GreenSpeed GT3 User Manual

f o l d i n g t r i k e m a n u a l

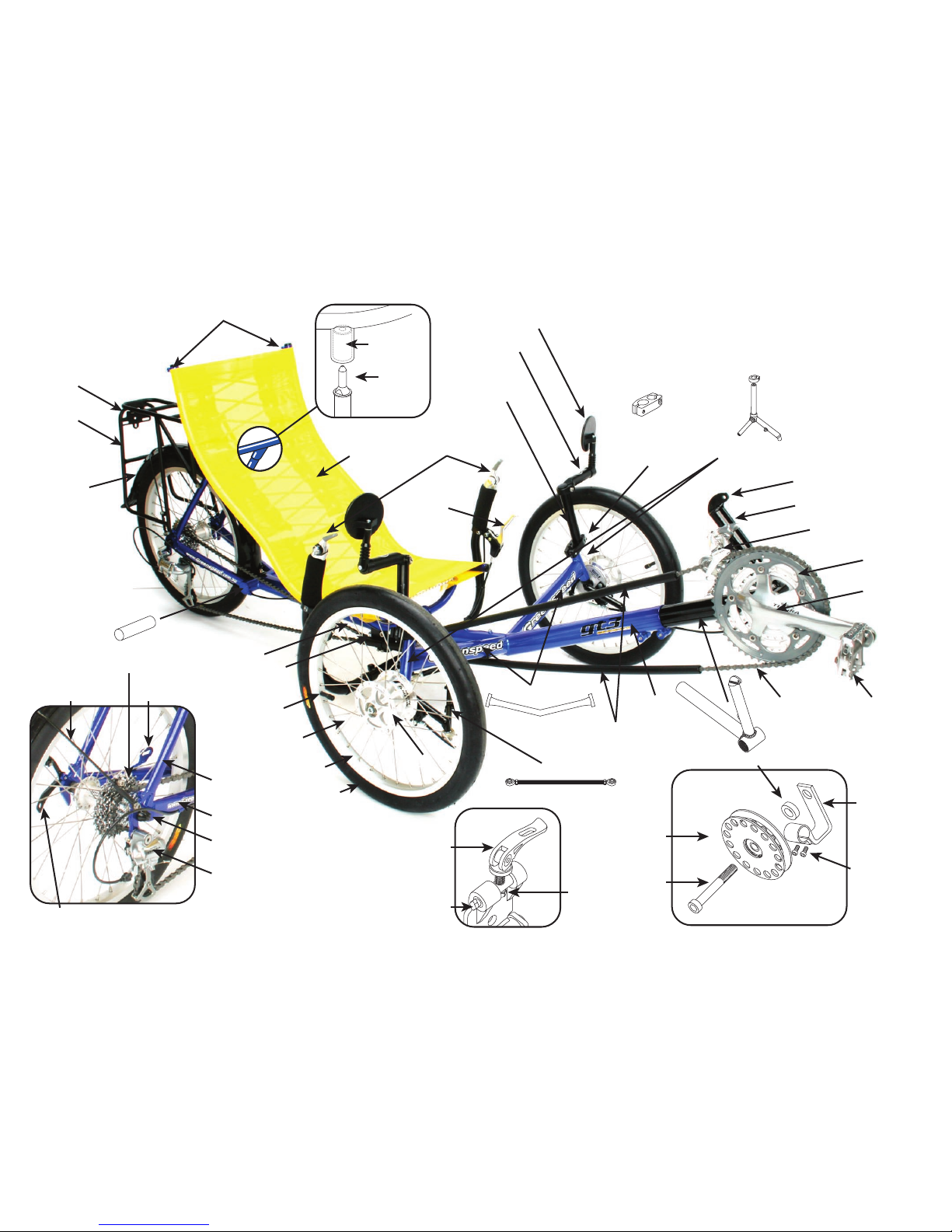

Pedal

(optional

cleated)

Cranks

Kingpin Assemblies

clamp

Steering Rods

Boom

Cross Members

Spokes

Rim

Tube Valve

Tire

Chain

Front Derailleur

Front Hub

Bar End

Gear Shifters

Brake

Lever

Seat

Tail Light and Flag Mounts

Crank

Extension

Rear Derailleur

Quick Release Nut

Quick Release Skewer

Dyanmo mount

Cluster or Rear Cogs

Fender stay

Chain Stay

Seat Stay

Guide Pulley

Bracket

Quick

Release

Nut

Guide

Pulley

Quick

Release

Lever

Pin

Guide

Pulley

Thru-bolt

Clamp

Screws

Spacer

Front Derailleur Post

Front Light Tag

Accessory

clamp

(optional)

