Page 1

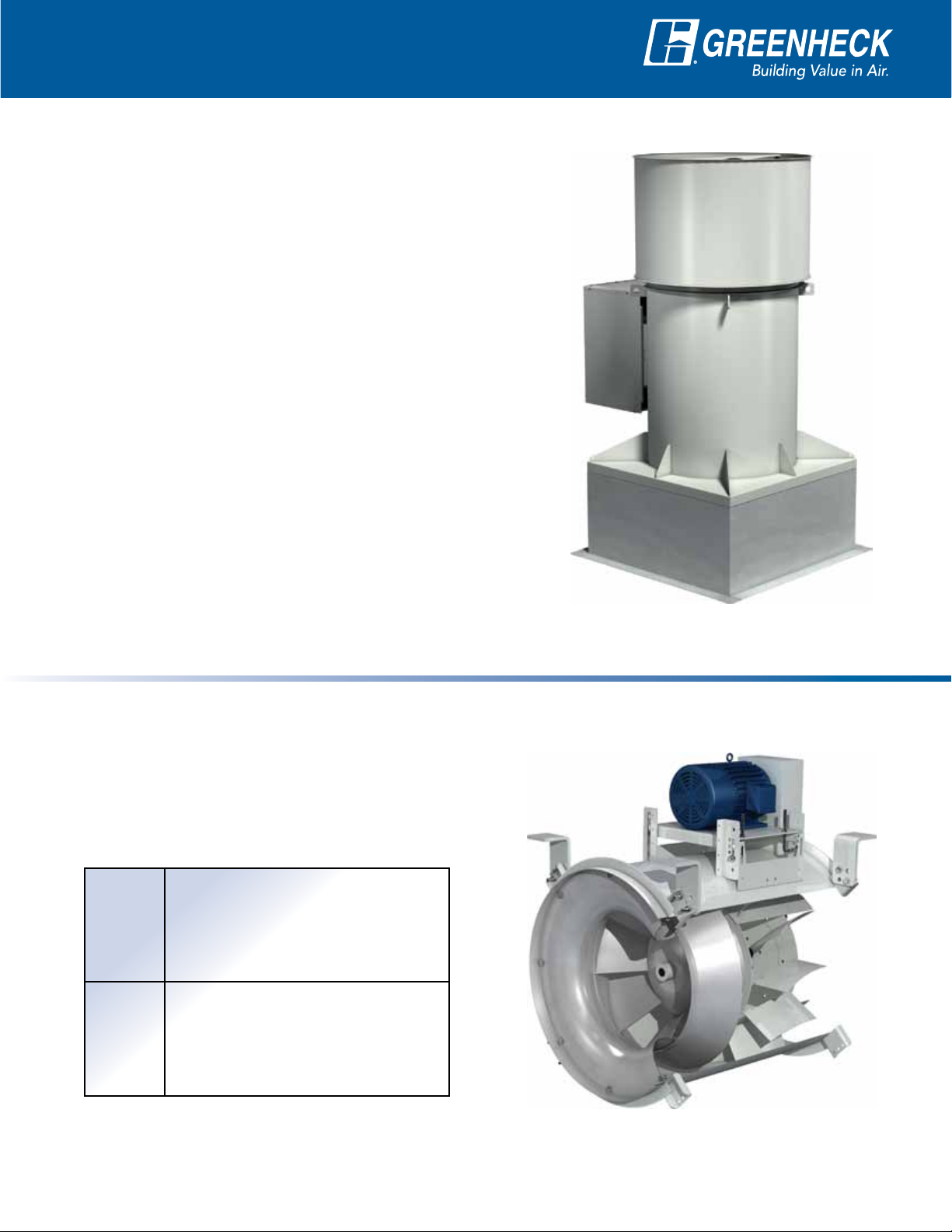

Mixed Flow Fans

Models QEI and QEID

Belt and Direct Drive

April

2010

Page 2

Quiet & Efficient, Inline

Mixed Flow Fan—QEI & QEID

Mixed flow inline fans can be used with clean air

for supply, exhaust, or return air installations. Our

patented design excels in commercial applications

where low sound is critical. In addition, the Models

QEI / QEID are more efficient than comparably

sized tubular centrifugal and vane axial fans, thus

reducing the required motor horsepower and lowering

operating costs.

The Models QEI and QEID mixed flow fans are the

quietest tubular inline fans in the industry!

• Performance as cataloged is assured. All sizes are

licensed to bear the AMCA Certified Sound (both

inlet and outlet) and Air Performance Seal.

• The QEI & QEID are UL/cUL 705 Listed for electrical,

UL Emergency Smoke Evacuation and UL 762

Restaurant Grease Exhaust (UL Listings optional).

• All sizes are operated and vibration tested before

they leave the factory to ensure trouble free

operation at the job site.

• Compact size and “Universal Mounting System”

make tight space considerations and last minute

mounting changes easy to handle at the job site.

• The QEI uses air handling quality bearings that are

100% inspected for swivel torque, noise levels, and

bore tolerances.

• Greenheck subjects these products to extensive life

testing, assuring you that the fans will provide many

years of reliable performance.

Model QEI – Belt Drive

• 17 sizes available (9 thru 60)

• Two classes of construction

• Volume Range: 500 - 115,000 cfm

(850 - 195,386 m

• Static Pressure: Up to 8.5 in. wg (2120 Pa)

Patented (QEI/QEID): USA Patent No. 7048499

China (P.R.) Patent No. CN1294361C

Mexico Patent No. 243465

3

/hr)

Model QEID – Direct Drive

• 15 sizes available (12 thru 54)

• 50 - 100% wheel widths

• Volume Range: 800 - 83,000 cfm

(1,360 - 141,000 m3/hr)

• Static Pressure: Up to 10.5 in. wg (2370 Pa)

Typical Mixed Flow Applications:

The models QEI and QEID are recommended for any

ventilation application that requires low sound and

high efficiency.

