This supplement to the TCB Installation Operation and Maintenance Manual is intended to provide additional

information when dealing with fans used in applications involving grease laden air. Refer to the TCB Installation,

Operation and Maintenance Manual (PN 456557) for items that are not specifically addressed (handling, storage,

start-up, troubleshooting and maintenance) in this supplement.

READ AND SAVE THESE INSTRUCTIONS

PN 464115

Installation Operation and Maintenance Manual

Supplement for UL-762 Listed (Restaurant Exhaust) Fans

Supplement for Model TCB with UL-762

Installation Practices

• All units used in applications with grease laden air are to be installed in

accordance to NFPA 96, IMC 2203 and local codes. Consult local code

authorities for your specific requirements.

• Fans shall be located in an easily accessible area of adequate size to allow

for service or removal. Exhaust fans with ductwork connected to both ends

shall have access for cleaning and inspection within 3 ft (0.92 m) of each end

of the fan (NFPA 96).

• Maintain a minimum clearance of at least 18 inches (457 mm) to combustible

material and 6 inches (125.4 mm) to either limited-combustible or

noncombustible material (NFPA 96).

• Fans are to be installed with the motors in the 3 or 9 o’clock (C or G) positions. Motors located in this

configuration may cause an unbalanced load that should be considered if isolators are to be used. Equalized

loading between isolators can be achieved through the use of mounting rails. Refer to the TCB IOM for details

and installation instructions involving mounting rails.

