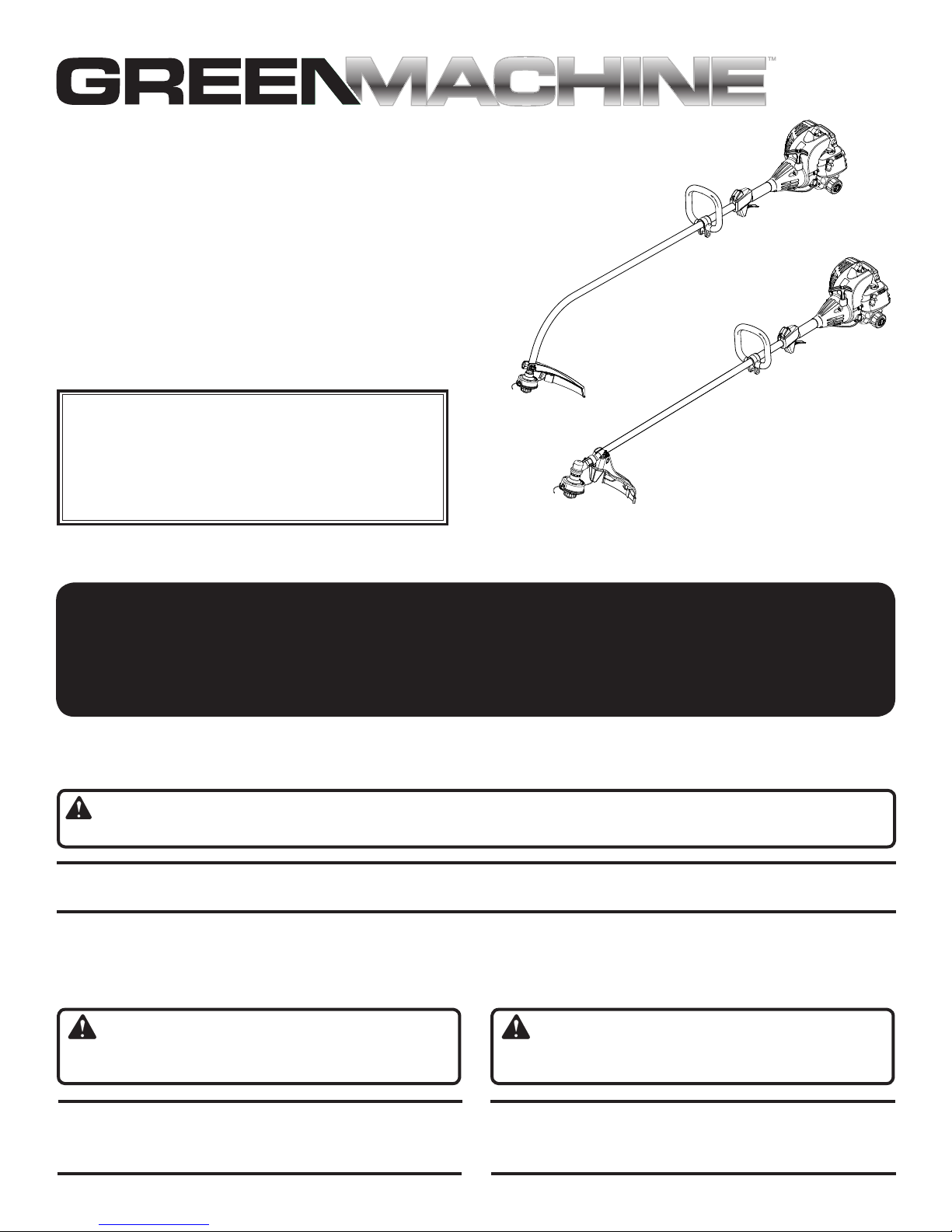

Green Machine 26CS GM22000, 26SS GM23000 Operator's Manual

OPERATOR’S MANUAL

MANUEL D’UTILISATION / MANUAL DEL OPERADOR

26cc STRING TRIMMERS

TAILLE-BORDURES À LIGNE 26 cc

RECORTADORAS DE HILO 26 cc

ALL VERSIONS

TOUTES LES VERSIONS / TODAS LAS VERSIONES

To register your Green Machine product, please visit:

http://register.greenmachinetools.com/

Pour enregistrer votre produit de Green Machine, s’il vous

plaît la visite: http://register.greenmachinetools.com/

Para registrar su producto de Green Machine por favor

visita: http://register.greenmachinetools.com/

26CS

GM22000

26SS

GM23000

NOTICE: Do not use E15 or E85 fuel (or fuel containing greater than 10% ethanol) in this product. It is a violation

of federal law and will damage the unit and void your warranty.

AVIS : Ne pas utiliser d’essence E15 ou E85 (ou un carburant contenant plus de 10 % d’éthanol) dans ce produit. Une telle

utilisation représente une violation de la loi fédérale et endommagera l’appareil et annulera la garantie.

AVISO: No utilice combustibles E15 o E85 (ni combustibles que contengan más de 10 % de etanol) con este producto.

Esto constituye una violación a la ley federal, dañará la unidad y anulará la garantía.

Your string trimmers has been engineered and manufactured to high standards for dependability, ease of operation, and

operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Ce taille-bordures à ligne a été conçue et fabriquée conformément

aux strictes normes de fiabilité, simplicité d’emploi et sécurité

d’utilisation. Correctement entretenue, elle vous donnera des

années de fonctionnement robuste et sans problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’employer ce produit.

Su recortadoras de hilo ha sido diseñada y fabricada de conformidad

con las estrictas normas para brindar fiabilidad, facilidad de uso

y seguridad para el operador. Con el debido cuidado, le brindará

muchos años de sólido y eficiente funcionamiento.

ADVERTENCIA: Para reducir el riesgo de lesiones, el

usuario debe leer y comprender el manual del operador antes

de usar este producto.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

See this fold-out section for all of the figures

referenced in the operator’s manual.

Consulter l’encart à volets afin d’examiner

toutes les figures mentionnées dans le manuel

d’utilisation.

