Page 1

Document 460983

Models TDI,

®

TBI-CA and TBI-FS

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

General Safety Information

Only qualified personnel should install this unit.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

TDI

TBI-CA

Level 3, 4 and 5

Cast Aluminum Propeller

Fabricated Steel Propeller

TBI-FS

Level 3, 4 and 5

Table of Contents

Receiving, Unpacking Handling and Storage ...... 2

Removing from Storage ...................... 2

Lifting ..................................... 3

Effects of Installation on Performance ........... 3

Typical Installation ........................... 4

Operation and Unit Start-Up

Electrical Connections ..................... 5

Pre-Start-Up Checks ...................... 5

Maintenance

Fasteners and Set Screws .................. 6

Bearings ................................ 6

Lubrication bearings and motor .............. 6

Motor .................................. 6

Belts ................................... 6

Removal of dust, dirt and debris ............. 7

Parts List .................................. 7

Commitment ............................... 8

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

1. Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), the National

Fire Protection Agency (NFPA), where applicable.

Follow the Canadian Electric Code (CEC) in Canada.

2. The rotation of the propeller is critical. It must

be free to rotate without striking or rubbing any

stationary objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan propeller faster than the maximum

cataloged fan rpm. Adjustments to fan speed with

Variable Frequency Drives (VFD) may affect motor

load. If the fan RPM is changed, the motor current

should be checked to make sure it is not exceeding

the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

DANGER

Always disconnect power before working on or near a

unit. Lock and tag the disconnect switch or breaker to

prevent accidental power up.

CAUTION

When servicing the unit, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

®

Tubular Inline Fans

1

Page 2

Receiving

Upon receiving the product, check the bill of lading to

ensure all items were received. Inspect each crate for

shipping damage before accepting delivery. Notify the

carrier if any damage is noticed. The carrier will make

notification on the delivery receipt acknowledging any

damage to the product. All damage should be noted on

all the copies of the bill of lading which is countersigned

by the delivering carrier. A Carrier Inspection Report

should be filled out by the carrier upon arrival. If

damaged upon arrival, file claim with carrier. Any

physical damage to the unit after acceptance is not the

responsibility of Greenheck Fan Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative to

arrange for obtaining missing parts. Sometimes it is not

possible that all items for the unit be shipped together

due to availability of transportation and truck space.

Confirmation of shipment(s) must be limited to only

items on the bill of lading.

Handling

Handle in such a manner as to keep from scratching

or chipping the coating. Fans should not be lifted by

the motor shaft, motor housing or fan accessories.

Damaged finish may reduce ability of unit to resist

corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

INDOOR — The ideal environment for the storage of

units and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain, or snow. Temperatures

should be evenly maintained between 30°F (-1°C)

and 110°F (43°C) (wide temperature swings may

cause condensation and “sweating” of metal parts).

All accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To avoid

“sweating” of metal parts allow cold parts to reach room

temperature. To dry parts and packages, use a portable

electric heater. Leave coverings loose to permit air

circulation and to allow for periodic inspection.

The unit should be stored at least 3½ inches (89 mm)

off the floor on wooden blocks covered with moisture

proof paper or polyethylene sheathing. Aisles between

parts and along all walls should be provided to permit

air circulation and space for inspection.

OUTDOOR — Units designed for outdoor applications

may be stored outdoors, if absolutely necessary. Roads

or aisles for portable cranes and hauling equipment are

needed.

The fan should be placed on a level surface to prevent

water from leaking into the unit. The unit should be

elevated on an adequate number of wooden blocks so

that it is above water and snow levels and has enough

blocking to prevent it from settling into soft ground.

