Centrifugal Roof Exhaust Fans

Series L

Low Silhouette

Louvered Penthouse Style

LDP/LBP

Fabra Hood Style

LD/LB

April

2008

Series L

Centrifugal Roof Exhaust Fans

Greenheck’s Series L, low silhouette, models LD, LB, LDP, and LBP centrifugal roof exhaust fans provide the

industry’s best performance and durability for general clean air applications.

• Broadest performance in the industry, up to 1.25 in. wg (311 Pa) and 37,500 cfm (63,713 m

• Performance as cataloged is assured. All fan sizes are tested in our AMCA Accredited Laboratory, and all

models are licensed to bear the AMCA sound and air performance seals.

• UL Listed for electrical.*

• Greenheck subjects these products to extensive life testing, assuring you the fans will provide years of

reliable performance.

3

/hr).

Greenheck Fan Corporation certifies the

models LD, LDP, LB, and LBP shown

herein are licensed to bear the AMCA seal.

The ratings shown are based on tests

and procedures performed in accordance

with AMCA Publication 211 and AMCA

Publication 311 and comply with the

requirements of the AMCA Certified

Ratings Program.

Leading Edge Technical Support

When you need extensive product or installation and operating manual (IOM)

information, our products are supported by the industry’s best product literature,

electronic media and computer aided product selection (CAPS) program. You’ll

also find this information on our website at www.greenheck.com

You can always count on personal service and expertise from our national and

international representative organization. To locate your nearest Greenheck

representative, call 715-359-6171 or visit our website at www.greenheck.com

Quick Build Programs

Our Quick Build (QB) Program ensures rapid response time when your

needs require a fast turnaround. Select from more than 40 configurations

of the Series L, low silhouette model fan and we will manufacture and ship

them within ten days. We have strategically located many warehouses

across the United States and internationally to fill your request at a

moments notice.

* UL is optional and must be specified.

Models LD, LDP, LB, and LBP are

listed for electrical (UL/cUL 705)

File no. E40001.

World Class Manufacturing

Greenheck’s skilled production workers use cost-effective machines and unique dies designed and built by our

own engineers to add innovative features and greater strength to our centrifugal roof exhaust fans. Our advanced

manufacturing processes and quality control procedures always ensure the highest product quality. And just to

be sure you get the peace-of-mind you expect when you specify Greenheck, our assembly inspectors test run

and monitor every fan before it leaves the factory. Results of these tests are kept in permanent records for future

reference.

2

Unique Construction Features

All sizes feature a

d

h.

ibili

,

louver blade has a material

080 inch

d

s

.

e

All si

A

.

All si

s

.

e

ll

30

y

g

o.

d

.

s

i

.

abra Hood Styl

• Hinged Hood-

hich may be hinged to provide quick

ccess to the motor and drive assembly.

ccess may be gained by simply removing

two of the four hood fasteners or all

fasteners for complete removal

• Large Interior Dimensions

complete accessibility. Interior dimension

offer clearance for inspection, cleaning, or

maintenance of the motor, wheel, belt(s),

nd drives

• Strength & Weather Resistance - Th

ood is designed with arched panels

manufactured of heavy gauge, precision ro

formed steel with interlocking edges. Each

nterlocking rib creates a tight, weather

resistant seal. Heavy gauge steel support

members provide structural strength. The

rst hood was put into service over

ears a

zes feature a hood

zes allow

Louvered Penthouse Style

Hinged Cover

aluminum cover which may be hinged to

rovide quick access to the motor an

rive assembly. Covers are fastened down

with a quick release hood latc

Large Interior Dimensions

omplete access

mensions offer clearance for inspection,

leaning, or maintenance of the motor,

wheel, belt(s), and drives.

Strength & Weather Resistant - Each unit

tures storm resistant aluminum louver

ades with mitered corners. For decades

ur storm resistant blades have proven

highly effective. Each sturdy extruded

minum

ckness of 0.

All sizes allow

ty from above. Interio

e

n

Greenheck’s interlocking rib design combines

four material thicknesses with I-beam design

principles producing a hood far superior

in strength to

designs (an

important feature

in high wind

regions)

ensure weather tightness.

