Green Technik CIP 1300 Operation And Maintenance Handbook

AZIENDA CON SISTEMA QUALITÀ

CERTIFICATO

==UNI EN ISO 9001/2008

R

1300

PROFESSIONAL

CHIPPER

OPERATION AND

MAINTENANCE HANDBOOK

By: GREEN-PRODUZIONE s.r.l.

Via Mons. Vigolungo, 2 - 12040 VEZZA D'ALBA -

www.green-technik.com

info.green@green-technik.com

R

CAUTION !

Rev. 01/03

Befor using the machine, carefully read this Handbook!

INSTRUCTION MANUAL CONTENTS

CHAPTER PAR. DESCRIPTION PAGE

01

02

03

04

05

06

Information

1.1 Preamble 3

1.2 Main warnings 4

General information

2.1 Introduction 6

2.2 Regulatory references 6

2.3 Purpose of the document 6

2.4 Use of the manual 7

2.5 Compliance with legislation 7

2.6 Keeping the manual 7

2.7 Information for the User 8

Technical description of the machine

Basic parts of the machine and their

positions

Safety guards and protection devices

Residual risks concerning the machine

6.1 Considerations regarding safety

conditions and residual risks

3

6

9

10

11

12

12

07

08

09

10

Transporting the machine

Checks

Starting the machine

Using the machine

10.1 Positioning the discharge conveyor 17

10.2 Control bar 18

10.3 Clogging of the discharge mouth 21

14

15

16

17

CIP1300 – Use and Maintenance Manual

1

11

Ordinary maintenance

22

11.1 Adjusting the rotation speed of the rollers 22

11.2 Immobilising the flywheel for maintenance

23

operations

11.3 Adjusting the blades and the counter-

24

blade

11.4 Replacing the blades 25

11.5 Replacing the counter-blade 26

11.6 Sharpening the blades and the counter-

26

blade

11.7 Maintenance of the spark ignition engine 27

11.8 Checking and replacing the hydraulic oil 27

11.9 Replacing the hydraulic filter 27

11.10 Lubricating the flywheel supports 28

11.11 Lubricating the mobile roller running

28

guides

11.12 Lubricating the coupling collar of the

28

discharge conveyor

11.13 Checking and replacing the multiplier oil (PTO

28

version)

11.14 Checking the tension of / Replacing the

29

transmission belt (Tractor PTO version)

11.15 Checking the tension/Replacement of the

30

transmission belt (motorised version)

12

13

14

15

16

17

18

No-Stress Device

12.1 Adjustment of the No-stress device

31

31

(optional)

Malfunctions

13.1 Possible malfunctions

32

32

Causes and solutions

Pictographs and symbols

33

14.1 Pictographs and symbols 33

Electrical system

15.1 No-Stress device electrical system (on

34

34

request)

Identification plate of the machine

Demolition of the machine

Warranty

35

36

37

CIP 1300 – Use and Maintenance Manual

Warranty slip

38

2

K

Chapter 1 INFORMATION

GENERAL INFORMATION CONCERNING THE USE AND

MAINTENANCE MANUAL OF THE CIP1300 CHIPPER

1.1 Preamble

“CAUTION”: This term is used to identify eventualities that can

compromise the integrity of the machine.

These are shown in italics.

“WARNING”: This term, on the hand, is used to identify eventualities

that can compromise the safety of the operator.

These are shown in italics and in some case in bold.

N.B. In all the chapters of this Instruction Manual, the location of the

accessories and the various parts of the machine is always given as in

the diagram shown below.

BAC

RIGHT SIDE

LEFT SIDE

FRONT

CIP1300 – Use and Maintenance Manual

3

Chapter 1 INFORMATION

1.2 Main warnings

The protection guards have been put in place by the

manufacturer to protect the safety of the operator.

During operation the protection guards must not be

removed for any reason..

It is extremely important that no one passes through the

work area of the machine except the operator. The

operator must in no case climb onto the structure of the

machine.

All the maintenance, adjustment and replacement

operations described in this Manual must only be carried

out after stopping the machine.