Locate parts far enough apart to permit air circulation,

sunlight, and space for periodic inspection. To minimize

water accumulation, place all unit parts on blocking

supports so that rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Inspection and Maintenance during Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan propeller by hand ten to fifteen

revolutions to distribute lubricant on motor. Every three

months, the fan motor should be energized. If paint

deterioration begins, consideration should be given to

touch-up or repainting. Fans with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lint-free

cloths. Polish any remaining rust from surface with

crocus cloth or fine emery paper and oil. Do not destroy

the continuity of the surfaces. Wipe thoroughly clean

with Tectyl® 506 (Ashland Inc.) or the equivalent. For

hard to reach internal surfaces or for occasional use,

consider using Tectyl® 511M Rust Preventive or WD-40®

or the equivalent.

REMOVING FROM STORAGE — As units are removed

from storage to be installed in their final location, they

should be protected and maintained in a similar fashion,

until the equipment goes into operation.

Prior to installing the unit and system components,

inspect the unit assembly to make sure it is in working

order.

1. Check all fasteners on the fan, propeller, motor base,

and accessories for tightness.

2. Rotate the fan propeller by hand and assure no parts

are rubbing.

3. Fans should not be lifted by the motor shaft, motor

housing or fan accessories.

Tubular Inline Fans

2

®

Page 3

Lifting

DISCHARGE DUCT TURNS

1 Fan

Dia.

Good

Poor

3 Diameters of

Straight Duct

DISCHARGE DUCT TURNS

INLET DUCT TURNS

Air Flow

Air Flow

Fans should not be lifted by the motor, motor shaft,

motor cover, belt guard, tie down points, belt tube,

damper frame, windband, or fan accessories.

Flanged Housing Only

Use a minimum of four bolt holes, two per flange, or

attach two suitable chains / straps around the entire fan

housing, one near each duct flange when lifting large

horizontal fans. Secure the fan housing to prevent the

weight of a top or side mounted motor from rotating the

housing while being lifted.

For vertical hanging installations, attach a suitable lifting

device to the fan housing or inlet/outlet flange.

With Mounting Brackets

Fans are to be rigged by either the optional brackets

provided or by the skid when a forklift is used. Slings

can be attached as described above or to mounting

brackets located at the ends of the fan housing.

Effects of Installation on

Performance

Any installation with inlet or discharge configurations

that deviate from these recommendations may result in

reduced fan performance. Restricted or unstable flow

at the fan inlet can cause pre-rotation of incoming air or

uneven loading of the fan propeller yielding large system

losses and increased sound levels. Free discharge or

turbulent flow in the discharge ductwork will also result

in system effect losses.

The most common inlet and discharge conditions which

affect fan performance are:

