GreenMech EcoTMP Operator's Manual

EcoTMP

Tractor Mounted Chipper

Operator’s Manual

EcoTMP CONTENTS 1

©GreenMechLtd - 1 - 06/12

SECTION:

1. Introduction and Purpose

2. Technical Specifications, Dimensions, Noise Level, and

Lifting points

3. Safety and Symbols

3.1 Ensure!

3.2 Never!

3.3 Always!

3.4 Safety controls and switches

3.5 Control cut-outs (not applicable)

3.6 'No Stress' system

3.7 Symbols

4. Machine Preparation

4.1 Fitting to tractor

4.2 Infeed chute

4.3 Discharge chute

4.4 PTO (Power take off) Shaft length

5. Operation

5.1 Pre-work checks

5.2 Starting machine

5.3 Stopping machine

5.4 Adjustable Feed roller control

5.5 Operating Hints

5.6 Blockage Removal

5.7 Preparing for Transport on completion of work

6. Maintenance

6.1 Routine Maintenance schedule and lubrication points

6.2 Drive Belts

6.3 Drive Belt Tension

6.4 Hydraulic Connections

6.5 Steam Cleaning

6.6 Bearings and Pivots

6.7 Disc blades

6.8 Gearbox

6.9 Electrical Connections

6.10 Mountings

6.11 No Stress system

6.12 Fault finding chart

6.13 Blade sharpening

EcoTMP CONTENTS 2

©GreenMechLtd - 2 - 06/12

7. Storage

7.1 Storage

7.2 Removal from storage

8. Disposal

9. Appendix

9.1 Hydraulic Circuit

9.2 Electrical Circuits

9.3 Certificate of Conformity

9.4 Risk Assessment

9.5 Noise Assessment

9.6 Parts List

9.7 Transcript of HSE leaflet 604

EcoTMP 1. INTRODUCTION AND PURPOSE 1-1

©GreenMechLtd 1-1 04/07

INTRODUCTION

This manual explains the proper operation of your machine. Read these instructions

thoroughly before operating and maintaining the machine. Failure to do so could result in

personal injury or equipment damage. Consult your GreenMech supplier if you do not

understand the instructions in this manual.

CAUTION! This symbol indicates important safety messages in this

manual. When you see this symbol, be alert to the possibility of injury to

yourself or others, and carefully read the message that follows.

We recommend that you keep this manual with the machine in the box provided. Note

here the serial number and quote it in any communications. This is important when

ordering spares. Remember to include all numbers and letters.

VIN Number:…….…………………………

Serial Number:….…………………………

Write in the number!

This manual covers the following model.

EcoTMP tractor mounted chipper

Note: Normal build infeed chute position is Left Hand side (nearside) of tractor. This can

be changed to Right Hand side by factory fitted reversal of the gearbox.

The information in this manual is correct at the time of publication. However, in the

course of development, changes to the machine specification are inevitable. Should you

find any information to vary from the machine in your possession please contact your

GreenMech dealer for up to date information.

The manual may contain standard and optional features and is not to be used as a

machine specification.

PURPOSE

CAUTION! This machine is designed solely to chip wood and must not be

used for any other purpose. The machine should only be used by trained

operators who are familiar with the content of this instruction manual. It is

potentially hazardous to fit or use any parts other than genuine GreenMech

parts. The company disclaims all liability for the consequences of such use,

which in addition voids the machine warranty.

S/N EcoTMP

Serial Number plate

EcoTMP 2. SPECIFICATIONS 2-1

©GreenMechLtd 2-1 04/07

TECHNICAL SPECIFICATION EcoTMP

Max Capacity 150mm (6-inches)

Chipping Disc 500mm x 25mm (19.86 x 1.01inch)

Speed 2600 rpm

Chipping Blades 2 Discs

Feed Rollers 2 x Hydraulic

Power Control No-Stress Electronic Feed Roller Controller

Power Unit Tractor 25-45hp (see below)

Length (Transport) 2320mm

Width 1060mm

Height 2130mm

Weight 487Kg

Fig 2.1 EcoTMP Main Features

PTO connection

Infeed Chute catch

Discharge chute

Chipper disc cover

Infeed chute

Control bar

Feed roller pivot

3 Point hitch

Reset bar

Gearbox

Legs

Tractor hoses & cable

EcoTMP 2. SPECIFICATIONS 2-2

©GreenMechLtd 2-2 04/07

Noise

Noise levels vary depending on type of material being processed. Also duration of

operation is variable. Noise emission tests have been carried out and the guaranteed

sound power level is displayed on the CE plate as follows: Lwa 120dba

Minimise noise by switching to idle or stopping the tractor engine whenever chipping is not

in progress.

To reduce tractor noise level, optional 1000rpm PTO speed may be selected provided

tractor engine speed is reduced by approximately 50% accordingly.

CAUTION! Do not operate above 540rpm.

Full details are included in the Risk Assessment in the Appendix.

CAUTION! Operators must wear appropriate ear protection. Bystanders must be

kept away from proximity of machine.

Lifting Points

There are three lifting points by the chipper disc cover.

Tractor requirement

25 – 40HP at 6 spline 540rpm PTO shaft with provision for 22 litres/min (4.8 gall/min) at

172 bar (2500 lbf/in2) continuous flow remote oil supply and trailer light socket for No

Stress system.

EcoTMP 3. SAFETY 3-1

©GreenMechLtd 3-1 04/07

3.1 ENSURE:

3.1.1 All Operators must be fully trained in

the use of their machine.

(Certificated Operator training courses are

available on request.)

3.1.2 The Operators Manual is read and

understood.

3.1.3 The enclosed HSE guidance notes

are read and understood.

