Page 1

APPLICATION

H*

W*

Model SMD-401M is a class I leakage rated modulating smoke

damper. The model SMD-401M serves the function of

both a control damper and smoke damper. High strength airfoil

blades ensure the lowest resistance to airflow in HVAC systems

with velocities to 2000 fpm (10.2 m/s ) and 4 wg (1 kPa). Model

SMD-401M may be installed vertically (with blades running

horizontal) or horizontally and is rated for airflow and leakage in

either direction.

RATINGS

Leakage Class: I

Operational Rating: Actual ratings are size dependent.

Max. Velocity: up to 2000 fpm (10.2 m/s)

Max. Pressure: 4 in. wg (1 kPa)

Temperature: 250°F (121ºC) with all actuators.

STANDARD CONSTRUCTION

Frame: 5 in. x 1 in. (127mm x 25mm)

galvanized steel hat channel with

reinforced corners. A low profile

head and sill are used on sizes

less than 17 in. (432mm) high to

maximize free area and

performance.

Blades: Airfoil shape constructed of

heavy gauge extruded aluminum.

Structural reinforcement through

the entire length.

Seals: Extruded silicone rubber blade

seals. Flexible stainless steel

jamb seals.

Linkage: Concealed in jamb.

Axles:

Bearings: Bronze sleeve type.

1

⁄2 in. (13mm) dia. plated steel.

SMD-401M

Smoke Dampers

Extruded Airfoil Blades

UL 555S Leakage Class I

Model SMD-401M meets the requirements for smoke

dampers established by:

National Fire Protection Association

NFPA Standards 92A, 92B, 101 & 105

IBC International Building Codes

ICBO Uniform Building Codes

New York City (MEA listing #260-91-M)

CSFM California State Fire Marshal

Leakage (Smoke) Damper Listing (#3230-0981:108)

“UL CLASSIFIED (see complete marking on

product)”

“UL CLASSIFIED to Canadian safety standards

(see complete marking on product)”

Standard 555S (Listing #R13317)

LH

SIZE LIMITATIONS:

Minimum Size:

(203mm W x 203mm H)

Maximum Size:

Single Section: 36 in. W x 36 in. H

(914mm W x 914mm H)

Multi Section: 144 in. W x 36 in. H

(3658mm W x 914mm H)

8 in. W x 8 in. H

Optional Features:

• Galvanized steel sleeves.

• Stainless steel bearings

• OCI (Open closed indication switches)

• Electric or pneumatic actuators to accomplish smoke

management and system functions.

• POC Retaining angles

• Smoke detector

• Momentary switch

• Transitions (R, C, O)

• Sealed transitions and sleeves

*W&H dimensions furnished approximately 1/4 in. (6mm) undersize.

(Add sleeve thickness for overall sleeved damper dimension)

Right hand drive is shown. Left hand drive is available upon request.

