Page 1

TBI Tubular Belt Inline Fan

TDI Tubular Direct Inline Fan

RECEIVING

Greenheck model TBI / TDI fans are thoroughly inspected and test run at the factory. Items such as proper propeller

alignment, balance, and workmanship are analyzed by personnel using state-of-the art equipment. However, damage may

occur during handling and shipping. Therefore, it is important that the unit be carefully inspected for visible and concealed

damage before beginning installation. In addition, check to see that all accessory items are accounted for.

STORAGE - Indoor and Outdoor

When a fan is to be stored for a period of time, it must be protected from dirt and moisture. Use of a tarp to cover the unit

will aid in keeping it clean and dry, but avoid using a black plastic tarp as it will promote condensation. Improper storage

which results in damage to the fan will void the warranty. If the storage period is lengthy, the propeller and motor should be

rotated periodically and the bearings purged with fresh grease. In humid, dusty, or corrosive atmospheres, rotate the fan and

purge the bearings once a month. Under normal conditions, this procedure should be repeated once every three months.

TDI

Level 3, 4 & 5

TBI-CA, TBI-FS

Level 3, 4 & 5

HANDLING

Fans should NOT be lifted by the shaft, housing, motor, belt guard, or any

accessories.

Units - Flanged Housing Only

Use a minimum of four bolt holes, two per flange, or attach two suitable chains /

straps around the entire fan housing, one near each duct flange, when lifting large

horizontal fans. Secure the fan housing to prevent the weight of a top or side

mounted motor from rotating the housing while being lifted.

For vertical hanging installations, attach a suitable lifting device to the fan housing or

inlet/outlet flange.

Units - With Mounting Brackets

Fans are to be rigged by either the optional brackets provided or by the skid when a

forklift is used. Slings can be attached as described above or to mounting brackets

located at the ends of the fan housing (Fig. 1).

Fig. 1

GREENHECK

P.O. BOX 410 SCHOFIELD, WISCONSIN 54476-0410

PH. 715-359-6171

www.greenheck.com

®

READ AND SAVE THESE INSTRUCTIONS

PN 460983

Installation Operation and Maintenance Manual

Report any damaged equipment to the shipper immediately!