Mirror Mount

or

Accessory post

(optional)

GrabHandle

(optional)

Mirror

(optional)

Chainrings

Chain Guide Tubes

Pulley (fig 3)

fig 2

fig 1

fig 3

Hinge (fig 2)

“T”-piece

Tail Light Mount

(inc with Rack)

Rack

(optional)

Rear

Fender

(optional on

x-series)

pin

elastomer

(inside)

2

trike anatomy

Congratulations on your purchase of a Greenspeed folding

trike. We believe that you have purchased the finest recumbent

tricycle available in the world today. It is also our belief that

the present level of motorised transport on this small planet is

not sustainable, in environmental and social terms. Thus your

Greenspeed has been designed for everyday use, whether it be

shopping, commuting, rehabilitation, touring the world or just

exercising and having fun! With care, it should last a lifetime.

Included in this manual are instructions on how to assemble,

maintain and get the most from your folding trike.

2

3

4

5

6

7

8

a s s e m b l y

The major feature of these trikes is the fold. By removing one

capscrew, with a 6mm key, the seat can be removed.

Then releasing the quick release lever on the frame hinge

allows the rear wheel and frame to be folded over the front,

halving the size of the trike, and allowing it fit into most car

boots (trunks) and other small spaces. To fit into even smaller

spaces, the wheels are easily removed.

Another feature of this trike is the 16" wheels, which make

it more compact than trikes with 20" wheels, and the special

Scorcher tyres give it outstanding performance with a very

smooth ride.

The famous Greenspeed cross over steering now has NSR

geometry, which allows straight line, one handed braking,

and gives a very small turning circle, making it a delight to

ride. A number of accessories are available from GS dealers.

welcome to the family

9

10

11

12

13

14

w h a t ’s n e x t ?

