Page 1

Part # 461006

MODEL PVF

INDIRECT GAS FIRED FURNACES FOR ENERGY RECOVERY UNITS

Installation, Operation and Maintenance Manual

®

RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

WARNING!!!

Improper installation, adjustment, alteration, service or maintenance can cause injury or death.

Read the installation, operating and maintenance instructions thoroughly before installing or

servicing this equipment.

CAUTION!!!

Units are designed for outdoor installation only. DO NOT locate units indoors.

Shipping

Check the unit for shipping damage. If any shipping damage is found, it should be reported to the last carrier

and your local Greenheck representative.

Indirect Fired Gas Unit Installations

Units are listed for installation in the United States and Canada

• Installation of gas fired duct furnaces must conform with local building codes. In the absence of local

codes, installation must conform to the National Fuel Gas code, ANSI Z223.1 or in Canada,

CAN/CGA-B149 installation codes.

• All electrical wiring must be in accordance with the regulation of the National Electric Code,

ANSI/NFPA No. 70.

•Unit is approved for installation downstream from refrigeration units. In these conditions, condensate

could form in the duct furnace and provision must be made to dispose of the condensate.

Refer to Part Number 460945 for any unit information other than that pertaining to the Indirect Fired Furnace.

R

Page 2

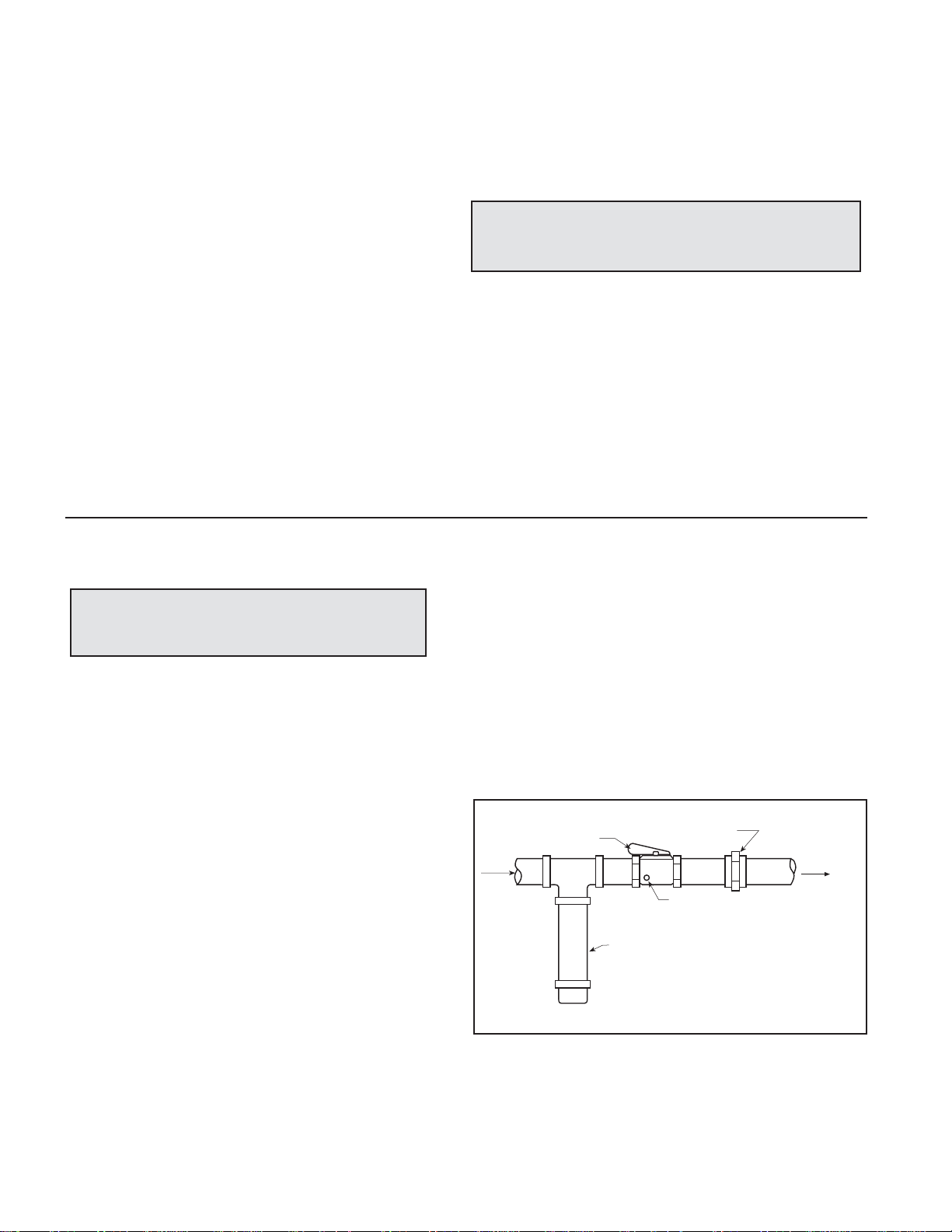

1. Single furnaces (furnace input 100 to 400 MBH)

have a single 3⁄4 inch connection. Double furnaces

(furnace input 500 to 800 MBH) have two 3⁄4 inch

connections, and triple furnaces (furnace input

1050 to 1200 MBH have three

3

⁄4 inch connections.

2. When connecting the gas supply, the length of the

run must be considered in determining the pipe

size to avoid excessive pressure drop. Refer to a

Gas Engineer’s Handbook for gas pipe capacities.

3. A drip leg should be installed in the pipe run to the

unit.

4. Install an easily accessible ground joint union and a

manual shut off valve (these are required by some

local codes) for emergency shut off and easy

servicing of the controls.

5. A

1

⁄8 inch NPT plugged tap shall be installed

immediately ahead of the gas supply connection to

the furnace.

6. After gas piping is completed, carefully check all

piping connections for gas leaks. Use soap solution

or equivalent for testing. DO NOT use a flame or

other source of ignition to check for gas leaks.

7. When leak testing pressures above 14 in. wg (

1

⁄2 psi),

close the field installed shutoff valve, disconnect

the furnace and its gas train from the gas supply

line, and plug the supply line before testing.

8. When leak testing at pressures equal to or less than

14 in. wg (

1

⁄2 psi) close the field-installed shutoff

valve to isolate the unit from the gas supply line

before testing.

1. Do not install units in locations where flue products

can be drawn into adjacent building openings such

