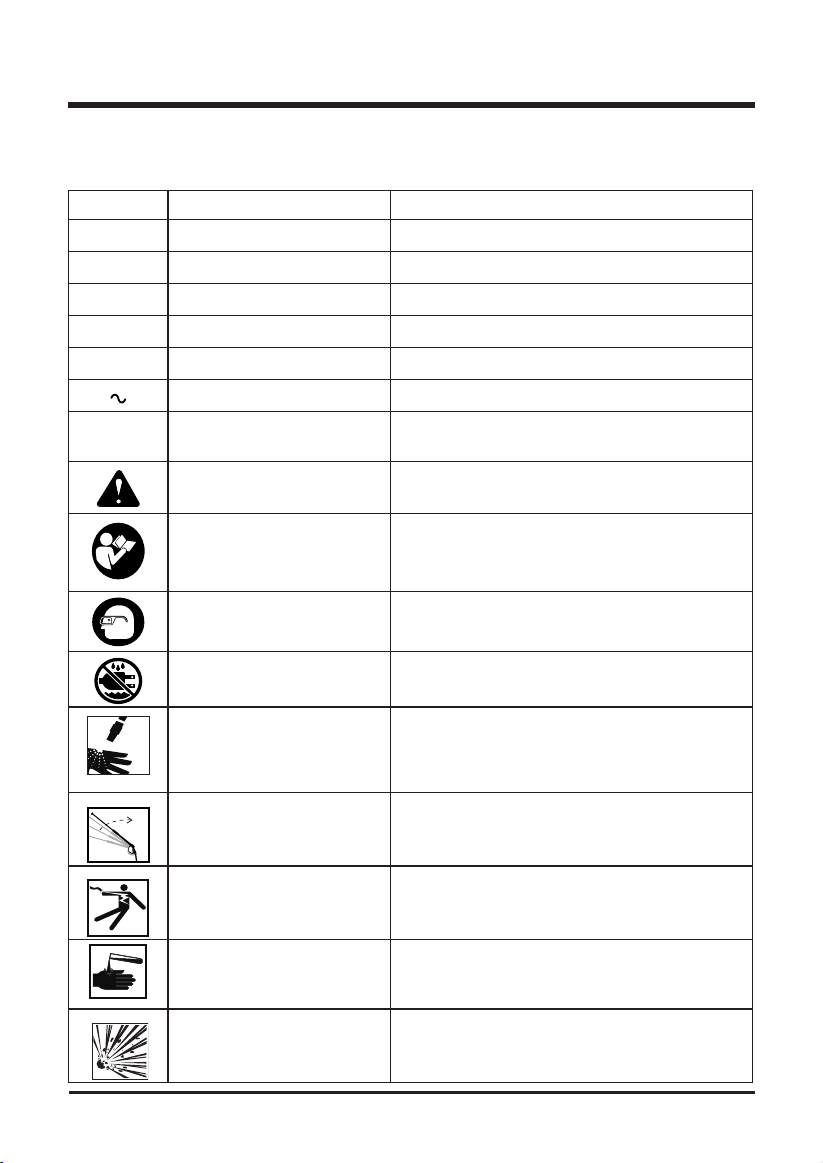

SYMBOLS

Some of the following symbols may be used on this product. Please study them and learn their

meaning. Proper interpretation of these symbols will allow you to operate the product better and

safer.

SYMBOLS DESIGNATION EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watts Power

no No Load Speed Rational speed, at no load

Alternating Current Type of current

/min Per Minute

Safety Alert Indicates a potential personal injury hazard.

Revolutions, strokes, surface speed, orbits, etc.,

per minute

Read The Operator’s Manual

Eye Protection

Wet Conditions Alert

Risk of Injection

Kickback

Electric Shock

Chemical Burns

Risk of Explosion

To reduce the risk of injury, user must read and

understand operator’s manual before using this

product.

Always wear eye protection with side shields

marked to comply with ANSI Z87.1.

Do not expose to rain or use in damp locations.

To reduce the risk of injection or injury, never

direct a water system toward people or pets or

place any body part in the stream. Leaking hoses

and ttings are also capable of causing injection

injury. Do not hold hoses or ttings.

To reduce the risk of injury from kickback, hold the

spray wand securely with both hands when the

machine is on.

Failure to use in dry conditions and to observe

safe practices can result in electric shock.

To reduce the risk of injury or damage, DO

NOT USE ACIDS, ALKALINES, BLEACHES,

SOLVENTS, FLAMMABLE MATERIAL, OR

INDUSTRIAL GRADE SOLUTIONS in this product.

Do not spray ammable liquids. Flammable liquids,

fuel, and their vapors are explosive and can cause

severe burns or death.

6

6

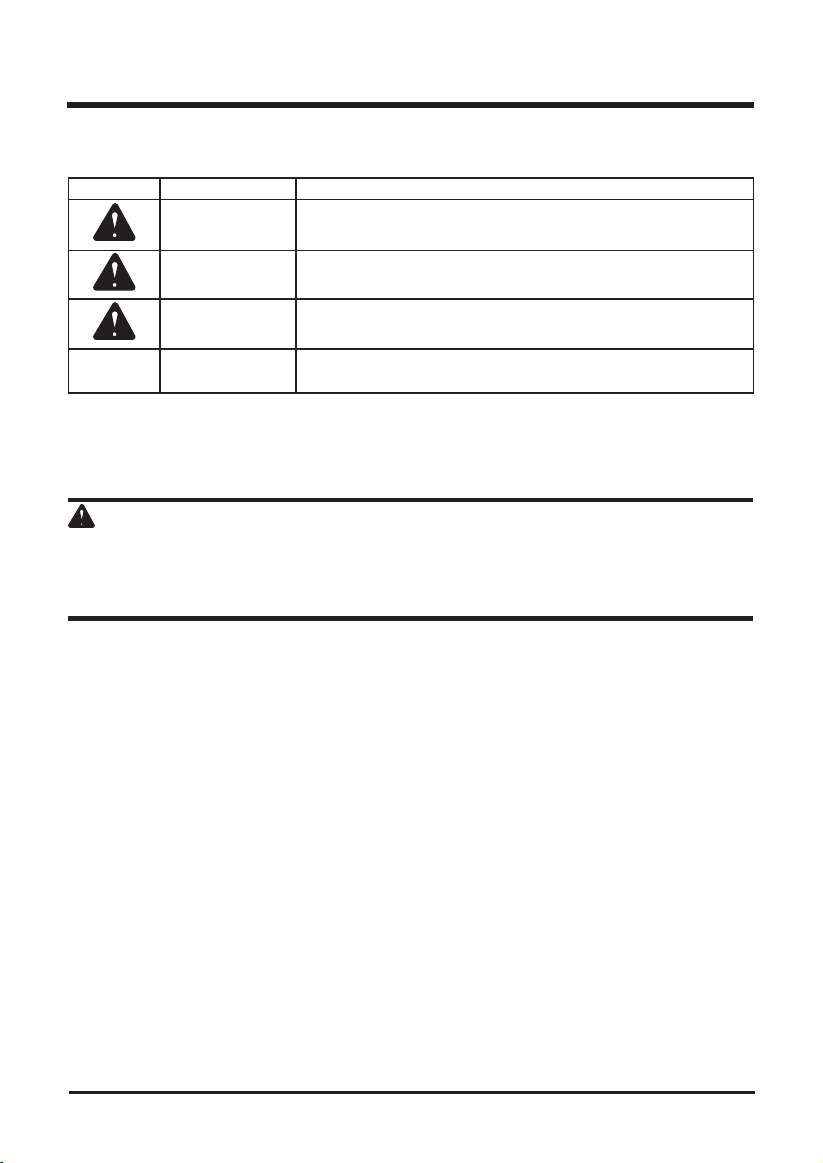

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated

with this product.

SYMBOL SIGNAL MEANING

DANGER

WARNING

CAUTION

CAUTION

SERVICE

Servicing requires extreme care and knowledge and should be performed only by a qualied

service technician. For service we suggest you return the product to your nearest

SERVICE CENTER

for repair. When servicing, use only identical replacement parts.

WARNING

To avoid serious personal injury, do not attempt to use this product until you have read this Owner’s

Manual thoroughly and understand it completely. If you do not understand the warnings and

instructions in this Owner’s Manual, do not use this product. Call the Toll-free Helpline (1-833-493-

5483) for assistance.

Indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may

result in property damage.

AUTHORIZED

SAVE THESE INSTRUCTIONS

7

ELECTRICAL

ELECTRICAL CONNECTION

This product has a precision-built electric motor. It should be connected to a power supply that

is 120 volts, 60 Hz, AC only (normal household current). Do not operate this product on direct

current (DC). A substantial voltage drop will cause a loss of power and the motor will overheat.

DRIP LOOP

To prevent water from owing along the power cable, and possibly reaching the electrical outlet

and plug, we recommend using a simple drip loop as shown below.

Power cord

Drip Loop

Fig. 1

WARNING

Keep the extension cord clear of the working area. Position the cord so that it will not get caught on

lumber, tools, or other obstructions while you are working with a power tool. Failure to do so can

result in serious personal injury.

8

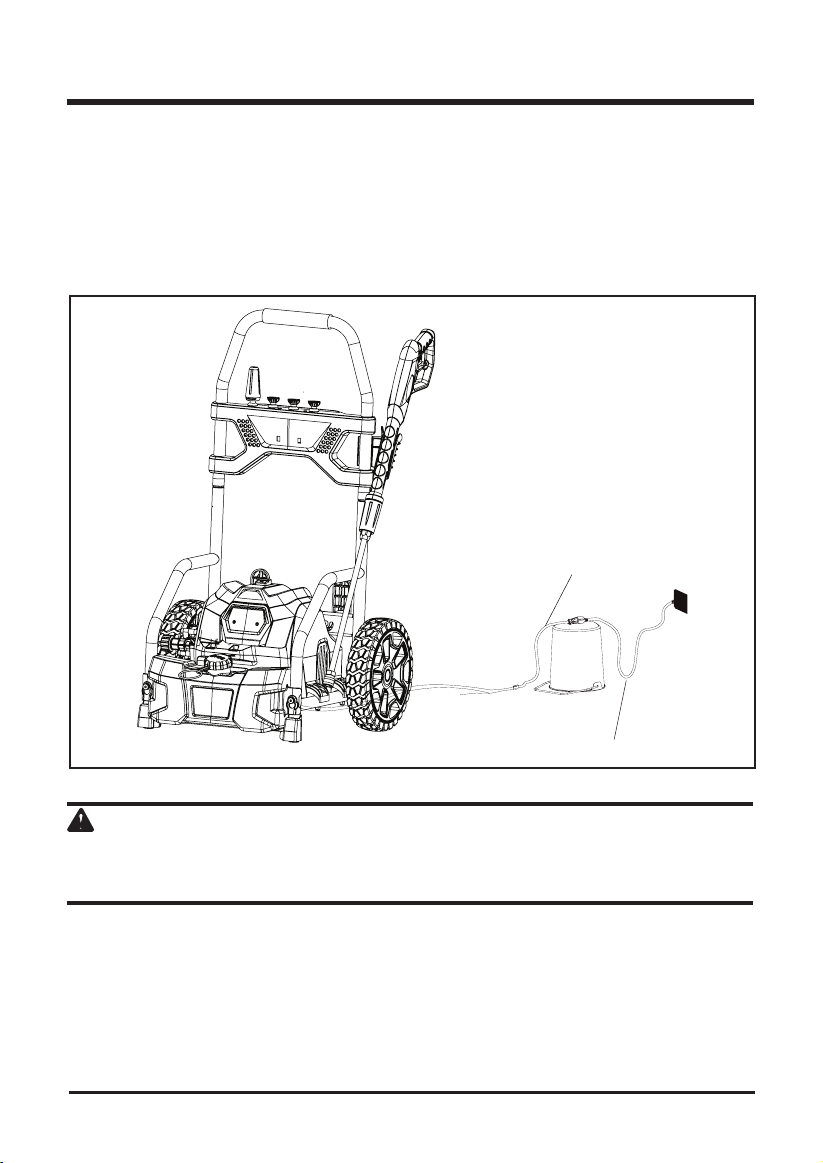

KNOW YOUR PRESSURE WASHER

The safe use of this product requires an understanding of the information on the tool and in this

operator’s manual as well as a knowledge of the project you are attempting. Before use of this

product, familiarize yourself with all operating features and safety rules.(See Figure 2.)

Tip Storage

Trigger and

wand assembl

ON/OFF Switch

Detergent

Tank

Power Cord

Storage

Fig. 2

DETERGENT TANK

Remove the cap from the detergent tank to add detergent to the pressure washer.

GFCI PLUG

The pressure washer power cord is equipped with a GFCI plug to guard against the hazards of

ground fault currents. This plug does not protect against short circuits, overloads, or shocks.

AUTO ON/OFF SWITCH:

This pressure washer is equipped with an Auto Start/Stop feature. To operate: Set power switch

to the On (I) position. Pump will pressurize and shut down immediately. Once the trigger of the

gun is depressed the unit will turn on. Unit will shut off and be in standby mode when trigger is

released.

POWER CORD STORAGE

The power cord can be wrapped and stored around the hook.

TRIGGER AND WAND ASSEMBLY

The Trigger and Wand allows you to operate the pressure washer by depressing the trigger to

activate the pump to spray water using the desired spray tip.

9

ASSEMBLY INSTRUCTIONS

www.GreenWorksTools.com

Rev:02

Connect garden hose to pressure

Once the trigger of the gun is depressed the unit will turn on.

Unit will shut off and be in standby mode when trigger is

released.

This Quick Start Guide is not a substitute for reading the operator's manual. To reduce the risk

of injury or death, user must read and understand operator's manual before using this product.

WARNING:

Set-up

Installing the wheels

Insert the axle through the wheel.