3

tricycle anatomy

design

tools

frame

fitting your wheels

~ drum

~ disc

~ disc with hollow axles

fitting disc brake calipers

removing hollow axle

wheels

adjusting your handle bars

fitting your seat

fitting your crank

extension

adjusting for your leg

length

check derailluer cables

fitting your chain

joining your chain with

split links

adjusting your brakes

~ drum brakes

~ disc brakes

adjusting your gears

~ front derailleur

~ rear derailleur

alighnment of your

steering

design

1819chain

steering

tyre presure

warranty

community

resources

m a i n t e n a n c er i d i n g

15

16

17

17

steering

gears

1st ride, stamina

pedals

negotiating doorways

regular folding

tyre repair

tools to have while riding

Q&A’s

t r o u b l e s h o o t i n g

contents

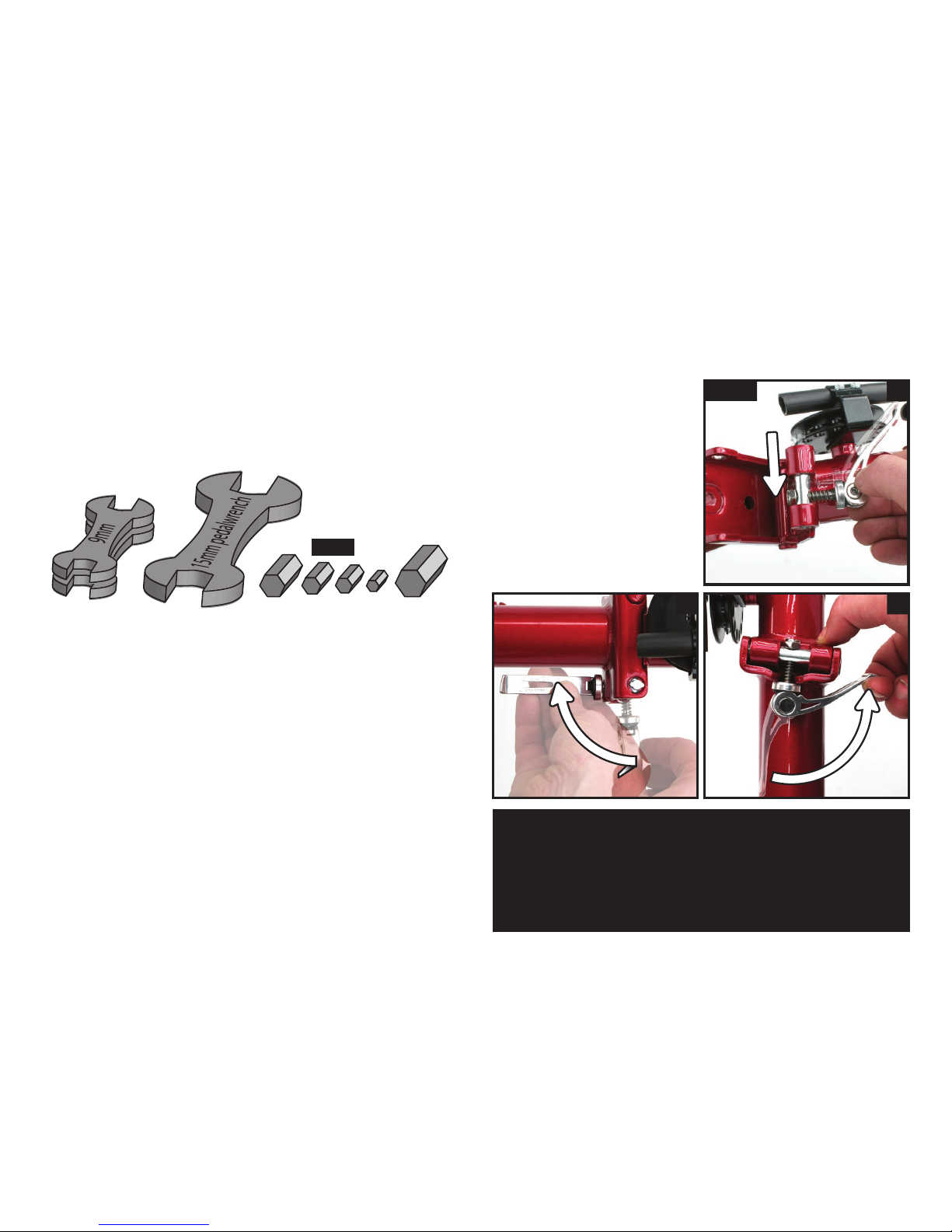

Your trike’s main feature is its ability to be folded / assembled

with the minimum of tools / effort. Here are the tools required

to build your trike, but there after the quick fold will only require

the 6mm Allen key.

(drum brake

only)

(hollow axle

hubs only)

fig 1

The frame is now ready to unfold. Start by holding the back

section and lifting it away from the frame and straightening the

frame out. Note the pin needs

to be slid to the left to allow

the frame to unfold all the way

(fig 2a). Once it has been

unfolded all the way, you rotate

the Quick Release downward so

the keyway is lined up, push it

through, pull the quick release

twowards the back of the frame

(fig 2b). Once the quick release

in it’s slot you can tighten it up

(fig 2c).

Important. If you are unfamiliar with a quick release

mechanism, PLEASE get a Greenspeed Dealer or bike mechanic

show you the finer points of safe use. The quick release on

the frame is slightly different to a wheel quick release in that

it requires a 10mm wrench to add tightness to it should the

adjustment loosen off with time/wear. Please keep it tight

enough that you can release/tighten with moderate hand effort.

fig 2

a

b c

Assembly of your folding trike is as follows. If you are

assembling from a boxed state, you start by unpacking it all

carefully. Once all the packaging has been removed, the fun bit

begins.

