Page 1

GREENHECK

P.O. BOX 410 SCHOFIELD, WISCONSIN 54476-0410

PH. 715-359-6171

®

Installation, Operation and Maintenance Instructions

for Neutralizer 100% Outdoor Air Ventilators

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating, and maintenance instructions thoroughly before

installing or servicing this equipment.

This manual is the property of the owner, and is required for future maintenance.

Please leave it with the owner when you complete the job.

Part # 457502

June 1998

Page 2

TABLE OF CONTENTS

Warranty............................................................................................................Pg. 2

Installation Instructions:

NV-45

•Horizontal Discharge................................................................................Pg. 3

•Downblast Discharge............................................................................Pg. 4-5

NV-90 and NV-120

•Slab, Rail, Curb Installation...................................................................Pg. 6-7

•Equipment Supports, Discharge Locations............................................Pg. 8

•Curb Installation .................................................................................Pg. 9-11

•Installing Filter/Coil Section and Weatherhood.................................Pg. 10-11

Electrical Instructions......................................................................................Pg. 12

System Startup.................................................................................................Pg. 13

Coil Instructions..........................................................................................Pg. 14-16

Trouble Shooting..............................................................................................Pg. 17

General Dimensions and Weights.....................................................................Pg. 18

Maintenance.....................................................................................................Pg. 19

Maintenance Notes...........................................................................................Pg. 20

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a

period of one year from the purchase date. Any units or parts which prove to be defective during

the warranty period will be repaired or replaced at our option.

The motor is warranted by the motor manufacturer for a period of one year. Should the motor

prove defective during this period, it should be returned to an authorized motor service station.

Greenheck will not be responsible for any installation or removal costs

.

Due to continuing research, Greenheck reserves the right to change specifications without notice.

2

Page 3

INTAKE

DISCHARGE

DISCHARGE

INTAKE

C

L

C

L

Equipment

Support

Footprint

C

L

A

A

(fig.4)

Roof mounted arrangement HZ

with weatherhood, mounted on three equipment supports.

Ductwork is attached to discharge collar with rubber

boot transition.

(fig.5)

Arrangement HZ shown as an indoor

hanging installation with intake and

discharge ductwork installed.

(Hanging support structure for unit is by others).

(fig.2) (fig.3)

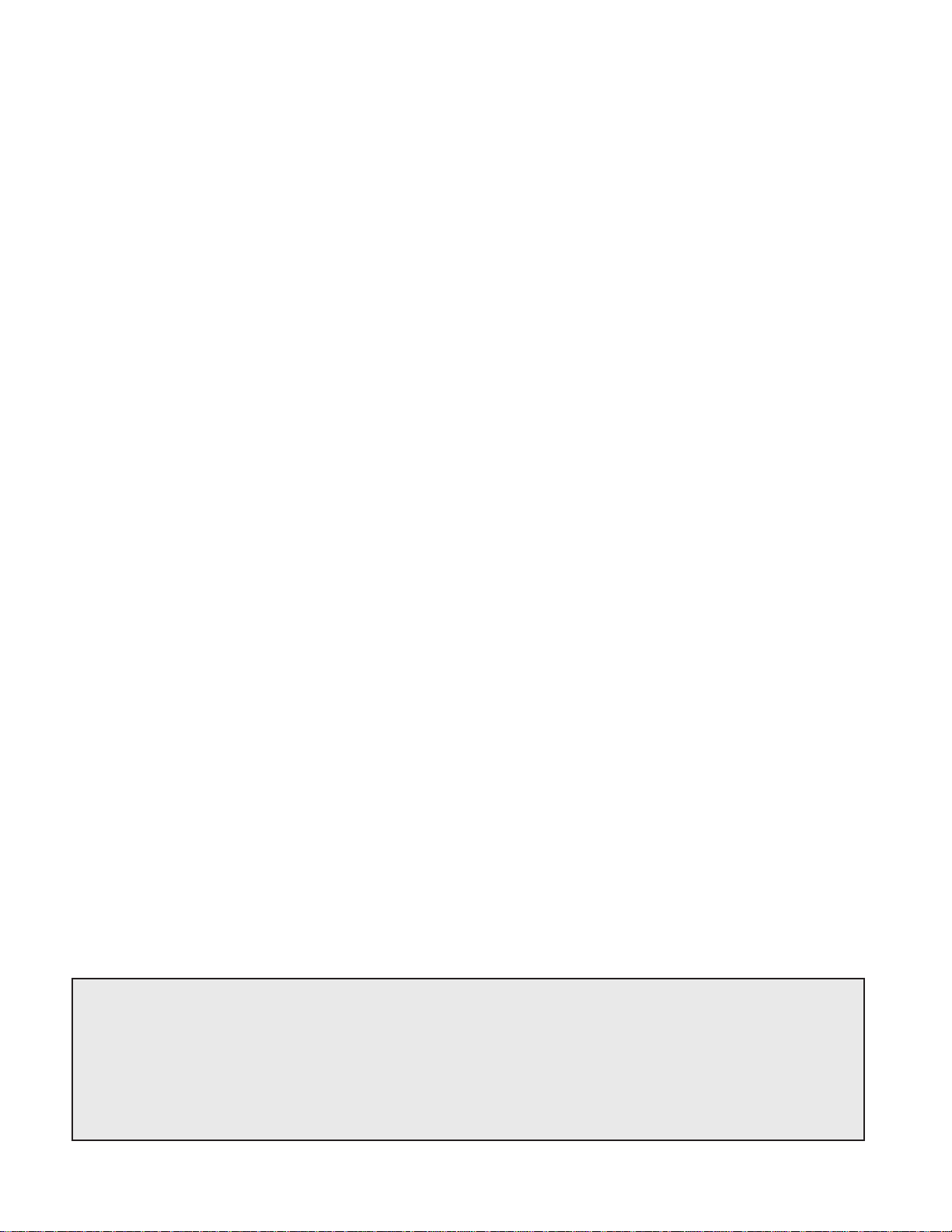

Step 1 Mounting the Unit

Arrangement HZ can be mounted on a curb

with an equipment support (see curb inst.) or

on three equipment supports (figs. 1&4).

