Greenwood Fusion HRV2HT Installation Instructions Manual

Fusion

HRV2HT

Mechanical Ventilation with Heat Recovery

Installation Instructions

Commissioning Data:

To be completed by the Commissioning Engineer.

Refer to User/Homeowner Guide also supplied.

Page | 2

Contents

1. General Description /

Physical Specification

Page 2

2.

Installation Instructions

Page 3

General Preparation

Page 3

Positioning

Page 3

Mounting

Page 6

Condensate Drain

Page 9

Ducting Guidelines

Page 9

Electrical

Page 10

Wiring Diagrams

Page 11

Connecting to the BMS

Page 12

On Site Commissioning

Page 14

3.

Guarantee

Page 23

1.0 General Description / Physical Specification

1.1

1.1.1

1.1.2

1.1.3

1.1.4

1.1.5

1.1.6

1.1.7

1.1.8

Overview

The HRV2HT is a ventilation system designed to provide improved indoor air quality in dwellings. As a whole

house system, the unit continuously extracts air from the non-habitable rooms and supplies fresh, filtered air

to habitable rooms. Heat that is recovered from the air drawn from the bathrooms and kitchen is passed

through a heat exchanger and the heat that is recovered is transferred, to temper the supply air in habitable

rooms to provide a comfortable indoor environment.

A boost speed facility is provided to increase the ventilation rate, e.g. when cooking or showering, providing

a comfortable indoor environment. A wireless boost switch (not supplied) such as GRF1 or GRF2 can be

used to provide this operation. Alternatively a GS2 Switch Live boost switch can be used to provide this

operation (See Section 2.6 Electrical).

This product features on SAP Appendix Q as a high efficiency version and part of the process requires the

Installation Checklist for MVHR products to be completed and submitted to building control, available at

www.sap-appendixq.org.uk, along with all other relevant paperwork.

Record sheets for commissioning information are provided, please refer to section 6 of the User/Homeowner

Guide also supplied with HRV2HT.

Ancillary Items Required

125mm Ducting (rectangular ducting can be used, where appropriate)

GRF1 Digital radio frequency device for commissioning and switching between trickle, medium and

boost

GRF2 Radio frequency switch providing switching between trickle, medium and boost (option)

GS2 Hardwired switch providing switching between trickle and boost (option)

Packaging Includes –

1 x HRV2HT Unit

1 x Wall Fixing Bracket

1 x Installation Instructions

1 x User/Homeowner Guide

The appliance is not intended for use by young children or infirm persons unless they have been adequately

supervised by a responsible person to ensure that they can use the appliance safely. Young children should

be supervised to ensure that they do not play with the appliance.

Siting Notes: Where an open-flued oil or gas-fuelled appliance is installed in the kitchen, extract ventilation

can cause the spillage of flue gases. Care must be taken to ensure ventilation is reduced appropriately, as

set out in the Building Regulations. Kitchens with solid-fuel appliances should not have extract fans fitted.