Hoods are available in galvanized steel,

nventional

nd snow loa

rmed channel

acent to the ribs provide water drainage to

nted steel, or aluminum construction

reenheck’s louvered

enthouse hoods feature

eavy gauge extrude

aluminum louvers

with mitered corner

or a clean, finished

appearance and weather

resistant construction

e interior vertical edge of the curb cap

orms the throat and weathershield. Each

orner is also shielded to prevent leakage.

enthouses are available in aluminum for

asting durability and appearance.

3

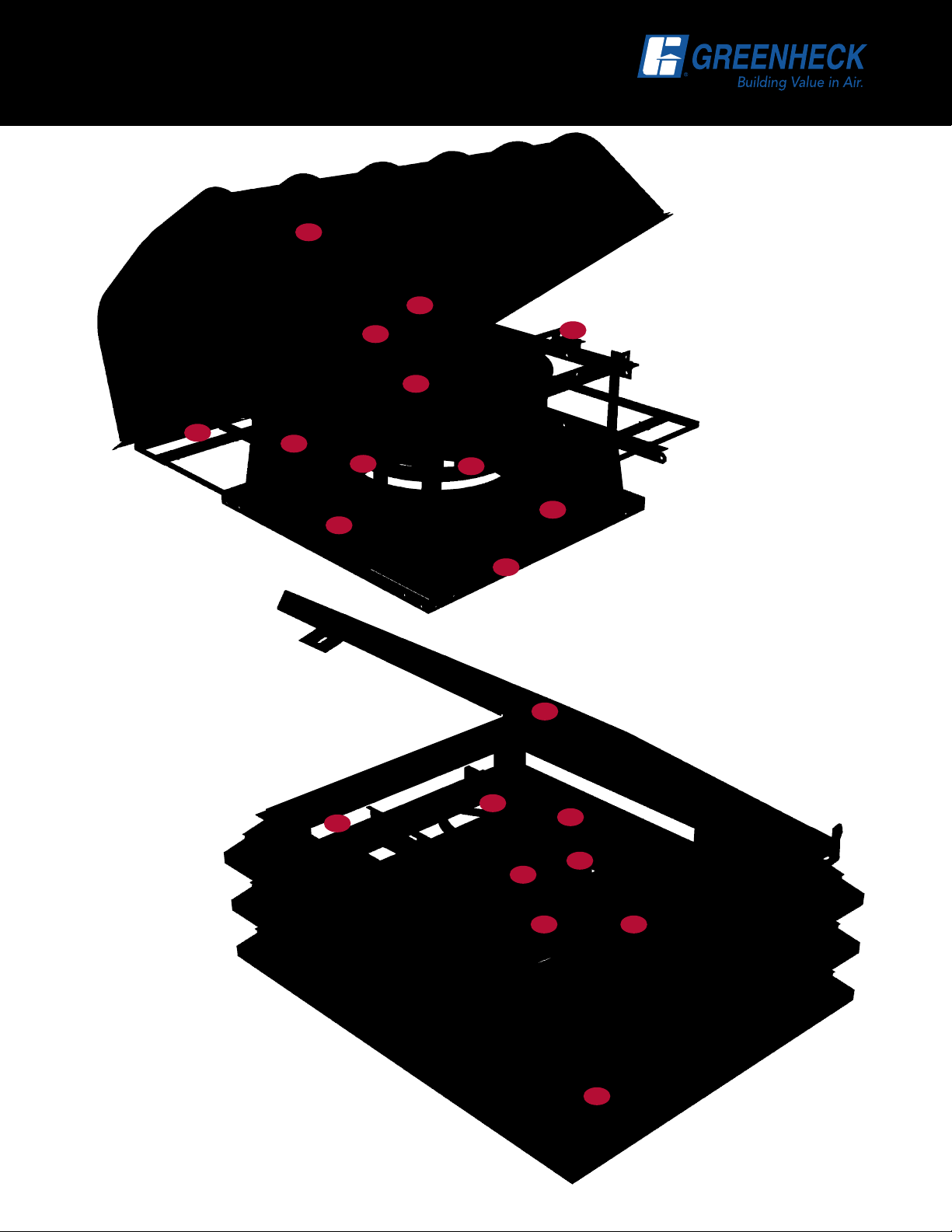

1

6

10

5

12

2

9

15

13

13

11

14

LB/LD

8

4

6

7

FABRA HOOD STYLE

10

11

LBP/LDP

LOUVERED PENTHOUSE STYLE