1

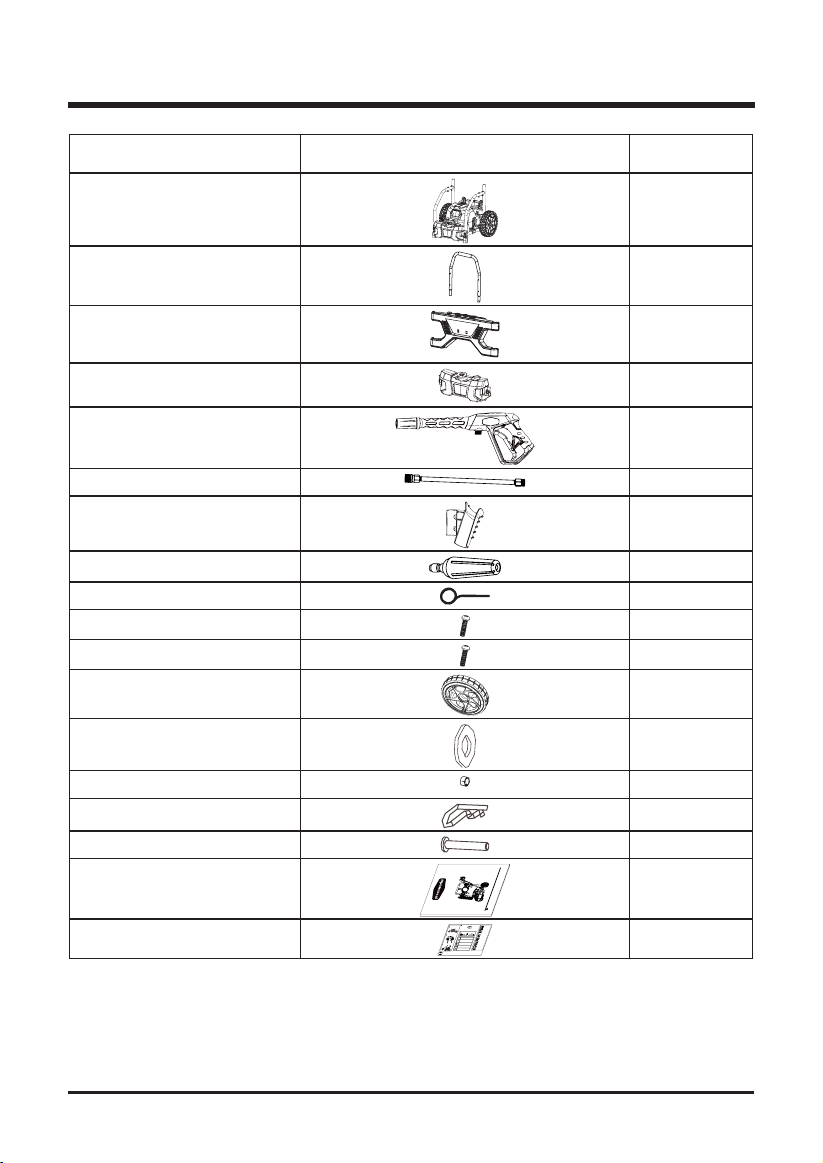

PART NAME FIGURE PART NO.

Pressure Washer 1

Upper Handle

Spray tip panel assy(spray tip

included) 1

Soap tank 1

Trigger Assembly 1

Spray Wand 1

Gun Holder 1

Turbo Nozzle 1

Spray Tip Cleaning Tool 1

Screw 2

Screw 4

Wheels 2

Washer 2

Axle sleeve 2

Pin 2

Axle 2

.

l

o

o

t

)

s

i

7

h

5

t

7

g

6

.

n

i

9

t

0

a

r

9

.

e

8

R

p

8

o

E

8

(

e

r

S

o

f

SH

e

K

L

b

A

R

m

A

y

M

l

o

l

O

W

c

u

P

.

f

s

e

E

l

r

o

ANU

a

R

o

c

t

1 G

00

M

.

s

U

s

8

k

1

n

S

r

o

o

/

i

t

R’

SS

w

c

n

W 1

u

O

E

r

SI

e

t

T

P

e

R

s

r

A

n

P

g

i

P

G

R

d

Operator’s Manual

Quick Start Guide

w.

n

w

IC

a

800

w

s

1

R

OPE

e

l

T

u

r

C

y

t

E

e

f

L

a

s

E

l

l

a

d

LL-FREE HELPLINE: 1-888-90W

a

e

O

R

T

Slide the washer over the axle pass the pin hole.

washer water intake.

Insert the axle and wheel through the frame. Slide the washer

over the axle and insert the pin through the hole to firmly fasten

the wheel assembly.

2

Assemble pressure washer gun to spray wand.

1800 PSI / 1.1 GPM

Wheel

ELECTRIC PRESSURE WASHER

GPW 1800

USING DETERGENT

3

Connect desired pressure tip.

Put pressure washer detergent in detergent tank.

25

Axle

WasherPin

Install blue or black soap nozzle.

Squeeze trigger and wait approx.1 minute for soap.

Installing the gun holder

5

2

Line up the screw sleeves with the holes in the upper handle

and push through.

4

Insert the screw and turn clockwise with a Phillips head

Insert high pressure hose into trigger

screwdriver (not included) until the screw is tight.

handle.

SPRAY TIPSPRAY TIP APPLICATION

Red - Stream tip (0° )

5

Connect the high pressure hose to the

The red 0 degree tip provides a straight line of spray. It provides the highest

O

water outlet connector.

0

amount of pressure. It is best used for removing hard, stuck-on grime or dirt.

Green - Narrow fan tip (25° )

The green pressure washer tip provides high versatility with its 25 degree angle tip.

Referred to as the washing tip, because it provides adequate pressure to remove

O

dirt from surfaces, but is designed to not damage many surfaces. This pressure

6

Turn on water at outlet.

25

washer tip is designed for “sweeping” foliage or debris given its wide angle. This tip

is versatile due to its wide area of cleaning and strong pressure application.

White - Wide fan tip (40° )

Installing the upper handle

The white 40 degree tip, referred to as the “fan” tip creates the widest area of

7

Run water hose for 30 seconds with the

cleaning with relatively low pressure. This pressure washer tip is best used for light

Push and hold the push-pin buttons on the sides of the upper

O

motor in OFF position. This helps drain air

or delicate cleaning applications. It is recommended for light cleaning on wood

handle assembly (1) as you slide the handle onto the frame (2).

40

from the tank and lines.

decks and other soft or delicate surfaces.

S

30

(1)

Black - Soap spray tip

8

Connect power cord to wall outlet

The black soap spray tip, is used for soap application. Soap is applied under low

Extension cord not recommended.

pressure high volume for optimum performance. Soap cannot be applied under

Push-pin

(2)

SOAP

high pressure with this machine.

9

Turbo Nozzle Tip

Turn on Pressure Washer

The nozzle rotates in a zero to 15 degree spray pattern in a circular motion to

IMPORTANT: Ensure water outlet is On

break down tough dirt and grime. The spray pattern can cover area of 4 to 8 inches

before turning power On to avoid damage

wide, depending on a distance between the tip and the surface being cleaned.

to the pump.

NOTE:

AUTO ON/OFF SWITCH: This Pressure washer is equipped

Missing parts, accessories or need a service center?

with an Auto Start/Stop feature.

Do Not Return to Store

To operate: Turn the power switch to the On (I) position.

Call : 1-888-909-6757

Pump will pressurize and shut down immediately.

1

1

1

10

ASSEMBLY INSTRUCTIONS

UNPACKING

This product requires assembly.

• Carefully remove the product and any accessories from the box. Make sure that all the

contents from the packaging list are included.

• Inspect the product carefully to make sure no breakage or damage occurred during shipping.

• Do not discard the packing material until you have carefully inspected and satisfactorily

operated the product.

• If any parts are damaged or missing, please call 1-833-493-5483 for assistance.

WARNING

Do not use this product if any parts on the Packing List are already assembled to your product

when you unpack it. Parts on this list are not assembled to the product by the manufacturer and

require customer installation. Use of a product that may have been improperly assembled could

result in serious personal injury.

WARNING

If any parts are damaged or missing do not operate this product until the parts are replaced. Use

of this product with damaged or missing parts could result in serious personal injury.

WARNING

Do not connect to power supply until assembly is complete. Failure to comply could result in

accidental starting and possible serious personal injury.

WARNING

Do not attempt to modify this product or create accessories not recommended for use with this

product. Any such alteration or modication is misuse and could result in a harzardous condition

leading to possible serious personal injury.

11

ASSEMBLY INSTRUCTIONS

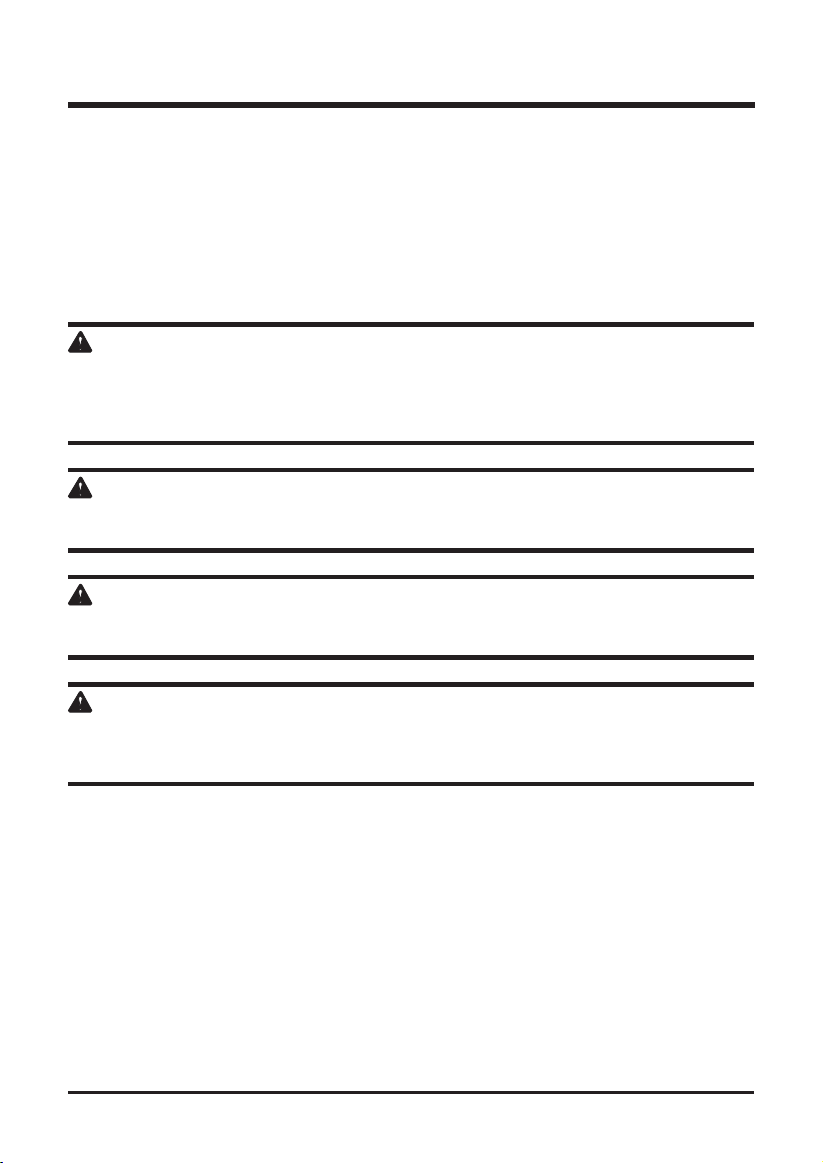

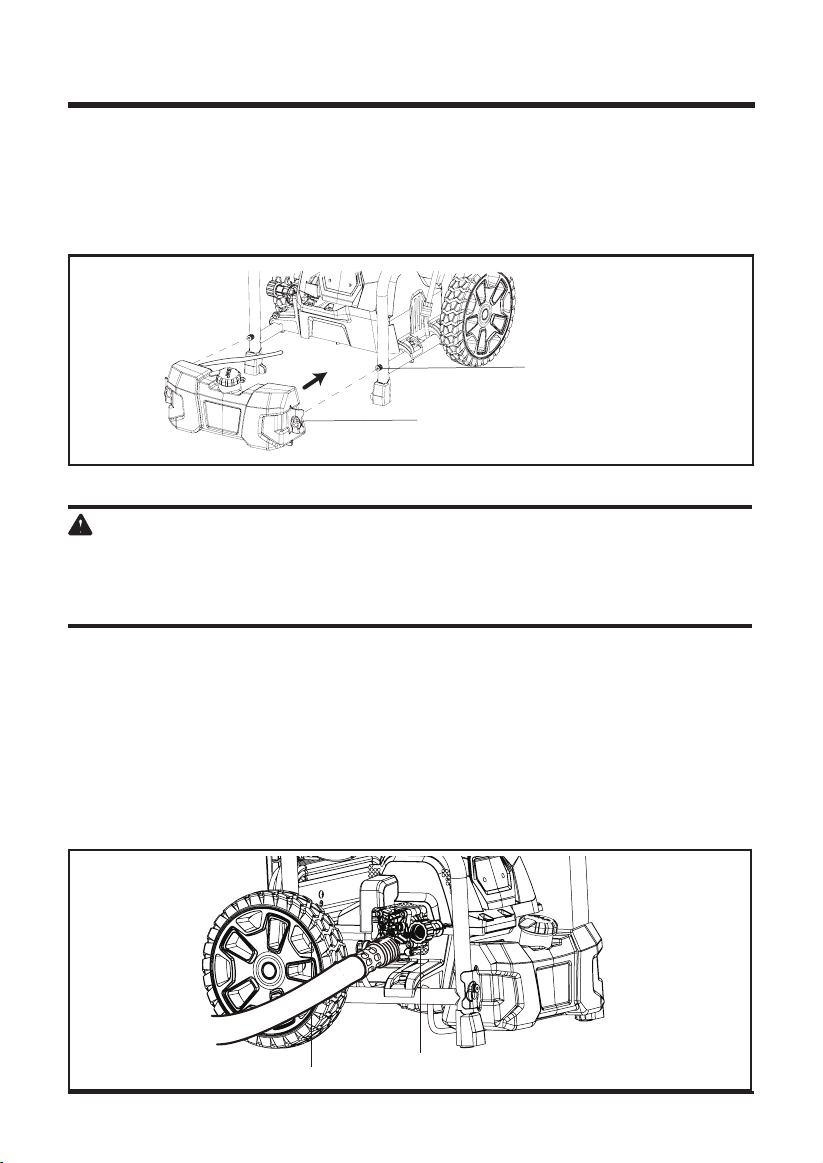

ASSEMBLING THE WHEELS

• Insert an axle (A) through a wheel (I), the axle sleeve (M), the frame of the unit and then a

washer (J).

