Page 1

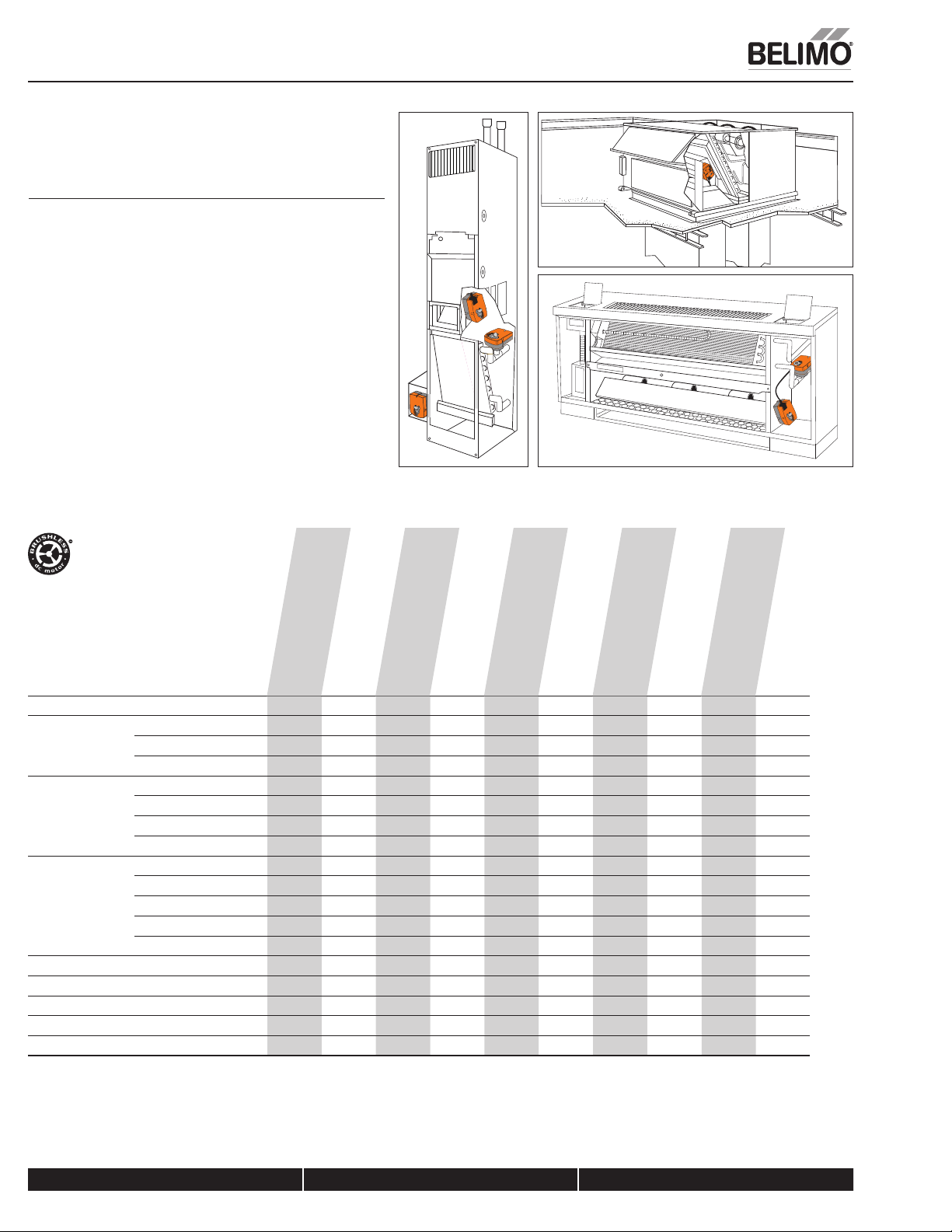

TF Series Spring Return Direct Coupled Actuator

Minimum 18 in-lb torque

L For damper areas up to 4.5 sq-ft*

Applications

Cost effective quality and performance

for a range of applications including:

s #LASSROOM5NIT6ENTILATORS

s &AN#OIL5NITS

s %CONOMIZER5NITS

s !IRHANDLERS

s #ONTROL$AMPERS

s 6!64ERMINAL5NITS

All Actuators

have BDCM

TF Series – At A glance

TF24 US (p. 96)

Torque: 18 in-lb

Power supply: 24 VAC/DC**

120 VAC

230 VAC

Control signal: On/Off

floating point

proportional 2 to 10 VDC

Multi-Function

Running time motor: <75 sec

< 30 sec

95 sec constant

Adj. 75 to 300 sec***

spring: <25 sec

External direction of rotation switch

Plenum rated cable

Appliance cable

Conduit fitting

Built-in auxiliary switch

General wiring ...............................(p. 113) Installation instructions ...........(p. 108-111)

Start-up and checkout .............(p. 114)

*Based on 4 in-lb/ft2 damper torque loading. Parallel blade. No edge seals. **Note: TF24-3 (-S) US is only 24 VAC. ***Default 150 seconds

LLLLLLLLLL

LL LLLLL

LLLLL

LLLL

LLLLLLLLLL

LLLLL L L

LLLLLLLLLL

TF24-S US (p. 96)

LLLLL

TF120 US (p. 98)

LLL

LLL

TF120-S US (p. 98)

TFC120-S US (p. 100)

L

TF24-3 US (p. 102)

LL

LLLL

LLLLL

LLL

TF24-3-S US (p. 102)

TF24-SR US (p. 104)

LL

TF24-SR-S US (p. 104)

TF24-MFT US (p. 106)

L

L

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

94

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 2

A CLOSER LOOK…

L

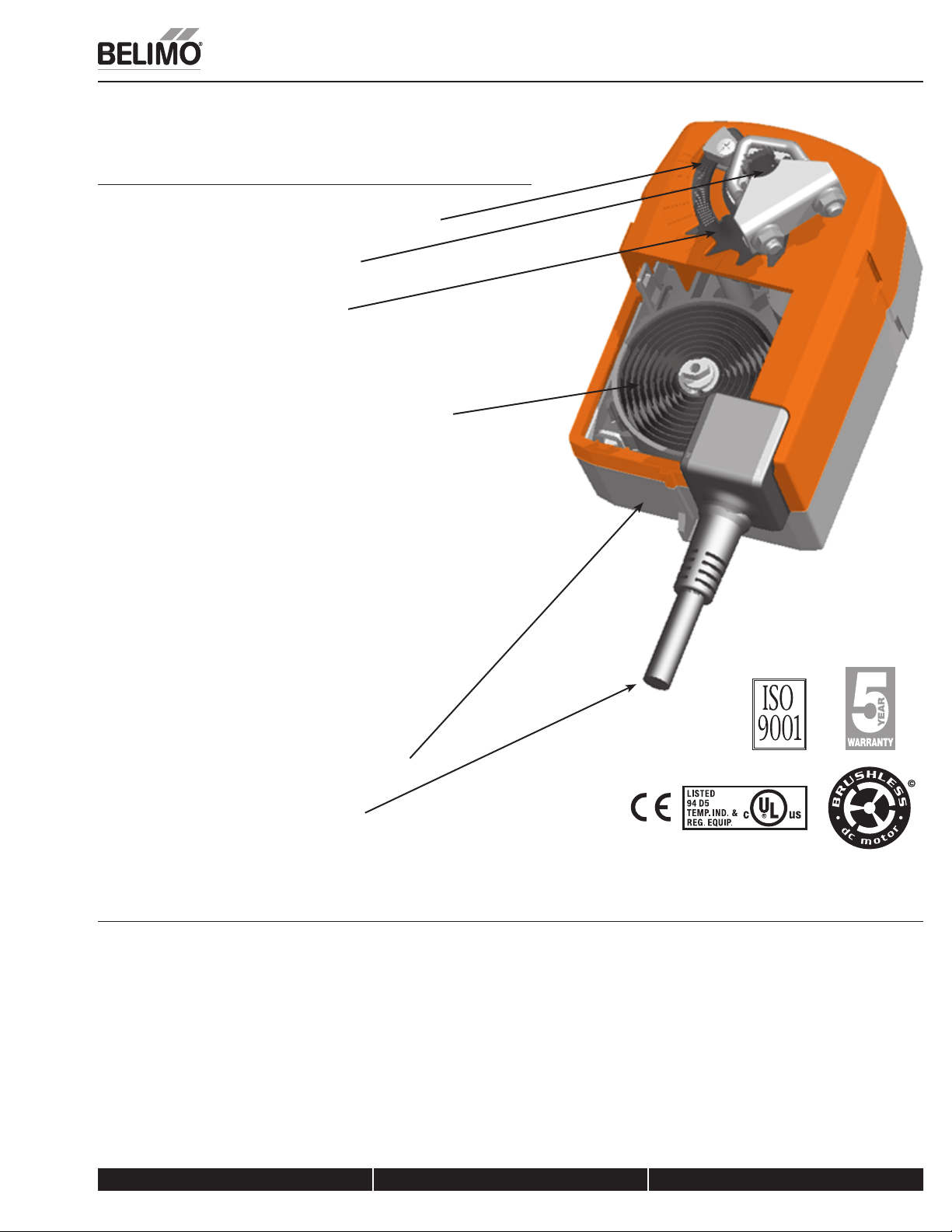

Easy-to-adjust mechanical stop to limit damper rotation.

L

Cut labor costs with simple direct coupling.

Actuator Centers on 1/2” shaft.

L

Clockwise or counterclockwise fail-safe

mounting for fail-safe.

L

Compact size with the shortest shaft-center to edge

distance in the industry - 0.77”.

L

True mechanical spring return – the most reliable fail-safe.

L

Single line voltage model for on/off application has

100 to 240V (-15/+10%), 50/60 Hz supply power.

TF Series Spring Return Direct Coupled Actuator

L

Check damper position easily with clear position indicator.

L

Don’t worry about actuator burn-out.

Belimo is overload-proof throughout rotation.

L

Need to change control direction?

Do it easily with a simple switch (modulating actuators).

L

Built-in auxiliary switch is easy to use, offers feedback

or signal for additional device.

L

Microprocessor-controlled brushless DC motor

increases actuator life span and reliability, provides

constant running time (modulating actuators).

L

Rugged housing withstands rough handling in the

mechanical room.

L

3 ft. standard cable and conduit connector

(not shown) eases installation.

The Belimo Difference

L

Customer Commitment.

Extensive product range. Application assistance.

Same-day shipments. Free technical support. Five year warranty.

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

L

Low Installation and Life-Cycle Cost.

Easy installation. Accuracy and repeatability.

Low power consumption. No maintenance.

L

Long Service Life.

Components tested before assembly. Every product tested before shipment.