• Office Buildings • Parking Garages

• Concert Halls • Libraries

• Educational Facilities

Greenheck Fan Corporation certifies

that the Models QEI and QEID Mixed

Flow Inline fans shown herein are

licensed to bear the AMCA seal.

The ratings shown are based on

tests and procedures performed in

accordance with AMCA Publication

211 and AMCA Publication 311 and

comply with the requirements of the

AMCA Certified Ratings Program.

For QEID performance pages showing AMCA licensed

data for sound and air performance, please refer to

the QEID Sound and Air Performance Supplement

found on our Web site at www.greenheck.com.

See page 10 for details.

2

All Greenheck products are

supported by the industry’s

best product literature,

electronic media, and

Computer Aided Product

Selection program (CAPS).

You’ll also find extensive product and Installation and

Operation Manual (IOM) information on the Internet.

And, of course, you can always count on the personal

service and expertise of our national and international

representative organization. To locate your nearest

Greenheck representative call 715-359-6171 or visit

our Web site at www.greenheck.com

Page 3

Standard Construction

Housing

Tubular housings are constructed of welded steel to

eliminate air leakage. Integral straightening vanes are

constructed from steel and welded into place.

Wheel – Mixed Flow

Fabricated wheels are constructed from steel. The

blade profiles are angled and contoured for the most

efficient and quiet performance.

Bearings (Belt Drive)

Standard bearings are premium air handling quality,

grease lubricated, self-aligning, ball or roller type in

flange mounts. Bearings are selected with a basic

rating fatigue life (L

excess of 80,000 hours (L

maximum operating speed.

), per ABMA standards, in

10

at 400,000 hours ) at the

50

Bolted Access Door

A bolted access door provides an opening through

the fan housing for cleaning or visual inspection of

the wheel. A hinged access door is available as an

accessory.

Belt Guard (Belt Drive)

A totally enclosed belt guard provides protection

from rotating pulleys and belts. Belt guards meet

OSHA Standards.

Slip-Fit Duct Connection

Inlets and outlets are designed with extended collars

for slip-fit duct connections as standard.

Adjustable Motor Bases (Belt Drive)

Rigid, heavy gauge steel motor bases are welded to

the fan housing and include heavy duty adjustment

screws for belt tensioning.

Extended Lube Lines

Belt drive units have nylon lubrication lines with

grease fittings that allow bearing lubrication without

disassembling the fan. Grease fittings are mounted

on the outside of the fan housing. Direct drive units

with NEMA 254T frame size motors and larger also

have extended lubrication lines for lubricating the

motor bearings. Smaller frame sized motors are

sealed and not lubricatable.

Permatector™ Coating

Greenheck’s Permatector™ coating is a

thermosetting polyester urethane, electrostatically

applied to provide uniform thickness and a clean

appearance. Permatector™ coatings also provide

excellent corrosion characteristics for general

applications, both indoor and outdoor. For corrosive

environments (ie. outdoor, coastal), see page 9 for

information on our zinc-rich basecoat technology.

Model Number Nomenclature

The model number code provides a numbering system designed to identify the fan model,

size and horsepower.

*Model code applies to belt and direct drive, however, the code identified with blue text is

specific to direct drive model QEID.

*QEI D - 36 - I - 70 - A 30

Belt Drive

Direct Drive

Fan Size

9, 12, 15, 16, 18, 20,

22, 24, 27, 30, 33, 36,

40, 44, 49, 54, 60

Belt Drive available in sizes 9 through 60

Direct Drive available in sizes 12 through 54

Fan Class

I or II

Percent Wheel Width

50 through 100

Motor Horsepower

4 = ¼ 30 = 3 300 = 30

3 = 50 = 5 400 = 40

5 = ½ 75 = 7½ 500 = 50

7 = ¾ 100 = 10 600 = 60

10 = 1 150 = 15 750 = 75

15 = 1½ 200 = 20 1000 = 100

20 = 2 250 = 25

3

RPM

A = 1770 C = 870 J = 1425 M = 3600

B = 1170 F = 690 K = 950

33

Page 4

Value Added Features

Vibration Testing

Before shipment, every mixed flow fan is vibration tested as a complete assembly. The maximum allowable

vibration on a QEI at the fan bearings is 0.15 in/sec. peak velocity, filter-in, for the specified fan RPM. QEID

maximum vibration is 0.08 in/sec. peak, filter-in, on the fan housing for the specified RPM. A record of any

vibration test result is available upon request.

By performing the vibration test, we are

able to provide more than simply trim

balancing; it is also a diagnostic tool

for finding potential problems. A

defective bearing or motor, bent

shaft or misaligned sheaves

may cause excessive vibration.

A complete vibration test will

find these problems before

the fan leaves the factory.

Electrostatic Powder Coatings

Powder coatings offer a uniform, durable and high-quality finish.

Standard powder coating is a one-coat process applied over

a phosphatized surface that generally meets or exceeds the

corrosion resistance of a comparable wet paint.

Greenheck offers a number

of in-house coatings applied

via “electrostatic powder.” The

standard coating, Permatector™, is

excellent for indoor or outdoor applications

and is resistance to many common chemicals. Consult

Greenheck’s Product Application Guide, Performance

Coatings for Ventilation Products, for a complete listing of coatings

and a relative resistance chart. For corrosive environments (i.e.

outdoor, coastal), see page 9 for information on our zinc-rich

basecoat technology.

Maintenance / Serviceable Construction Advantages

The following value added features are incorporated into the design to allow for quick and easy field service.

QEI service advantages

• Bearing lubrication is performed through extended grease fittings located on the

outside of the fan housing.