Page | 3

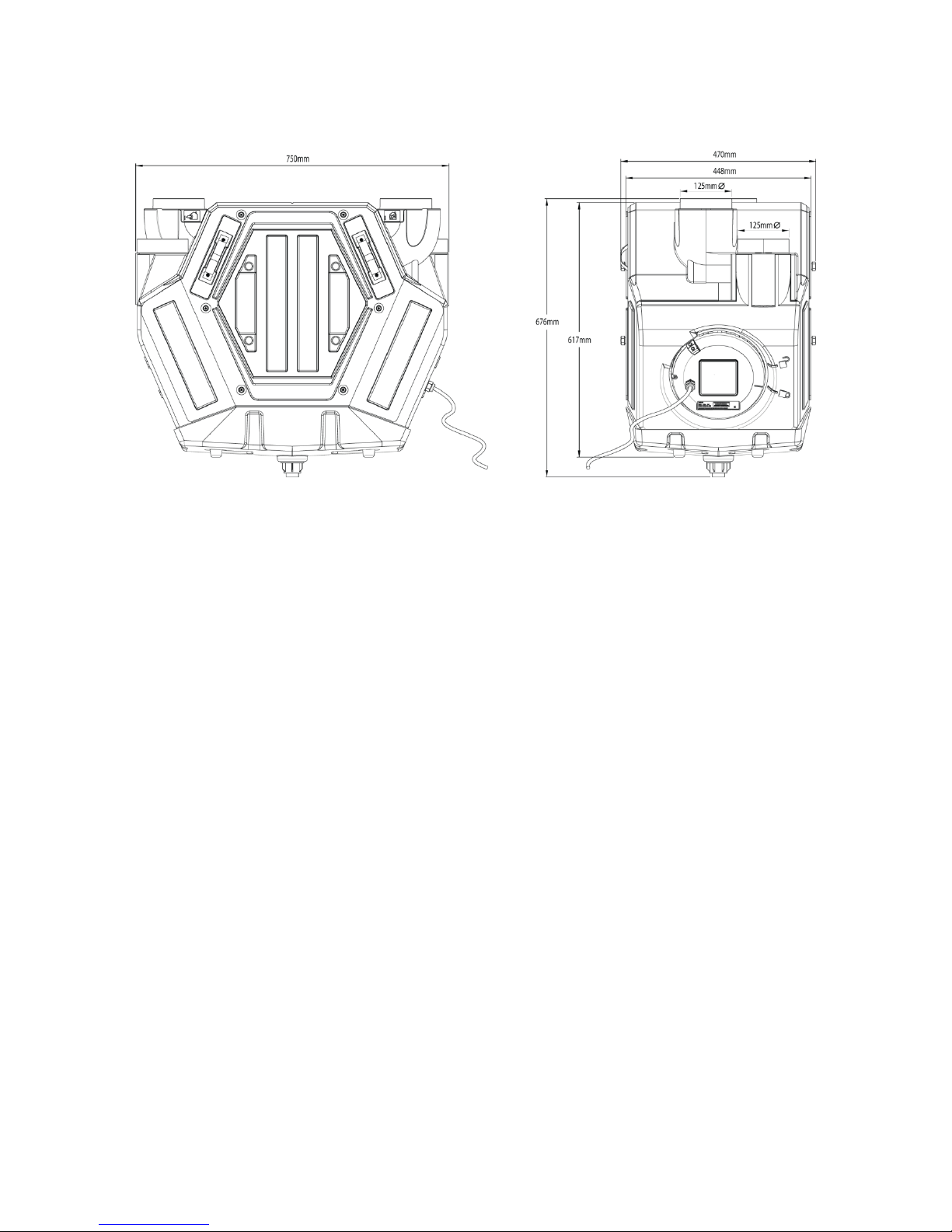

1.2

Physical Specification

Front View Side View

2.0 Installation Instructions

2.1

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

2.2

2.2.1

2.2.2

2.2.3

2.2.4

General Preparation

The HRV2HT unit is supplied with 4 x 125mmØ spigots.

125mm ducting with connectors can be used (see ancillary section page 2) to provide performance levels

required for compliance with Building Regulations.

Installation of the HRV2HT should be in accordance with the current editions of Building Regulations and

BS7671: IEE Wiring Regulations.

The design, material specification and installation must only be carried out by ‘competent persons’. Electrical

installation must be carried out by a qualified Electrician.

IMPORTANT NOTE Gases from fuel-burning equipment must not be drawn into any living areas. If any

room, where air is extracted, contains a fuel burning appliance such as a central heating boiler, then either of

the following should be undertaken:

– The flue must be of the room sealed or balanced flue type or;

– Allowance must be made for an adequate supply of air into the room.

Positioning

The unit must be installed vertically and wall mounted to enable effective condensate drainage in either a

service cupboard or secured to a vertical structure in the loft space. Duct spigots must be upright at top of

unit.