3.1.4 The machine is positioned on level

ground and the machine must be level with

the infeed chute at no less than 600mm

(23.62 inches) above ground level (fig

3.4.3).

3.1.5 not applicable

3.1.6 All guards are fitted and in good

condition.

3.1.7 Blades are in good condition and

secure.

3.1.8 All blades are sharpened or replaced

in “Sets”.

3.1.9 All fasteners are checked regularly

for tightness.

3.1.10 Only “WOODEN” materials free of

nails etc., are fed into the machine.

3.1.11 Correct First Aid Kit including large

wound dressing is available on site.

3.1.12 Fire extinguisher is available on site.

3.2 NEVER:

3.2.1 Work on the machine until the

chipper disc is stationary and engine or

PTO has stopped.

3.2.2 Operate the machine without

protective clothing (Eye protection,

Earmuffs, and Gloves), or high visibility

clothing when working on roadside.

3.2.3 Operate with loose articles of

clothing, including loose cuffs on gloves.

3.2.4 Work under a raised component

without adequate safety support.

3.2.5 Operate the machine with untrained

personnel or with individuals present who

are not involved in the chipping operation.

3.2.6 Leave the machine unattended with

engine running at full operating speed.

(See section 4)

3.2.7 Put any part of your body into the

infeed chute while the machine is running.

3.2.8 Operate the machine whilst under the

influence of alcohol or drugs.

3.2.9 Operate inside a building or confined

space.

3.2.10 Climb on the infeed chute.

3.3 ALWAYS:

3.3.1 Check machine before starting (see

Section 4 Preparation and Section 5.1

Operation: Pre-work checks).

3.3.2 Be aware of potential hazards in the

work area, i.e. uneven ground, tree roots,

trip/slip hazards, obstructions and type of

materials being fed into the machine.

3.3.3 Feed from the side.

3.3.4 Have a second trained operator

within easy reach of the machine.

3.3.5 Maintain strict discipline at all times.

3.3.6 Service machine at specified periods.

(see Section 6: Routine Maintenance).

3.3.7 Note direction of discharge chute and

if necessary note the wind direction to

prevent debris from being blown into

highway or where it could affect members

of the public.

3.3.8 Remove key before doing any

maintenance.

EcoTMP 3. SAFETY 3-2

©GreenMechLtd 3-2 04/07

3.4 Safety Controls and Switches

3.4.1 Emergency Stop/Control Bar (fig

3.4.1)

In the event of an emergency, push the

emergency stop bar to STOP the feed

rollers. This will lock in position.

3.4.1.1 Once the emergency has been

rectified the following sequence should be

carried out:

3.4.1.2 To restart rollers pull the reset

lever, the control bar can then be returned

to the Feed In position.

3.4.1.3 Should the stop bar be tripped

accidentally in normal working conditions

i.e. NOT an emergency, then the rollers can

be recovered by performing the above

sequence.

3.4.1.4 To reverse the rollers (feed out)

push the control bar into the middle detent.

To regain forward (feed in) pull the control

bar away from the chipper. It is not

necessary to use the reset bar.

3.4.2 PTO stop

3.4.2.1 To stop the PTO use the tractor

control or tractor engine stop.

CAUTION! Do not restart until hazard

has been removed.

3.5 Control cut-outs

Not applicable for tractor mounted model

3.6 No Stress system

3.6.1 Speed sensor disables feed roller

FEED IN or FEED OUT mode when engine

speed is below factory pre-set value.

