Green Technik CIP 1000 Operation And Maintenance Manual

Rev. 01/03

1000

60

R

www.green-technik.com

info.green@green-technik.com

By: GREEN-PRODUZIONE s.r.l.

Via Mons. Vigolungo, 2 - 12040 VEZZA D'ALBA -

R

AZIENDA CON SISTEMA QUALITÀ

CERTIFICATO

==UNI EN ISO 9001/2008

PROFESSIONAL

CHIPPER

OPERATION AND

MAINTENANCE HANDBOOK

CAUTION !

Befor using the machine, carefully read this Handbook!

Dear Sir,

We would thank you very much for giving your preference to the high quality of our

machines Green-technik

Please read carefully and comply with the instructions included in this Use and

Maintenance Handbook in order to insure your CIP1000 machine a long life and

several years of profitable working activity.

Have a good job !

Ver. 01/01

CIP1000 User's Handbook

INTRODUCTION

Green technik is a registered trademarks

C

R

Page 1

LIST OF CONTENTS

FOREWORD

Machine data plate Page 2

How to use and preserve this User's Handbook Page 3

Safety warning Page 3

Intended conditions of use Page 5

Prohibited conditions of use Page 6

Personnel training Page 7

Safety equipment: checking and setting Page 8

Other possible hazards and emergency conditions Page 8

Machine technical description Page 10

Controls and stops Page 11

Instructions for use, calibration and set-up of the machine Page 12

Machine handling Page 14

Page 14

Maintenance instructions Page 15

Instructions for routine repairs Page 16

Spare parts Page 18

MAINTENANCE MEMORANDUM Page 24

GUARANTEE RULES AND CONDITIONS Page 25

SECTION A: GENERAL INFORMATION

SECTION B: INSTRUCTIONS FOR THE MACHINE USE

SECTION C: EXPLOSION ENGINE USER'S HANDBOOK

SECTION D: MAINTENANCE AND REPAIR

FOR USING THE MACHINE IN SAFETY

FINAL DISMANTLING Page 23

CIP1000 User's Handbook

Page 2

CIP1000 User's Handbook

This Handbook, including the instructions for use and maintenance of the

concerned machine, has been drawn up in compliance with the EEC-Directive

2006/42/CE,Attachment I, para. 1.7.4 and following amendments.

The manufacturer reserves the right to apply any changes in the machine, without

prior advice, however taking for granted its main safety features.

A CE Identification Dataplate and a CE Evidence of Conformity are attached to every

machine, by the terms of and in compliance with the EEC-Directive 2006/42/CE and

following amendments.

Sound pressure level at driver's place 98,7 dB(A)

Sound power level 111,4 dB(A)

Sound pressure level at driver's place 93,5 dB(A)

MACHINE DATAPLATE

NOISE EMISSION

Full rated running, on-load:

Full rated running, no-load:

MODEL:

CIP1000-H13 CIP1000-H20

Manufacturer's name and address:

Green-Produzione.via Mons. Vigolungo ,2 - 12040 VEZZA D'ALBA(CN) ITALIA

Tel. 0173/65609 - Fax 0173/65618

http://www.green-technik.com

E-mail: info.green@green-technik.com

FOREWORD

MODELLO - MODEL

MASSA - WEIGHT KG.

N SERIE - Nr. SERIES

ANNO-YEAR * MADE IN ITALY *

CIP 1000

GPreen- roduzioneGP

Borbore di VEZZA D'ALBA (CN) ITALY

By:

www.green-technik.com

Page 3

CIP1000 User's Handbook

FOREWORD

HOW TO USE AND PRESERVE THIS USER'S HANDBOOK

SAFETY WARNING

- This User's Handbook intends to be a sound reference and working tool to them

who will use our shredder CIP 1000; it includes some practical guidelines on

how to use the machine according to its design principles and technical features

as well as to move, install, assemble, adjust and use it correctly. Besides this

Handbook includes a few hints on your personnel's training and suggests how to

service your machine, to order spare parts easily and avoid any risk of damages

or injury.

- This Handbook has to be considered an integral part of the machine supply

volume and it should be carefully preserved for any future reference during the

machine operating life time.

- This Handbook should be kept in an easily accessible place, near the machine,

to allow the personnel to promptly find and consult it, and put in a dry place,

sheltered from the sunlight.

- In case of loss, a copy of this Handbook may be ask for to the machine

manufacturer,by specifying the machine model and Series Number.

- This Handbook reflects the technical engineering level reached at the time of

machine delivery and it has to be considered as corresponding to the state of the

art even if some further revisions will be applied later for the sake of adaptation to

the latest know-how.

- Green Technik reserve the right to update their products and Handbooks, without

being obliged to retrofit or revise also their previously delivered products and

Handbooks.

In order to insure highest working reliability, Green Technik carried out a careful

selection of materials and components to be used for the manufacture of their

shredder/chippers, and careful tests and inspection are performed before the

machine delivery to customers. Of course, the good operation of a machine in the

long run depends also on its correct use as well as on a suitable preventive

maintenance, to be carried out in conformity with the directions included in this

Handbook.