During blade removal, adjustment and replacement

operations, the operator must wear protective gloves to

avoid possible accidents.

(The manufacturer of the machine supplies a pair)

While processing is being carried out the operator is

required to wear anti-noise muffs given the high noise

level of the production cycle (the sound pressure level

measured at a distance of 1 m exceeds 80 dB).

During processing the operator must wear a pair of

glasses to protect the eyes from sawdust from the

processing.

CIP 1300 – Use and Maintenance Manual

4

Chapter 1 INFORMATION

Do not throw away residual hydraulic oil, but dispose of it

in accordance with regulations in force.

Do not, for any reason, interfere with the hydraulic system

of the machine, in particular with reference to regulation of

the oil pressure which is set by the Manufacturer and will

never require further action.

The manufacturer has placed on the machine various

pictographs and symbols, in conformity to current

legislation, so as to warn the operator about residual risks

5%

during operation.

While moving the machine in its travel position, there is

the risk of it overturning.

You must therefore check beforehand the slopes and

unevenness of the route to be taken before attempting to

move the machine.

The path taken must not have a gradient greater than 5%.

Do not allow persons not authorised and not assigned to

the work to have access to the controls of the machine.

It is extremely important that no one passes through the

work area. Any persons not connected with the operation

must not pass through or be in the area of the machine’s

movement.

The machine must only be used by one person at a time.

CIP1300 – Use and Maintenance Manual

5

Chapter 2 INFORMATION

GENERAL INFORMATION CONCERNING THE INSTRUCTION MANUAL

2.1 Introduction

This Manual is a useful aid to knowing your machine and using it correctly: so you

need to read the Manual carefully before using it.

Every machine is sold together with its own INSTRUCTION MANUAL.

The User is responsible for looking after this Manual for the whole life of the machine

and will see to its destruction only when the machine itself is dismantled.

The Green Produzione. firm will not be answerable for any tampering with this

Manual or for any changes made to the User’s machine, after delivery, and not

provided for in this document.

The Manufacturer reserves the intellectual property rights of this Manual and forbids

its distribution, in whole or in part, in any form (print, photocopy, microfilm, or other

means) and also its elaboration, reproduction or distribution via systems, or legal or

physical persons, without its approval and recording.

2.2 Regulatory references

When putting together the Manual, indications contained in the following documents

have been used:

Directive 2006/42/CE, Appendix and modifications

UNI EN ISO 12100-1 – Safety of machinery: Terminology

UNI EN ISO 12100-2 – Safety of machinery: Technical specifications and

principles

2.3 Purpose of the document

The purpose of the Manual is to provide the User with the instructions and

information that should be scrupulously followed for correct use of the machine and

for protecting the safety of the operator called upon to interact with it.

For this reason the User is invited to:

Make this document available in the workplace and make it known and show it to

all the operators.

Pass on the Manual to later owners of the machine.

CIP 1300 – Use and Maintenance Manual

6

Chapter 2 INFORMATION

2.4 Use and conservation of the Manual

This Manual is intended for the User of the machine, those in charge of the moving,

installation, use, supervision and final dismantling of the machine.

The purpose of the Manual is to indicate the intended use for which the machine was

designed and its technical features; it provides instructions for moving it, its proper

and safe installation, its assembly, adjustment and use; it provides information for

carrying out maintenance operations, facilitates the ordering of spare parts and

provides indications concerning possible residual risks.

In particular, it must always be possible to consult it for the following information:

Intended conditions of use of the machine;

The work position occupied by the operator;

Instructions relating to:

Putting the machine into operation, its use, transportation, installation, assembly

and disassembly, adjustment, maintenance and repair work, and any training

instructions there may be.

2.5 Complying with legislation

As well as the rules of this Manual, specific legislative provisions in the field of

accidents at work must be followed.

2.6 Keeping the Manual

The Manual is considered an integral part of the machine and must be kept in good

condition until final disposal of the machine.

The Manual must be kept in a protected place, dry, and sheltered from the sun’s

rays, and must always be easy to find and available for consultation, near the

machine.