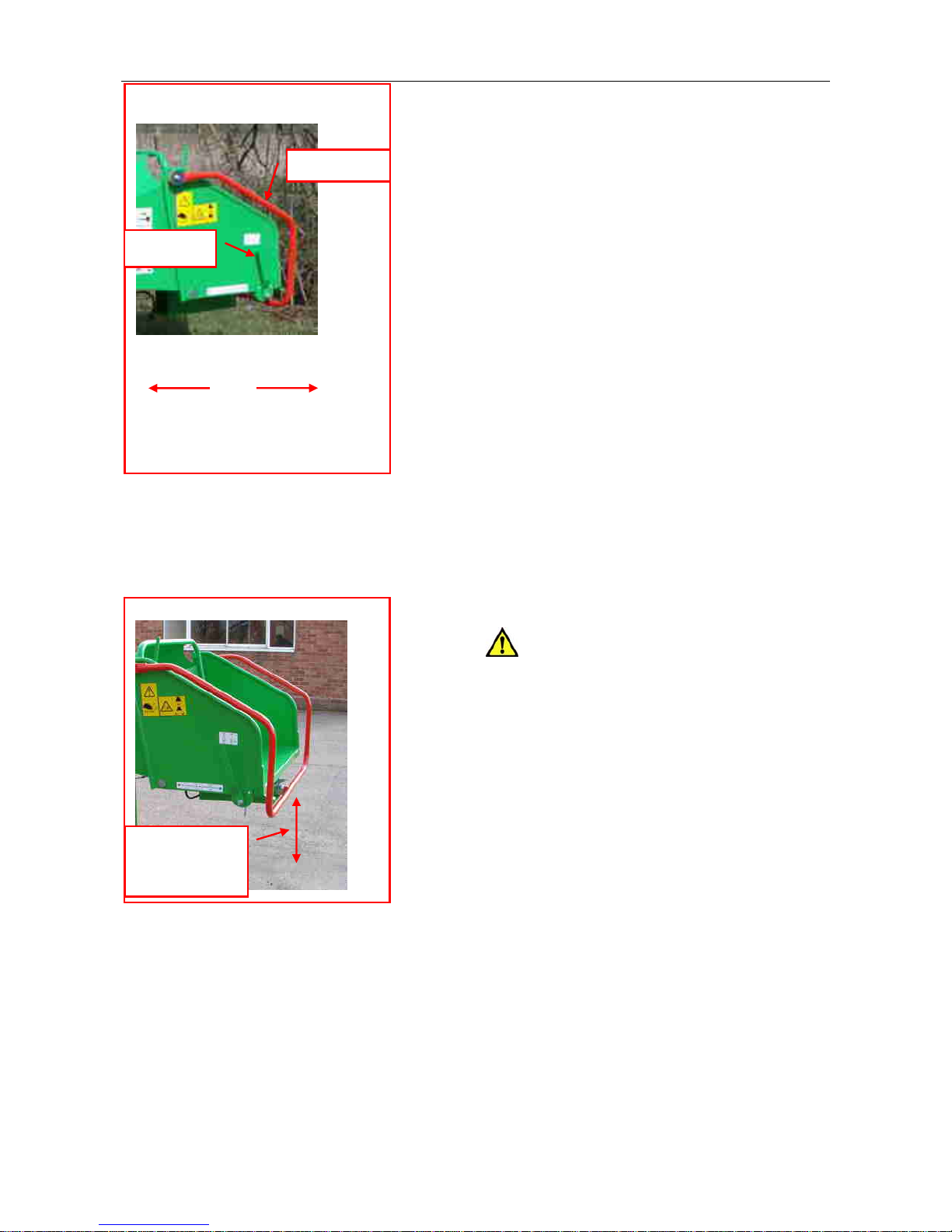

Fig 3.4.1 Control Bar and Reset

Lever

Control Bar positions

(Nearside)

STOP FEED OUT FEED IN

FEED IN FEED OUT STOP

(Offside)

Reset bar

Control bar

Fig 3.4.3 Infeed chute height

Infeed chute

height 600mm

min. (24")

EcoTMP 3. SAFETY 3-3

©GreenMechLtd 3-3 04/07

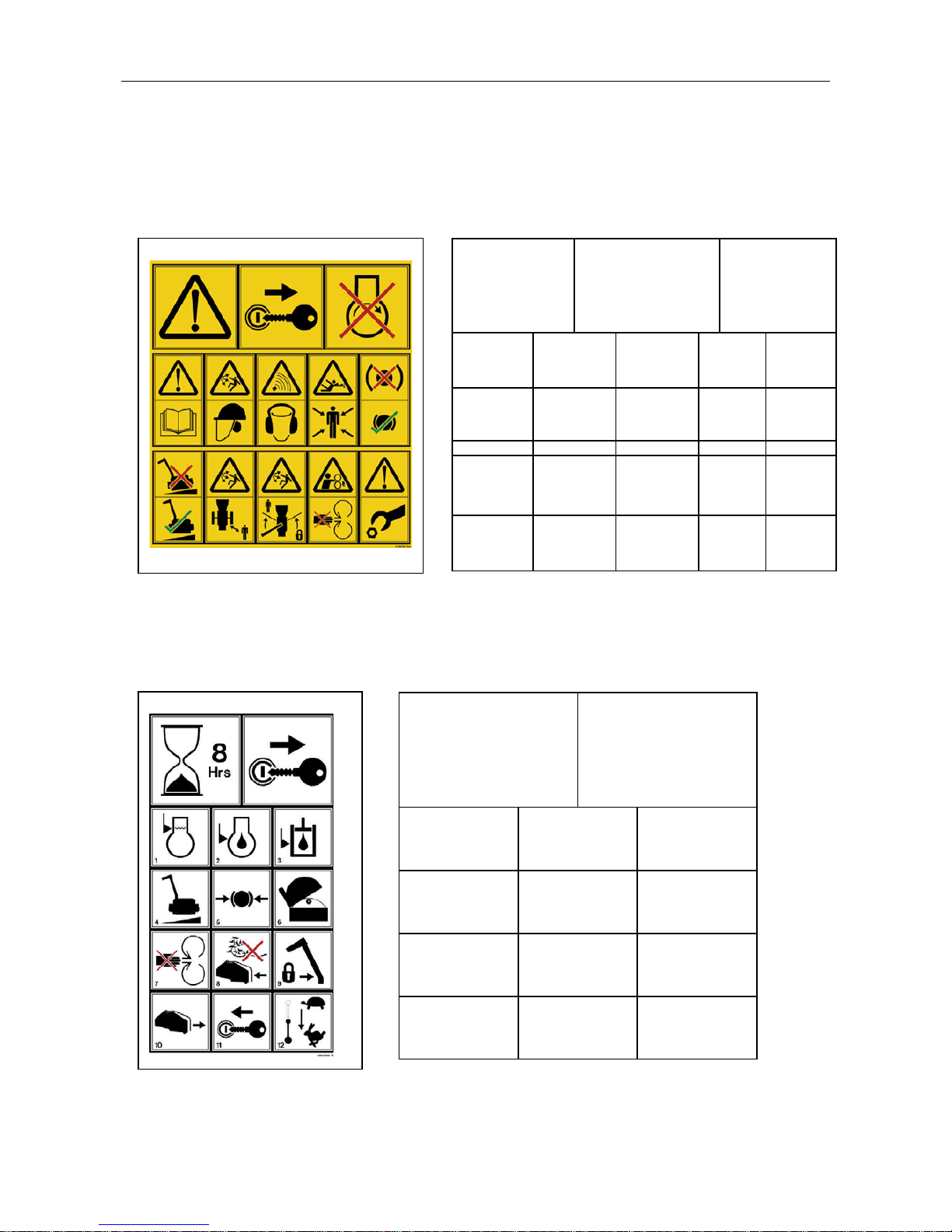

3.7 SYMBOLS on the MACHINE

These relate to operator safety, correct use and maintenance of machine. Check that all

personnel understand and are familiar with meanings before using the machine.