Arrangement HZ can also be used for indoor

applications mounted hanging (fig. 5), inline

as part of an air handling system, or base

mounted. Mounting hardware to be provided

by others.

In any case, adequate support of the unit is

required.

Step 2 Attach Ductwork to Unit Discharge

Chart and drawing (fig.2) below shows opening size (ID)

and location for a discharge collar. Also included is the

recommended straight duct length for optimal

performance. Greenheck recommends attaching

ductwork to collar using a rubber duct section at the

unit to eliminate vibration.

Step 3 Attach Ductwork to Unit Intake

For non-weatherhood installations, fig. 3 below shows

dimensions for supply opening (ID). Attach ductwork to

perimeter flange using a rubber duct section at the unit

to eliminate vibration. Design the remaining ductwork

for minimal losses to allow the unit to operate properly.

A -Equip. Support CL441/4"

(fig.1)

Typical Installations

3

Recommended Duct Size/Location

and Intake Dimensions

Minimum Straight Duct Length - 54”

16

16

48

43

12

23

Installation Instructions for:

NV-45 w/Horizontal Discharge

Page 4

4

B

C

L

C*

Rectangular

Curb

Footprint

C

L

C

L

A

A/2

A

Roof

Opening

A/2

C*

C*

*C- Determine equal dimension for these 3 locations

Sealant

Ductwork

Duct Adaptor

Supply

Ductwork

by Others

Step 1 Roof Opening

Determine the center of the supply duct roof

opening. The chart below shows the maximum

recommended roof opening dimensions. These

sizes can be smaller based on codes and

ductwork sizes.

A - Max Roof Open. Sq. 47"

Supply Duct CL to

B - 881/2"

Equip. Support C

L

Before beginning this installation:

Make sure that there is room to access the unit from all sides.

Make sure inlet of unit is located well away from any exhaust fans.

Step 3 Install Ductwork

The chart shows at left shows the duct

sizes and straight lengths recommended

for optimal performance (AMCA Publication

201-90). Using duct sizes less then

recommended lengths will affect fan

performance. Good duct installation

practices should be followed for the

remaining ductwork. The use of a duct

adapter with the supply duct is strongly

recommended to properly align the

ductwork with the supply fan discharge.

The duct adaptor is only a guide and is not

intended to be used as support for the

ductwork.

Step 4 Apply Sealant

Before installing unit apply a sealant or a

gasket around the perimeter of the supply

duct adaptor to isolate the fan and

minimize vibration.

For Installations using rectangular curb

Recommended Supply

Ductwork Sizes

Straight

Duct Duct

Size Length

16 x 16 54"

Installation Instructions for:

NV-45 w/Downblast Discharge

Step 2 Install Roof Curb and

Equipment Support

For rectangular curbs, center curb on 3 sides of roof opening, as shown in above installation diagram, by

determining C dimension (varies per unit/curb size). For either installation, level the curb and shim if necessary.

Attach curb to roof and flash in place.

If equipment support is needed, refer to chart in step 1 for dimensional location based on NV unit size. Attach to

roof in the same manner as the curb. Remove metal cover, flash to wooden nailer, and reinstall cover.

Page 5

5

Model TSU

Supply Unit

Lifting Lugs

(4 places)

