Page 1

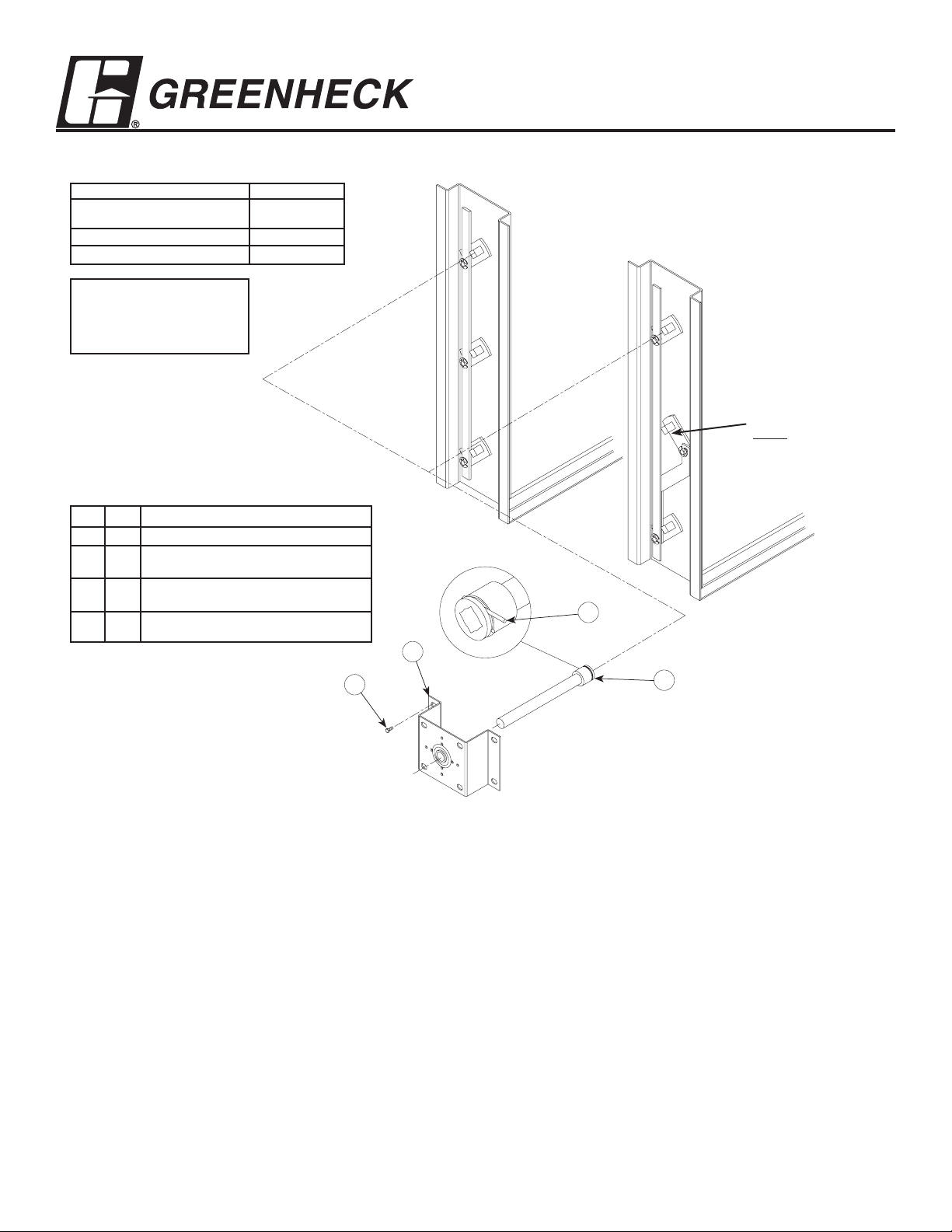

1

3

2

4

Kit Part Numbers

1

⁄2 in. Extension Pin Kit Part #809735

1

⁄2 in. Extension Pin Kit & Part #815607

Manual Quadrant Kit

1

⁄2 in. Manual Quadrant Kit Part #811518

1 in. Manual Quadrant Kit Part #813938

TOOLS REQUIRED:

5

⁄16 in. Hex Nut Driver

3⁄8 in. Electric Drill

1⁄2 in. Open End Wrench

1

⁄2 in. Extension Pin Kit Part Numbers

No. Qty. Description

1 4 Screws (by others)

2 1 Stand off bracket with ball bearing

Part #815027

3 1 Extended Control Shaft

Part #452509

4 1 Retaining Clip

Part #451738

Part Number 455049

Extension Pin Kit &

Manual Quadrant Operators

on Control Dampers

FIELD INSTALLATION INSTRUCTIONS

NOTE: FOR DAMPERS

INSTALLED IN DUCTS

Extended Control Shaft is

installed from outside of duct

after damper is installed.