• Insert a cotter pin (K) through the hole in the axle to secure. Repeat for second wheel.

A

See Figure 3.

A

K

J

M

I

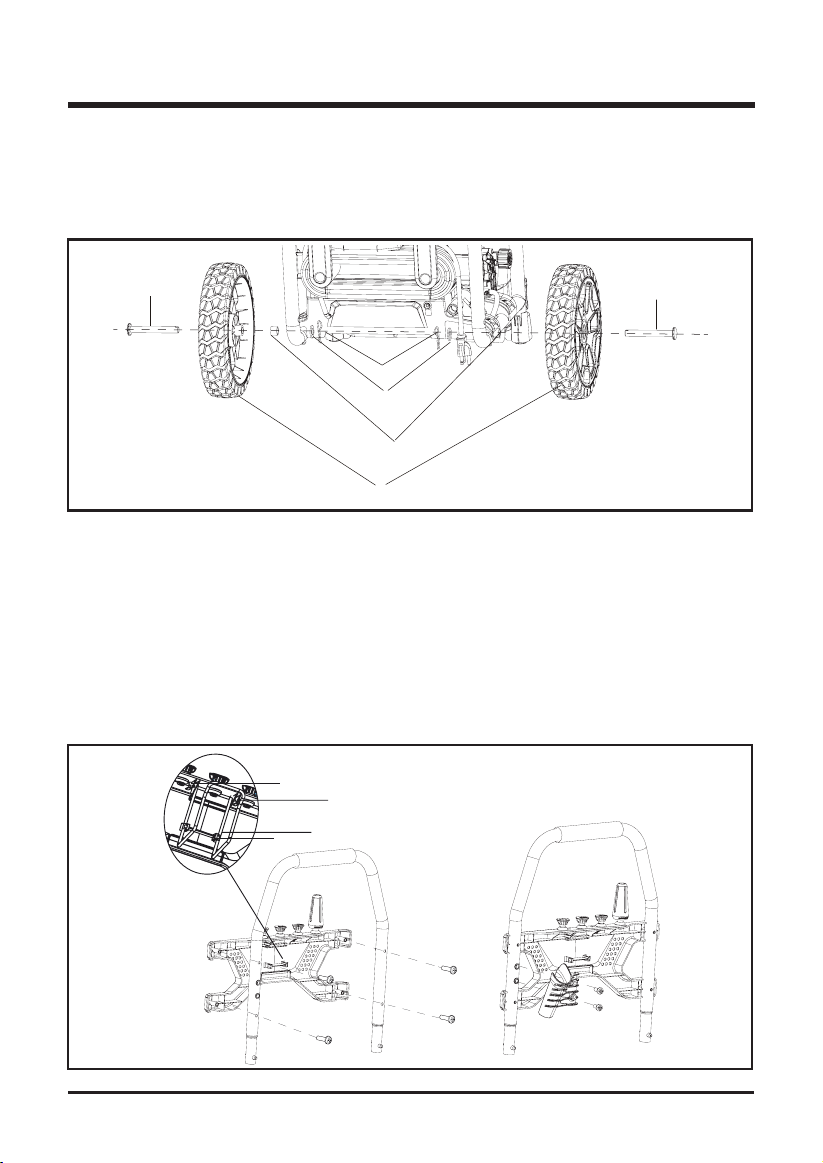

ASSEMBLING THE FRONT PANEL AND GUN HOLDER

• Line up the screw sleeves with the holes in the upper handle and push through.

• Insert the screw and turn clockwise with a phillips head screw driver (not included) until the

screw is tight.

ASSEMBLING THE HOSE HOOK

• Line up the hose hook upper end with the holes on the back of the front panel

• Insert the hose hook end into the hole and push through.

• Press the hose hook lower end into the clip on the back of the front panel.

See Figure 4.

See Figure 4.

Fig. 3

upper end

clip

hole

lower end

Fig. 4

12

ASSEMBLY INSTRUCTIONS

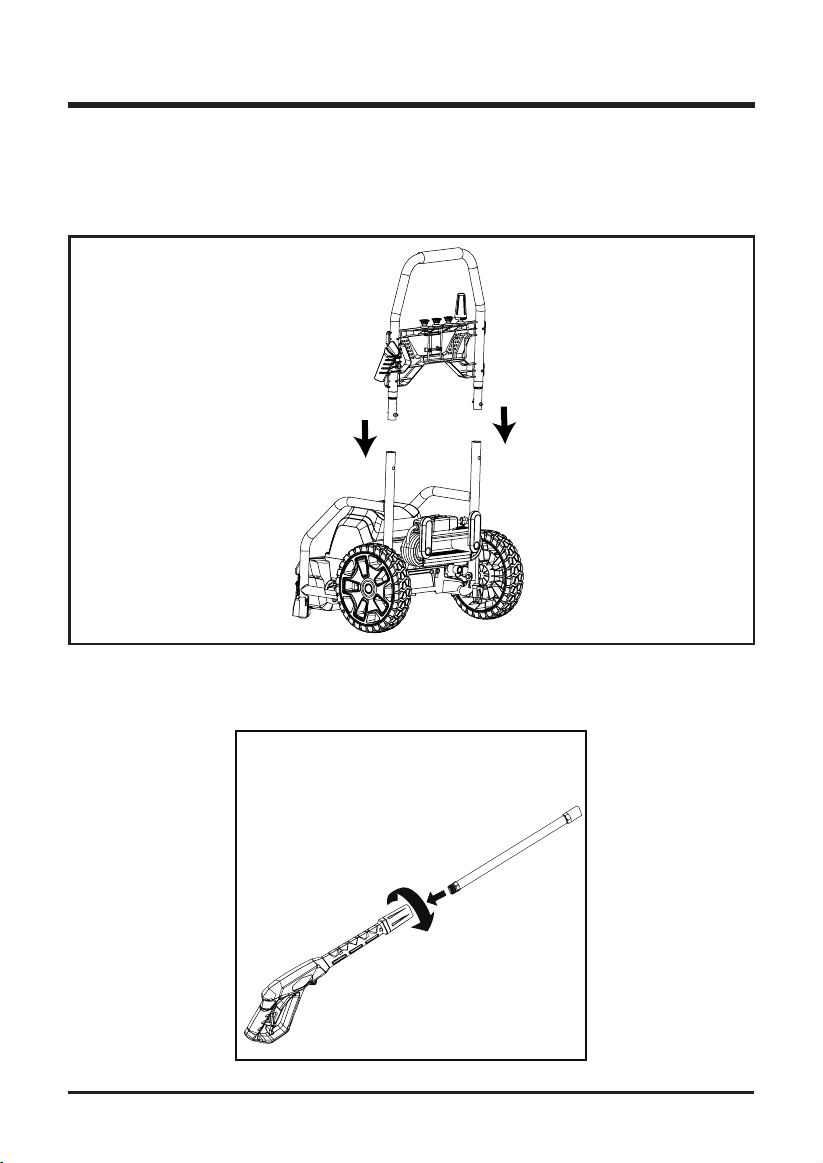

See Figure 5.

INSTALLING THE HANDLE

• Push and hold the button on the handle as you slide the handle into the holes in the frame.

NOTE:

Before use, pull the handle up until the lock button snaps through the locking slot to

secure the handle in place.

ASSEMBLING THE SPRAY WAND

• Push the end of the spray wand into the trigger handle and rotate clockwise to secure.

• Pull on the spray wand to be certain it is properly secured.

Fig. 5

See Figure 6.

13

Fig. 6

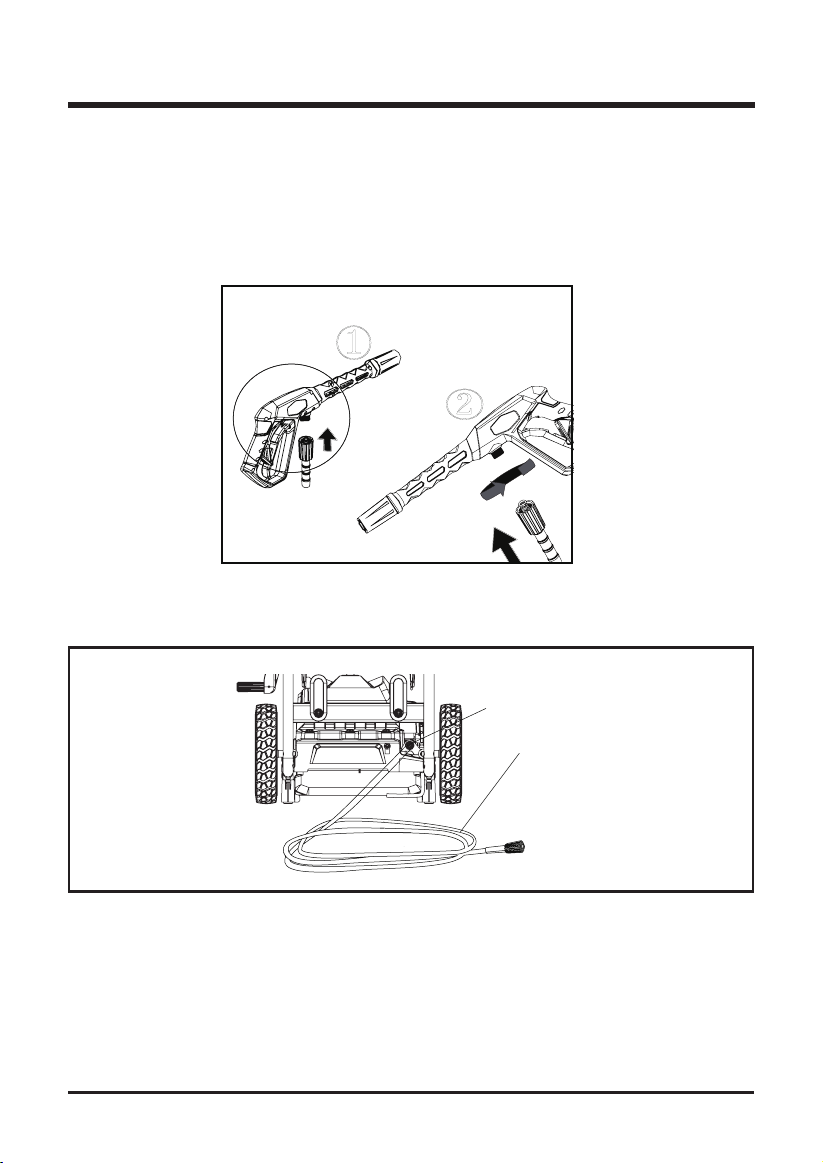

ASSEMBLY INSTRUCTIONS

See Figure 7.

CONNECTING HIGH PRESSURE HOSE TO TRIGGER HANDLE

• Align the pressure hose with the trigger handle and push up and into position.

• With hose pushed into position on the trigger handle, secure in place by turning the hose lock

clockwise until fully tightened.

NOTE:

For easier installation of the hose to the unit or trigger, it is suggested to add pressure

washer or dish detergent to the rubber seal at each end of the hose. This will allow for easier

installation and a snug t.

①

②

Fig. 7

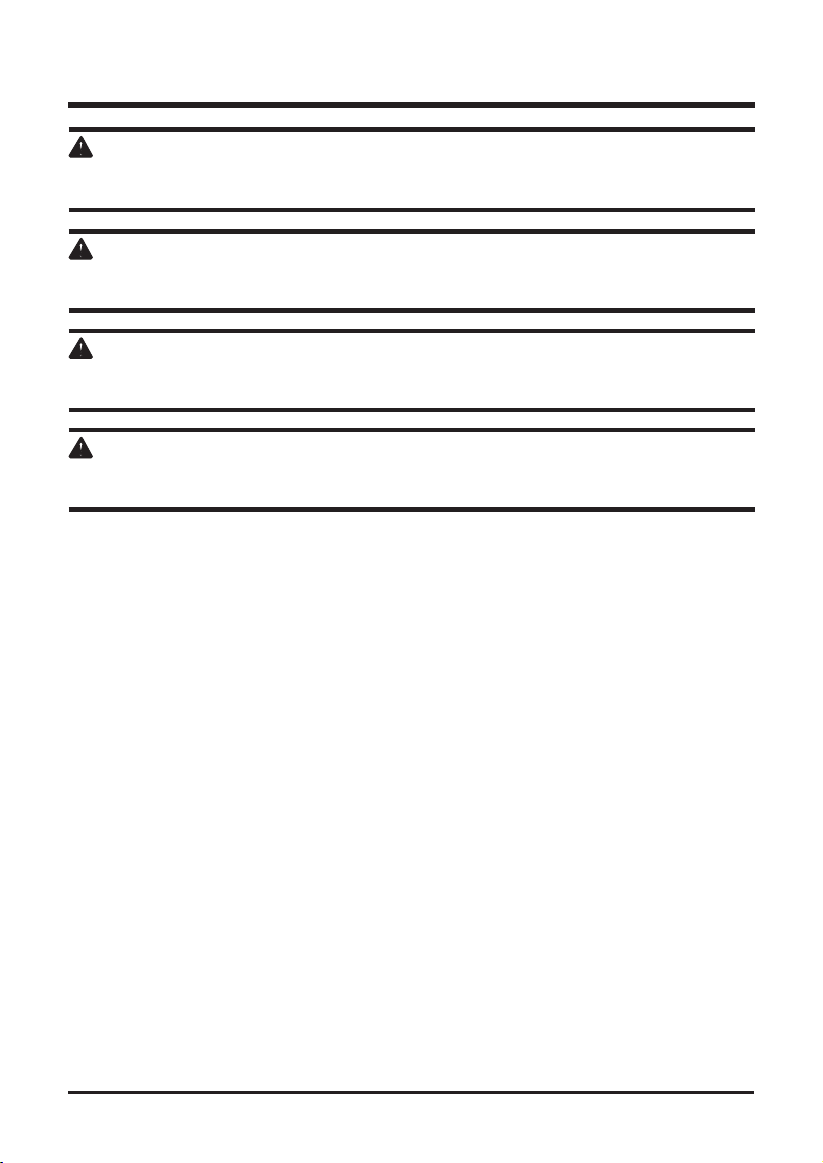

CONNECTING HIGH PRESSURE HOSE TO PRESSURE WASHER

• Connect one end of the hose to the water outlet connector and the other end to the trigger

gun.

