Page 1

Fan Selection

Application-Based Selection

Performance Theory

Page 2

SELECTING THE RIGHT FAN FOR THE JOB

This book is designed to help you select the fan that will best

fit the application for which it is intended. With the large

number of different fan types and sizes available it's

necessary to know which fan model does the best job in

certain applications and then be able to select the most

economical fan size for the job.

With that in mind, this guide is constructed in three sections.

Section One describes how to select a fan using catalog

performance tables with a given air volume and static

pressure. This section also interprets Greenheck model

numbers and illustrates the relationship between fan speed

and airflow.

Section Two covers the basics of fan selection—determining

the proper fan model, air volume, static pressure and

loudness appropriate for a given application. This is

important when your customer does not know the amount of

air to be moved or the resistance to airflow that will be

encountered. This section also illustrates proper fan

installation and proper wheel rotation.

Section Three goes beyond fan selection with information

of a more comprehensive and technical nature about air

movement and air systems.

Page 3

TABLE OF CONTENTS

SECTION 1

INTRODUCTION TO FAN SELECTION

Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Model Designation . . . . . . . . . . . . . . . . . . . . . .4

Reading Performance Charts . . . . . . . . . . . . . .5

Matching a Specification . . . . . . . . . . . . . . . . .7

Cross Reference Chart . . . . . . . . . . . . . . . . . . .8

SECTION 2

FAN SELECTION BASED ON FAN APPLICATION

Basic Overview. . . . . . . . . . . . . . . . . . . . . . . . .9

Commercial Kitchen Ventilation . . . . . . . . . . .10

General Commercial Ventilation . . . . . . . . . . .12

High Static Pressure Ventilation . . . . . . . . . .15

Determining CFM . . . . . . . . . . . . . . . . . . . . . .16

Determining Static Pressure . . . . . . . . . . . . .17

Sound Levels . . . . . . . . . . . . . . . . . . . . . . . . .19

Motor Horsepower . . . . . . . . . . . . . . . . . . . . .19

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Wheel Rotation . . . . . . . . . . . . . . . . . . . . . . . .20

SECTION 3

FAN PERFORMANCE

Fan Dynamics . . . . . . . . . . . . . . . . . . . . . . . . .21

System Dynamics . . . . . . . . . . . . . . . . . . . . . .21

Combining Fan and System Dynamics . . . . . .22

Adjusting Fan Performance . . . . . . . . . . . . . .23

Fan Laws . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Page 4

INTRODUCTION TO FAN SELECTION

This is the first and most basic of this manual’s three

sections, all of which are designed to enable you to

select the right fan for the job. Look at this first section

as a “user’s manual” for Greenheck literature. It will

answer the following questions (and more): What is a

SONE? How are model numbers and performance

tables used to select a fan? How are direct drive and

Terms

cfm - Cubic Feet Per Minute. A measure of airflow.

Ps - Static Pressure. Resistance to airflow measured in inches of water gauge.

sone - A measure of loudness. One sone can be approximated as the loudness of a quiet

refrigerator at a distance of 5 feet. Sones follow a linear scale, that is, 10 sones are

twice as loud as 5 sones.

Bhp - Brake Horsepower. A measure of power consumption. Used to determine the proper

motor horsepower and wiring.

hp - Horsepower. Used to indicate a fan’s motor size.

rpm - Revolutions Per Minute. Measure of fan speed.

TS - Tip Speed. The speed of the tip of a fan wheel or prop measured in feet per minute.

AMCA - Air Movement and Control Association. A nationally recognized association which

establishes standards for fan testing and performance ratings. AMCA also licenses air

volume and sound certified ratings.

belt driven fans different? What types of motors and

accessories are used with these fans? Are there

Greenheck fans that will match the size and

performance of fans from other manufacturers? The

goal is to understand and use the Greenheck literature

as an important tool in filling a customer’s fan order.

Model Designation

For Greenheck belt drive models, the model

designation tells the model type, size and the motor hp.

EXAMPLE: GB-090-6

Model is GB hp is 1/6

Nominal Wheel Dia. 9 in.

For direct drive units, the model designation tells the

model type, the size and the motor/fan rpm.

EXAMPLE: G-121- B

Model is G rpm is 1140

Nominal Wheel Dia. 12 in.