Important Safety symbols

Take the correct action shown on the display below the stated hazard (see table)

Important Operating Checks Notice

Before use carry out daily the stated checks in the order shown (see table)

Caution! Remove key

Do NOT

start engine

Caution!

Beware

flying

object

hazard

Beware

noise

hazard

Beware

trapping

hazard

Brakes

off

-incorrect

Read

instruction

manual

Wear

helmet &

visor

Wear ear

protectors

Wear

proper

clothes

Brakes

on

-correct

Machine

not level

-incorrect

Beware

flying

object

hazard

Beware

flying

object

hazard

Beware

exposed

drives

hazard

Caution!

Machine

level

-correct

Keep

bystanders

away

Position

and lock

discharge

chute

Fit all

guards

Keep

nuts tight

Every 8 Hours –

Daily checks

Remove key

stop engine

1. Check

coolant level

2. Check engine

oil level

3. Check

hydraulic oil

level

4. Check

machine is level

5. Check brakes

are on

6. Check

chipper disc is

clear of debris

7. Check all

guards are in

place

8. Check infeed

chute is clear of

debris

9. Lock

discharge chute

10. Pull control

bar to work

position

11. Start engine

12. Increase

from Idle to Run

General Safety

Daily Checks

EcoTMP 3. SAFETY 3-4

©GreenMechLtd 3-4 04/07

Important Safety Information

Sound level

Ear defenders must be

worn

Caution! Beware of thrown

object hazard

Action: Keepaway from fast

discharge chute

Caution! Beware of thrown

object hazard

Action: Stand to side of infeed

chute, NOT in centre.

Caution!

Do NOT operate with infeed

chute at less than 600mm from

ground (bottom bar machine).

Transport Lock

Lock this

component before

moving machine

Lift Point

PTO Direction

Face shield must

be worn

Ear defenders must

be worn

EcoTMP 3. SAFETY 3-5

©GreenMechLtd 3-5 04/07

Maintenance Information

Operating Information

Grease point

40 hours / weekly

Reset lever: Left hand shown

Push to stop : Pull to reset

Control Bar (bottom bar). Left hand shown

Push to stop: Centre-feed out: Pull–feed in

Discharge chute control

Green is UP: Blue is DOWN

High temperature

Grease 40 hours

EcoTMP 4. MACHINE PREPARATION 4-1

©GreenMechLtd 4-1 04/07

4.1 Fitting to tractor

4.1.1 Remove the top, and lower linkage

pins on the chipper (fig 4.1.1)

4.1.2 Lower the three-point linkage on the

tractor and reverse up to the chipper.

4.1.3 Locate the two lower linkage pins

through the lower arms and the chipper

frame.

4.1.4 Secure the pins with the clips

provided.

4.1.5 Adjust the top link to the correct

length and locate the linkage pin through

the frame and arm, secure with the clips

provided.

4.1.6 Switch off the tractor engine.

4.1.7 Check that the PTO shaft is the

correct length for the tractor make and

model. See section 4.4 below

CAUTION! The PTO shaft is equipped

with shear bolt protection and this end of

the shaft MUST be fitted to the tractor PTO

shaft. (Pictograms stamped on PTO shaft

cover may be incorrect.)

4.1.8 Depress the two spring buttons and

slide onto the tractor shaft until the buttons

spring out into the correct locations.

4.1.9 Depress the single spring button on

the ratchet clutch end and slide onto the

chipper gearbox shaft until the button

springs out into the correct location.