See Figure 8.

14

Outlet

Connector

High pressure

L

hose

Fig. 8

ASSEMBLY INSTRUCTIONS

See Figure 9.

ATTACHING THE SOAP TANK

• Align the keyhole slots with the mounting posts.

• Slide onto mounting posts and push down to hold in place.

• Route the detergent injection hose under the unit and onto the detergent injection hose tting

on the back of the pump as shown.

Mounting post

CONNECTING THE GARDEN HOSE

Key hole

See Figure 10.

Fig. 9

CAUTION

Always observe all local regulations when connecting hoses to the water main. Some areas have

restrictions against connecting directly to public drinking water supply to prevent the feedback of

chemicals into the drinking water supply. Direct connection through a receiver tank or back ow

preventer is usually permitted.

• Uncoil the garden hose.

NOTE:

There must be a minimum of 10 feet of unrestricted garden hose between the water

intake and the garden hose faucet or shut off valve (such as a “ Y” shut off connector).

• Run water through the hose (A) for 30 seconds to clean any debris from the hose.

• Inspect the screen in the water intake (B).

• If the screen is damaged, do not use the machine until the screen has been replaced.

• If the screen is dirty, clean it before connecting the garden hose to the machine.

• With the hose faucet turned completely off, attach the end of the garden hose to the water

intake. Tighten by hand only.

A

B

Fig. 10

15

OPERATION INSTRUCTION

WARNING

Do not allow familiarity with tools to make you careless. Remember that a careless fraction of a

second is sufcient to inict serious injury.

WARNING

Always wear eye protection with side shields marked to comply with ANSI Z87.1. Failure to do so

could result in objects being thrown into your eyes resulting in possible serious injury.

WARNING

Do not use any attachments or accessories not recommended by the manufacturer of this tool.

The use of attachments or accessories not recommended can result in serious personal injury.

WARNING

Never direct a water stream toward people or pets, or any electrical device. Failure to heed this

warning could result in serious injury.

APPLICATIONS

You may use this product for the purposes listed below:

• Cleaning boats, cars, trucks, motorcycles, outdoor furniture, grills, house siding, driveways,

patios and decks.

DETERGENT ADDING AND USE

Use only detergents designed for pressure washers; household detergents, acids, alkalines,

bleaches, solvents, ammable material, or industrial grade solution can damage the pump. Many

detergents may require mixing prior to use. Prepare cleaning solution as instructed on the solution

bottle.

SOAP APPLICATION

Soap is applied under low pressure high volume for optimum performance.

Soap can not be applied under high pressure with this machine.

Soap/detergent can only be applied with this machine when the black (75 degree) soap tip is

installed.

To add detergent:

• Place pressure washer upright on a at surface.

• Remove cap from detergent tank.

• Pour detergent into tank.

• Reinstall cap.

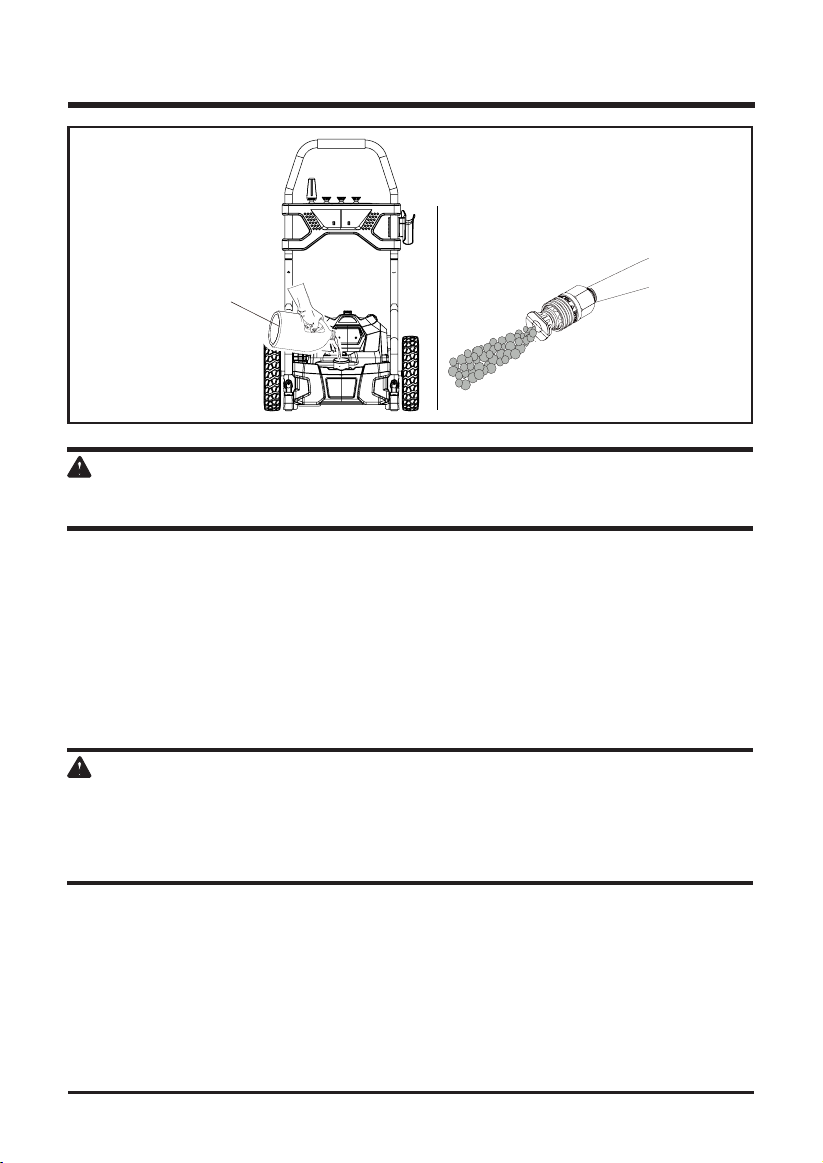

See Figure 11.

16

OPERATION INSTRUCTION

Use Black Soap Tip Only

Detergent

Fig. 11

CAUTION

Use only approved pressure washer cleaners. Do not use bleach, chlorine,or any cleaners

containing acids.

To use:

• Connect low pressure black soap spray tip to the wand connector.

• Squeeze the trigger and the detergent will automatically be mixed with the water and dispensed

from the spray tip.

NOTE:

Use a funnel, if needed, to prevent accidental spilling of the detergent outside the tank.

If any detergent is spilled during the lling process, make sure the unit is cleaned and dried

before proceeding.

STARTING AND STOPPING THE PRESSURE WASHER

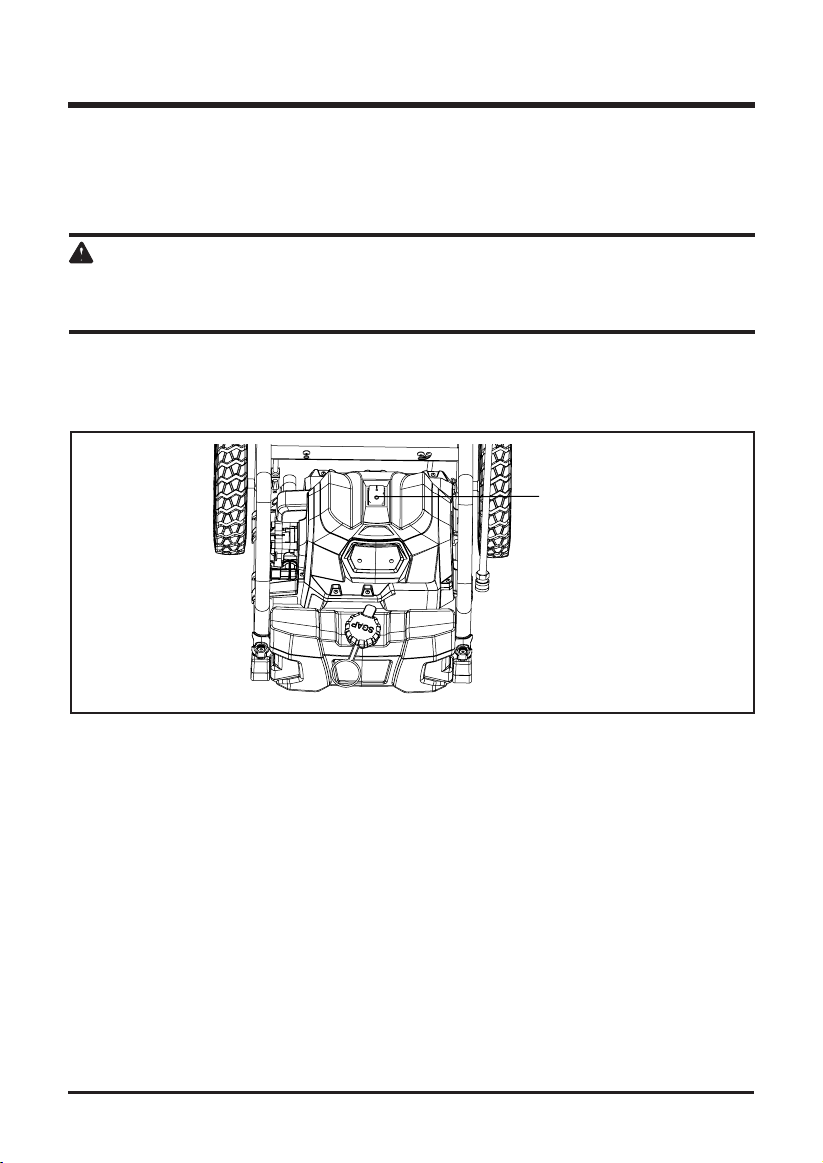

See Figure 12.

CAUTION

Do not run the pump without the water supply connected and turned on.

• Connect the garden hose.

• Turn the water supply on, then squeeze the trigger and run water hose with motor in OFF

position until a steady stream of water appears. This helps drain air from tank and lines.

NOTE:

If the pressure washer pulsates and the water stream is intermittent turn the pressure

washer off and continue to bleed air out of the system. Ensure to check that the garden hose is

fully turned on and not kinked.

• After ensuring the On/Off switch is in the OFF ( O ) position, connect the pressure washer

to the power supply.

• Press the reset button on the pressure washer’s plug to make sure the unit is ready for

operation.

17

OPERATION INSTRUCTION

• Press the switch to ON ( I ) position to start the motor.

• To stop the motor, release the trigger and press the switch to OFF( O ) position.

NOTE:

The pressure washer may be on and the system may have pressure even when the

pump and/or motor cannot be heard running. Always use caution around the pressure washer.

CAUTION

Hold the trigger handle securely with both hands. Expect the trigger handle to move when the

trigger is pulled due to reaction forces. Failure to do so could cause loss of control and injury to

yourself and others.

NOTE:

AUTO ON/OFF SWITCH: This pressure washer is equipped with an auto start /stop

feature. To operate: Set the power switch to the On (I) position. Pump will pressurize and shut

down immediately. Once the trigger of the gun is depressed, the unit will turn on. Unit will shut

off and be in standby mode when trigger is released.