4

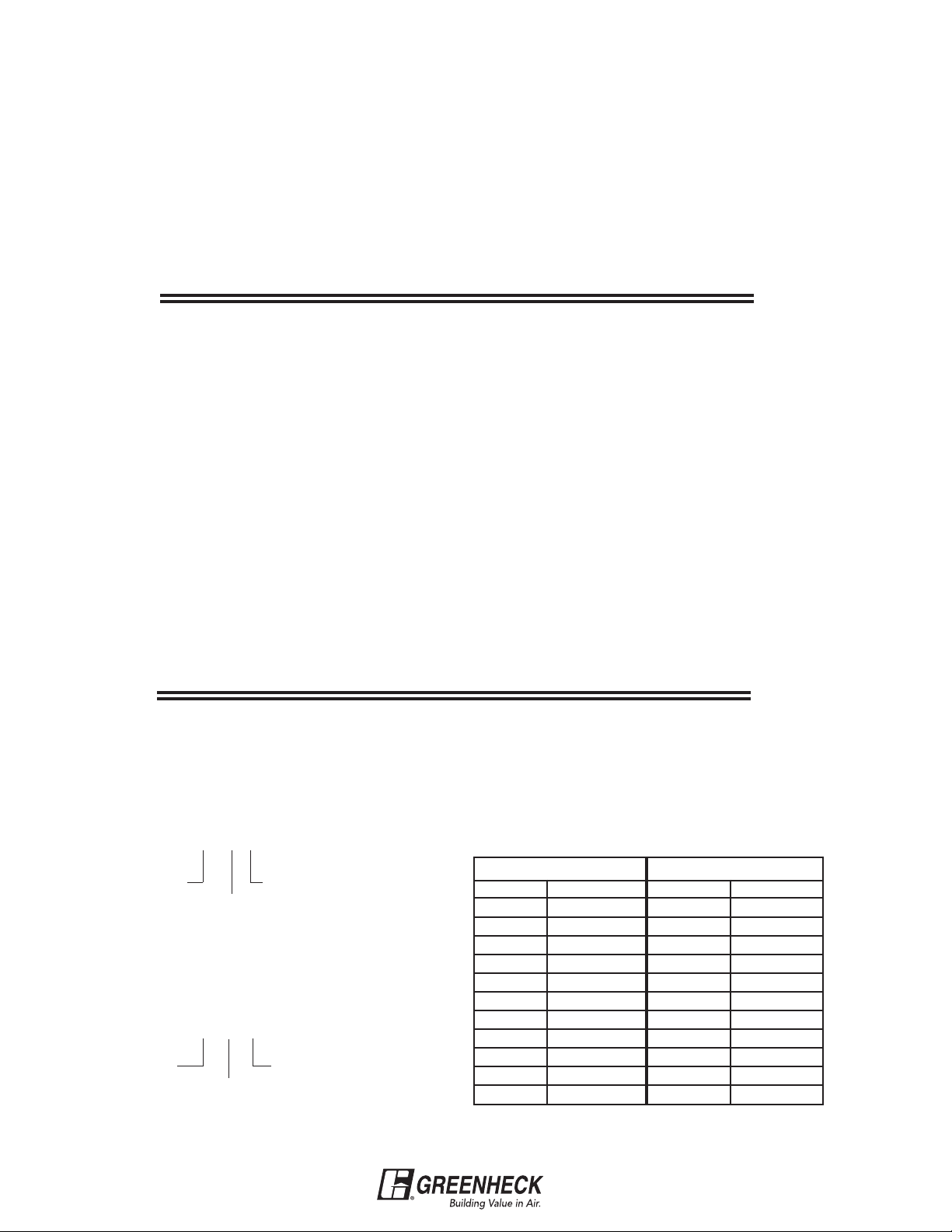

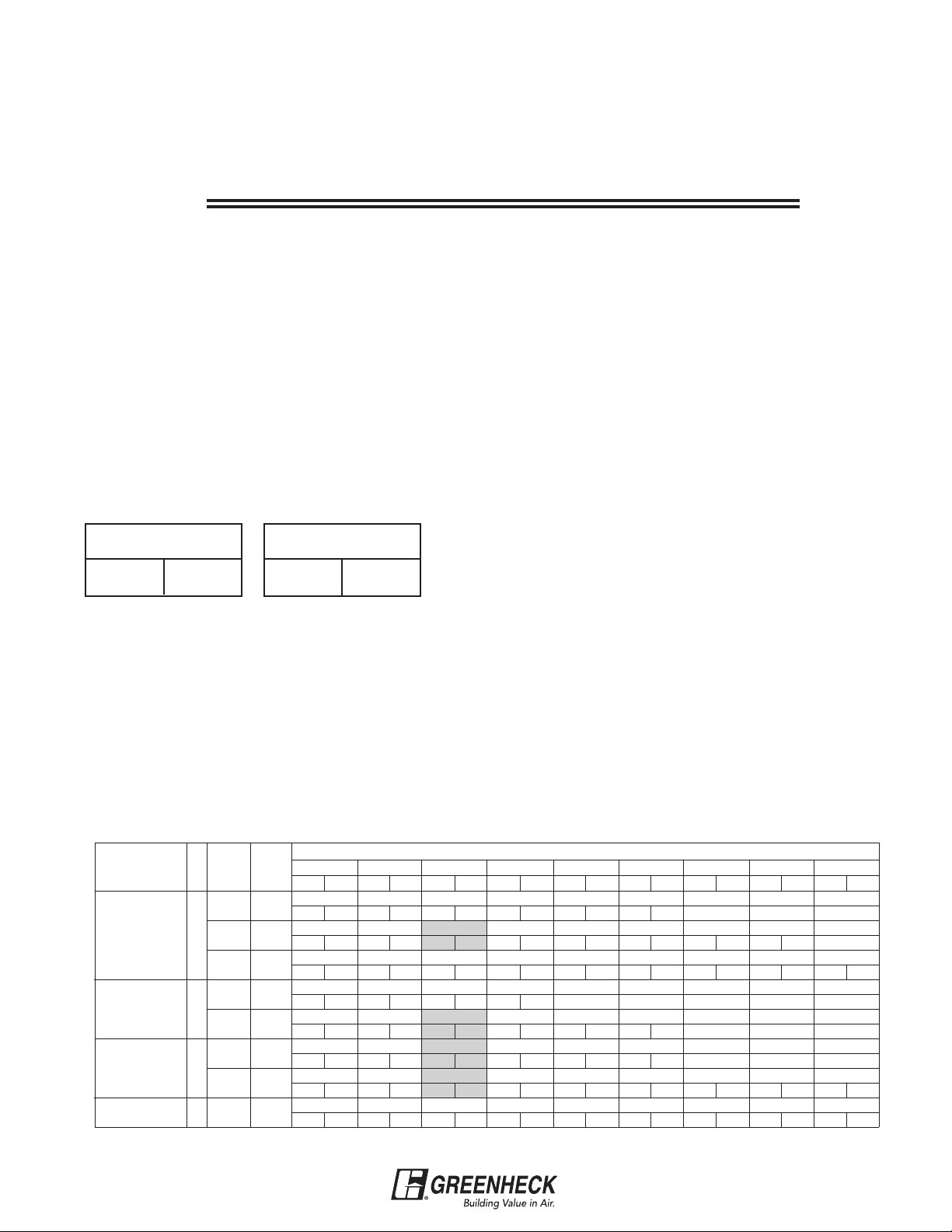

The table below lists model designation suffixes for

motor horsepower and fan rpm.

Belt Drive

Suffix Motor hp Suffix Fan rpm

6

4

3

5

7

10 1 E 1050

15 11/2 F 680

20 2 P 1625

30 3

50 5

75 71/2

1

/6 A 1725

1

/4 B 1140

1

/3 C 860

1

/2 D 1550

3

/4 G 1300

Direct Drive

Page 5

Reading Performance Charts

The most important part of selecting a fan is the ability

to read the performance charts. Most of the

performance charts in the catalog are similar and are

read in the same manner. Models RSF and BCF are

Belt Drive Selection

Assume that a job requires a belt drive roof exhauster

to move 1000 cfm against 0.25 in. Ps. Refer to the

performance model at the bottom of this page. Start at

the top of the chart with the 0.25 in. Ps column. (All

numbers in this column correspond to .25 in. Ps.) Now

follow the column downward until a value is found that

slightly exceeds 1000 cfm. In this case, 1012 cfm is the

first box that meets the requirements.

Note: Notice that each performance box is divided into

3 smaller boxes. The numbers refer to cfm, Sones and

Bhp.

Example:

CFM

Sone Bhp

At this performance point, the sone value is 11.1 and

the fan Bhp required is 0.16. Now by following the row

to the left, we can determine fan rpm and fan model.

In this case, the fan rpm is 1510 and the model is

GB-090-4 which has a 1/4 hp motor.

Notice that the GB-090-4 is not the only model to

choose from. If we follow the 0.250 in. Ps column down

further, we find a performance point at 1010 cfm.

1012

11.1 0.16

exceptions to this rule. The selection procedure for

these models is handled separately. Direct drive and

belt drive fans are also addressed separately.

At this point, the sone value is 7.9 and the Bhp is 0.14.

Following across to the left we find the rpm to be 1355.

The model is GB-101-4-R1, which also has a 1/4 hp

motor.

Both the GB-090-4 and the GB-101-4-R1 will perform

the air movement task equally as well. However, the

sound generated by the fan may have to be

considered. Compare the sone values: 7.9 sones for the

GB-101 and 11.1 for the GB-090. The GB-101 is about

30% quieter. Where a low sound fan is required, the

GB-101 would be a better selection. If loudness is not a

factor, the GB-090 would be a better selection because

it is less expensive.

Another possibility for this particular selection is a

GB-100-4-R2. Even though there is no performance

box showing close to 1000 cfm, there are two

performance boxes that bracket 1000 cfm. At 921 cfm

the fan will be running at 1260 rpm. At 1269 cfm the fan

will be running at 1635 rpm. Therefore, there is an rpm

for this model that will correspond to 1000 cfm

(obviously somewhere within the 1260-1635 rpm

range). As with all Greenheck belt drive fans,

intermediate cfm values are easily achieved by

adjusting the motor pulley (see illustration on next

page).

Table 2

MODEL

(rpm RANGE)

GB-090-4

(1290-1710)

GB-101-4-R1

(1020-1400)

GB-101-4-R2

(1260-1635)

GB-101-3

hp

1/4

1/4

1/4

1/3

RPM

1360 3983

1510 4422

1710

1070 3116

1355 3946

1260

1635

1800 5242

TS

5008

3669

4761

STATIC PRESSURE / CAPACITY

0.000 0.125 0.250 0.375 0.500 0.625 0.750 0.875 1.000

Sone Bhp Sone Bhp Sone Bhp Sone Bhp Sone Bhp Sone Bhp Sone Bhp Sone Bhp Sone Bhp

1030

10.1 0.11 9.9 0.12 9.6 0.12 9.3 0.12 8.8 0.13 8.5 0.13

1144

0.15 11.2 0.16 11.1 0.16 10.7 0.17 10.4 0.17 10.0 0.17 9.8 0.17 9.5 0.17

11.4

1295 1237 1179 1121 1061 999 934 866 785

13.4 0.22 13.3 0.23 13.2 0.23 13.0 0.24 12.7 0.24 12.4 0.25 12.1 0.25 11.8 0.25 11.6 0.25

906

6.0 0.060 5.4 0.065 5.0 0.070 4.3 0.070

1148 1077 1010 943 856 739

0.12

8.5

1067 991 921 840 735 385

0.099 7.1 0.104 6.8 0.112 6.5 0.115 5.9 0.115 4.4 0.083

7.6

1385 1325 1269 1214 1161 1094 1019 928 792

11.1 0.22 10.8 0.22 10.4 0.23 10.2 0.24 9.8 0.25 9.3 0.25 8.9 0.25 8.4 0.25 7.8 0.24

1525 1471 1418 1367 1320 1270 1208 1141 1064

0.29

13.2

8.1

12.8

957

1078

818

0.13

0.30

884

1012 946 875 800 720 607

731

7.9 0.14 7.8 0.14 7.2 0.14 6.8 0.14

0.30

12.5

807

607

0.31 12.2 0.33 11.3 0.33 10.8 0.33 10.6 0.33 10.1 0.33

12.3

725

632

5

Page 6

One advantage of choosing the GB-101-4-R2 over the

GB-101-4-R1 is that it is capable of running at higher

rpm’s, which enables the fan to move more air if

necessary.