Lifting Locations

with optional

mounting brackets

June 2001

Page 2

INSTALLATION

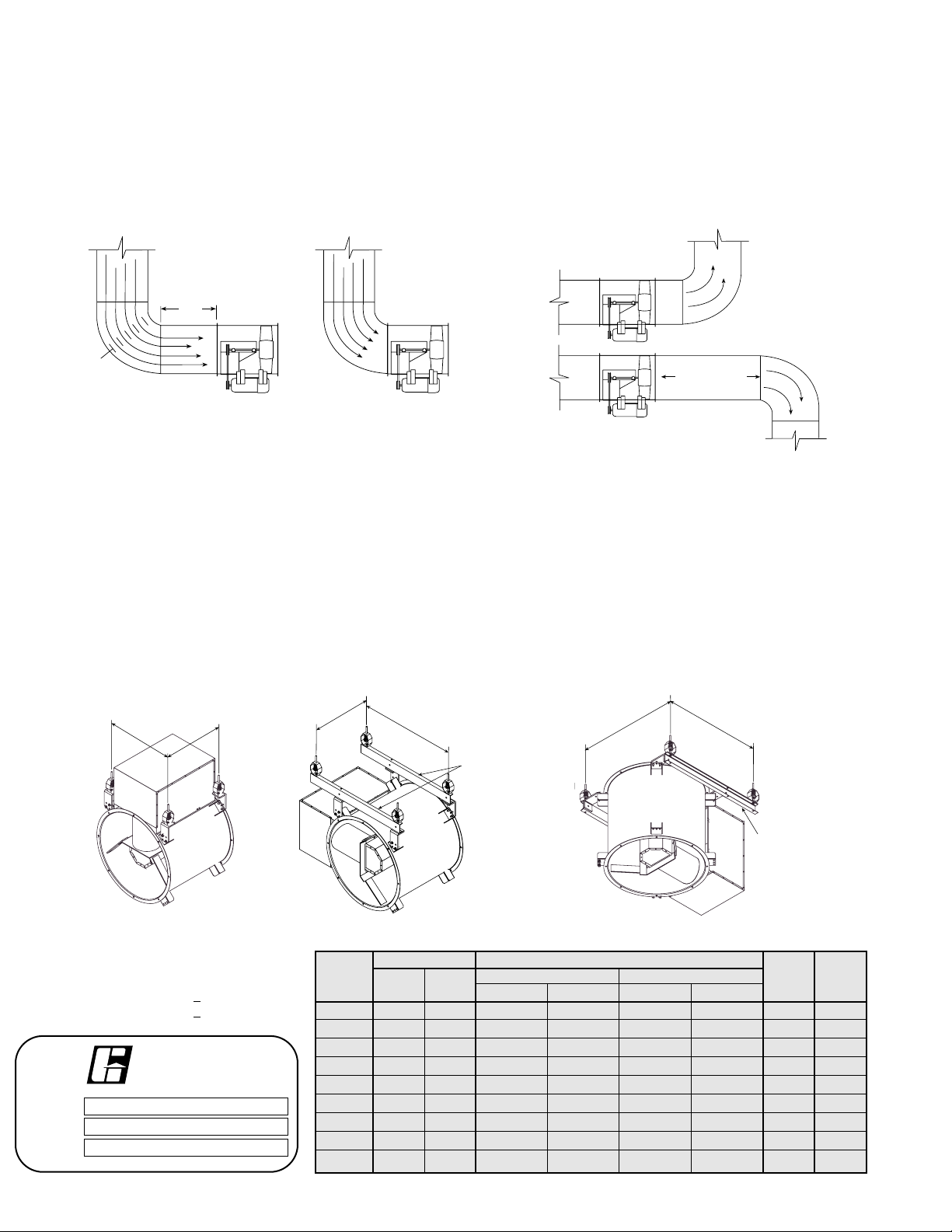

EFFECT OF INSTALLATION ON PERFORMANCE

Any installation with inlet or discharge configurations that deviate from these recommendations may result in reduced fan

performance. Restricted or unstable flow at the fan inlet can cause pre-rotation of incoming air or uneven loading of the fan

prop yielding large system losses and increased sound levels. Free discharge or turbulent flow in the discharge ductwork

will also result in system effect losses.

The most common inlet and discharge conditions which affect fan performance are:

INLET DUCT TURNS

Installation of a duct turn or elbow too close to the fan inlet

reduces fan performance because air is loaded unevenly into

the fan prop. To achieve full fan performance there should

be at least one to two fan prop diameters between the turn

or elbow and the fan inlet.

DISCHARGE DUCT TURNS

Fan performance is reduced when duct turns are made

immediately off the fan discharge. To achieve cataloged

fan performance, there should be at least one equivalent

duct diameter of straight ductwork between the fan

discharge and any duct turns.

Motor at 3 or 9 o’clock position

Horizontal

Vertical

g

TYPICAL INSTALLATIONS - WITH MOUNTING BRACKETS

Following are typical mounting installations for models with mounting brackets. Diagrams show dimensions for ceiling hung

installations, the dimensions for floor or base mount installations are mirror images of these. For TBI's with motor in the 3 or

9 o'clock position or vertical installations, additional mounting rails are recommended. Mounting rail dimensions are shown

for field fabrication.

Unit Level Identification - Refer to

fan name plate

Example: TBI-3L42 (level 3)

TBI-4H30 (level 4)

TBI/TDI A B C D

Fan Belt Direct Belt Drive Direct Drive Belt Belt

Size Drive Drive Level 3 Level 4/5 Level 3 Level 4/5 Drive Drive

18 17.63 17.63 17.38 21.38 13.38 21.38 26.00 28.00

20 19.00 19.00 17.38 22.38 14.38 21.38 28.50 29.25

24 21.88 21.88 18.38 23.38 14.38 21.38 33.00 33.75

30 26.13 26.13 19.38 28.38 16.38 25.88 37.00 38.75

36 30.50 30.50 21.88 26.88 13.88 23.38 44.00 47.00

42 34.75 34.75 22.88 31.88 19.88 26.38 50.00 51.25

48 42.00 42.00 25.38 36.38 19.38 31.38 56.00 61.00

54 46.75 46.75 29.88 40.38 NA 31.38 62.00 65.50

60 51.00 51.00 32.38 41.38 NA 31.38 71.00 70.00

Mounting Hole Locations

GREENHECK

P.O. BOX 410 SCHOFIELD, WISCONSIN 54476-0410

PH. 715-359-6171

www.greenheck.com

®

MODEL

S/N

MARK

Turning

Vanes

1 Fan

Wheel

Dia.