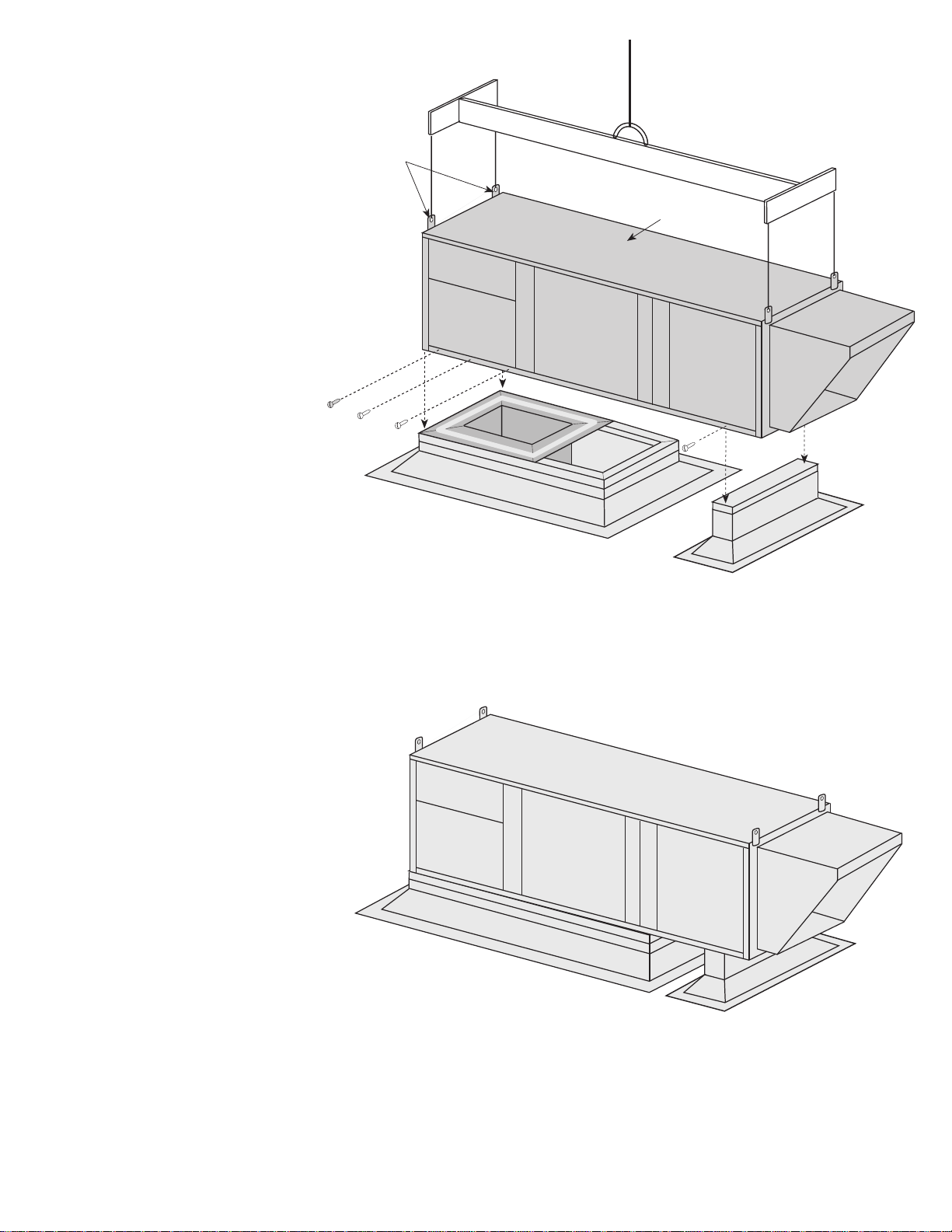

Step 5 Install Supply Unit

Use a crane and a spreader bar

hooked to the factory lifting lugs

(as shown in the diagram) to lift

and center the NV unit on the

curb and equipment support. Use

self-tapping sheet metal screws

to fasten unit to the curb and

equipment support through holes

provided.

Electrical and pipes connections

can be made at this time.

Complete Installation

Illustration shows the complete

installation of downblast NV with

filter section and weatherhood.

Page 6

6

GREENHECK

®

Before beginning this installation:

Make sure that there is room to access the unit from all sides.

Make sure inlet of unit is located well away from any

exhaust fans.

Installation Instructions for:

SLAB, RAIL, AND CURB MOUNTING

NV-90 and NV-120

w/Horizontal Discharge

Lifting Lugs (4)

Spreader Bar

NV Unit

Intake

1a. Slab Construction

Recommended Size: 1ft. wider and

longer than total unit size.

Recommended Material: Concrete at

least 4" thick.

Slab should be set and leveled on a

sufficient bed of gravel for proper

drainage.

1b. Install Unit

Use a crane and spreader bar to

prevent damage to unit. Lifting lugs are

provided as shown in illustration.

Its is highly recommended that all

accessory items be lifted separately

and attached after the NV unit is in

place.

Unit may be fastened to slab through

lifting lugs.

Page 7

7

Rails located 6-12" in

from sides of unit.

Rails extend 6" from

end of filter section

Rails extends 6" from

discharge end of unit

Lifting Lugs (4)

Spreader Bar

2. Rail Mounting

For proper support, rails should be located

6-12" in from sides of unit and should

extend at least 6" beyond both discharge

end of unit and filter section.

3. Curb Mounting

(See page 9 for curb assembly)

Install unit on curb using a crane and

spreader bar to prevent damage to unit.

Lifting lugs are provided as shown in

illustration.

It is highly recommended that all accessory

items be lifted separately and attached

after the unit is set in place.

Page 8

4. Optional Up-stream Heating Coil

If an optional up-stream heating coil is provided with the unit an additional equipment support may be required. If

filters only are provided in this section, additional support is not needed. Follow the guidelines below for

determining the coil section support required. Page 18 lists unit weights for equipment support load

requirements.

Equipment Support Requirements:

Equipment Support

Cement Slab

Slab/Rail Mount Curb Mount

NV-90 None Curb Height

NV-120 12” Curb Height + 12”

Coil Section

Typical NV-120 installation

on cement slab with

optional up-stream heating

coil section .

See page 10 for attachment

instructions.

5. Attach Ductwork to Unit Discharge

Chart and drawing below show opening size (ID) and location for discharge collar. Also included is the

recommended straight duct lengths for optimal performance. Greenheck recommends attaching

ductwork using a rubber duct section at the unit to eliminate vibration.

D

Discharge Opening Sizes

A B C D

NV-90 161/4 24 34 1/2223/8 81

1

NV-120 16

/4 251/2 34 231/4 96

Straight

Duct Length

Straight Duct Length

B

A

Back View

NV-90 and NV-120

C

8

Page 9

9

Installation Instructions for:

CURB MOUNTING*

NV-90 and NV-120

*For installations using Greenheck's

optional roof curb.