Installation instructions available at www.greenheck.com

RH

Page 2

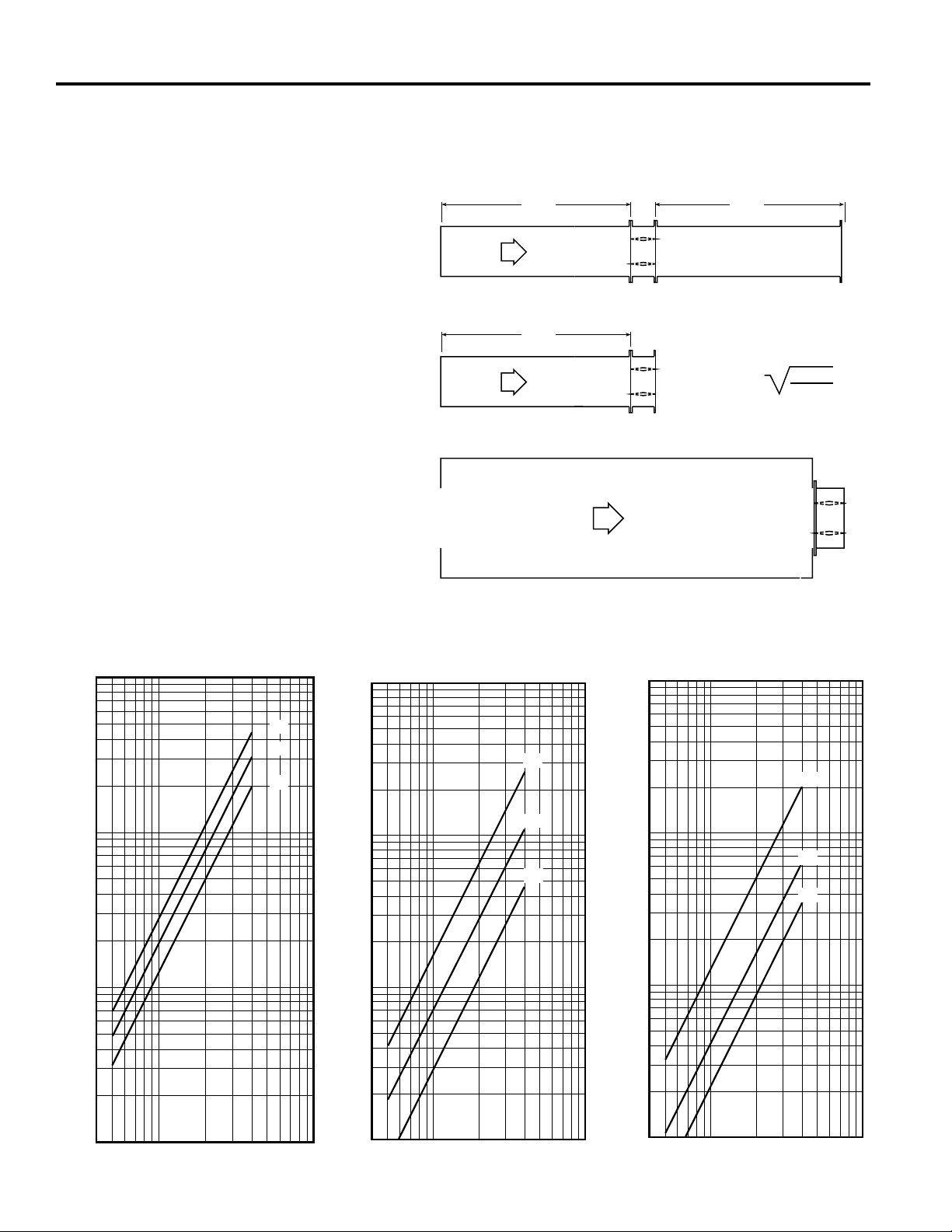

SMD-401M Pressure Drop Data

5D 6D

5D

D

4 (W) (H

)

3.14

Velocity (fpm)

4 5 6 7 8 9 10

x 100

x 1000

Pressure Loss (in. wg)

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

2 3 4 5 6 7 8 9 10

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.10

0.09

0.08

0.07

0.06

0.05

0.04

0.03

0.02

Velocity (fpm)

4 5 6 7 8 9 10

x 100

x 1000

Pressure Loss (in. wg)

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

2 3 4 5 6 7 8 9 10

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.10

0.09

0.08

0.07

0.06

0.05

0.04

0.03

0.02

Velocity (fpm)

4 5 6 7 8 9 10

x 100

x 1000

Pressure Loss (in. wg)

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

2 3 4 5 6 7 8 9 10

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.10

0.09

0.08

0.07

0.06

0.05

0.04

0.03

0.02

This pressure drop testing was conducted in accordance with AMCA Standard 500-D using the three configurations shown.

All data has been corrected to represent standard air at a density of .075 lb/ft

Actual pressure drop found in any HVAC system is a combination of many factors. This pressure drop information along with

an analysis of other system influences should be used to estimate actual pressure losses for a damper installed in a given

HVAC system.

AMCA Test Figures

Figure 5.3 Illustrates a fully ducted damper. This

configuration has the lowest pressure drop of the

three test configurations because entrance and

exit losses are minimized by straight duct runs

upstream and downstream of the damper.

Figure 5.2 Illustrates a ducted damper exhausting air into an open area. This configuration has

a lower pressure drop than Figure 5.5 because

entrance losses are minimized by a straight duct

run upstream of the damper.

Figure 5.5 Illustrates a plenum mounted damper.

This configuration has the highest pressure drop

because of extremely high entrance and exit

losses due to the sudden changes of area in the

system.

Figure 5.3

Figure 5.2

3

(1.201 kg/m3 ).

Figure 5.5

Damper Size

12 in. x 12 in.

(305mm x 305mm)

5.5

5.2

5.3

Damper Size

24 in. x 24 in.

(610mm x 610mm)

5.5

5.2

5.3

Damper Size

36 in. x 36 in.

(914mm x 914mm)

5.5

5.2

5.3

Page 3

Application Data

53/8"

5"

Right hand drive is shown

Left hand drive available upon request

A

Sleeve Length

Varies

6"

33/4"

11/2" max.

B*

S

T*

A

5 in.

12 in.**

6 in.

53/8 in.

5 in.A

Sleeve Length

Varies

33/4 in.

1

1

/2 in. max.