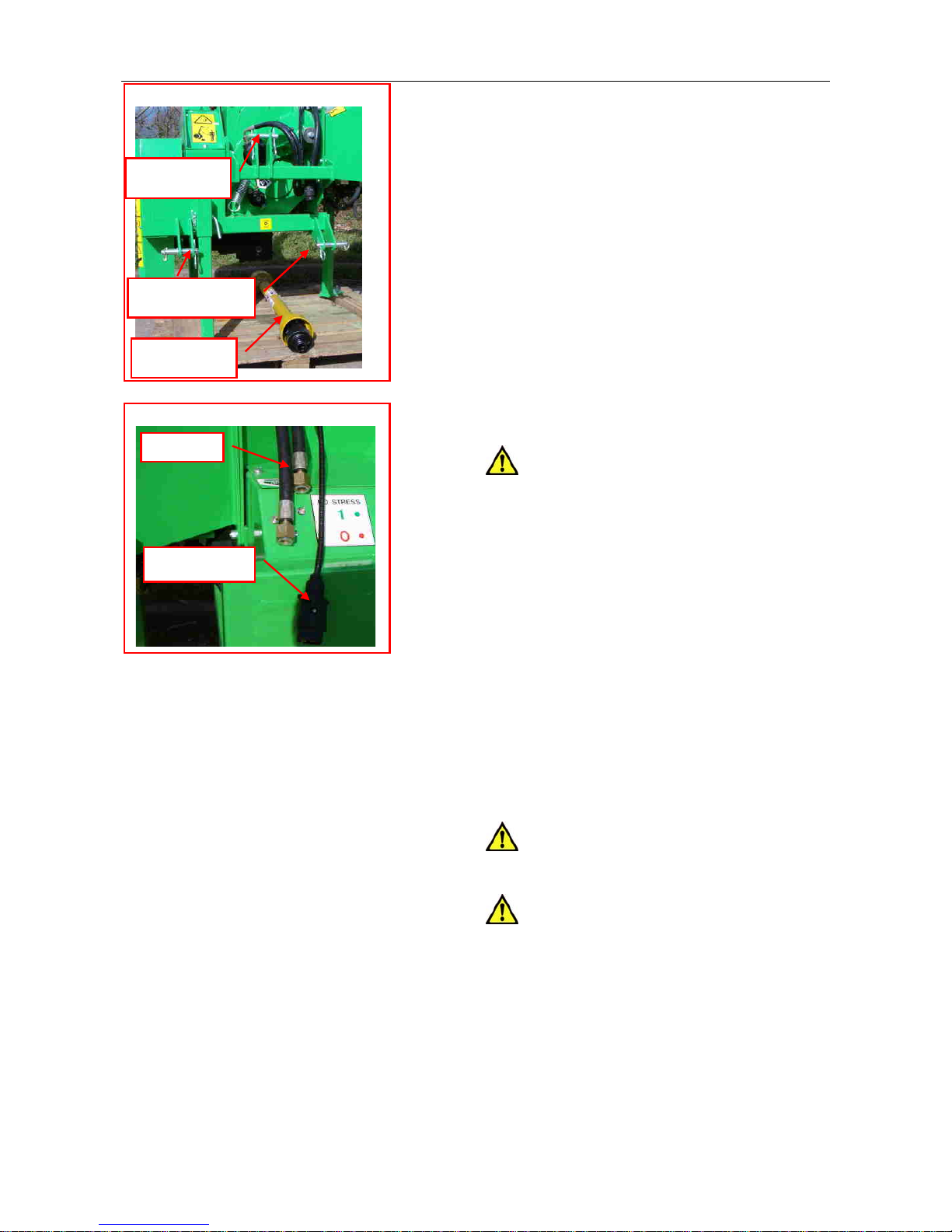

4.1.10 Connect up the hoses to the tractor

remote supply. (fig 4.1.2)

4.1.11 Connect the cable to the trailer

socket on the tractor.

4.1.12 Turn on the tractor’s sidelights to

provide power for the No-Stress system.

CAUTION! Check that the discharge

chute does not hit the tractor cab when the

chipper is lifted up.

CAUTION! Do not operate the

machine when not fully attached to the

tractor

4.1.13 Unfold infeed chute as 4.2 below.

4.1.14 Start tractor engine slowly and

check PTO. operation.