as windows, fresh air intakes, etc. Distance from

vent terminal to adjacent public walkways,

adjacent buildings, operable windows, and

building openings shall conform with the local

codes. In the absence of local codes, installation

shall conform with the National Fuel Gas Code,

ANSI Z223.1, or the CAN/CGA B-149 Installation

Codes.

2. Building materials that will be affected by flue

gases should be protected.

3. Avoid locating in an area where deep snow is likely

to accumulate. During the winter months, keep

snow clear on the access side of the unit to

prevent any blockage of combustion air inlet or

flue exhaust openings.

4. Maintain minimum horizontal clearance of 4 feet

from electric meters, gas meters, regulators, and

relief equipment. In Canada, the minimum

clearance is 6 feet.

5. Local codes may supercede any of the above

provisions.

6. Be sure that the minimum clearances to

combustible materials are maintained.

Venting

1. Do not modify or obstruct the combustion air inlet

cover or the combustion blower weatherhood.

2. During the winter months, periodically clear snow

from access side of unit to prevent blockage of the

inlet and exhaust openings.

3. Do not add any vents other than those supplied by

the manufacturer.

From

Gas

Gas Cock

1/8 in. Plugged

6 in. Trap

Ground Joint Union

To Controls

Unit Clearances to Combustible Materials

Gas Connection

Figure 1: Recommended Piping to Controls

Location Recommendations

Gas Supply Pressure Requirements

Natural: 6 to 14 in. wg

LP: 11 to 14 in. wg

Combustion blower discharge must be located

42 in. from any combustible materials.

2

Page 3

1. Installation of wiring must conform with local building codes. In the absence of local codes, installation

must conform to the National Electric Code ANSI/NFPA 70-Latest Edition. Unit must be electrically

grounded in conformance with this code. In Canada, wiring must comply with CSA C22.1, Canadian

Electrical Code.

2. All furnaces are provided with a wiring diagram located on the inside of the access panel. Refer to this

wiring diagram for all wiring connections.

3. The combustion blower motor will not run unless the furnace is turned on and the gas controls are calling

for heat.

WARNING!!!

• Disconnect power supply before making wiring connections to prevent electrical shock and

equipment damage.

• All appliances must be wired strictly in accordance with wiring diagram furnished with the unit. Any

wiring different from the diagram could result in a hazard to persons and property.

• Any original factory wiring that requires replacement must be replaced with wiring material having a

temperature rating of at least 105°C.

1. Two-stage temperature controls - Controls the

furnace stages based on the unit discharge

temperature.

2. Combustion blower - Exhausts the products of

combustion from the furnace tubes.

3. Ignition controller - Continually monitors,

analyzes, and controls the proper operation of

the gas burner.