30 years direct coupled actuator design.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

95

Page 3

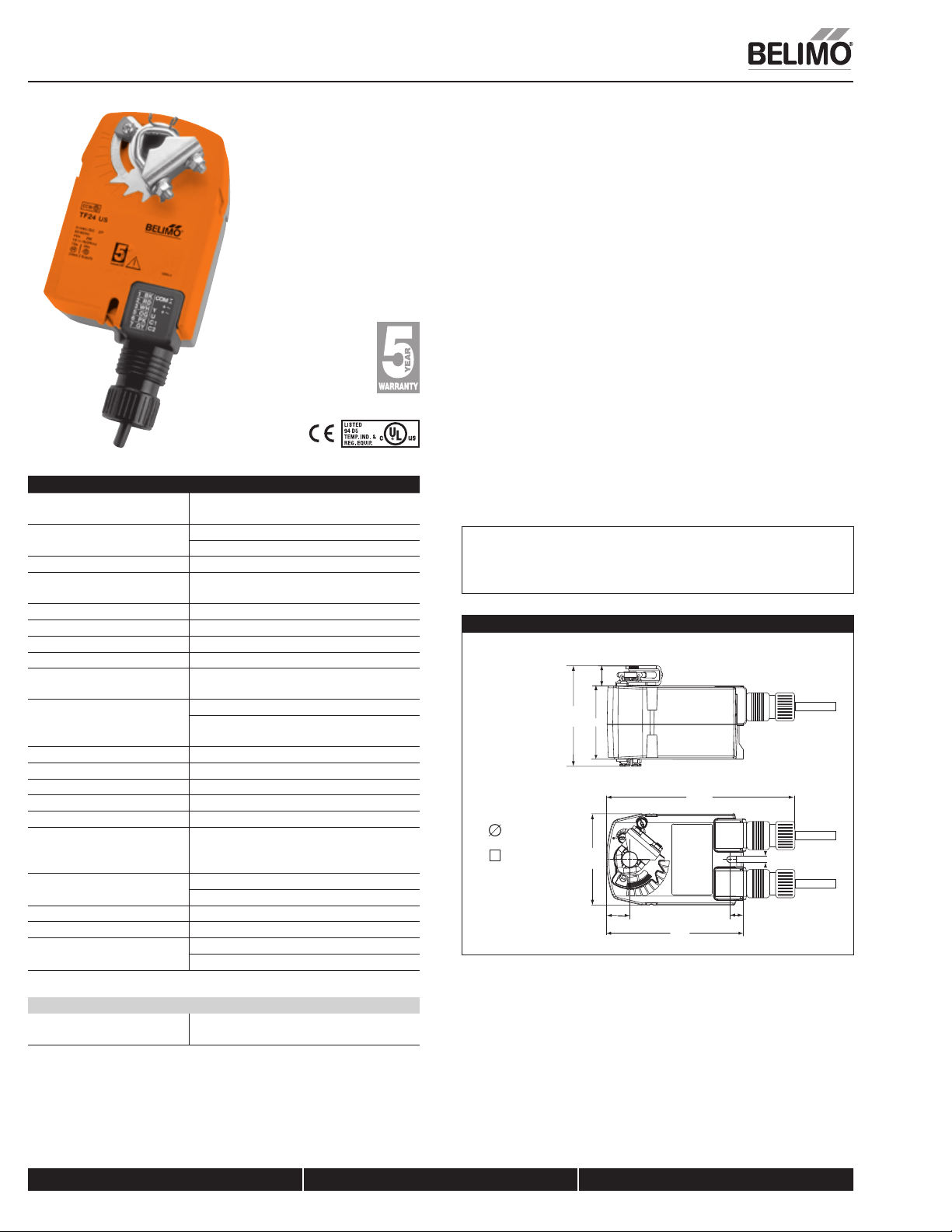

TF24(-S) US

On/Off, Spring Return Fail-Safe, 24V

Technical Data TF24(-S) US

Power supply 24VAC ± 20%, 50/60Hz

Power consumption running 2 W

Transformer sizing 5 VA (class 2 power source)

Electrical connection

(-S models have 2 cables)

Overload protection electronic throughout 0 to 95° rotation

Angle of rotation max 95°, adjust. with mechanical stop

Torque min. 18 in-lb [2 Nm]

Direction of rotation reversible with cw/ccw mounting

Position indication visual indicator, 0° to 95°

Running time motor < 75 sec (0 to 18 in-lb)

(nominal) spring < 25 sec @-4°F to 122°F [-20°C to 50°C]

Humidity 5 to 95% RH non-condensing

Ambient temperature -22°F to 122°F [-30°C to 50°C]

Storage temperature -40°F to 176°F [-40°C to 80°C]

Housing NEMA type 2 / IP42, UL enclosure type 2

Housing material UL94-5VA

Agency listings† cULus acc. to UL60730-1A/-2-14, CAN/CSA

Noise level (max) running < 50 db (A)

spring return 62 dB (A)

Servicing maintenance free

Quality standard ISO 9001

Weight TF24 1.4 lbs (0.6 kg)

TF24-S 1.5 lbs (0.7 kg)

† Rated Impulse Voltage 800V, Type of action 1.AA (1.AA.B for -S version), Control Pollution Degree 3.

TF24-S US

Auxiliary switch 1 x SPDT 3A (0.5A) @ 250 VAC, UL Approved

24VDC ± 10%

holding 1.3 W

3 ft, 18 GA appliance cable

1/2” conduit connector

(0° spring return position)

< 60 sec @-22°F [-30°C]

E60730-1:02, CE acc. to 2004/108/EC (and

2006/95/EC for -S versions)

adjustable 0° to 95°

Torque min. 18 in-lb, for control of air dampers

Application

For On/Off, fail-safe control of dampers in HVAC systems. Actuator sizing should

be done in accordance with the damper manufacturer’s specifications. Control is

On/Off from an auxiliary contact, or a manual switch.

The actuator is mounted directly to a damper shaft from 1/4” up to 1/2” in

diameter by means of its universal clamp, 1/2” shaft centered at delivery. A

crank arm and several mounting brackets are available for applications where the

actuator cannot be direct coupled to the damper shaft.

Operation

The TF series actuators provide true spring return operation for reliable fail-safe

application and positive close off on air tight dampers. The spring return system

provides consistent torque to the damper with, and without, power applied to the

actuator.

The TF series provides 95° of rotation and is provided with a graduated position

indicator showing 0° to 90°.

The actuator may be stalled anywhere in its normal rotation without the need of

mechanical end switches. Power consumption is reduced in holding mode.

The TF24-S US versions are provided with 1 built-in auxiliary switch. This SPDT

switch is provided for safety interfacing or signaling, for example, for fan startup. The switching function is adjustable between 0° and 95°.

SAFETY NOTE

Screw a conduit fitting into the actuator’s bushing. Jacket the actuator’s

input and output wiring with suitable flexible conduit. Properly terminate the

conduit in a suitable junction box.

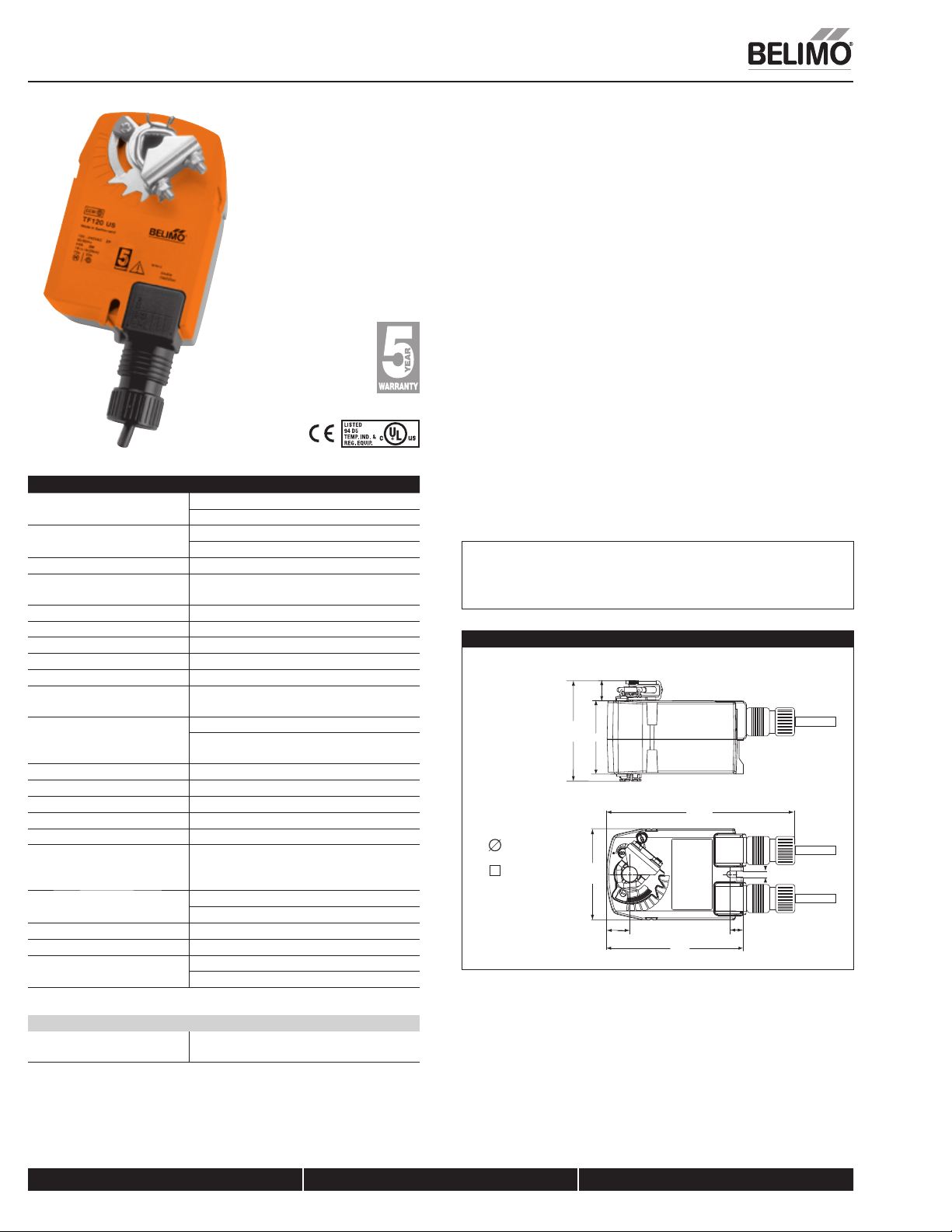

Dimensions (Inches [mm])

0.68" [16.7]

3.30"

[83.72]

2.40"

[61]

6.28"

4.5"

[114]

[159.5]

0.43" [11]

0.2"

[5.2]

Standard:

1/4" to 1/2"

1/4" to 5/16"

3.0"

[76.2]

0.77" [19.5]

D096

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

96

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 4

TF24(-S) US

On/Off, Spring Return FailS-Safe, 24 V

Accessories

Tool-06 8mm and 10 mm wrench

KH-TF Crankarm for up to 1/2” round shaft

ZG-TF2 Crankarm adaptor kit for TF

ZG-TF112 Mounting bracket, kit for TF

ZS-100 Weather shield (metal)

ZS-150 Weather shield (polycarbonate)

NOTE: When using TF24 US and TF24-S US actuators, only use accessories listed on this page.