• The entire shaft and bearing assembly can be removed as a single assembly from

the inlet end of the fan housing.

• An adjustable motor base is provided for tightening the fan belts.

QEID service advantages

• Grease lubrication on motor bearings is done through extended grease fittings

for NEMA motor frame sizes 254T and over. Smaller frame motors use sealed

bearings and are permanently lubricated.

4

Page 5

Inlet and Outlet Sound Power Levels

All sizes and configurations have AMCA licensed sound power levels for both

the fan inlet and outlet.

Application and installation determines which sound

power reading (inlet, outlet, or both) is critical. The

differences between the generated sound from the

inlet and outlet are important and noticeable. AMCA

licensed inlet and outlet sound power data provides

complete sound information to select a fan based

on the acoustical requirements.

Field Rotatable Housing / Compact Size

The QEI is designed to accommodate changing fan mounting

positions and motor orientation in the field. Mounting fixtures

are securely bolted to the fan casing and can be relocated to

reposition how the fan is installed or the motor orientated.

Flexibility in a motor’s location is important for easier access

and can determine where the unit will fit. Last minute design

changes or unexpected obstacles during installation are no

longer a problem.

The QEI and QEID were designed for compact size. Keeping

size to a minimum is important when fitting into tight spaces like

mechanical rooms or air handlers.

Patented (QEI/QEID)

USA Patent No. 7048499

China (P.R.) Patent No. CN1294361C

Mexico Patent No. 243465

AutoCAD® and 3-D Revit® Models

Slip-Fit Duct Connections

The inlet and outlet ends of the QEI and QEID are designed to

accept “slip-fit” connections. Often companion flanges are bolted

to the fan to provide a slip-fit connection for a flexible sleeve. This

extra step is now eliminated by directly attaching the flexible sleeve to

the duct and fan. This saves time and money in the installation process.

It is recommended to use a flexible sleeve connection instead of a rigid

duct connection.

The advantages of a flexible transition are:

• Decreased sound transmission in

the ductwork

• Flexible connections allow for minor

misalignment

• Accommodates the use of thrust

restraints to resist thrust loads

Scaled AutoCAD® drawings and Revit® models

are available through Greenheck’s Web

site or from the Greenheck CAPS program

which retrieves drawings and places them

automatically into a job folder.

5

5

Page 6

Design & Performance

QEI

Typical Vane Axial

Typical Tubular Centrifugal

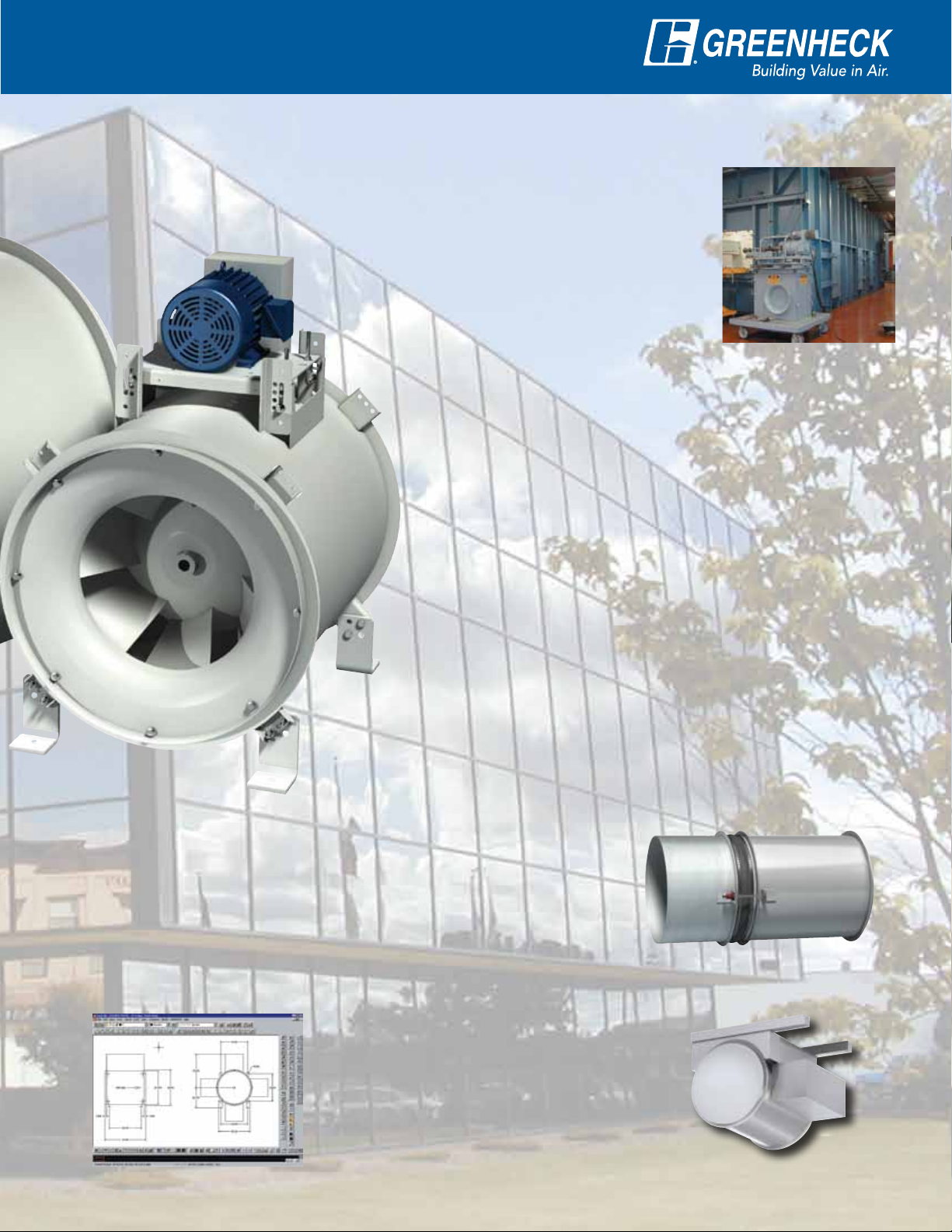

Mixed Flow: Axial/Centrifugal Hybrid

A mixed flow wheel is a hybrid between an axial propeller and a

centrifugal wheel. The result is a design that combines the best axial

and centrifugal properties: highly efficient air movement, increased

pressure capabilities, extremely low sound levels, and a steep fan

performance curve. To further enhance the fan’s performance,

straightening vanes are incorporated in the housing. These serve

to convert swirling airflow into a straight axial flow with a resulting

static pressure rise and energy savings.