Consulte esta sección desplegable para ver todas

las figuras a las que se hace referencia en el

manual del operador.

ii

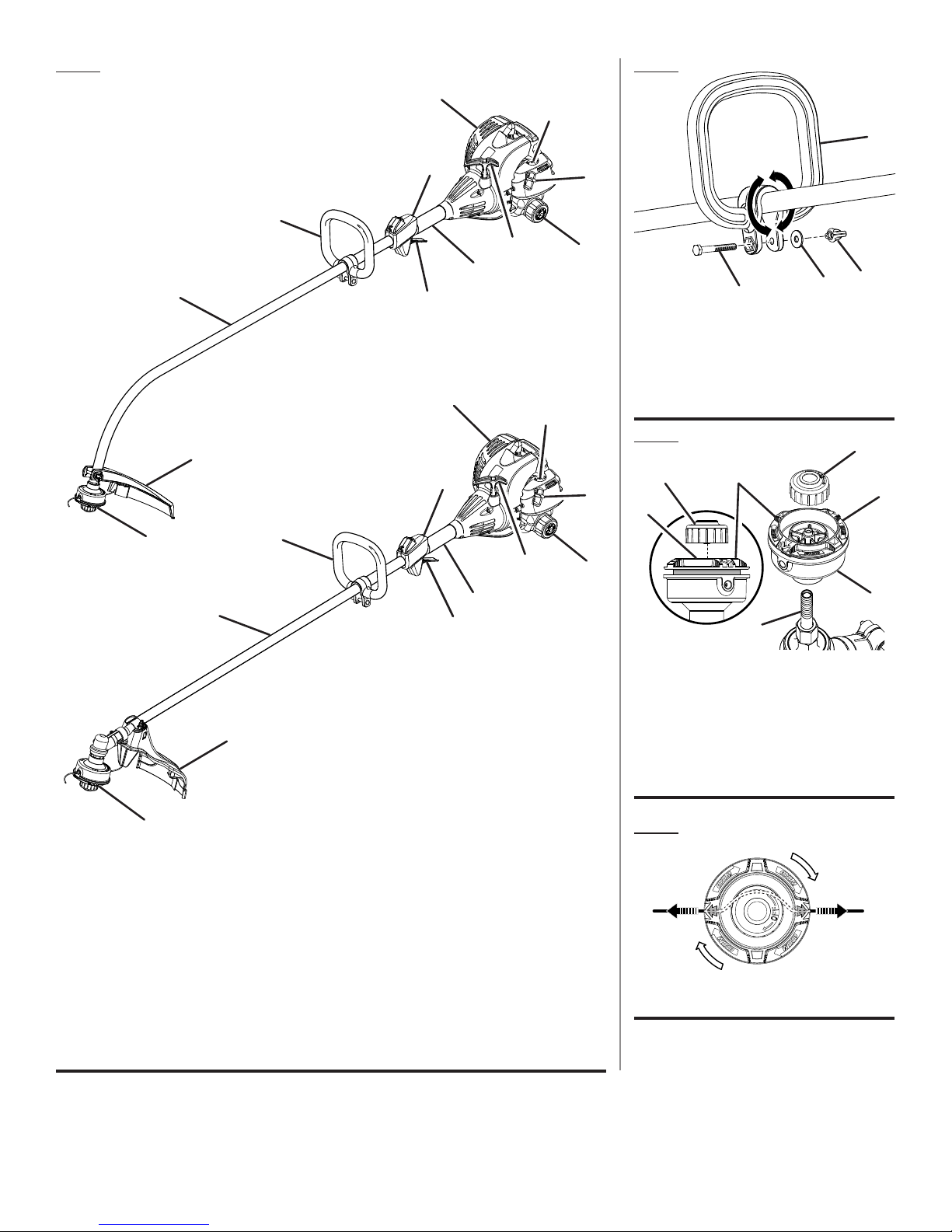

Fig. 1

26CS

Fig. 2

G

H

A

26SS

D

J

C

F

I

E

D

B

K

A - Front handle (poignée avant, mango

delantero)

B - Washer (rondelle, arandela)

C - Bolt (boulon, perno)

D - Wing nut (écrou à oreilles, tuerca de

G

mariposa)

C

B

H

Fig. 3

L

D

J

A

B

C

F

I

E

B

A

K

C

A

B

D

E

M

A

A - Dual line string head (tête de cordon à ligne

double, cabezal del hilo doble)

B - Drive shaft housing (logement d’arbre

moteur, alojamiento del eje de impulsión)

C - Front handle (poignée avant, mango

delantero)

D - Stop switch (commutateur d’arrêt,

interruptor del apagado)

E - Rear handle (poignée arrière, mango

trasero)

F - Starter grip and rope (poignée du lanceur et

corde, mango del arrancador y cuerda)

G - Muffler (silencieux, silenciador)

H - Primer bulb (poire d’amorçage, bomba de

cebado)

I - Fuel cap (bouchon de carburant, tapa del

tanque)

J - Start lever (levier de volet de départ, palanca

de arranque)

K - Throttle trigger (gâchette d’accélérateur,

gatillo del acelerador)

L - Curved shaft grass deflector (déflecteur

d’herbe d’arbre courbe, deflector de pasto

del eje curvo)

M- Straight shaft grass deflector (déflecteur

d’herbe d’arbre droit, deflector de pasto para

eje recto)

A - Drive shaft (arbre moteur, eje de impulsión)

B - Spool retainer (retenue de bobine, retén del

carrete)

C - Plastic seal (étanchéité en plastique, sello de

plástico)

D - Spool (bobine, carrete)

E - String head assembly (ensemble de tête de

couple, conjunto del cabezal de hilo)

Fig. 4

A

A - Pull lines (tirer vers l’extérieur, tira del hilo)