4

5

9

3

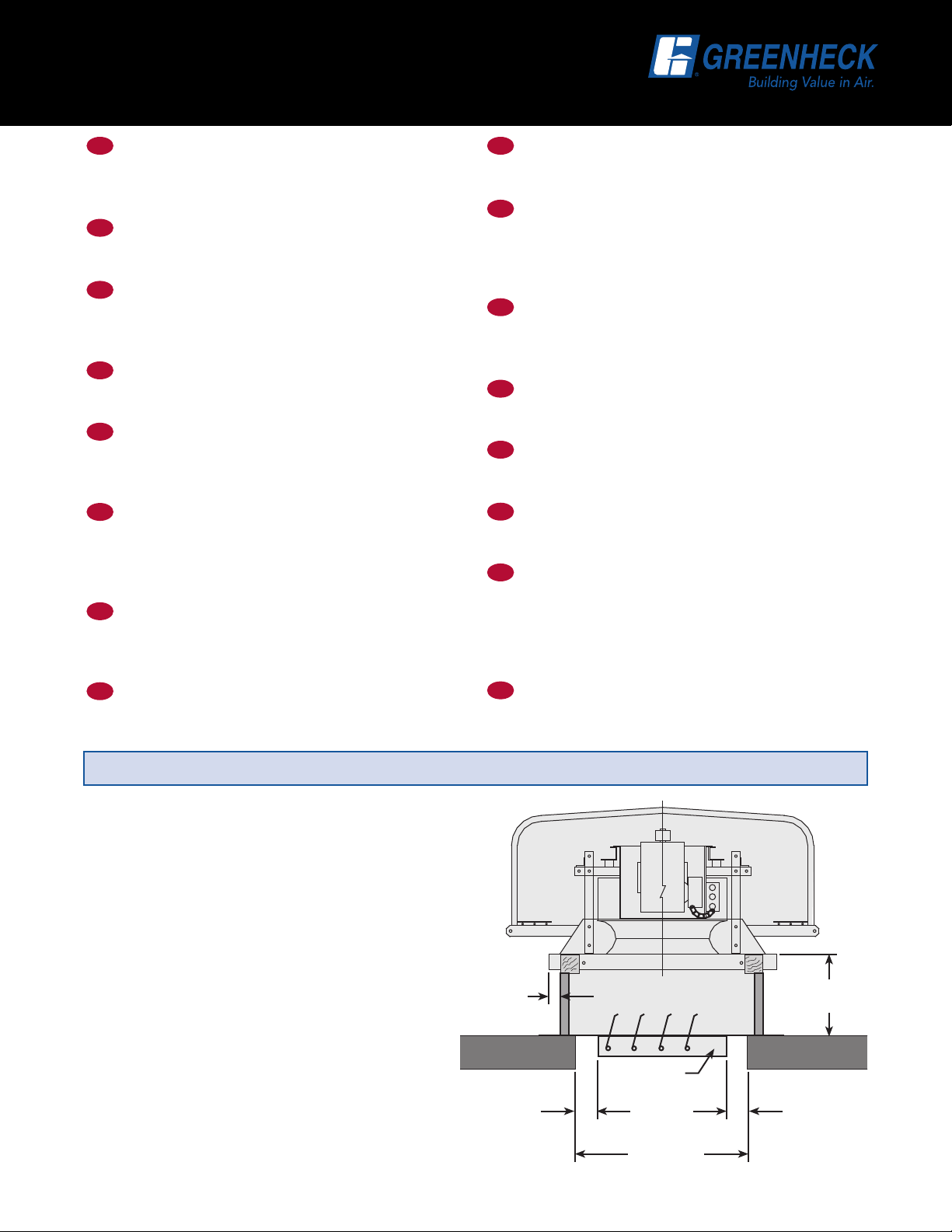

Unique Construction Features

Recommended

Duct and

Damper Size

Recommended

Roof Opening

1 1/4 in.

(32 mm)

3/4 in.

(19 mm)

Damper

8 to 12 in.

(203 to 305 mm)

1 1/4 in.

(32 mm)

1

FABRA HOOD STYLE - Models LD and LB have

a rib-lock aluminum housing. Hood panels are

interlocked and attached to sturdy aluminum

rails. (Galvanized housings are optional).

HINGED ACCESS - The entire hood assembly

2

on models LD and LB can be hinged open for

access to the internal fan components.

LOUVERED PENTHOUSE - Models LDP and

3

LBP penthouse style housings are constructed

of heavy extruded aluminum louvers with

mitered and welded corners.