Airflow Profiles

Axial Centrifugal Mixed Flow

Centrifugal

Mixed Flow

Axial

Static Pressure

CFM

Axial Fans: Straight through

nearly linear airflow.

Centrifugal Fans: Two 90°

deflections, before airflow

exits the fan.

Mixed Flow QEI Fan: Slight

airflow deflection from

straight through.

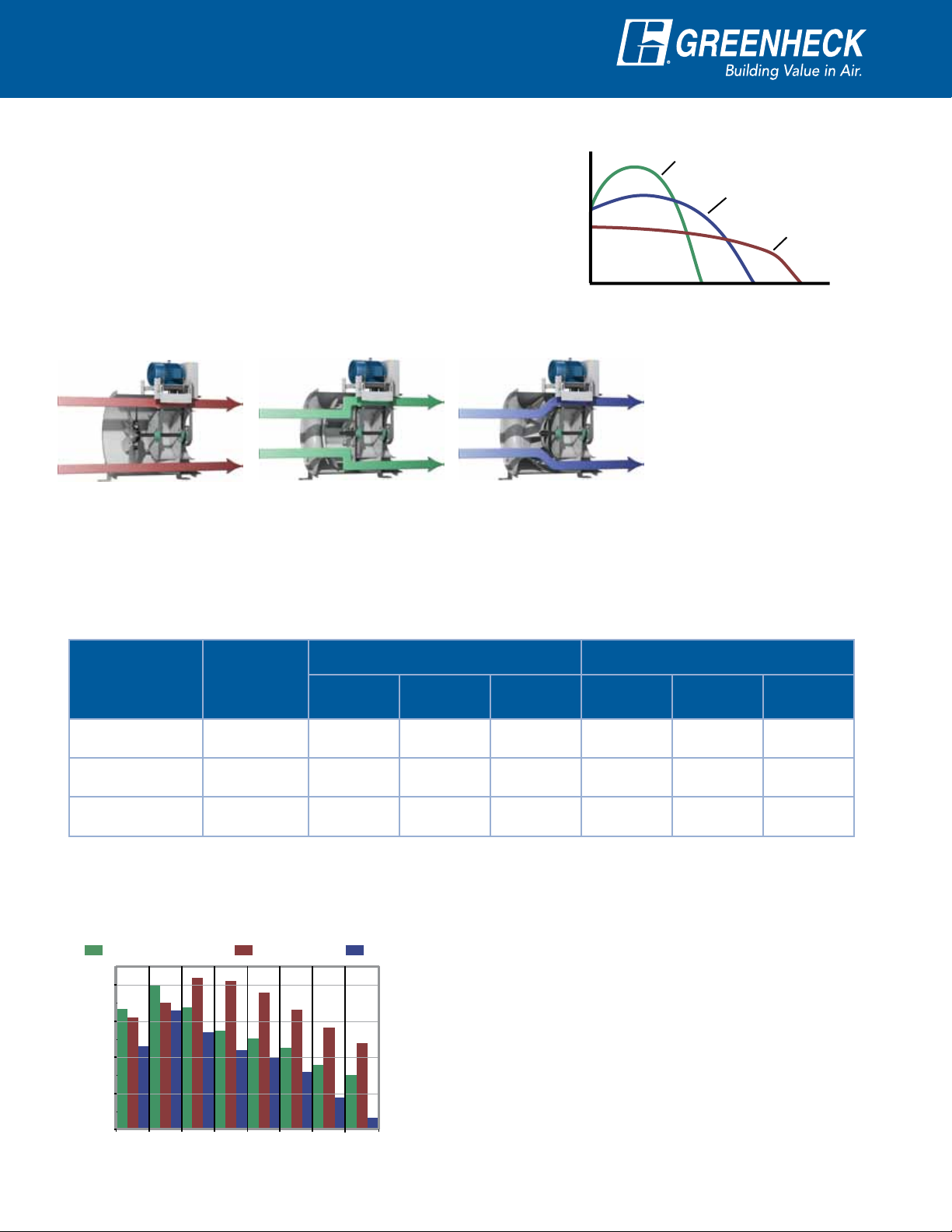

Sound and Efficiency

Sound power levels and fan efficiency are two very important factors when selecting a fan. There is a noticeable

difference between impeller types. The table and chart below compare the sound power (LwA) and the static

efficiency of the QEI wheel versus tubular centrifugal and vane axial inline fans. Over a wide range of operating

points, the QEI provides the quietest and most efficient selection.

Sound Power (LwA) Static Efficiency

Performance QEI Size

QEI

15,000 cfm

@ 1.0 in. wg

25,000 cfm

@ 2.0 in. wg

50,000 cfm

@ 4.0 in. wg

(Model comparisons based on similar outer tube diameters.)