iii

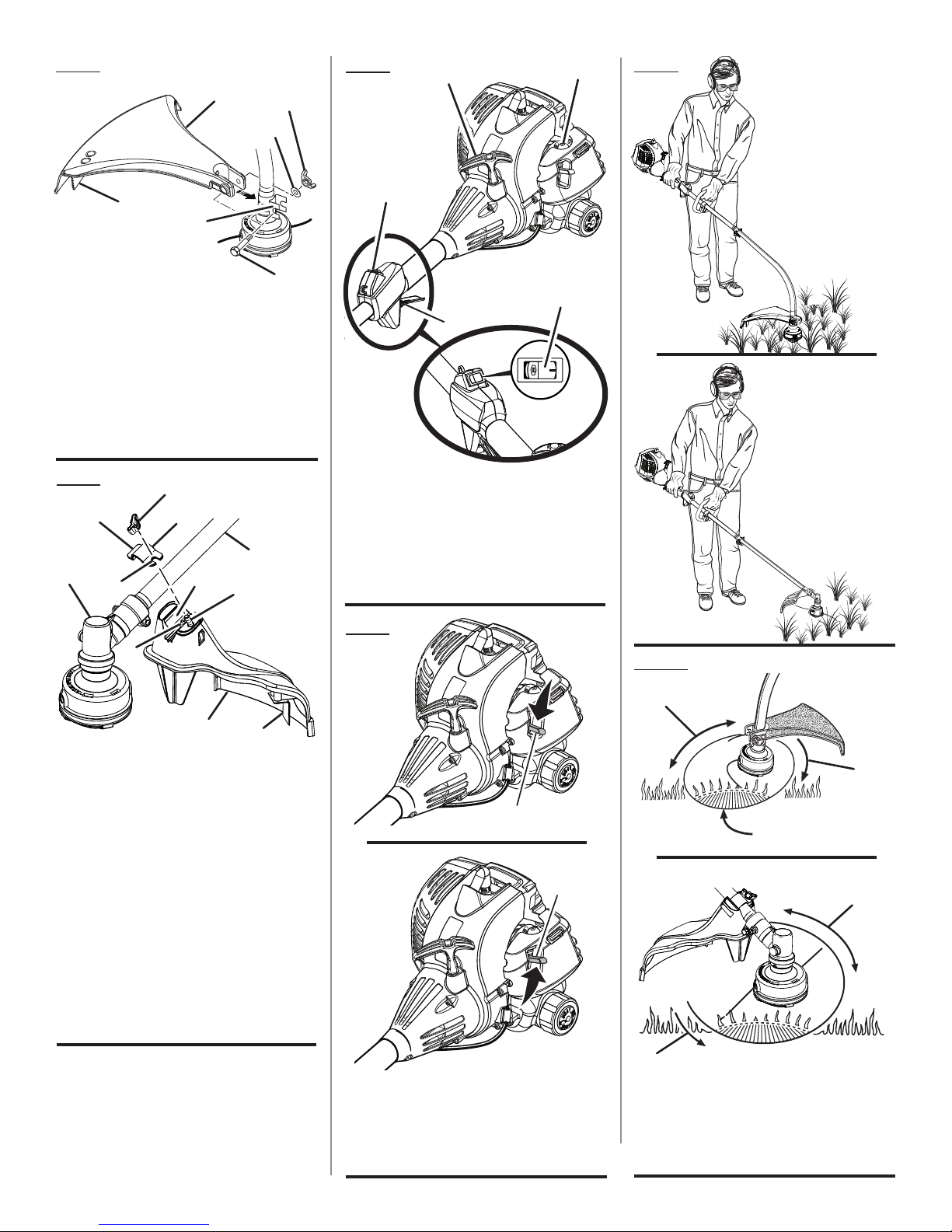

Fig. 5

D

F

E

A - Wing nut (écrou à oreilles, tuerca de

mariposa)

B - Washer (rondelle, arandela)

C - Bolt (boulon, perno)

D - Curved shaft grass deflector (déflecteur

d’herbe d’arbre courbée, deflector de pasto

del eje curvo)

E - Bracket (support, soporte)

F - Line cut-off blade (lame de sectionnement

de ligne, cuchilla de corte)

A

B

C

Fig. 7

D

B

Fig. 9

PROPER OPERATING

POSITION

BONNE POSITION DE

TRAVAIL

POSICIÓN CORRECTA

PARA EL MANEJO DE LA

HERRAMIENTA

A

26CS

A

C

Fig. 6

C

D

E

F

A

B

B

G

H

I

J

A - Gear head (carter d’engrenages, cabezal de

engranajes)

B - Slot (fente, ranura)

C - Square tab (languette carrée, orejeta

cuadrada)

D - Wing nut (écrou à oreilles, tuerca de

mariposa)

E - Mounting bracket (support de montage,

soporte de montaje)

F - Drive shaft housing (logement d’arbre

moteur, alojamiento del eje de impulsión)

G - Screw (vis, tornillo)

H - Pin (axe, pasador)

I - Straight shaft grass deflector (déflecteur

d’herbe d’arbre droit, deflector de pasto para

eje recto)

J - Line cut-off blade (lame de sectionnement

de ligne, cuchilla de corte)

A - Stop switch (commutateur d’arrêt, interruptor

del apagado)

B - Primer bulb (poire d’amorçage, bomba de

cebado)

C - Throttle trigger (gâchette d’accélérateur,

gatillo del acelerador)

D - Starter grip and rope (poignée du lanceur et

corde, mango del arrancador y cuerda)

Fig. 8

A

C

B

C

Fig. 10

A

26SS

26CS

B

C

26SS

A

A - Full choke position (position de volet de

départ ouvert, posición de arranque)

B - Run position (position de marche, posición

de marcha)

C - Choke lever (levier de volet de départ,

palanca de arranque)

iv

B

A - Dangerous cutting area (zone de coupe

dangereuse, área peligrosa de corte)

B - Direction of rotation (sens de rotation,

sentido de rotación)

C - Best cutting area (zone d’efficacité

maximum, mejor área de corte)