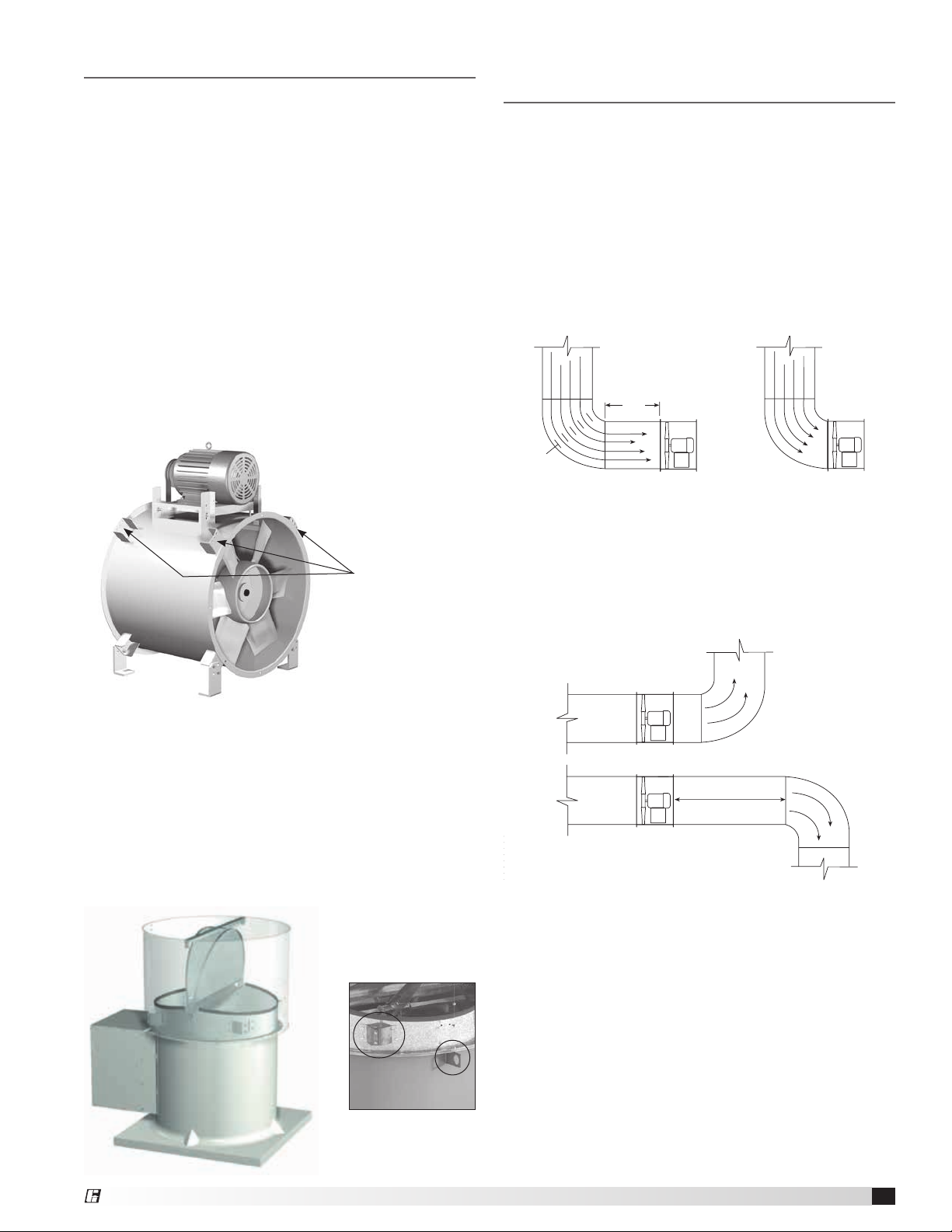

Inlet Duct Turns

1 Fan

Dia.

Turning

Vanes

Lifting Point

(4 places)

Roof Upblast

Attach a suitable chain or strap to the four (4) windband

gussets located between the butterfly damper section of

the fan and the exterior windband unless welded lifting

lugs are provided on fan housing. Carefully lift the fan to

the roof curb and install fasteners in all holes provided

in the unit base. The windband need not be removed for

the lifting operation. A spreader bar is recommended to

prevent damage to the damper section when lifting.

Good Poor

Installation of a duct turn or elbow too close to the

fan inlet reduces fan performance because air is

loaded unevenly into the fan prop. To achieve full fan

performance there should be at least one to two fan

diameters between the turn or elbow and the fan inlet.

Discharge Duct Turns

Poor

3 Diameters of

Straight Duct

Good

Fan performance is reduced when duct turns are made

immediately off the fan discharge. To achieve cataloged

fan performance, there should be at least three

equivalent fan diameters of straight ductwork between

the fan discharge and any duct turns.

®

Tubular Inline Fans

3

Page 4

D

A

C

Optional

Mounting

Rails

Typical Installations

With Mounting Brackets

Following are typical mounting installations for models

with mounting brackets. Diagrams show dimensions for

ceiling hung installations. The dimensions for floor or

base mount installations are mirror images of these.

For TBI models with motor in the 3 or 9 o’clock position

or vertical installations, additional mounting rails are

recommended. Mounting rail dimensions are shown for

field fabrication.