All the machine structural components, connecting members and controls has

been designed and manufactured with such a high level of safety to resist

anomalous stresses, even higher than specified in this Handbook. The high-grade

materials used on the machine are the best assurance for no damages, wear or

malfunctions.

However,at least the following guidelines should be complied with:

1) NEVER USE OR INTERVENE ON THE MACHINE WITHOUT FIRST READING

AND WELL UNDERSTANDINGTHE GUIDELINES IN THIS HANDBOOK.

Page 4

CIP1000 User's Handbook

FOREWORD

2) IN PARTICULAR, THE PRECAUTIONARY MEASURES SHOULD BE TAKEN

AS LISTED UNDER SECTION ”A” - SAFETY REGULATIONS AND

INFORMATION.

3) IT IS STRICTLY PROHIBITED TO USE THE MACHINE UNDER CONDITIONS

OTHER THAN EXPRESSLY INDICATED IN THIS HANDBOOK. GREEN

TECHNIK CANNOT BE DEEMED RESPONSIBLE FOR ANY TROUBLES,

FAILURES OR INJURY ARISING FROM THE NON-COMPLIANCE WITH THE

ABOVE MENTIONED PROHIBITION.

This Handbook consists of four sections:

dealing with SAFETY REGULATIONSAND INFORMATION

dealing with MACHINE FEATURES - INSTRUCTIONS FOR USE - TRANSPORT STORAGE.

including some advice for a correct use of the internal combustion engine and its

ordinary maintenance

dealing with the MAINTENANCE OPERATIONS required and including a LIST OF

SPARE PARTS

SECTION A:

SECTION B:

SECTION C:

SECTION D:

CAUTION

Avoid tampering, altering or changing, even partly, the

SHREDDER/CHIPPER components, in particular the guards

provided as a safeguard to the people.

Page 5

INTENDED CONDITIONS OF USE

While thanking you for your trust in our products, our CHIPPER Mod. CIP 1000 in

particular, we would remind you that the use of this machine is representative of a

style of life, where the environment protection is a basic principle and the recycling

practice takes the place of an indiscriminate disposal of waste.

Before starting to chip the trimmings and the wooden matters in general,

separate the materials according to the size in order to favour their inlet into the

chipper mouth.

Avoid triturating unsuitable materials as plastics or printed paper.

The chipper is intended for operating outdoor; of course, in case of bad

weather conditions, avoid using the machine and store it in a suitable and

sheltered place.

CIP1000 User's Handbook

SECTION A: GENERAL INFORMATION

CAUTION

Green Technik undertakes no responsibility in case any safety guards or

loading hoppers installed on the machine are changed or removed, as well

as in case of non-compliance with the obligations and/or prohibitions

expressly specified in this paragraph and, in general, of any of the rules and

provisions set forthin this Handbook.

Page 6

PROHIBITED CONDITIONS OF USE

Working materials other than specified in this Handbook could give rise to serious

damages to the machine, not to say of the risks of injury to the operator. Besides

this, it is expressly prohibited to put other materials into the machine as e.g. ballast

and rock pieces, section irons, glass, plastic materials, parts of wooden boxes with

nails or iron wires left therein, trunks and/or branches having diameter larger than

specified on the transfer affixed near the mouth of every loading hopper.

This machine has been designed and manufactured to work on flat surfaces,

compact and level as much as possible; therefore, avoid to work on steep slopes,

friable or damp grounds or however under any condition which could cause the

machine to tilt during the operation or susceptible to be prejudicial to its stability.

Whenever the machine has to be moved, the engine must be compulsorily switched

off or, in case the machine is power supplied, the main cable must be plugged out,

afterwards waiting until all the machine moving parts stand still.

The same is for when the machine has to be tilted or lifted for cleaning or

adjusting purposes or any rotating element, possibly jammed on the machine, has

to be released.

Furthermore, it is strictly prohibited to open the rubber gate placed at the inlet to

the chipper hopper, to visually check for no material inside, until the machine is quite

still.

To prevent the operator from getting in touch with any moving element of the

machine, some fixed or movable safety guards have been installed, and the upper

and side loading hoppers are such in length as to avoid hands from going up to the

rotating parts.

CIP1000 User's Handbook

SECTION A: GENERAL INFORMATION

CAUTION

Green Technik undertakes no responsibility in case any safety guards or

loading hoppers installed on the machine are changed or removed, as well

as in case of non-compliance with the obligations and/or prohibitions

expressly specified in this paragraph and, in general, of any of the rules and

provisions set forthin this Handbook.

