Page 1

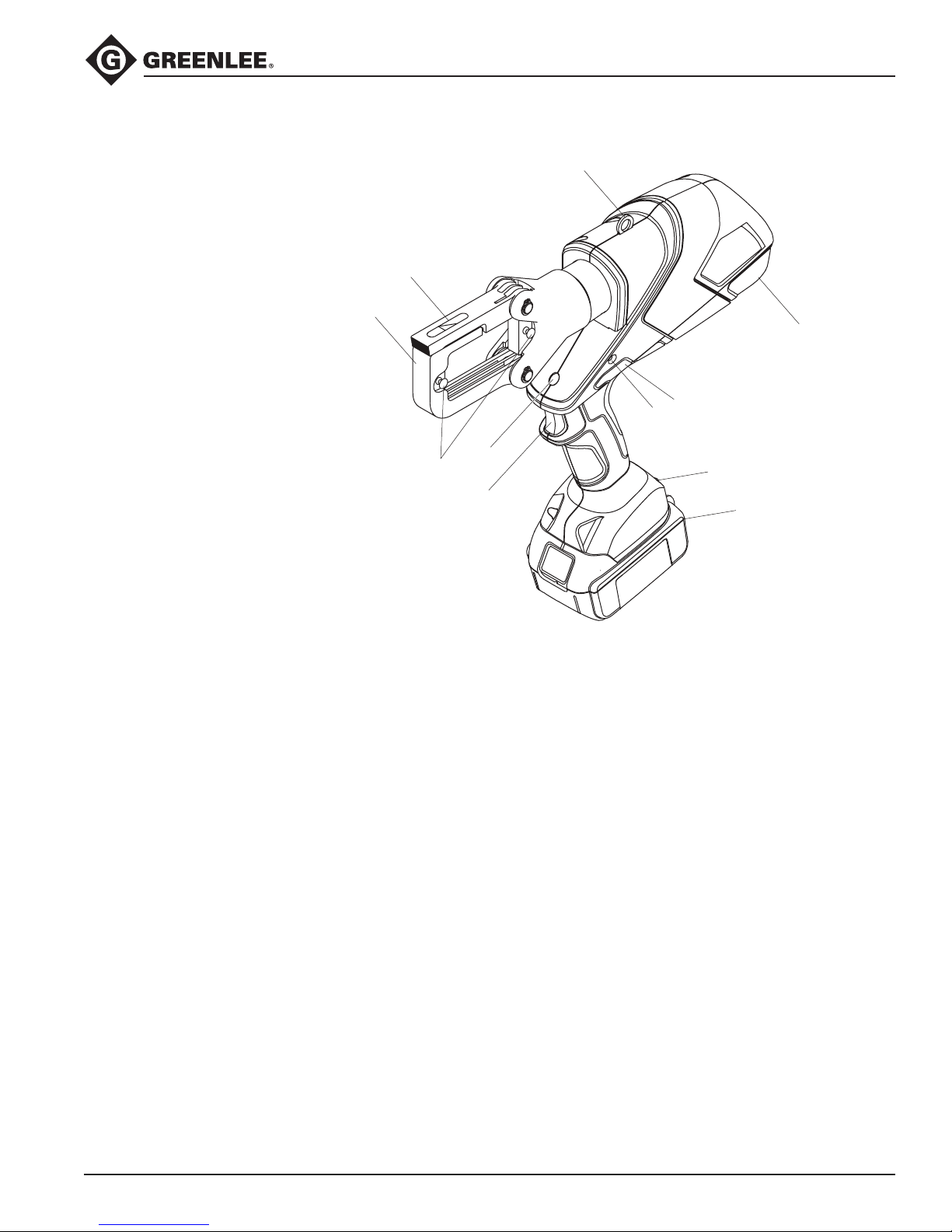

OPERATION MANUAL

Serial Number

Battery-powered Tool

Read and understand all of the instructions and

safety information in this manual before operating

or servicing this tool.

52080026 REV 2 © 2017 Greenlee Textron Inc. 3/17

E6CCXLX

GATOR®

Register this product at www.greenlee.com

Page 2

E6CCXLX Battery-powered Tool

Table of Contents

Description .................................................................... 2

Safety ............................................................................ 2

Purpose of this Manual ................................................. 2

Important Safety Information .....................................3–4

Identication .................................................................. 5

Specications ................................................................ 5

Operation ..................................................................6–14

Crimping .................................................................7–8

Cutting ....................................................................... 9

Punching .............................................................10–14

Available Adapters ....................................................... 15

Die Selection ............................................................... 16

Connector Selection .................................................... 16

LCD Screen ................................................................. 17

Maintenance ................................................................ 18

Troubleshooting ........................................................... 19

Description

E6CCXLX Battery-powered, High-speed Tool is a handheld, self-contained tools intended to crimp cable,

cut cable and threaded rod, and punch holes with the

proper adapters.