Horizontal

A

Vertical

D

A

B

C

B

C

Motor at 3 or 9 o’clock position

Optional

Mounting

Rails

Continuous Duty and Emergency Exhaust

TBI-FS with optional high temperature construction

are factory-modified for operation in high temperature

continuous duty applications. With propeller on the

discharge end of the fan, negative pressure is created in

the belt tube during operation. Ambient air is drawn in

through the belt tube and cools the belts and bearings.

For the greatest amount of internal cooling, discharge

static pressure should be kept to a minimum while

keeping most of the pressure on the inlet side. Locate

the fan at ends of the duct runs and near the discharge

point in the system. This set-up will promote the

ambient air cooling effect.

Roof

Ambient temperature

not to exceed 120°F

Duct to heat source

Minimum duct

Airflow

Cooling air for

drives and

bearings

Wall and/or ceiling should enclose

fan when used for emergency heat

and smoke exhaust.

at discharge

Optional

Mounting

Rails

Mounting Hole Locations

A B

Fan

Size

Belt

Drive

Direct

Driect

Belt Drive Direct Drive

Level 3Level

Level 3Level

4/5

4/5

18 17.63 17.63 17.38 21.38 13.38 21.38 26.00 28.00

20 19.00 19.00 17.38 22.38 14.38 21.38 28.50 29.25

24 21.88 21.88 18.38 23.38 14.38 21.38 33.00 33.75

30 26.13 26.13 19.38 28.38 16.38 25.88 37.00 38.75

36 30.50 30.50 21.88 26.88 13.88 23.38 44.00 47.00

42 34.75 34.75 22.88 31.88 19.88 26.38 50.00 51.25

48 42.00 42.00 25.38 36.38 19.38 31.38 56.00 61.00

54 46.75 46.75 29.88 40.38 NA 31.38 62.00 65.50

60 51.00 51.00 32.38 41.38 NA 31.38 71.00 70.00

Dimensions shown are in inches.

C

Belt

Drive

To determine unit level, refer to the fan nameplate.

Example TBI-3L42 (level 3) or TBI-4H30 (level 4)

D

Belt

Drive

Tubular Inline Fans

4

®

Page 5

Operation and Unit Start-Up

Electrical Connections

The electrical supply must be compatible with the

fan motor voltage, phase and amperage capacity.

The electrical supply line must be properly fused and

conform to local and national electrical codes.

For direct drive units, the electrical supply may be

routed internally and exit through a hole provided in the

fan housing if an optional service disconnect switch is

provided.

For belt drive units, the electrical supply line may be

routed internally and exit the fan housing through a hole

provided below the belt tube opening. The electrical

supply line should then be either: (1) connected to an

optional service disconnect switch, or (2) wired directly

to the motor.

For belt drive units in continuous high

temperature installations, the electrical supply

must be kept out of the airstream. This means bringing

the supply lines off the roof deck not through the fan.

The electrical supply line should then be either: (1)

connected to an optional service disconnect switch, or

(2) wired directly to the motor.

The supply wires are then connected to an optional

safety disconnect switch (if supplied) or wired directly to

the motor.

For belt drive units in emergency smoke removal

installations, the electrical supply must be kept out of

the airstream. They may also require an isolated power

supply so that if power is cut to the building in the event

of a fire, the fan will continue to operate. Check the

local and national electrical codes for emergency smoke

removal fans.

Pre-Start-Up Checks

1. Check all fasteners for tightness. This includes motor

bolts, bearing bolts, and any set screws or locking

collars attaching the propeller to the shaft and shaft

to the bearings.

If roof upblast configuration, lift the butterfly dampers

to verify they open and close without binding.

2. Rotate the propeller by hand

to ensure it turns freely and

does not rub on the fan tube.

Propeller rotation should always

be checked by turning the unit

on momentarily. Rotation should

be in the same direction as the

Rotation

rotation decal affixed to the unit. Actual direction

of rotation will vary by model. To reverse rotation

on three phase installations, simply interchange

two of the three electrical leads. For single phase

installations, follow the wiring diagram located on the

motor.