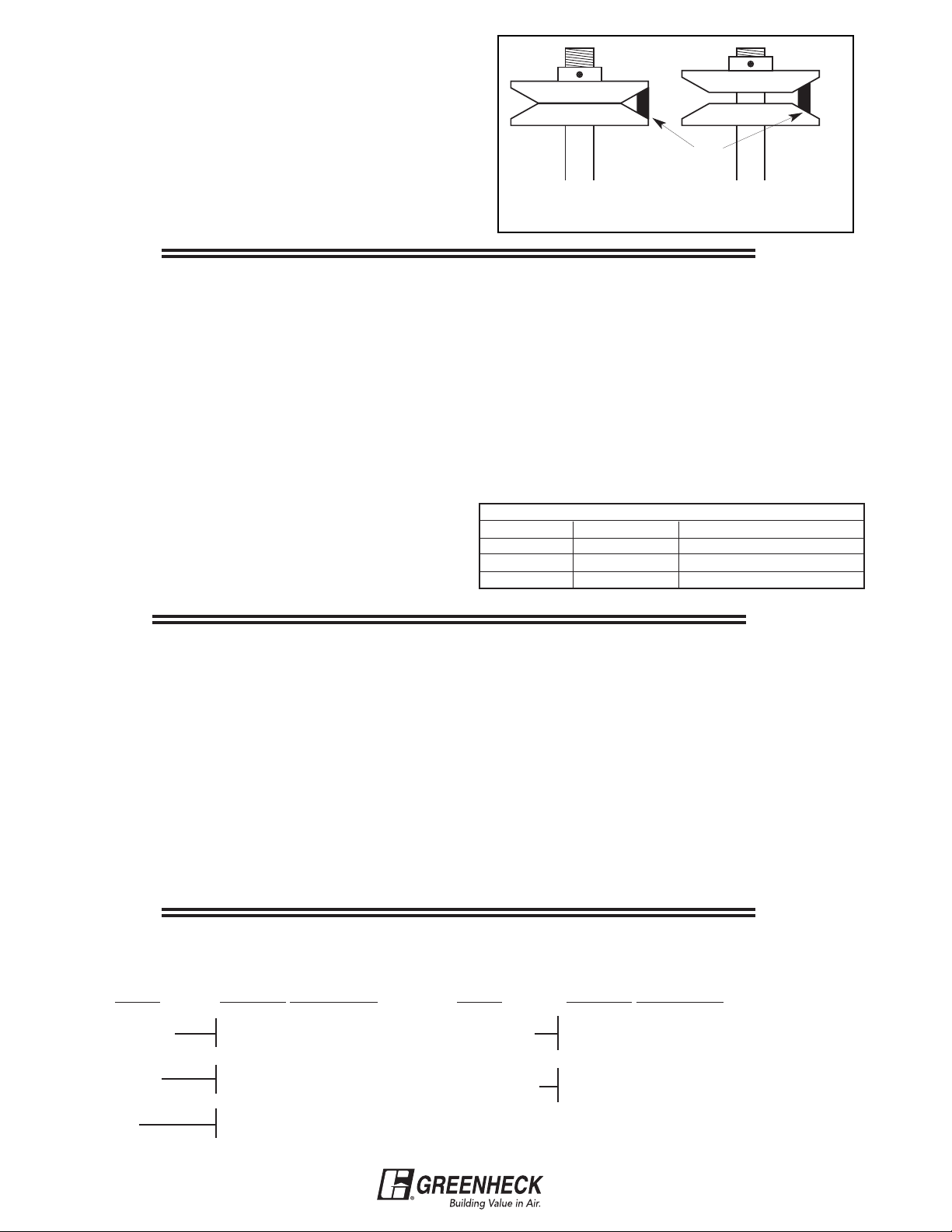

Motor pulleys are adjusted by loosening the set screw

and turning the top half of the pulley (see illustrations at

right). This causes the pulley diameter to change, which

results in changing the fan rpm.

Direct Drive Selection

Selection of direct drive fans (those with the motor shaft

connected to the fan wheel or propeller) is nearly the

same as belt drive selection. However, there are two

differences worth noting. Where belt drive fan speed

can be altered by adjusting the motor pulley, direct

drive fans (since they have no pulleys) must use a

different method.

1. To adjust a direct drive fan's speed (also motor

speed) or to provide a means of meeting an exact

performance requirement, a speed control can be

furnished. Speed controls vary the voltage supplied

to the fan and slows it down; a principle similar to

the way dimmer light switches work.

Belt

Opening the pulley decreases fan rpm.

Closing the pulley increases fan rpm.

2. Models CUE and CW, sizes 060-095 and Model SQ,

sizes 60-95, are provided with 115 volt, 60 cycle

motors. The three speeds are 1550 rpm (D), 1300

rpm (G) and 1050 rpm (E). Changing a motor lead is

all that is necessary to change speeds. When

selecting a model with 3 speed motors, it is

recommended that the G speed be chosen whenever

possible. This is the middle speed, which gives the

greatest flexibility in air volume because airflow can

be increased or decreased simply by changing a

motor lead.

Typical Motor Tag

Electrical Instructions

Suffix Letter Motor Speed Wiring Connections

D 1550 rpm White to L1 Black to L2

G 1300 rpm White to L1 Blue to L2

E 1050 rpm White to L1 Red to L2

Motor Information (Belt Drive Only)

When specifying a belt drive fan, the model designation

does not completely describe the unit. Additional

information about the motor is necessary. These items

are listed below:

Motor Enclosure

This will be either “Open” (open, drip proof), “TE”

(totally enclosed) or “EXP” (explosion resistant). Open

is the most common and will be supplied unless

otherwise specified.

Speeds

Motors are available in either single speed or two

speed. Single speed motors are 1725 rpm. Two speed

motors will be 1725/1140 rpm. Single speed will be

supplied unless otherwise specified.

Electrical Characteristics

Voltage and phase. Voltage can be 115, 208, 230 or

460. Phase is either single or 3 phase. A 115 volt, single

phase motor is shown as 115/1. Typically, motors of

1/2 hp and less are single phase. Motors of 3/4 hp and

greater are 3 phase.

Accessories

Most fans are ordered with accessories. Here are some common accessories for selected models:

Model Common Accessories

G & GB

CUBE

SB

Roof Curb

Backdraft Damper

Roof Curb

Grease Trap

Wall Mount Housing or

Wall Mount Collar

Model Common Accessories

SP & CSP

SQ & BSQ

Speed Control

Discharge Vents

Backdraft Damper

Vibration Isolators

6

Page 7

Matching a Specification

There will be times when a Greenheck model will have

to be matched to a competing manufacturer’s unit. To

aid in these circumstances, we have provided a cross

reference chart which includes our nine most common

competitors. If the manufacturer you need is not on this

chart, contact Greenheck for assistance.

To use the cross reference chart, on next page, start

with the manufacturer at the top. Then follow down

until the model in question is found. Follow across to

the left to determine which Greenheck model is

equivalent. Once this is determined, refer to the

Greenheck catalog to find the best size to meet the

specified performance.

Hint: Typically, when matching a Greenheck fan to a

competitive model, the size should also be matched. If

you are unsure of the size of the competitive unit,

compare fan rpm. Fans of equal size should move

approximately the same amount of air.

