Page 1

Part #455308

®

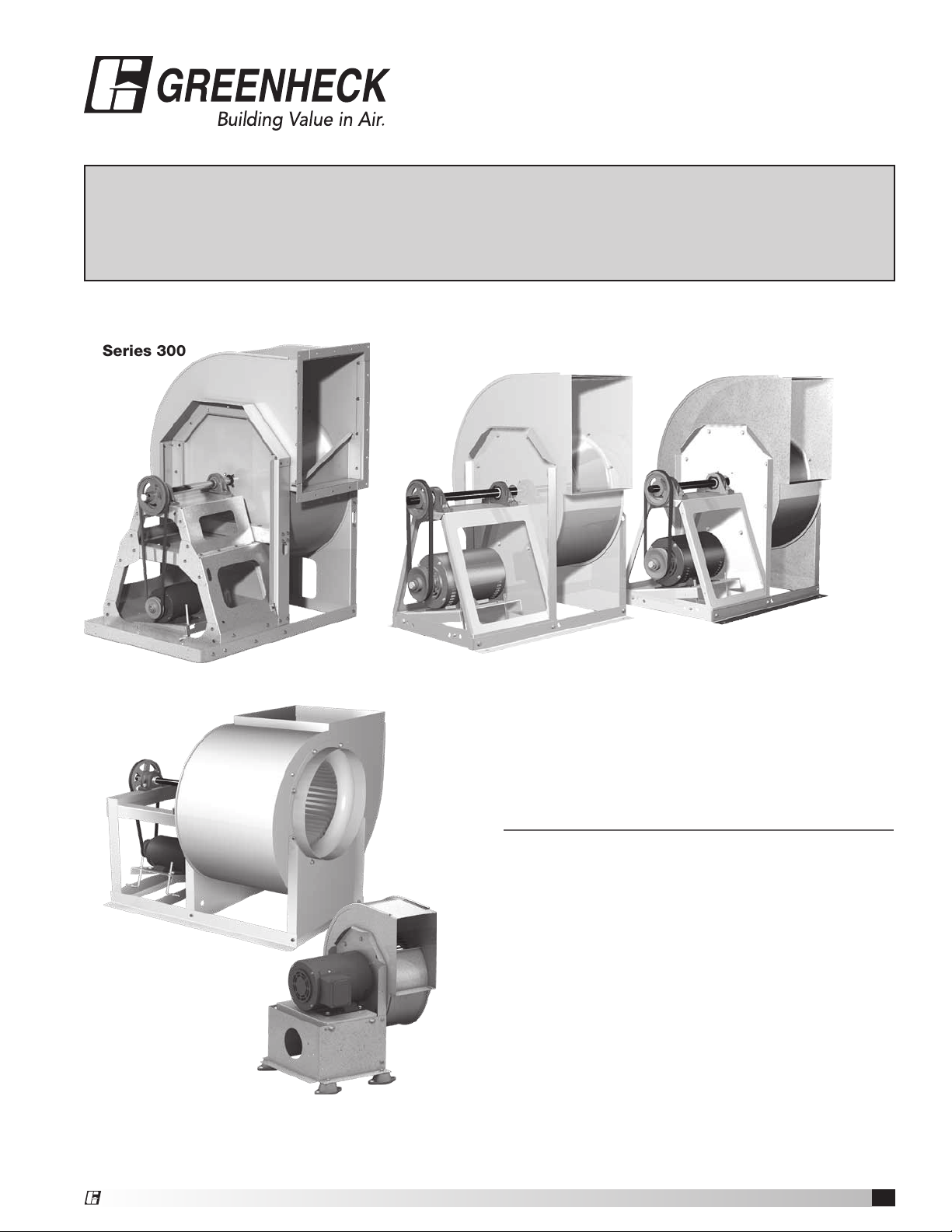

Centrifugal Utility Fans

Model SWB - Series 100, 200 and 300

Models SFB and SFD

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

Model SWB

Series 300

Model SWB

Series 200

Model SWB

Series 100

Model SFB

Table of Contents

Motor and Drive Installation

(Units Shipped from Stock) ................ 2

Installation ............................... 3

Affect of Installation on Performance ......... 3

UL/cUL 762 - Restaurant Exhaust ............ 4