For Actuator Wiring Information and Diagrams, Please See Belimo Wiring Guide (pg 349).

Typical Specification

On/Off spring return damper actuators shall be direct coupled type which

require no crankarm and linkage and be capable of direct mounting to a shaft

up to a 1/2” diameter and center a 1/2” shaft. The actuators must be designed

so that they may be used for either clockwise or counterclockwise fail-safe

operation. Actuators shall be protected from overload at all angles of rotation.

If required, 1 SPDT auxiliary switch shall be provided having the capability of

being adjustable. Actuators with auxiliary switch must be constructed to meet

the requirements for Double Insulation so an electrical ground is not required

to meet agency listings. Actuators shall be cULus listed certified, have a 5 year

warranty, and be manufactured under ISO 9001 International Quality Control

Standards. Actuators shall be as manufactured by Belimo.

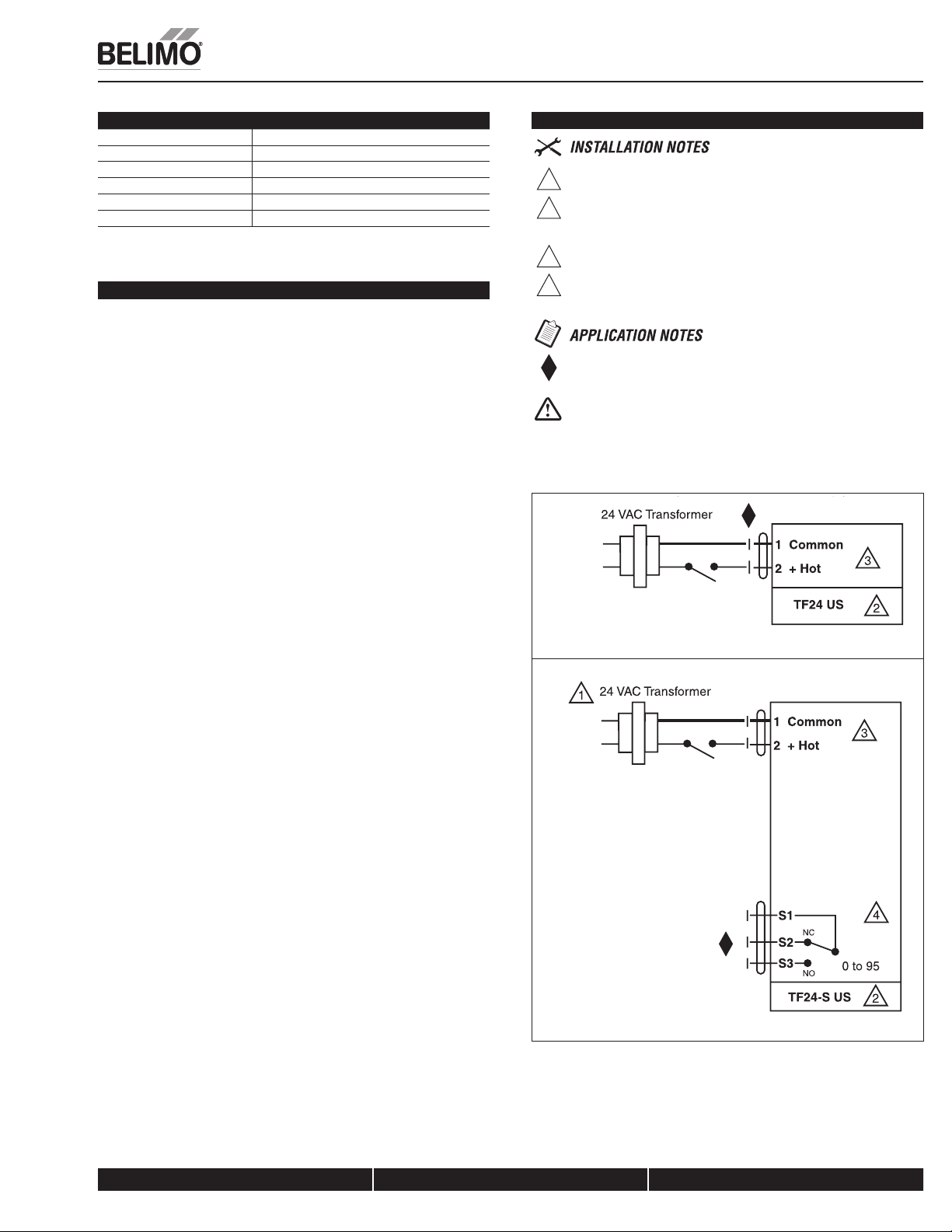

Wiring Diagrams

Provide overload protection and disconnect as required.

1

CAUTION Equipment damage!

2

Actuators may be connected in parallel.

Power consumption must be observed.

Actuators may also be powered by 24 VDC.

3

For end position indication, interlock control, fan startup, etc., TF24-S

4

US incorporates a built-in auxiliary switch: 1 x SPDT, 3A (0.5A) @250

VAC, UL Approved, adjustable 0 to 95.

Meets cULus requirements without the need of an electrical ground

connection.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

W567_08

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

On/Off wiring for TF24 US

W238_08

On/Off wiring for TF24-S US

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

97

Page 5

TF120(-S) US

On/Off, Spring Return Fail-Safe, 100 to 240 VAC

Technical Data TF120(-S) US

Power supply nominal 100 to 240 VAC, 50/60 Hz

tolerance 85 to 265 VAC, 50/60 Hz

Power consumption running 2.5 W

holding 1.3 W

Transformer sizing 5 VA (class 2 power source)

Electrical connection

(-S models have 2 cables)

Overload protection electronic throughout 0 to 95° rotation

Electrical protection actuators are double insulated

Angle of rotation max 95°, adjust. with mechanical stop

Torque min. 18 in-lb [2 Nm]

Direction of rotation reversible with cw/ccw mounting

Position indication visual indicator, 0° to 95°

Running time motor < 75 sec (0 to 18 in-lb)

Humidity 5 to 95% RH non-condensing

Ambient temperature -22°F to 122°F [-30°C to 50°C]

Storage temperature -40°F to 176°F [-40°C to 80°C]

Housing NEMA type 2 / IP42, UL enclosure type 2

Housing material UL94-5VA

Agency listings† cULus acc. to UL60730-1A/-2-14, CAN/CSA

Noise level (max) running < 50 db (A)

spring return 62 dB (A)

Servicing maintenance free

Quality standard ISO 9001

Weight TF120 1.4 lbs (0.6 kg)

TF120-S 1.5 lbs (0.7 kg)

† Rated Impulse Voltage 4kV, Type of action 1.AA (1.AA.B for -S version), Control Pollution Degree 3.

3 ft, 18 GA appliance cable

1/2” conduit connector

(0° spring return position)

spring < 25 sec @-4°F to 122°F [-20°C to 50°C]

< 60 sec @-22°F [-30°C]

E60730-1:02, CE acc. to 2004/108/EC (and

2006/95/EC for -S versions)

Torque min. 18 in-lb, for control of air dampers

Application

For On/Off, fail-safe control of dampers in HVAC systems. Actuator sizing should

be done in accordance with the damper manufacturer’s specifications. Control is

On/Off from an auxiliary contact, or a manual switch.

The actuator is mounted directly to a damper shaft from 1/4” up to 1/2” in

diameter by means of its universal clamp, 1/2” shaft centered at delivery. A

crank arm and several mounting brackets are available for applications where the

actuator cannot be direct coupled to the damper shaft.

Operation

The TF series actuators provide true spring return operation for reliable fail-safe

application and positive close off on air tight dampers. The spring return system

provides consistent torque to the damper with, and without, power applied to the

actuator.

The TF series provides 95° of rotation and is provided with a graduated position

indicator showing 0° to 90°.

The actuator may be stalled anywhere in its normal rotation without the need of

mechanical end switches. Power consumption is reduced in holding mode. The

actuator is double insulated so an electrical ground connection is not necessary.

The TF120-S US versions are provided with 1 built-in auxiliary switch. This SPDT

switch is provided for safety interfacing or signaling, for example, for fan startup. The switching function is adjustable between 0° and 95°.

SAFETY NOTE

Screw a conduit fitting into the actuator’s bushing. Jacket the actuator’s

input and output wiring with suitable flexible conduit. Properly terminate the

conduit in a suitable junction box.

Dimensions (Inches [mm])

0.68" [16.7]

3.30"

[83.72]

2.40"

[61]

6.28"

4.5"

[114]

[159.5]

0.43" [11]

0.2"

[5.2]

Standard:

1/4" to 1/2"

1/4" to 5/16"

3.0"

[76.2]

0.77" [19.5]

D096

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

TF120-S US

Auxiliary switch 1 x SPDT 3A (0.5A) @ 250 VAC, UL Approved

adjustable 0° to 95°

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

98

Page 6

TF120(-S) US

On/Off, Spring Return Fail-Safe, 100 to 240 VAC

Accessories

Tool-06 8mm and 10 mm wrench

KH-TF Crankarm for up to 1/2” round shaft

ZG-TF2 Crankarm adaptor kit for TF

ZG-TF112 Mounting bracket, kit for TF

ZS-100 Weather shield (metal)

ZS-150 Weather shield (polycarbonate)

NOTE: When using TF120 US and TF120-S US actuators, only use accessories listed on this page.

For Actuator Wiring Information and Diagrams, Please See Belimo Wiring Guide (pg 349).

Typical Specification

On/Off spring return damper actuators shall be direct coupled type which

require no crankarm and linkage and be capable of direct mounting to a shaft

up to a 1/2” diameter and center a 1/2” shaft. The actuators must be designed

so that they may be used for either clockwise or counterclockwise fail-safe

operation. Actuators shall be protected from overload at all angles of rotation.

If required, 1 SPDT auxiliary switch shall be provided having the capability of

being adjustable. Actuators must be constructed to meet the requirements

for Double Insulation so an electrical ground is not required to meet agency

listings. Actuators shall be cULus listed and have a 5 year warranty, and

be manufactured under ISO 9001 International Quality Control Standards.