tools

assembly

4

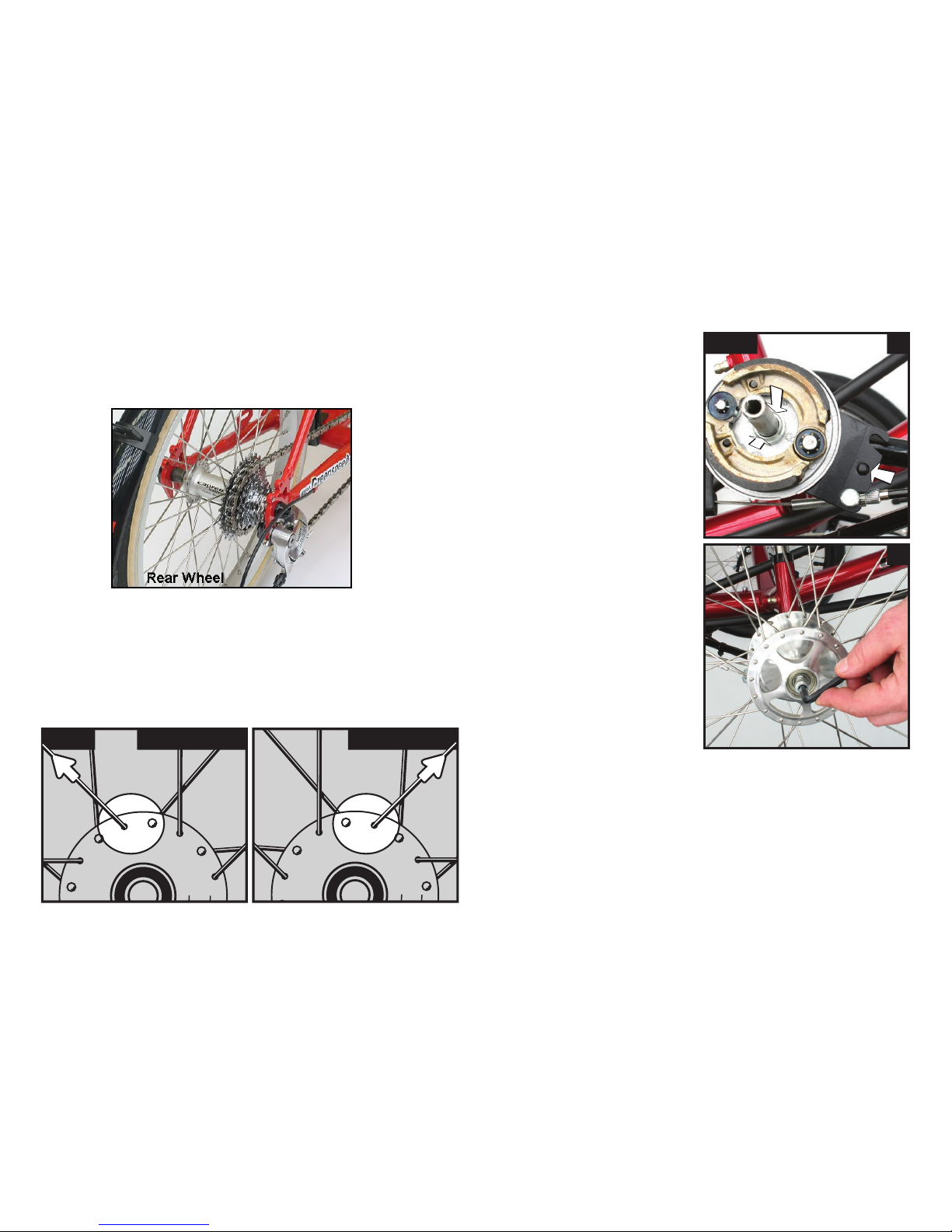

Next you install your wheels. Put the rear wheel in first and

tighten up the quick release. The cogs go on the right hand side of

the trike. That is, as if you are seated in the trike ;-)

fig 3 left wheel right wheel

Outside spoke points to the left Outside spoke points to the right

fitting your wheels

Now install the front wheels. Fig 3a and 3b, shows that there are

left and right wheels. They can be identified by looking at the top

of the hub and following the top outside spoke (that is the spoke

with its head on the inside). When this spoke goes to the right,

it is the right wheel, and vice versa! Be sure to try and install

them this way in the future, as this will prolong spoke life.

fig 4 a

b

~ drum brakes

The brake assembly backing

plate should be checked that

it is sitting hard against the

axle and that the retaining pin

is engaged (fig.4a).

Now is also a good time to

hook up brake cable (fig 16).

~ disc brakes

Disc brake wheels slide straight onto the axle the same way drum

brake hubs do and the screw at the end holds them in place.

The exception however is our hollow alloy axle disc brake set up.

Hollow alloy axles use a different method where by the alloy axle

goes through the hub and then into the kingpin assembly.

Use the provided short cap

screw to hold the wheel on

(fig.4b). Some models are

also provided with a shaped

hub cap washer.

Do the same on the other side.

