Green Hobby Daisy G, Daisy E, Daisy Q Building Instructions

GREEN HOBBY Part No. Daisy G/E/Q

Building Instructions RC- Electric Aircraft "DAISY"

Motor or Glider Version

Technical Information:

Wingspan: 1480 mm

Length: 850 mm

Wing Airfoil Design: S 7055

Total Area: 24.1 dm 2

Flight Weight: 450 g Glider

800 g Electric

Electric Version: 1 AeroNaut Race 400 6.0V Motor Part No 7000/42

2 AeroNaut Race 480 7.2V Black Power Part No 7000/48

3 Mega Motor Brushless Mega 16.15.4 or Mega 400.12.

Nimh Battery: 8 cells choice of three - Part Nos KAN1050/GP1100/GP2000

Propeller: Folding 6x3" Glass + Integral Middlepiece Part No 7235/05

Or 6x3" Carbon + Integral Middlepiece Part No 7236/05

Or…. brushless option 7 x 4.5 blades + 3.2mm integral spinner

Assembly Notes for "DAISY"

Before opening the glue, oil the threads on all bolts with "After-Run" oil (available from Green Hobby),

this prevents all kind of problems later! Wherever instructions suggest gluing to the epoxy fuselage, preroughen up the smooth epoxy with fine sandpaper to give the glue a better "key" to adhere onto.

USEFUL TOOLS:

Needle or point nose pliers; "pin vise" modellers drill, drill bits from 2mm to 4mm, needle files, small wire

cutters, scalpel set, a little oil, epoxy glue, matchsticks for introducing epoxy into difficult to reach places,

soldering iron with electronic grade solder & flux paste, connecting plugs for nimh battery connections to

speed controller. All modelling tools are available from Green Hobby, and once purchased, will last you

for many years.

SAFETY: All electric aircraft have self start capability, this is absent in glow engined models. Because

of this both new modellers and modellers new to electric flight should always bear in mind the possibility

of the prop beginning to spin unexpectedly, if there is a nimh battery connected up. We call plugging in

the nimh "arming the plane", if your plane is armed, the transmitter should be "ON" to shout down

background interference that might switch the motor on. Ensure throttle stick is at down-throttle off.

The plane should be on a stand, so the prop is free to spin, and the motor will not burn out due to a

stalled prop. The modeller should also never stand to the side of a spinning prop - in front OK (if the

plane is stationery!), behind OK (recommended), but never to the side, a prop blade (or stone) could fly

out at high speed without warning, injuring anybody present there.

Remember: this is a REAL aircraft, it will be dangerous if not used carefully. Keep away from

bystanders. Even when being used properly, mishaps will occasionally happen, so due caution should

be exercised. Give respect to the propeller which is extremely sharp, the batteries which if shorted can

cause fire, the aircraft which needs maintenance before flights, your piloting skills which will improve but

never achieve perfection, and radio interference. In short - allow for problems and fly safely.