HOOD COVER - Models LDP and LBP

4

aluminum hood covers are hinged and

removable for access.

DRIVE FRAME - Constructed from heavy

5

gauge galvanized steel. Belt adjustment is

accomplished by loosening fasteners, sliding

the motor plate, and retightening fasteners.

FAN SHAFT - Precisely sized, ground, and

6

polished so the first critical speed is at least

25% over the maximum operating speed. Close

tolerances between the shaft and bearing result

in longer bearing life.

BEARINGS - 100% factory tested and designed

7

specifically for air handling applications with

a minimum L10 life in excess of 100,000 hours

(L50 average life of 500,000 hours).

CURB CAP - Curb cap has prepunched

8

mounting holes to ensure correct attachment to

the curb.

9

MOTOR - Permanently lubricated, sealed ball

bearing motors are selected to provide years of

trouble-free operation.

DRIVE ASSEMBLY - Drives are oversized 150%

10

of driven horsepower. Machined cast iron

pulleys are factory set to the required RPM and

are adjustable for final system balancing. Belts

are static free and oil resistant.

11

WHEEL - An aluminum, backward inclined,

non-overloading, centrifugal wheel is utilized

to deliver maximum efficiency. Each wheel is

statically and dynamically balanced.

VIBRATION ISOLATORS - Support the drive

12

assembly and wheel without steel to steel

contact providing long life and quiet operation.

BIRDSCREEN - Galvanized rigid wire protects

13

the fan’s discharge from birds or small objects.

(Aluminum birdscreen is optional).

WINDBAND - Lower windband assembly

14

ensures weathertight and rigid unit

construction.

DISCONNECT SWITCH - NEMA-1 switch is

15

factory mounted and wiring is provided from

the motor to the disconnect enclosure as

standard. All wiring and electrical components

comply with the National Electric Codes (NEC)

and are UL Listed or Recognized.

CONDUIT CHASE - A large diameter conduit for

16

installing electrical wiring through the curb cap

into the motor compartment. (Not shown)

STANDARD INSTALLATION

Models LB, LD, LBP, and LDP exhaust fans are designed

to meet the needs of general clean air applications. Tests

have been conducted to ensure safe and reliable fans

capable of withstanding normal exhaust conditions.

When roofing materials extend to the top of the curb,

roof curbs should be 1

on a side) less than the unit curb cap to allow for

roofing and flashing.

For recommended duct size, damper size, and

roof opening dimensions, refer to CAPS or the

performance data pages.

Installation must include a means for inspecting,

cleaning, and servicing the exhaust fan.

Due to the varying airstreams encountered in

commercial ventilation, system designers must

be aware of national, state, and local codes and

guidelines governing these installations. Local code

authorities should be consulted before proceeding

with any ventilation project.

1

⁄2 in. (38 mm) (3/4 in. (19 mm)

5

Options and Accessories

BIRDSCREEN - Galvanized mesh is standard.

Optional aluminum or stainless steel rigid wire are

also available.

HOOD INSULATION - Hood insulation is dual-

density to minimize condensation, reduce thermal

transfer, and enhance sound absorption at high and

low frequencies.

LIFTING LUGS - Four heavy gauge steel brackets

are available to provide lifting points when raising

the fan to the roof.

TIE DOWN POINTS - Four heavy gauge steel

brackets are available to secure the fan in heavy

wind applications. Cables and anchors by others.

COATINGS - All Greenheck coatings and resistance

charts can be found in the performance coatings

catalog. A wide variety of coatings and colors are

available in two categories:

Decorative coatings – Sixteen standard colors

are available.

Protective coatings – Five electrostatic applied

powder coatings are available to protect against

most environments.

DAMPERS - Designed to prevent

outside air from entering back

into the building when fan is

off. Options include gravity and

motorized dampers. Damper

sizes are shown on each

performance data page.

CURB SEAL - Rubber seal between fan and curb to

ensure proper sealing when attached to a curb.

DISCONNECT SWITCHES - A wide selection

of NEMA rated switches are

available for positive electrical

shutoff and safety, including:

dust-tight, rainproof, and

corrosion-resistant. Switches

may be internally or externally

mounted.

SPEED CONTROLLERS - Available for use with

shaded pole and permanent split capacitor (PSC)

open motors on models LD and LDP fans. They

provide an economical means of system balancing

with direct drive fans.