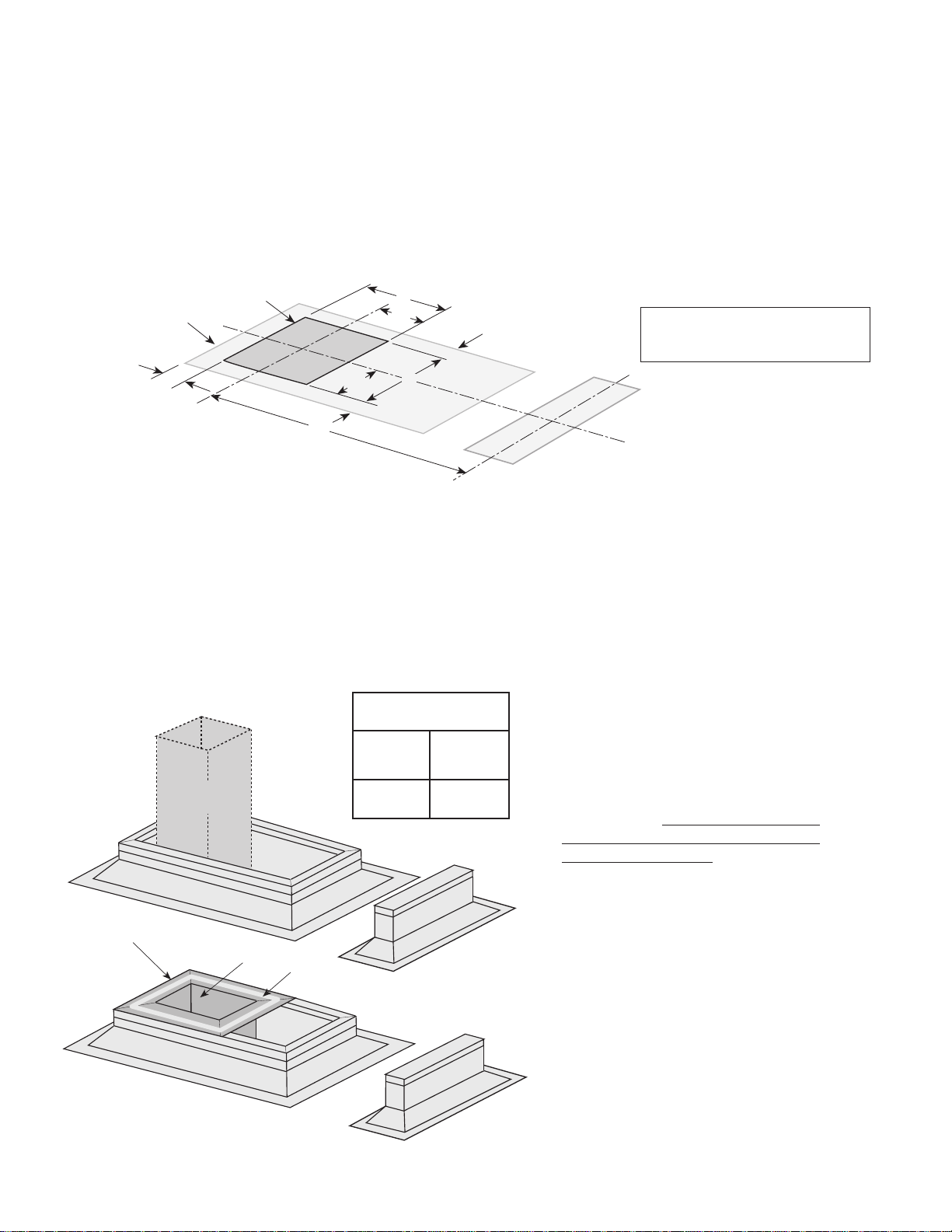

1. Assemble Roof Curb

Curbs are shipped knockdown and require assembly

by others. Assembly instructions are also included

with curb.

Assemble curb sections as shown using hex bolts and

lock nuts supplied with curb.

Detail shown is typical for all four corners.

Recommended

Roof Opening

(36"x36")

1031/2

431/4

405/8

241/4

41/2

Roof Curb

813/16

4. Install Ductwork

The following chart shows the duct sizes and straight

lengths recommended for optimal performance (AMCA

Publication 201-90). Using duct sizes less than

recommended lengths will affect fan performance. Good

duct installation practices should be followed for the

remaining ductwork.

Roof Opening

B

C

D

Ductwork

by Others

Roof Curb

A

Straight

A B C D

Duct Length

NV-90 24 93/8 24 301/4 81

NV-120 26 9

1

/2 26 291/4 96

Duct Locations:

2. Locate and Cut Roof Opening

When locating unit, make sure there is room to access unit

from all sides. Make sure inlet of this unit is located well

away from exhaust fans.

Roof Opening for NV-120 and NV-90 = (A) 36" x (B) 36"

3. Install Curb

Located curb over roof opening with dimensions shown to

the right and fasten in place.

Check that diagonal dimensions are within

± 1/8" of each other and adjust as necessary. Shim as

required to level.

Page 10

10

5. Install Unit.

Use a crane and spreader bar to prevent damage

to unit. Lifting lugs are provided as shown in

illustration.

It is highly recommended that all accessory items

be lifted separately and attached after the unit is

in place.

Electrical and pipe connections can be made at

this time.

Lifting Lugs (2)

Spreader Bar

Butt units together

Fasten through

both flanges.

KSU Unit

Filter/Coil Section

Filter /Coil section fastener locations

typical for entire section.

Top fasteners are accessed from

outside, side fasteners are accessed

from inside, bottom fasteners are

accessed from underneath filter section

(Note: bottom fasteners are not required

for slab mounted units).