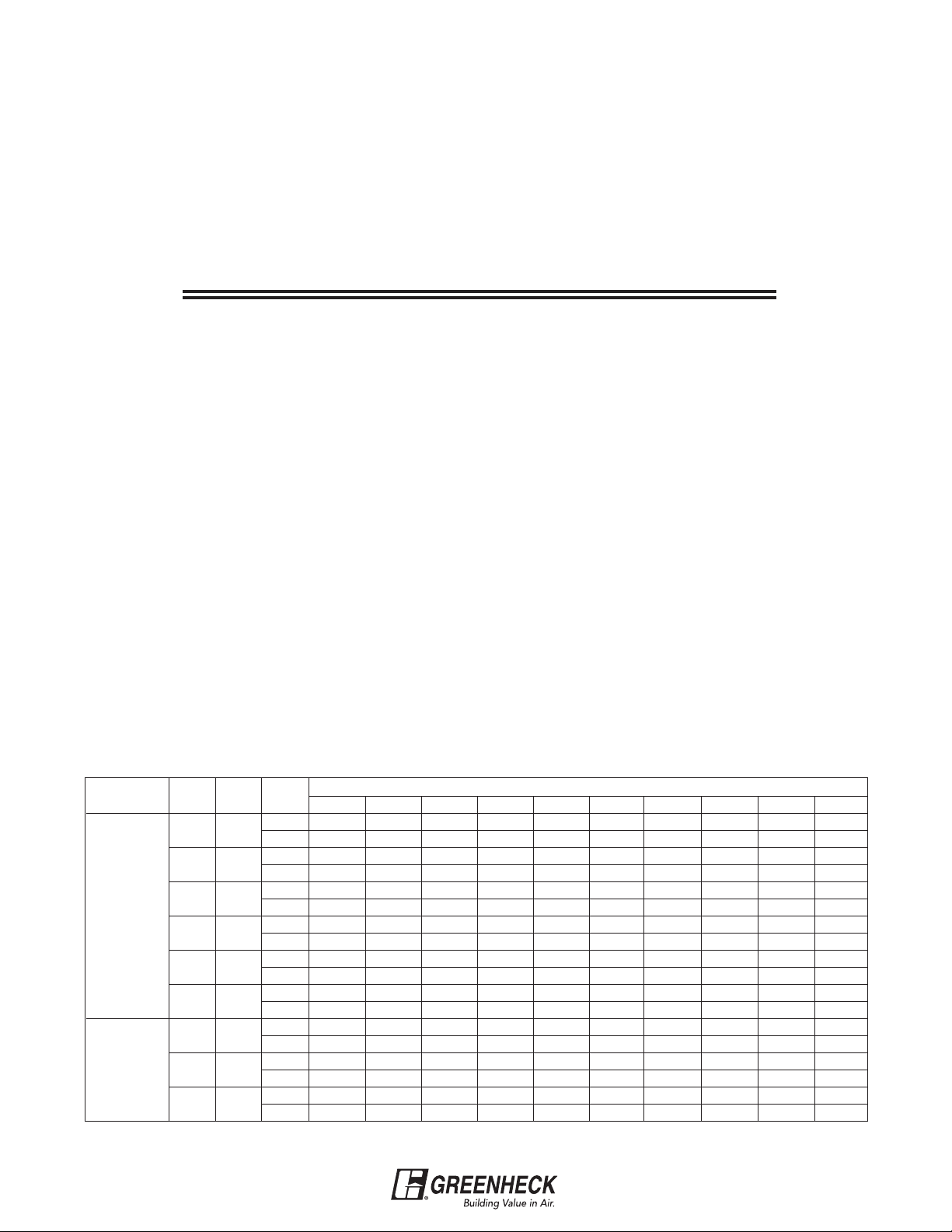

Model RSF and BCF Selection

The RSF and BCF selection charts are different from all

other selection charts. For these models, the cfm

values are at the left side of the chart in a single column

and the rpms are in the performance boxes. It is just the

opposite for other models. The reason for this is that

the RSF and BCF models are forward curved, and the

fan industry historically catalogs forward curved fans in

this fashion.

Sample problem:

Choose the fan size and appropriate motor horsepower

to move 980 cfm against 0.625 in. Ps.

Solution: (Refer to table below)

The first row in the chart corresponds to 980 cfm.

Follow across to the right to the 0.625 in. Ps column.

The performance box reveals that size 90 will meet this

performance at 893 rpm and will require 0.20 Bhp.

Motor hp selection for forward curved fans is more

complicated. The Bhp is only 0.20, which suggests that

a 1/4 hp motor is adequate. However, forward curved

fans draw more horsepower at low Ps than at high Ps.

Assume this fan was running at about 893 rpm, but

instead of 0.625 in. Ps, it was operating at only 0.25 in.

Ps. The new performance box in the 0.25 in. Ps column

reveals 894 rpm at 0.45 Bhp. The airflow would then be

1860 cfm.

Notice that as the Ps was reduced from 0.625 in. to 0.25

in., the Bhp increased from 0.20 to 0.45. This would

burn out the 1/4 hp motor quickly. With this in mind, it is

good practice to size RSF and BCF motors at least one

size larger than necessary based on the Bhp value in

the performance box, especially if the estimated Ps is

questionable.

For this case, an RSF-90-3 (1/3 hp motor) would be a

good selection if we had confidence in the estimated

Ps. Otherwise, use an RSF-90-5 (1/2 hp motor).

RSF-90-4 (1/4 hp motor) is not recommended for this

job.

MODEL

RSF-90

RSF-100

CFM

980 1065

1200

1420 1543

1640 1783

1860 2022

2080 2261

1240 1097

1780

2140

OV

1304

1575

1894

rpm

Bhp

rpm

Bhp

rpm

Bhp

rpm

Bhp

rpm

Bhp

rpm

Bhp

rpm

Bhp

rpm

Bhp

rpm

Bhp

STATIC PRESSURE / CAPACITY

0.125 0.250 0.375 0.500 0.625 0.750 1.000 1.250 1.500 1.750

521 630 725 812 893 967

0.08 0.11 0.13 0.16 0.20 0.23

593 685 771 849 925 994 1125

0.13

668

0.19 0.23 0.27 0.31 0.35 0.39 0.48 0.57 0.67

746 819 887 953 1016 1077 1191 1298

0.28

828 894 954 1014 1073 1128 1236

0.40 0.45 0.50 0.55 0.60 0.65 0.76

910 970 1027 1080 1134

0.54 0.60 0.66 0.71 0.77

476 572 656 733 807 876

0.10

605 679 748 813 873 931 1040 1143 1240

0.24 0.29 0.33 0.38 0.42 0.47 0.56 0.66 0.77

699

0.40 0.45 0.50 0.56 0.61 0.67 0.78 0.89 1.00 1.12

0.16 0.19 0.23 0.26 0.30 0.38

747

0.33

0.13

763

825

0.37

0.16

823 880 935 989 1086 1181 1269 1354

898

0.42 0.46 0.51 0.61 0.71

0.19

966

0.23

1031

0.27

1153

1267 1371

7

Page 8

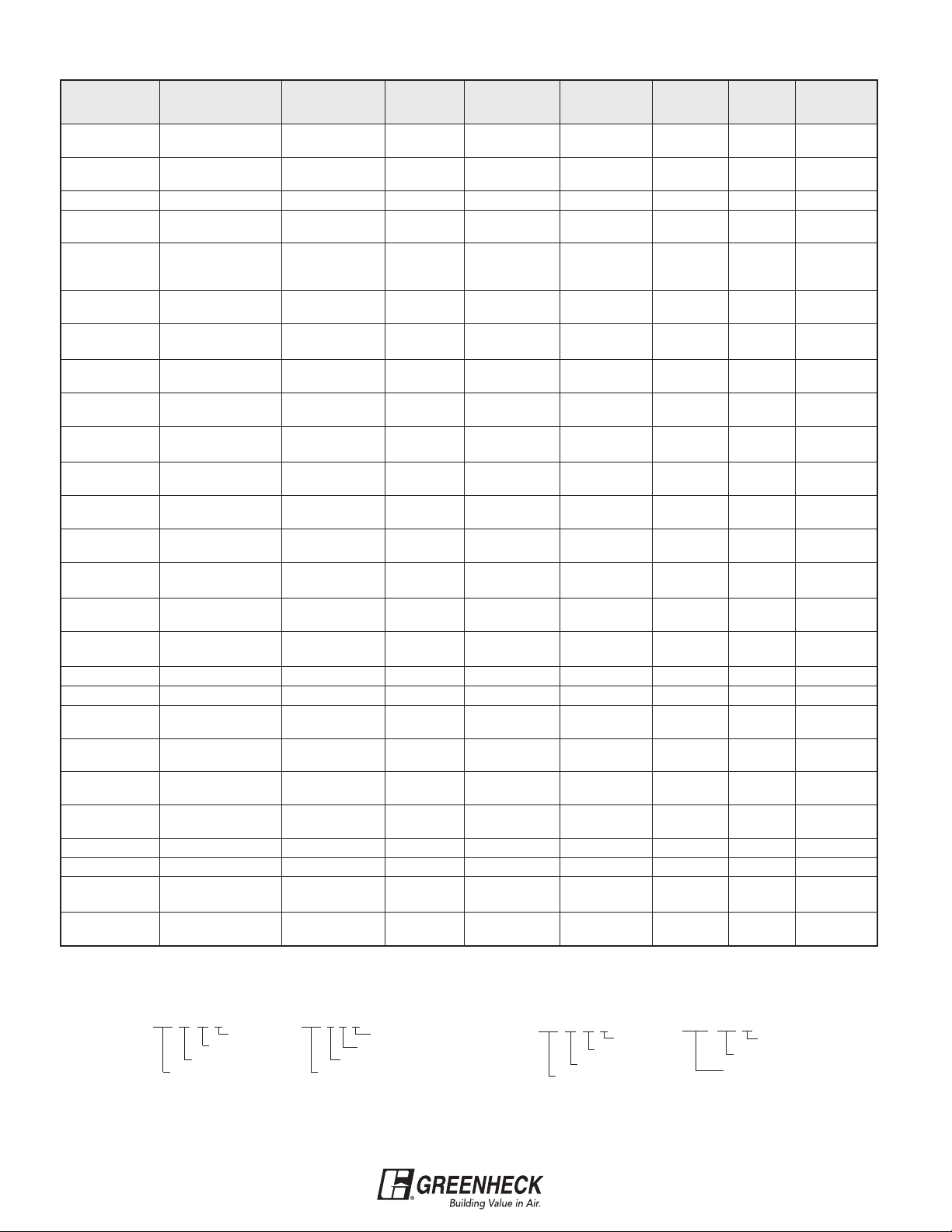

Cross Reference Chart

(Models in italics refer to older models)

Greenheck

G

CE,CX,CH

GB

CDE, CBX

Cook

Updated 12-7-2004

ACED

C-D,CVD,TCD

ACEB

C-B,TCB,UCB

Penn Acme

Domex DX

XQ,XR,AT,AW

Domex DXB

KB,JB,MB,AB,LB

PRN CRD VEDK

PN,PNN,PV NBCR

CUE ACRUD, VCRD Fumex FX PDU n/a VUDK CUD, UBD n/a DU

CUBE

UCBE,UCBH

CW

SW,GW

CWB

GWB

ACRUB,VCR

URB,R-B,BTD

ACWD

CW

ACWB

CWB,TWB

SP Gemini GC Zephyr

CSP Gemini Inline GN Zephyr

SQ

DSQ,SQD

SQID,SQND

CV-D

BSQ SQIB,SQNB,

Fumex FXB

FMXB

Fumex WFX

Domex

WX,WA,WB

Fumex WFXB

Domex WCB,WLB

PNU

PUB,PU,PUH

PDU-W

PW

PNU-W

PWB

VQ/VQL J,EC,L VCDB,VCDC,

Z, (RA,TD)