CURB EXTENSIONS - Extensions raise the fan

discharge above the roof line and provide an

accessible mounting location for dampers. Insect

screen bases

constructed with

a removable

fine mesh are

recommended for

applications where insect

entry must be prevented. Curb

extensions are not available with LDP and LBP

severe duty construction models.

ROOF CURBS - Prefabricated roof curbs reduce

installation time and costs by ensuring compatibility

between the fan, curb, and roof opening. All curbs

are insulated with fiberglass. A

wide variety of roof curbs

are available including

flanged, pitched, and

sound-absorbing.

6

Severe Duty Option

OUTSIDE CURB DIMENSION

ROOF OPENING

12, 18 OR 24 INCHES

(305, 457, 610 MM)

THROAT DIMENSION

(ROOF OPENING)

1 INCH (25 MM) INSULATION

6 INCH x 3 INCH

(152 MM x 76 MM)

STEEL MOUNTING ANGLE

(12 GAUGE MINIMUM)

RECOMMENDED

DUCT & DAMPER SIZE

1 1/4 INCH (32 MM)

4 IN.

(102 MM)

1 3/4 INCH (44 MM)

3/4 INCH (19 MM)

4 IN.

(102 MM)

4 INCH

(102 MM)

4 INCH

(102 MM)

1 3/4 INCH

(44 MM)

2 1/2 INCH (64 MM)

2 1/2 INCH (64 MM)

1 3/4 INCH (44 MM)