4. Manifold pressure test port - Used for checking

the manifold gas pressure.

5. Time Delay relay - Allows burner to stay at high

fire for 10 seconds upon being lit.

6. Air pressure switch - Tests to ensure the

combustion blower is operating.

7. Two-stage gas valve - Contains main pressure

regulator, safety shut-off valves, and manual

shut off knob. It controls the furnace to 50% or

100% fire.

8. Ignitor - Provides spark for burner ignition.

9. Flame Sensor - Ensures that each burner has

ignited.

Control Center Layout

1

2

3

4

5

6

7

8

9

Electrical Connections

Figure 2: Furnace Control Center

3

Page 4

Power-up/Standby

After power is supplied to the unit:

1. The ignition control will reset and perform a selfcheck routine.

2. The diagnostic LED will flash for up to four

seconds.

3. The ignition control will begin scanning the

thermostats.

Heat Mode

When the thermostat or discharge temperature

controls call for heat:

1. The ignition control will check that the pressure

switch for the combustion blower is open.

2. The combustion blower will be energized and the

15-second pre-purge begins.

3. The gas valve is energized and the igniter will spark

for up to 10 seconds.

Natural Gas - If a flame is not sensed during the

trial for ignition, two additional trials will be

attempted before going into lockout for one hour.

LP Gas - If a flame is not sensed during the trial for

ignition, the control will go into lockout for one

hour.

4. When a flame is sensed, sparking stops

immediately. The gas valve and combustion blower

remain energized.

5a. Two-stage control: The burner will light at 100%

fire and remain there for 10 seconds. The

thermostat will then operate the burners at high or

low fire, depending on the demand for heat.

5b. Electronic Modulation - The burner will light at

100% fire and remain there for 10 seconds. The

main burner gas valve will then modulate from

100% down to 50% as needed. If the burner

remains on low fire for an extended period of time,

the burner will shut off and re-light as necessary.

6. The ignition control constantly monitors the

thermostat, pressure switch, and burner flame to

assure proper operation.

7. When the thermostat or discharge temperature

controls are satisfied, the main valve is deenergized and the combustion blower shuts off

following a 30-second post-purge period.

Recovery from Lockout

The ignition control will automatically reset after 1 hour

if the thermostat is still calling for heat. Prior to 1 hour,

a manual reset (cycle power to unit) is required. The

thermostat may be reset or the power interrupted for a

period of 5 seconds. See page 7 for

Ignition Control

Diagnostics

.

Sequence of Operation

1. Turn off power to the unit at the disconnect switch.

Close all manual gas valves.

2. Check that all gas and electrical connections are

weatherized.

3. Make sure that the combustion air inlet and the

combustion blower discharge are free from

obstructions.

4. Inspect the unit to make sure that no damage has

occurred during installation.

5. With the furnace control center access panel

removed, connect a “U” tube manometer to the

manifold pressure test port as shown in Figure 2.

This will be used for checking the manifold gas

pressure.

6. Set the thermostat or discharge temperature

controls to lowest setting.

7. Open all manual gas valves including the

combination gas valve and turn power on.

8. Call for heat with the thermostat or discharge

temperature controls and allow the burner to light.

Greenheck duct furnaces are equipped with an

automatic spark ignition system which

automatically lights the burner. DO NOT attempt to

light the burners manually.

9. After the burner is lit, check to make sure that the

supply blower is operating.

10.Verify that the gas controls sequence properly (see

Sequence of Operation below).

11.Check the manifold gas pressure (see

Burner

Adjustments

on pages 5 and 6).

Start-Up Procedure

4

Page 5

Setting Manifold Pressure for Two Stage Gas Control

1. Set the unit to high fire by setting the

discharge temperature control or

thermostat to its maximum setting. If the

ambient temperature is warm, the unit

may not stay at high fire.

2. Measure the burner manifold pressure at

the manifold pressure test port (see

Control Center Layout on page 3) using a

“U” tube manometer. The pressure on

high fire should be 3.5 in. wg for natural

gas and 10 in. wg for LP gas. To change

the pressure, adjust the regulator

adjustment screw on the combination gas

valve.

3. Set the unit to low fire by removing the

wire from the high fire terminal on the

combination gas valve.

4. The manifold pressure on low fire for natural gas

should be 0.88 in. wg and 2.5 in. wg for LP gas. To

change the pressure, use the low fire adjustment

screw on the combination gas valve.

Staged Burner Adjustments

Furnace Controls

For Energy Recovery Units without Temperature Control Package

The furnace stage controls are located in the furnace control center. One control is

provided for each stage of heating. The discharge temperature setting is located on

the control furthest to the left. The offset and differential settings for each stage are

preset at the factory; however, field-adjustments may be made to get the best control

for your application. See the literature provided with the controls for further

information.