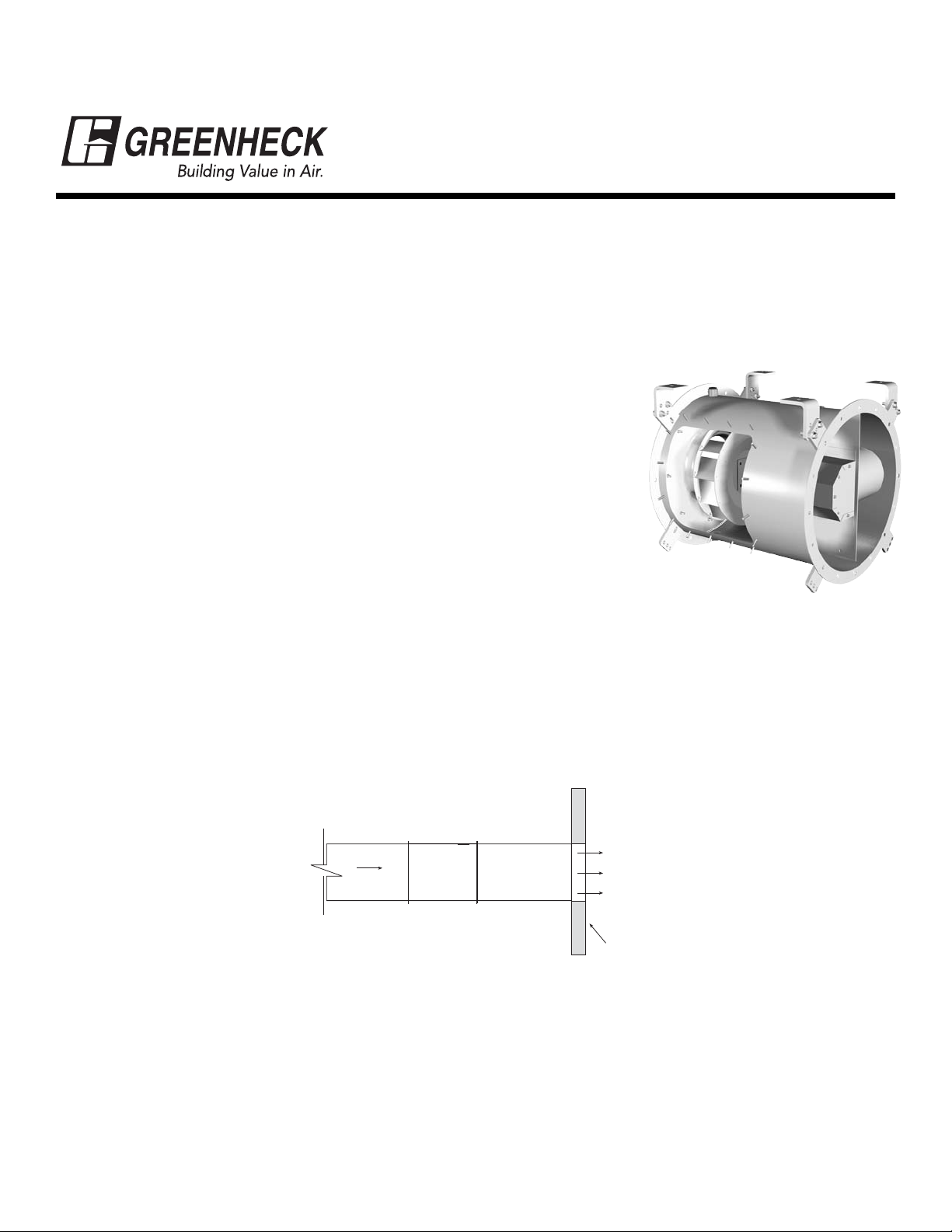

• It is recommended to install the fan near the end of the duct run. This limits the amount of positive pressure in

the system. The diagram below illustrates an inline fan exhausting air near the final termination point. See local

codes and NFPA 96 for any restrictions and requirements for wall terminations.

• A drain is provided for single-point drainage of water and residue. When installed correctly, one of the two

housing drains will be located on the bottom. This drain is used to remove any accumulated grease and / or

cleaning solutions. Some means for collection of this residue must be provided, either a container directly under

the drain or use an adapter and pipe to carry the residue to a remote collection point. Remove drain plug prior

to connection to grease collection device.

• Provision to open and remove the access door is required for periodic cleaning and maintenance. The access

door is clearly labeled and indicates that access to this location must be maintained. Any enclosure openings

required to reach the access panel shall be large enough to allow for the removal of the panel.