It is not advisable to install the unit directly above a bedroom or living room ceiling, or in an area that is part

of a living area or bedroom.

Consideration must be given to allow for adequate access for servicing, maintenance and any fault

diagnostics (See Figure 9 on Page 7).

The unit can be configured for right and left hand installation (See Figures 1 to 3 overleaf).

Page | 4

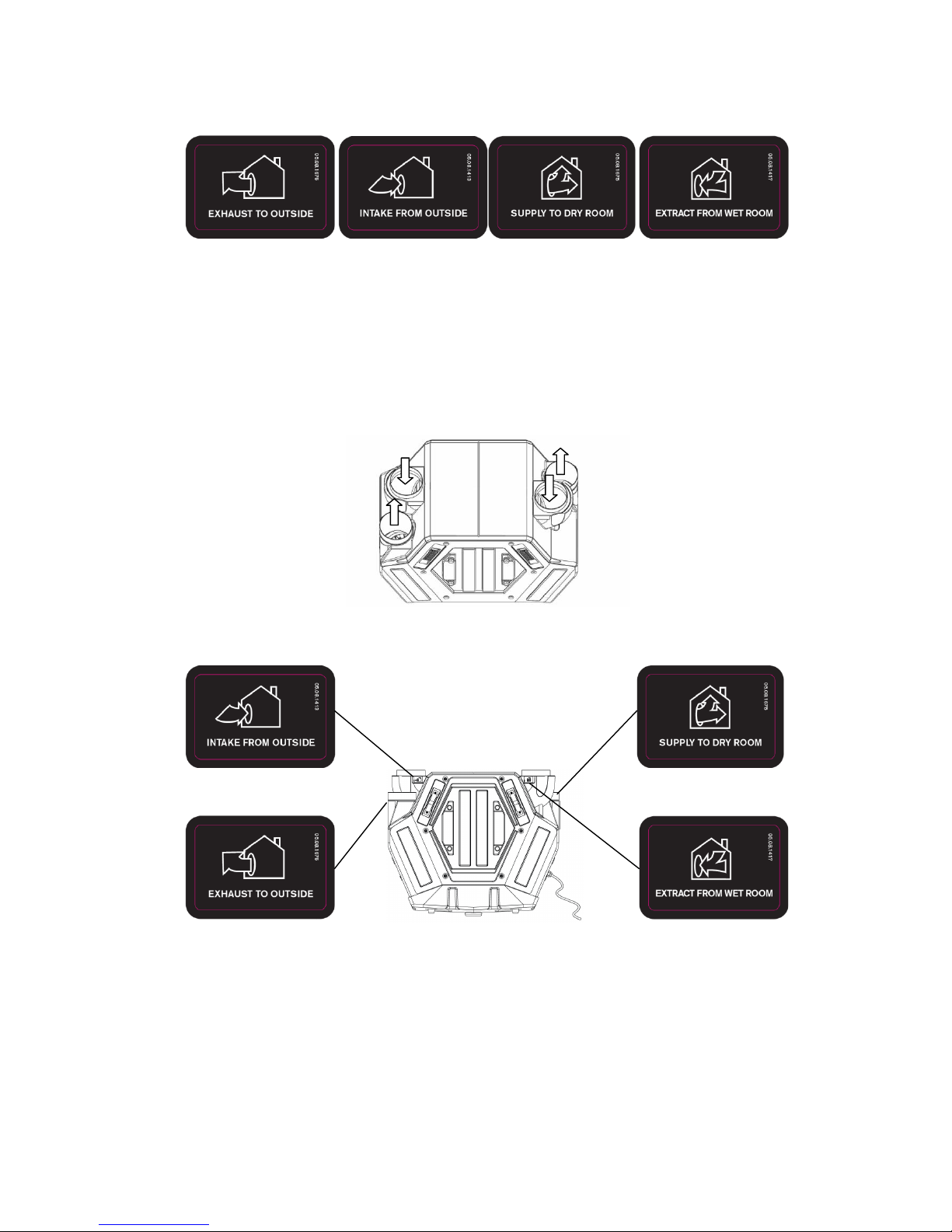