CONCRETE

ROOF TRUSS

CORRUGATED

ROOF DECK

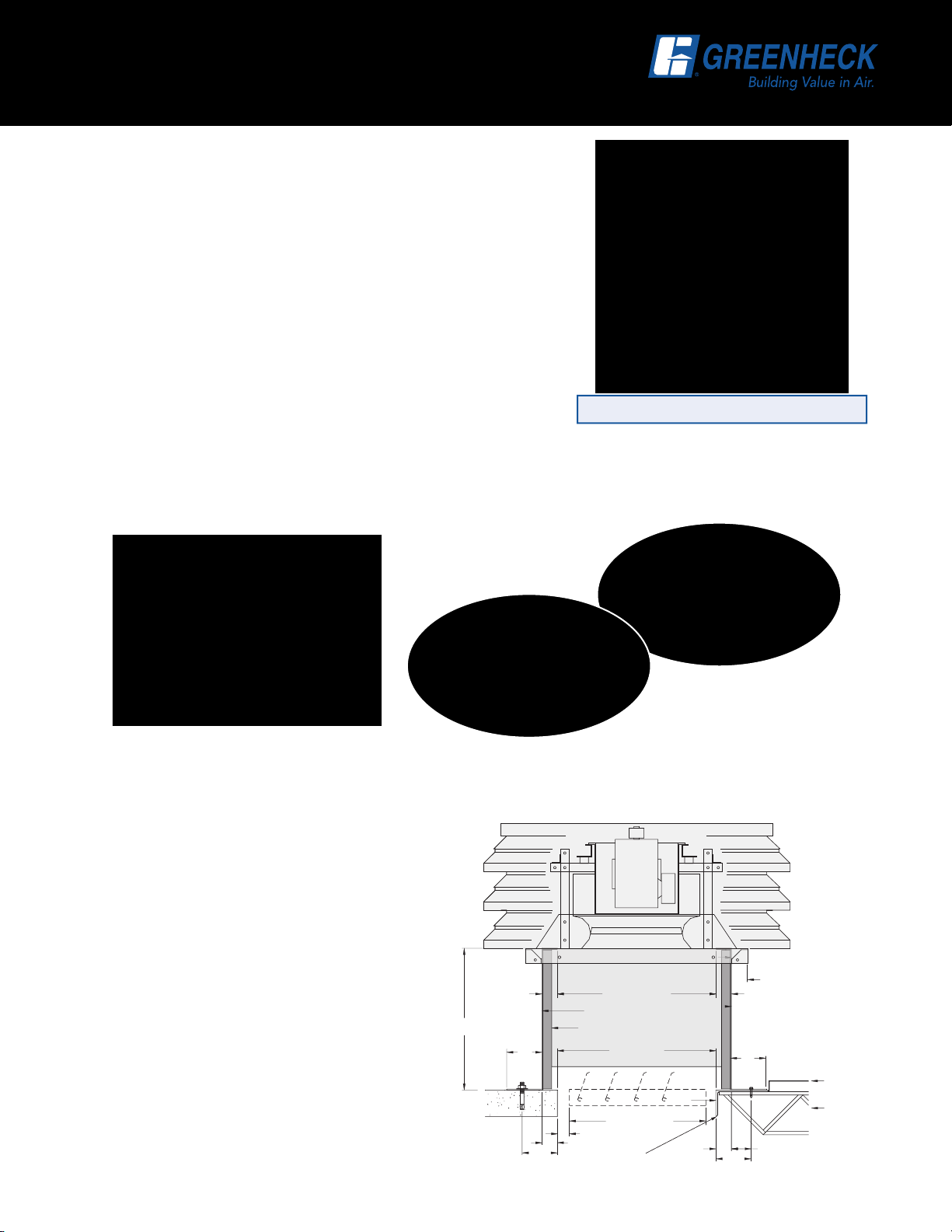

SEVERE DUTY - Specifically designed for applications with

extremely high structural design load requirements. The severe

duty models LDP and LBP are far superior to any centrifugal roof

exhaust fan currently in the market. Designed with structural steel

supports and ESD-603D louver blades, the severe duty louver

enclosure (SDLE) may be used in any application which requires a

fan to endure high winds with the potential of wind blown debris.

The louvered housing has been tested in accordance with the

following Miami-Dade test protocols:

• Large Missile Impact Test - TAS-201-94

• Uniform Static Air Pressure - TAS-202-94

• Uniform Cyclic Wind Loading - TAS-203-94

To meet the above protocols, the severe duty fan must be mounted

on a severe duty roof curb, which is attached directly to the building

structure. Maximum design load is 140 psf.

Available on sizes

• LDP - 60 though 120

• LBP - 10 through 30

Weights and dimensions will vary from standard LDP and LBP construction.

NOTICE OF ACCEPTANCE NUMBER 03-0422.05

Severe Duty Installation

Models LDP and LBP severe duty exhaust fans are designed to meet the needs of general clean air

applications. Tests have been conducted to ensure safe, rugged and reliable fans capable of withstanding

severe exhaust conditions.

The severe duty roof curb model SD is supplied

with this product and is designed with 12 gauge

welded steel construction. Greenheck

recommends the severe duty curb to be

anchored to the structure of the building.

Dependent upon roofing material it shall be

bolted and welded. For recommended duct

size, refer to CAPS or installation manual.

Installation must include a means for

inspecting, cleaning, and servicing the

exhaust fan.

Due to the varying airstreams encountered

in commercial ventilation, system designers

must be aware of national, state, and local

codes and guidelines governing these

installations. Local code authorities should

be consulted before proceeding with any

ventilation project.