24 90 dB 100 dB 103 dB 43% 17% 34%

36 86 dB 93 dB 102 dB 68% 45% 56%

49 92 dB 98 dB 111 dB 71% 60% 59%

Lower Sound Power, Better Sound Quality

Sound power levels shown at each frequency:

Typical Tubular Centrifugal Typical Vane Axial QEI

100

90

80

70

Sound Power, dB

60

62 125 250 500 1000 2000 4000 8000

Frequency, Hz

Inline

Centrifugal

Vane

Axial

QEI

Inline

Centrifugal

Vane

Axial

The sound quality of the QEI is as beneficial to low sound

design as is the reduced overall sound power. The sound

chart compares units of similar outer tube diameters at an

operating point of 20,000 cfm with 1.5 inches wg of static

pressure (Ps). Tubular centrifugals (green) have dominant

tones in the 63 Hz through 250 Hz octave bands, while

vane axials (red) have more mid to high frequency sound.

The QEI (blue) does not have a dominant tone. A bystander

would hear a more bland sound that is quieter than a tubular

centrifugal or vane axial.

6

Page 7

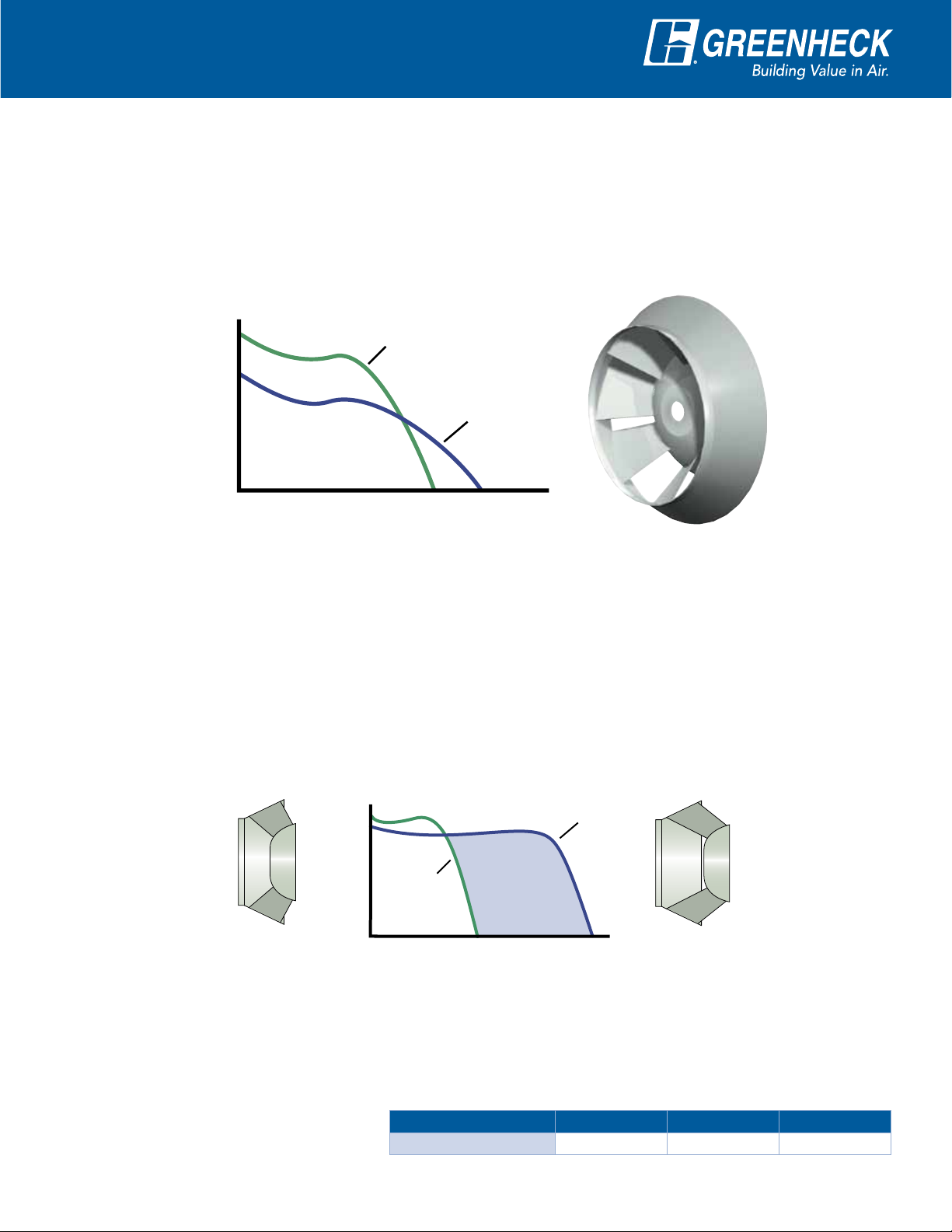

Wheel Characteristics

Static Pressure

CFM

50%

Wheel

Width

50% Wheel Width

100%

Wheel

Width

Intermediate

Wheel

Widths

50%

Wheel

Width

100%

Wheel

Width

Intermediate

Wheel

Widths

Belt Drive: Fan Class

Class I and II fans have different wheel designs with different performance characteristics.

Class I mixed flow wheels are optimized for performances involving low pressures and high volumes. Class II

wheels are designed for a steeper fan curve with higher pressure capabilities. This is illustrated in the graph

with the two different class wheels plotted at identical fan RPMs.

When selecting a mixed flow fan, it cannot be assumed that moving into a Class II fan will produce the same

results as a Class I mixed flow fans.

Class II

Class I

Static Pressure

CFM

Direct Drive: Percent Wheel Width

Direct drive mixed flow fans are optimized for performance requirements by the use of partial wheel widths. This

is necessary because the fan RPM is commonly fixed and identical to the motor RPM. A reduction in the width

of the wheel (or the air passage) results in reduced airflow capacity and a steeper fan curve. This is similar to

the effect of a reduced pitch in a direct drive vane axial fan. QEID wheels are available in 5% increments from

50 - 100% wheel width.