The tools has a retraction stop feature which allows

the operator to stop the retraction motion of the ram to

shorten cycle time.

The tool has a Bluetooth® connectivity and an LCD

screen.

The tool is a protected by U.S. Patent No. 6,206,663,

6,276,186, 6,401,515, and 6,532,790.

Model X-E6CCXLX—FCC ID: 2AGL2X; IC ID: 20646X

This device complies with Part 15 of the FCC Rules and

with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired

operation

Note: Change or modifications made to this equipment

not expressly approved by Greenlee may void the FCC

authorization to operate this equipment.

All specications are nominal and may change as design

improvements occur. Greenlee Textron Inc. shall not be liable for

damages resulting from misapplication or misuse of its products.

GATOR and Kwik Stepper are registered trademarks of

TextronInnovations Inc.

Bluetooth is a registered trademark of Bluetooth SIG, Inc.

Blackburn is a registered trademark of Thomas & Betts.

Safety

Safety is essential in the use and maintenance of

Greenlee tools and equipment. This manual and any

markings on the tool provide information for avoiding

hazards and unsafe practices related to the use of this

tool. Observe all of the safety information provided.

Note: For body worn operation, this device has been

tested and meets the FCC RF exposure guidelines for

an uncontrolled environment. The maximum reported

SAR value is 0.08 mW/g

Purpose of this Manual

This manual is intended to familiarize all personnel with

the safe operation and maintenance procedures for the

following Greenlee tool:

• E6CCXLX Battery-powered, High-speed Tool

Keep this manual available to all personnel.

Replacement manuals are available upon request at

no charge at www.greenlee.com.

Do not discard this product or throw away!

For recycling information, go to www.greenlee.com.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