C

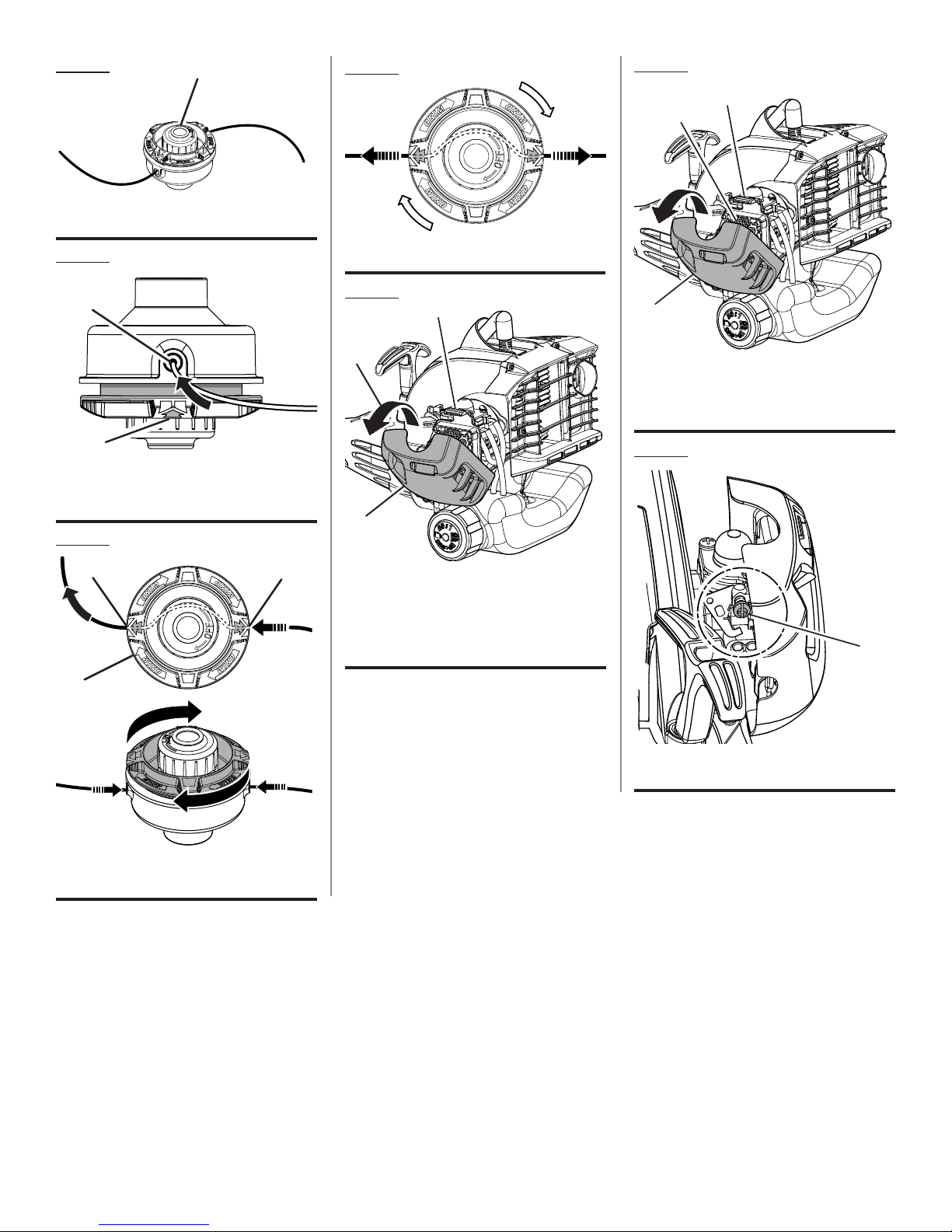

Fig. 11

A - Spool retainer (retenue de bobine, retén del

carrete)

A

Fig. 14

A A

Fig. 16

A

B

Fig. 12

A

B

A - Eyelet (œillets, ojillo)

B - Arrow on spool (flèche sur la bobine, flecha

en el carrete)

Fig. 13

B

A

B

A - Pull lines (tirer vers l’extérieur, tira del hilo)

Fig. 15

A

B

C

A - Latch (loquet, pestillo)

B - Pull cover to open (tirer sur le couvercle

pour l’ouvrir, tire de la tapa para abrirla)

C - Air filter cover (couvercle du filtre à air, tapa

del filtro de aire)

C

A - Latch (loquet, pestillo)

B - Filter screen (filtre écran, filtro pantalla)

C - Air filter cover (couvercle du filtre à air, tapa

del filtro de aire)

Fig. 17

A

A - Spool (bobine, carrete)

B - Eyelets (œillets, ojillos)

A - Idle speed screw (vis de ralenti, tornillo de

ajuste de la velocidad en vacío)

v

TABLE OF CONTENTS

TABLE DES MATIÈRES / ÍNDICE DE CONTENIDO

Introduction ......................................................................................................................................................................2

Introduction / Introducción

General Safety Rules ........................................................................................................................................................ 3

Règles de sécurité générales / Reglas de seguridad generales

Specific Safety Rules ........................................................................................................................................................ 3

Règles de sécurité particulières / Reglas de seguridad específicas

Symbols ............................................................................................................................................................................ 4

Symboles / Símbolos

Features ............................................................................................................................................................................5

Caractéristiques / Características

Assembly .......................................................................................................................................................................5-6

Assemblage / Armado

Operation .......................................................................................................................................................................6-8

Utilisation / Funcionamiento

Maintenance ................................................................................................................................................................9-11

Entretien / Mantenimiento

Troubleshooting .........................................................................................................................................................12-13

Dépannage / Solución de problemas

Warranty ....................................................................................................................................................................14-15

Garantie / Garantía

Parts Ordering and Service ...............................................................................................................................Back Page

Commande de pièces et réparation / Pedidos de piezas y servicio ......................................................... Page arrière / Pág. posterior

INTRODUCTION

INTRODUCTION / INTRODUCCIÓN

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.

* * *

Ce produit offre de nombreuses fonctions destinées à rendre son utilisation plus plaisante et satisfaisante. Lors de la

conception de ce produit, l’accent a été mis sur la sécurité, les performances et la fiabilité, afin d’en faire un outil facile à

utiliser et à entretenir.

* * *

Este producto ofrece numerosas características para hacer más agradable y placentero su uso. En el diseño de este producto

se ha conferido prioridad a la seguridad, el desempeño y la fiabilidad, por lo cual se facilita su manejo y mantenimiento.

2

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure to follow

all instructions listed below may result in electric shock,

fire and/or carbon monoxide poisoning which will cause

death or serious personal injury.

READ ALL INSTRUCTIONS

For safe operation, read and understand all instructions

before using this product. Follow all safety instructions.

Failure to follow all safety instructions listed below, can

result in serious personal injury.

Do not allow children or untrained individuals to use this

unit.

Never start or run the engine in a closed or poorly ventilated

area; breathing exhaust fumes can kill.

Clear the work area before each use. Remove all objects

such as rocks, broken glass, nails, wire, or line which

can be thrown or become entangled in the cutting line

or blade.

Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

Wear heavy, long pants, long sleeves, boots, and gloves.

Do not wear loose fitting clothing, short pants, sandals,

or go barefoot. Do not wear jewelry of any kind.

Product users on United States Forest Service land, and in

some states, must comply with fire prevention regulations.

This product is equipped with a spark arrestor; however,

other user requirements may apply. Check with your

federal, state, or local authorities.

Never operate this unit on the operator’s left side.

Secure long hair above shoulder level to prevent

entanglement in moving parts.

Keep all bystanders, children, and pets at least 50 ft.

away. Bystanders should be encouraged to wear eye

protection.

Do not operate this unit when you are tired, ill, or under

the influence of alcohol, drugs, or medication.

Do not operate in poor lighting.

Keep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or exposure

to hot surfaces. Keep cutting attachment below waist.

To avoid hot surfaces, never operate the unit with the

bottom of the engine above waist level.

Keep all parts of your body away from any moving part.

Do not touch area around the muffler or cylinder of the

unit; these parts get hot from operation.

Always stop the engine and remove the spark plug wire

before making any adjustments or repairs except for

carburetor adjustments.

Inspect the unit before each use for loose fasteners, fuel

leaks, etc. Replace any damaged parts before use.