CIP1300 – Use and Maintenance Manual

7

Chapter 2 INFORMATION

2.7 Information for the User

1 - This manual reflects the current technical state of the machine and cannot be

considered inadequate simply because it is later updated on the basis of new

experience.

2 - The Manufacturer reserves the right to update production and manuals, without

being obliged to update previous production and manuals.

3 - The characteristics of materials can be changed at any moment, in accordance

with technical developments, without prior notice.

4 - Where the machine is without an electric control and protection device (on board

electric panel) , the Manufacturer does not assume any responsibility concerning

safety problems deriving from electrical parts not conforming to what is advised

and/or laid down.

In any case compliance with all electricity related Laws and Regulations for

equipment the machine is fitted with shall be exclusively the responsibility of the

Customer, who shall install it to the required standard and fit for the purpose for

which it is to be used.

5 - The Manufacturer considers itself relieved of any responsibility where the machine

has been put to:

Q improper use;

Q use by untrained staff;

Q use contrary to what is set out in this Manual;

Q use contrary to Regulations and Legislation currently in force;

Q use with a mains power supply defect;

Q use with serious lack of specified maintenance;

Q use with modifications or work carried out not explicitly authorised by a written

note from the Manufacturer;

Q use of non-original spare parts or spare parts not specifically defined for the

model;

Q use with total or partial failure to observe the instructions contained in this

Manual.

6 - The general sales warranty is void in case of:

Q poor conservation;

Q mishaps through incorrect use;

Q use by inexperienced personnel;

Q exceeding performance limits;

Q excessive mechanical and/or electrical and hydraulic stress

Q use under the non-optimal conditions described in point 5.

Any requests for further copies of this document must be formalised with a purchase

order forwarded to Green Produzione.

CIP 1300 – Use and Maintenance Manual

8

Chapter 3

TECHNICAL DESCRIPTION OF THE MACHINE

The CIP 1300 chipper has been designed for the reduction in volume of

pruning residues, branches or woody debris into small size fragments.

The material introduced into the loading mouth is pulled by two rollers against

the cutting disk.

The two pulling rollers are powered by independent speed-adjustable hydraulic

motors.

On the cutting disk, that rotates at a speed of 1500 rpm, two blades are

assembled that reduce the material to splinters of a 5-20 mm. length and a

counter-blade, fixed to the structure, that further reduces the splinters into

“chips”.

The “chips”, through the centrifugal action of the cutting disk, are projected into

a discharge conveyor.

The conveyor can be pointed in the required direction of discharge.