KEEP THIS MANUAL

2

Page 3

E6CCXLX Battery-powered Tool

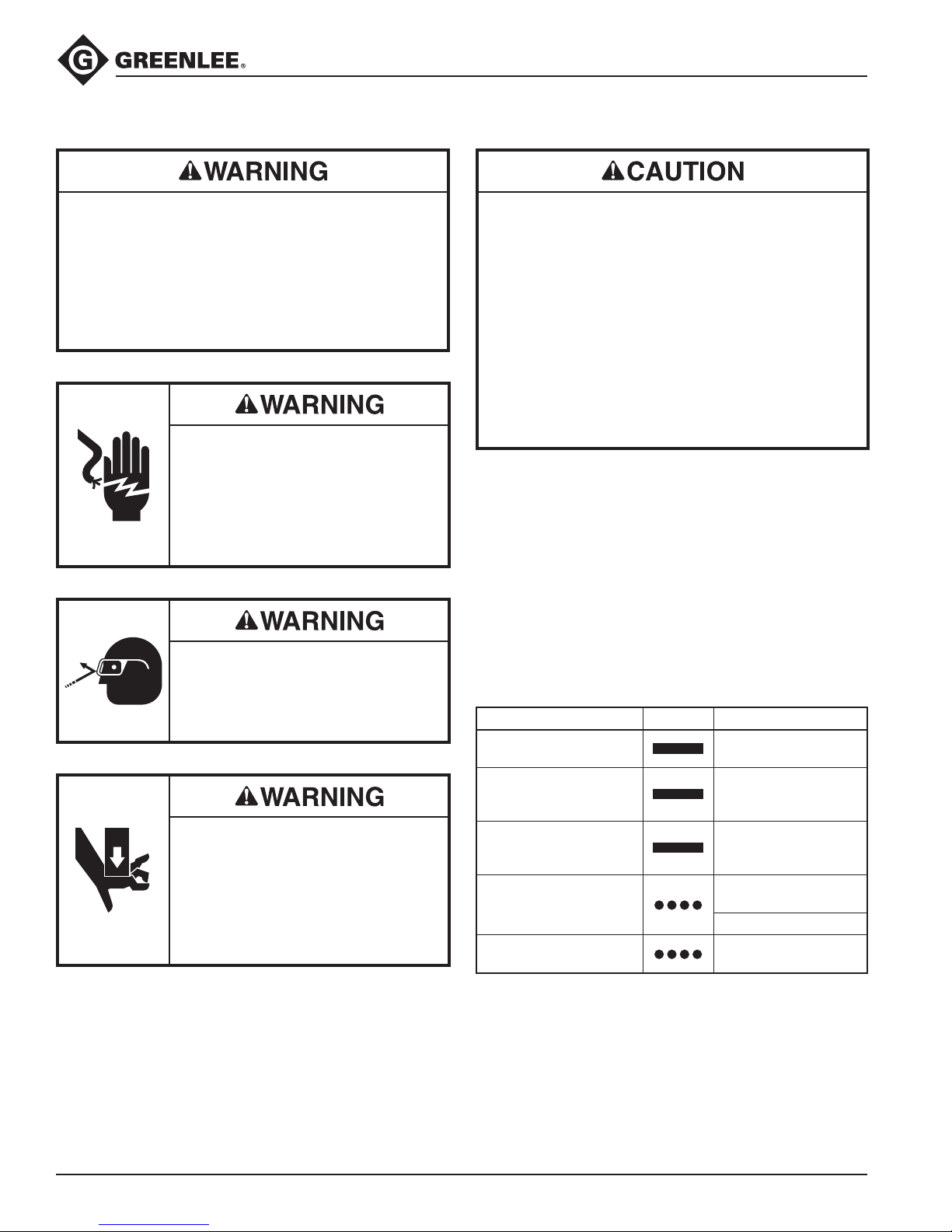

IMPORTANT SAFETY INFORMATION

SAFETY

ALERT

SYMBOL

This symbol is used to call your attention to hazards

or unsafe practices which could result in an injury or

property damage. The signal word, dened below,

indicates the severity of the hazard. The message

after the signal word provides information for preventing or avoiding the hazard.

Immediate hazards which, if not avoided, WILL result

in severe injury or death.

Hazards which, if not avoided, COULD result in

severe injury or death.

Hazards or unsafe practices which, if not avoided,

MAY result in injury or property damage.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from ying

debris or hydraulic oil.

Skin injection hazard:

Do not use hands to check for oil

leaks. Oil under pressure easily punctures skin. If injured, seek medical

attention immediately to remove oil.

Failure to observe this warning could

result in serious injury, gangrene, or

death.

Do not use solvents or ammable

liquids to clean the tool body.

Solvents or ammable liquids could

ignite and cause serious injury or

property damage.

Read and understand all of the

instructions and safety information

in this manual before operating or

servicing this tool.

Failure to observe this warning could

result in severe injury or death.

Electric shock hazard:

This tool is not insulated. When using

this unit on or near energized electrical lines, use proper personal protective equipment.

Failure to observe this warning could

result in severe injury or death.

An incomplete crimp can cause a re.

• Use proper die, connector, and cable combinations.

Improper combinations can result in an incomplete

crimp.

• The relief valve sounds and the ram automatically

retracts to indicate a completed crimp. If you do not

hear the sound of the relieve valve or the ram does

not automatically retract, the crimp is not complete.

Failure to observe these warnings could result in

severe injury or death.

Pinch points:

• Remove battery before changing

dies, adapters, or jaws.

• Keep hands away from the crimping tool head when crimping.

Failure to observe these warnings

could result in severe injury or death.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

3

Page 4

E6CCXLX Battery-powered Tool

IMPORTANT SAFETY INFORMATION

Do not dispose of batteries in a re. They will vent

fumes and may explode.

Failure to observe this warning could result in severe

injury from harmful fumes or burns from ying debris.

Remove the battery before transporting the T version

of this tool by air.

Failure to observe this warning could result in severe

injury or death.

• Inspect tool and dies before use. Replace any

worn or damaged parts. A damaged or improperly assembled tool can break and strike nearby

personnel.

• Carrying strap is for carrying only, not to be used to

hang or suspend tool.

Failure to observe these warnings could result in

severe injury or death.

• Do not use this tool for continuous use. After 30 to

40 cycles, allow the tool to cool for 15 minutes.

• Do not secure this tool in a vise. This tool is

designed for hand-held operation.

• This tool may be used in damp or wet environments; however, air-drying is recommended before

use if the tool becomes soaked. Damage may result

when the tool is operated prior to thorough drying

when electrical components are soaked.

• Use this tool for the manufacturer’s intended

purpose only.

Failure to observe these precautions may result in

injury or property damage.

Do not allow anything to contact the battery

terminals.

• Do not immerse the batteries in liquid. Liquid may

create a short circuit and damage the battery. If batteries are immersed, contact your service center for

proper handling.

• Do not place the battery into a pocket, tool pouch,

or tool box with conductive objects. Conductive

objects may create a short circuit and damage the

battery.

• Do not place a battery on moist ground or grass.

Moisture may create a short circuit and damage the

battery.

Failure to observe these precautions may result in

injury or property damage.

• Do not store the battery at more than 122 °F (50°C)

or less than –4 °F (–20 °C). Damage to the battery

can result.

• Do not use another manufacturer’s charger. Other

manufacturers’ chargers may overcharge and

damage the battery.

• Do not attempt to open the battery. It contains no

user-serviceable parts.

Failure to observe these precautions may result in

injury or property damage.

Do not perform any service or maintenance other than

as described in this manual. Injury or damage to the

tool may result.

Failure to observe this precaution may result in injury

and property damage.