Install as shown below.

Crossover Blade Axle

(Do not attach Control

Shaft here!)

Before Installing Damper in the Duct

1. If damper has more than one blade, determine which

blade axle will be driven by the extended control

shaft. Always attach extended control shaft to a blade

axle which is directly connected to the main linkage

tiebar. DO NOT attach extended control shaft to a

crossover blade axle.

2. Cut hole approximately 1 in. (25mm) diameter in

duct where damper drive blade axle will be located.

Hole must provide clearance for enlarged portion of

extended control shaft.

After Damper Is Installed in Duct

1. Push extended control shaft through hole in duct and

onto drive blade axle. Retainer clip should "click" into

groove on drive blade axle and hold shaft into place.

Standard Control Shaft location is the third blade

from the bottom on dampers with three or more blades.

Control Shaft location is the first blade from the bottom

on dampers with one or two blades.

2. Install the stand off bracket with bearing over the

extended control shaft and screw bracket to duct. Make

sure screws (provided by others) do not interfere with

damper linkage or blade movement.

Caution

Stand off bracket with bearing is needed to support

the extended control shaft. If not installed as directed,

the extended control shaft may not operate the damper

correctly.

Page 2

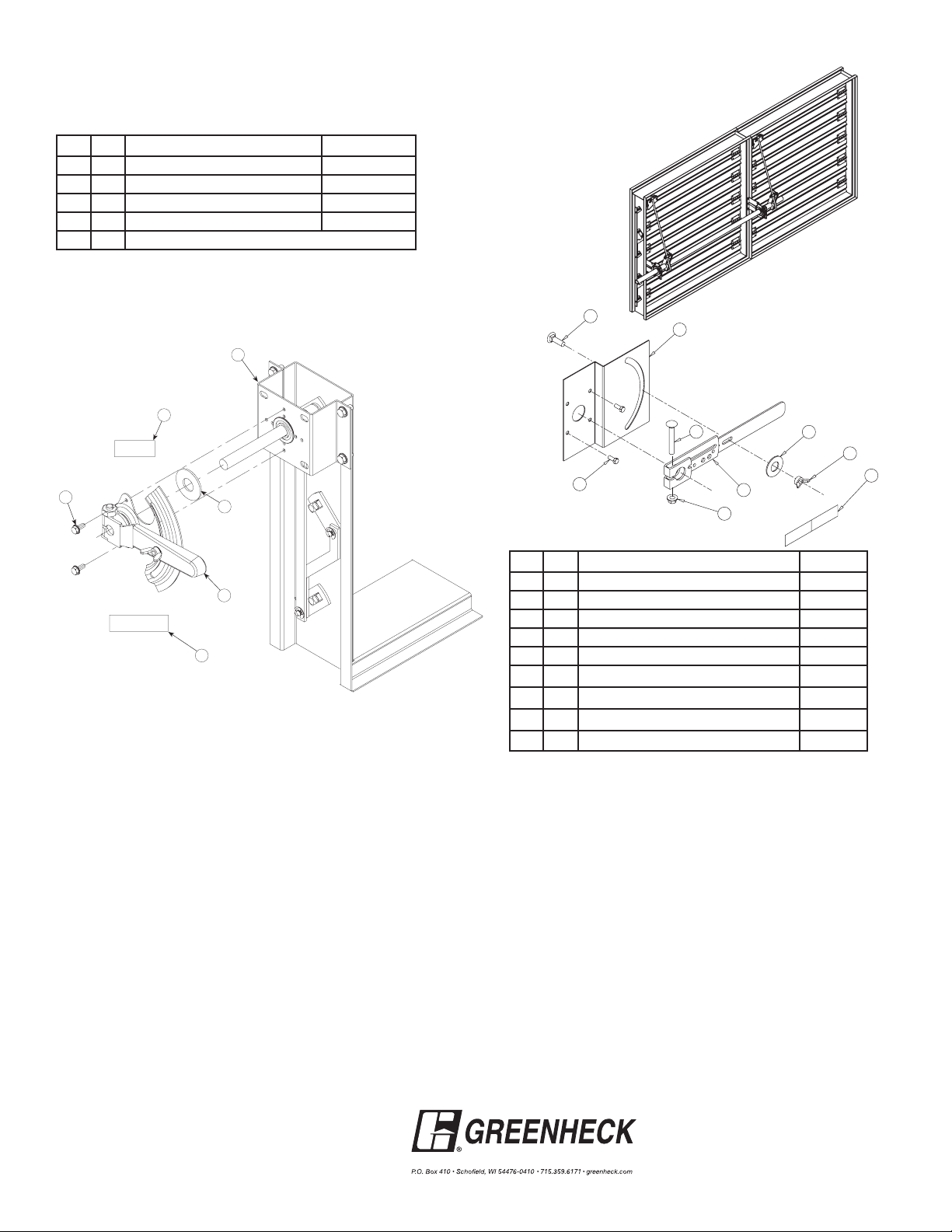

CONTINUED INSTALLATION INSTRUCTIONS for

1

3

2

4

CLOSED

OPEN

4

5

6

8

3

4

7

1

5

2

CLOSEOPEN

9

Manual Quadrant Operator

Manual Quadrant & Extension Pin Kit Part Numbers

No. Qty. Description Part Number

1 1 Extension Pin Kit Assembly See Page 1

2 2 #10 x

3 1 1⁄2 in. Dia. Manual Quadrant 455648

4 1 OPEN & CLOSED Labels 452690

5 1 Washer (included with Part #455648)

* The 1⁄2 in. manual quadrant kit (Part #811518)

does not include Item #1 above. Kit part #815607

includes both the 1⁄2 in. manual quadrant kit and the