7

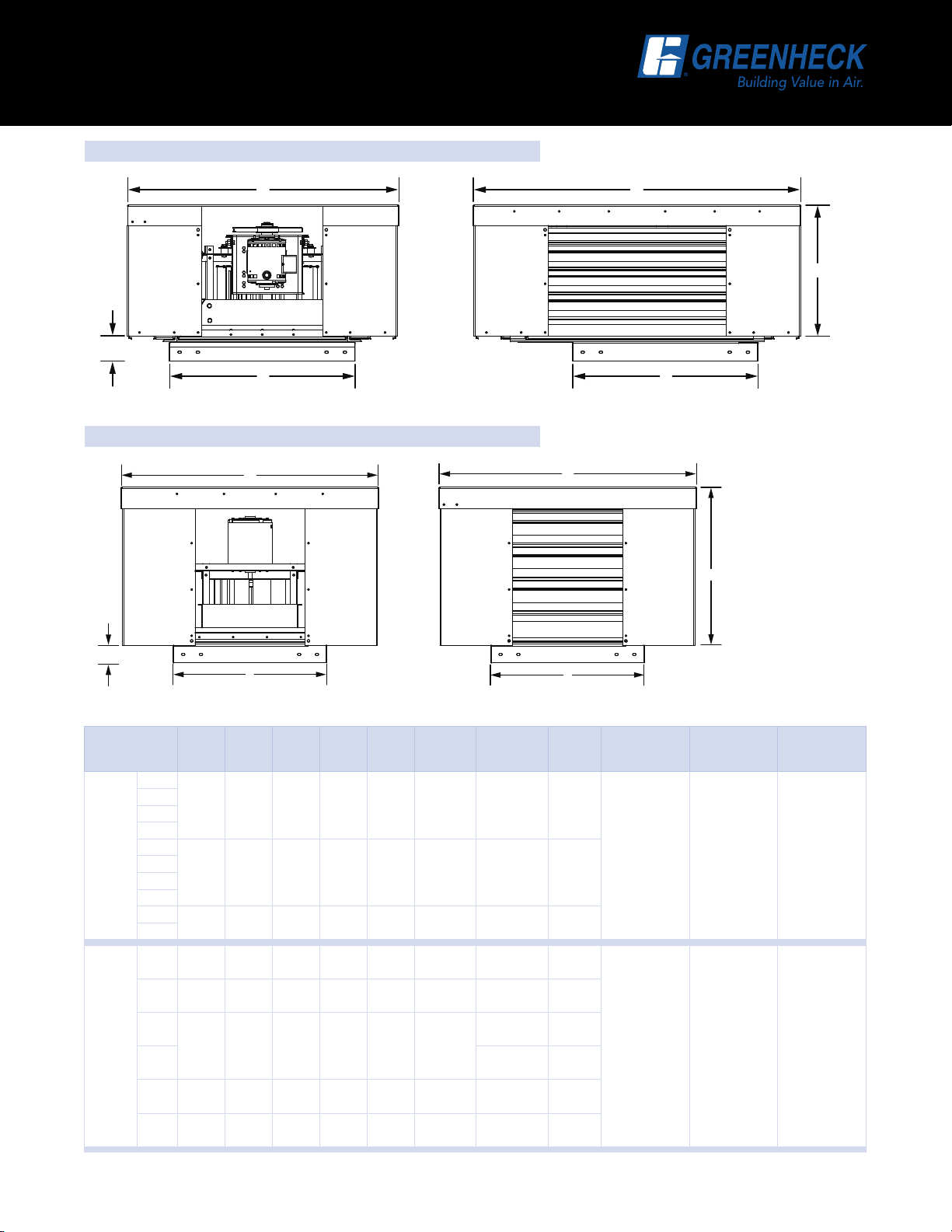

Severe Duty Dimensions

LDP - SEVERE DUTY DIMENSIONS

E

LBP - SEVERE DUTY DIMENSIONS

CB

D

AA

B

C

D

E

A

Model

Number

ABCDE

Damper

Size

(square)

60

65

17

70

(432)

347⁄8

(886)

347⁄8

(886)

175⁄8

(448)

13⁄4

(44)

8

(203)

75

LDP

80

85

90

19

(483)

367⁄8

(934)

367⁄8

(934)

175⁄8

(448)

13⁄4

(44)

10

(254)

95

LBP

100

120

10

14

18

21

24

30

(559)

(559)

(660)

(762)

(864)

(1016)

22

22

26

30

34

40

397⁄8

(1013)

397⁄8

(1013)

437⁄8

(1114)

477⁄8

(1216)

517⁄8

(1318)

577⁄8

(1470)

397⁄8

(1013)

503⁄8

(1280)

517⁄8

(1318)

577⁄8

(1470)

617⁄8

(1572)

697⁄8

(1775)

195⁄8

(498)

181⁄8

(460)

181⁄8

(460)

245⁄8

(625)

245⁄8

(625)

271⁄4

(692)

13⁄4

(44)

13⁄4

(44)

13⁄4

(44)

13⁄4

(44)

13⁄4

(44)

13⁄4

(44)

12

(305)

12

(305)

16

(406)

18

(457)

24

(610)

30

(762)

All dimensions are in inches (millimeters). Weight in pounds (kilograms). *Weight shown is the largest cataloged Open Drip Proof motor.

Roof

Opening

(square)

101⁄2

(267)

121⁄2

(318)

141⁄2

(368)

101⁄2

(267)

101⁄2

(267)

101⁄2

(267)

1

10

(267)

101⁄2

(267)

101⁄2

(267)

A

Weight*

Cover

Thickness

375

(170)

0.100

400

(181)

(0.045)

aluminum

425

(193)

550

(249)

550

(249)

550

(249)

⁄2

700

(318)

0.100

(0.045)

aluminum

800

(363)

950

(431)

Louver

Thickness

0.125

(0.056)

aluminum

0.125

(0.056)

aluminum

Curb Cap

Thickness

0.25

(0.113)

steel

0.25

(0.113)

steel

8

Loading...

Loading...