Note: Keep all decals clean and legible, and replace

when necessary.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

4

Page 5

Identification

1. LED Work Light (white)

2. Adapter Release Buttons

3. Head

4. Latch (for opening head)

5. Lanyard Ring

6. Housing

7. Retract Button

8. LED Indicator (red)

9. LCD Screen

10. Battery

11. Trigger

E6CCXLX Battery-powered Tool

5

4

3

6

7

8

1

2

11

9

10

Specifications

Tool

Length ...............................................................................................15.3" (388 mm)

Width ................................................................................................... 3.00" (76 mm)

Height (with battery) .......................................................................... 12.9" (328 mm)

Weight ................................................................................................10.2 lb (4.6 kg)

Crimping Force ................................................................................. 6.7 tons (60 kN)

Hydraulic Oil ............................................... 52057878 biodegradable hydraulic uid

Recommended Operating Temperature Range .............. 5 °F to 122 °F (–15 °C to 50 °C)

Crimping Tool

Maximum Crimping Cable Size ................... 600 kcmil copper; 350 kcmil aluminum

Cutting Tool

Maximum Cutting ................................... 1-1/2" (40 mm) kcmil aluminum or copper

Battery Charger .............................................................Read the instructions supplied

with the battery charger

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

5

Page 6

Operation

E6CCXLX Battery-powered Tool

• Inspect tool and dies before use. Replace any

worn or damaged parts. A damaged or improperly assembled tool can break and strike nearby

personnel.

• Carrying strap is for carrying only, not to be used to

hang or suspend tool.

Failure to observe these warnings could result in

severe injury or death.

Electric shock hazard:

This tool is not insulated. When using

this unit on or near energized electrical lines, use proper personal protective equipment.

Failure to observe this warning could

result in severe injury or death.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from ying

debris or hydraulic oil.

Pinch points:

• Remove battery before changing

dies, adapters, or jaws.

• Keep hands away from the crimping tool head when crimping.

Failure to observe these warnings

could result in severe injury or death.

• Do not use this tool for continuous use. After 30 to

40 cycles, allow the tool to cool for 15 minutes.

• Do not secure this tool in a vise. This tool is

designed for hand-held operation.

• This tool may be used in damp or wet environments; however, air-drying is recommended before

use if the tool becomes soaked. Damage may result

when the tool is operated prior to thorough drying

when electrical components are soaked.

• Use this tool for the manufacturer’s intended

purpose only.

Failure to observe these precautions may result in

injury or property damage.

Charging the Battery

Read the instructions supplied with the battery charger.

LED Work Light (white)

This LED automatically turns on when the trigger is

pulled. It remains on for 10 seconds after the trigger is

released.

LED Indicator (red)

This tool is equipped with a special circuit board incorporating several important features to inform the user

about the current status of the unit. The LED signals in

the following cases:

What happens Signal What it means

Constant light for 20seconds

at end of cycle

Tool will not start, and

constant light for 20seconds

when trigger is released

Tool will stop, and constant

light for 20seconds after

trigger is released

Tool will stop, and flashing

light for 20seconds when

trigger is released

Flashing light for 20 seconds

at end of cycle

* Running the battery below 16 V can damage the battery.

Battery charge is below

17V at beginning of cycle*

Battery charge is below

16V at beginning of cycle*

Battery voltage drops

below 13V during cycle*

Motor current exceeds

20A during cycle

Circuit has become too hot

Send tool in for service

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

6

Page 7

Operation—Crimping

E6CCXLX Battery-powered Tool

Setup

1. Open the tool head.

2. Remove any accessories from the tool head.

3. Select the appropriate set of dies. Use the

table provided below to select the corresponding

adapter set.

4. Install the adapters and dies—one set in each

groove. If either the adapters or dies have W-type

tabs, lock them in place with the W-type detents.

Important: W-type dies must be locked into place

or the die detents will be damaged.

5. Visually check the dies to ensure that they are

aligned correctly so that they will complete the

crimping operation.

6. Close the tool head.

Accessory Table

Dies Adapter Set

Greenlee K22, KA22, KC22-type UA22

Greenlee W-type UAW

Kearney “OD” UAK

Thomas & Betts “6TON” UAK

D3 Prole UAW

Blackburn® “O” UAK

Huskie “HT” UAK

FCI Burndy “W” UAW

Huskie “HT-58” UAW

ILSCO “ND-60” UAW

Izumi “N58” UAW

Panduit “CD-2001” UAW

Preparing the Cable

Follow the lug manufacturer’s instructions for appropriate cable strip length.

Crimping Direction

(evenly spaced)

First Compression

Crimping Direction

SIDE B

(evenly spaced)

First Compression

SIDE A

First Compression

Crimping Direction

SIDE A

(evenly spaced)

SIDE B

W-type

K22-type

Kearney

Important: W-type dies

must be locked into

place or the die detents

will be damaged.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

W-type Detents: Press

and slide the adapter

and/or die into place.

Release to lock.

7

Page 8

Operation—Crimping (cont’d)

E6CCXLX Battery-powered Tool

Crimping Procedure

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from ying

debris or hydraulic oil.

An incomplete crimp can cause a re.

• Use proper die, connector, and cable combinations.