Page 7

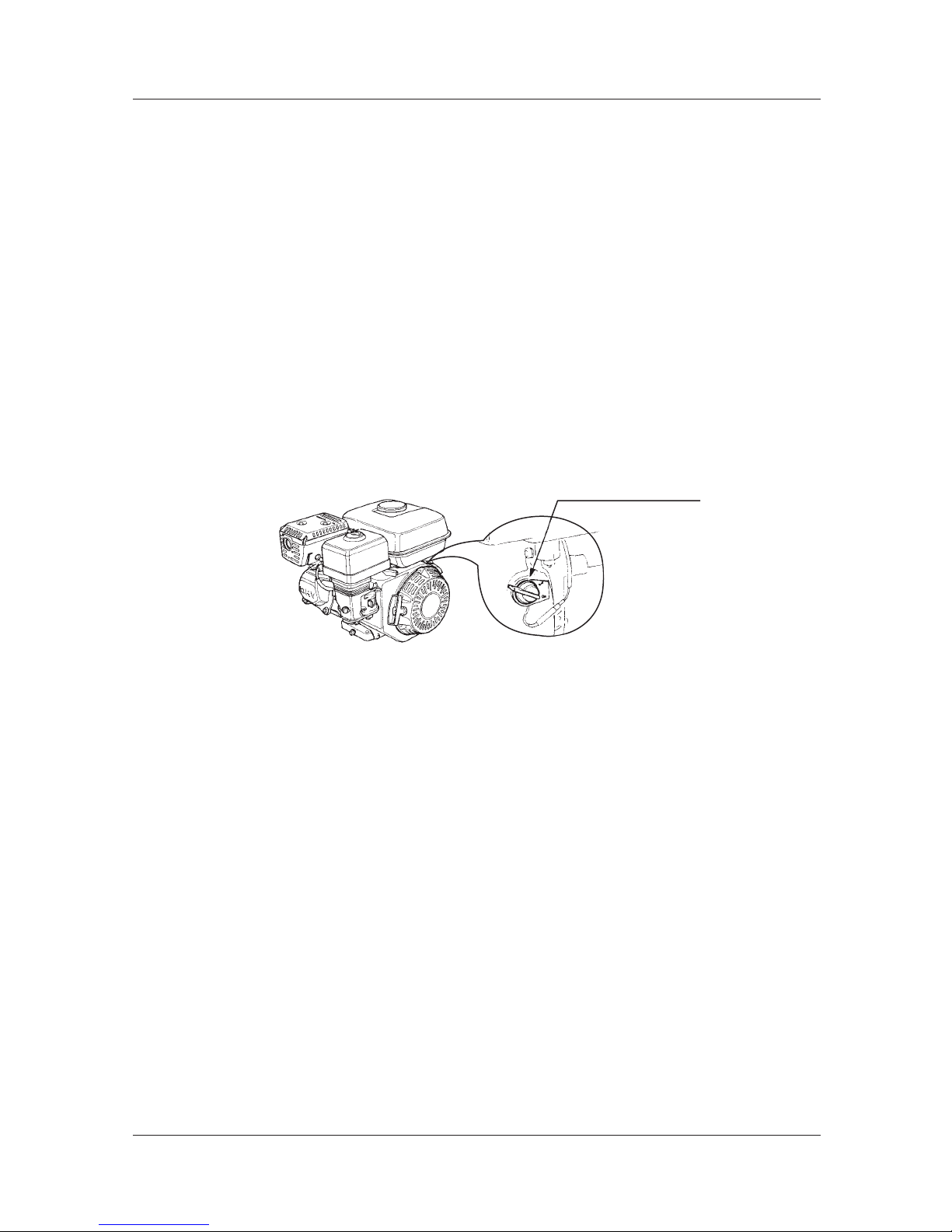

Pulsante arresto

fig. 1

CIP1000 User's Handbook

SECTION A: GENERAL INFORMATION

PERSONNELTRAINING

GENERAL REMARKS

This machine has been designed and manufactured to meet the users' hobby or for

semiprofessional use ; however, the machine should not be operated by persons

aged less than 18 years.

Should the user detect any operating trouble, malfunction or however a condition

that might be dangerous for himself or other people, he must immediately stop the

machine by pressing the stop push-button placed on the electric motor or, in case

the machine is equipped with explosion engine, on the right hand of the engine, and

avoid to carry out any intervention he is not familiar with, but promptly inform a

supervisor or call for the Green Technik's service center.

It is up to the operator to do his utmost to keep the machine clean and in

full working order.

To this purpose, the machine should be carefully cleaned after every working run;

cleaning must be carried out with machine still and stable and possibly in cooperation with an assistant.

When cleaning is carried out using pressurized air or water, the operator must wear

safety goggles and a safety faceplate and no people must stand by around the

machine, to avoid running the risk of being affected by jets of materials or dust. To

prevent the hammer assembly from oxidizing during long times of inactivity, we

recommend to carefully lubricate all its parts with oil or other oxidation inhibitors.

The use of flammable fluids during the cleaning operations is prohibited.

From time to time check the state of labels and warning tags and replace them, when

required.

Once the machine cleaning is complete, check for no worn, damaged or loose parts.

Should this be the case, and if the detected trouble cannot be solved on your own,

promptly call for a service man or inform the Green Technik Service Center.

Loading...

Loading...