3. Belt Drive Fan RPM - adjustable motor pulleys are

preset at the factory for the specified fan RPM. Fan

speed can be increased by closing or decreased by

opening the adjustable pulley. Multi-groove variable

pitch pulleys must be adjusted an equal number of

turns open or closed.

4. Belt Drive Roof Upblast Fan RPM - adjustable

motor pulley on motors less than 10 HP is preset

at the factory to the customer-specified RPM. Fan

speed can be increased or decreased by adjusting

the pitch diameter of the motor pulley. Multi-groove

variable pitch pulleys must be adjusted an equal

number of turns open. Motors 10 HP and larger will

have a constant speed pulley.

NOTE

Any change, increase or decrease, in fan speed

can represent a substantial increase in horsepower

required from the motor. Always check motor load

amperage and compare to nameplate rating when

changing fan speed.

®

Tubular Inline Fans

5

Page 6

Maintenance

Belt Span

Deflection =

Belt Span

64

CORRECT WRONG

WRONG WRONG

Belt Span

Deflection =

Belt Span

64

WARNING

Always disconnect power before working on or near a

unit. Lock and tag the disconnect switch or breaker to

prevent accidental power up. Failure to comply with

this safety precaution could result in serious injury or

death.

Once the fan has been put into operation, a periodic

maintenance program should be set up to preserve the

reliability and performance of the fan.

Items to be included in this program are:

• Fasteners and set screws

• Bearings

• Lubrication of bearings and motor

• Belts

• Removal of dust, dirt and debris

• Dampers for roof upblast configuration

Fasteners and Set Screws - Normal fan vibration has

a tendency to loosen mechanical fasteners. Periodic

inspection should include checking all fasteners, set

screws, and locking collars attaching the propeller to

the shaft and the shaft to the bearings. Loose bearing

set screws and locking collars will lead to premature

failure of the fan shaft.

Bearings on belt drive fans - Bearings are the most

critical moving part of the fan and should be inspected

at periodic intervals. Locking collars and set screws,

in addition to fasteners attaching the bearing to the

bearing plate, must be checked for tightness.

In a clean environment and temperature between 32°

and 200°F (0 to 93°C), fan shaft bearings with grease

fittings should be lubricated semi-annually using a high

quality lithium based grease. Bearings operating outside

these temperature parameters require special high

or low temperature grease. If unusual environmental

conditions exist, such as temperatures below 32°F

(0°C) and above 200°F (93°C), high moisture, or

contaminants, more frequent lubrication is required.

With the unit running, add grease very slowly with a

manual grease gun. Be careful not to unseat the seal by

over lubricating or using excessive pressure. Bearings

without grease fittings are lubricated for life.

Bearings are one of the most critical parts of a fan and

should be inspected at regular intervals. Locking collars,

set screws and fasteners attaching the bearings to the

fan should also be checked.

Model TBI fans are equipped with extended lubrication

lines as standard. The grease fittings are located on the

exterior of the fan housing next to the motor cover and

should be wiped clean before adding grease.

Motors - Lubrication of motors is intended only when

fittings are provided. Many fractional horsepower

motors are permanently lubricated for life and require

no further lubrication. Motors supplied with grease

fittings should be greased in accordance with the

manufacturer’s directions on the motor nameplate.

Belts - Premature belt failures are frequently caused

by improper belt tension (either too loose or too tight),

misaligned pulleys, or by prying belts on and off pulleys.

The proper tension for operating a V-belt is the lowest

tension at which the

belts will not slip at peak

Fig. 2

load conditions. For

initial tensioning, the

proper belt deflection is

1/64-inch for each inch

of belt span, measured

half way between the

pulley centers.

For example, if the belt span is 64 inches, the belt

deflection should be one inch using moderate thumb

pressure at midpoint of the drive (Fig. 2).

Check belt tension two times during the first 24 hours of

operation, after 100 hours of operation, and periodically

thereafter. To adjust belt tension, simply pivot the motor

on the motor plate. Use the bolts in the slotted brackets

and adjustment rods with bolts as adjustment points

until proper belt tension is attained.