ON/OFF Switch

Fig. 12

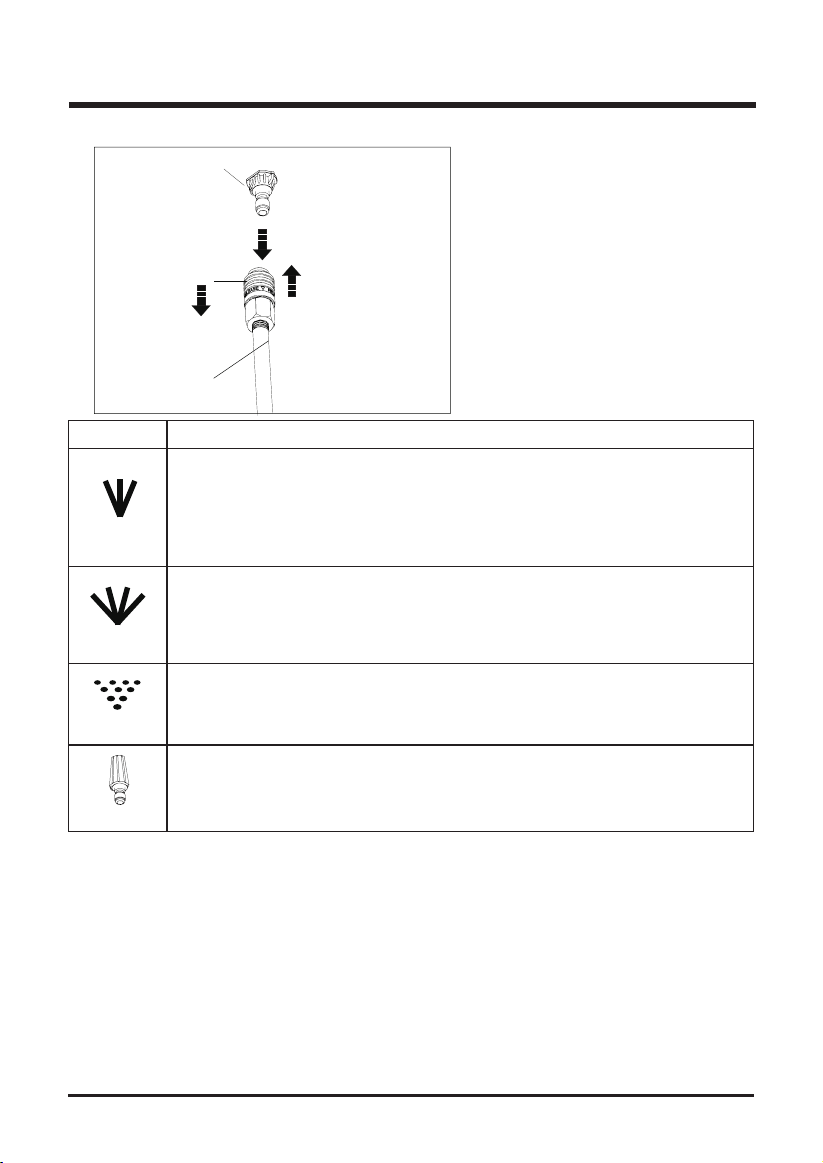

USING THE SPRAY TIPS (See Figure 13)

Each of the spray tips has a different spray pattern. Before starting any cleaning job, determine

the best spray tip for the job. The following chart offers some general guidelines to help you

choose the best spray tip for your application.

NOTE: Always try spray tip in an inconspicuous area rst.

• Turn off the pressure washer and shut off the water supply. Pull trigger to release water

pressure.

• Engage the lock-out on the trigger handle by pushing the trigger lock button to the right.

• Pull out the desired spray tip from the tip storage on the handle.

• Pull back the quick-connect collar on the spray wand.

• Push the spray tip into place in the spray wand.

• Push the collar forward so that the spray tip is secured properly. Check to see that the spray tip

is secure.

NOTE: Make sure the faucet is turned on fully and that there are no kinks or leaks in the hose.

18

OPERATION INSTRUCTION

r

Spray Tip

1

SPRAY TIP

O

25

O

40

SOAP

TURBO

2

3

Spray Wand

Green - Narrow fan tip (25° )

■ The green pressure washer tip provides high versatility with its 25

degree angle tip. Referred to as the washing tip, because it provides

adequate pressure to remove dirt from surfaces, but is designed to

not damage many surfaces. This pressure washer tip is designed for

“sweeping” foliage or debris given its wide angle. This tip is versatile

due to its wide area of cleaning and strong pressure application.

White - Wide fan tip (40° )

■ The white 40 degree tip, referred to as the “fan” tip creates the widest

area of cleaning with relatively low pressure. This pressure washer tip is

best used for light or delicate cleaning applications. It is recommended

for light cleaning on wood decks and other soft or delicate surfaces.

Black - Soap spray tip

■ The black soap spray tip, is used for soap application. Soap is applied

under low pressure high volume for optimum performance. Soap cannot

be applied under high pressure with this machine.

Turbo Nozzle Tip

■ This nozzle rotates in a zero to 15 degree circular motion spray pattern

to break down tough dirt and grime. The spray pattern can cover area of

4 to 8 inches wide, depending on the distance between the tip and the

surface being cleaned.

Fig. 13

APPLICATION

1-Pull back the quick-connect colla

2-Push the spray tip into place

3-Push the collar forward

19

OPERATION INSTRUCTION

WARNING

NEVER change spray tips without engaging the lock-out on the trigger handle and NEVER point

the wand at your face or at others. The quick-connect feature contains small springs that could

eject the spray tip with some force. Failure to heed this may cause personal injury.

TO DISCONNECT A SPRAY TIP FROM THE SPRAY WAND ONCE THE CLEANING

JOB IS COMPLETE:

• Turn off the pressure washer and shut off the water supply. Pull trigger to release water

pressure.

• Remove the spray tip by placing hand over spray then pulling back the quick-connect collar.

Place spray tip in the tip storage area on the units folding handle.

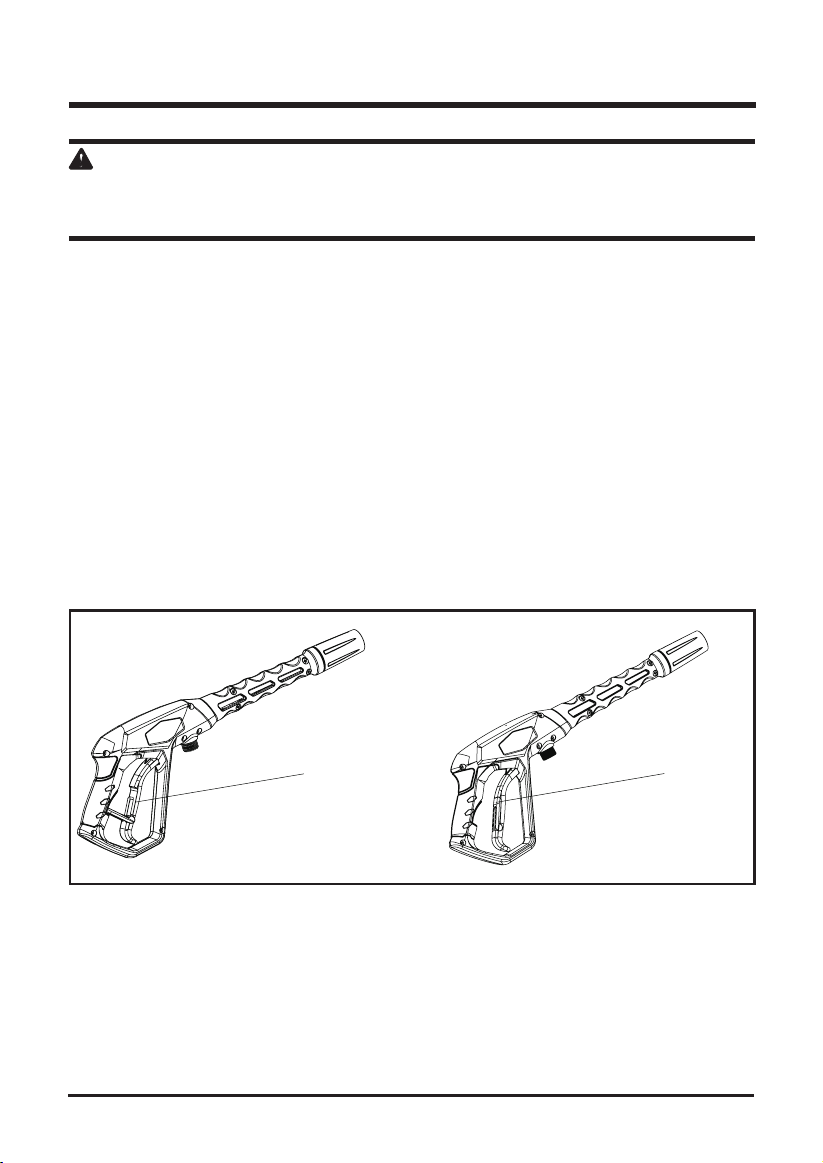

USING THE SPRAY WAND TRIGGER (See Figure 14)

For greater control and safety, keep both hands on the trigger handle at all times.

• Pull back and hold the trigger to operate the pressure washer.

• Release the trigger to stop the ow of water through the tip.

TO ENGAGE THE LOCK-OUT:

• Push the lock-out down until it clicks into the slot.

TO DISENGAGE THE LOCK-OUT:

• Push the lock-out up and into its original position.

Locked

Unlocked

Fig. 14

20

OPERATION INSTRUCTION

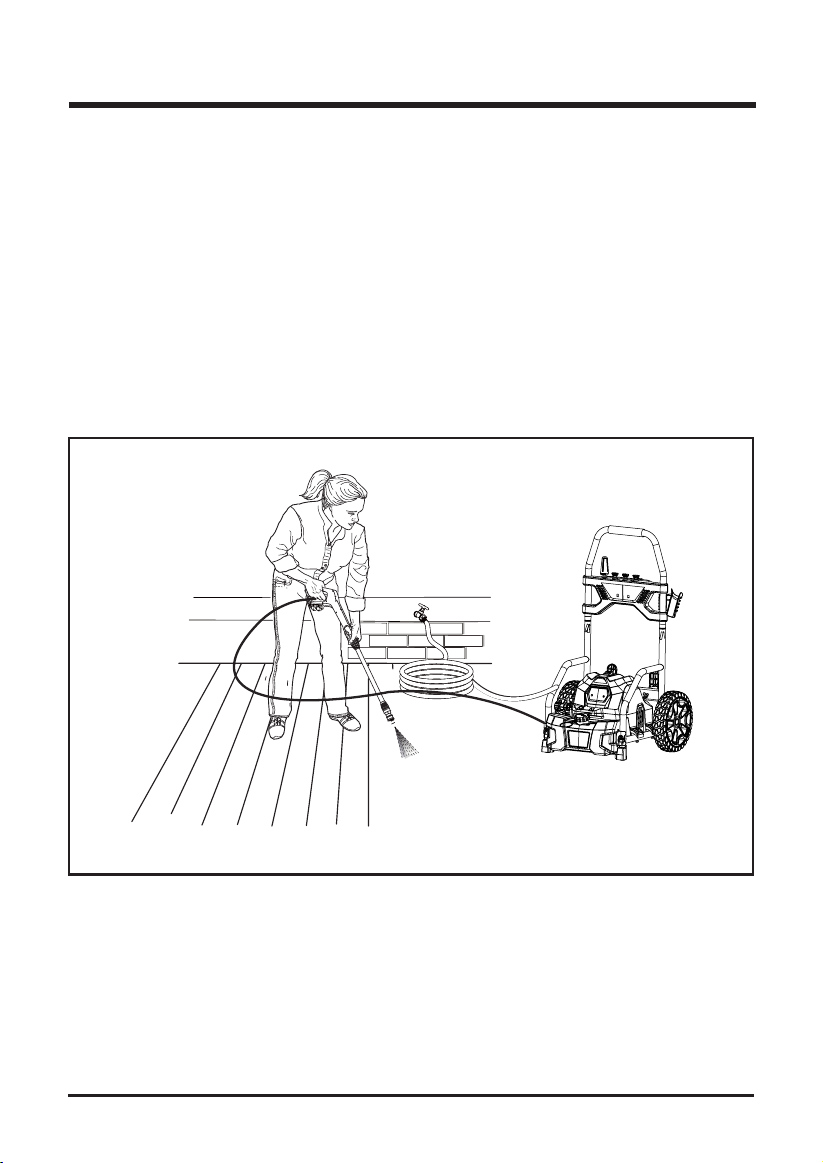

OPERATING THE PRESSURE WASHER (See Figure 15)

Use only detergents designed for pressure washers. Many detergents may require mixing prior to

use. Prepare cleaning solution as instructed on the solution bottle.

a. To clean:

• Pour detergent in the detergent tank.

• Install the black soap tip on the spray wand.

• Start the pressure washer and spray the detergent on a dry surface using long, even,

overlapping strokes. To prevent streaking, do not allow detergent to dry on the surface.

b. To rinse:

• Using the 25° spray tip, spray away from the rinsing surface for approximate 10 seconds to

allow any remaining detergent to be ushed from the line.

• Start at the top of the area to be rinsed and work down, overlapping the strokes.

For the most effective cleaning, the spray tip should be between 8 in. and 24 in. from the surface

to be cleaned. If the spray is too close it can damage the surface.

Fig. 15

MOVING THE PRESSURE WASHER

To move the pressure washer:

• Turn the pressure washer off. Point the spray wand in a safe direction and pull trigger to release

water pressure.

• Tilt the machine toward you until it balances on the wheels, then roll the machine to the desired

position.

21

MAINTENANCE

WARNING

When servicing, use only identical replacement parts. Use of any other parts may create a

hazard or cause product damage.

WARNING

Before inspecting, cleaning or servicing the machine, turn off the unit, unplug from the outlet, pull

trigger to release water pressure and disconnect the high pressure hose. Failure to follow these

instructions can result in serious personal injury or property damage.

GENERAL MAINTENANCE

WARNING

Do not at any time let brake uids, gasoline, petroleum-based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals can damage, weaken or destroy plastic which may

result in serious personal injury.

Only the parts shown on the parts list are intended to be repaired or replaced by the customer. All

other parts should be replaced at an authorized service center.