2.2.5

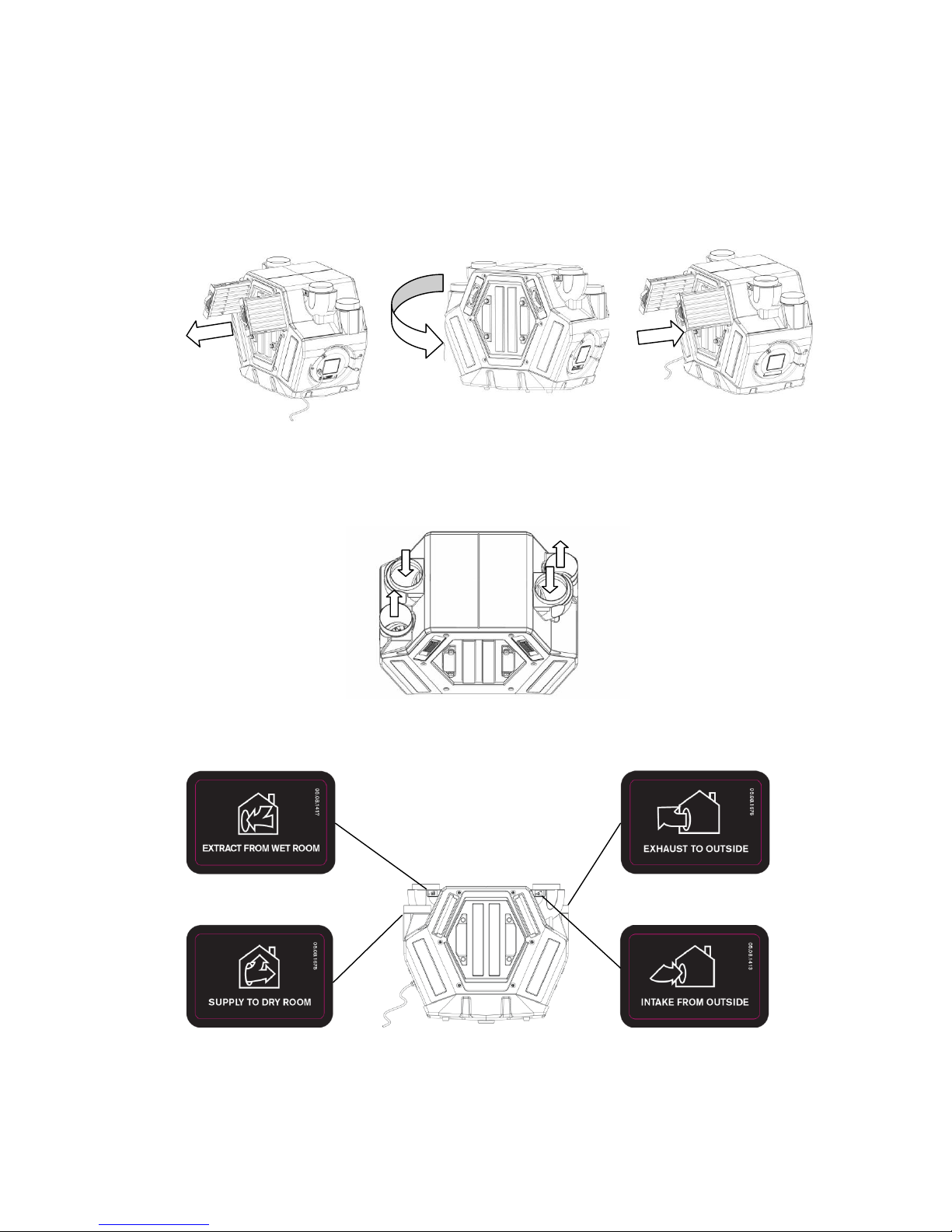

Configuration Symbols

Exhaust Air Intake Air Supply Air Extract Air

Exhaust Air

Intake Air

Supply Air

Extract Air

– Port to exhaust stale air to outside

– Port to intake fresh air from outside

– Port to supply fresh air to dry rooms

– Port to extract stale air from kitchen and wet rooms

Right Hand Configuration (factory setting) (See Figure 1)