The string head will rotate during carburetor adjustments.

It has been reported that vibrations from hand-held tools

may contribute to a condition called Raynaud’s Syndrome

in certain individuals. Symptoms may include tingling,

numbness, and blanching of the fingers, usually apparent

upon exposure to cold. Hereditary factors, exposure to

cold and dampness, diet, smoking, and work practices

are all thought to contribute to the development of these

symptoms. It is presently unknown what, if any, vibrations

or extent of exposure may contribute to the condition.

There are measures that can be taken by the operator to

possibly reduce the effects of vibration:

a) Keep your body warm in cold weather. When operating

the unit wear gloves to keep your hands and wrists

warm. It is reported that cold weather is a major factor

contributing to Raynaud’s Syndrome.

b) After each period of operation, exercise to

increase blood circulation.

c) Take frequent work breaks. Limit the amount of

exposure per day.

d) Keep the product well maintained, fasteners tightened

and worn parts replaced.

If you experience any of the symptoms of this condition,

immediately discontinue use and see your physician about

these symptoms.

Mix and store fuel in a container approved for gasoline.

Do not smoke while fueling or mixing fuel.

3 — English

GENERAL SAFETY RULES

Mix fuel outdoors where there are no sparks or flames.

Wipe up any fuel spillage. Move 30 ft. away from refueling

site before starting engine.

Stop the engine and allow to cool before refueling or

storing the unit.

SPECIFIC SAFETY RULES

Replace string head if cracked, chipped, or damaged

in any way. Be sure the string head is properly installed

and securely fastened. Failure to do so can cause serious

injury.

Make sure all guards, straps, deflectors, and handles are

properly and securely attached.

Never use blades, flailing devices, wire, or rope. Use only

the manufacturer’s replacement line in the cutting head.

Do not use any other cutting attachment. To install any

other brand of cutting head to this string trimmer can

result in serious personal injury.

Allow the engine to cool; empty the fuel tank into a

container approved for gasoline and secure the unit from

moving before transporting in a vehicle.

Never operate unit without the grass deflector in place

and in good condition.

Maintain a firm grip on both handles while trimming. Keep

string head below waist level. Never cut with the string

head located over 30 in. or more above the ground.

This product is intended for infrequent use by homeown-

ers and other occasional users for such general applications as trimming light and heavy vegetation, etc. It is not

intended for prolonged use. Prolonged periods of operation can cause circulatory problems in the user’s hands

due to vibration. For such use, it may be appropriate to

use a product having an anti-vibration feature.

4 — English

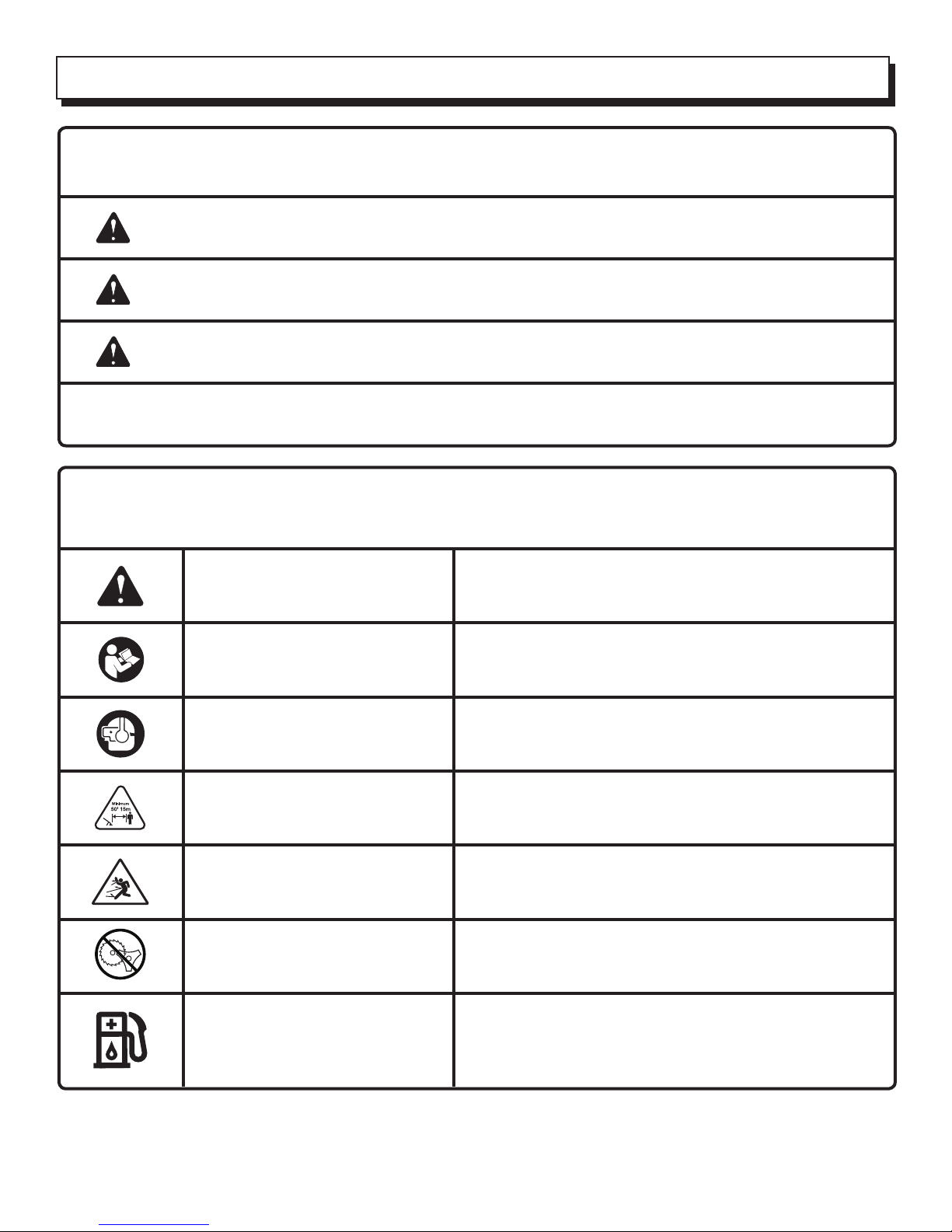

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

CAUTION:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may result in property

damage.

SYMBOL NAME EXPLANATION

Safety Alert Symbol Indicates a potential personal injury hazard.

Read Operator’s Manual

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Eye and Hearing Protection

Keep Bystanders Away Keep all bystanders at least 50 ft. away.