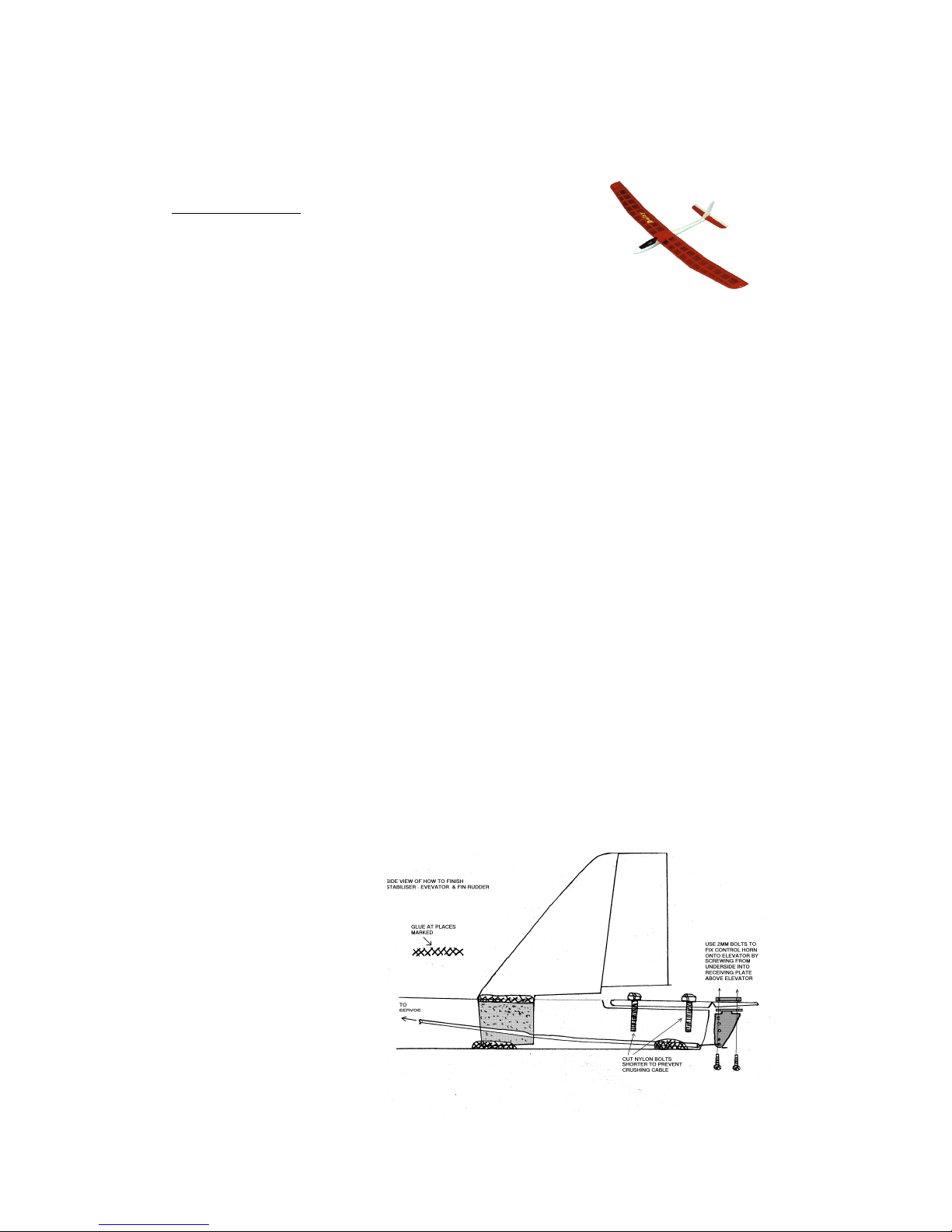

TAIL: Locate the two pairs of

holes in the top of the epoxy

fuselage, near the tail. The

rearward pair are tapped with a

thread to accept bolts holding the

stabiliser-elevator on later. The

forward pair of holes, not tapped

give you correct location of the

vertical stabiliser fin-rudder.

Using a Stanley knife or scalpel,

make two cuts joining the forward

pair of holes, and remove the thin

strip of epoxy, making a slot. Now

you can trial fit your fin, sanding

the slot with a fine file, or scraping

with the scalpel for best fit.

Now fit the flat stabiliser -elevator onto the rearward tapped holes with two nylon bolts. You can now

see the clear space required under the vertical fin for flat stabiliser's free movement in flight. Trial fit fin

again until completely satisfied.

To fit the fin, apply epoxy to three

places - the fin sides above the

epoxy fuselage, the fin sides under

the epoxy fuselage, and the fin base

with epoxy gluing it to the fuselage

floor at the front edge of the fin.

A matchstick is handy for application

of glue to the difficult to reach places.

The best position is with the forward

edge of the fin base lower, touching

the fuselage floor. Lift the underside

of the fin's trailing edge up slightly by

resting the hinged rudder part on a

piece of matchstick until the glue

sets. This allows better access to

remove the elevator bolts after

completion, for easier transport of

your aircraft.

When happy, wipe off excess glue and leave to harden, with the fin in a perfectly vertical orientation.

Try to keep the amount of epoxy used to a minimum, it's heavy! Try also to avoid getting epoxy on the

flat stabiliser nylon bolts inside the fuselage, you pre-oiled them but even so don't take chances of

gluing them in permanently!

WINGS: Trial fit the wing pegs in wing holes. The front edges are best sanded slightly rounded for

easier fit into fuselage holes. If too tight the wing can not be put correctly onto the fuselage. So take a

little time here. Ease the fit (if necessary) by using a 4mm drill bit gently in a "pin vice drill" or between

your fingertips. Only when you can locate the pegs in the holes in the fuselage AND press the wing

trailing edge down so the nylon wing bolts can be screwed home without danger of breakage, THEN you

are ready to glue.

Oil the peg holes in the epoxy fuselage. The pegs have a tendency to slide too far into the wings while

dry fitting the wings, so try to have them go into the oiled fuselage holes without being pushed back into

the wing holes. Epoxy the pegs into the wings, wipe off excess epoxy, fit wings until glue sets.

After pegs harden into wing, remove the wings for convenience during the rest of the assembly.

MOTOR: This is pre-fitted in some versions of the kit. If not ask the Green Hobby team for an AeroNaut

6.0V Race 400 direct drive motor. The motor is fitted using two steel 2.5x8mm machine bolts. A

downward tilt, or downthrust is noticeable, this is intentional, and indeed is necessary for the excellent

flying characteristics of the aircraft on full power. If the prop is not pre-fitted, test the motor for free

rotation before fitting. Draw centreline on wood. Drill two 2.5mm holes 3mm out from the centre hole in

mounting plate.

It can happen that the motor mounting bolts reach sufficiently far into the motor that they foul the rotor

and prevent it spinning (stalled prop). If this happens, applying power will burn out your motor, so always

test the motor spins free before applying power. The cure is simple, add a couple of 3mm washers

under the bolt heads before the bolt goes through the hardwood motor mounting plate, this shortens the

length of bolt inside the motor, preventing any problem.

PROPELLER: Installation of the types of propeller supplied by Green Hobby is simple. It is pre-installed

on most non-aileron versions of the DAISY. Assemble the prop and fit onto the motor shaft with the

Allen keys supplied. Do not overtighten or you might "pull" the threads in the plastic prop assembly. Try

to have a 1 to 1.5mm gap between the propeller rear and the fuselage front, this aids cooling, prevents

the bolt heads fouling the prop, (same problem as for the motor bolts!), and also gives a tiny shock

absorber in bumpy landings as the prop can "give" a little as it slides back under the impact. Remember

to release the prop from possible locking up after any nose down landings however! The free-spinning

prop test for the motor finds any problems here, before power is applied.

ELECTRONIC SPEED CONTROLLER: This is pre-fitted on most non-aileron versions of DAISY. The

polarity of speed controller-to-motor connection is not vital to the life of the speed controller. This

determines the direction of prop rotation. The polarity of speed controller-to-nimh battery connection IS

VITAL if you get this wrong even for a split second you will short out the speed controller and destroy it.

No warranty will cover this damage. Read the manufacturers instructions carefully.

Solder on appropriate connecting plugs that prevent plugging in the wrong way round. Red-to-red positive (+), black-to-black-negative (-). Cover bare solder-wire ends with heatshrink of the correct

Loading...

Loading...