VQ/VQL n/a VCDB IL DCF n/a

Z, (TDA)

Centrex SX XD ISD

Centrex SX-BC XB ILB VIBK

SQN-HP

SE/SS

SDE

SWD

SD

P FQ GDW

SCE/SCS AWD BC FN n/a LRDA,LNDA CDC HV, HVE

SBE/SBS

SPFE/SPFS

SBE/SBS-3

SPNE/SPNS

XLW,XMW

SWB SPB

BBK,BFL DC TBW LWBK,LMBK

XLWH,XMWH BF DCH LBW LJDB, LKDB,

SBCE/SBCS AWB BC,BAT DCK, K HBW LRBA,LNBA CBC HA

RBS/RBE

RPE,RPS

HXSL, HXSM,

HXEL, HXEM

AF EC/EC-S n/a LTBA,LGBA PB n/a n/a

RBCE/RBCS HEE,HES AC EC, ECH HBRE,HBRS n/a PBC n/a n/a

RE/RS HEE-D/HES-D AF n/a n/a LTDA,LGDA PD n/a n/a

RBU

PBU,PUB

LEU, LXUL, LXUM

AVB,VB

HF,HS,HZ

(cast)

UBG BRU LUBA JBH,JBC

RBUMO SUBH, SUB HX UBH available LUKA n/a RUBDX

RDU AUD HZ,HC UD DRU LUDA JDC UP

RSF ASP

CFS

Muffan MU AFSN

PLS

RSFP ASP-T n/a AFSL n/a VHBB n/a n/a n/a

SFD CPF-D n/a FCE FCD n/a n/a UDF n/a

SFB CPF-B n/a FCF, FCD,

FCA

SWB CPV,CPS Dynamo D,QX

GWB

QBR JVS VBBA VSBC UXB BI

Jenn

(Breidert)

(Stanley)

Carnes

VEDB,VEDC

VEBK

BCR

NBTD

NBRTD

VEBC

VUBK,VRBK

VUBB,URBA

CWD VWDK

VWDB

NBTD

NBRTD (UL 762)

VWBK

VWBB

VCDD

VIDK

ILD

VIDB,AMDA

COOLAIR

(ILG)

AirMaster

(Chelsea)

CRD CDD

RDD

CRB

LSB

UBC,CUB

CVB

CWD

CWF

CBD

RDB

CBU

CUBA

CDU

WDC

CWB CBU

WBC

CF NCF

CF

SQDA

CLD

n/a CVIDK

Captive Aire

DR

DD

NCA

DU

NCA

CFA

SQBA SBCL CVIBK

VIBA

HDW,FDW

LYDK,LZDK

LWDA

UDU/UDFPVEPR

WFA

C-EPR

n/a

PLFA

TYPE T

CBL,CBHPFHA

IND, FHA

CPB

CBHX n/a n/a

LRDA, LNDA

n/a

IND

(cast)

UPB

RUBA

CUPB

n/a

(cast)

CUPD

RUDA

BCFS VSBB

VSBA

CFS CAS n/a

FCB VFBA VSFC UXF n/a

(Flow Air)

Competitor Model Number Deciphering Hints

Cook-

Direct Drive

120 W 10 D

Direct Drive

rpm x 100

Model ACW

Wheel Size

Letter Designations

C=ACE (G,GB)

R=ACRU (CUBE)

W=ACW (CW,CWB)

V=VCR (CUBE)

Belt Drive

150 V 6 B

Belt Drive

3/4 hp

Model VCR

Wheel Size = 15 in.

Horsepower Designations

/4

3

=1/6 hp

2

3=1/4

4=1/3

=1/2

5

=

6

7=1

8=1

=

9

1

/2

2

8

=

0

1

11=5

12=7

Acme -

Direct Drive

PW 135 A 8

860 rpm

1/20 hp

Wheel Size =13.5 in.

Model PW

Direct Drive rpm Designation

3

1

/2

8 = 860 rpm

6 = 1160 rpm

4 = 1725 rpm

Belt Drive

PNN 163 G

1/2 hp

Wheel Size = 16.3 in.

Model PNN

Horsepower Designation

1/20 hp

=

A

B=1/12

C=1/8

1/6

=

D

E=1/4

=

F

G=1/2

H=3/4

=

J

K=1

1/3

1

2

=

L

M=3

N=5

1

7

=

/2

P

1

/2

R=10

Page 9

FAN SELECTION BASED ON FAN APPLICATION

Basic Overview

Ventilating a building simply replaces stale or foul air

with clean, fresh air. Although the ventilation process is

required for many different applications, the airflow

fundamentals never change:

Undesired air out, fresh air in

The key variables that do change depending on

applications are the fan model and the air volume flow

rate (cfm). Other considerations include the resistance

to airflow (static pressure or Ps) and sound produced

by the fan (Sones).

Fan specification is usually not a precise science and

can be done confidently when the fan application is

understood.

Based on the application, four parameters need to be

determined. They are:

1. Fan Model

2. cfm

3. Static Pressure (Ps)

4. Loudness limit (sones)

Occasionally, a customer will require a fan to perform a

particular function, yet does not know which model to

use or even what cfm is necessary. In this case, some

fan specification work must be done.

Fan Model

Fans all perform the basic function of moving air from

one space to another. But the great diversity of fan

applications creates the need for manufacturers to

develop many different models. Each model has

benefits for certain applications, providing the most

economical means of performing the air movement

function. The trick for most users is sorting through all

of the models available to find one that is suitable for

their needs. Here are some guidelines.

The information that follows will help walk you through

this type of problem and enable you to select the right

fan for the job.

Propeller vs. Centrifugal Wheel

Propeller fans provide an economical method to move

large air volumes (5,000+ cfm) at low static pressures

(0.50 in. or less). Motors are typically mounted in the

airstream which limits applications to relatively clean

air at maximum temperatures of 110°F.

Centrifugal fans are more efficient at higher static

pressures and are quieter than propeller fans. Many

centrifugal fan models are designed with motors

mounted out of the airstream to ventilate contaminated

and high temperature air.

Direct Drive vs Belt Drive

Direct drive fans are economical for low volume (2000

cfm or less) and low static pressure (0.50 in. or less).

They require little maintenance and most direct drive

motors can be used with a speed control to adjust the

cfm.

Belt drive fans are better suited for air volumes above

2000 cfm or static pressures above 0.50 in..Adjustable

pulleys allow fan speed and cfm to be adjusted by

about 25%. High temperature fans (above 120°F) are

almost always belt driven.

Fan Location

Fan models are designed to be mounted in three

common locations: on a roof, in a wall, or in a duct.

Whatever the location, the basic fan components do

not change. Only the fan housing changes to make

installation as easy as possible.

Determining the best location for a fan depends on the

airflow pattern desired and the physical characteristics

of the building. By surveying the building structure and

visualizing how the air should flow, the place to locate

the fan usually becomes evident.

Examples of fans installed in common applications are

illustrated on the following 6 pages. Even if you come

across an application that is not shown in this manual,

the concepts remain the same.

9

Page 10

Commercial Kitchen Ventilation

Recommended Exhaust Fans

Model CUBE Model USGF Model CWB Model SWB

Belt Drive Belt Drive Belt Drive Belt Drive

Upblast Roof Exhaust Upblast Roof Exhaust Sidewall Exhaust Utility Blower

300-30,000 cfm 300-7,000 cfm 300-12,000 cfm 500-30,000 cfm

Up to 5.0 in. wg Up to 3 in. wg Up to 2.75 in. wg Up to 5.0 in. wg

The above models are designed for exhausting dirty or grease laden air up and away from the roof line or away

from the wall in commercial restaurant applications. All three models are UL 762 listed for restaurant applications

and for operation with air temperatures up to 300°F.

Recommended Supply Fans

Model DG

Direct Gas-Fired

Make-Up Air

800-15,000 cfm

Up to 2.0 in. wg

Model RSF

Filtered Roof Supply

650-14,300 cfm

Up to 2.0 in. wg

Model IG

Indirect Gas-Fired

Make-Up Air

800-7,000 cfm

Up to 2.0 in. wg

Model BSQ Model SQ

Belt Drive Inline Direct Drive Inline

150-28,000 cfm 120-5,000 cfm

Up to 4.0 in. wg Up to 1.75 in. wg

Model TCB

Belt Drive Inline Fan

Roof Upblast, Supply

360-24,000 cfm

Up to 4.5 in. wg

The above models are designed to provide efficient economical make-up air to replenish the air exhausted

through the kitchen hood. Provisions for make-up air must be considered for proper kitchen ventilation.