It is very important that the drive pulleys remain in

proper alignment after adjustments. (Fig. 3)

Fig. 3

CORRECT WRONG

WRONG WRONG

When replacing belts, always use the same size and

type as originally supplied by the factory. Check pulleys

for wear and replace both pulleys and belts if wear is

evident. Misalignment of pulleys will result in premature

belt and bearing failure, noise and loss of fan efficiency.

Tubular Inline Fans

6

®

Page 7

Removal of dust, dirt and debris - Dirt clogs cooling

openings on the motor housing, contaminates bearing

lubricant, and collects on the propeller causing severe

imbalance if left unchecked.

Periodically, thoroughly clean the exterior surface only

of the motor. If optional motor cover is installed, remove

it and clean the motor of dust, dirt and debris to aid

in motor cooling. Use caution and do not allow water

or solvents to enter the motor or bearings. Under no

circumstances should motors or bearings be sprayed

with steam or water.

Accumulations of dirt and debris on the propeller

blades may cause an unbalanced condition resulting

in excessive vibration and premature failure of the

propeller and bearings.

Dampers for Roof Upblast Configuration - If

exhausting dirty or contaminated air, the propeller

and butterfly damper assembly should be cleaned

periodically. Excessive buildup of dirt on the damper

blades may cause binding and sticking blade hinges

resulting in loss of fan performance. Clean as needed.

These fans have heavy-duty fusible link damper lifters

under very high spring tension that must be pinned so

they cannot be accidentally tripped when servicing the

fan. The fusible link damper lifters are located under

the butterfly damper blades. Point “A” shows where

the safety pin MUST be placed when the fan is being

serviced. Point “B” shows where the safety pin is placed

for storage when the fan is in service.

Fan sizes 24, 30 and 36 also have fusible link damper

lifters, but they do not have the ability to be pinned

when servicing due to differences in lifter designs.

In either case, extreme care must be taken when

working around the damper lifter assemblies or serious

bodily injury or death may result.

Parts List

Each fan bears a manufacturer’s nameplate with

embossed model and serial number. This information, in

addition to the shown parts diagram, will assist the local

Greenheck representative and the factory in providing

service and replacement parts.

Motor Cover

(optional)

Motor Plate

Bearing

Support

Universal

Mounting

Brackets (8)

Mounting

Supports (4)

MotorMotor Pulley

Belt

Belt Tube

Shaft Pulley

Bearing Cover

Bearings

Propeller

Shaft

®

Spring Lifter Tube

Point “B”

Pin Storage Location

Lock Plate

Fusible Link Assembly

Point “A”

Install pin here to

lockout damper fifters

Spring

Lifter Arm

Spring Bracket

Butterfly Dampers

Damper Hinge Rod

Windband Gussets

Weatherhood

Motor Plate

Motor

Motor Pulley

Belt(s)

Curb Cap

Inlet Guard

(optional)

Outlet Screen

Windband

Tie Down Points

Propeller

Bearing Cover

Shaft Bearings

Shaft Pulley

Fan Pulley

Access Door

Tubular Inline Fans

(optional)

(optional)

7

Page 8

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Specific Greenheck product warranties are located on greenheck.com within the product area tabs and in the

Library under Warranties.

Greenheck catalogs, Medium Pressure Axial Fans and Tube

Axial Inline Fans, provides additional information describing

the equipment, fan performance, available accessories, and

specification data.

®

Phone: 715.359.6171 • Fax: 715.355.2399 • Parts: 800.355.5354 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

460983 • TDI, TBI-CA, TBI-FS, Rev. 2, December 2013 Copyright 2013 © Greenheck Fan Corporation

8

AMCA Publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans, provides

additional safety information. This publication can be obtained

from AMCA International, Inc. at www.amca.org.

Loading...

Loading...