GreenTec LRS 1601 Handbook & Spareparts

Page 1 af 20

LRS 1601

QUADSAW

Handbook & Spareparts

5. Edition March 2016

©GreenTec Machinery Limited

Page 2 af 20

Contents

Contents

Introduction ................................................................................................................... 3

Important ....................................................................................................................... 4

Mounting the Quadsaw ................................................................................................. 5

Operation / Introduction ............................................................................................... 6

Maintenance .................................................................................................................. 6

Driving recommendations ............................................................................................. 6

Belt diagram .................................................................................................................. 7

Correct belt adjustment ................................................................................................. 8

Technical data and description of working tool ........................................................... 9

Safety ........................................................................................................................... 10

Main Frame 1 .............................................................................................................. 11

Main frame 2 ............................................................................................................... 12

Belt tensioner box 1 ..................................................................................................... 15

Belt tensioner box 2 ..................................................................................................... 16

Knife shaft 1 ................................................................................................................. 17

Knife shaft 2 ................................................................................................................. 18

Stickers......................................................................................................................... 19

Noise measuring .......................................................................................................... 20

Suplierinformation and CE-declarations .................................................................... 20

CE-declaration ............................................................................................................ 20

Warnings, ban and directions. .................................................................................... 20

Disassemble ................................................................................................................. 20

Page 3 af 20

Introduction

Dear customer!

GreenTec LRS 1601 Quadsaw is designed

with a background of 20 years of experience

with cutting-tool technology, and building of

special machines. They are made from the

latest technology and recognized safety technical regulations, standards and regulations.

It is our goal to make a product available in

such a way that, neither during transit by further processing and compilation process or the

subsequent use is damage.

This manual contains information and instructions there are important and useful for the

preservation of LRS 1601 Quadsaw reliability,

dependability and value. Read this manual

carefully and pay particular attention to the

instructions for the avoiding of damage.

The content also makes you familiar with connectivity, use, care and maintenance. And then it helps

to prevent injuries.

We hope, you are happy with your new LRS 1601 Quadsaw.

Best regards:

John Christensen

Sales Director, GreenTec A/S

Page 4 af 20

Important

Please ensure that this manual is handed to the operator before using the machine for the first time.

The operator must fully understand the contents of this manual before using this machine.

(If the machine is resold the Manual must be given to the new owner.)

Please, fill out the following information. It is practical information that is useable when ordering

spare parts.