10

Page 11

Commercial Kitchen Ventilation

This drawing shows a commercial kitchen with a typical

kitchen ventilation system consisting of a roof mounted

CUBE upblast exhaust fan and a Model RSF supply fan.

Exhaust fan variations include the model CWB sidewall

exhaust fan (also shown) when penetrating the roof is not

practical. The Model SWB utility blower is recommended

when higher static pressure capability is required to pull

exhaust through long duct runs (typically 3 stories or

more).

Fan Sizing

Exhaust

When not specified by local codes, the following guidelines may be used

to determine the minimum kitchen hood exhaust cfm. Some local codes

require 100 cfm/ft.2 of hood area for wall style hoods.

Supply

Recommended supply airflow is 90% of

exhaust cfm. The remaining 10% of

supply air will be drawn from areas

adjacent to the kitchen, which helps

prevent undesirable kitchen odors from

drifting into areas such as the dining

room.

NFPA Considerations

The National Fire Protection Association specifies

minimum distance criteria for restaurant exhaust and

supply fans as shown below:

10 ft. Horizontal Separation

1. Roof deck to top of exhaust fan windband - 40 in. min.

2. Roof deck to top of curb - 18 in. min.

3. Supply fan intake - 10 ft. min. from all exhaust fans.

3 ft. Horizontal Separation

For applications where the 10 ft. horizontal distance

cannot be met, vertical separation between exhaust and

supply must be at least 3 feet.

Light Duty Oven, Range, Kettle 50

Medium Duty Fryer, Griddle 75

Heavy Duty Charbroiler, Electric Broiler 100

Static pressure typically ranges from .625 in. to 1.0 in. for 1 story buildings.

Type of Cooking Equipment cfm/ft.2 of Hood

11

Page 12

General Commercial Ventilation

Model G

Direct Drive Roof Exhaust

90-3,200 cfm

Up to 1.0 in. wg

Model GB

Belt Drive Roof Exhaust

80-44,700 cfm

Up to 3.25 in. wg

The above models are designed for exhausting relatively clean air at temperatures up to 130°F. Motors

are out of the airstream. Direct drive sizes 60-95 are equipped with 3-speed motors for maximum airflow

flexibility. All direct drive units except 1725 rpm (A speed) can be used with a speed control.

Model CW

Direct Drive Wall Exhaust

80-6,000 cfm

Up to 2.25 in. wg

Model CWB

Belt Drive Wall Exhaust

300-12,000 cfm

Up to 2.75 in. wg

Model SP

Ceiling Exhaust Fan

50-1,600 cfm

Up to 1.0 in. wg

Model CSP

Inline Cabinet Fan

100-3,800 cfm

Up to 1.0 in. wg

Models SP and CSP are designed for exhausting relatively

clean air at temperatures up to 110°F. Motors are in the

airstream. All models are direct drive and can be used with

a speed control.

Model BSQ

Belt Drive Inline Fan

150-28,000 cfm

Up to 4.0 in. wg

Model SQ

Direct Drive Inline Fan

120-5,000 cfm

Up to 1.75 in. wg

Models SQ and BSQ are versatile

fans that can be used for exhaust

or supply and can be mounted in

any position. Two removable side

panels provide access for service.

12

Page 13

Typical Commercial Ventilation Installations

13

Page 14

Model SB

Belt Drive

Propeller Sidewall

3,600-85,000 cfm

Up to 1.0 in. wg

General Industrial Ventilation

Model RBU

Belt Drive

Propeller Upblast

4,000-65,000 cfm

Up to 1.0 in. wg

Model RB

RBS-Supply

RBE-Exhaust

RBF-Filtered

Belt Drive Propeller Roof

2,000-86,500 cfm

Up to 1.5 in. wg

Model RBUMO

Belt Drive

Propeller Upblast

3,000-60,000

Up to 1.0 in. wg

Typical Applications

Propeller fans are ideal for ventilating high air volumes at low static pressures (0.50 in. or less). Industrial

applications often include factories and warehouses. A variety of fan models offer flexibility for roof or wall mount

as well as exhaust or supply. However, because the motors are mounted in the airstream, these models are not

recommended for temperatures above 110°F.

14

Page 15

High Static Pressure Ventilation

Model SWB

Belt Drive Utility Blower

500-30,000 cfm

Temperatures up to 400°F

Up to 5.0 in. wg

Model BSQ

Belt Drive Inline Fan

150-28,000 cfm

Temperatures up to 180°F

Up to 4.0 in. wg

Typical Applications

Models SWB and BSQ are general, all-purpose fans that are capable of moving high air volumes

against high static pressures (up to 5.0 in wg). High static pressures are generated by long or complex

duct systems, especially when capture hoods are present. Both models can be used for either exhaust

or supply. Model SWB is designed to be mounted indoors or outdoors, while model BSQ can be used

indoors only.

15

Page 16

Determining CFM (cfm)

After the model is known, the cfm must be determined.

Consult local code requirements or the table below for

suggested air changes for proper ventilation.

The ranges specified will adequately ventilate the

corresponding areas in most cases. However, extreme

conditions may require “Minutes per Change” outside

of the specified range. To determine the actual number

needed within a range, consider the geographic

location and average duty level of the area. For hot

Suggested Air Changes for Proper Ventilation

climates and heavier than normal area usage, select a

lower number in the range to change the air more

quickly. For moderate climates with lighter usages,

select a higher number in the range.

To determine the cfm required to adequately ventilate

an area, divide the room volume by the appropriate

“Minutes per Change” value.

cfm =

Area Min./Chg. Area Min./Chg. Area Min./Chg.

Assembly Hall 3-10 Dance Hall 3-7 Machine Shop 3-6

Attic 2-4 Dining Room 4-8 Mill 3-8

Auditorium 3-10 Dry Cleaner 2-5 Office 2-8

Bakery 2-3 Engine Room 1-3 Packing House 2-5

Bar 2-4 Factory 2-7 Projection Room 1-2

Barn 12-18 Foundry 1-5 Recreation Room 2-8

Boiler Room 1-3 Garage 2-10 Residence 2-6

Bowling Alley 3-7 Generator Room 2-5 Restaurant 5-10

Cafeteria 3-5 Gymnasium 3-8 Rest Room 5-7

Church 4-10 Kitchen 1-5 Store 3-7

Classroom 4-6 Laboratory 2-5 Transfer Room 1-5

Club Room 3-7 Laundry 2-4 Warehouse 3-10

Sample problem:

A building requires an exhaust fan to ventilate a general

office (see diagram below) which measures 30 ft. x 40

ft. x 8 ft. The office is often crowded.

Solution:

The total room volume is 30 ft. x 40 ft. x 8 ft. = 9600

cubic feet. From the chart, the range for general offices

is 2-8 minutes per change. Since the office has heavier

than normal usage, 4 minutes per change is

recommended. Therefore, the required exhaust is:

9600 ft

4 min.

Room Volume

Min./Chg.

3

= 2400 cfm

Room Volume = L x W x H (of room)

Since the air to be exhausted is relatively clean, this is

an ideal application for a model GB fan.

Note: In this example, make-up air was provided

through a set of louvers at the wall farthest from the

exhaust fan. If there were no provisions for make-up air

in this room, a supply fan would also have to be sized.

The supply cfm should equal the exhaust cfm. Supply

fan location should be as far as possible from the

exhaust fan.

16

Page 17

Determining Static Pressure (Ps)

The pressures generated by fans in ductwork are very small.

Yet, accurately estimating the static pressure is critical to

proper fan selection.

Fan static pressure is measured in inches of water gauge.

One pound per square inch is equivalent to 27.7 in. of water

gauge. Static pressures in fan systems are typically less

than 2 in. of water gauge, or 0.072 Psi. The drawing to the

right illustrates how static pressures are measured in

ductwork with a manometer.

A pressure differential between the duct and the atmosphere

will cause the water level in the manometer legs to rest at

different levels. This difference is the static pressure

measured in inches of water gauge.

In the case of the exhaust fan at right, the air is being drawn

upward through the ductwork because the fan is producing

a low pressure region at the top of the duct. This is the same

principle that enables beverages to be sipped through a straw.

The amount of static pressure that the fan must overcome depends on the air velocity in the ductwork, the number

of duct turns (and other resistive elements), and the duct length. For properly designed systems with sufficient

make-up air, the guide lines in the table below can be used for estimating static pressure:

Exhaust Fan

STATIC PRESSURE GUIDELINES

Non-Ducted 0.05 in. to 0.20 in.

Ducted 0.2 in. to 0.40 in. per

100 feet of duct (assuming duct

air velocity falls within 1000-1800

feet per minute)

Fittings 0.08 in. per fitting

(elbow, register, grill, damper, etc.)

Kitchen Hood Exhaust 0.625 in. to 1.50 in.