Improper combinations can result in an incomplete

crimp.

• The relief valve sounds and the ram automatically

retracts to indicate a completed crimp. If you do not

hear the sound of the relieve valve or the ram does

not automatically retract, the crimp is not complete.

Failure to observe these warnings could result in

severe injury or death.

completely.

6. To stop the ram from returning fully, activate the

trigger for a brief moment. This activation will close

the retraction valve and stop the retraction motion.

7. Lift the latch to open the crimping head and remove

the connector.

Note: If it is necessary to retract the ram before a

crimp cycle is complete, push the retract button.

Pushing the retract button will result in complete

retraction of the ram.

After completing the last crimp on an aluminum

connector, wipe off the excess oxide inhibitor.

Retraction Stop

1. To stop the ram from returning fully, activate the

trigger for a brief moment. This activation will close

the retraction valve, stop the retraction motion, and

set the semi-automatic retraction stop position.

2. Depress the trigger to advance the ram. Hold the

trigger down until the ram automatically retracts.

The ram will partially retract to the set position and

allow the tool to be repositioned.

3. If full retraction is desired, release the trigger at the

end of the crimp.

1. Press the latch and open the tool head.

2. Insert the properly assembled connector into the

tool head.

3. Close the tool head.

4. Depress the trigger to advance the ram. Hold the

trigger down until the ram automatically begins to

retract.

Note: If the crimping tool does not automatically

retract, the crimp is incomplete.

It is normal for the battery load display to light at

both the beginning and near the end of the crimping

cycle.

5. Release the trigger until the ram retracts

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

8

Page 9

Operation—Cutting

place or the die detents will be damaged.

Electric shock hazard:

This tool is not insulated. When using

this unit on or near energized electrical lines, use proper personal protective equipment.

Failure to observe this warning could

result in severe injury or death.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from ying

debris or hydraulic oil.

E6CCXLX Battery-powered Tool

Accessory Table

Task Blade

Copper and aluminum

26 mm (1.00") max.

Copper and aluminum

40 mm (1.56") max.

ACSR

Copperweld

ACAR

Guy strand

EHS guy strand

Ground rod

Anchor rod

Soft bolts

Rebar

Threaded rod Threaded rod

UC26

UC40

UCACSR

Setup

1. Open the tool head.

2. Remove any accessories from the tool head.

3. Select the appropriate set of blades, using the

table provided on this page.

4. Install one blade in each groove. If the blades have

W-type tabs, lock them in place with the W-type

detents.

Important: W-type dies must be locked into place

or the die detents will be damaged.

5. Visually check the blades to ensure that they are

aligned correctly so that they will complete the

butting operation.

6. Close the tool head.

W-type Detents:

Press and slide the

adapter and/or die

into place.

Release to lock.

Important: W-type dies must be locked into

Cutting Procedure

1. Press the latch and open the tool head.

2. Position the item to be cut in the tool head.

3. Close the tool head.

4. Pull the trigger to cut the item.

5. Release the trigger when the cut is complete.

6. The ram returns automatically.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

9

Page 10

Operation—Punching

E6CCXLX Battery-powered Tool

Electric shock hazard:

Do not use this tool as a punch driver

on or near live circuits. This includes,

but is not limited to, the following

circumstances:

• Energized electrical lines

• Energized circuit breaker panels

and fuse boxes

• Junction boxes with energized

circuits

Failure to observe this warning could

result in severe injury or death.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from ying

debris or hydraulic oil.

Do not attempt to punch a hole

through two or more thicknesses of

material. This will bend or break the

draw stud, and could throw parts with

great force.

Failure to observe this warning could

result in severe injury or death.

A component failure could throw

broken parts.

• Do not allow anyone to stand in

front of the punch.

• Close access doors or covers on

any equipment that is in line with

the punch.

Failure to observe this warning could

result in severe injury or death.

Set up the tool properly. An improper setup could

cause a component to fail and strike nearby

personnel with great force.

• Thread the punch completely onto the draw stud.

All of the punch threads must be engaged by the

draw stud threads. Incomplete assembly could

cause a component failure.

• Use only Greenlee punches, dies, and draw studs.

Other manufacturers’ components might not withstand the forces generated by this punch driver.

Failure to observe these warnings could result in

severe injury or death.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

10

Page 11

Operation—Punching (cont’d)

E6CCXLX Battery-powered Tool

Setup and Punching Procedure

1. Open the tool head.

2. Remove any accessories from the tool head.

3. Install the punch driver so that the drive piston is

toward the yoke, as shown.

4. Close the tool head.

5. Select the punch, die, and draw stud to make the

appropriate size hole. Refer to the illustrations on

the following pages.

6. Determine and mark the exact location for the hole.

Use a Greenlee Kwik Stepper® drill bit to drill a hole

that is slightly larger than the draw stud. This is the

pilot hole.

7. Push the retract button and hold the button until the

ram is completely retracted.