E

xhaus

t air

exiting the

b

uildin

g

M

inimu

m duct

at discharge

F

a

n

E

xterio

r Wa

ll

A

irflo

w

®

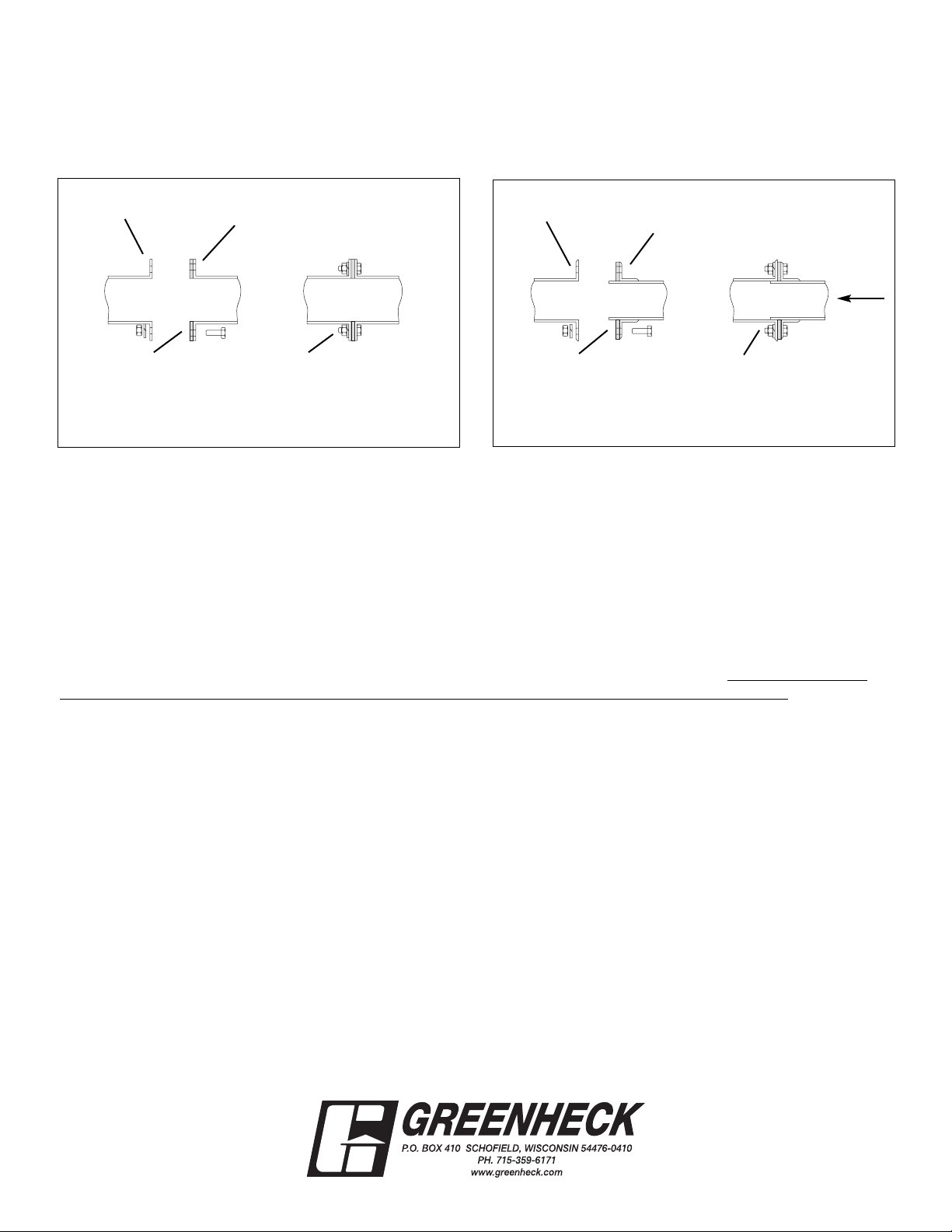

Fan flange

Fan flange

Minimum 1 inch

(25.4 mm) flange

1/4 inch (6.25 mm) carbon

or stainless steel bolts

1/4 inch (6.25 mm)

carbon or stainless steel

bolts

Welded companion flange or

1x1x1/4 inch (25.4x25.4x6.25

mm) angle

Gasket rated for

1500

o

F (815oC)

Sealant rated for

1500oF (815oC)

Over-lapping Connection

Sealant Connection

Cleaning, Maintenance and Repair

Cleaning of Internal Components

• Entire wheel should be cleaned during routine duct cleaning. Partial cleaning may result in an unbalanced wheel

that can cause premature bearing failure or excessive vibration.

• Grease / cleaning solution should drain freely through the provided drain connection. Remove any obstructions

inhibiting proper drainage.

• Only the access door is removed during routine duct cleaning. The bearing cover is not removed during routine

cleaning. The bearing cover is removed only when inspecting or changing the bearings, fan shaft or driven pulley.

Bearing Lubrication

See bearing manufacturer’s instructions or label on the fan housing for lubrication schedule. Lubricate bearings

with high temperature grease conforming to NLGI grade 2 such as Mobil Mobilith SHC 100 or 200.

Sealant / Gasket / Seal Replacement

Fan to Duct Sealant / Gasket Replacement

Repair or replace sealant / gasket as needed. Replacement sealant or gasket shall be rated for 1500oF (815oC) and

shall be grease tight such as 3M Fire Barrier 2000+ Silicone Sealant. See Sealant and Over-lapping Connection

figures for proper installation.

Access Door / Bearing Cover Gasket Replacement

Replace access door or bearing cover gasket material as needed. Gasket material for the access door is 1/2 x 1/2

inch (12.7 x 12.7 mm) Greenheck part number 220145. Gasket for the bearing cover is 1/8 x 1/2 inch (3.17 x 12.7

mm) Greenheck part number 220144. Both items are ordered by the foot.

Mechanical Seal

A mechanical seal, located inside the bearing cover, is used to keep grease from penetrating into this area. Contact

Greenheck with the fan’s serial number for appropriate sizing and part number for a replacement mechanical seal.

Refer to the TCB IOM (PN 456557) for other maintenance procedures.

TCB with UL-762 Supplement IOM

Rev. 1 March 2004

Copyright © 2004 Greenheck Fan Corp.

• Inline fans shall be connected to the exhaust duct by flanges securely bolted as shown in the figures below

(NFPA 96). Flexible connectors shall not be used. Units supplied with matching companion flanges are to have

this part welded to the ductwork and then bolted to the fan. Gaskets used in the Over-lapping Connection style

shall not be positioned in a manner to have direct contact with the grease.

Installation Practices (Continued)

Airflow

Loading...

Loading...