5

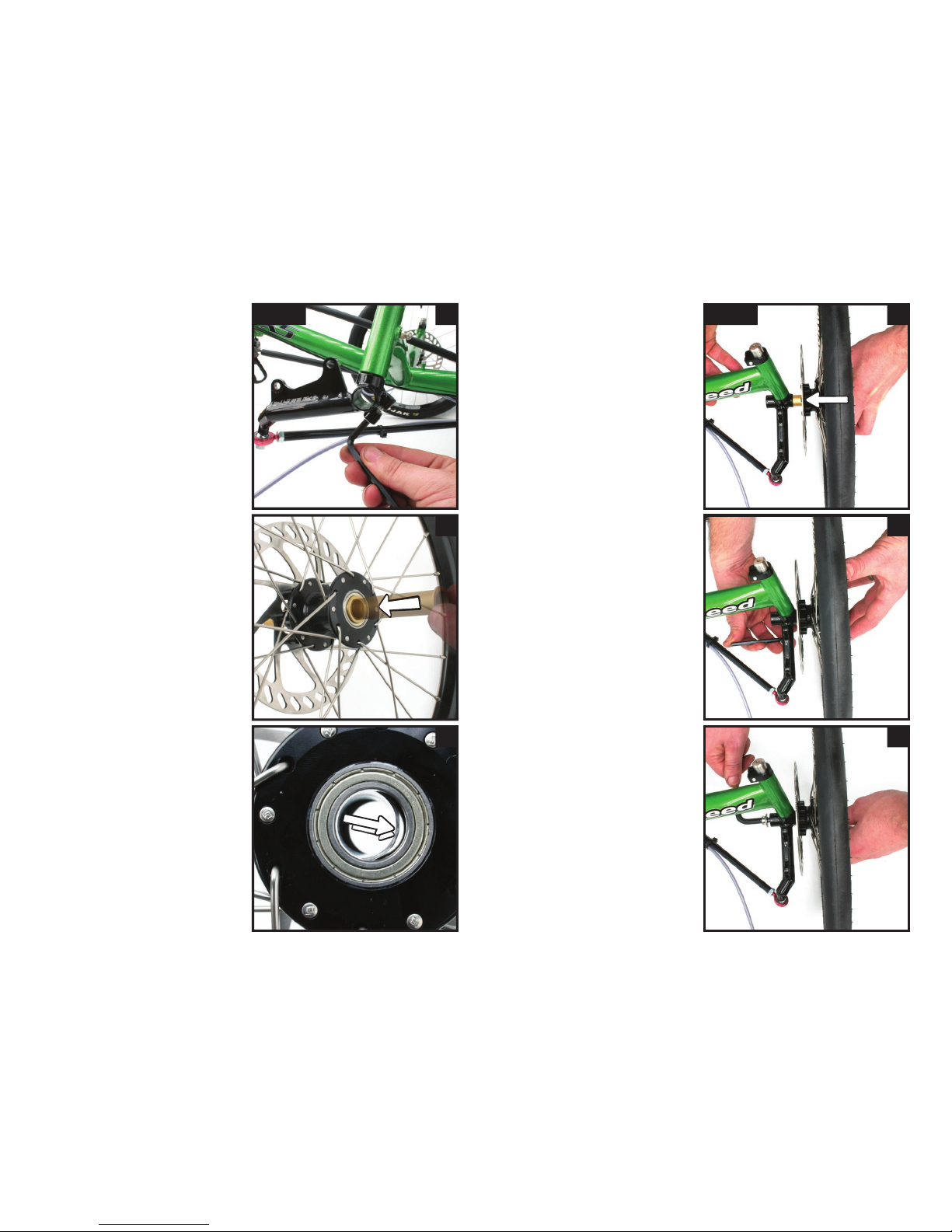

fig 5

First make sure the

kingpin pinch clamp is

undone (fig 5a) so the

axle can be inserted (it’s

a good idea to either

remove this screw or nip

it up when transporting

your trike so as not have it

rattle loose!).

a

b

c

Insert the axle from the

outside of the hub

(fig 5b).

Some times the crush

tube inside the hub may

be misaligned (fig 5c), use

the axle to realighn it.

~ disc brakes with

hollow axles

Place the axle into the kingpin

assembly (fig 5d). The axle

should be a neat fit but

NO hammering should be

required!

fig 5

d

e

f

Once the axle is installed,

cinch up the clamp screw (fig

5e) tighter than finger tight,

but not tensioned right up

(this is to help prevent the axle

rotating whilst performing the

next step).

Insert the axle preload bolt

(fig 5f) and snug it up (6Nm).

Finish tightening up the pinch

clamp (12Nm) and you’re

done! Well one completed….

other side to go!

6

Loading...

Loading...