8. Thread the 3/4" draw stud or 3/4" adapter completely into the punch driver. Refer to the illustrations on the following pages.

Note: For a punch and die with a 3/8" center hole,

thread the 3/8" draw stud into the end of the 3/4"

adapter.

9. Install a spacer, if necessary. Refer to the illustrations on the following pages.

10. Slide the die over the draw stud with the open end

of the die facing away from the punch driver.

11. Insert the draw stud through the pilot hole.

12. Thread the punch onto the draw stud with the

cutting surfaces of the punch facing the material.

Tighten the punch by hand until the spacer, die,

material, and punch contact each other.

Note: All of the punch threads must be engaged by

the draw stud threads. If any of the punch threads

are not engaged, disassemble the setup, remove the

spacer, and reassemble the setup.

13. Pull the trigger.

Note: A “popping” sound indicates that the tool has

reached relief pressure. This may indicate that the

attempted operation is beyond the capacity of the

tool.

14. Release the trigger when the punch completes the

hole. The ram returns automatically.

15. Unscrew the punch. Remove slugs from the die.

Remove the spacer and unscrew the draw stud.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

11

Page 12

E6CCXLX Battery-powered Tool

Operation—Punching (cont’d)

Round Punches

Metric: 22.5 mm (max.)

Conduit Size: 1/2" (max.)

Actual Size: 0.885" (max.)

Punch

Round Punches

Metric: 28.3 mm to 61.5 mm

Conduit Size: 3/4" to 2"

Actual Size: 1.115" to 2.416"

1/2" (12.7 mm)

Pilot Hole

Die

7/8" (22.2 mm)

Pilot Hole

UA12P

Punch Driver

33967

3/4" Adapter

03248

Spacer

30043

3/8" Draw Stud

UA12P

Punch Driver

3/4"

Draw Stud

Die

UA12P

Punch Driver

Punch

1/2" (12.7 mm)

Pilot Hole

Punch—1-1/4"

31874

7/16" to 3/4"

Adapter

(optional)

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

(ø 1.701" [43.2 mm])

Conduit

Maximum Size

12

29451

7/16" Draw Stud

(optional)

Die

Page 13

E6CCXLX Battery-powered Tool

Operation—Punching (cont’d)

Square and Rectangular Punches

Metric: 12.7 mm square

Inches: 1/2" square

Metric: 11.1 mm x 22.2 mm rectangular

Inches: 7/16" x 7/8" rectangular

Punch

05244

1/4" Counter Nut

1/4" Draw Stud

Pilot Hole

3/8" Draw Stud

UA12P

Punch Driver

60114

1/4" Adapter

60115

03248

Spacer

End with Long Threads

Die

UA12P

Punch Driver

33967

3/8" Adapter

60116

Square and Rectangular Punches

Metric: 15.9 mm to 24.0 mm square

Inches: 5/8" to 0.945" square

Metric: 17.0 mm x 19.0 mm rectangular

Inches: 0.670" x 0.749" rectangular

Square and Rectangular Punches

Metric: 25.4 mm square

Inches: 1" square

Metric: 19.1 mm x 29.0 mm to

31.8 mm x 35.1 mm rectangular

Inches: 0.750" x 1.140" to

1.250" x 1.380" rectangular

Punch

04638

3/8" Counter Nut

Punch

Pilot Hole

3/8" Draw Stud

03248

Spacer

End with Long Threads

Threads with Flats

Die

UA12P

Punch Driver

60167

1/2" Adapter

60117

03248

Spacer

End with Long Threads

Threads with Flats

Die

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

Pilot Hole

60258

1/2" Counter Nut

13

Page 14

E6CCXLX Battery-powered Tool

Operation—Punching (cont’d)

Square and Rectangular Punches

Metric: 46.0 mm to 68.0 square

Inches: 1.811" to 2.677" square

Metric: 33.3 mm x 66.7 mm to

35.0 mm x 65.0 mm rectangular

Inches: 1.312" x 2.625" to

1.378" x 2.559" rectangular

Punch

3/4" Counter Nut

60235

Pilot Hole

UA12P

Punch Driver

60118

3/4" Draw Stud

End with Long Threads

Die

UA12P

Punch Driver

Adapter

“D”, Double “D”, and

Key Punches

Electronic Connector

Panel Punches

Punch

Counter Nut

Punch

Pilot Hole

Draw Stud

03248

Spacer

End with Long Threads

Die

UA12P

Punch Driver

33967

3/8" Adapter

34421

3/8" Draw Stud

03248

Spacer

End with Long Threads

Threads with Flats

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

04638

3/8" Counter Nut

Die

7/16" (11.1mm)

Pilot Hole

14

Page 15

Available Adapters

E6CCXLX Battery-powered Tool

Adapter

UA22 50070622 Adapter for Greenlee 22-Series dies

UAK 50070339 Adapter for Kearney and T&B dies

UAW 50070355 Adapter for W-type dies, D3

UC26 50067141 Cutter blades for copper and aluminum 26 mm (1") max.