53/8"

5"

A

Sleeve Length

33/4"

11/2" max.

Damper Sideplate and Sleeve Dimensional Data

The drawings below illustrate the factory standard sideplate and sleeve mountings for the SMD-401M. The standard "A"

dimensions listed in the table provide adequate space for the mounting of actuators and controls.

If space constraints are a problem the "A" dimension can be varied between 5

3

⁄8 in. (136mm) and 12 in. (305mm).

Sideplate

"A" Dimension

in. (mm)

Standard Maximum

Sleeve

Sideplate

All Dampers* 7 3/16 (183) 12 (305) 6 3/16 (157)

When height is

11 in. (279) or

11 3/16

(284)

12

(305)

10 3/16

(259)

less with OCI

*With the exception of dampers 11 in. (279mm) high or less (12 in.

(305mm)high or less if width is greater than 64 in. (1625mm)) with OCI

option.

** On dampers 11 in. (279mm) high or less (12 in. (305mm)high or less if

width is greater than 64 in. (1625mm)) with OCI option, sideplate is 16 in.

(406mm)

Space Envelopes Required for

Actuators and Accessories

Externally mounted actuators always require space

outside of the damper sideplate or sleeve. The “S”

dimension illustrates the clearance required for various

available actuators.

Sleeve

* For dampers 18 in.(457mm) or more in height these dimensions are 0 in.

1

On dampers less than 18 in. (457mm) high, actuators

may also require clearances above and/or below the

sideplate or sleeve. “B” and “T” dimensions are worst

case clearance requirements for some dampers less

than 18 in. (457mm) high. All damper sizes under 18

in. (457mm) high do not require these worst case

Actuator Type/Model

B* T*

With OCI With OCI

Pneumatic

clearances. If space availability above or below the

damper sleeve is limited, each damper size should be

individually evaluated.

331-2976 2 1/2 in. (64mm) 5 1/4 in. (133mm) 6 in. (152m)

Note: This actuator requires field calibration for the zero and span setting.

S

Page 4

Transitioned Damper Dimensions

D* +

2 in. (51mm) +T

s

D*

TYPE R

16 in. (406mm)

Min.

21/8 in.

D* + 2 in. (51mm)+T

s

TYPE O

W

*

H*

W*

+ 2 in. (51mm)+T

s

H* + 2 in. (51mm)+T

s

W*

H*

TYPE C

H* + 2 in. (51mm)+T

s

(54mm)

16 in. (406mm)

Min.

21/8 in.

(54mm)

16 in. (406mm)

Min.

W*+ 2 in. (51mm)+T

s

(54mm)

21/8 in.

When a fire/smoke damper is being used in conjunction with round or oval ductwork, the SMD-401M can be supplied in a

factory sleeve with round or oval transitions on both ends of the sleeve. Dampers should be ordered to the duct dimensions.

Drawings below show overall damper size.

These dimensions are furnished approximately

*

approximately

1/8 in. (3mm) undersize.

1

/4 in. (6mm) undersize, except round and oval dimensions which are

Ts = (2)(Sleeve Thickness)

Specifications

Smoke Dampers meeting the following specifications

shall be furnished and installed where shown on plans

and/or as described in schedules. Dampers shall meet

the requirements of NFPA 90A, 92A, 92B, 101 and 105 and

further shall be tested, rated and labeled in accordance with

the latest edition of UL Standard 555S. Smoke dampers

shall be of low leakage design qualified to UL 555S Leakage

Class I.

Each damper /actuator combination shall have a UL555S

elevated temperature rating of 250°F (121ºC) minimum and

shall be rated to operate at maximum design airflow at its

installed location. Each damper shall be supplied with an

appropriate actuator installed by the damper manufacturer

at the time of damper fabrication. Damper actuator shall be

(specifier select one of the following) electric type for 24 volt

operation.

Damper blades shall be hollow extruded aluminum airfoil

type with structural reinforcing tube running full length of

each blade. Damper frame shall be galvanized steel formed

into a structural hat channel shape with reinforced corners.

Bearings shall be sintered bronze sleeve type rotating in

extruded holes in the damper frame. Blade edge seals

shall be silicone rubber designed to inflate and provide a

tighter seal against leakage as pressure on either side of

the damper increases. Jamb seals shall be stainless steel

compression type. Damper must be rated for mounting

vertically (with blades running horizontal) or horizontally and

be UL 555S rated for leakage and airflow in either direction

through the damper.

The basis of design is Greenheck Model SMD-401M.

Copyright © 2007 Greenheck Fan Corporation

SMD-401M Rev. 5 April 2007

Loading...

Loading...