Ricochet

No Blade

Gasoline and Lubricant

Always wear eye protection with side shields marked to comply with ANSI Z87.1, along with hearing protection.

Thrown objects can ricochet and result in personal injury or

property damage.

Do not install or use any type of blade on a product displaying this symbol.

Use unleaded gasoline intended for motor vehicle use with

an octane rating of 87 [(R + M) / 2] or higher. This product is

powered by a 2-cycle engine and requires pre-mixing gasoline

and 2-cycle lubricant.

5 — English

FEATURES

PRODUCT SPECIFICATIONS

Weight (dry)

26CS ..................................................................................................................................................................... 9.3 lbs.

26SS ......................................................................................................................................................................10 lbs.

Line cutting width ........................................................................................................................................................... 17 in.

Engine displacement ....................................................................................................................................................... 26cc

Line diameter .............................................................................................................................................................. .080 in.

KNOW YOUR STRING TRIMMER

See Figure 1.

The safe use of this product requires an understanding of

the information on the tool and in this operator’s manual as

well as a knowledge of the project you are attempting. Before

use of this product, familiarize yourself with all operating

features and safety rules.

GRASS DEFLECTOR

The trimmer includes a grass deflector that helps protect

you from flying debris.

ASSEMBLY

UNPACKING

This product requires assembly.

Carefully remove the product and any accessories from

the box. Make sure that all items listed in the packing list

are included.

WARNING:

Do not use this product if any parts on the Packing List

are already assembled to your product when you unpack

it. Parts on this list are not assembled to the product by

the manufacturer and require customer installation. Use

of a product that may have been improperly assembled

could result in serious personal injury.

Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have carefully

inspected and satisfactorily operated the product.

If any parts are damaged or missing, please call

1-800-332-1631 for assistance.

STRING HEAD TAP ADVANCE SYSTEM

The String Head Tap Advance System allows easy line

advance during trimmer operation.

TOP-MOUNTED MOTOR

The top-mounted motor improves balance and is located

away from the dust and debris of the cutting area.

PACKING LIST (continued)

Straight Shaft Grass Deflector – 26SS

Bottle of 2-Cycle Lubricant

Operator’s Manual

WARNING:

If any parts are damaged or missing, do not operate this

product until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

WARNING:

Do not attempt to modify this product or create accessories not recommended for use with this product. Any

such alteration or modification is misuse and could result

in a hazardous condition leading to possible serious

personal injury.

PACKING LIST

Trimmer Assembly

Front Handle

String Head Assembly

Spool Retainer

Curved Shaft Grass Deflector – 26CS

WARNING:

To prevent accidental starting that could cause serious

personal injury, always disconnect the engine spark plug

wire from the spark plug when assembling parts.

6 — English

ASSEMBLY

FRONT HANDLE

See Figure 2.

Loosen and remove the wing nut, lock washer, washer,

and bolt from the handle.

Install the handle on the drive shaft housing at the loca-

tion indicated by the label on the shaft.

Adjust handle up or down, if necessary, to desired operat-

ing position.

Reinstall the bolt, washer, lock washer, and wing nut.

Tighten wing nut to secure.

NOTE: On units with curved shafts, for shipping purposes

only, the handle is located underneath the drive shaft housing.

The handle must be rotated before operating the trimmer.

Slightly loosen the wing nut on the handle.

Rotate the handle on the drive shaft housing at the loca-

tion indicated by the label on the shaft.

Retighten the wing nut to secure the handle in place.

STRING HEAD ASSEMBLY

See Figures 3 - 4.

Place the string head assembly on the end of the drive

shaft. Make sure the hex-shaped opening on the string

head assembly seats completely on the drive shaft. Install

the spool retainer to secure.

Install the spool retainer:

Turn the spool retainer clockwise for 26CS.

Turn the spool retainer counterclockwise for 26SS.

Remove the plastic seal from the string head assembly.

Pull outward on the lines to rotate the spool into the cutting position.

Push the spool retainer down while pulling on line(s) to

manually advance the line and to check for proper assembly of the string head.

CURVED SHAFT GRASS DEFLECTOR – 26CS

See Figure 5.

WARNING:

The line cut-off blade on the grass deflector is sharp.

Avoid contact with the blade. Failure to avoid contact

can result in serious personal injury.

Remove the bolt, washer, and wing nut from grass deflector.

Press the grass deflector onto the bottom of the curved

shaft as shown.

Insert the bolt through the grass deflector and the bracket

on the curved shaft.

Place the washer on the bolt.

Place the wing nut on the bolt and tighten securely.

STRAIGHT SHAFT GRASS DEFLECTOR –

26SS

See Figure 6.

Remove the wing nut and mounting bracket from the grass

deflector.

Assemble straight shaft grass deflector to drive shaft so

that the pin in the grass deflector fits in the locator hole

in the lower side of the drive shaft near the gear head.

Place the mounting bracket over the drive shaft so the

square tab on the mounting bracket fits into the slot in

the straight shaft grass deflector.

Rotate the mounting bracket so the screw on the grass

deflector goes into the slot on the mounting bracket.

Reinstall the wing nut and tighten securely.

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

OPERATION

WARNING:

Never use blades, flailing devices, wire, or rope on this

product. Do not use any attachments or accessories not

recommended by the manufacturer of this product. The

use of attachments or accessories not recommended

can result in serious personal injury.

7 — English

OPERATION

WARNING:

Operation of this equipment could create sparks that

can start fires around dry vegetation. A spark arrestor

may be required. The operator should contact local fire

agencies for laws or regulations relating to fire prevention

requirements.

WARNING:

Gasoline and its vapors are highly flammable and explosive. To prevent serious personal injury and property

damage, handle it with care. Keep away from ignition

sources and open flames, handle outdoors only, do not

smoke and wipe up spills immediately.

FUELING AND REFUELING THE TOOL

FUEL MIXTURE

This product is powered by a 2-cycle engine and requires

pre-mixing gasoline and 2-cycle lubricant. Pre-mix unleaded

gasoline and 2-cycle engine lubricant in a clean container

approved for gasoline. DO NOT mix quantities larger than

usable in a 30-day period.

Recommended fuel: This engine is certified to operate on

unleaded gasoline intended for automotive use.

NOTE: We recommend you use high-quality synthetic

2-cycle lubricant in this product. Mix at 2.6 oz. per gallon

(US).

Do not use automotive lubricant or 2-cycle outboard

lubricant.

HIGH QUALITY 2-CYCLE ENGINE LUBRICANT

GASOLINE LUBRICANT

1.0 gal. (US) (3.8 liter) 2.6 oz. (76 ml)

2.5 gal. (US) (9.5 liter) 6.4 oz. (189 ml)

FILLING TANK

Clean surface around fuel cap to prevent

contamination.