Detail A

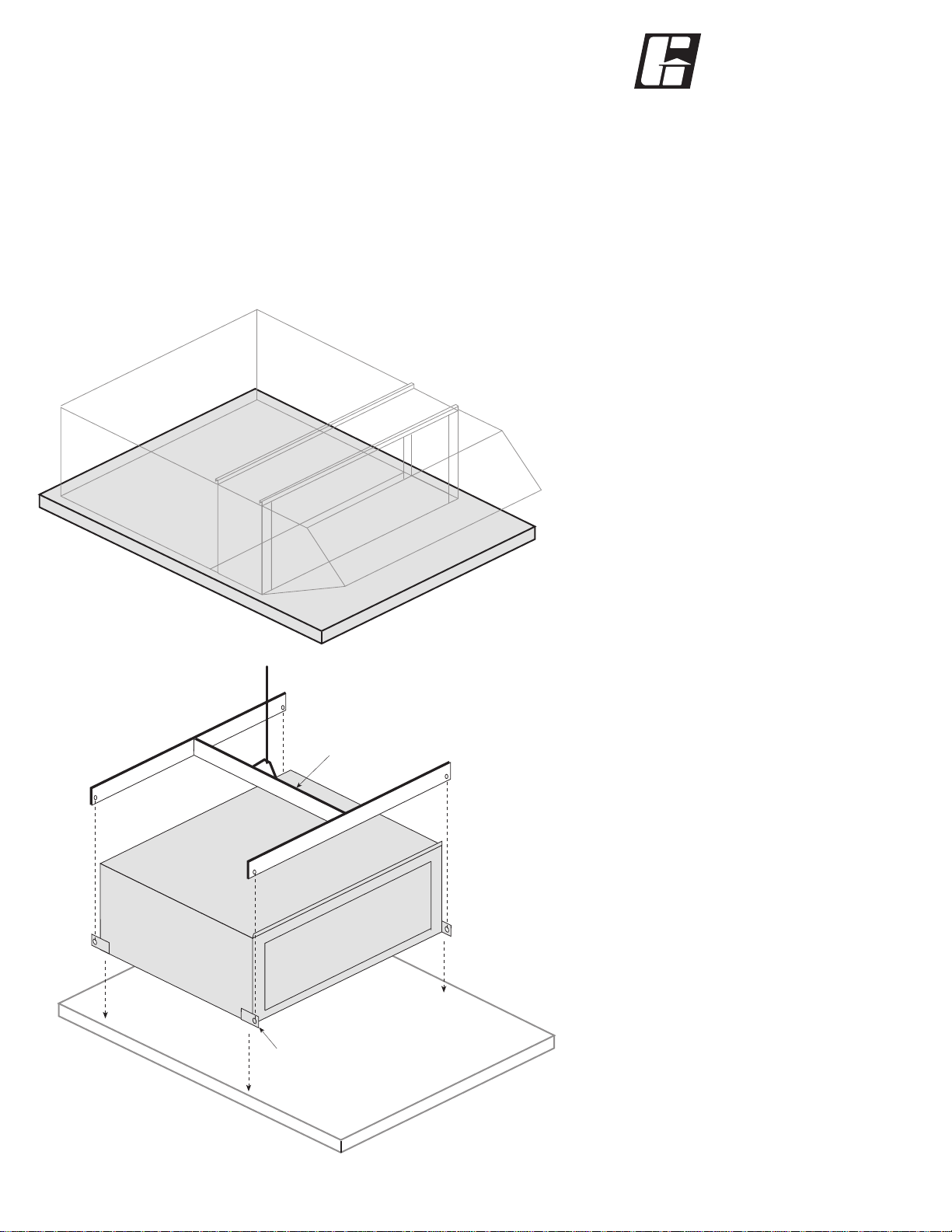

6. Attach Filter/Coil Section (if included)

Use a crane and spreader bar hooked to factory

lifting lugs (as shown in diagram) to lift and center the filter section on the NV unit. Note that the top Ushaped flange on the filter section fits over the vertical flange of the NV unit (see detail A). Use sheet metal

screws to fasten the filter section to NV unit. Mounting holes are prepunched, see diagram for approximate

hole locations.

Filters ship separately. To install, remove side panel on filter section and slide into filter channels. Note

arrows on filters for correct orientation.

Note:

If the optional up-stream heating coil

section is included with the unit, special

support for this section is required. See

page 8 for requirements.

Page 11

11

Weatherhood fastener locations

typical for entire section.

Top fasteners are accessed from

outside, side and bottom fasteners

are accessed from inside.

Lifting Lugs (2)

Spreader Bar

7. Attach Weatherhood

Use a crane and spreader bar hooked

to factory lifting lugs (as shown in

diagram) to lift and center the

weatherhood on the filter section (same

procedure as shown in previous step).

If there is no filter section, the

weatherhood attaches directly to NV

unit in same manner. Fastener

instructions are same as Step 6.

8. Attach Support Legs

Support Legs are required

on weatherhood section.

Attach through prepunched holes in

weatherhood using

supplied fasteners.

Install 1stslide to side

Install 2ndslide to side

Install last

Birdscreens simply slide up and into

opening, resting on channels. Install side

screens first and slide to edges of unit.

Install center screen last. No fasteners

are required.

Filters simply side down into filter tracks

as shown. No fasteners are required.

Note arrows on filters for correct airflow.

9. Install Birdscreen or Optional Weatherhood Filters

Support Legs (2)

Page 12

12

Sequence for wiring NV unit:

For units without control centers:

The motor nameplate is to be used for determining the voltage and amperage required by

the unit.

For units with control centers:

1. The unit’s nameplate states the voltage and total amperage required.

The main feeder supplying power to the unit should be sized for the label’s voltage and amperage.

2. The main power line should be connected to the disconnect switch.

Make sure that the disconnect lugs are securely tightened.

3. Connect control panel wiring to terminal strip in the control center.

Greenheck’s standard control voltage is 120/60/1.

4. When an optional convenience outlet is provided, a separate power supply must be provided to

the receptacle. This circuit must be on a ground fault breaker.

CAUTION !

If any of the original wire must be replaced,

the replacement wire must have a temperature

rating of at least 105°C, except for energy cut-off

or sensor lead wire which must be 150°C.