Important: Static pressure requirements are significantly affected

by the amount of make-up air supplied to an area. Insufficient

make-up air will increase static pressure and reduce the amount of

air that will be exhausted. Remember, for each cubic foot of air

exhausted, one cubic foot of air must be supplied.

To calculate the system losses, one must know the

ductwork system configuration (see Ductwork figure).

This duct is sized for air velocities of 1400 feet per minute.

Referring to the static pressure chart, that will result in

about 0.3 in. per 100 feet. Since we have 10 feet of total

ductwork, our pressure drop due to the duct is:

.3 in.

100 ft.

There is also a 0.08 in. pressure drop for each resistive

element or fitting. For this example, there are 5 fittings:

x 10 ft. = .03 in.

Ductwork

one grill, two duct turns, one damper and louvers in

the wall of the office. The total pressure drop for

fittings is:

5 x 0.08 in. = 0.4 in.

Therefore, the total pressure drop is:

0.03 in. + 0.40 in. = 0.43 in.

For convenience in using selection charts, round this

value up to the nearest 1/8 in., which would be 0.50 Ps.

17

Page 18

Preliminary Selections

At this point we know the model, cfm and Ps. With this

information we can refer to the GB performance charts

to determine the sizes available to move 2400 cfm

against 0.50 in. Ps.

In our case, all of the criteria can be met by more than

one size of a particular model. When this occurs,

choose the size that provides the greatest airflow range

about the desired cfm. For example, many direct drive

fans have three speeds. If possible, choose a size that

uses the middle rpm. This will allow some final system

adjustment if the actual cfm the job requires is

somewhat higher or lower once the fan is installed. Belt

driven fans have adjustable motor pulleys which allow

the fan speed to be varied. With belt drive units, avoid

Stability Considerations

Whenever there is more than one size to choose from,

it is not recommended to select from the performance

box in the far right column for any given rpm unless the

Ps is known to be accurate. For example, the GB-200

selection (see table below) of 2493 cfm at 0.50 in. Ps is

the far right selection at 700 rpm.

selecting near the maximum rpm of a size to allow for

final adjustments if necessary.

There are four GB sizes to choose from in the QD

catalog. These sizes along with their performance data

are in the table below.

Model and

Size

Performance Box Data

CFM Sones Bhp

RPM

GB-141 2556 16.8 .76 1545

GB-161 2614 13.5 .53 1100

GB-180 2375 8.6 .35 810

GB-200 2493 7.8 .40 700

The next box to the right (0.625 in. Ps) is empty

because the performance at that point is unstable. This

means that 2494 cfm at 0.50 in. is marginally stable.

For more information on fan stability, contact

Greenheck.

MODEL

(rpm RANGE)

GB-141-5

(1125-1360)

GB-141

GB-161-4

(634-865)

GB-161-5

(852-1100)

GB-180-3

(618-810)

GB-180-5

(700-940)

GB-180-7

(764-1055)

GB-180

GB-200-5

(512-770)

RPM

hp

1/2

1360 5207

3/4

1545 5915

1/4

1/2

1100 4787

1/3

1/2

1000 4843

3/4

1055 5109

1185 5739

1

1335 6465

11/2

1460 7071

2

1/2

Tip

Speed

785 3416

865 3764

985 4287

770 3729

810 3923

900 4359

940 4553

700 3917

770 4308

STATIC PRESSURE / CAPACITY

0.000 0.125 0.250 0.375 0.500 0.625 0.750 0.875 1.000

Sone Bhp Sone Bhp Sone Bhp Sone Bhp Sone Bhp Sone Bhp Sone Bhp Sone Bhp Sone Bhp

2522 2433 2346 2258 2166 2062 1942 1792 1602

14.6 0.48 14.3 0.50 13.9 0.51 13.5 0.52 13.1 0.52 12.7 0.52 12.2 0.53 11.6 0.52 11.0 0.51

2866 2787 2709 2634 2556 2475 2384 2286 2176

17.6 0.71 18.0 0.72 17.4 0.74 17.1 0.75 16.8 0.76 15.9 0.77 14.9 0.77 14.8 0.77 14.7 0.78

2318 2104 1875 1587

8.9 0.18 8.5 0.19 8.3 0.19 7.8 0.19

2555 2359 2162 1932 1624

10.6 0.24 10.1 0.25 9.7 0.26 9.4 0.26 8.8 0.25

2909 2737 2567 2382 2176 1914 1550

0.35

13.4

3249

15.3 0.48 14.7 0.50 14.1 0.52 13.8 0.53 13.5 0.53 13.0 0.53 12.5 0.52 12.0 0.50

2994 2833 2651 2427 2139 1700

8.1 0.25 9.2 0.26 9.1 0.29 8.5 0.30 7.8 0.30 7.4 0.28

3150 2997 2832 2624 2375 2053

10.6 0.29 10.3 0.31 10.0 0.33 9.3 0.35 8.6 0.35 8.2 0.34

3500 3364 3219 3052 2858 2624 2347 1821

12.7 0.40 12.4 0.42 12.1 0.44 11.3 0.46 10.5 0.48 10.2 0.48 9.8 0.47 9.2 0.43

3655

13.6

0.46 13.4 0.47 13.1 0.49 12.3 0.52 11.4 0.54 11.0 0.55 10.6 0.54 10.1 0.52

3888

15.2

0.55 14.7 0.57 13.7 0.58 13.3 0.62 13.0 0.64 12.4 0.66 11.9 0.66 11.6 0.65 11.1 0.63

4102

16.2

0.65 15.7 0.67 14.9 0.68 14.4 0.72 14.0 0.74 13.5 0.76 12.9 0.77 12.7 0.77 12.4 0.77

4607

19.0

0.91 18.4 0.94 17.8 0.96 17.4 0.98 17.1 1.03 16.7 1.05 16.2 1.07 15.8 1.10 15.4 1.10

5191

22.0

1.31 22.0 1.33 21.0 1.36 21.0 1.37 21.0 1.41 20.0 1.47 19.9 1.49 19.5 1.51 19.2 1.54

5677

26.0

1.71 25.0 1.74 24.0 1.77 24.0 1.79 24.0 1.81 24.0 1.86 23.0 1.93 23.0 1.95 23.0 1.97

3873

0.39

10.3

4260

0.52

12.1

0.36

12.7

3094

3527 3388 3234 3052 2844 2601 2272

3768 3638 3504 3339 3164 2952 2712 2387

3989 3866 3741 3596 3432 3251 3050 2811

4507 4400 4290 4179 4045 3900 3753 3575

5102 5010 4912 4814 4715 4599 4474 4343

5595 5514 5424 5335 5245 5155 5049 4938

3591

0.40

9.6

4013

0.53

11.0

0.37 11.9 0.38 11.5 0.38 10.9 0.37 10.2 0.35

12.3

2943 2786 2614 2428 2197 1899

3307 2973 2493

0.41

9.2

3744

0.55

10.7

8.6

10.2

0.41

3477

0.55

7.8

9.8

3140

0.40

0.55

2643

9.3 0.52

18

Page 19

Sound Levels

In many cases, the sound generated by a fan must be

considered. For the fan industry, a common unit for

expressing sound pressure level is the sone. In

practical terms, the loudness of one sone is equivalent

to the sound of a quiet refrigerator heard from five feet

away in an acoustically average room.

Sones are a linear measurement of sound pressure

levels. For example, a sound level of 10 sones is twice

as loud as 5 sones.

Refer to the Suggested Limits for Room Loudness chart

to determine the acceptable sone range for the

application. As a general guideline, choose a fan that

has a sone value within the range specified.

Note: Rooms with a hard construction (concrete block,

tile floors, etc.) reflect sound. For these rooms, select

fans on the lower end of the range. Rooms with soft

construction or those with carpeting and drapes, etc.,

absorb sound. For these rooms, fans near the higher

end of the range may be selected.

Our example describes an exhaust fan for an office.

Referring to the “Suggested limits for Room Loudness”

chart, offices should have a loudness range from 4 to

12 sones. Of our remaining three selections, only the

GB-180 has a sone value of less than 12. Therefore, the

GB-180 is the best selection for this application.

Suggested Limits for Room Loudness

Sones DBA

1.3-4 32-48 Private homes (rural and suburban)

1.7-5 36-51 Conference rooms

2-6

2.5-8

3-9 44-60 Court rooms, museums,

4-12 48-64 Restaurants, lobbies,

5-15 51-67 Corridors and halls, cocktail lounges,

7-21 56-72 Hotel kitchens and

12-36 64-80 Light machinery, assembly lines

15-50 67-84 Machine shops

25-60 74-87 Heavy machinery

From AMCA Publication 302 (Application of Sone Ratings

for Non Ducted Air Moving Devices with Room-Sone-dBA

correlations).

38-54 Hotel rooms, libraries,

movie theatres, executive offices

41-58 Schools and classrooms,

hospital wards, and operating rooms

apartments, private homes urban)

general open offices, banks

washrooms and toilets

laundries, supermarkets

Motor Horsepower

The motor horsepower for direct drive fans is always

sized by Greenheck and does not require further

consideration. For belt drive models, the catalog

identifies which horsepower is recommended.