Actuators shall be as manufactured by Belimo.

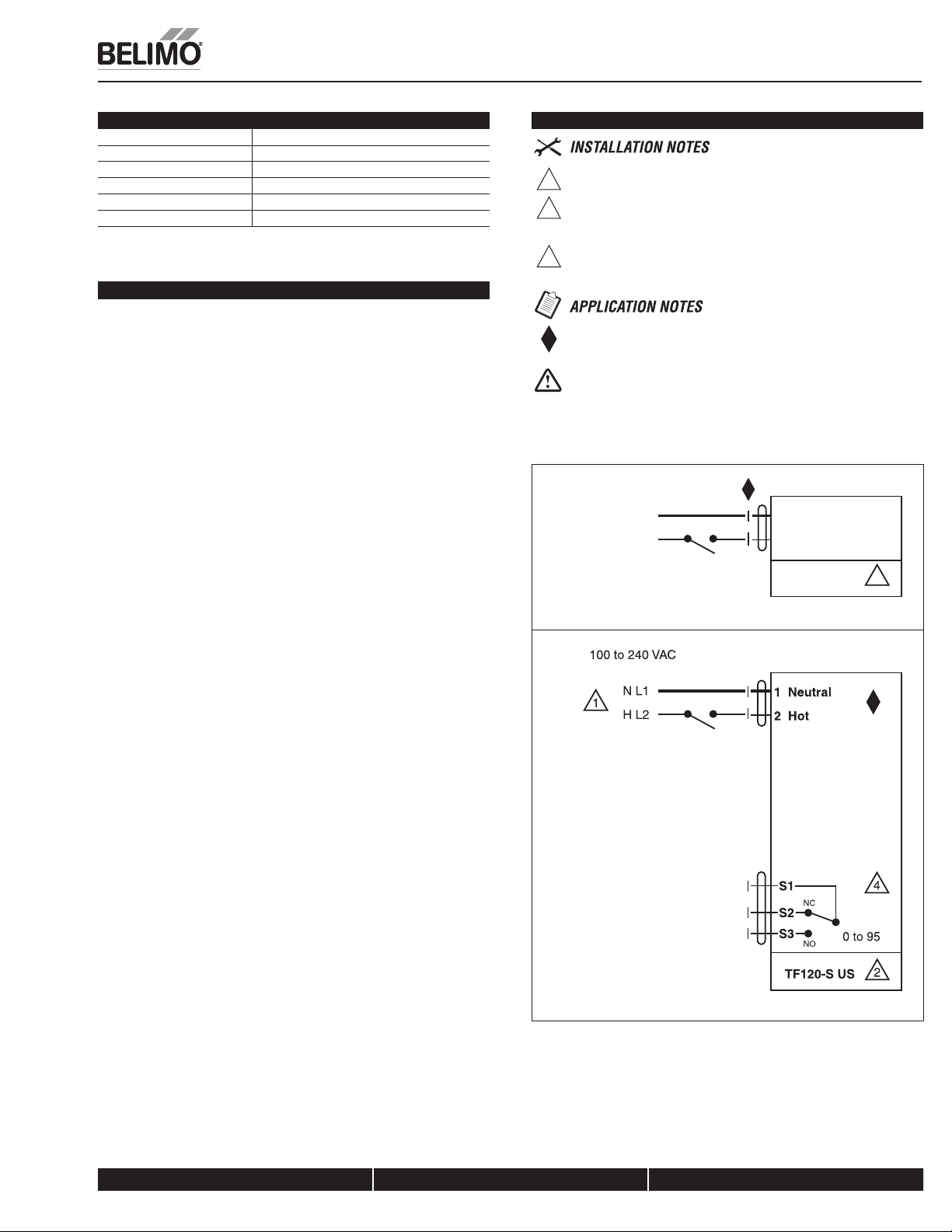

Wiring Diagrams

Provide overload protection and disconnect as required.

1

CAUTION Equipment damage!

2

Actuators may be connected in parallel.

Power consumption must be observed.

For end position indication, interlock control, fan startup, etc., TF120-S

4

US incorporate one built-in auxiliary switch: 1 x SPDT, 3A (0.5A)

@250 VAC, UL Approved, adjustable 0° to 95°.

Meets cULus requirements without the need of an electrical ground

connection.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

100 to 240 VAC

N L1

H L2

1 Neutral

2 Hot

W568

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

On/Off wiring for TF120 US

On/Off wiring for TF120-S US

TF120 US

2

W218_08

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

99

Page 7

TFC120-S US

On/Off, Spring Return Fail-Safe, 100-240 VAC

Technical Data TFC120-S US

Power supply nominal 100 to 240 VAC, 50/60 Hz

tolerance 85 to 265 VAC, 50/60 Hz

Power consumption running 3 W

holding 1.5 W

Transformer sizing 6 VA (class 2 power source)

Electrical connection Two 3 ft, 18 GA appliance cable

1/2” conduit connector

Overload protection electronic throughout 0 to 95° rotation

Electrical protection actuators are double insulated

Angle of rotation max 95°, adjust. with mechanical stop

Torque min. 18 in-lb [2 Nm]

Direction of rotation reversible with cw/ccw mounting

Position indication visual indicator, 0° to 95°

(0° spring return position)

Auxiliary switch 1 x SPDT 3A (0.5A) @ 250 VAC, UL Approved

adjustable 0° to 95°

Running time motor < 30 sec (0 to 18 in-lb)

spring < 25 sec @-4°F to 122°F [-20°C to 50°C]

< 60 sec @-22°F [-30°C]

Humidity 5 to 95% RH non-condensing

Ambient temperature -22°F to 122°F [-30°C to 50°C]

Storage temperature -40°F to 176°F [-40°C to 80°C]

Housing NEMA type 2 / IP42, UL enclosure type 2

Housing material UL94-5VA

Agency listings† cULus acc. to UL60730-1A/-2-14,

CAN/CSA E60730-1:02, CE acc. to 2004/108/

EC, and 2006/95/EC

Noise level (max) running < 56 db (A)

spring return 63 dB (A)

Servicing maintenance free

Quality standard ISO 9001

Weight 1.5 lbs (0.7 kg)

† Rated Impulse Voltage 4kV, Type of action 1.AA.B, Control Pollution Degree 3.

Torque min. 18 in-lb, for control of air dampers

Application

For On/Off fast running, fail-safe control of dampers in HVAC systems. Actuator

sizing should be done in accordance with the damper manufacturer’s

specifications. Control is On/Off from an auxiliary contact, or a manual switch.

The actuator is mounted directly to a damper shaft from 1/4” up to 1/2” in

diameter by means of its universal clamp, 1/2” shaft centered at delivery. A

crank arm and several mounting brackets are available for applications where the

actuator cannot be direct coupled to the damper shaft.

Operation

The TF series actuators provide true spring return operation for reliable fail-safe

application and positive close off on air tight dampers. The spring return system

provides consistent torque to the damper with, and without, power applied to the

actuator.

The TF series provides 95° of rotation and is provided with a graduated position

indicator showing 0° to 90°.

The actuator may be stalled anywhere in its normal rotation without the need of

mechanical end switches. Power consumption is reduced in holding mode. The

actuator is double insulated so an electrical ground connection is not necessary.

The TFC120-S US versions are provided with 1 built-in auxiliary switch. This

SPDT switch is provided for safety interfacing or signaling, for example, for fan

start-up. The switching function is adjustable between 0° and 95°.

SAFETY NOTE

Screw a conduit fitting into the actuator’s bushing. Jacket the actuator’s

input and output wiring with suitable flexible conduit. Properly terminate the

conduit in a suitable junction box.

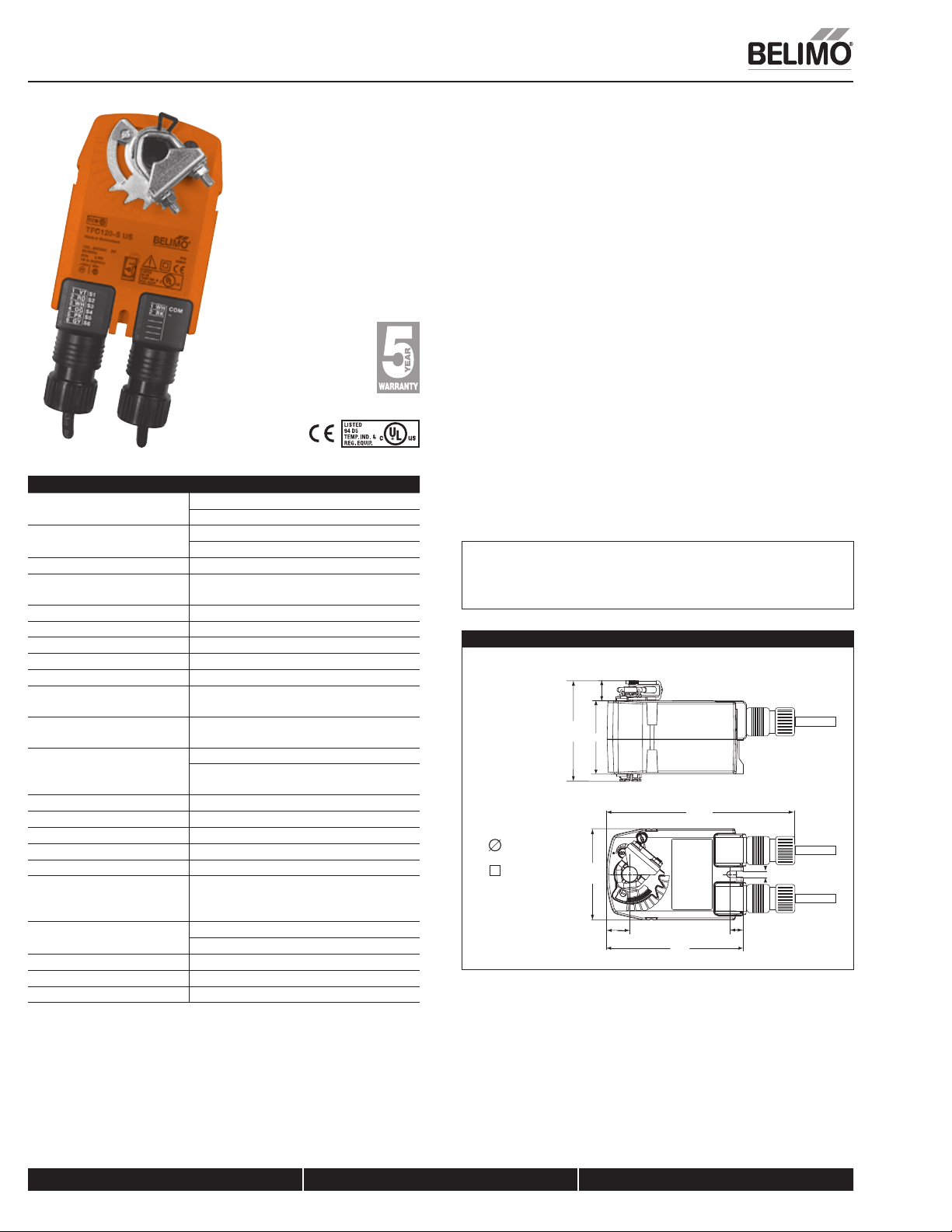

Dimensions (Inches [mm])

0.68" [16.7]

3.30"

[83.72]

2.40"

[61]

6.28"

4.5"

[114]

[159.5]

0.43" [11]

0.2"

[5.2]

Standard:

1/4" to 1/2"

1/4" to 5/16"

3.0"

[76.2]

0.77" [19.5]

D096

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

100

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 8

TFC120-S US

On/Off, Spring Return Fail-Safe, 100-240 VAC

Accessories

Tool-06 8mm and 10 mm wrench

KH-TF Crankarm for up to 1/2” round shaft

ZG-TF2 Crankarm adaptor kit for TF

ZG-TF112 Mounting bracket, kit for TF

ZG-TF113 Mounting bracket, kit for TF

ZS-100 Weather shield (metal)

ZS-150 Weather shield (polycarbonate)

NOTE: When using TFC120-S US actuators, only use accessories listed on this page.