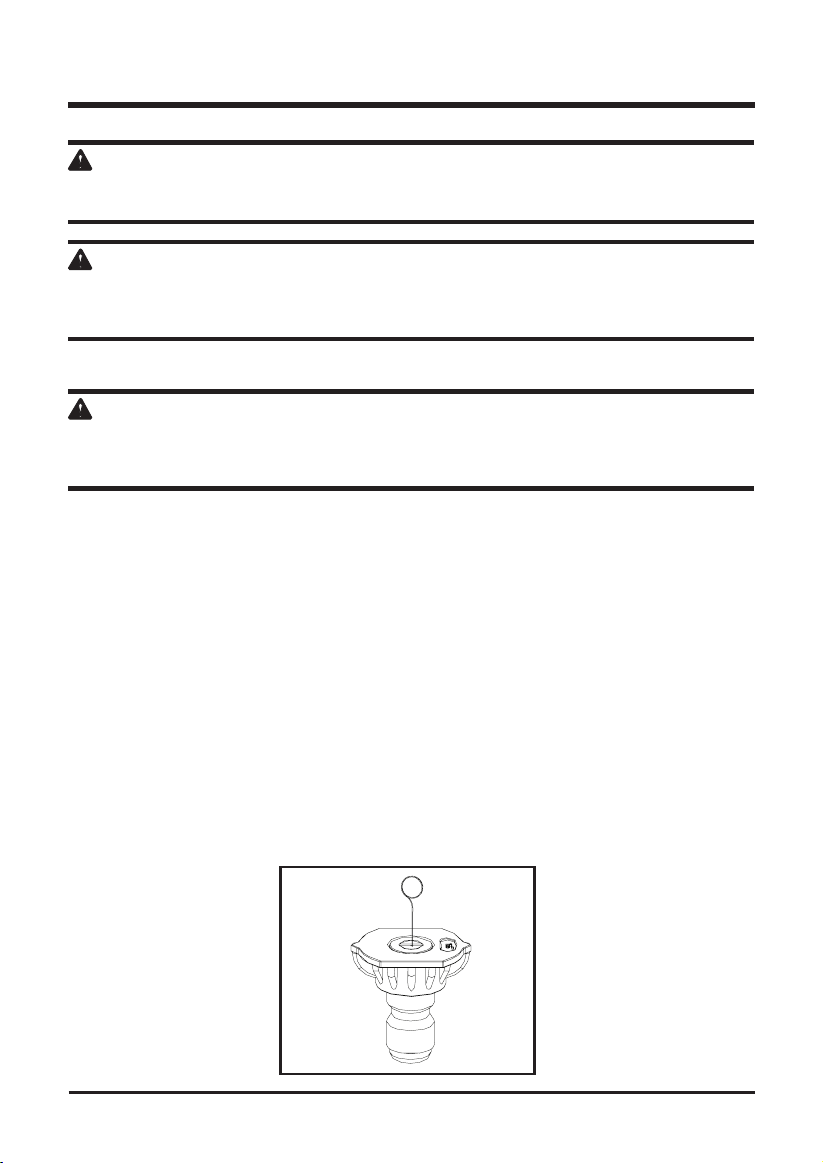

SPRAY TIP MAINTENANCE(See Figure 16)

a. Excessive pump pressure (a pulsing sensation felt while squeezing the trigger) may be the

result of a clogged or dirty spray tip.

• Unplug the pressure washer.

• Turn off the pressure washer and shut off the water supply. Pull trigger to release water

pressure.

• Remove the spray tip from the spray wand.

NOTE: Never point the spray wand at your face.

b. Using the spray tip cleaning tool provided, free any foreign materials clogging or restricting the

spray tip opening.

• Using a garden hose, flush debris out of the spray tip by back flushing (running the water

through the spray tip backwards or from the outside to the inside).

• Reconnect the spray tip to the spray wand.

• Turn on the water supply.

22

Fig. 16

MAINTENANCE

STORING THE PRESSURE WASHER

Store in a dry, covered area where the weather can’t damage it. It is important to store this

product in a frost-free area. Always empty water from all hoses, the pump, and the detergent

container before storing.

NOTE: Use of a pump saver will give you better performance and increase the life of the

machine.

QUICK WINTERIZING PROCEDURE

You can protect your pressure washer from winter damage by doing below:

• Disconnect all water connections.

• Turn on the machine for a few seconds until the remaining water in the pump exits. Turn off

immediately.

• Do not allow high-pressure hose to become kinked.

• Store the machine and accessories in a room that does not reach freezing temperatures. Do

not store near furnace or other sources of heat as it may dry out the pump seals.

CAUTION

Drain gun assembly of any remaining water. Aim gun downwards and squeeze trigger.

SHUTTING DOWN AND CLEANING UP

• (If you are not using detergent, go directly to Step 2.) When you have finished using the

detergent injection system, ll detergent bottle with clean water. Siphon water at low-pressure

for one minute so that all detergent is ushed through system. Remove detergent bottle and

rinse it thoroughly.

• Disconnect the garden hose from the water inlet on the unit.

• Press trigger to release any remaining water pressure.

• Set the switch to “OFF” (O) position.

• Unplug the power cord from the outlet.

• Engage gun safety lock.

TAKING A BREAK

If taking a break of ve minutes or more:

• Engage gun safety lock.

• Set unit to “OFF” (O) position.

• Unplug the power cord from the outlet.

IMPORTANT

The use of a pump protector is recommended when storing to help prevent a against freezing

over the winter months. It also help prevent the seals from drying out while sitting in storage in all

climates.

23

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Motor will not

start.

Unit does not

reach high

pressure.

Output pressure

varies high and

low.

Motor buzzes

but fails to run.

No water.

On/Off switch is in the “OFF”

(O) position.

Power cord is not plugged in. Plug in power cord.

Electrical outlet does not

supply adequate power.

Tripped pressure washer circuit

breaker.

Power switch is ON however gun

trigger is not squeezed ON.

Diameter of garden hose is too

small.

Water supply is restricted.

Not enough water supply. Open water source fully.

Pressure Tip has not been

installed on wand assembly.

Water intake lter is clogged. Remove lter and rinse in warm water.

Not enough inlet water supply.

Pump is sucking air.

Water inlet lter clogged. Remove lter and rinse in warm water.

Supply voltage below

minimum.

Calcied gun, hose or power

spray tip.

Supply voltage below

minimum.

System has residual pressure.

Voltage loss due to extension

cord.

Pressure washer not used for

long periods.

Residual friction among

components. Unit might hum.

Water supply is OFF. Turn ON water supply.

Kink in the garden hose. Remove kink in garden hose.

Set switch to the “ON” ( | ) position.

Try a different outlet.

Allow to cool, and restart unit.

With power switch ON push in on the gun

trigger which will engage the AUTO ON switch.

Replace with a 1” (25 mm) or 5/8” (16 mm)

garden hose.

Check garden hose for kinks, leaks and

blockage.

Add desired pressure tip to end of wand.

Turn water on fully. Check garden hose for

kinks, leaks or blockage.

Check that hoses and ttings are airtight. Turn

“OFF” machine, and purge pump by squeezing

trigger gun until a steady ow of water emerge

through the spray tip.

Verify that only the pressure washer is running

on this circuit.

Run distilled vinegar through detergent tank.

Verify that only the pressure washer is running

on this circuit.

Turn unit “OFF”, squeeze trigger on spray

wand to release pressure, then turn unit “ON”.

Unplug any extension cords attached and plug

the unit directly into the outlet.

Call customer service.

Disconnect water supply and power ON for 2

to 3 seconds, repeat couple times or until the

motor starts.

24

LIMITED WARRANTY

1

YEAR/ANS/AN

CHARGER WARRANTY

GARANTIE DE

INSTRUMENT

GARANTIE DU

CHARGEUR

GREENWORKS ELITE hereby warranties this product, to the original purchaser with

of purchase

GREENWORKS ELITE, at its own discretion will repair or replace any and all parts found to

be defective, through normal use, free of charge to the customer. This warranty is valid only for

units which have been used for personal use that have not been hired or rented for industrial/

commercial use, and that have been maintained in accordance with the instructions in the

owners’ manual supplied with the product from new.

, 1 year consumer warranty against defects in materials, parts or workmanship.

proof

ITEMS NOT COVERED BY WARRANTY:

1. Any part that has become inoperative due to misuse, abuse, neglect, accident, improper

maintenance, or alteration.

2. The unit, if it has not been operated and/or maintained in accordance with the owner's

manual.

3. Normal wear, except as noted below.

4. Routine maintenance items such as lubricating or sharpening.

5. Normal deterioration of the exterior nish due to use or exposure.

GREENWORKS ELITE HELPLINE:

Warranty service is available by calling our toll-free helpline at

1-833-493-5483.

TRANSPORTATION CHARGES:

Transportation charges for the movement of any power equipment unit or attachment are the

responsibility of the purchaser. It is the purchaser’s responsibility to pay transportation charges

for any part submitted for replacement under this warranty unless such return is requested in

writing by

GREENWORKS ELITE

.

25

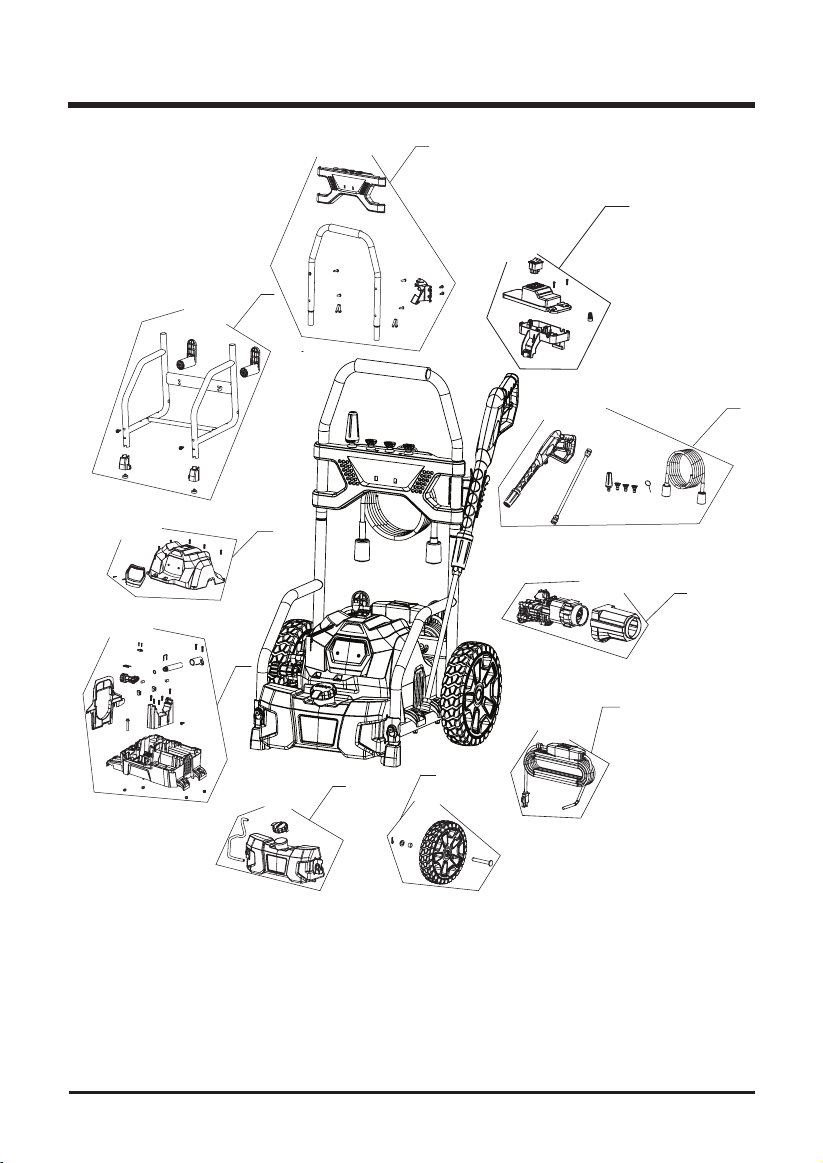

EXPLODED VIEW

2

3

4

5

7

8

10

9

1

6

26

PARTS LIST

NO. PART NO. QTY DESCRIPTION

1 311062584 1 KIT, ACCESSARY

2 311063570 1 KIT, HANDLE

3 311023570 1 KIT, LOWER HOLDER

4 311082583 1 KIT, SWITCH BOX

5 311053570 1 KIT, UPPER HOUSING

6 311112584 1 KIT, MOTOR

7 311073570 1 KIT, LOWER HOUSING

8 364002583 1 KIT, POWER CORD

9 311033570 1 KIT, WHEEL

10 311051823 1 KIT, SOAP TANK

27

TOLL-FREE HELPLINE: 1-833-493-5483

Rev: 00 (01-17-2018)

Greenworks Tools

PO Box 1238

Mooresville, NC 28115

NETTOYEUR HAUTE PRESSION DE

2000 PSI

EPW-2000

Guide d'utilisation

LIGNE D’ASSISTANCE SANS FRAIS: 1-833-493-5483

www.greenworkselite.com

Avant d’utiliser le produit, veuillez lire et suivre toutes les consignes de

sécurité et les instructions d’utilisation.

MATIÈRES

Matières ............................................................................................................................... 2

Fiche technique ................................................................................................................... 2

Instructions importantes concernant la sécurité .................................................................. 3

Symboles ............................................................................................................................. 6

Électricité ............................................................................................................................. 8

Apprendre à connaître le nettoyeur haute pression ............................................................. 9

Instructions pour l’assemblage .......................................................................................... 10

Mode d’emploi .................................................................................................................... 16

Entretien ............................................................................................................................ 23

Dépannage ........................................................................................................................ 25

Garantie limitée ................................................................................................................. 27

Vue éclatée ........................................................................................................................ 28

Liste des pièces ................................................................................................................. 29

FICHE TECHNIQUE

HIGH PRESSURE WASHER

Modèle ............................................................................................................EPW-2000

Moteur universel ......................................................................... 120 V~ 60 Hz, 14 Amps

Pression maximale en livre par pouce carré................................................. 2000 lb/po2

Calibration du débit par minute ........................................................................... 1.2 gpm

Température maximale de l’eau entrante .....................................................104°F (40°C)

Unités de nettoyage ......................................................................................2,400 unités

Poids .................................................................................................... 30.9 lbs. ( 14 kg)

1

YEAR/ANS/AN

CHARGER WARRANTY

GARANTIE DE

INSTRUMENT

GARANTIE DU

CHARGEUR

2

INSTRUCTIONS IMPORTANTES CONCERNANT LA

SÉCURITÉ

AVERTISSEMENT

Assurez-vous de lire et de comprendre toutes les instructions avant d’utiliser cet article.