1

⁄2 in. extension pin kit.

1

⁄2 in. Self Drilling SMS 415555

Jackshafted Damper

No. Qty. Description Part No.

1 1 1 in. Quadrant Bracket 649366

2 1 Quadrant Lever Arm Assembly 814406

3 1 3/8-16 Spinlock Nut ZP 415457

4 1 3/8-16 x 2.50 Carriage Bolt 415485

5 1 3/8-16 x 1 Short Shank Crg. Bolt 415820

6 1 3/8-16 Wing Nut 415821

7 4 1/4-20 1/2 Self Threading Screw 415264

8 1 Label - Open/Close 452690

9 1 5/8 in. Flat 415381

Non-jackshafted Dampers

Control damper should be mounted in the duct and the shaft

extension mounted onto the correct blade of the damper before

continuing with these instructions.

After Extended Shaft is Installed

1. Assemble Manual Quadrant to extension bracket

assembly (screws provided).

2. With damper either fully open or closed, lock manual

quadrant to extended control shaft so manual quadrant

can move damper between open and closed. Note:

Tighten down bolt on manual quadrant to 250 in. lb. of

torque. Apply "OPEN" and "CLOSED" labels if damper

movement is opposite to that engraved in the manual

quadrant.

Jackshafted Dampers

1. The jackshaft is, either, 1⁄2 in. diameter or 1 in.

diameter depending upon the size of the damper.

The manual quadrant kit for the 1⁄2 in. diameter

jackshaft is Part #811518 and the manual quadrant

kit for a 1 in. diameter jackshaft is Part #813938.

2. With damper either fully open or closed, lock

manual quadrant to jackshaft so manual quadrant

can move damper between open and closed. Note:

Tighten down bolt on manual quadrant to 250 in.

lb. of torque. Apply "OPEN" and "CLOSED" labels

if damper movement is opposite to that engraved

in the manual quadrant.

3. Set damper to desired position and tighten wing

nut on manual quadrant to hold damper in place.

3. Set damper to desired position and tighten wing nut on

manual quadrant to hold damper in place.

Extension Pin Kit and Manual Quadrant FS

Rev. 4 Aug 2008

Loading...

Loading...