Pre-Starting Checks ......................4-5

Belt Drive Fan Maintenance ................. 6

Bearing Lubrication Schedule ............... 6

Motor Maintenance (Belt and Direct Drive) ..... 6

Parts List ................................ 7

Troubleshooting Chart ..................... 8

Model SFD

®

Centrifugal Utility Fans

1

Page 2

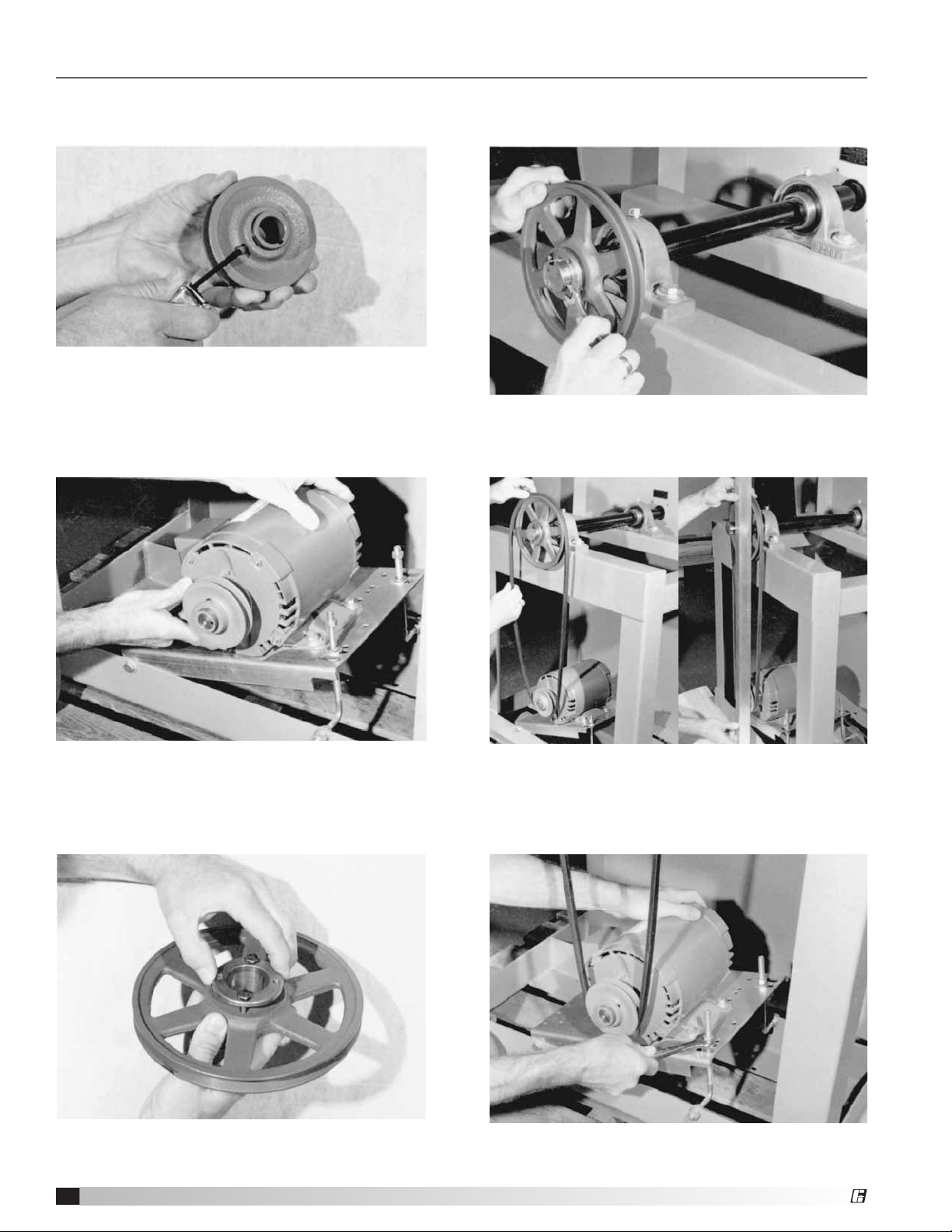

Motor and Drive Installation Instructions

Model SWB units are shipped from stock without motors or drives.