Le non-respect des instructions ci-dessous peut entraîner une décharge électrique, un

incendie ou des blessures graves.

AVERTISSEMENT

Lorsque vous utilisez ce produit, respectez les mesures de sécurité élémentaires suivantes.

LISEZ TOUTES LES INSTRUCTIONS AVANT D’UTILISER CE PRODUIT

• An de réduire les risques de blessure, une surveillance étroite est de rigueur lorsqu’un

appareil est utilisé à proximité d’un enfant.

• Assurez-vous de bien connaître les commandes. Sachez comment arrêter l’appareil et

évacuez la pression rapidement.

• Restez vigilant et faites preuve de maîtrise. Prêtez attention à ce que vous faites et faites

preuve de bon sens. N’utilisez pas l’appareil lorsque vous êtes fatigué. Ne vous pressez pas.

• N’utilisez pas l’appareil lorsque vous êtes sous l’effet de drogues, d’alcool ou de

médicaments.

• Assurez-vous de garder toutes les personnes, en particulier les jeunes enfants, et les

animaux à l’extérieur de la zone d’utilisation.

• Ne vous étirez pas pour étendre votre portée et n’essayez pas de vous tenir sur une surface

instable. Gardez une posture sécuritaire et un bon équilibre en tout temps.

• Suivez les directives d’entretien de ce manuel.

AVERTISSEMENT

Risque d’injection ou de blessure – ne dirigez pas le jet de sortie vers des personnes ou des

animaux.

RALLONGES

• Lorsque vous devez travailler à une grande distance de la source d’alimentation, utilisez une rallonge qui a la capacité de gérer le courant tiré par le produit. Une rallonge de

calibre insufsant causera une baisse de la tension secteur, ce qui peut provoquer une

surchauffe, une perte de puissance et des dommages au disjoncteur. Utilisez le tableau

ci-dessous pour déterminer le calibre minimum nécessaire pour la rallonge. Seuls les cordons à gaine ronde se trouvant dans la liste des Underwriter’s Laboratories (UL) doivent

être utilisés. Lorsque vous utilisez l’article à l’extérieur, servez-vous d’une rallonge conçue

pour être utilisée à l’extérieur. La gaine de ces types de rallonges est marquée des sigles

« WA » ou « W ». Avant d’utiliser une rallonge, vériezla pour vous assurer qu’elle ne

comporte pas de ls lâches ou dénudés et pour conrmer le bon état de l’isolation (sans

coupure ni signe d’usure). Il est possible de nouer la rallonge et le cordon d’alimentation

ensemble an d’éviter qu’ils ne se débranchent quand vous utilisez le produit. Faites un

noeud, puis branchez la che du cordon d’alimentation sur la prise de la rallonge. Il est

également possible d’employer cette méthode pour nouer deux rallonges ensemble.

AVERTISSEMENT

An de réduire les risques d’électrocution, gardez le cordon d’alimentation dans un

endroit sec, audessus sol. Ne touchez pas à la che avec les mains mouillées.

AVERTISSEMENT

Vérifiez la rallonge électrique avant chaque utilisation. Si elle est endommagée, remplacez-

la immédiatement. N'utilisez jamais le produit avec un câble endommagé car toucher la zone

endommagée peut provoquer un choc électrique et entraîner des blessures graves.

3

INSTRUCTIONS IMPORTANTES CONCERNANT LA

SÉCURITÉ

AVERTISSEMENT

Gardez la rallonge à l’écart de la zone de travail. Disposez-la de façon à ce qu’elle ne s’accroche

pas à des pièces de bois, à des outils ou à d’autres obstacles pendant que vous utilisez l’outil

électrique. Sinon, vous risquez de subir de graves blessures.

• Connaissez bien votre produit. Lisez attentivement le guide d’utilisation. Assurez-vous de

connaître le fonctionnement et les restrictions de la machine ainsi que les dangers potentiels

liés à son utilisation.

• An de réduire les risques de blessure, gardez les enfants et les autres personnes à l’écart.

Tous les visiteurs doivent porter des lunettes de sécurité et se tenir à une distance sécuritaire

de l’aire de travail.

• Utilisez l’outil convenant à votre tâche. Ne tentez pas d’utiliser un outil ou l’un de ses

accessoires pour effectuer un travail pour lequel il n’est pas conçu. N’utilisez pas le produit

pour un usage autre que celui auquel il est destiné.

• Habillez-vous convenablement. Ne portez pas de vêtements amples, de gants, de cravate ou

de bijoux. Ces articles pourraient se coincer dans les pièces en mouvement. Le port de gants

de caoutchouc et de chaussures antidérapantes est recommandé lorsque vous travaillez à

l’extérieur. Couvrez également vos cheveux s’ils sont longs.

• N’utilisez pas l’appareil lorsque vous êtes pieds nus ou lorsque vous portez des sandales ou

d’autres chaussures légères. Portez des chaussures de protection qui protégeront vos pieds

et qui amélioreront votre adhérence sur les surfaces glissantes.

• Faites preuve de prudence pour éviter de glisser ou de tomber.

• Portez toujours des lunettes de sécurité pourvues d’écrans latéraux, conformes à la norme

ANSI Z87.1. En suivant cette règle, vous réduirez les risques de blessures graves.

• Utilisez uniquement les accessoires recommandés. L’utilisation d’accessoires inappropriés

pourrait entraîner des blessures.

• Vérifiez si des pièces sont endommagées. Avant de poursuivre l’utilisation du produit,

inspectez attentivement toutes les pièces an de déterminer s’il fonctionnera correctement

et accomplira sa tâche. Vérifiez si les pièces mobiles sont désalignées ou bloquées, si

les pièces sont brisées ou mal montées ou si elles sont dans un état pouvant nuire à leur

fonctionnement. Si une pièce comme un protecteur ou toute autre pièce est endommagée,

elle doit être réparée ou remplacée par un centre de service autorisé pour éviter les risques

de blessure.

• Ne laissez jamais le produit en marche sans supervision. Coupez l’alimentation électrique. Ne

vous éloignez pas du produit tant qu’il ne s’est pas complètement arrêté.

• Gardez le moteur exempt d’herbe, de feuilles ou de graisse afin de réduire les risques

d’incendie.

• Suivez les recommandations du fabricant pour un chargement, un déchargement, un

transport et un stockage sécuritaires de la machine.

• Gardez le produit sec, propre et exempt d’huile et de graisse. Utilisez toujours un linge propre

pour le nettoyage. N’utilisez jamais de liquide de frein, d’essence, de produits à base de

pétrole ou de solvants forts pour nettoyer le produit.

• Examinez la zone de travail avant chaque utilisation. Enlevez tous les objets qui pourraient

être projetés par l’appareil ou y rester coincés, comme les cailloux, les éclats de verre, les

clous, les câbles ou les ls.

• N’utilisez pas le produit si l’interrupteur ne fonctionne pas. Les interrupteurs défectueux sont

remplacés par un centre de service autorisé.

• Évitez les environnements dangereux. N’exposez pas l’article à la pluie. Gardez l’aire de

travail bien éclairée.

4

INSTRUCTIONS IMPORTANTES CONCERNANT LA

SÉCURITÉ

• N’utilisez pas le cordon d’alimentation de façon abusive. Ne transportez jamais un outil

électrique en le tenant par son cordon, et ne tirez jamais sur le cordon pour débrancher la

che. Tenez le cordon d’alimentation éloigné des sources de chaleur, de l’huile, des objets

coupants et des pièces mobiles. Remplacez immédiatement les cordons endommagés.

Les risques de choc électrique doivent être plus élevés si le cordon d’alimentation est

endommagé.

• Ne dirigez jamais le jet d’eau vers une personne, un animal ou un appareil électrique.

• Avant de commencer toute opération de nettoyage, fermez les portes et les fenêtres.

Dégagez l’aire à nettoyer de tout débris, jouet, meuble d’extérieur ou autre objet susceptibles

de poser des risques.

• N’utilisez pas d’acides, de produits alcalins, de solvants, de matériaux inammables, d’agent

de blanchiment ou de solutions industrielles dans ce produit. Ces produits peuvent causer

des blessures physiques à l’opérateur et des dommages irréversibles à la machine.

AVERTISSEMENT

Les jets à haute pression peuvent être dangereux s’ils sont mal utilisés. Le jet ne doit pas

être orienté vers les gens, les animaux, les appareils électriques ni vers l’appareil en tant

que tel.

• Gardez le moteur à l’écart des liquides inammables et des autres matières dangereuses.

• Vérifiez les boulons et les écrous fixant la coquille de la laveuse à pression avant toute

utilisation. Un boulon ou un écrou desserré peut causer de graves problèmes de moteur.

• Laissez le moteur refroidir avant de ranger l’article.

• Lors de l’entretien, utilisez seulement des pièces de rechange identiques aux pièces d’origine.

L’utilisation de toute autre pièce peut endommager l’outil ou être source de danger.

• Utilisez UNIQUEMENT de l’eau froide.

• Assurez un dégagement minimal de 0,91 m de tout matériau combustible.

• Branchez la laveuse à pression uniquement à un circuit de dérivation individuel.

• Tenez la poignée et la baguette de pulvérisation fermement avec vos deux mains.

Attendezvous à un mouvement de la poignée de la gâchette lorsque vous appuyez sur la

gâchette en raison des forces de réaction. Ne pas le faire pourrait entraîner une perte de

contrôle et des blessures pour vous ou d’autres personnes.

• Conservez ces instructions. Consultez-les souvent et utilisez-les pour donner des directives

aux autres utilisateurs. Si vous prêtez ce produit à quelqu’un, remettez-lui également les

présentes instructions.

AVERTISSEMENT(PROPOSITION65)

La poussière créée pendant le ponçage, le sciage, le polissage, le perçage et d’autres activités

liées à la construction peut contenir des produits chimiques entraînant le cancer, ainsi que

des anomalies congénitales et d’autres problèmes liés aux fonctions reproductrices. Voici des

exemples de ces produits chimiques :

• Le plomb provenant de peintures à base de plomb,

• La silice cristalline provenant de la brique, du ciment ou d’autres matériaux de maçonnerie

• L’arsenic et le chrome provenant du bois d’oeuvre traité avec un produit chimique

Les risques liés à l’exposition à ces produits varient en fonction de la fréquence à laquelle vous

effectuez ce type de travaux. An de limiter votre exposition à ces produits chimiques : travaillez

dans un endroit bien ventilé en vous munissant de l’équipement de sécurité approuvé tel que

des masques antipoussières conçus spécialement pour ltrer les particules microscopiques.

5

SYMBOLES

Certains des symboles suivants peuvent figurer sur cet article. Familiarisez-vous avec eux

et apprenez leur signification. En comprenant ces symboles, vous serez en mesure de faire

fonctionner cet article de façon adéquate et sécuritaire.

SYMBOLES DESCRIPTION DÉFINITION

V Volts Tension

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watts Alimentation

no Vitesse à vide Vitesse de rotation à vide

Courant alternatif Type de courant

/min Par minute

Alerte de sécurité Indique un risque de blessure.

Tours, coups, battements, vitesse de surface,

orbites, etc., par minute.

Lire le guide d’utilisation

Lunettes de sécurité

Avertissement relatif aux

conditions humides

Recul

Risque d’injection

Choc électrique

Brûlures chimiques

Risque d’explosion

An de réduire les risques de blessure, l’utilisateur

doit lire et comprendre le guide d’utilisation avant

d’utiliser cet article.

Portez toujours des lunettes de sécurité pourvues

d’écrans latéraux, conformes à la norme ANSI Z87.1.

N’exposez pas cet outil à la pluie et évitez de

l’utiliser dans des endroits humides.

Pour réduire le risque d’injection ou de blessure, ne

dirigez jamais le jet d’eau vers une personne, un

animal ou une partie du corps. Les tuyaux et raccords

qui fuient peuvent également provoquer des blessures

d’injection. Ne tenez pas les tuyaux ni les raccords.

Pour réduire le risque de blessures causé par le

recul, tenez la baguette de pulvérisation fermement

à deux mains lorsque la machine est en marche.

L’utilisation dans des conditions humides et

le nonrespect des règles de sécurité peuvent

entraîner un choc électrique.

Pour réduire le risque de blessures ou de dommages,

N’UTILISEZ PAS D’ACIDES, DE PRODUITS

ALCALINS, D’AGENT DE BLANCHIMENT, DE

SOLVANTS, DE MATÉRIAUX INFLAMMABLES OU

DE SOLUTIONS INDUSTRIELLES dans ce produit.

Ne pas vaporiser de liquides inammables.

Liquides inammables, de carburant, et leurs

vapeurs sont explosifs et peuvent entraîner des

brûlures graves ou mortelles.

6

6

SYMBOLES

Les mots indicateurs suivants et leurs signications servent à expliquer les niveaux de risque

associés à cet appareil.

SYMBOLE MOT INDICATEUR SIGNIFICATION

DANGER

AVERTISSEMENT

ATTENTION

ATTENTION

ENTRETIEN

L’entretien exige une grande prudence et de bonnes connaissances et ne devrait être effectué

que par un technicien qualié. Rapportez l’appareil au

plus près de chez vous pour tout travail d’entretien ou de réparation. Lors de l’entretien, utilisez

seulement des pièces de rechange identiques aux pièces d’origine.