UC40 50070363 Cutter blades for copper and aluminum 40 mm (1-1/2") max.

UCACSR 50070371

UCUNC14 50070380 Cutter blades for 1/4" threaded rod

UCUNC38 50070398 Cutter blades for 3/8" threaded rod

UCUNC12 50072749 Cutter blades for 1/2" threaded rod

UA12P 50118900 Punch driver adapter

Greenlee

Part No.

Description

Cutter blades for ACSR, ACAR, standard guy wire, EHS guy wire, copperweld,

ground rod, anchor rod, soft bolts, rebar

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

15

Page 16

E6CCXLX Battery-powered Tool

95R7

Die Selection

Crimps made on copper cable with Greenlee KC22-type dies and the copper connectors listed here are

cUL and UL classied.

Crimps made on copper or aluminum cable with Greenlee KA22-type dies and the dual-rated aluminum connectors

listed here are cUL and UL classied.

Refer to “Connector Selection” for brand names and model numbers of appropriate lugs as well as crimping

instructions.

W-type or X-type dies can be used to crimp 8 AWG to 500 kcmil copper and 8 AWG to 4/0 AWG aluminum.

Dies for Copper Connectors

Catalog No. UPC No. Cable Size Color Code

KC22-8 03079 8 AWG Red

KC22-6 03080 6 AWG Blue

KC22-4 03081 4 AWG Gray

KC22-2 03082 2 AWG Brown

KC22-1 03083 1 AWG Green

KC22-1/0 03084 1/0 AWG Pink

KC22-2/0 03085 2/0 AWG Black

KC22-3/0 03086 3/0 AWG Orange

KC22-4/0 03087 4/0 AWG Purple

KC22-250 03088 250 kcmil Yellow

KC22-300 03089 300 kcmil White

KC22-350 03090 350 kcmil Red

KC22-400 03091 400 kcmil Blue

KC22-500 03092 500 kcmil Brown

KC22-600 03093 600 kcmil Green

Dies for Dual-rated Aluminum Connectors

Catalog No. UPC No. Cable Size

KA22-8 06744 8 AWG

KA22-6 06745 6 AWG

KA22-4 06746 4 AWG

KA22-2 06747 2 AWG

KA22-1 06749 1 AWG

KA22-1/0 06750 1/0 AWG

KA22-2/0 06751 2/0 AWG

KA22-3/0 06752 3/0 AWG

KA22-4/0 06753 4/0 AWG

KA22-250 06754 250 kcmil

KA22-300 06755 300 kcmil

KA22-350 06756 350 kcmil

Connector Selection

Tool Range: Copper — 8 AWG to 600 kcmil; Dual-rated Aluminum — 8 AWG to 350 kcmil

When used with KC22-type dies, this tool is cUL and UL classied for use with the following connector brands:

Connector

Type

Copper Splice

Copper Lugs

Barrel

Anderson Blackburn

Type

Short VHSS CSP YS-L CT SCSS/SCS 54504–54520 BCU A

Long VHS CU YS CTL SCL/SCH 54804–54820 BBCU B

Short VHCS CTL-2/CTL

Long VHCL CTL-L/LCN YA-2N

®

Burndy ILSCO Panduit T&B

YA-2LN/YA-L/YA-2L

YA/YA-L-TC/YA-L-2TC

CSW

CRA/CRB

CLN/CLW

CRA-L/CRB-L

CRA-2L/CRB-2L

LCAS/LCA

LCD

LCB/LCC

54104–54120

54204–54218

54930BE–54920BE

54850BE–54878BE

PennUnion

BLU A

BBLU B

No. of

Crimps*

When used with KA22-type dies, this tool is cUL and UL classied for use with the following connector brands:

Connector

Type

Dual-rated

Aluminum

Splice

Dual-rated

Aluminum

Lugs

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

Barrel

* Use the number of crimps listed in the last column instead of the number provided with the connector:

A — 8 to 1/0 AWG: 1 crimp

2/0 AWG to 600 kcmil: 2 crimps

** 6 AWG to 350 kcmil

Anderson Blackburn

Type

— VACS ASP YS-A

— VACL ATL

®

Burndy ILSCO Panduit T&B

AS

ASN

YA-A

YA-ATN

B — 8 to 1/0 AWG: 2 crimps

2/0 to 3/0 AWG: 3 crimps

4/0 AWG to 600 kcmil: 4 crimps

ACL/ACN

2ACL/2ACN

ALNS/ALNN/ALND

SA

**

LAA/LAB **60101–60166

60501–60565 PIK C

60230–60267

C — 8 to 2 AWG: 2 crimps

1 to 3/0 AWG: 3 crimps

4/0 AWG to 350 kcmil: 4 crimps

PennUnion

BLUA C

No. of

Crimps*

16

Page 17

LCD Screen

E6CCXLX Battery-powered Tool

This tool has an LCD screen, which displays information about the tool. Turn on the screen by inserting the

battery and jogging the tool. If there are any problems

with the tool, an error code appears.