DANGER !

High voltage electrical input is needed for this

equipment. This work should be performed by a

qualified electrician.

Before connecting power to the unit, read and

understand the following instructions and

wiring diagrams. Complete wiring diagrams

are attached inside the door(s) of the unit.

All wiring should be done in accordance with

the National Electrical Code ANSI/NFPA 70latest edition and any local codes that may

apply. In Canada, wiring should be done in

accordance with the Canadian Electrical

Code. The equipment must be properly

grounded.

NOTE: Any wiring running through the NV unit in the airstream must be protected by

flexible metal conduit, metal clad cable, or raceways.

Electrical Instructions

CAUTION

Any wiring deviations may result in personal injury or property damage. Greenheck is not

responsible for any damage to, or failure of the NV unit caused by incorrect final wiring.

NV-45 NV-90-120

Electrical Location

Electrical Power Connection

Electrical Controls Door

Electrical Controls Door

Electrical Power

Connection

Page 13

SYSTEM STARTUP

For proper unit function and safety, follow everything in this startup procedure in the order presented. This is to

be done after the electrical connections are complete.

• Voltage meter

• Incline manometer or equivalent

Special Tools Required • Tachometer

• Thermometer

• Amperage meter

1. Check Voltage

Before starting the unit compare the supplied voltage with the unit’s nameplate voltage and the motor

voltage.

2. Check Blower Rotation

First hand rotate the blower to ensure that the wheel is not rubbing against

the scroll. If the blower is rotating in the wrong direction, the unit will move

some air but not perform properly. To check the rotation, open the blower

access door and run the blower momentarily to determine the rotation. To

reverse the rotation, turn the power off and use the following procedure:

• For single phase units, rewire the motor per the instructions on

the motor.

• For three phase units, interchange any two power leads.

This can be done at the motor starter.

3. Air Volume Check and Measurement

Along with the building balance, the units air volume (cfm) should be measured and compared with its rated air

volume. This unit is flexible for varying air volume (units above 15 Hp may have fixed drives), but the actual air

volume should be known for making final adjustments.

The most accurate way to measure the air volume is by using the pitot traverse method in the ductwork away

from the blower. Other methods can be used but should be proven and accurate.

To adjust the air volume, change the fan RPM or the system losses. See Trouble Shooting Section in this

guide.

4. Measure Motor Voltage, Amperage and Fan RPM

All access doors must be installed except the control center door. Measure and record the input voltage and

motor amperage(s).

To measure the fan RPM, the blower door will need to be removed. Minimize measurement time because the

motor may over amp with the door removed.

With blower door in place compare measured amps to the motor nameplate full load amps and correct if

overamping. See the trouble shooting section in this guide.

5. Settings for Optional Components

Freeze Protection:

This de-energizes the blower if the output temperature is below the set point. A timer allows the blower to

operate during startup. This will reset when turned off.

Typical settings are:

Discharge temperature = 35°F Timer = 5 minutes

Blower

Housing

R

o

t

a

t

i

o

n

13

Page 14

Instructions for Coils

Steam Coils

Application Recommendations:

Satisfactory operation and service life are best ensured when coils are installed with proper piping, trap, and

support arrangement. The following notes and figure 1 (page 15) are recommended for the coil unit installation

and operation.

General:

1. Provide separate supports and hangers for the unit and the piping.

2. Be certain that adequate piping flexibility is provided. Stresses resulting form expansion of closely

coupled piping and coil arrangement can cause serious damage.

3. Standard steam coils are pitched in the casings when installed for horizontal air flow. The CASING MUST

BE LEVELafter the unit is installed for proper condensate drainage. If condensate is not removed the coil

will suffer from water hammering and will have a shortened life. On vertical air flow applications, the coils

must be pitched when installed.

4. Do not reduce pipe size at the coil return connection. Carry return connection size through the dirt pocket,

making the reduction at the branch leading to the trap.

5. It is recommended that vacuum breakers be installed on all applications to prevent retaining condensate

in the coil. Generally, the vacuum breaker is to be connected between the coil inlet and the return main.

The vacuum breaker should be open to the atmosphere and the trap design should allow venting of large

quantities of air.

6. Do not drip supply mains through the coil.

7. Do not attempt to lift condensate when using modulating or on-off control.

8. Do not reduce the pipe size leaving the coil.

Traps:

1. Size traps in accordance with the manufacturer’s recommendations. Be certain that the required pressure

differential will always be available. DONOTUNDERSIZE.

2. Float and thermostatic or bucket traps are recommended for low pressure steam. On high pressure

systems, bucket traps are normally recommended. The thermostatic traps should be used only for air

venting.

3. Bucket traps are recommended for use with on-off control only.

4. Locate traps at least 12 inches below the coil return connection.

Controls:

1. On high pressure installations, a two-position steam valve with a face and bypass

arrangement is preferred where modulating control is required.

2. Modulating valves must be size properly. DONOTUNDERSIZE.

Freezing Conditions (Entering air below 35

1. 5 PSIsteam must be supplied to the coil at all times.

2. Provision should always be made to thoroughly mix fresh air and return air before it enters the coil on

return air units. Also, temperature control elements must be properly located to obtain true air mixture

temperatures.

3. As additional protection against freeze-up, the trap should be installed sufficiently far below the coil to

provide an adequate hydrostatic head to ensure removal of condensate during an interruption in the steam

pressure. Estimate 3 feet for each 1 PSIof trap differential required.