For Actuator Wiring Information and Diagrams, Please See Belimo Wiring Guide (pg 349).

Typical Specification

On/Off spring return damper actuators shall be direct coupled type which

require no crankarm and linkage and be capable of direct mounting to a shaft

up to a 1/2” diameter and center a 1/2” shaft. The actuators must be designed

so that they may be used for either clockwise or counterclockwise fail-safe

operation. Actuators shall be protected from overload at all angles of rotation.

If required, 1 SPDT auxiliary switch shall be provided having the capability of

being adjustable. Actuators must be constructed to meet the requirements

for Double Insulation so an electrical ground is not required to meet agency

listings. Actuators shall be cULus listed and have a 5 year warranty, and

be manufactured under ISO 9001 International Quality Control Standards.

Actuators shall be as manufactured by Belimo.

Wiring Diagrams

Provide overload protection and disconnect as required.

1

CAUTION Equipment damage!

2

Actuators may be connected in parallel.

Power consumption must be observed.

For end position indication, interlock control, fan startup, etc., TFC-

4

20-S US incorporate one built-in auxiliary switch: 1 x SPDT, 3A (0.5A)

@250 VAC, UL Approved, adjustable 0° to 95°.

Meets cULus requirements without the need of an electrical ground

connection.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

W564_08

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

On/Off wiring for TFC120-S US

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

101

Page 9

TF24-3(-S) US

On/Off, Spring Return Fail-Safe, Reversible, Floating Point, 24V

Technical Data TF24-3(-S) US

Power supply 24 VAC ± 20%, 50/60 Hz

Power consumption running 2.5 W

holding 1 W

Transformer sizing 4 VA (class 2 power source)

Electrical connection

(-S models have 2 cables)

Overload protection electronic throughout 0 to 95° rotation

Input impedance 1000 7 (0.6w) control inputs

Electrical protection actuators are double insulated

Angle of rotation max 95°, adjust. with mechanical stop

Torque 18 in-lb [2 Nm]

Direction of rotation spring reversible with cw/ccw mounting

Position indication visual indicator, 0° to 95°

Running time motor 95 sec constant, independent of load

Humidity 5 to 95% RH non-condensing

Ambient temperature -22°F to 122°F [-30°C to 50°C]

Storage temperature -40°F to 176°F [-40°C to 80°C]

Housing NEMA type 2 / IP42, UL enclosure type 2

Housing material UL94-5VA

Agency listings† cULus acc. to UL60730-1A/-2-14, CAN/CSA

Noise level (max) running < 35 db (A)

spring return 62 dB (A)

Servicing maintenance free

Quality standard ISO 9001

Weight TF24-3 1.4 lbs (0.6 kg)

TF24-3-S 1.5 lbs (0.7 kg)

† Rated Impulse Voltage 800V, Type of action 1.AA (1.AA.B for -S version), Control Pollution Degree 3.

3 ft, 18 GA plenum rated cable

1/2” conduit connector

motor reversible with built-in switch

(0° spring return position)

spring < 25 sec @-4°F to 122°F [-20°C to 50°C]

< 60 sec @-22°F [-30°C]

E60730-1:02, CE acc. to 2004/108/EC,

(and 2006/95/EC for -S versions)

Torque min. 18 in-lb, for control of air dampers

Application

For modulation or On/Off control of dampers in HVAC systems. Actuator sizing

should be done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft from 1/4” up to 1/2” in

diameter by means of its universal clamp, 1/2” shaft centered at delivery. A crank

arm and several mounting brackets are available for applications where the

actuator cannot be direct coupled to the damper shaft.

Control is floating point from a triac or relay, or On/Off from an auxiliary contact

on a fan motor contactor, controller, or manual switch.

Operation

The TF series actuators provide true spring return operation for reliable fail-safe

application and positive close-off on air tight dampers. The spring return system

provides consistent torque to the damper with, and without, power applied to the

actuator.

The TF series provides 95° of rotation and is provided with a graduated position

indicator showing 0 to 95°.

The TF24-3(-S) US uses a brushless DC motor which is controlled by an

Application Specific Integrated Circuit (ASIC) and a microprocessor. The

microprocessor provides the intelligence to the ASIC to provide a constant

rotation rate. The ASIC monitors and controls the brushless DC motor’s rotation

and provides a digital rotation sensing function to prevent damage to the

actuator in a stall condition. The actuator may be stalled anywhere in its normal

rotation without the need of mechanical end switches.

Power consumption is reduced in holding mode.

The TF24-3-S US version is provided with 1 built-in auxiliary switch. This SPDT

switch is provided for safety interfacing or signaling, for example, for fan startup. The switching function is adjustable between 0° and 95°. The auxiliary

switch in the TF24-3-S US is double insulated so an electrical ground is not

necessary.

Dimensions (Inches [mm])

0.68" [16.7]

3.30"

[83.72]

2.40"

[61]

6.28"

4.5"

[114]

[159.5]

0.43" [11]

0.2"

[5.2]

Standard:

1/4" to 1/2"

1/4" to 5/16"

3.0"

[76.2]

0.77" [19.5]

D096

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

TF24-3-S US

Auxiliary switch 1 x SPDT 3A (0.5A) @ 250 VAC, UL Approved

adjustable 0° to 95° (double insulated)

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

102

Page 10

TF24-3(-S) US

Line

Volts

The indication of direction is valid

for switch position CW.

Blk ( 1) Common

Red (2)

~

Wht (W3) ~

Or (W4) ~

24 VAC Transformer

TF24-3 (-S) US

b

CCW

CW

stop

a

(3) (4)

stop stop stop

Installation Side

Direction of Rotation Switch

x

x

x

x

x

x

x

x

xx

x

x

xx

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

CW

CCW

Switch

Positions

CCW

CW

a

b

7

Blk (1) Common

Red

(2) ~ Hot

Wht

(W3) ~

Or (W4) ~

ComHot

Controller

Line

Volts

TF24-3 (-S) US

The indication of direction

is valid for switch position CW.

2

24 VAC Transformer

7

Blk (1) Common

Red

(2) ~ Hot

Wht

(W3) ~

Or (W4) ~

ComHot

Controller

Line

Volts

TF24-3 (-S) US

The indication of direction is valid for switch position CW.

2

3

4

24 VAC Transformer

7

Blk (1) Common

Red

(2) ~ Hot

Wht

(W3) ~

Or (W4) ~

ComHot

Controller

Line

Volts

TF24-3 (-S) US

The indication of direction is valid for switch position CW.

2

4

24 VAC Transformer

Line

Volts

24 VAC Transformer

7

On/Off, Spring Return Fail-Safe, Reversible, Floating Point, 24V

Accessories

Tool-06 8mm and 10 mm wrench

KH-TF Crankarm for up to 1/2” round shaft

ZG-TF2 Crankarm adaptor kit for TF

ZG-TF112 Mounting bracket, kit for TF

ZS-100 Weather shield (metal)

ZS-150 Weather shield (polycarbonate)

NOTE: When using TF24-3(-S) US actuators, only use accessories listed on this page.

For Actuator Wiring Information and Diagrams, Please See Belimo Wiring Guide (pg 349).

Typical Specification

Floating point, On/Off spring return damper actuators shall be direct coupled

type which require no crankarm and linkage and be capable of direct mounting

to a shaft up to a 1/2” diameter and center a 1/2” shaft. The actuators must be

designed so that they may be used for either clockwise or counterclockwise

fail-safe operation. Actuators shall have an external direction of rotation switch to

reverse control logic. Actuators shall use a brushless DC motor and be protected

from overload at all angles of rotation. If required, 1 SPDT auxiliary switch shall

be provided having the capability of being adjustable. Actuators with auxiliary

switch must be constructed to meet the requirements for Double Insulation so

an electrical ground is not required to meet agency listings. Run time shall be

constant and independent of torque. Actuators shall be cULus listed certified,

have a 5 year warranty, and be manufactured under ISO 9001 International Quality

Control Standards. Actuators shall be as manufactured by Belimo.

Wiring Diagrams

Installation Side

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

xx

x

x

x

x

xx

xx

x

x

x

x

xx

xx

x

x

CCW

Switch

Positions

a

(3) (4)

b

CW

Direction of Rotation Switch

CCW

CW

CW

stop

stop stop stop

CCW

Floating Point control

for TF24-3(-S) US

Auxiliary switch

of TF24-3(-S) US

S1

NC

S2

S3

NO

TF24-3-S US

W240

W241

5

0° to 95°

W242

2

3

4

5

7

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

CAUTION Equipment damage!

Actuators may be connected in parallel.

Power consumption must be observed.

The Common connection from the actuator must be connected to the

Hot connection of the controller.

The actuator Hot must be connected to the control board Common.

For end position indication, interlock control, fan startup, etc., TF243-S US incorporates one built-in auxiliary switch: 1 x SPDT, 3A (0.5A)

@250 VAC, UL Approved, adjustable 0° to 95°.

Actuators with plenum rated cable do not have numbers on wires; use

color coded instead. Actuators with appliance rated cable use numbers.

TF24-3-S US has an Orange wire #5 instead of #4.