1. Adjust motor pulley to its closed position for

maximum fan speed or increments of 1/2 turn

open (maximum of 5 turns open) for reduced fan

speed. Tighten set screw on flat area only.

4. Install shaft pulley to fan shaft.

2. Install motor pulley to the motor shaft and install

motor to the motor plate. Pre-punched holes are

provided for most common motor frame sizes.

3. If supplied, install taperlock bushing into

shaft pulley.

Centrifugal Utility Fans

2

5. Install drive belt(s). Belts should not be forced

over pulleys. Align motor and shaft pulleys with a

straight edge. Tighten all set screws.

6. Adjust belt tension.

See page 6 for belt tensioning instructions.

®

Page 3

Installation

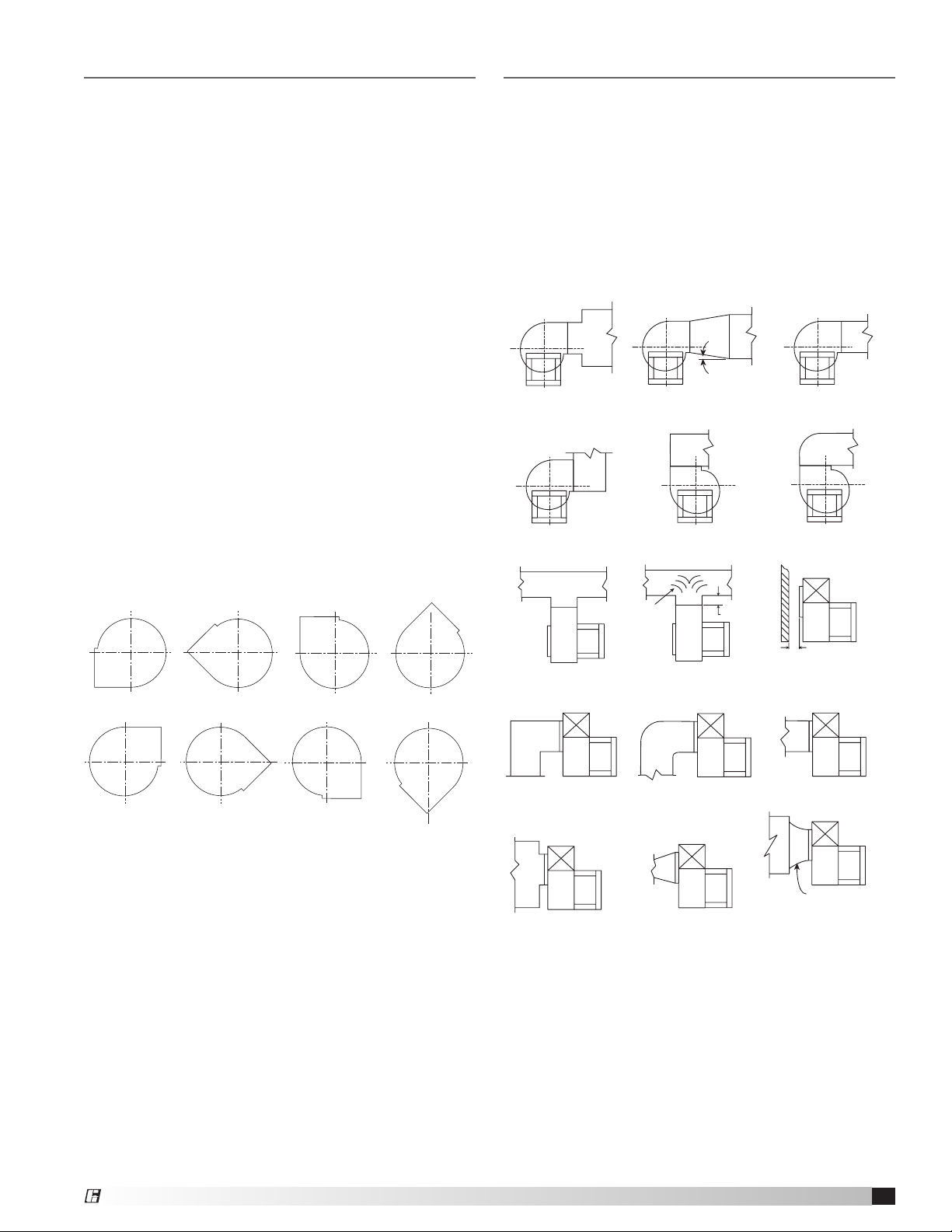

Affect of Installation on Performance

Inspect the unit for any damage and report it to

the shipper immediately. Also, check to see that all

accessory items are accounted for.