4. On start up, admit steam to coil ten minutes before admitting outdoor air.

5. Provision must be made to close fresh air dampers if steam supply pressure falls below minimum

specified.

o

F):

14

Page 15

15

Steam Main

Return Main

Gate Valve

Control Valve, Modulating

Two-Position

Check Valve-Vacuum Breaker

Float and Thermostat Trap

Strainer

Direct Expansion Coils

Application Recommendations:

1. Piping should be in accordance with accepted industry standards.

2. The condensate drain pipe should be sized adequately to ensure the condensate

drains properly. The bottom of the drain pan should be twice the distance of the internal static pressure

water column above the exit of the trap.

3. When connecting suction and liquid connections make sure the coil is free from all foreign material. Make

sure all joints are tight and free of leakage.

4. Greenheck does not supply compressor or condensing units, for further instruction on DX coil installation

and operation contact your compressor and/or condenser manufacturer.

Figure 1

Recommended Steam Coil Piping

Greenheck does not

supply coil controls, all

control elements shown

are supplied by others.

Page 16

16

Coil Maintenance

Filters:

Filters upstream of the coil should be checked regularly for dirtiness and clogging. If the filters are dirty, they

should be cleaned or replaced. It is important that the coils stay clean to maintain maximum heat transfer

capability.

Cleaning:

1. Coils must be clean to obtain maximum performance. Soiled fins reduce the capacity of the coil, demand

more energy from the fan, and create a medium for order and bacteria to grow and spread through the

conditioned zone. High pressure water (700 Psi or less) may be used to clean coils with fin thickness over

.0095 inches thick. TEST THE SPRAY PRESSURE over a small corner of the coil to determine if the fins will

withstand the spray pressure. For coils with fragile fins or high fin density, foaming chemical sprays and

washes air available. Many coil cleaners contain harsh chemicals, so they must be used with caution by

qualified personnel only. Care must be taken not to damage the coils. FINS ARE SHARP! Use caution when

working with coils.

2. Drain pans in any air conditioning unit will contain moisture; therefore, algae and other organisms will grow

due to airborne spores and bacteria. Scheduled cleaning is necessary to prevent build-up from clogging the

drain. The drain pans should also be kept clean to prevent growth of bacteria and the spread of disease.

Winterizing Coils:

During any extended down time, all water should be drained from the coil. The coil should then be thoroughly

flushed with a glycol solution to prevent freeze damage.

WARNING: Biological Hazard! All drain pans and coils should be cleaned on a regular

schedule by qualified personnel to prevent the growth of bacteria.

Water Coils

Application Recommendations:

1. Piping should be in accordance with accepted industry standards.

2. Connect the WATER SUPPLY TO THE BOTTOM CONNECTION on the air leaving side and the WATER

RETURN TO THE TOP CONNECTION on the air entering side. The extra bottom connection can be used for

an auxiliary manual drain connection, and the extra top connection can be used for an automatic air vent or

the extra connections can be capped. Connecting the supply and/or return in any other manner will result

in very poor performance.

3. The air vent at the uppermost point should be temporarily opened during system start-up to release all

of the air from the coil. To maintain heat transfer capacity, periodically vent any air in coil.

4. Water coils are not normally recommended for use with entering air temperatures below 40oF; however,

special high pressure water coils have been used successfully on high temperature hot water jobs with low

entering air temperatures when correctly controlled. No control system can be depended on to be 100%

safe against freeze-up with water coils. Glycol solutions or brines are the only safe media for operation of

water coils with low entering air conditions.

5. When fresh and return air are to be heated by a hot water coil, care should be used in the design of the

duct work to ensure thorough mixing before the air enters the coil. The return air should always enter the

bottom of the duct and the fresh air should enter the top of the duct. The greater the distance between the

mixing point and the entrance to the coil, the better the application. Temperature control elements should

be located to sense the lowest temperature air that will enter the coil. Always install gasketed fresh air

dampers which are automatically controlled to close whenever the water leaving the coil is too cool, or the

fan stops. Care should be used in designing fresh air intake to prevent stack effect (or wind) from forcing

cold air through the coils when the fan is shut down. Two sets of dampers are frequently required.

CONTINUOUS WATER CIRCULATION THROUGH THE COIL AT ALL TIMES IS HIGHLY RECOMMENDED.

6. Pipe sizes for the system must be selected on the basis of the head (pressure) available from the

circulation pump. The velocity should not exceed 8 feet per second and the friction loss should be

approximately 3 feet of water column per 100 feet of pipe.

7. For chilled water coils, the condensate drain pipe should be sized adequately to ensure the condensate

drains properly.

Page 17

17

TROUBLE SHOOTING

Blower Unit

Symptom Possible Cause Corrective Action

Blower fails Blown fuse or open circuit breaker Replace fuse or reset circuit breaker and

to operate check amps

Broken fan belt Replace

Defective motor or capacitor Replace

Motor starter overloaded Reset starter and check amps

Motor overamps CFMs too high Check CFMs and adjust drives if needed

Static pressures are higher or lower If higher, ductwork should be improved

than design If lower, fan RPMs should be lower

Blower rotation is incorrect Check rotation and correct

Motor voltage incorrect Check motor nameplate and supplied voltage

Motor horsepower too low See specifications and catalog for fan

curves to determine if horsepower is sufficient.

Shorted windings in motor Replace motor.

Insufficient airflow Unit damper not fully open Adjust damper linkage or replace

damper motor

System static pressure too high Improve ductwork to eliminate losses

using good duct practices

Blower speed too low Check for correct drives and RPMs

with catalog data

Dampers or registers closed. Open and adjust

Dirty or clogged filters Clean or replace

Leaks in ductwork. Repair

Elbows, or other obstructions

Correct or improve ductwork

may restrict fan outlet.