QEID fans are commonly used in conjunction with variable frequency drives (VFD’s) for variable air volume

(VAV) systems. In these applications, the wheel width is optimized to ensure efficient operation and stable

performance throughout the turndown range. VFD’s are also used for final system balancing and to reduce the

airflow during initial phases of building construction. In this case, the fan and wheel width are selected using the

final design CFM and static pressure.

100%

Wheel

Width

50%

Wheel

Width

Static Pressure

50% Wheel Width

Sound Power versus Sound Pressure

The sound values displayed on the performance pages are in terms of inlet sound power (L

power (L

A). These values are the acoustic power radiating from the inlet and outlet of the fan, respectively.

Wo

Sound pressure, expressed as dBA, is the acoustic pressure at a point in space which can be measured with a

microphone or can be heard. To convert sound power (LwA) into sound pressure (dBA), the following corrections

are applied for a hemispherical free field.

dBA = LwA - correction

Note: Refer to AMCA Publication 303, Application of Sound Power Level Ratings for additional information on calculating typical sound pressure levels for fan installation.

Distance from Fan 3 ft. (0.9 m) 5 ft. (1.5 m) 10 ft. (3.0 m)

Correction 7 db 11.5 db 17.5 db

Intermediate

Wheel

Widths

CFM

100% Wheel Width

A) and outlet sound

Wi

7

Page 8

Optional Features

Sure-Aire™

The Sure-Aire™ airflow monitoring station measures fan

flow within an accuracy of 2-3%. Unlike traditional flow

probes mounted in the fan venturi that create a system

effect hindering fan performance, the Sure-Aire™ does not

interfere with airflow and will not impact the fan’s air or

sound performance. This option is available on all QEI and

QEID models and ships completely assembled from our

factory.

An electronics package with pressure transmitter and

digital read out is available with the Sure-Aire™ system. The

electronic kits are available for 50 or 60 Hz power supplies

and provide a 4-20 mA output that can be tied into the

building’s automation system.

Sound Sensitive Areas

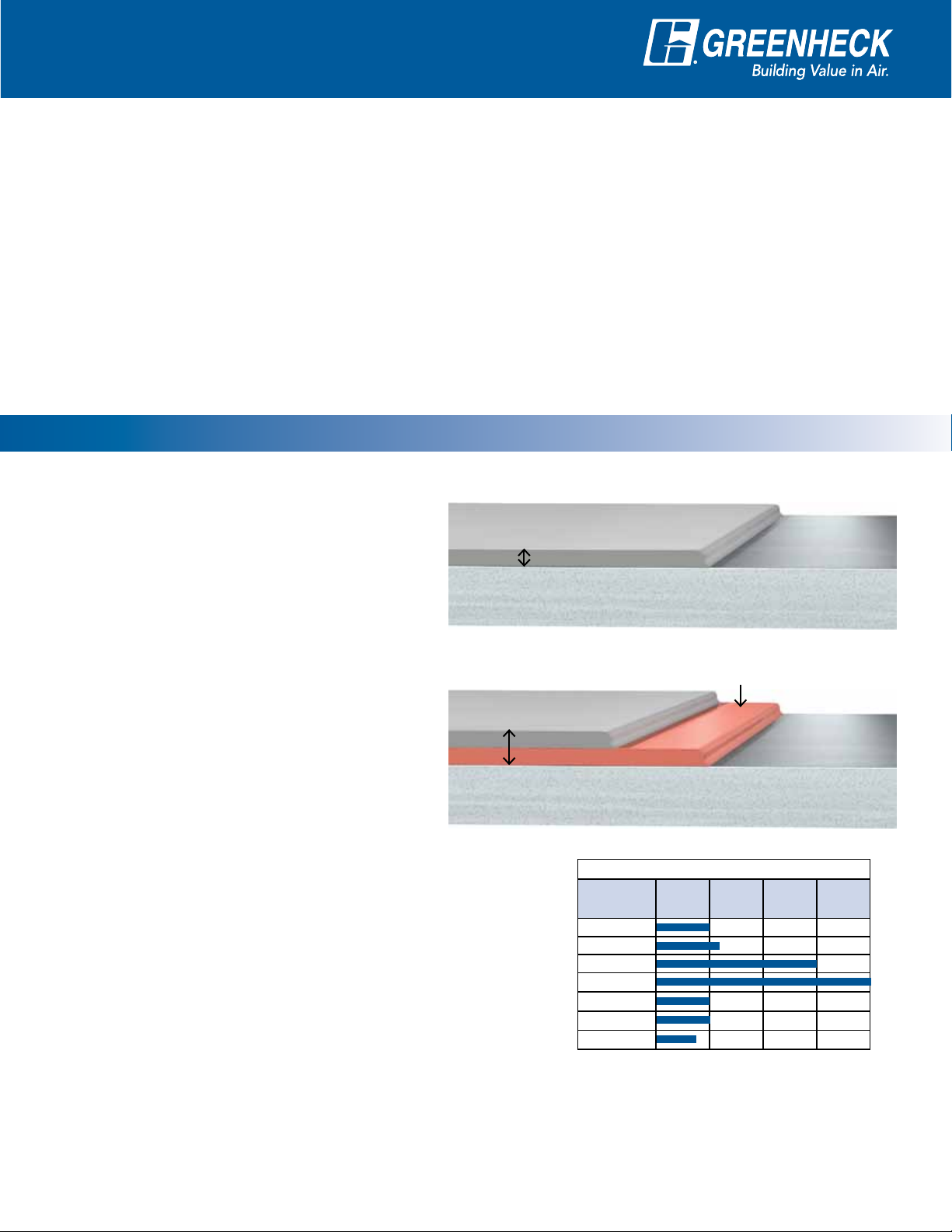

Sound Vault Housing - Radiated Sound Enclosure

The Sound Vault housing is an excellent product for fans that will be positioned adjacent to an occupied work

space or in sound critical applications. It locks in radiated sound from the fan casing, motor, and drives and

minimizes vibration transmission. Standard construction includes an acoustically lined housing, integral spring

isolators, and internal flexible connections between the fan’s inlet and outlet to effectively isolate the fan from

the system. Vertical or horizontal mounting configurations are available.