Move the fan to the desired location and fasten

securely through mounting holes provided in the base

angles. The unit must be set level (shimming may be

necessary). Flexible duct connections and vibration

isolators should be used where noise is a factor.

The motor voltage and ampere rating must be

checked for compatibility with the electrical supply

prior to final electrical connection. Supply wiring to the

fan must be properly fused, and conform to local and

national electrical codes.

The discharge is factory set as specified by customer

order, however, it can be rotated to other discharge

positions in the field if necessary. Removal of the

housing bolts allows the discharge to be rotated to

the clockwise positions below. For TAD, BD and BAD

discharge positions, a portion of the frame angle must

be removed.

Clockwise rotation shown. Counterclockwise

discharge positions are a mirror image of those

shown. Fan rotation is always specified from the

drive side of the housing.

Restricted or unstable flow at the fan inlet can cause

pre-rotation of incoming air or uneven loading of the

fan wheel, yielding large system losses, increased

sound levels and structural failure of the fan wheel.

Free discharge or turbulent flow in the discharge

ductwork will also result in system effect losses.

The examples below show the system layout and

inlet and discharge configurations which can affect

fan performance.

Discharge Configurations

7o MAX.

POOR

POOR

FAIR

POOR

GOOD

FAIR

Discharge Positions

CW BH CW BAU CW TAUCW UB

CW TH CW TAD

CW DB

CW BAD

POOR

POOR

POOR

Turning

Varies

FAIR

FAIR

POOR

One

Impeller

Dia.

Should be at least

1/2 Impeller Dia.

GOOD

GOOD

Not Greater than

o

Including Angle

60

FAIR

®

Centrifugal Utility Fans

3

3

Page 4

Gap

Wheel

Radial

Gap

Overlap

Wheel

Installation of UL/cUL 762 Listed

Gap

Wheel

Fans for Restaurant Exhaust

The UL/cUL 762 listing for restaurant exhaust is

available on Series 200 and 300 SWB fan model

sizes 206 - 224 and 327 - 349 with a weatherhood.

UL/cUL 762 fans are listed for a maximum operating

temperature of 375°F (191°C) and includes an access

door and 1inch (25.4 mm) drain connection. An

outlet guard is strongly recommended when the fan

discharge is accessible. An upblast discharge is

recommended. The fan discharge must be a minimum

of 40 inches (1016 mm) above the roof line and the

exhaust duct must be fully welded to a distance of

18inches (457mm) above the roof surface.

Upblast Discharge

Optional Companion

40 in.**

(1016 mm)

**Per NFPA 96 the fan discharge must

be a minimum of 40 in. (1016 mm)

above the roof surface.

Weatherhood

Flange

3 Wheel

Diameters

This drawing is for dimensional information only. See

the latest edition of NFPA 96 Standard for Ventilation

Control and Fire Protection of Commercial Cooking

Operations for detailed installation instructions,

materials, duct connections and clearances.

Series 200 & 300 SWB models

are listed for grease removal

(UL/cUL 762) File no. MH11745.

18 in.*

(457 mm)

Duct

from

*Per NFPA 96 the duct

kitchen

must be of all-welded

hood

construction to a

minimum distance of

18 inches (457 mm)

above the roof surface.

Alignment of Pulleys and Belts

Check pulleys and belts for proper alignment to avoid

unnecessary belt wear, noise, vibration and power

loss. Motor and drive shafts must be parallel and

pulleys in line as shown below.