AVERTISSEMENT

Pour éviter des blessures graves, ne tentez pas d’utiliser cet article avant d’avoir lu le guide

d’utilisation attentivement et de l’avoir bien compris. Si vous ne comprenez pas les avertissements

et les instructions de ce guide d’utilisation, n’utilisez pas cet article. Appelez le Service à la

clientèle Greenworks pour obtenir de l’aide au 1-833-493-5483.

Indique un danger imminent qui, s’il n’est pas évité, peut

entraîner des blessures graves ou la mort.

Indique une situation potentiellement dangereuse qui,

si elle n’est pas évitée, pourrait entraîner la mort ou des

blessuresgraves.

Indique un danger potentiel qui, s’il n’est pas évité, peut

causer des blessures mineures ou modérément graves.

(Aucun symbole d’alerte de sécurité) Indique une situation qui

pourrait entraîner des dommages matériels.

CENTRE DE SERVICE AUTORISÉ

le

CONSERVEZ CES INSTRUCTIONS

7

ELECTRICAL

BRANCHEMENT ÉLECTRIQUE

Cet article comprend un moteur électrique conçu avec précision. Il devrait être connecté à

une source d’alimentation électrique de 120 V c.a. et de 60 Hz (courant domestique normal).

N’alimentez pas l’articleà partir d’une source de courant continu (c.c.). Une chute de tension

importante entraînera une perte de puissance et une surchauffe du moteur.

BOUCLE D’ÉGOUTTEMENT

Afin d’éviter que de l’eau s’écoule le long du cordon d’alimentation et n’atteigne la prise

électrique et la che, nous recommandons d’utiliser une simple boucle d’égouttement, comme

l’illustre la gure suivante.

CORDON D’ALIMENTATION

BOUCLE D’ÉGOUTTEMENT

Fig. 1

AVERTISSEMENT

Gardez la rallonge à l’écart de la zone de travail. Disposez-la de façon à ce qu’elle ne s’accroche

pas à des pièces de bois, à des outils ou à d’autres obstacles pendant que vous utilisez l’outil

électrique. Sinon, vous risquez de subir de graves blessures.

8

APPRENDRE À CONNAÎTRE LE NETTOYEUR HAUTE

PRESSION

La sécurité d’utilisation de ce produit exige la compréhension des informations apposées sur l’outil

et contenues dans ce manuel d’utilisation, ainsi que la connaissance du travail à exécuter. Avant

d’utiliser ce produit, se familiariser avec toutes ses fonctions et règles de sécurité.(Voir la gure 2.)

CONSEIL DE RANGEM ENT

ASSEMBLAGE DE LA

GÂCHETTE ET DE LA BAGUETTE

INTERRUPTEUR

RÉSERVOIR DE

DÉTERGENT

RANGEMENT

DU CÂBLE

D’A LI MENTAT ION

Fig. 2

RÉSERVOIR À DÉTERGENT

Retirez le bouchon du réservoir à détergent pour ajouter du détergent dans le nettoyeur haute

pression.

PRISE GFCI

Le câble d'alimentation du nettoyeur à pression est équipé d'une prise GFCI pour prévenir les

risques dus à une non conformité du branchement à la terre. Cette prise ne protège pas contre

les courts-circuits, les surcharges ou les chocs.

INTERRUPTEUR AUTOMATIQUE MARCHE/ARRÊT :

Ce nettoyeur à pression est équipé d'une fonction de mise en marche / arrêt automatique.

Fonctionnement : Réglez l'interrupteur d'alimentation en position de marche (I). La pompe se

mettra sous pression et s'éteindra immédiatement. Une fois que la gâchette du pistolet est

enfoncée, l'appareil se met en marche. L'appareil s'éteindra et se mettra en mode de veille

lorsque la gâchette sera relâchée.

RANGEMENT DU CÂBLE D'ALIMENTATION

Pour faciliter le rangement, le câble d'alimentation peut être enroulé et rangé sur le crochet.

ASSEMBLAGE DE LA GÂCHETTE ET DE LA BAGUETTE

La gâchette et la baguette vous permettent de faire fonctionner le nettoyeur haute pression en

appuyant sur la gâchette pour activer la pompe an de vaporiser de l'eau en utilisant l'embout de

pulvérisation désiré.

9

INSTRUCTIONS POUR L’ASSEMBLAGE

www.GreenWorksTools.com

Rev:02

Connect garden hose to pressure

Once the trigger of the gun is depressed the unit will turn on.

Unit will shut off and be in standby mode when trigger is

released.

This Quick Start Guide is not a substitute for reading the operator's manual. To reduce the risk

of injury or death, user must read and understand operator's manual before using this product.

WARNING:

Set-up

Installing the wheels

Insert the axle through the wheel.

1

NOM DES PIÈCES FIGURE QTÉ

Nettoyeur haute pression 1

Poignée supérieure

Assemblage du panneau de

l’embout de pulvérisation (embout

inclus)

Réservoir de savon 1

A s s e m b l a g e d e l a g â c h e t t e 1

lance de pulvérisation 1

Support à pistolet 1

Embout turbo 1

Outil de nettoyage à pointe de

pulvérisation

Vis 2

Vis 4

Roues 2

Rondelle 2

Gaine d’essieu 2

Broche 2

Essieu 2

.

l

o

o

t

)

s

i

7

h

5

t

7

g

6

.

n

i

9

t

0

a

r

9

.

e

8

R

p

8

o

E

8

(

e

r

S

o

f

SH

e

K

L

b

A

R

m

A

y

M

l

o

l

O

W

c

u

P

.

f

s

e

E

l

r

o

ANU

a

R

o

c

t

1 G

00

M

.

s

U

s

8

k

1

n

S

r

o

o

/

i

t

R’

SS

w

c

n

W 1

u

O

E

r

SI

e

t

T

P

e

R

s

r

A

n

P

g

i

P

G

R

d

Manuel d’utilisation

Guide rapide de démarrage

w.

n

w

IC

a

800

w

s

1

R

OPE

e

l

T

u

r

C

y

t

E

e

f

L

a

s

E

l

l

a

d

LL-FREE HELPLINE: 1-888-90W

a

e

O

R

T

Slide the washer over the axle pass the pin hole.

washer water intake.

Insert the axle and wheel through the frame. Slide the washer

over the axle and insert the pin through the hole to firmly fasten

the wheel assembly.

2

Assemble pressure washer gun to spray wand.

1800 PSI / 1.1 GPM

Wheel

ELECTRIC PRESSURE WASHER

GPW 1800

USING DETERGENT

3

Connect desired pressure tip.

Put pressure washer detergent in detergent tank.

25

Axle

WasherPin

Install blue or black soap nozzle.

Squeeze trigger and wait approx.1 minute for soap.

Installing the gun holder

5

2

Line up the screw sleeves with the holes in the upper handle

and push through.

4

Insert the screw and turn clockwise with a Phillips head

Insert high pressure hose into trigger

screwdriver (not included) until the screw is tight.

handle.

SPRAY TIPSPRAY TIP APPLICATION

Red - Stream tip (0° )

5

Connect the high pressure hose to the

The red 0 degree tip provides a straight line of spray. It provides the highest

O

water outlet connector.

0

amount of pressure. It is best used for removing hard, stuck-on grime or dirt.

Green - Narrow fan tip (25° )

The green pressure washer tip provides high versatility with its 25 degree angle tip.

Referred to as the washing tip, because it provides adequate pressure to remove

O

dirt from surfaces, but is designed to not damage many surfaces. This pressure

6

Turn on water at outlet.

25

washer tip is designed for “sweeping” foliage or debris given its wide angle. This tip

is versatile due to its wide area of cleaning and strong pressure application.

White - Wide fan tip (40° )

Installing the upper handle

The white 40 degree tip, referred to as the “fan” tip creates the widest area of

7

Run water hose for 30 seconds with the

cleaning with relatively low pressure. This pressure washer tip is best used for light

Push and hold the push-pin buttons on the sides of the upper

O

motor in OFF position. This helps drain air

or delicate cleaning applications. It is recommended for light cleaning on wood

handle assembly (1) as you slide the handle onto the frame (2).

40

from the tank and lines.

decks and other soft or delicate surfaces.

S

30

(1)

Black - Soap spray tip

8

Connect power cord to wall outlet

The black soap spray tip, is used for soap application. Soap is applied under low

Extension cord not recommended.

pressure high volume for optimum performance. Soap cannot be applied under

Push-pin

(2)

SOAP

high pressure with this machine.

9

Turbo Nozzle Tip

Turn on Pressure Washer

The nozzle rotates in a zero to 15 degree spray pattern in a circular motion to

IMPORTANT: Ensure water outlet is On

break down tough dirt and grime. The spray pattern can cover area of 4 to 8 inches

before turning power On to avoid damage

wide, depending on a distance between the tip and the surface being cleaned.

to the pump.

NOTE:

AUTO ON/OFF SWITCH: This Pressure washer is equipped

Missing parts, accessories or need a service center?

with an Auto Start/Stop feature.

Do Not Return to Store

To operate: Turn the power switch to the On (I) position.

Call : 1-888-909-6757

Pump will pressurize and shut down immediately.

1

1

1

1

1

10

INSTRUCTIONS POUR L’ASSEMBLAGE

DÉBALLAGE

Cet article est entièrement assemblé avant son expédition.

• Retirez prudemment le produit et les accessoires de la boîte. Assurez-vous que tous les

articles énumérés dans la liste de colisage sont inclus.

• Assurez-vous que le produit n’a pas subi des dommages ou de bris pendant le transport.

• Ne jetez pas le matériel d’emballage avant d’avoir soigneusement inspecté l’outil et de l’avoir

fait fonctionner de manière satisfaisante.

• Si des pièces sont manquantes ou endommagées, veuillez appeler au 1-833-493-5483 pour

obtenir de l’aide.

AVERTISSEMENT

N’utilisez pas ce produit si des pièces gurant sur la liste des pièces contenues dans l’emballage

sont déjà assemblées sur votre produit au moment où vous le déballez. Les pièces figurant

sur cette liste n’ont pas été assemblées au produit par le fabricant et devront être installées

par le client. L’utilisation d’un article qui pourrait avoir été mal assemblé pourrait entraîner des

blessures graves.

AVERTISSEMENT

S’il y a des pièces manquantes ou endommagées, ne tentez pas d’utiliser cet article tant que ces

pièces n’auront pas été remplacées. Le non-respect de cet avertissement pourrait entraîner de

graves blessures.

AVERTISSEMENT

Ne branchez pas l’appareil à une source d’alimentation électrique tant que l’assemblage

n’est pas terminé. Le non-respect de ces consignes pourrait provoquer des mises en marche

accidentelles ainsi que de graves blessures.

AVERTISSEMENT

Ne tentez pas de modier cet article ou de créer des accessoires qui ne sont pas recommandés

pour cet article. Toute modication est considérée comme un usage inapproprié et peut créer

une situation dangereuse susceptible d’entraîner des blessures graves.

11

INSTRUCTIONS POUR L’ASSEMBLAGE

ASSEMBLAGE DES ROUES Voir gure

• Insérez un essieu (A) dans une roue (I), une rondelle (J), le cadre de l’appareil, puis une autre

rondelle (J).

• Insérez une goupille fendue (K) dans le trou de l’essieu pour xer le tout. Faites de même

pour la deuxième roue.

A

3.

A

K

J

M

I

ASSEMBLAGE DU PANNEAU AVANT ET DU PORTE-PISTOLET Voir gure

• Alignez les gaines de vis avec les trous de la poignée supérieure et insérez-les.

• Insérez la vis et tournez-la dans le sens des aiguilles d’une montre avec un tournevis

cruciforme (non inclus) jusqu’à ce que la vis soit bien serrée.

ASSEMBLAGE DU CROCHET DE TUYAU Voir gure

• Alignez l’extrémité supérieure du crochet du tuyau avec les trous à l’arrière du panneau avant

• Insérez l’extrémité du crochet dans le trou et enfoncez-le.

• Enfoncez l’extrémité inférieure du crochet dans le clip situé à l’arrière du panneau avant.

4.

Fig. 3

4.

upper end

clip

hole

lower end

Fig. 4

12

INSTRUCTIONS POUR L’ASSEMBLAGE

ASSEMBLAGE DE LA POIGNÉE Voir gure

• La poussée et tient le bouton sur la poignée comme vous glissez la poignée dans les trous

dans le cadre.

REMARQUE:

poussoirs s’enclenchent dans les fentes de verrouillage. La poignée sera ainsi bien xée en

place.

Avant d’utiliser l’appareil, tirez sur la poignée jusqu’à ce que les boutons-

ASSEMBLAGE DE LA BAGUETTE DE PULVÉRISATION Voir gure

• Poussez le bout de la baguette de pulvérisation dans l’assemblage de la gâchette et tournez

dans le sens des aiguilles d’une montre pour le xer.

• Tirez sur la baguette de pulvérisation pour vous assurer qu’elle est bien xée.

5.

Fig. 5

6.

13

Fig. 6

INSTRUCTIONS POUR L’ASSEMBLAGE

RACCORDEMENT DU TUYAU À HAUTE PRESSION À LA POIGNÉE DE LA

GÂCHETTE Voir gure

• Alignez le tuyau à pression sur la poignée à gâchette, puis appuyez sur le tuyau pour l’insérer

dans la poignée.

• Lorsque le tuyau est bien inséré dans la poignée à gâchette, tournez le dispositif de xation

du tuyau dans le sens des aiguilles d’une montre jusqu’à ce qu’il soit bien serré.

REMARQUE:

d’ajouter un détergent à laveuse à pression ou à vaisselle au joint en caoutchouc de chaque

extrémité du tuyau. L’installation sera ainsi plus facile et assurera un ajustement parfait.

Pour faciliter l’installation du tuyau sur l’unité ou la gâchette, il est conseillé

7.

①

②

Fig. 7

RACCORDEMENT DU TUYAU HAUTE PRESSION AU NETTOYEUR PRESSION Voir gure