Belt slippage Adjust belt tension

Too much airflow Blower fan speed too high Check for correct fan RPM

Filter(s) not in place. Install filters

Insufficient static pressure (SP) Induce SP into system ductwork.

(airflow resistance)

Excessive noise Wheel rubbing on housing Center wheel

or vibration

Loose wheel on shaft Tighten wheel setscrew

Loose motor or blower sheave Tighten sheave setscrew

Belts too loose Adjust belt tension after 24 hours

of operation

Belts too tight Loosen to maintain 3/8” deflection

per ft. of span between sheaves

Worn belt Replace

Motor base or blower loose Tighten mountings bolts

Worn bearings Replace

Bearing and drive alignment Realign

Motor out of balance Replace

Wheel out of balance Replace or rebalance

Sheaves eccentric or out of balance Replace or rebalance

Accumulation of material on wheel Clean wheel and housing

Page 18

18

General Dimensions and Weights

PLAN VIEW

Motor

Control

Center

Optional

Filter/Heating

Section

Optional Heating Coil

Cooling Coil

110

1

/2

ELEVATION VIEW

88

Optional Curb

or Support

Blower/Motor

Access Door

50

1

/2

17

46

1

/4

Optional

Weatherhood

501/2 (NV-90)

62

(NV-120)

Optional Inlet

Damper

Optional Motorized

Damper

PLAN VIEW

Heat Pipe

Optional

Heating Coil

Optional Weatherhood

Optional Filters

ELEVATION VIEW

46

128 30

Optional Heating Coil

Cooling Coil

Motor Control

Center

52

Heat Pipe

NV-45 1680 lbs

NV-45 w/Heating Coil 1780 lbs

NV-90 2650 lbs

NV-120 3150 lbs

NV-90 w/Heating Coil 2870 lbs

NV-120 w/Heating Coil 3370 lbs

NV-90/120 250 lbs

Weatherhood

NV-90/120 200 lbs

Filter Section

NV-90/120 420 lbs

Filter Section w/Coil

Page 19

19

Maintenance

Greenheck recommends these procedures to insure trouble free operation of this unit. Most unit failures can be

attributed to poor setup or poor maintenance.

A record of maintenance performed on this unit should be kept. This information will provide essential information

if problems are encountered. A section at the back of this manual is provided for recording the unit's maintenance

history.

CAUTION: When performing any maintenance on this

unit be sure that the power is disconnected and cannot

be accidently turned on. The control center disconnect

can be locked in the off position .

2 weeks after startup

Check belt tension - Belts tend to stretch after a period of

time. They should be periodically checked for wear and

tightness. Approximately 3/8" of deflection per ft. of span

between sheaves is standard for belt tightness. When

replacing belts, use the same type as supplied with the unit.

Matched belts should always be used on units with

multigroove pulleys.

Replacement of belts - should be accomplished by loosening the tensioning device to the point where the belts

can be removed by hand. Do not force belts on or off as this may cause breakage of cords leading to premature

belt failure. Belts should be adjusted as shown above.

Every 3 Months

The filter in the unit should be inspected at least every 3 months. Depending on the environment filters could

require changing or cleaning more or less often. The filters can be slid out of either side of the unit.

If washable filters are installed, they can be washed in warm soapy water. An adhesive spray can be applied to

increase filter efficiency.

If disposable filters are installed, check by holding up to a light source. If light cannot pass through the filter, it

should be replaced. Replacement filters should be of the same manufacturer and size.

When reinstalling filters, be sure to install with the airflow in the correct direction indicated on the filter and with

any factory spacers that came with the unit.

Yearly

All bearings on units 108 to 118 are permanently lubricated and require no further lubrication under normal use.

Normal use being considered -20°F to 120°F and in a relatively clean environment. Units from sizes 120 to 220

should be checked monthly for lubrication.

Motor maintenance is generally limited to cleaning and lubrication (where applicable). Cleaning should be limited

to the exterior surfaces only. Removing dust and grease buildup on motor housing assures proper motor cooling.

Greasing of motors is intended only when grease fittings are provided. Many fractional motors are permanently

lubricated and require no further lubrication. Motors supplied with grease fittings should be greased in

accordance with manufacturer's recommendations. When motor temperature does not exceed 104°F (40°C), the

grease should be replaced after 2000 hours of running time as a general rule.

Wheels require very little attention when moving clean air. Occasionally oil and dust may accumulate on the wheel

causing imbalance. When this occurs the wheel and housing should be cleaned to assure smooth and safe

operation.

Routinely check all fasteners for tightness.

Belt Tension

Adjustment

Screw

Blower

Housing

Motor

Too Loose

Too Tight

R

o

t

a

t

i

o

n

NOTE: For motors of 1 HP or less a smaller sliding base

bracket is used to attach to blower.

Page 20

20

Job Information

Job Name:________________________________________

Address: _________________________________________

City: ________________ State: ________ Zip: __________

Phone: __________________ Fax: ____________________

Contact Person:___________________________________

Service Organization: ______________________________

Address: _________________________________________

City: ________________ State: ________ Zip: __________

Phone: __________________ Fax: ____________________

Work Done By: ____________________________________

Name Plate Information

Model: ___________________________________________

Volts: ___________ Hertz: __________ Phase:__________

Amps: __________________ Mark: ___________________

Supply Hp: _______________________________________

Serial Number: ____________________________________

Motor Voltage:

Motor Amperage:

Fan RPM:

Maintenance Documentation

Maintenance

Date Time Notes:

Field Start-Up Documentation

Actual Voltage: Hertz: Phase:

Actual Amperage:

Blower Rotation ❏Correct

Air Volume Design CFM

Actual CFM

NV-IOM-R

Loading...

Loading...