Error Code Meaning

1 Overcurrent fuse

2 Overcurrent comparator

3 Overheated circuit board

4 Overheated battery

5 Battery empty; operation stops

6 Faulty crimp; complete cycle

7 Faulty crimp; incomplete cycle

8 Low battery

9 Battery empty; tool won’t run

10 Real-time clock battery low

11 Tool deactivated

12 Service necessary

13 Real-time clock not found

14 Bluetooth® unit not found

15

16 Pressure sensor not found

17 Burst pressure exceeded

18 Battery temperature too low

If there is no error code, cycle through the various

displays using the left and right buttons on either side of

the screen. There are seven displays in total.

Display Information Shown

Bluetooth® status, battery charge, current

1

pressure, max. pressure

Firmware, available rmware update,

2

serialnumber

Current user. Press and hold both buttons to

3

change user, select with right button, and conrm

by jogging the tool.

4

5

6 Cycles until next service

Since manufacturing: operating hours, capacity,

7

number of cycles

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

17

Page 18

Maintenance

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from ying

debris or hydraulic oil.

Skin injection hazard:

Do not use hands to check for oil

leaks. Oil under pressure easily punctures skin. If injured, seek medical

attention immediately to remove oil.

Failure to observe this warning could

result in serious injury, gangrene, or

death.

E6CCXLX Battery-powered Tool

Daily

Before use:

1. Inspect the tool for wear or damage, such as cracks,

gouges, or chips.

2. Inspect the tool for damage or leaks.

3. Inspect the rotation of the head assembly. Fully

retract the ram. The head should rotate no more

than 360°. If damage is detected, contact Greenlee

customer service at 800-435-0786 for warranty

service or repair.

After use:

1. Use a damp cloth and mild detergent to clean the

housing. Allow the housing to dry.

2. Fully retract the ram. Place the tool in the carrying

case and store in a cool, dry place.

3. If necessary, recharge the batteries. Refer to the

instructions supplied with the battery charger.

Monthly

Thoroughly clean all surfaces.

Do not use solvents or ammable

liquids to clean the tool body.

Solvents or ammable liquids could

ignite and cause serious injury or

property damage.

Pinch points:

• Remove battery before changing

dies, adapters, or jaws.

• Keep hands away from the crimping tool head when crimping.

Failure to observe these warnings

could result in severe injury or death.

Relief valve adjustments must be done by an

authorized service center.

Annually or After 10,000 Crimps

Contact Greenlee customer service at 800-435-0786 for

warranty service or repair, and hydraulic oil replacement.

Periodic Pressure Relief Valve Check

The crimping tool’s relief valve may require occasional

adjustment. To determine whether this adjustment is

necessary, contact Greenlee customer service at

800-435-0786 for warranty service or repair.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

18

Page 19

Troubleshooting

E6CCXLX Battery-powered Tool

Before You Begin

1. Make sure that the battery is charged. Recheck

the battery after several minutes to make sure the

battery is holding its charge.

Problem Possible Cause Probable Remedy

Tool is inoperative. Battery charge low. Charge or replace battery.

Dirt, contaminants, etc., in

ram area oftool.

Tool components worn or

damaged.

Motor is inoperative. Low or uncharged battery. Try known charged battery. Inoperative battery may

Broken switch components. Contact Greenlee customer service at

Motor runs but tool will not

complete a cycle.

Oil level low. Contact Greenlee customer service at

Air in hydraulic system. Pull trigger and hold retract button simultane-

2. Use a nonflammable contact cleaner or pencil

eraser to clean the electrical contacts on the battery

and tool.

3. Reinstall the battery and check the tool again.

Clean tool.

Contact Greenlee customer service at

800-435-0786 for warranty service or repair.

be discharged or may have reached life expectancy.

800-435-0786 for warranty service or repair.

800-435-0786 for warranty service or repair.

ously. Run for approximately 10 seconds, and then

attempt to crimp. If unsuccessful, contact Greenlee

customer service at 800-435-0786 for warranty

service or repair.

Cold oil. Pull trigger and hold retract button simultaneously

to warm oil. Store tool in warm area.

Tool loses oil. Damaged seal. Contact Greenlee customer service at

800-435-0786 for warranty service or repair.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

19

Page 20

4455 Boeing Drive • Rockford, IL 61109-2988 • USA • 815-397-7070

An ISO 9001 Company • Greenlee Textron Inc. is a subsidiary of Textron Inc.

www.greenlee.com

USA Tel: 800-435-0786

Fax: 800-451-2632

Canada Tel: 800-435-0786

Fax: 800-524-2853

International Tel: +1-815-397-7070

Fax: +1-815-397-9247

Loading...

Loading...