Wrong Wrong Right

The adjustable motor pulley is set at the factory for

the fan RPM specified by the customer. Fan RPM can

be increased by closing or decreased by opening the

adjustable motor pulley. Multigroove variable pitch

pulleys must be adjusted an equal number of turns

open or closed. Any increase in fan speed represents

a substantial increase in load on the motor.

To avoid motor overheating and possible burnout,

motor load amperes should always be checked and

compared to nameplate rating when fan speed is

increased.

Wheels

Wheels must rotate freely and not rub on the inlet

venturi. Model SWB wheels overlap the inlet venturi as

shown in Figure 1. Refer to the SWB fan wheel overlap

and radial gap chart for proper dimensions.

Pre-Starting Checks

WARNING

Always disconnect power before working on or near

a fan. Lock and tag the disconnect switch or breaker

to prevent accidental power up.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive

atmospheres.

Models SFD and SFB wheels do not overlap the

venturi, but have a gap between the inlet venturi

and the wheel (Fig. 2). Wheel position is preset at

the factory and the unit is test run. Wheel movement

may occur during shipment or installation and wheel

alignment may be necessary.

Model SWB

Fig. 1

Model SFD or SFB

Fig. 2

Centrifugal Utility Fans

4

®

Page 5

On belt drive units, centering can be accomplished

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

ta

t

io

n

R

o

ta

t

io

n

Backward Inclined

Forward Curved

Airflow

Airflow

Backward Inclined Forward Curved

Airflow

These are the original drawings on the Illustrator file

when I opened it. The IOM had the wheel layered on

top of the scroll.

I will incorporate the

wheel on the scroll

without creating

an additional

layer in the

InDesign file.

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Airflow

Airfoil

R

o

ta

t

io

n

R

o

ta

t

io

n

Backward Inclined

Forward Curved

Airflow

R

o

t

a

t

i

o

n

Airflow

Airfoil

Airfoil

by (a) loosening the inlet cone bolts to move the inlet

cone or by (b) loosening the bearings in order to

move the shaft. Wheel and inlet cone overlap can be

adjusted by loosening the wheel hub set screws and

moving the wheel to the desired position. Tighten all

fasteners and set screws securely and realign drive

pulleys after adjustment.

Approximate Wheel Clearance Dimensions

Unit Size

SWB

SWB

SFD SFB

Series

100

Series

200

SWB

Series

300

6 106 206 — — —3⁄8

7.5 107 207 — — —3⁄8

9 9 108 208 — — —1⁄2

10 10 110 210

12 212

113 213

15 115 215

116 216

18 118 218

20 120 220

22 222

124 224

25 — — — —3⁄4

27 3277⁄8

30 33015⁄16

11

333 11⁄16

336 13⁄16

340 11⁄4

344 17⁄16

349 19⁄16

SWB SFD SFB

Overlap

7

3

3

1

1

5

5

3

⁄16

⁄8

⁄8

⁄2

⁄2

⁄8

⁄8

⁄16

⁄4

(10)

(10)

(11)

(13)

(13)

(16)

(16)

(18)

(19)

(22)

(24)

(27)

(30)

Tolerance

(32)

(37)

(40)

Overlap

inches (mm)

1

(6)

⁄4

1

(6)

⁄4

1

(6)

⁄4

1

(6)

⁄4

1

(6)

⁄4

3

(10)

⁄8

3

(10)

⁄8

3

(10)

⁄8

3

(10)

⁄8

1

(6)

⁄4

3

(10)

⁄8

3

(10)

⁄8

3

(10)

⁄8

3

(10)

⁄8

3

(10)

⁄8

1

(13)

⁄2

Radial

Gap

5

(4)

⁄32

5

(4)

⁄32

5

(4)

⁄32

5

(4)

⁄32

5

(4)

⁄32

5

(4)

⁄32

5

(4)

⁄32

5

(4)

⁄32

5

(4)

⁄32

3

(5)

⁄16

3

(5)

⁄16

3

(5)

⁄16

3

(5)

⁄16

1

(6)

⁄4

5

(8)

⁄16

5

(8)

⁄16

Gap Gap

(10)

(10)

1

(13)

1

1

(13)

⁄2

—1⁄2

—1⁄2

—1⁄2

— —

—1⁄2

—5⁄8

—5⁄8

— —

—3⁄4

—3⁄4

— —

— —

— —

— —

— —

Wheel Rotation

Rotation direction of the wheel is critical and incorrect

rotation will result in reduced air performance,

increased motor loading and possible motor burnout.