Top View

Front View

Supply Air

Extract

Intake

Exhaust

Figure 1

2.2.6

Page | 5

2.2.7

Left Hand Configuration

The handing of the unit can be changed by following the 3 steps as shown below (See Figure 2), and does

not require any internal changes.

1) Remove both filters from the unit.

2) Rotate unit through 180 degrees.

3) Reinsert both filters into the unit.

Step 1 Step 2 Step 3

The unit is now in left hand configuration mode with altered duct connections (See Figure 3).

Top View

Front View

Intake

Exhaust

Supply Air

Extract

Figure 3

180○

Figure 2

Page | 6

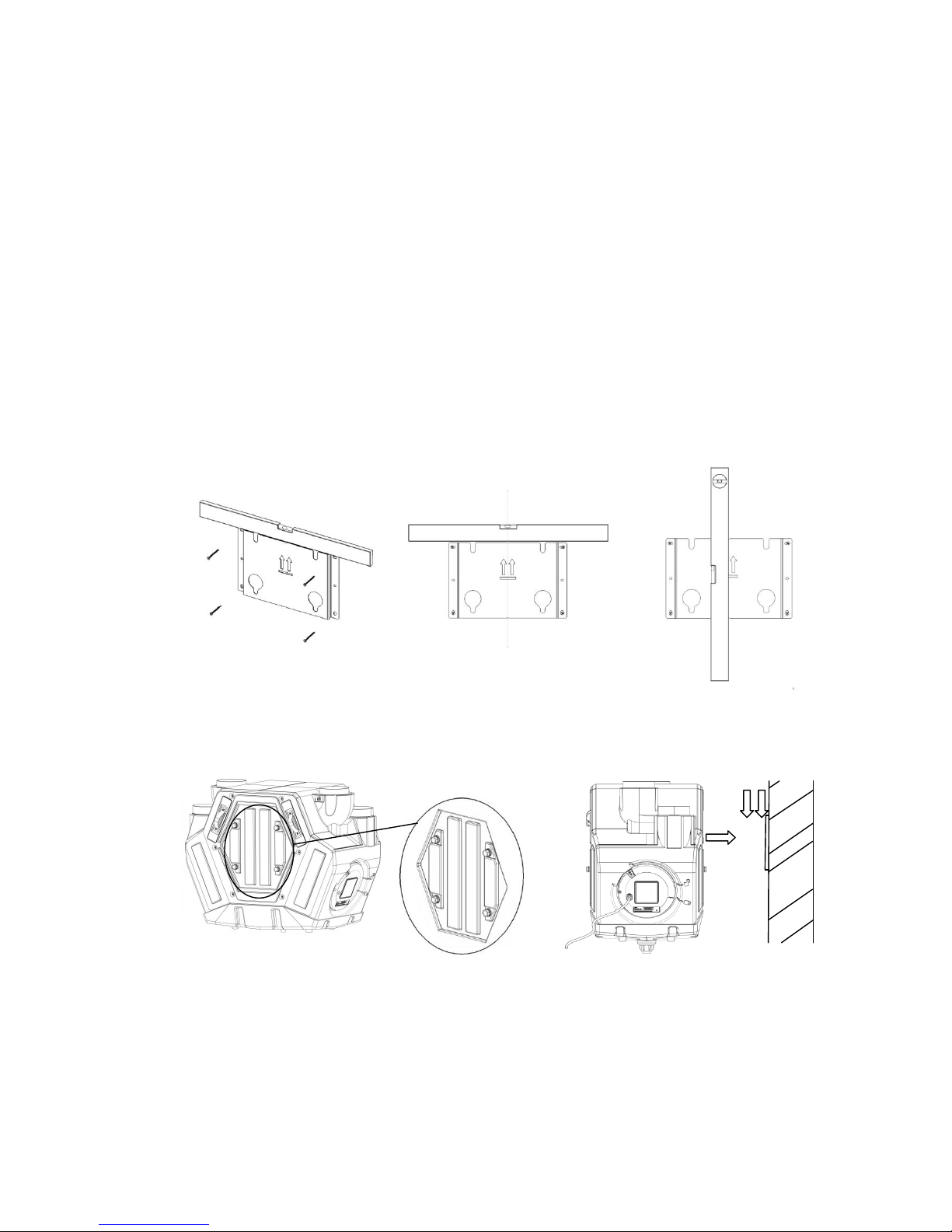

2.3

2.3.1

2.3.2

2.3.3

2.3.4

Mounting (Vertical Installation Only)

The HRV2HT unit is supplied with one wall fixing bracket. The bracket has six fixing points available; four of

these are slotted, and located in each corner. Minimum acceptable number of fixing points for mounting is

four. Screws and fixings not supplied.

Proceed to align the wall bracket taking into account the available wall space to mount the unit, ensuring that

the wall can support 20kg.

Use a spirit level to assist mounting and levelling the bracket (See Figures 4 & 5). Use ‘V’ slots located top

and bottom of bracket to mark a vertical pencil line (See Figure 6), and securely fix bracket to wall using

suitable fixings. Total product weight when running 20kg.

The HRV2HT unit fixes to the bracket by aligning the four mounting studs on the rear panel (See Figure 7),

with the large holes and slots on the fixing bracket (See Figure 4 or 5). You can also use the pencil line

drawn earlier as a guide (See Figure 6), using the V cut out on the front of the product to align. Once the

mounting studs are located correctly, slide the product downwards so that it is securely mounted to the wall

(See Figure 8).

Note;

There should be no movement once correctly located and the filters should be accessible from the

front of the unit.