Why use a Sound Vault?

• Sound power attenuation levels determined by

sound intensity tests on actual units

• Ships fully assembled with fan

• Internal isolation to limit breakout noise

• Access panels for inspection of fan and motor

• Bearing lubrication lines extended to outside of

enclosure

• Formed mounting rails with prepunched holes

for easy installation

• Can be used on both QEI and QEID through

size 27 fans

This table lists the radiated sound

reductions from total sound power

levels for each octave band with

the Sound Vault housing.

8

Center Frequencies [Hz] 63 125 250 500 1000 2000 4000 8000

Attenuation Value (dB) 13 20 25 31 34 35 36 36

Page 9

Optional Two Coat

Paint System

In 1972, Greenheck took the lead as the first commercial and industrial fan manufacturer to introduce

electrostatic powder coatings. Today, Greenheck continues to lead by being the first to offer a superior zinc-rich

powder basecoat and powder coating finish.

This zinc-rich basecoat technology is used extensively outside the HVAC industry to protect bridge beams,

automotive components and other heavy-gauge steel products. Now, this advanced technology is available on

Greenheck welded steel products.

Greenheck’s coating process starts with a minimum of five wash stages to treat all components prior to

painting. Cleaner parts result in better coating adhesion and durability. We then use an advanced two coat

powder application method that includes a basecoat of zinc-rich powder and a topcoat of Greenheck’s

Permatector™ or Hi-Pro Polyester. The combination of these two topcoats over our new zinc-rich basecoat

results in the two new coatings Perma-Z and Hi-Pro-Z. These oven-cured coatings provide superior corrosion

resistance along with a tough, uniform finish to combat the most extreme conditions.

Zinc Advantage

When compared to a traditional single coat

One Coat Process

application, the benefits of the two coat

system include:

• An automatic powder coat application

that produces uniform coverage and

unmatched paint quality.

• A double coat thickness that provides

superior durability and protection from

air and water.

Two Coat Process

• A zinc-rich basecoat that includes

an epoxy component that provides

additional corrosion protection.

• A zinc-rich basecoat that provides

chemical protection of exposed steel

to prevent corrosion.

The protection offered by the zinc-rich basecoats in

Perma-Z and Hi-Pro-Z result in extraordinary corrosion

resistance. Test data demonstrates our two coat paint

system offers three (Perma-Z) and four (Hi-Pro-Z) times

the corrosion resistance of other coatings commonly

available within the fan industry. See table for salt spray

life for various coatings.

Coating fans with Perma-Z or Hi-Pro-Z has reduced our

customers annual paint maintenance costs by three to

four times!

For more information, see Greenheck’s Coatings for

Extreme Applications catalog, available on-line at

www.greenheck.com

Topcoat

2-3 mils

Topcoat

4-6 mils Total

Permatector™

Hi-Pro Poly

Perma-Z

Hi-Pro-Z

Baked Phenolic

Epoxy Phenolic

Fluorocarbon

Salt Spray ASTM B117 is a comparative test

that indicates the corrosion resistance of

powder paint coatings.

Standard

Surface Preparation

Base Steel

Zinc-rich Primer

(70% zinc)