Loosen fuel cap slowly, by turning it counterclockwise.

Rest the cap on a clean surface.

Carefully pour fuel into the tank. Avoid spillage.

Prior to replacing the fuel cap, clean and inspect the

gasket.

Immediately replace fuel cap and hand tighten by turning

it clockwise. Wipe up any fuel spillage.

Move at least 30 ft. away from refueling area before starting

the product.

NOTE: It is normal for smoke to be emitted from a new

engine after first use.

WARNING:

Always shut off engine before fueling. Never add fuel to a

machine with a running or hot engine. Move at least 30 ft.

from refueling site before starting engine. Do not smoke

and stay away from open flames and sparks. Failure to

safely handle fuel could result in serious personal injury.

OXYGENATED FUELS

NOTICE: DO NOT USE E15 OR E85 FUEL (OR FUEL

CONTAINING GREATER THAN 10% ETHANOL) IN THIS

PRODUCT. IT IS A VIOLATION OF FEDERAL LAW AND

WILL DAMAGE THE UNIT AND VOID YOUR WARRANTY.

NOTE: Fuel system damage or performance problems

resulting from the use of an oxygenated fuel containing more

than the percentages of oxygenates stated below are not

covered under warranty.

Ethanol. Gasoline containing up to 10% ethanol by volume

(commonly referred to as E10) is acceptable. E15 and E85

are not.

STARTING AND STOPPING

See Figures 7 - 8.

Trimmer should be on a flat, bare surface for starting.

To start a cold engine:

Slowly press the primer bulb 10 times.

NOTE: After the 7th press, fuel should be visible in the

primer bulb. If it is not, continue to press the primer until

you see fuel in the bulb.

Set the choke lever to the FULL CHOKE position.

Squeeze the throttle trigger fully and pull starter grip and

rope sharply until engine attempts to run. Do not pull the

starter grip and rope more than four (4) times.

NOTE: Keep throttle trigger squeezed fully.

Set the choke lever to the HALF CHOKE position.

Pull the starter grip and rope until the engine runs. Do not

pull the starter grip and rope more than six (6) times.

NOTE: If the engine does not start, return to the FULL

CHOKE position and repeat the steps that follow.

Allow the engine to run for 10 seconds, then set the choke

lever to the RUN position.

To restart a warm engine:

Slowly press the primer bulb 10 times.

Set the choke lever to the RUN position.

Squeeze the throttle trigger fully and pull the starter grip

and rope until the engine runs.

To stop the engine:

To stop the engine, release the throttle trigger and depress

the STOP switch to the stop position “ ”.

8 — English

OPERATION

IF ASSISTANCE IS REQUIRED FOR THIS PRODUCT:

Do not return this product to the retail store where it was

purchased. Please call our Customer Service Department

for any issues you may have.

For Help Call: 1-800-332-1631.

OPERATING THE STRING TRIMMER

See Figure 9.

WARNING:

Engine housing can become hot during trimmer operation. Do not rest or place your arm, hand, or any body

part against the engine housing during trimmer operation.

Only hold the trimmer as shown in Figure 9 with all body

parts clear of engine housing. Extended contact with

the engine housing may result in burns or other injuries.

WARNING:

Always position the unit on the operator’s right side. The

use of the unit on the operator’s left side will expose the operator to hot surfaces and can result in possible burn injury.

WARNING:

To avoid burns from hot surfaces, never operate unit with

the bottom of the engine above waist level.

Hold the trimmer with your right hand on the rear handle

and your left hand on the front handle. Keep a firm grip with

both hands while in operation. Trimmer should be held at a

comfortable position with the rear handle about hip height.

Always operate trimmer at full throttle. Cut tall grass from the

top down. This will prevent grass from wrapping around the

shaft housing and string head which may cause damage from

overheating. If grass becomes wrapped around the string

head, STOP THE ENGINE, disconnect the spark plug wire,

and remove the grass. Prolonged cutting at partial throttle

will result in lubricant dripping from the muffler.

CUTTING TIPS

See Figure 9 - 10.

Avoid hot surfaces by always keeping the tool away from

your body. (Proper operating position shown in figure 9.)

Keep the trimmer tilted toward the area being cut; this is

the best cutting area.

The curved shaft trimmer cuts when passing the unit from

right to left. The straight shaft trimmer cuts when passing

the unit from left to right. This will avoid throwing debris at

the operator. Avoid cutting in the dangerous area shown

in figure 10.

Use the tip of line to do the cutting; do not force string

head into uncut grass.

Wire and picket fences cause extra line wear, even break-

age. Stone and brick walls, curbs, and wood may wear

line rapidly.

Avoid trees and shrubs. Tree bark, wood moldings, siding,

and fence posts can easily be damaged by the line.

ADVANCING LINE USING THE STRING HEAD

TAP ADVANCE SYSTEM

Line advance is controlled by tapping string head on grass

while running engine at full throttle.

Run engine at full throttle.

Tap string head on ground to advance line. Line advances

each time the head is tapped.

Several taps may be required until line strikes the cut off

blade.

Resume trimming.

NOTE: If the line is worn too short you may not be able to

advance the line by tapping it on the ground. If so, STOP

THE ENGINE, disconnect the spark plug wire, and manually

advance the line.

ADVANCING THE LINE MANUALLY

With the engine off and the spark plug wire disconnected,

push the spool retainer down while pulling on line(s) to manually advance the line.

WARNING:

Always hold the string trimmer away from your body,

keeping clearance between your body and the product.

Any contact with the housing or string trimmer cutting

head can result in burns and/or other serious personal

injury.

CUT-OFF BLADE

This trimmer is equipped with a cut-off blade on the grass

deflector. For best cutting, advance line by tapping the string

head until the line is trimmed to length by the cut-off blade.

Advance line whenever you hear the engine running faster

than normal, or when trimming efficiency diminishes. This

will maintain best performance and keep line long enough

to advance properly.

9 — English

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

WARNING:

Before inspecting, cleaning, or servicing the machine,

shut off engine, wait for all moving parts to stop, and

disconnect spark plug wire and move it away from spark

plug. Failure to follow these instructions can result in

serious personal injury or property damage.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, lubricant, grease, etc.

NOTE: Make sure the arrows on the spool are aligned

with the eyelets in the string head housing. Push down

and hold the spool and housing together while completing the installation.

Reinstall the spool retainer to secure.

To install the spool retainer:

Turn the spool retainer clockwise for 26CS.