2

1

Figure 4

Figure 5

Figure 7

Figure 8

Figure 6

Page | 7

2.3.5

2.3.6

2.3.7

Access for Maintenance

Figure 9

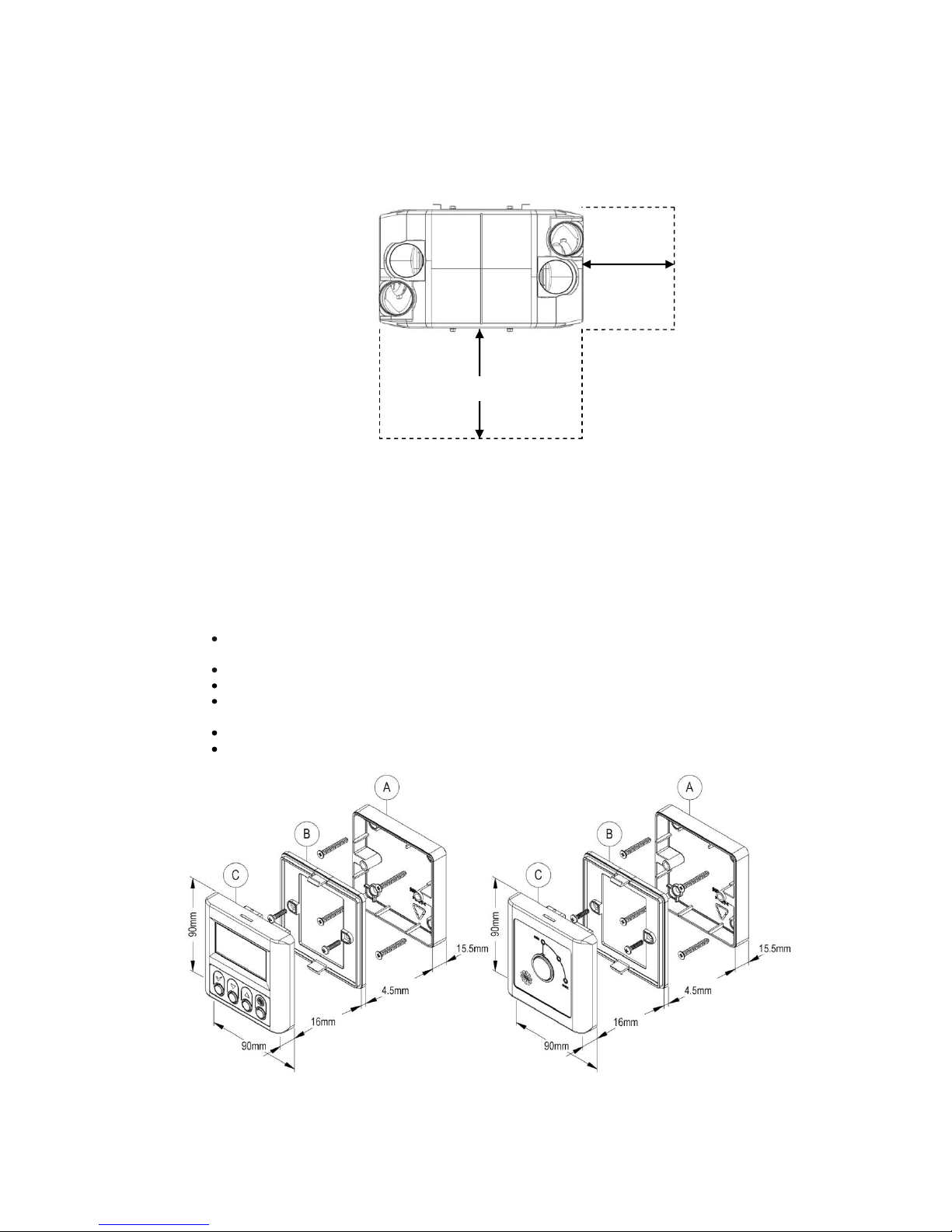

Controller Mounting

The GRF1 and GRF2 controllers can be mounted to the wall, however only the GRF1 controller can be

mounted to the HRV2HT unit. The controller is supplied with one back box, one fixing plate and one screw

and raw plug set.

Wall Mounting (See Figure 10)

Using the four countersunk screws and four raw plugs supplied, mount the back box (A) to a flush

surface.

Using the remaining two pan head screws, mount the fixing plate (B) to the back box.

Place the control panel (C) onto the fixing plate until the top and bottom clips are fully engaged.

The controller must not be mounted in a bathroom or above / closer than 1mtr to a cooker where

the screen could be affected by excessive heat or moisture.

Surface mounted depth 36mm

Recess mounted depth 20.5mm

Figure 10

GRF1 Controller GRF2 Controller

Footprint of HRV2HT (top view)