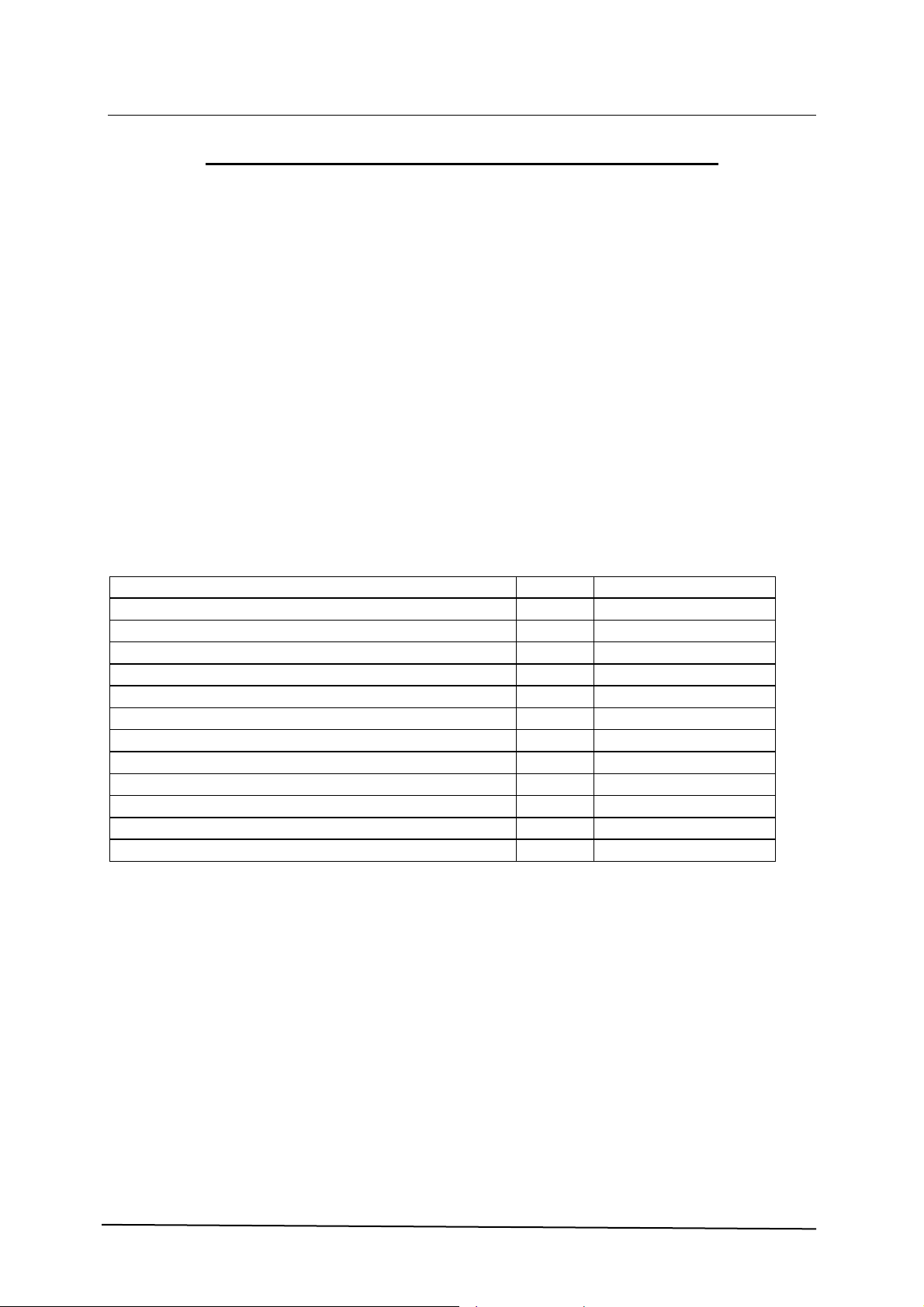

Technical features

• size of loading mouth

• MAX shreddable diameter

• diameter of flywheel

• thickness of flywheel

• blades

• rotation speed of flywheel (max)

• length of shredded material

• diameter of feeder rollers

• maximum width between the rollers

• power of independent motor (YANMAR / HONDA)

• hourly production

• airborne noise produced by the machine

• weight

( 1 ) The MAX noise level indicated is measured in the operator area, during work

? Greater than 85 dB: the use of muffs is compulsory

mm 960 x 670

mm 130

mm 680

mm 25

n° 2

g/min. 1500

mm 6 ÷ 12

mm 120 -120

mm 140

kW 8,2 ÷ 13.5

3

3 ÷ 5

m

( 1 )

Db (A)

Kg 420 ÷ 490

?