Check wheel rotation by momentarily energizing the

unit and noting if rotation is in the same direction as

the airflow at the outlet and conforms to the rotation

decal affixed to the unit.

NOTE

Models SFD and SFB units should be operated only

when attached to the system for which they were

designed. Without proper system static pressure,

—

—

(13)

⁄2

(13)

⁄2

(13)

(13)

(13)

(13)

(16)

(16)

(19)

(19)

(19)

the motor could be overloaded.

Wheels as viewed from the drive side:

Backward Inclined

Forward Curved

Airflow

Airfoil

Airflow

n

o

i

t

a

t

o

R

R

o

t

a

t

i

o

n

Airflow

®

Centrifugal Utility Fans

5

Page 6

Blower Maintenance (Belt Drive)

Belts tend to stretch after a period of time. They

should be periodically checked for tension and wear.

When replacing belts, use the same type as supplied

with the unit. Replacement of belts should

be accomplished by loosening the tensioning

“L-Bolts” so the belts may be removed by hand. Do

not force belts on or off as this may cause breakage

of cords and lead to premature belt failure.

Belt tension should be adjusted to allow 1/64 in. of

belt deflection per 1 in. of belt span. For example,

a 16 in. belt span should have 16/64 in. or 1/4 in. of

deflection with moderate thumb pressure at mid-point

between the pulleys. (Fig. 3). Refer to Greenheck’s

Product Application Guide, “Measuring Belt Tension”

for additional information—FA/127-11 found online at

www.greenheck.com under the library section.

Fig. 3

Belt Span

Deflection =

Belt Span

64

• Lubrication interval is based on 12 hour per

day operation and maximum 160°F housing

temperature. For 24 hour per day operation, the

interval should be cut in half.

• Lubricant should be added with the shaft rotating

and until clean grease is seen purging from the

bearing. The lubrication interval may be modified

based on the condition of the purged grease. If

bearing is not visible to observe purged grease,

lubricate with number of shots indicated in chart

for bore size.

• For conditions including high temperatures,

moisture, dirt or excessive vibration, consult the

factory for a specific lubrication interval for your

application.

• Lubricant should be a high quality lithium complex

grease conforming to NLGI Grade 2. Factory

recommends Mobilux EP-2.

• The use of synthetic lubricants will increase

lubrication intervals by approximately 3 times.

In addition to lubricating the bearings at specified

intervals, set screws in the bearing collars should be

checked for tightness. A bearing collar which has

loosened will cause premature failure of the fan shaft.

Fasteners attaching the bearings to the drive frame

should also be checked.

Shaft bearings are the most critical moving part of a

fan. Therefore, special attention should be given to

keeping the bearings clean and well lubricated. Proper

lubrication provides for reduction in friction and

wear, transmission and dissipation of heat, extended

bearing life and prevention of rust.

In order for a lubricant to fulfill these tasks, the proper

grease applied at regular intervals is required. See the

recommended bearing lubrication schedule below.

If unusual conditions exist - temperatures below 32°F

or above 200°F, moisture or contaminants - more

frequent lubrication is required.

Recommended Bearing Lubrication Schedule

Relubrication Schedule in Months

Standard Grease

Fan

RPM

To 250 12 12 12 12 12

500 12 12 11 10 8

750 12 9 8 7 6

1000 12 7 6 5 4

1250 12 6 5 4 3

1500 12 5 4 3 2

2000 12 3 3 2 1

2500 12 2 2 1 0.5

3000 12 2 1 0.5 0.25

3500 12 1 0.5 0.25 x

4000 12 0.5 0.25 x x

5000 12 0.25 x x x

Number

of Shots

1

⁄2

-1

4 8 8 10 16

Bearing Bore, inches

1

1

⁄8

- 1

1

⁄2

15⁄8

- 1

7

⁄8

115⁄16

- 2

3

27⁄16

⁄16

- 3

Motor Maintenance (Belt & Direct Drive)

Motor maintenance is generally limited to cleaning

and lubrication (where applicable). Cleaning should be

limited to exterior surfaces only. Removing dust and

grease buildup on the motor housing assures proper

motor cooling. Use caution and do not allow water

or solvents to enter the motor or bearings. Under no

circumstances should motors or bearings be sprayed

with steam, water or solvents.