Turn the spool retainer counterclockwise for 26SS.

Install line as described in Line replacement.

LINE REPLACEMENT

See Figures 12 - 14.

Stop the engine and disconnect the spark plug wire.

Rotate the spool clockwise as necessary to align the

arrows on the spool with the eyelets in the string head

housing.

Cut one piece of trimmer line 15 ft. long. Insert the line

into the eyelet on the string trimmer housing. Push until

the end of the line comes out the other side of the string

head. Pull the line from the other side until equal amounts

of line appear on both sides of the spool.

Rotate the spool clockwise to wind the line on the spool

until approximately 6 in. of line is showing on each side.

Push the spool retainer down while pulling on line(s) to

manually advance the line and to check for proper assembly of the string head.

WARNING:

Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating lubricants, etc., come in contact with plastic parts. Chemicals can damage, weaken or

destroy plastic which can result in serious personal injury.

You can often make adjustments and repairs described here.

For other repairs, have the trimmer serviced by an authorized

service dealer.

SPOOL REPLACEMENT STRING HEAD TAP

ADVANCE SYSTEM

See Figures 11 - 12.

If replacing line only, refer to Line Replacement later in

this manual.

Use only .080 in. trimmer line.

Stop the engine and disconnect the spark plug wire. Hold

the string head and unscrew the spool retainer.

To remove the spool retainer:

Turn the spool retainer counterclockwise for 26CS.

Turn the spool retainer clockwise for 26SS.

Remove the empty spool from the string head.

NOTE: It is not necessary to remove the string head

housing from the drive shaft.

Insert the new spool into the string head.

CLEANING THE EXHAUST PORT, MUFFLER,

AND SPARK ARRESTOR

NOTE: Depending on the type of fuel used, the type and

amount of lubricant used, and/or your operating conditions, the exhaust port, muffler, and/or spark arrestor screen

may become blocked with carbon deposits. If you notice a

power loss with your gas powered tool, you may need to

remove these deposits to restore performance. We highly

recommend that only qualified service technicians perform

this service.

The spark arrestor must be cleaned or replaced every 50

hours or yearly to ensure proper performance of your product. Spark arrestors may be in different locations depending

on the model purchased. Please contact your nearest service

dealer for the location of the spark arrestor for your model.

CLEANING THE AIR FILTER SCREEN

See Figures 15 - 16.

For proper performance and long life, keep air filter screen

clean.

Remove the air filter cover by pushing down on the latch

with your thumb while gently pulling on the cover.

Brush the air filter screen lightly to clean.

Replace the air filter cover by inserting the tabs on the

bottom of the cover into the slots on the air filter base;

push the cover up until it latches securely in place.

10 — English

MAINTENANCE

FUEL CAP

WARNING:

Check for fuel leaks. A leaking fuel cap is a fire hazard and

must be replaced immediately. If you find any leaks, correct the problem before using the product. Failure to do so

could result in a fire that could cause serious personal injury.

The fuel cap contains a non-serviceable filter and a check

valve. A clogged fuel filter will cause poor engine performance. If performance improves when the fuel cap is loosened, check valve may be faulty or filter clogged. Replace

fuel cap if required.

WARNING:

The cutting attachment should never turn at idle. Turn

the idle speed screw counterclockwise to reduce the

idle RPM and stop the cutting attachment, or contact a

service dealer for adjustment and discontinue use until

the repair is made. Serious personal injury could result

from the cutting attachment turning at idle.

SPARK PLUG

This engine uses a Champion RCJ6Y or equivalent spark

plug with .025 in. electrode gap. Use an exact replacement

and replace annually, or more frequently if necessary.

IDLE SPEED ADJUSTMENT

See Figure 17.

WARNING:

The cutting head will move when adjusting the idle speed.

Wear all protective clothing and keep all bystanders,

children, and pets at least 50 ft. away. Make adjustments

with the unit supported by hand so that the cutting head

does not contact the ground or any object. Keep all parts

of your body away from the cutting head and muffler.

Failure to follow these instructions could result in serious

personal injury.

If the cutting attachment turns at idle, the idle speed screw

needs adjusting on the engine. Turn the idle speed screw

counterclockwise to reduce the idle RPM and stop the cutting attachment movement. If the cutting attachment still

moves at idle speed, contact a service dealer for adjustment

and discontinue use until the repair is made.

STORING THE PRODUCT

Clean all foreign material from the product. Store idle unit

indoors in a dry, well-ventilated area that is inaccessible

to children. Keep away from corrosive agents such as

garden chemicals and de-icing salts.

Abide by all ISO and local regulations for the safe storage

and handling of gasoline.

When storing 1 month or longer:

Drain all fuel from tank into a container approved for

gasoline. Run engine until it stops.

HIGH ALTITUDE ENGINE OPERATION

Please have an authorized service center adjust this engine

if it is to be run above 2000 feet. Failure to do so may result

in poor engine performance and increased emissions. An

engine adjusted for high altitudes can not be run at 2000

feet or lower. In doing so, the engine will overheat and cause

serious engine damage. Please have an authorized service

center restore high altitude modified engines to the original

factory specification before operating below 2000 feet.

11 — English

MAINTENANCE

THIS PRODUCT WAS MANUFACTURED WITH A CATALYST MUFFLER

Congratulations! You have made an investment toward protecting the environment. In order to maintain this product’s

original emission level, please refer to the maintenance section below.

Inspect Clean Replace Replace

Maintenance Before Every Every 25 Hours Every

Part Each Use 5 Hours or Yearly 50 Hours

* CATALYTIC MUFFLER ASSEMBLY..................................................................................................................X

SPARK SCREEN ...............................................................................................................................................X

* AIR FILTER ASSY

includes:

Filter Screen ........................................................................ X

* CARBURETOR ASSY

includes:

Gaskets ........................................ X

* FUEL TANK ASSY

includes:

Fuel Lines ..................................... X

Fuel Cap ....................................... X

Fuel Filter................................................................................................................... X

* IGNITION ASSY

includes:

Spark Plug ................................................................................................................. X

* NOTICE: THE USE OF EMISSION CONTROL COMPONENTS OTHER THAN THOSE DESIGNED FOR THIS UNIT

IS A VIOLATION OF FEDERAL LAW.

MAINTENANCE SCHEDULE

CALL

1-800-332-1631

www.greenmachinetools.com

CALL US FIRST

For any questions about operating or maintaining your product,

call the GREEN MACHINE™ Help Line!

Your product has been fully tested prior to shipment to ensure

your complete satisfaction.

12 — English

Loading...

Loading...