For Energy Recovery Units with Temperature Control Package

If two-stage control is ordered with a Temperature Control Package, the controller in

the unit’s main control center will control the stages of heating. The temperature set

point may be adjusted on the controller (See Temperature Controller IOM).

Staged Temperature Controls

Performance Data

Ratings shown are for elevations up to 2000 ft. For higher elevations, the input should be reduced by 4% per 1000 ft. of

elevation above sea level. In Canada, from 2000 to 4500 ft in elevation, the unit must be derated to 90% of the input listed

above. The unit shall also be used in accordance with standard CGA 2.17.

High Fire Adjustment

Low Fire Adjustment

Solenoid

High Fire

Terminal

Air Temperature Rise Through Unit (°F)

Model Input Output 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Number (MBH) (MBH) CFM

PVF 100 100 80 3704 2963 2469 2116 1852 1646 1481 1347 1235 1140 1058 988 926 871 823 780 741

PVF 150 150 120 5556 4444 3704 3175 2778 2469 2222 2020 1852 1709 1587 1481 1389 1307 1235 1170 1111

PVF 200 200 160 7407 5926 4938 4233 3704 3292 2963 2694 2469 2279 2116 1975 1852 1743 1646 1559 1481

PVF 250 250 200 9259 7407 6173 5291 4630 4115 3704 3367 3086 2849 2646 2469 2315 2179 2058 1949 1852

PVF 300 300 240 11111 8889 7407 6349 5556 4938 4444 4040 3704 3419 3175 2963 2778 2614 2469 2339 2222

PVF 350 350 280 12963 10370 8642 7407 6481 5761 5185 4714 4321 3989 3704 3457 3241 3050 2881 2729 2593

PVF 400 400 320 14815 11852 9877 8466 7407 6584 5926 5387 4938 4558 4233 3951 3704 3486 3292 3119 2963

Figure 3: Staged Controls

Figure 4: Combination Gas Valve

5

Page 6

1. Set the unit to high fire by placing a jumper between terminals 7 and 8 on the Maxitrol amplifier.

2. Measure the burner manifold pressure at each furnace at the pressure test port (see Figure 2) using a high

quality manometer that can measure low gas pressures. The pressure at high fire should be 3.5 in. wg for

natural gas and 10.0 in. wg for LP Gas. To change the pressure, adjust the high fire screw on the combination

gas valve.

3. To get the unit to low fire: Remove the wire from terminal 3 on the amplifier and isolate it from touching

anything. Set the discharge temperature selector to the highest setting. If there is a room override thermostat,

turn the dial to the highest setting.

4. Measure the manifold pressure on low fire, it should be 0.88 in. wg for natural gas and 2.5 in. wg for LP gas.

5. To adjust the low fire, remove the bypass cap (A) and turn screw (B) as shown in diagram. Adjust the screw

indicated in Figure 5 on the modulating valve.

6. Reconnect wire to terminal 3.

7. Remove jumper and place all wires back to where they were and plug the manifold pressure port.

Electronic Modulation Temperature Controls

For Energy Recovery Units without Temperature

Control Package

A Discharge Temperature Dial is used for temperature

control for electronic modulation. The temperature dial

will be located in the furnace control center.

For Energy Recovery Units with Temperature Control

Package

The Temperature Controller in the unit’s main control

center will provide the electronic modulation control.

High and Low Fire Settings for Electronic Modulation

Figure 5: Electronic Modulation Valves

Check the high and low gas pressures on initial start up per the instructions below. These settings are pre-set at

the factory, but should be adjusted in the field if necessary. Set the high fire first and the low fire second. The low

fire must always be checked if the high fire is changed.

Modulating Valve

Low fire adjustment

Combination Gas Valve

High fire adjustment

A

B

6

Page 7

Ignition Control Diagnostic LED

During normal operation, the LED is shut off. The LED

will be on or flashing during a fault condition. If a fault

condition is occurring, turn the unit off and on again. If

the LED is still flashing, refer to the following

troubleshooting section.

LED Indication Error Mode

Steady on Internal control failure

1 flash Air flow fault

2 flashes Flame with no call for heat

3 flashes Ignition lockout

Troubleshooting

Possible Cause Solution

Manual gas valve not open Open manual valve

Air in the gas line Bleed gas line

Supply gas pressure too high or too low Check that supply pressure is between 6 in. wg and 14 in. wg for

natural gas and 11 in. wg and 14 in. wg for LP.