Meets cULus requirements without the need of an electrical ground

connection.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Triac source

W243

Triac sink

W244

Triac sink with separate transformers

103

Page 11

TF24-SR(-S) US

Proportional Damper Actuator, Spring Return Fail-Safe, 24 V for 2 to 10 VDC, or 4 to 20 mA Control Signal.

Torque min. 18 in-lb, for control of air dampers

Application

For proportional modulation of dampers in HVAC systems. Actuator sizing should

be done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft from 1/4” up to 1/2” in

diameter by means of its universal clamp, 1/2” shaft centered at delivery. A

crank arm and several mounting brackets are available for applications where the

actuator cannot be direct coupled to the damper shaft.

The actuator operates in response to a 2 to 10 VDC, or with the addition of a

500 7 resistor, a 4 to 20 mA control input from an electronic controller or

positioner.

Operation

The TF series actuators provide true spring return operation for reliable fail-safe

application and positive close-off on air tight dampers. The spring return system

provides consistent torque to the damper with, and without, power applied to the

actuator.

The TF series provides 95° of rotation and is provided with a graduated position

indicator showing 0 to 95°.

The TF24-SR (-S) US uses a brushless DC motor which is controlled by an

Technical Data TF24-SR(-S) US

Power supply 24 VAC ± 20% 50/60 Hz

Power consumption running 2 W

Transformer sizing 4 VA (class 2 power source)

Electrical connection

(-S models have 2 cables)

Overload protection electronic throughout 0 to 95° rotation

Operating range Y 2 to 10 VDC, 4 to 20mA

Input impedance 100 k7 (0.1 mA), 500 7

Angle of rotation max 95°, adjust. with mechanical stop

Torque 18 in-lb [2 Nm]

Direction of rotation spring reversible with cw/ccw mounting

Position indication visual indicator, 0° to 95°

Running time motor 95 sec constant, independent of load

Humidity 5 to 95% RH non-condensing

Ambient temperature -22°F to 122°F [-30°C to 50°C]

Storage temperature -40°F to 176°F [-40°C to 80°C]

Housing NEMA type 2 / IP42, UL enclosure type 2

Housing material UL94-5VA

Agency listings† cULus acc. to UL60730-1A/-2-14, CAN/CSA

Noise level (max) running < 35 db (A)

spring return 62 dB (A)

Servicing maintenance free

Quality standard ISO 9001

Weight TF24-SR 1.4 lbs (0.6 kg)

TF24-SR-S 1.5 lbs (0.7 kg)

† Rated Impulse Voltage 800V, Type of action 1.AA (1.AA.B for -S version), Control Pollution Degree 3.

24 VDC ± 10%

holding 1 W

3 ft, 18 GA plenum rated cable

1/2” conduit connector

motor reversible with built-in switch

(0° spring return position)

spring < 25 sec @-4°F to 122°F [-20°C to 50°C]

< 60 sec @-22°F [-30°C]

E60730-1:02, CE acc. to 2004/108/EC (and

2006/95/EC for -S versions)

Application Specific Integrated Circuit (ASIC) and a microprocessor. The

microprocessor provides the intelligence to the ASIC to provide a constant

rotation rate and to know the actuator’s exact fail-safe position. The ASIC

monitors and controls the brushless DC motor’s rotation and provides a digital

rotation sensing function to prevent damage to the actuator in a stall condition.

The actuator may be stalled anywhere in its normal rotation without the need of

mechanical end switches. Power consumption is reduced in holding mode.

The TF24-SR-S US version is provided with 1 built-in auxiliary switch. This SPDT

switch is provided for safety interfacing or signaling, for example, for fan startup. The switching function is adjustable between 0° and 95°. The auxiliary

switch in the TF24-SR-S US is double insulated so an electrical ground in not

necessary.

Dimensions (Inches [mm])

0.68" [16.7]

3.30"

[83.72]

2.40"

[61]

4.5"

[114]

[159.5]

Standard:

1/4" to 1/2"

1/4" to 5/16"

3.0"

[76.2]

0.77" [19.5]

6.28"

0.43" [11]

0.2"

D096

[5.2]

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

TF24-SR-S US

Auxiliary switch 1 x SPDT 3A (0.5A) @ 250 VAC, UL Approved

adjustable 0° to 95° (double insulated)

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

104

Page 12

TF24-SR(-S) US

Proportional Damper Actuator, Spring Return Fail-Safe, 24 V for 2 to 10 VDC, or 4 to 20 mA Control Signal.

Accessories

Tool-06 8mm and 10 mm wrench

KH-TF Crankarm for up to 1/2” round shaft

ZG-TF2 Crankarm adaptor kit for TF

ZG-TF112 Mounting bracket, kit for TF

ZS-100 Weather shield (metal)

ZS-150 Weather shield (polycarbonate)

NOTE: When using TF24-SR (-S) US actuators, only use accessories listed on this page.

For Actuator Wiring Information and Diagrams, Please See Belimo Wiring Guide (pg 349).

Typical Specification

Spring return control damper actuators shall be direct coupled type which

require no crankarm and linkage and be capable of direct mounting to a shaft

up to a 1/2” diameter and center a 1/2” shaft. The actuator must provide

proportional damper control in response to a 2 to 10 VDC or, with the addition

of a 500 7 resistor, a 4 to 20 mA control input from an electronic controller or

positioner.The actuators must be designed so that they may be used for either

clockwise or counterclockwise fail-safe operation. Actuators shall use a brushless DC motor controlled by a microprocessor and be protected from overload

at all angles of rotation. Run time shall be constant, and independent of torque.

If required, 1 SPDT auxiliary switch shall be provided having the capability of

being adjustable. Actuators with auxiliary switch must be constructed to meet

the requirements for Double Insulation so an electrical ground is not required

to meet agency listings. Actuators shall be cULus listed certified, have a 5 year

warranty, and be manufactured under ISO 9001 International Quality Control

Standards. Actuators shall be as manufactured by Belimo.

Wiring Diagrams

24 VAC Transformer

Line

Volts

Control Signal

2 to 10 VDC

(–)

(+)

2 to 10 VDC control of TF24-SR(-S) US

Auxiliary switch of TF24-SR-S US

6

Blk (1) Common

Red (2) + Hot

Wht (3) Y Input, 2 to 10V

TF24-SR US

3

1

2

W245

W246_08

W247_08

CAUTION Equipment damage!

2

Up to 4 actuators may be connected in parallel. With 4 actuators wired

to one 500 7 resistor, a +2% shift of control signal may be required.

Power consumption must be observed.

Actuator may also be powered by 24 VDC.

3

Only connect common to neg. (–) leg of control circuits.

5

Actuators with plenum rated cable do not have numbers on wires; use

6

color codes instead.

For end position indication, interlock control, fan startup, etc., TF24-

7

SR-S US incorporates one built-in auxiliary switch: 1 x SPDT, 3A

(0.5A ) @250 VAC, UL Approved, adjustable 0° to 95°.

Meets cULus requirements without the need of an electrical ground

connection.

The ZG-R01 500 7 resistor converts the 4 to 20 mA control signal to

2 to 10 VDC.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

4 to 20 mA control of TF24-SR(-S) US

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

105

Page 13

TF24-MFT US

Proportional damper actuator, Spring Return Fail-Safe, Multi-Function Technology

s 4ORQUEMININLB

s #ONTROLTO6$#$EFAULT

s &EEDBACKTO6$#$EFAULT

Application

For proportional modulation of dampers in HVAC systems. Actuator sizing should

be done in accordance with the damper manufacturer’s specifications.

Default/Configuration

Default parameters for 2 to 10 VDC applications of the TF24-MFT US actuator are

assigned during manufacturing. If required, custom versions of the actuator can

be ordered. The parameters noted in the Technical Data table are variable.

These parameters can be changed by three means:

s0RESETCONFIGURATIONSFROM"ELIMO

s#USTOMCONFIGURATIONSFROM"ELIMO

s#ONFIGURATIONSSETBYTHECUSTOMERUSINGTHE-&40#TOOLSOFTWAREAPPLICATION

Operation

The TF series actuators provide true spring return operation for reliable fail-safe

application and positive close-off on air tight dampers. The spring return system

provides consistent torque to the damper with, and without, power applied to the

Technical Data TF24-MFT US

Power supply 24 VAC, ± 20%, 50/60 Hz

24 VDC, ±10%

Power consumption running 2.5 W

holding 1 W

Transformer sizing 4 VA (Class 2 power source)

Electrical connection 3 ft, 18 GA, plenum rated cable

1/2” conduit connector

Overload protection electronic throughout 0 to 95° rotation

Operating range Y* 2 to 10 VDC

4 to 20 mA (w/500 7, 1/4 7 resistor) ZG-R01

Input impedance 100 k7 for 2 to 10 VDC (0.1 mA)

500 7 for 4 to 20 mA

1500 7 for PWM, Floating point and

On/Off control

Feedback output U* 2 to 10 VDC, 0.5 mA max

Torque min 18 in-lb (2 Nm)

Direction of rotation* spring reversible with cw/ccw mounting

motor reversible with built-in switch

Mech. angle of rotation* max 95°, adjust with mechanical stop

Running time motor* 150 sec constant independent of load

spring <25 sec @-4°F to 122°F [-20°C to 50°C]

<60 sec @-22°F [-30°C]

Angle of Rotation Adaptation* Off (Default)

Override control* Min. (Min Position) = 0%

- ZS (Mid. Position) = 50%

- Max. (Max. Position) = 100%

Position indication visual indicator, 0° to 95°

Humidity 5 to 95% RH, non-condensing

Ambient temperature -22 to 122° F (-30 to 50° C)

Storage temperature -40 to 176° F (-40 to 80° C)

Housing NEMA 2, IP42, UL enclosure type 2

Housing material UL 94-5VA

Noise level (max) <35 dB (A)

spring return <65 dB (A)

Agency listings cULus acc. to UL60730-1A/-2-14,

CAN/CSA E60730-1:02,

CE acc. to 2004/108/EC

Quality standard ISO 9001

Servicing maintenance free

Weight 1.4 lbs. (0.6 kg)

* Variable when configured with MFT options

† Rated Impulse Voltage 800V, Type of action 1.AA, Control Pollution Degree 3.

actuator.

The TF series provides 95° of rotation and is provided with a graduated position

indicator showing 0 to 95°.

The TF24-MFT US uses a brushless DC motor which is controlled by an

Application Specific Integrated Circuit (ASIC) and a microprocessor. The

microprocessor provides the intelligence to the ASIC to provide a constant

rotation rate and to know the actuator’s exact fail-safe position. The ASIC

monitors and controls the brushless DC motor’s rotation and provides a digital

rotation sensing function to prevent damage to the actuator in a stall condition.