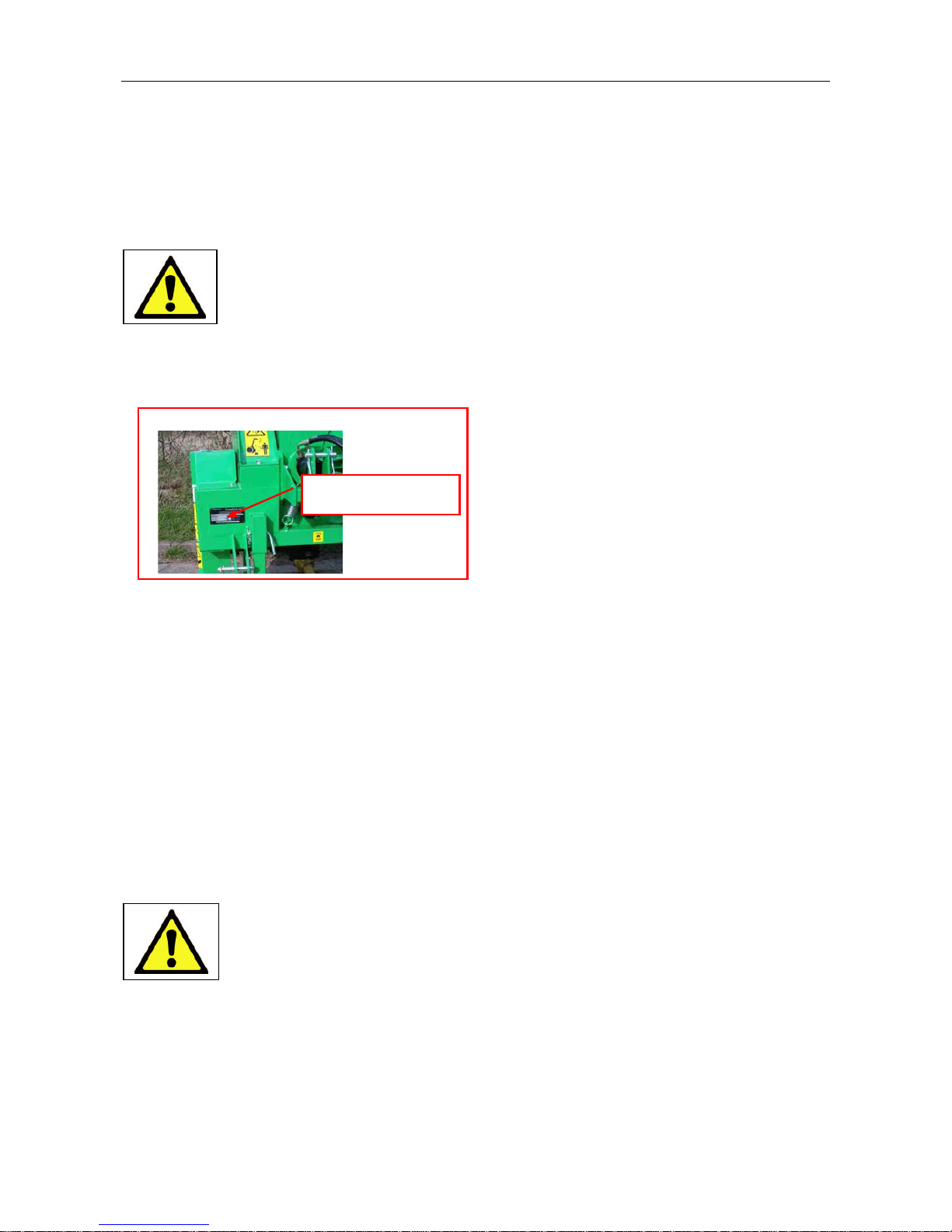

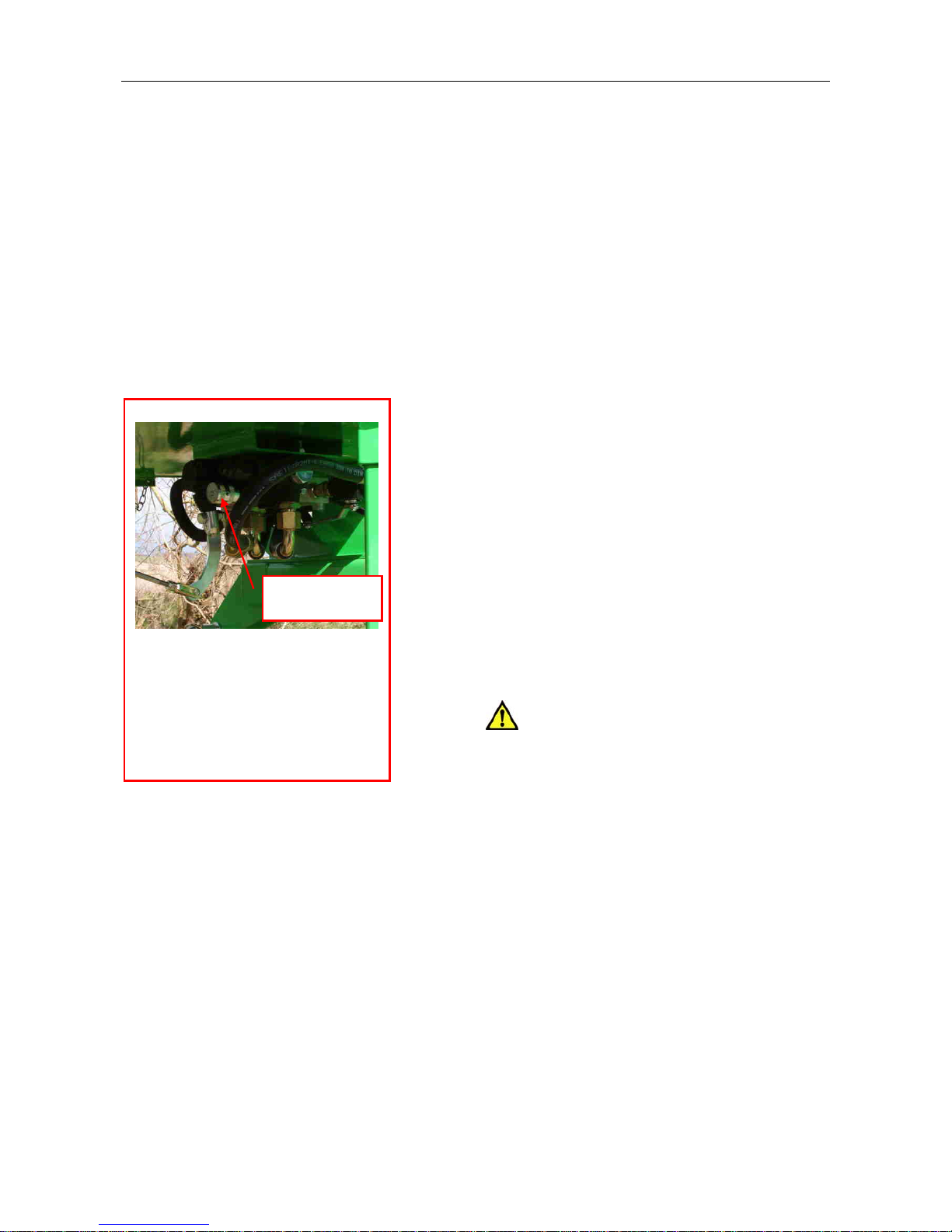

Fig 4.1.2 Tractor hoses and cable

Electric plug

Hoses

Fig 4.1.1 3 Point links and PTO shaft

Top link pin

Lower link pins

PTO Shaft

EcoTMP 4. MACHINE PREPARATION 4-2

©GreenMechLtd 4-2 04/07

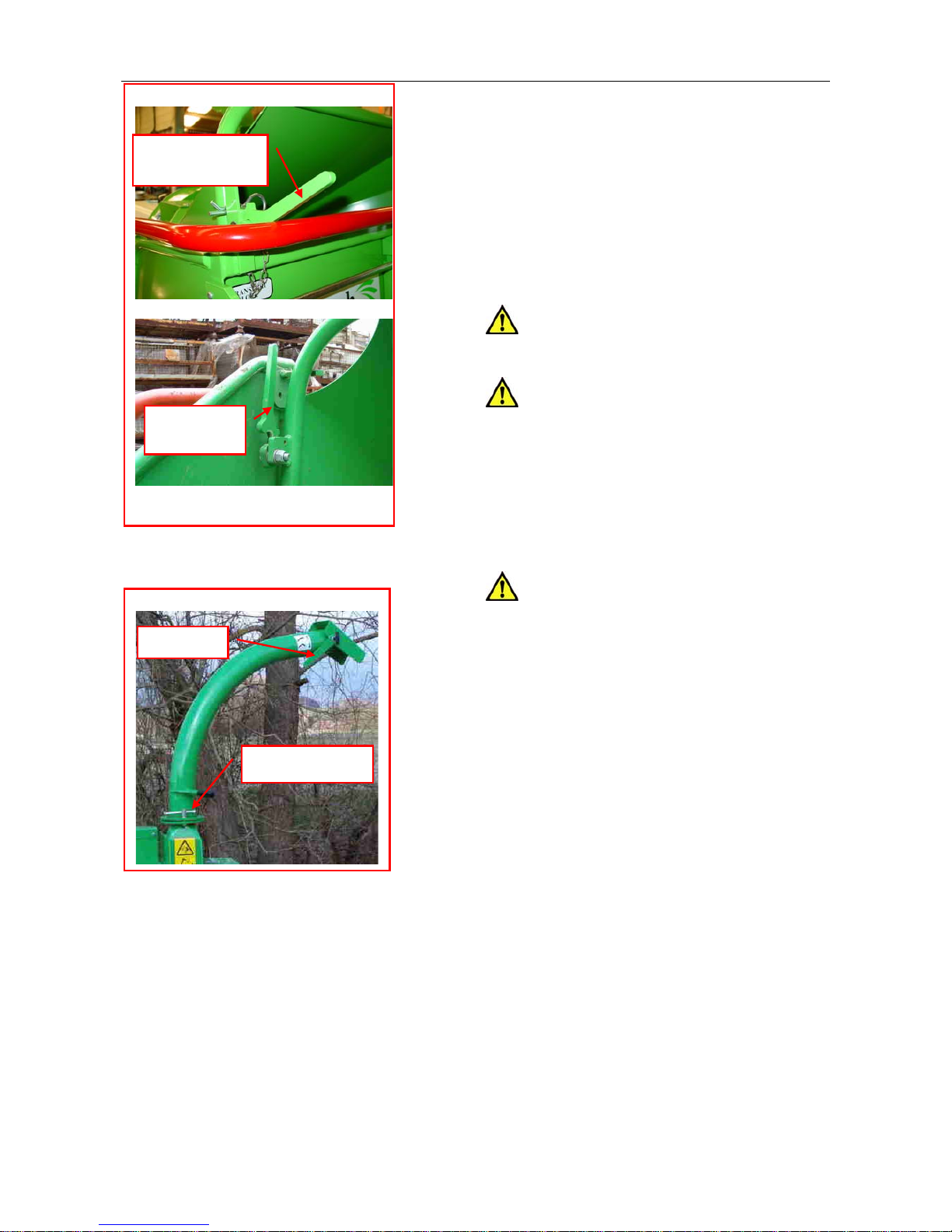

4.2 Infeed Chute

4.2.1 Remove the transport pin for the

infeed chute catch, release the catch (fig

4.2)

4.2.2 Using the tubular edge as a handle,

lower the infeed chute to the work position

and reset the catch.

4.2.3 Measure the height of the infeed

chute and adjust stands as required.

4.2.4 Pull the reset lever to release the

control bar for use.

CAUTION! The infeed chute must not

be used at less than 600mm from the

ground. (fig 3.4.2).

CAUTION! Before travelling, always

fold up and secure the infeed chute.

4.3 Discharge Chute (Fig 4.4)

4.3.1 Release the swivel clamps, point the

chute in the desired direction and tighten

the clamps.

4.3.2 Set the flap at the desired height and

tighten the clamp.

CAUTION! Lock the discharge chute

in the rearward position when travelling.

4.4 PTO shaft length

The PTO shaft must overlap by 150mm in

longest situation and not bottom out in

shortest situation. Always follow

instructions supplied with shaft if available.

4.4.1 To shorten PTO, separate each

section and refit to machine.

4.4.2 Raise machine on linkage until

shortest length is achieved.

4.4.3 Supporting the two sections side by

side, mark a point 25mm - 50mm back from

where the guard tube meets the joint guard

onto the other section. Repeat for the

opposite end.

4.4.4 Adjust the tractor linkage to set at

longest shaft length.

4.4.5 Check that 150mm minimum overlap

of sections is achieved between marks.

4.4.6 Saw off the surplus guard and shaft

at each mark and remove cuttings and

burrs.

4.4.7 Grease the shaft, reassemble to

machine, and test before use.

Fig 4.2 Infeed chute catch

Catch (transport)

Catch

(work)