Many fractional horsepower motors are permanently

lubricated for life and require no further lubrication.

Motors supplied with grease fittings should be

greased in accordance with the manufacturer’s

recommendations.

Wheel and Fastener Maintenance

Wheels require very little attention when exhausting

clean air, however, air heavily laden with grease or

dirt will tend to accumulate on the wheel causing

unbalance. Wheels exhausting dirty or grease-laden

air require frequent cleaning to assure smooth and

safe operation.

All fasteners, including set screws in the bearing

collars, should be checked for tightness each time

maintenance checks are performed.

A proper maintenance program will help preserve the

performance and reliability designed into the fan.

Centrifugal Utility Fans

6

®

Page 7

Parts List

1

4

6

12

7

5

8

2

3

9

10

Always provide the unit model and serial number when requesting parts or information.

Replacement Parts

1. Scroll housing

2. Drive frame - base angle

3. Intake support panel

4. Inlet ring and cone

5. Wheel (specify rotation)

®

11

6. Drive frame assembly

7. Pillow block bearings

8. Fan shaft

9. Shaft pulley

10. Belt

12

13

11. Motor pulley

12. Belt tensioning bolts

13. Motor plate

14. Motor

Centrifugal Utility Fans

14

7

Page 8

Troubleshooting

Problem Cause Corrective Action

Wheel Rubbing Inlet

V-Belt Drive

Excessive Noise

Bearings

Wheel Unbalance

Fan Check wheel for correct rotation. Increase fan speed.*

Low CFM

Duct System See page 4.

Fan Resize ductwork. Access door, filters, grills not installed.

High CFM

Duct System

Static Pressure

Wrong

Duct system has more

or less restriction than

anticipated

Fan Check rotation of wheel. Reduce fan speed.

High Horsepower

Duct System

Electrical Supply

Fan Doesn’t Operate

Drive Check for broken belts. Tighten loose pulleys.

Motor

Lubrication Check for excessive or insufficient grease in the bearing.

Overheated Bearing

Mechanical

NOTE: Always provide the unit model and serial numbers when requesting parts or service information.

* Always check motor amps and compare to nameplate rating. Excessive fan speed may overload the motor

and result in burnout.

Adjust wheel and/or inlet cone. Tighten wheel hub or bearing

collars on shaft.

Tighten sheaves on motor/fan shaft. Adjust belt tension. Align

sheaves properly (see page 4). Replace worn belts or sheaves.

Replace defective bearing(s). Lubricate bearings. Tighten

collars & fasteners.

Clean all dirt off wheel. Check wheel balance, rebalance in

place if necessary.

Change obstructions in system. Use correction factor to adjust

for temperature/altitude. Resize ductwork. Clean filters/coils.

Change fan speed.*

Check rotation of wheel. Adjust fan speed.

Resize ductwork. Check proper operation of face and bypass

dampers. Check filters and access doors.

Check fuses/circuit breakers. Check for switches off. Check for

correct supply voltage.

Assure motor is correct horsepower and not tripping overload

protector.

Replace damaged bearing. Relieve excessive belt tension.

Align bearings. Check for bent shaft.

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from the

shipment date. Any units or parts which prove to be defective during the warranty period will be replaced at our option

when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of one

year. Should motors furnished by Greenheck prove defective during this period, they should be returned to the nearest

authorized motor service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without notice.

Greenheck Centrifugal Utility Fan catalog provides additional

information describing the equipment, fan performance,

available accessories, and specification data.

®

Phone:(715)359-6171•Fax:(715)355-2399•E-mail:gfcinfo@greenheck.com•Website: www.greenheck.com

455308 • SWB / SFB / SFD, Rev. 6, June 2011 Copyright 2011 © Greenheck Fan Corporation

8

AMCA Publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans, provides

additional safety information. This publication can be

obtained from AMCA International, Inc. at www.amca.org.

Loading...

Loading...