The actuator may be stalled anywhere in its normal rotation without the need of

mechanical end switches. Power consumption is reduced in holding mode.

SAFETY NOTE

Screw a conduit fitting into the actuator’s bushing. Jacket the actuator’s

input and output wiring with suitable flexible conduit. Properly terminate the

conduit in a suitable junction box.

Dimensions (Inches [mm])

Standard:

1/4" to 1/2"

1/4" to 5/16"

®

D191

0.68" [16.7]

3.30"

[83.72]

2.40"

[61]

6.28"

[159.5]

3.0"

[76.2]

0.77" [19.5]

4.5"

[114]

0.43" [11]

0.2"

[5.2]

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

106

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 14

Proportional damper actuator, Spring Return Fail-Safe, Multi-Function Technology

Wiring Diagrams

Provide overload protection and disconnect as required.

1

CAUTION Equipment damage!

2

Actuators may be connected in parallel if not mechanically mounted to the

same shaft. Power consumption and input impedance must be observed.

Actuators may also be powered by 24 VDC.

3

The ZG-R01 500 7 resistor may be used.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

TF24-MFT US

®

W024_08

Standard Wiring

Override to Zero PositionOverride to 10V PositionOverride control to min, mid, max, positions

W025_08

Standard Wiring

Override to Zero PositionOverride to 20 mA Position

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

4 to 20 mA control signal

2 to 10 VDC control signal

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

107

Page 15

Installation Instructions

ZDB-TF

min 3/4”

[20]

min 3/4”

[20]

ZDB-TF

Quick-Mount Visual Instructions for Mechanical Installation

Quick-Mount Visual Instructions

1. Rotate the damper to its failsafe position. If the shaft rotates counterclockwise, mount the “CCW” side of the actuator out. If it rotates clockwise,

mount the actuator with the “CW” side out.

2. If the universal clamp is not on the correct side of the actuator, move it to the

correct side.

3. Slide the actuator onto the shaft and tighten the nuts on the V-bolt with an

8mm wrench to 6-8 ft-lb of torque.

4. Slide the anti-rotation strap under the actuator so that it engages the slot

at the base of the actuator. Secure the strap to the duct work with #8 selftapping screws.

NOTE: Read the “Standard Mounting” instructions, on page 92, for more

detailed information.

Dimensions (Inches [mm])

Standard

Mounting

min. 3-5/16”

[80]

1/4” to1/2”

[6-12]

min 3-5/16”

[84]

Preliminary Steps

1. Belimo actuators should be mounted indoors in dry, relatively clean environment free from corrosive fumes. If the actuator is to be mounted outdoors,

a protective enclosure must be used to shield the actuator. (See Mechanical

Accessories Section)

2. For new construction work, order dampers with extended shafts. Instruct

the installing contractor to allow space for mounting and service of the

Belimo actuator on the shaft.

3. For standard mounting, the damper shaft must extend at least 3 1/2" from

the duct. If the shaft extends less than 3 1/2", the actuator may be mounted

in its short shaft configuration.

Short Shaft

Mounting

min. 3/4”

[20]

1/4” to 1/2”

[6-12]

108

min 3-5/16”

[84]

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

Page 16

Mechanical Operation

The actuator is mounted directly to a damper shaft up to 1/2” in diameter by

means of its universal clamp. A crank arm and several mounting brackets are

available for applications where the actuator cannot be direct coupled to the

damper shaft.

The TF series actuators provide true spring return operation for reliable failsafe application and positive close-off on air tight dampers. The spring return

system provides consistent torque to the damper with, and without, power

applied to the actuator.

The TF series provides 95° of rotation and is provided with a graduated position

indicator showing 0 to 95°.

The TF…-S versions are provided with 1 built-in auxiliary switch. This SPDT

switch is provided for safety interfacing or signaling, for example, for fan startup. The switching function is adjustable between 0° and 95°.

Standard Mounting / Airtight Damper Procedure

1. See Figure B. Manually move the damper to the fail-safe position (a)

(usually closed). If the shaft rotated counterclockwise ( ), this is

a CCW installation. If the shaft rotated clockwise (

installation. In a Left Hand installation, the actuator side marked “CW”

faces out, while in a CW installation, the side marked “CCW” faces out. All

other steps are identical.

2. The actuator is usually shipped with the universal clamp mounted to the

“CW” side of the actuator. To test for adequate shaft length, slide the

actuator over the shaft with the side marked “CW” (or the “CCW” side if

this is the side with the clamp). If the shaft extends at least 1/8” through

the clamp, mount the actuator as follows. If not, go to the Short Shaft

Installation section.

3. If the clamp is not on the correct side as determined in step #1, re-mount

the clamp as follows. If it is on the correct side, proceed to step #5. Look

at the universal clamp. If you are mounting the actuator with the “CCW”

side out, position the clamp so that the pointer section of the tab is pointing

to 0° (see Fig. C) and the spline pattern of the clamp mates with spline of

the actuator. Remount the stroke limiter to this side then slip the clamp

over the spline. (Use the same procedure if the “CW” side is out.)

4. See Remounting the Stroke Limiter after the section Short Shaft Mounting

with IND-TF Position Indicator.

5. Lock the clamp to the actuator using the retaining clip.

6. Verify that the damper is still in its full fail-safe position. (a)

7. Mount the spring return actuator to the shaft. Tighten the universal clamp,

finger tight only.

8. Mount the anti-rotation strap at the base of the actuator. Do not tighten the

screws.

9. Remove the screw from one end of the mounting bracket and pivot it away

from the actuator.

10. Loosen the universal clamp and, making sure not to move the damper

shaft, rotate the actuator approximately 5° in the direction which would

open the damper.

11. Tighten the universal clamp to the shaft.

12. Rotate the actuator to apply pressure to the damper seals (b) and re-engage

the anti-rotation strap (c).

13. Tighten all fasteners.

), this is a CW

Installation Instructions

Mechanical Installation

min 3-5/16”

[84]

FIGURE B – Standard Mounting (Dimensions in Inches [mm])

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

FIGURE C – Universal Clamp

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

109

Page 17

ZDB-TF

min 3/4”

[20]

Installation Instructions

Mechanical Installation

Short Shaft Mounting with

IND-TF Position Indicator / Airtight Damper Procedure

If the shaft extends at least 3/4” from the duct, follow these steps:

1. (See Figure D) Move damper blades to the fail-safe position (a).

2. Determine the best orientation for the universal clamp on the back of the

actuator. The best location would be where you have the easiest access to

the V bolt nuts on the clamp.

3. Engage the clamp to the actuator as close as possible to the determined

location.

4. Lock the clamp to the actuator using the retainer clip.

5. Mount the spring return actuator to the shaft. Tighten the universal clamp,

finger tight only.

6. Mount the anti-rotation strap at the base of the actuator. Do not tighten the

screws.

7. Remove the screw from one end of the mounting bracket and pivot it away

from the actuator.

8. Loosen the universal clamp and, making sure not to move the damper

shaft, rotate the actuator approximately 5° in the direction which would

open the damper.

9. Verify that the damper is still in its full fail-safe position.

10. Tighten the universal clamp to the shaft.

11. Rotate the actuator to apply pressure to the damper seals (b) and reengage the anti-rotation strap (c).

12. Tighten all fasteners.

13. Use IND-TF accessory if position indication is needed.

Remounting the Stroke Limiter

1. Remove the stroke limiter by

inserting a small screwdriver, like

the one shown, and gently prying

upward. This procedure takes

very little force. See Figure 1.

2. While holding the back eye-let,

unscrew the end-stop so that eyelet separates from the end-stop.

3. Flip the limiter over, so the teeth

point the other direction. Replace

the eye-let and end-stop.

4. Flip the actuator over to the

opposite side (this reverses the

spring return direction of the

actuator). Replace the stroke

limiter assembly by inserting

the first two teeth as shown in

the orange circle. Then press

the stroke limiter into place

by pushing downward on the

adjustable stop.

5. Replace clamp and retaining clip.

FIGURE 1

FIGURE D – Standard Mounting (Dimensions in Inches [mm])

110

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 18

Installation Instructions

Mechanical Installation

Operational Information for TF Actuators

Initialization of the TF24-SR (-S) US

When power is applied, the internal microprocessor recognizes that the

actuator is at its full fail-safe position and uses this position as the base

for all of its position calculations. This procedure takes approximately

15 seconds. During this time you will see no response at the actuator.

The microprocessor will retain the initialized zero during short power

failures of up to 25 seconds. When power is applied during this period,

the actuator will return to normal operation and proceed to the position

corresponding to the input signal provided. For power failures over 25

seconds, the actuator will be at its fail-safe position and will go through

the start up initialization again.

Motor position detection TF24-SR (-S) US

Belimo brushless DC motors eliminate the need for potentiometers for positioning. Inside the motor are three “Hall Effect” sensors. These sensors

detect the spinning rotor and send pulses to the microprocessor which

counts the pulses and calculates the position to within 1/3 of a revolution

of the motor.

Overload protection

The TF, On/Off actuators are electronically protected against overload. The

TF, On/Off actuator have an internal current limiter which maintains the

current at a safe level which will not damage the actuator while providing

adequate holding torque.

The TF24, modulating, actuators (TF24-SR (-S) US, TF24-3 US) are

protected against overload by digital technology located in the ASIC. The

ASIC circuitry constantly monitors the rotation of the brushless DC motor

inside the actuator and stops the pulsing to the motor when it senses a

stall condition. The motor remains energized and produces full rated

torque during stall conditions. The actuator will try to move in the direction of the stall every 2 minutes, for a period of 32 minutes. After this, the

actuator will try again every 2 hours.

Mechanical Angle of Rotation Limiting

The TF actuators are provided with an adjustable stop to limit the rotation of the

actuator. This function works in conjunction with the universal clamp or the

optional position indicator. The adjustable stop is needed when rotation of less

than 95° is required. The TF actuator can be indefinitely stalled, in any position,

without harming the actuator.

37...100%

Using the Universal Clamp

1. Loosen the end stop fastening screw using a #2 Phillips screwdriver.

2. Move the stop block so the bottom edge of the block lines up with the number

corresponding to the desired degrees of rotation. (example: 45 degrees of

rotation = .5)

3. Lock the block in place with the fastening screw.

4. Check the actuator for proper rotation.

Using the IND-TF Position Indicator with Adjustable Stop

NOTE: preferred method if short shaft mounting is used.

1. With the actuator in its fail-safe position, place the IND-TF Position Indicator

so that it points to the 0 degree position.

2. Loosen the end stop fastening screw using a #2 Phillips screwdriver.

3. Move the stop block so the bottom edge of the block lines up with the number

corresponding to the desired degrees of rotation (example: 45 degrees of

rotation = .5).