However, there are times when it is wise to bump the

horsepower one size. For example, the hp

recommended for the GB-180 at 810 rpm is 1/3 hp.

Although a 1/3 hp motor is recommended, it is not

necessarily a good motor selection for this application.

Our static pressure of 0.5 in. was only an estimate. It

may actually turn out to be .625 in.

If this is the case, we will need a 1/2 hp motor because

our fan will have to run at almost 900 rpm (refer to

performance box - 2624 cfm at 0.625 in.Ps). Therefore,

choosing a 1/2 hp motor in this case is exercising good

judgement.

The complete model designation for this application is

GB-180-5.

Note: The GB-180-5 has an rpm range of 700-940

(refer to model column in catalog). This means

that if the static pressure is less than estimated,

say 0.25 in. Ps, the fan can be slowed down to

accommodate this condition.

19

Page 20

Installation

To ensure proper fan performance as cataloged,

caution must be exercised in fan placement and

connection to the ventilation system. Obstructions,

transitions, poorly designed elbows, improperly

selected dampers, etc., can cause reduced

performance, excessive noise, and increased

mechanical stressing. For the fan to perform as

published, the system must provide uniform and stable

airflow into the fan.

Uniform Flow Improperly sized or

obstructed damper

Wheel Rotation

A common problem is wheel rotation in the wrong

direction. For centrifugal fans, incorrect wheel rotation

will provide some airflow. However, the airflow will be

far below the cataloged value. Rotation should be

checked while the fan is coasting to a stop. Proper

rotation for the most common wheels are shown below.

Elbow too close

to fan inlet

When connecting a 3 phase motor, there is a 50%

chance that the fan will run backwards. Changing any

two supply power connections will reverse the direction

of rotation.

20

Page 21

FAN PERFORMANCE

The first two sections of this guide contain information

needed to select the right fan for the particular

application. The information in this section is useful

once the fan has been selected and installed on the job.

The fan curves and system resistance curves below will

help to solve fan performance problems that may be

encountered in a variety of applications.

Fan Dynamics

A fan is simply an air pump. The rate at which a fan can

“pump” air depends on the pressure the fan must

overcome. This principle also relates to water pumps.

A water pump is able to deliver more water through a

2 in. diameter hose than a 1 in. diameter hose because

the 1 in. hose creates more resistance to flow.

For a fan, every flow rate (CFM-Cubic Feet per Minute)

corresponds to a specific resistance to flow (Ps-Static

Pressure). The series of cfm, Ps points for a fan at a

constant rpm is called a fan curve. A fan curve at 700

rpm is shown below.

Fan Curve Varying Fan Curve

At 0.25 in. Ps, this fan will deliver 1000 cfm. If the

pressure increases, cfm decreases. If the pressure

decreases, cfm will increase.

At 700 rpm, the operating point will slide along the fan

curve as static pressure changes, but it will never lie off

the curve. In order for a fan to perform at a point off the

curve, the rpm must be changed.

The figure below illustrates how rpm affects the fan

curve. Notice that the general shape of the curves are

the same. Changing rpm simply moves the curve

outward or inward.

System Dynamics

For a given flow rate (cfm), an air distribution system

produces a resistance to airflow (Ps). This resistance is

the sum of all static pressure losses as the air flows

through the system. Resistance producing elements

include ductwork, dampers, grills, coils, etc.

A fan is simply the device that creates the pressure

differential to move air through the system.

The greater the pressure differential created by the fan,

the greater the volume of air moved through the

system. Again, this is the same principle that relates to

water pumps. The main difference in our case is that

the fan is pumping air.

Tests have established a relationship between cfm and

Ps. This relationship is parabolic and takes the form of

the following equation:

Ps = K x (cfm)

Where K is the constant that reflects the “steepness” of

the parabola. This equation literally states that Ps

varies as the square of the cfm.

For example, whenever the cfm doubles, the Ps will

increase 4 times. The figures on the next page

graphically illustrate this concept.

2

21

Page 22

System Resistance Curve Varying System Resistance Curve

Sample problem:

If a system is designed to move 1000 cfm at a

resistance of 0.25 in. Ps, what static pressure would the

fan have to overcome to produce 2000 cfm of airflow?

Solution:

Since static pressure varies as the square of cfm, we

can solve for the new Ps (Ps

equation:

2

cfm

Ps2= Ps1x

(

cfm

2

= 0.25 in. x

)

1

2 ) with the following

2000cfm

(

1000 cfm

2

)

= 1.0 in.

Note: Physically changing the system will alter the

system resistance. For example, closing a

damper from 100% open to only 50% open will

add resistance and increase the “steepness” of

the system resistance curve. The same effect

occurs as filters become dirty. The figure above

illustrates this point.

Curve A defines a system that requires 0.5 in. Ps to

move 1000 cfm. Curve B requires 0.75 in. Ps to move

the same amount of air. This is typical of how a system

reacts to increased resistance.

Referring to the figure above, this results in sliding up

the system resistance curve from Point A to Point B.

For this system, it is impossible to move 2000 cfm at

only 0.25 in. Ps. For any given system, every cfm

requires a unique Ps. This series of cfm/Ps points

forms a system resistance curve such as the one

above. Once the system resistance curve is defined,

changing the fan rpm will change the cfm and Ps

simultaneously, which results in sliding along the

system resistance curve.

Combining Fan and System Dynamics

The previous two sections introduced fan curves and

system resistance curves. This section will show how

these relate to each other to provide an understanding

of the way the fan-system operates as a complete

entity.

In this section, there are three key points to emphasize:

1. As airflow through a system changes, so does the

static pressure.

2. For a steady-state system, operating points must

lie on the curve defining that system’s cfm/Ps

characteristics.

3. As the system’s resistive elements change, the

steepness of the system resistance curve changes.

Remember that a fan curve is the series of points at

which the fan can operate at a constant rpm. Likewise,

a system resistance curve is the series of points at

which the system can operate. The operating point

(cfm, Ps) for the fan-system combination is where these

these two curves intersect.

22

Page 23

The operating point of the fan and the system is

the point where these two curves intersect. This

intersection will determine the cfm and Ps

delivered.

Operating Point

Adjusting Fan Performance

There is a direct relationship between cfm and rpm

within a system. Doubling the fan rpm will double the

cfm delivered.

Sample problem:

The figure on page 21 showed a fan curve at 700 rpm

which had an operating point of 1000 cfm at 0.25 in. Ps.

What rpm is required to move 2000 cfm through the

same system?

Solution:

Within a system, cfm is directly related to rpm.

Therefore, the new rpm (rpm2) can be determined from

the following equation:

cfm

rpm2= rpm1X

X

1

2000 cfm

(

1000 cfm

rpm

(

rpm

700 rpm x

=

Referring to figure at right, this results in sliding up the

system resistance curve from 700 rpm to 1400 rpm.

Notice that as we doubled our airflow from 1000 cfm to

2000 cfm, the Ps went up from 0.25 in. to 1.0 in. It must

be kept in mind that we are not changing the system,

only increasing fan speed. Therefore, we must remain

on the system resistance curve. Within a system, Ps

varies as the square of cfm. Since cfm and rpm are

directly proportional, an equation relating Ps and rpm

can be derived as follows:

Ps

Ps2=

(

cfm

2

1

2

)

1

)

2

)

= 1400 rpm

Varying Operating Points

For our example,

rpm

2

= 1.0 in.

)

Ps2= 0.25 in. X

This verifies the operating point on the 1400 rpm curve

(2000 cfm at 1.0 in. Ps). With this example, it should be

clear how cfm, rpm and Ps tie together in a steadystate system.

1400 rpm

(

700

23

Page 24

Fan Laws

In a steady-state system, as the fan rpm changes, cfm, Ps

and BHp (horsepower) also change. The equations below,

known better as fan laws, show the relationship between

these performance parameters.

rpm

cfm

New

=

rpm

New

Old

x cfm

Old

Ps

Bhp

New

New

rpm

=

(

rpm

=

(

rpm

New

Old

rpm

New

Old

)

2

x Ps

3

)

Old

x Bhp

Old

The first two equations have already been covered in the fan

and system dynamics section. Refer to the examples in those

sections on how to apply these equations.

The third equation relates horsepower to rpm. The change in

horsepower can be determined when the rpm is increased by

25%. This is shown below:

Bhp

= (1.25)3x Bhp

New

= 1.95 x Bhp

Old

Old

NOTE: a 25% increase in rpm results in a 95% increase in

horsepower. Considering this, initial fan selections should be

sized with motor horsepowers greater than necessary if any

increase in fan rpm is likely in the future.

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Fan Fundamentals Rev 2 June 2005

Copyright © 2005 Greenheck Fan Corp.

Loading...

Loading...