Good Poor

Poor

Length of Straight Duct

Good

B

A

B

C

Optional

Mountin

Rails

D

C

Optional

Mounting

Rails

Page 3

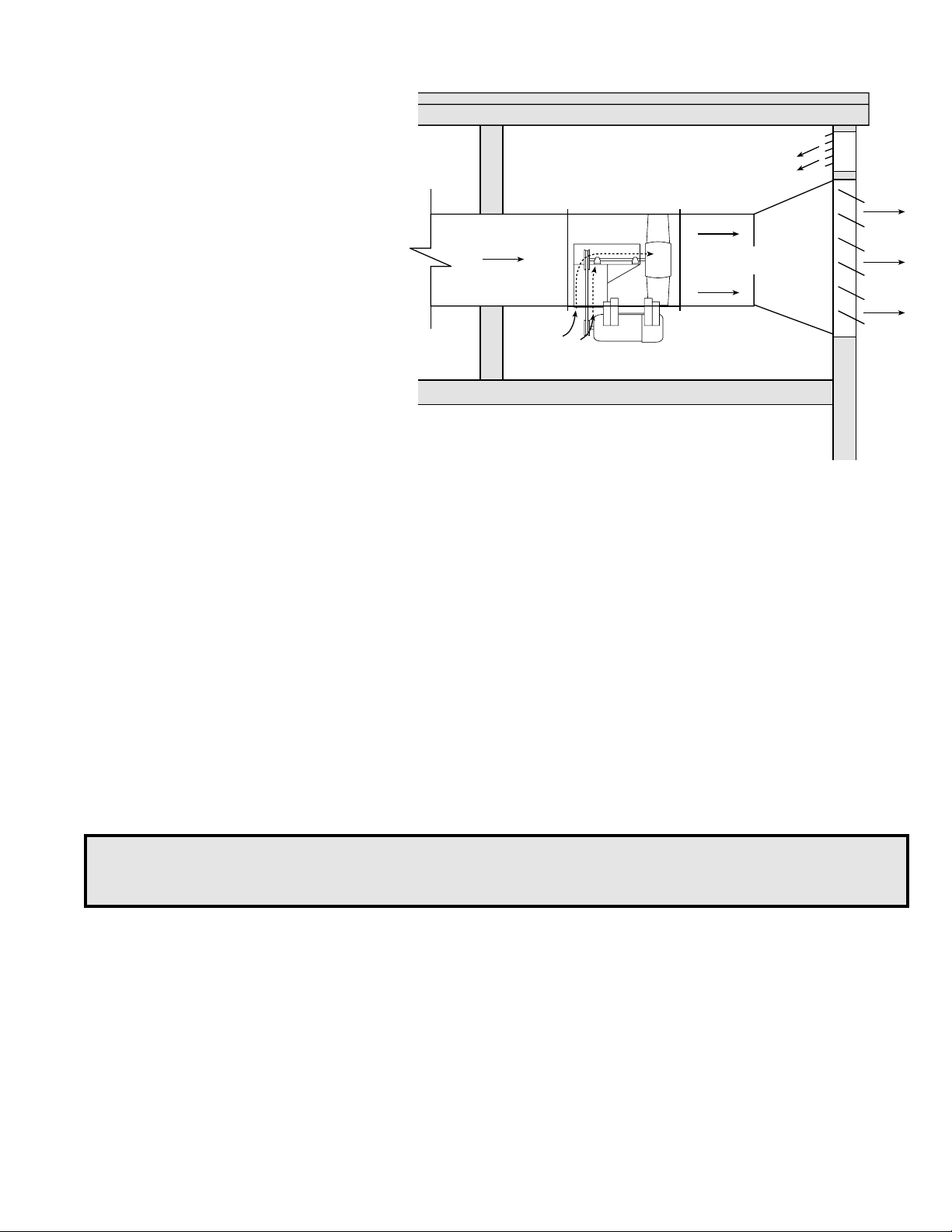

TYPICAL HIGH TEMPERATURE CONTINUOUS DUTY INSTALLATIONS

TBI-FS with optional high temperature

construction are factory modified for operation

in high temperature continuous duty

applications. With propeller on the discharge

end of the fan, negative pressure is created in

the belt tube during operation. Ambient air is

drawn in through the belt tube and cools the

belts and bearings.

For the greatest amount of internal cooling,

discharge static pressure should be kept to a

minimum while keeping most of the pressure

on the inlet side. Locate the fan at ends of the

duct runs and near the discharge point in the

system. This set-up will promote the ambient

air cooling effect.

OPERATION

ELECTRICAL CONNECTIONS

Before electrical connections are made, the supply voltage, phase and ampere capacity must be checked for compatibility

with the fan motor. In addition, the supply wiring must be properly fused and conform to local and national electrical codes.

The supply wires are then connected to an optional safety disconnect switch (if supplied) or wired directly to the motor.

PRE-START UP CHECKS

1. Check all fasteners for tightness. This includes motor bolts, bearing bolts, and any set screws or locking collars attaching

the propeller to the shaft and shaft to the bearings.

2. Prop rotation should be in the same direction as the rotation decal affixed to the unit. For 3-phase installations, fan

rotation can be reversed by simply interchanging any two of the three electrical leads. For single phase installations,

follow the wiring diagram located on the motor.

3. (Belt Drive) Adjustable motor pulleys are preset at the factory for the specified fan RPM. Fan speed can be increased by

closing or decreased by opening the adjustable pulley. Two or three groove variable pitch pulleys must be adjusted an

equal number of turns open or closed.

Note: Any change, increase or decrease, in fan speed can represent a substantial increase in

horsepower required from the motor. Always check motor load amperage and compare to name plate

rating when changing fan speed.