4. Lock the block in place with the fastening screw.

5. Check the actuator for proper rotation.

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

Direction of Rotation Switch

TF24-3 (-S) US and TF24-SR (-S) US actuators have a direction of rotation

switch on the cover labeled “CW-CCW”. Switch position indicates start point.

For the TF24-SR, with the switch in position “CW”, the actuator rotates clockwise with a decrease in voltage or current. With the switch in position “CCW”,

the actuator rotates counterclockwise with a decrease in voltage or current.

The TF24-3 (-S) US and TF24-SR (-S) US actuators rotate clockwise when the

switch is in the “CW” position and power is applied to wire #3. When power is

applied to wire #4 the actuator rotates counter clockwise.

Rotating the direction of rotation switch to “CCW” reverses the control logic.

During checkout, the switch position can be temporarily reversed and the actuator will reverse its direction. This allows the technician a fast and easy way to

check the actuator operation without having to switch wires or change settings

on the controller.

placed back to its original position.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

When the check-out is complete, make sure the switch is

111

Page 19

Installation Instructions

Mechanical Installation

Auxiliary Switches

The …-S model actuators are equipped with an adjustable auxiliary switch used

to indicate damper position or to interface additional controls or equipment.

Switching positions can be set over the full 0 to 95° rotation simply by setting a

switch on the actuator.

1. Set desired switch position.

(Example 60%)

2. As the actuator rotates, the switch

indicator moves from .6 (60%)

toward 0 (0%).

0

.2

.4

S2

S1

S3

.6

S2

S1

.8

1

S3

Switch Rating

Voltage Resistive load Inductive load

250 VAC 3 A 0.5 A

Control Accuracy and Stability

TF24-SR US actuators have built-in

brushless DC motors which provide

better accuracy and longer service life.

The TF24-SR US actuators are designed with a unique non-symmetrical

deadband. The actuator follows an increasing or decreasing control signal with a 80 mV resolution. If the signal changes in the opposite direction, the actuator will not respond until the control signal changes by 200

mV. This allows these actuators to track even the slightest deviation very

accurately, yet allowing the actuator to “wait” for a much larger change in

control signal due to control signal instability.

TF Actuator responds to a 80 mV signal when

not changing direction from stop position.

Satisfied

Control Position

80 mV

Minimum

Control Resolution

Non-Direct Mounting Methods

ZG-TF2 Crankarm Adaptor Kit

KG6

TF Actuator responds to a 200 mV signal when

reversing direction from stop position.

Minimum Reversed

Control Deadband

Prior to Normal Control

SH8

KG6

Dimensions (Inches [mm])

200 m

3.15"

[81]

V

1.59"

[40.5]

Control Position

Satisfied

[19.5]

[18]

0.43"

[11]

0.77"

0.71"

0.43"

[11]

TF_install

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

112

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 20

Installation Instructions

General Wiring

WARNING The wiring technician must be trained and experienced with

electronic circuits. Disconnect power supply before attempting any wiring

connections or changes. Make all connections in accordance with wiring

diagrams and follow all applicable local and national codes. Provide disconnect

and overload protection as required. Use copper, twisted pair, conductors only.

If using electrical conduit, the attachment to the actuator must be made with

flexible conduit.

Always read the controller manufacturer's installation literature carefully

before making any connections. Follow all instructions in this literature. If

you have any questions, contact the controller manufacturer and/or Belimo.

Transformers

The TF24 . . actuator requires a 24 VAC class 2 transformer and draws a

maximum of 5 VA per actuator. The actuator enclosure cannot be opened in the

field, there are no parts or components to be replaced or repaired.

– EMC directive: 89/336/EEC

– Software class A: Mode of operation type 1

– Low voltage directive: 73/23/EEC

CAUTION It is good practice to power electronic or digital controllers from a

separate power transformer than that used for actuators or other end devices.

The power supply design in our actuators and other end devices use half wave

rectification. Some controllers use full wave rectification. When these two

different types of power supplies are connected to the same power transformer

and the DC commons are connected together, a short circuit is created across

one of the diodes in the full wave power supply, damaging the controller. Only

use a single power transformer to power the controller and actuator if you know

the controller power supply uses half wave rectification.

Multiple Actuators, One Transformer

Multiple actuators may be powered from one transformer provided the following rules are followed:

1. The TOTAL current draw of the actuators (VA rating) is less than or equal to

the rating of the transformer.

2. Polarity on the secondary of the transformer is strictly followed. This means

that all No. 1 wires from all actuators are connected to the common leg on

the transformer and all No 2 wires from all actuators are connected to the

hotleg.

Mixing wire No. 1 & 2 on one leg of the transformer will result in

erratic operation or failure of the actuator and/or controls.

Multiple Actuators, Multiple Transformers

Multiple actuators positioned by the same control signal may be powered from

multiple transformers provided the following rules are followed:

1. The transformers are properly sized.

2. All No. 1 wires from all actuators are tied together and tied to the negative leg

of the control signal. See wiring diagram.

Wire Length for LF... Actuators

Keep power wire runs below the lengths listed in the table in Figure A. If more

than one actuator is powered from the same wire run, divide the allowable wire

length by the number of actuators to determine the maximum run to any single

actuator.

Example for TF24-SR US: 3 actuators, 16 Ga wire

550 Ft ÷ 3 Actuators = 183 Ft. Maximum wire run

TF24(-S) US / TF120(-S) US Maximum Wire Length

Wire Size Max. Feet. Wire Size Max. Feet

12 Ga 1300 Ft. 18 Ga 575 Ft.

14 Ga 1175 Ft. 20 Ga 300 Ft.

16 Ga 900 Ft. 22 Ga 150 Ft.

TF24-3(-S) US Maximum Wire Length

Wire Size Max. Feet. Wire Size Max. Feet

16 Ga 1125 Ft. 20 Ga 400 Ft.

18 Ga 725 Ft. 22 Ga 200 Ft.

TF24-SR(-S) US Maximum Wire Length

Wire Size Max. Feet. Wire Size Max. Feet

12 Ga 1800 Ft. 18 Ga 450 Ft.

14 Ga 1100 Ft. 20 Ga 275 Ft.

16 Ga 700 Ft. 22 Ga 125 Ft.

FIGURE A

Wire Type and Wire Installation Tips

For most installations, 18 or 16 Ga. cable works well with the TF24… actuators.

Use code-approved wire nuts, terminal strips or solderless connectors where

wires are joined. It is good practice to run control wires unspliced from the

actuator to the controller. If splices are unavoidable, make sure the splice can

be reached for possible maintenance. Tape and/or wire-tie the splice to reduce

the possibility of the splice being inadvertently pulled apart.

The TF24… proportional actuators have a digital circuit that is designed to ignore most unwanted input signals (pickup). In some situations the pickup may

be severe enough to cause erratic running of the actuator. For example, a large

inductive load (high voltage AC wires, motors, etc.) running near the power or

control wiring may cause excessive pickup. To solve this problem, make one or

more of the following changes:

1. Run the wire in metallic conduit.

2. Re-route the wiring away from the source of pickup.

3. Use shielded wire (Belden 8760 or equal).

ground. Do not connect it to the actuator common.

Ground the shield to an earth

Brushless DC Motor Operation

Belimo's brushless DC motor spins by reversing the poles of stationary

electromagnets housed inside rotating permanent magnets. The electromagnetic poles are switched by a microprocessor and a special ASIC (Application

Specific Integrated Circuit) developed by Belimo. Unlike the conventional DC

motor, there are no brushes to wear or commutators to foul.

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

113

Page 21

Startup and Checkout

Instructions For TF24-SR(-S) US

TF24-SR(-S) US Electrical check-out procedure

STEP Procedure Expected Response

1. Remove power to reset actuator.

Re-apply power.

Apply control signal to actuator.

2. Check power wiring. Correct any

problems. See Note 1.

3. Turn reversing switch to the correct

position. Make sure the switch is

turned all the way left or right.

4. Make sure the control signal positive

(+) is connected to Wire No 3 and

control signal negative (-) is connected to wire No. 1. Most control

problems are caused by reversing

these two wires. Verify that the

reversing switch is all the way CCW

or CW.

5. Check input signal with a digital volt

meter (DVM). Make sure the input

is within the range of the actuator.

For TF24-SR US this is 2 to 10 VDC

or 4 to 20 mA. Note: The input signal must be above the 2 VDC or 4

mA to have the actuator move.

6. Loosen the nuts on the V-bolt and

move the damper by hand from fully

closed to fully open.

7. Check damper torque requirement. Torque requirement is actuator’s

8. Actuator works properly. Test

controller by following controller

manufacturer's instructions.

Actuator will move to its “Control

Signal” position.

Power supply rating should be > the

total power requirement of the

actuator(s). Minimum voltage of

19.2 VAC or 21.6 VDC.

Actuator will move to its “Control

Signal” position.

Drives to “Control Signal” position. Actuator operates properly Step 8. Step 5.

Input voltage or current should be

±1% of what controller's adjustment

or programming indicate.

Damper will go from fully closed to

fully open.

minimum torque.

Gives Expected Response

Go To Step…

Actuator operates properly Step 8. No response at all Step 2.

Power wiring corrected, actuator

begins to drive Step 1.

Actuator operates properly Step 8. Does not drive toward “Control

Controller output (actuator input) is

correct. Input Polarity Correct

Step 6.

Damper moves

properly Step 7.

Defective Actuator.

Replace Actuator - See Note 2.

Operation is reversed Step 3.

Does not drive toward "Control

Signal Position" Step 4.

Power wiring corrected, actuator still

does not drive Step 4.

Signal Position” Step 4.

Reprogram, adjust repair or replace

controller as needed Step 1.

Find cause of damper jam and repair.

Move damper back to the fully

closed position and tighten the nuts

Step 1.

Recalculate actuator requirement and

correct installation.

Does Not Give

Expected Response

Go To Step…

NOTE 1 Check that the transformer(s) are sized properly.

s )FACOMMONTRANSFORMERISUSEDMAKESURETHATPOLARITYISOBSERVEDONTHESECONDARY4HISMEANSCONNECTALL.OWIRESTOONELEGOFTHETRANSFORMER

and all No. 2 wires to the other leg of the transformer.

s )FMULTIPLETRANSFORMERSAREUSEDWITHONECONTROLSIGNALMAKESUREALL.OWIRESARETIEDTOGETHERANDTIEDTOCONTROLSIGNALNEGATIVE

s #ONTROLLERSANDACTUATORSMUSTHAVESEPARATE6!#6$#POWERSOURCES

NOTE 2 If failure occurs within 5 years from original installation date, notify Belimo and give details of the application.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

114

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

Loading...

Loading...