500mm

150mm

Page | 8

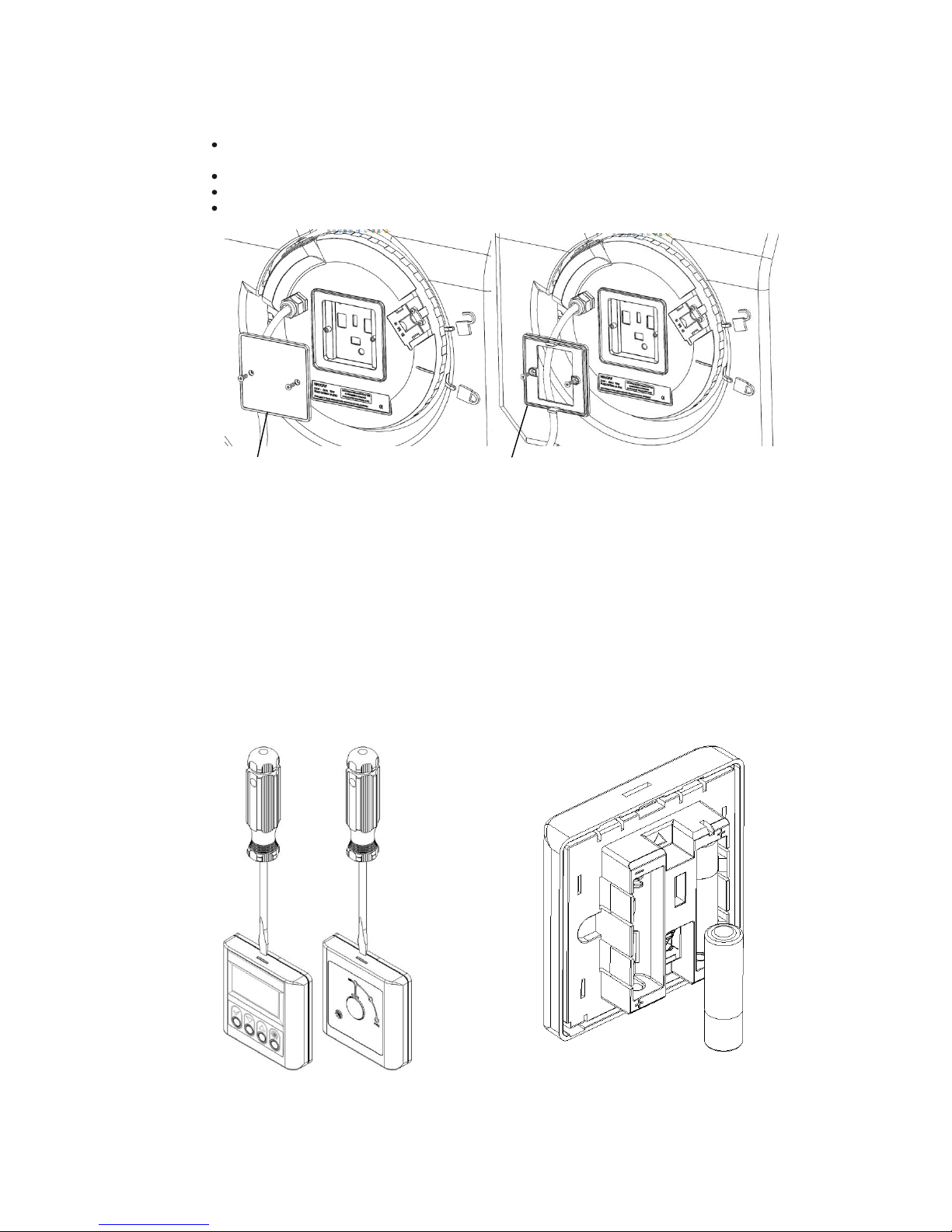

2.3.8

2.3.9

Unit Mounting for GRF1 only (See Figure 11 & 12)

Remove the ‘access for controls pairing’ panel (See Figure 11) located on the flying lead side of the

HRV2HT revealing the docking connector.

Using the original two screws, mount the fixing plate (See Figure 12) to the unit.

Remove any batteries from the controller

Place the GRF1 controller onto the fixing plate until the catch clicks into position.

Figure 11 Figure 12

Removal of the GRF1 and GRF2 Front Cover (for battery insertion / replacement)

The fixing clips (located at the top and bottom) hold the controller securely in place. Never attempt to pull

the controller away from the fixing plate without releasing the clips first, otherwise you could cause damage

to the fixing plate or controller.

Using the tip of a flat blade screwdriver, gently push in to free clips before easing off the controller to remove

(See Figure 13). Insert 2 x AA (non-rechargeable) batteries (See Figure 14). To refit the controller ensure

the correct orientation, before clicking the controller back onto the fixing plate, please ensure both clips at

the top and bottom are fully engaged.

Figure 13 – Recessed Image Illustration Figure 14

Fixing Plate

Access for controls

pairing panel

Loading...

Loading...