Serial number: ……………………………………………………

Delivery date: ……………………………………………………

Dealer name : ……………………………………………………

Address: ……………………………………………………

……………………………………………………

Tel. / Fax No.: ……………………………………………………

GreenTec A/S

Merkurvej 25

Dk-6000 Kolding

Tel: +45 7555 3644

Fax: +45 7555 4243

E-mail: info@greentec.eu

Http: www.greentec.eu

Page 5 af 20

Mounting the Quadsaw

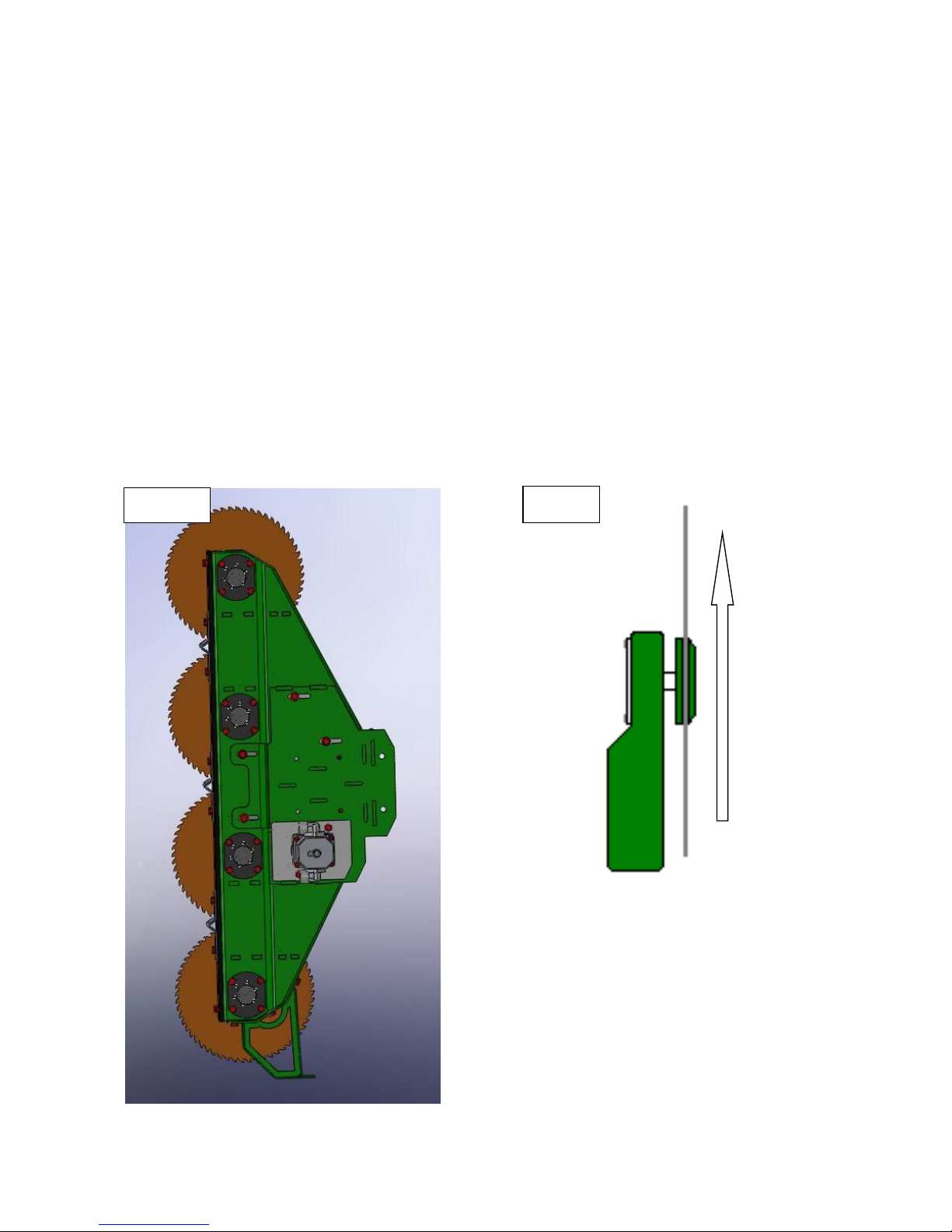

The blade is mounted, so the direction of rotation of the saw goes down (Fig. 1).

Saw is mounted in such a way, that the blade runs straight in the driving direction (Fig. 2).

Mount the hydraulic hoses so the blades are running in correct direction. The drain hose shall

go in free to the hydraulic oil tank.

Check the hydraulic system for leaks.

First time the machine is used. Measure the blades rpm 2600 – 2700 by 40 L/min.

Holding this speed is important for the best optimum performance.

This saw can NOT be changed from right to left mounting or vice versa .

Fig. 1.

Fig. 2.

Page 6 af 20

Operation / Introduction

The Quadsaw is used for cutting branches and trees up to a max. diameter of 100 mm without the

branches being torn.

Branches with a diameter over 70 mm, must be cut one of the time.

Vertical cutting is allowed up to a 45 degree angle. Horizontal cutting is possible on hedges with a

width up to. 1,0 m. and a branch diameter up to 40 mm. Thicker branches might stop the blades and

get stuck in the machine.

Maintenance

After 2 hours driving tighten everything. "Easy-Lock" connector with 14 Nm.

Allen-screws for the saw blades with 40 Nm.

After 10 hours work all bolts, screws and”Easy-Lock” retightened

All bolts shall be retightened / checked every 8 hour.

Plastic rail is adjusted down to the blades, with a distance of 1 mm. Is there more than

5 mm intervals, replace the list. Branch deflectors adjusted as closely as possible into the saw

blades, without touching the blades.

Dismount protection plate to the belts, and clean the house for dirt.

Inspect, and if necessary adjust the belts. (See belt diagram)

After inspection or service ALL protection plates and guards must be replaced.

Driving recommendations

Starting and stopping the saw shall always be at lowest pto. rpm.

It is recommended to travel at a slow forward speed when starting work in order to obtain and keep

the recommended rpm of the blades. Adjust the angle of the saw to approx 90 degrees in relation to

the branches. If a thick branch is approaching the branch reflectors , the working height must be adjusted for the branch to hit the saw blades straight on.

If small branches or other unwanted material get stuck in the blades, the machine must be stopped

and cleaned.

Always ensure that the blades are running vertical related to the direction of the travel. This will prevent the blades from bending too much.

Loading...

Loading...