Fig 4.3 Discharge Chute

Swivel clamps

Flap lever

EcoTMP 5. OPERATION 5-1

©GreenMechLtd 5-1 06/12

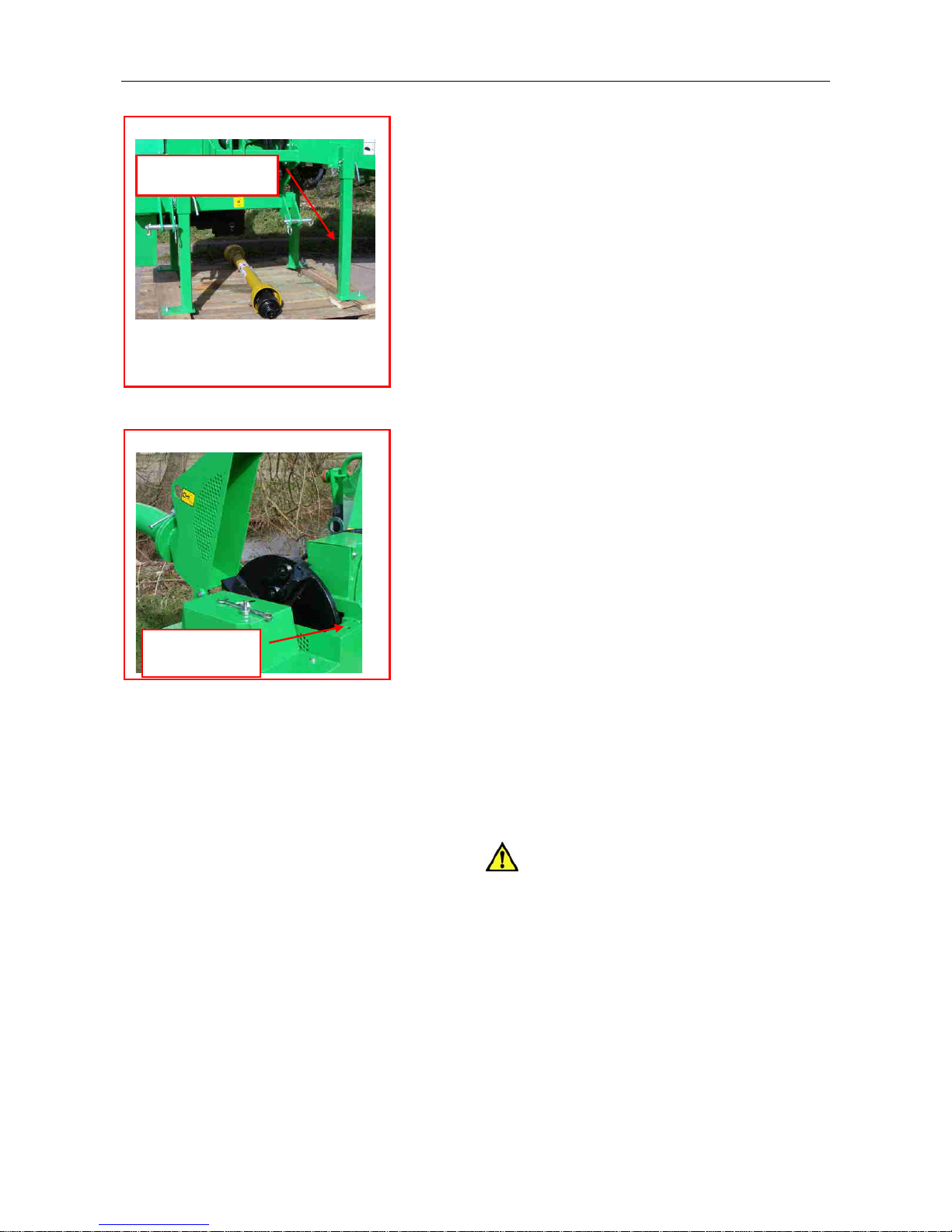

5.1 Pre-Work Checks:

5.1.1 Check tractor is stationary, engine

turned off and hand brake applied.

5.1.2 With machine held on tractor linkage,

set support legs approximately (fig 5.1.1).

5.1.3 Lower linkage, check that machine is

level and infeed chute is greater than

600mm from ground (fig 3.4.3).

5.1.4 Check fasteners for tightness and

hydraulic connections for leaks.

5.1.5 Check condition of disc blades.

5.1.5.1 Check nothing is rotating.

5.1.5.2 Remove the 1 bolt retaining chipper

disc cover (fig 5.1.2).

5.1.5.3 Using discharge chute handle as a

lever, swing back cover on to stop to

expose chipper disc and blades.

(fig 5.1.2)

5.1.5.4 Carefully rotate chipper disc to

check tightness of disc blade bolts and

condition of blades.

5.1.5.5 Remove any loose wood material.

5.1.5.6 If any bolts are loose, refer to

maintenance section for further action.

5.1.5.7 Replace chipper disc cover and

tighten bolts securely.

5.1.6 Check discharge chute is in desired

position and all clamps are tight. (see

Section 4.3)

5.1.7 Check infeed chute flap is lowered.

5.1.8 Check work area and erect signs

and cone off discharge area if necessary.

5.1.9 Check ALL safety procedures have

been followed.

CAUTION! Remember to raise infeed

chute flap and the chipper on the tractor

linkage before driving off.

Fig 5.1.1 Support Legs

Support Legs (4)

Fig 5.1.2 Chipper Disc Cover

Disc Cover

locating bolt

EcoTMP 5. OPERATION 5-2

©GreenMechLtd 5-2 06/12

5.2 Starting Machine:

5.2.1 Check all other personnel are clear

of machine.

5.2.2 Check that feed roller control bar is

pushed to the FEED OUT or STOP

position, to make the machine safe.

5.2.3 Start the tractor.

5.2.4 Engage PTO to start the chipper.

Check lights are ON.

5.2.5 Increase the speed to operating

speed (PTO 540 rpm), when No Stress light

goes Green.

Note: When used with larger tractors

having 1000 rpm PTO option, this may be

selected to enable use of slower engine

speed to reduce noise level and fuel

consumption. Always ensure that the No

Stress light remains Green.

5.2.6 Pull the reset lever to release the

control bar for work.

5.3 Stopping Machine

5.3.1 Push the control bar to STOP

position.

5.3.2 Disengage tractor PTO.

5.3.3 Stop tractor engine.

5.3.4 Wait for chipper disc to stop.

CAUTION! The chipper disc will take

several seconds to stop due to its inertia.

5.4 Adjustable Speed Feed Roller

Control

When chipping wood sizes larger than

120mm diameter it may be necessary to

reduce the feed roller speed to suit the

material being chipped.

5.4.1 Turn the valve control knob (fig 5.4)

clockwise until valve is closed.

5.4.2 Turn the knob anticlockwise to the

recommended setting in the table.

Fig 5.4 Adjustable feed roller control

Control knob settings

Material Setting

up to 120mm Fully open (3 turns)

120 - 150mm 1/2 to 3/4 turn

Control Knob

Loading...

Loading...