CIP1300 – Use and Maintenance Manual

9

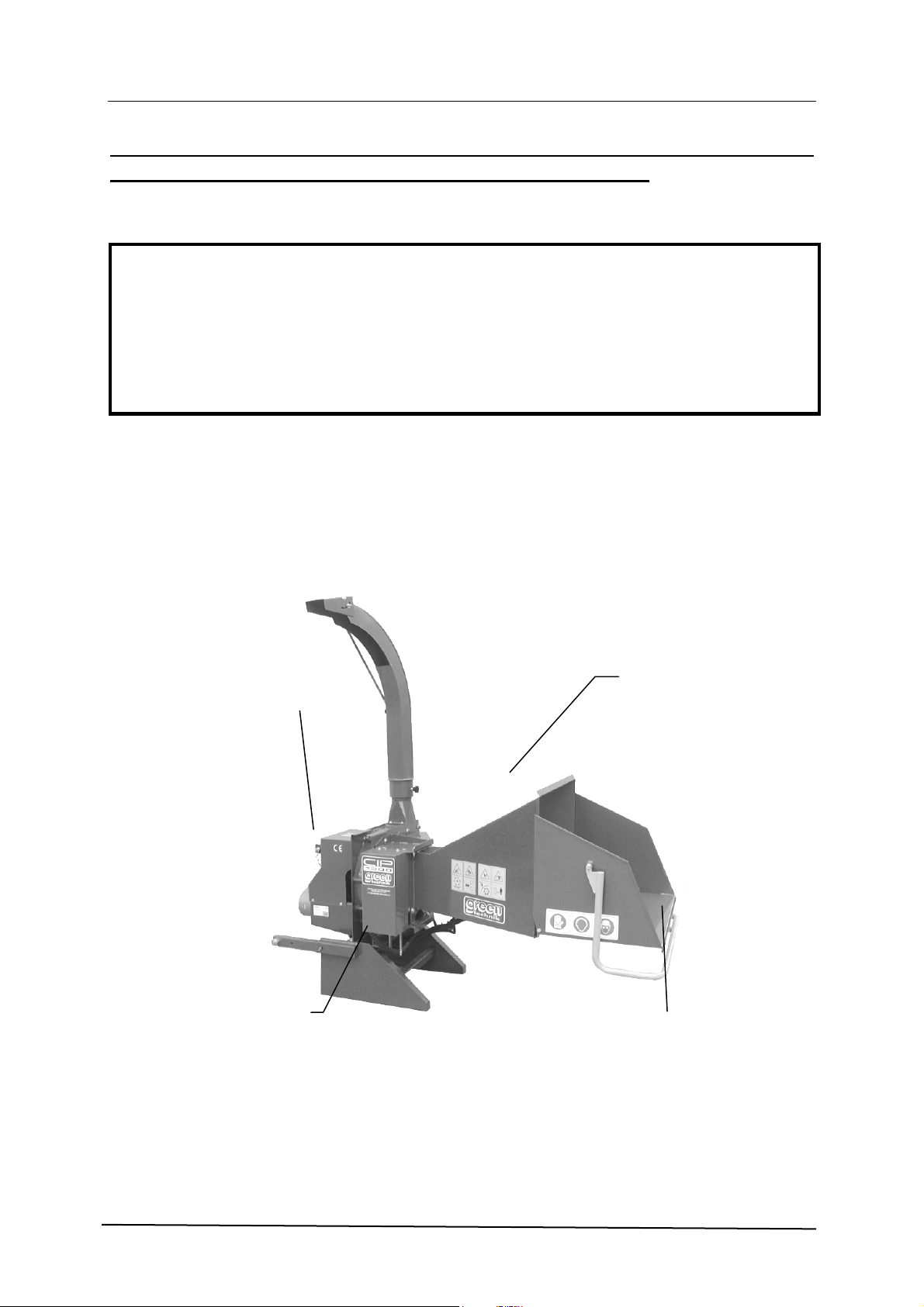

Chapter 4

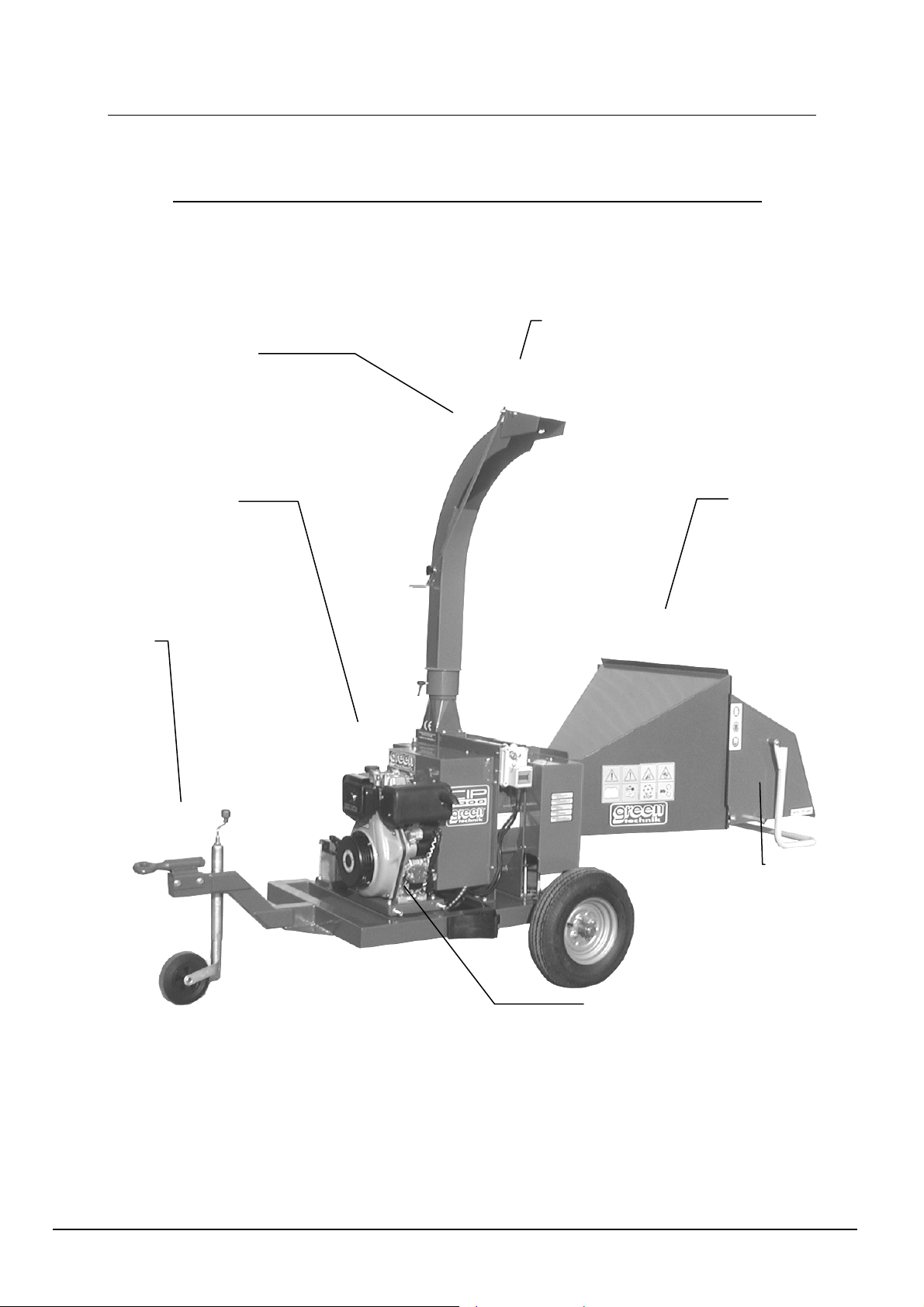

U

BASIC PARTS OF THE MACHINE AND THEIR POSITIONS

LAUNCH

T

DISCHARGE DEFLECTOR

BE

TOW BAR

ENGINE

LOADING

MOUTH

CONTROL

BAR

CHASSIS

CIP 1300 – Use and Maintenance Manual

10

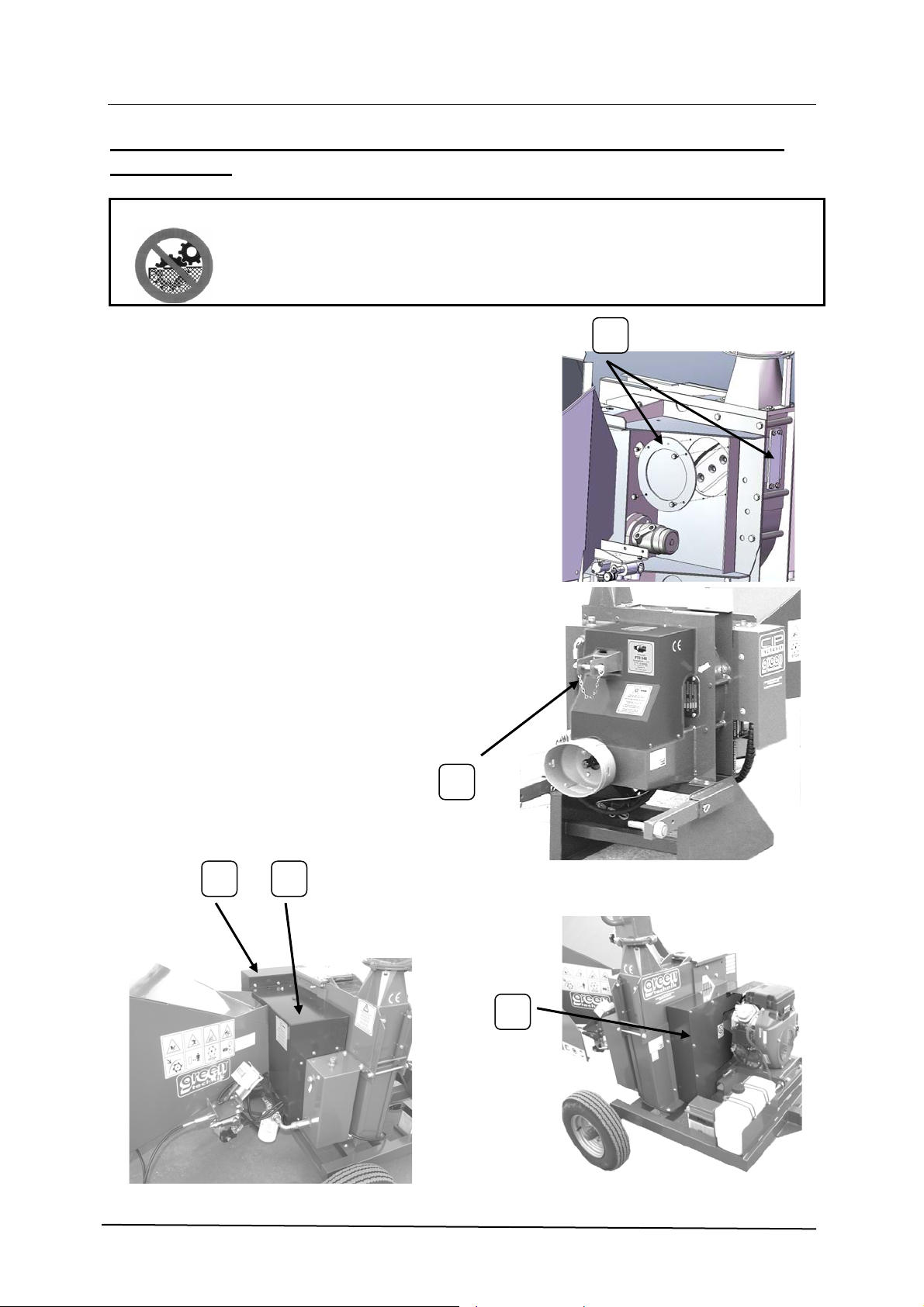

Chapter 5 SAFETY PROTECTION DEVICES

PROTECTION GUARDS AND DEVICES ADOPTED FOR REASONS

OF SAFETY

CAUTION:

A) Fixed guards to close off the flywheel

rotation area.

B) Hydraulic motor side protection case.

C) Hydraulic pump rear protection case.

D) Transmission belt fixed guard (PTO version

– CIP 1300PTO).

E) Transmission belt fixed guard (Motorised

version – CIP 1300Y18 - 1300H24)

N.B.: the guards must in no way be

removed: when carrying out

maintenance switch off the engine

and remove the key from the control

panel or, for the P.T.O. version,

disconnect the cardan shaft

The guards have been put in place by the manufacturer to

protect the safety of the operator.

During operation the guards must not be removed for any

reason.

A

D

C B

CIP1300 – Use and Maintenance Manual

E

11

Loading...

Loading...