Loose wire connections Check for tight wire connections.

No spark:

a. Transformer failure a. Check primary and secondary voltages of transformer. Replace

if necessary.

b. Spark electrode b. Ensure spark gap is 1⁄8 in. and ceramic insulator is not cracked.

Replace if necessary. Electrode is NOT field-adjustable.

c. Spark cable shorted to ground c. Replace spark cable

d. Ignition controller not grounded d. Check that the ignition controller is grounded to the furnace

control center.

High limit control tripped Check unit airflow and manifold pressure.

Faulty combination gas valve If 24 volts is measured between terminals MV and common, but

valve remains closed, replace valve.

Faulty ignition control Check diagnostic LED for steady on and for voltage between V1

and V2. If no voltage is present, replace ignition control.

Airflow Fault (1 Flash)

An airflow fault may occur for the following reasons:

• An airflow switch continually monitors the combustion airflow during an ignition sequence. During the initial

call for heat, if the pressure switch contacts are in the closed position for 30 seconds without an output to

the combustion blower, an airflow fault will be declared. The control will remain in this mode with the

combustion blower off.

• After the combustion blower output (L1 and IND) is energized and the airflow switch remains open for more

than 30 seconds, an airflow fault will be declared. The control will stay in this mode with the combustion

blower on, waiting for the airflow switch to close.

• If the airflow signal is lost while the burner is firing, the control will immediately de-energize the gas valve

and the combustion blower will remain on. If the call for heat remains, the control will wait for proper airflow

to return. If proper airflow is not detected after 30 seconds, an airflow fault will be declared. If proper airflow

is detected at any time, a normal ignition sequence will begin.

Once proper airflow is detected, the normal Sequence Of Operation for ignition will follow (see page 4).

Flame Fault (2 Flashes)

If the main valve fails to close completely and maintains a flame, the full-time flame sense circuit will detect it and

energize the combustion blower. Should the main valve later close completely and remove the flame signal, the

combustion blower will be de-energized.

Ignition Lockout (3 Flashes)

7

Page 8

Combustion Blower Motor

Motor maintenance is generally limited to cleaning.

Cleaning should be limited to exterior surfaces only.

Removing dust and grease build-up on the motor

housing assures proper motor cooling. Use caution

and do not allow water or solvents to enter the motor

or bearings. Under no circumstances should motors or

bearings be sprayed with steam, water or solvents.

The motor bearings are pre-lubricated and sealed,

requiring no further lubrication.

Burners and Orifices

Before each heating season, examine the burners and

gas orifices to make sure they are clear of any debris

such as spider webs, etc. Clean burner as follows:

• Turn off both electrical and gas supplies to the

unit.

• Disconnect union between manifold and gas

valve.

• Remove manifold and burner assembly.

• Inspect and clean orifices and burners as

necessary. Avoid using any hard or sharp

instruments which could cause damage to the

orifices or burners.

- Remove any soot deposits from the burner

with a wire brush.

-Clean the ports with an aerosol degreaser

or compressed air.

- Wipe the inside of the burner clean.

Cleaning the burner with a degreaser will

slow the future buildup of dirt.

• Before reinstalling the burner assembly, look

down the heat exchanger tubes to make sure

they are clear of any debris.

• Reinstall manifold and burner assembly,

reconnect wire leads, and gas supply piping.

• Turn on the electrical power and gas supply.

• Follow the start-up procedure to light the

burners and verify proper operation.

Heat Exchanger

The heat exchanger should be checked annually for

cracks and discoloration of the tubes. If a crack is

detected, the heat exchanger should be replaced

before the unit is put back into operation. If the tubes

are dark gray, airflow across the heat exchanger

should be checked to make sure the blower is

operating properly.

Flue Collector Box

The flue passageway and flue collector box should be

inspected prior to each heating season and cleared of

any debris.

Electrical Wiring

The electrical wiring should be checked annually for

loose connections or wiring deterioration.

Replacement Parts

When ordering replacement parts, include the

complete unit model number and serial number listed

on the unit rating plate.

CAUTION!!!

Turn off all gas and electrical power to the unit before performing any maintenance or

service operations to this unit.

Copyright © 2001 Greenheck Fan Corp.

ERCH - PVF IOM FS

Rev1 July 2001

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one

year from the purchase date. Any units or parts which prove to be defective during the warranty period will

be repaired or replaced at our option.

The motor is warranted by the motor manufacturer for a period of one year. Should the motor prove

defective during this period, it should be returned to an authorized motor service station.

Greenheck will not be responsible for any installation or removal costs.

Routine Maintenance

Loading...

Loading...