MAINTENANCE

Once the fan has been put into operation, a periodic maintenance program should be set up to preserve the reliability and

performance of the fan. Items to be included in this program are:

• BEARINGS • SET SCREWS • BELTS

• LUBRICATION • FASTENERS • REMOVAL OF DUST/DIRT

BEARINGS (Belt Drive)

Bearings are the most critical moving part of the fan and should be inspected at periodic intervals. Locking collars and set

screws, in addition to fasteners attaching the bearing to the bearing plate, must be checked for tightness. In a clean

environment and temperature above 32ºF (0ºC) and below 200ºF (93ºC), fan shaft bearings with grease fittings should be

lubricated semi-annually using a high quality lithium based grease. If unusual environmental conditions exist such as

temperatures below 32ºF (0ºC) and above 200ºF (93ºC), moisture or contaminants, more frequent lubrication is required.

With the unit running, add grease very slowly with a manual grease gun. Be careful not to unseat the seal by over lubricating

or using excessive pressure. Bearings without grease fittings are lubricated for life.

WARNING

Disconnect and secure to the “OFF” position all electrical power to the fan prior to inspection or

servicing. Failure to comply with this safety precaution could result in serious injury or death.

Roof

Ambient temperature

not to exceed 120∞F

Duct to heat source

Airflow

Minimum duct

at discharge

Cooling air for

drives and

bearings

Wall and/or ceiling should enclose

fan when used for emergency heat

and smoke exhaust.

Page 4

FASTENERS AND SET SCREWS (Belt & Direct Drive)

A periodic inspection should include checking all fasteners and set screws for tightness.

Particular attention should be paid to set screws and locking collars attaching the propeller

to the shaft and the shaft to the bearings. Loose bearing set screws and locking collars will lead to premature failure of the

fan shaft.

MOTOR LUBRICATION (Belt & Direct Drive)

Refer to the paragraph on bearings for bearing lubrication. Many fractional horsepower motors installed on the smaller fans

are lubricated for life and require no further attention. Greasing of motors is intended only when fittings are provided.

Motors equipped with oil holes should be oiled in accordance with the manufacturer’s instructions printed on the motor. Use

a high grade SAE 20 machine oil and use caution not to over lubricate. Motors supplied with grease fittings should be

greased according to directions printed on the motor.

REMOVAL OF DUST AND DIRT (Belt & Direct Drive)

Dirt clogs cooling openings on the motor housing, contaminates bearing lubricant, and collects on the impeller causing

severe imbalance if left unchecked. The exterior surface of the motor and impeller should be thoroughly cleaned periodically.

Use caution and do not allow water or solvents to enter the motor or bearings. Under no circumstances should motors or

bearings be sprayed with steam or water.

BELTS (Belt Drive)

Premature belt failures are frequently caused by improper belt tension (either too tight or

too loose) or misaligned pulleys. The proper tension for operating a V-belt is the lowest

tension at which the belts will not slip at peak load conditions. For initial tensioning,

the proper belt deflection half-way between pulley centers is 1/64” for each inch of belt

span. For example, if the belt span is 64 inches, the belt deflection should be one inch

using moderate thumb pressure at midpoint of the drive (Fig. 2).

Check belt tension two times during the first 24 hours of operation and periodically

thereafter. To adjust belt tension, simply pivot the motor on the motor plate. Use the

bolts in the slotted brackets and adjustment rods with bolts as adjustment points until

proper belt tension is attained.

It is very important that the drive pulleys remain in proper alignment after adjustments

are made. Misalignment of pulleys will result in premature belt wear, noise, vibration

and power loss (Fig. 3).

PARTS LIST

Each fan bears a

manufacturer's

nameplate with model

number and serial

number embossed. This

information in addition

to the shown parts

diagram will assist the

local Greenheck

representative and the

factory in providing

service and replacement

parts.

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from the

purchase date. Any units or parts which prove defective during the warranty period will be replaced at our option when returned

to our factory, transportation prepaid.

Motors are warranted by the motor manufacturer for a period of one year. Should motors furnished by Greenheck prove defective

during this period, they should be returned to the nearest authorized motor service station. Greenheck will not be responsible for

any removal or installation costs.

Fig. 3

Fig. 2

IOM TBI TDI

Rev. 1 June 2001

Copyright © 2001 Greenheck Fan Corp.

Deflection =

Belt Span

Belt Span

64

MOTOR

PULLEY

BEARINGS

MOTOR

PROPELLER

SHAFT

MOTOR

PLATE

BEARING

SUPPORT

MOUNTING

BRACKETS

(Qty. of 4)

MOTOR

COVER

(OPTIONAL)

BELT

BELT

TUBE

SHAFT

PULLEY

BEARING

COVER

Loading...

Loading...