Advanced

Surface Preparation

Base Steel

Salt Spray ASTM B117

Hours 1000 2000 3000 4000

99

Page 10

Certifications & Listings

Tau Bot

psi

7880

7090

6300

5510

4720

3930

3140

2350

1560

770

-20

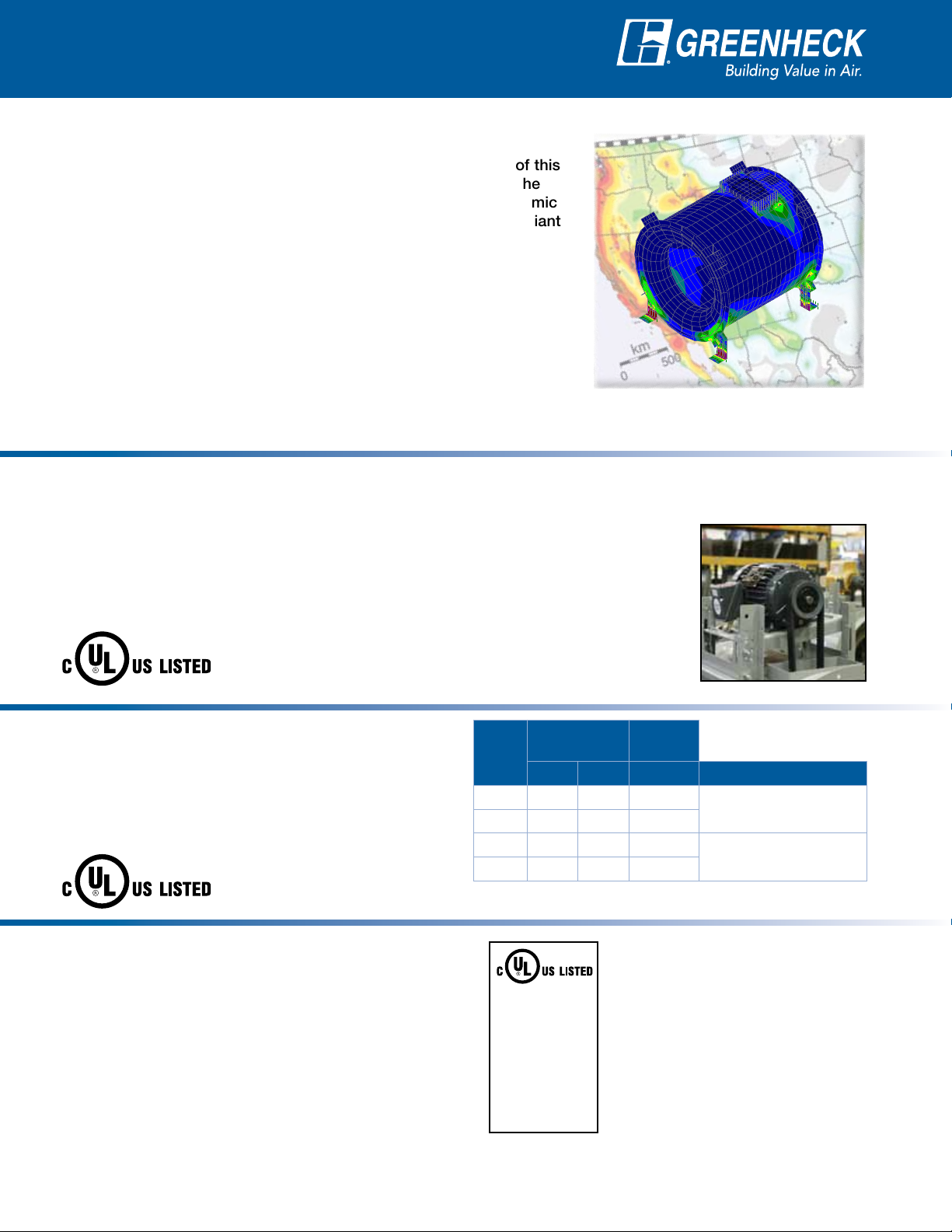

Seismic Certification

The International Building Code (IBC) has been adopted at the state

and local level throughout the United States. With the adoption of this

code, comes the introduction of standards intended to improve the

performance and design of non-structural systems subject to seismic

events. As an industry leader, Greenheck manufactures IBC compliant

seismic certified mixed flow fans that maintain structural integrity

during and after a seismic event.

How are Greenheck products seismically certified?

Our mixed flow fans are tested and certified using the most severe

seismic event that is found on the Spectral Response Map per IBC

Figures 1613.5 (1-2). Greenheck products are certified for use in all

seismic design categories (A through F), site classes and occupancy

categories, which means, regardless of location, a seismic rated

ventilation solution can be provided. The seismic analysis was

performed by third party professional engineers that hold professional

engineering licenses in all fifty states.

UL 705 Power Ventilator

QEI and QEID models are available with the UL/cUL 705 (Underwriters Laboratory) listing on a wide variety of 50

and 60 Hz motors. This listing ensures the use of UL approved electrical components.

Motors are available as either IEC (IP55) or NEMA (TEAO or ODP) designs. IEC design

motors are adjustable speed drive (ASD) compatible, have classF insulation and

are capable of wye-delta starting when over 5.5 kW. NEMA motors use across the

line starting with options for ASD compatibility. Motor (IEC or NEMA) using 50 Hz

power have a 1.0 service factor, while 60Hz

UL/cUL File #E40001

UL/cUL Listed Power Ventilator

power have 1.15 service factor. Design and

construction options for motors include

increased thermal insulation, overload

protection and extended motor leads.

Structural Finite Element Analysis of a

QEI in Seismic Design Category F

UL Emergency Smoke Evacuation

QEI and QEID models were tested and

rated for design time and temperature used

in emergency heat and smoke exhaust

applications.

UL/cUL File #MH17511

UL/cUL “Power Ventilators for Smoke Control Systems”

UL 762 Restaurant Exhaust

Inline grease exhaust fans are an excellent alternative

for kitchen applications when roof or wall mounted

ventilators are not practical. A QEI with UL 762 grease

option is designed to withstand the demands of high

temperature kitchen grease exhaust and high-pressure

duct washers.

A Tough Package to Beat

The QEI inline grease fan is tough to beat when packaged

with our full line of kitchen hoods and grease extraction

options. Take advantage of Greenheck’s expertise in

providing a total solution in kitchen ventilation equipment.

10

Model

Operating

Temperature

Time

Duration

ºC ºF Hours Comments

QEID 300 572 1

QEI 300 572 2

QEI 260 500 4

QEID 260 500 5

Consult your Greenheck representative for time and temperature

combinations other than those listed.

Per British Spec 7346

Per Industrial Risk

Insurers (North America)

UL 762 is concerned with fans designed

for removal of smoke and grease laden

vapors with airstream temperatures up

Listed Power

Ventilation for

Restaurant

Exhaust

Appliances

13G3 Maximum

Operating

Temperature

400°F.

to 400°F.

• Meets all UL 705 Requirements

• UL/cUL File #MH11745

“UL/cUL Power Ventilators for

Restaurant Exhaust Appliances”

• Bolted Access Door

• Drain Connection

• Meets requirements of NFPA 96

Ventilation Control and Fire Protection

of Commercial Cooking Operations

Page 11

Belt Drive versus Direct Drive

Belt Drive Advantages

• Lower sound levels

• Higher operating efficiencies

• Motor out of the airstream for easy access

• Motor size may be changed to accommodate

possible future air capacity requirements

• Final system balancing accomplished by

changing drives

Direct Drive Advantages

• Fewer wear components and less maintenance, no

shaft, bearings, pulleys, or belts

• More compact than equivalent belt drive size

• Motor in airstream for increased motor efficiency

and cooling

• Equal loading between mounting brackets

• Final system balancing accomplished by adjusting

the motor speed (ex. variable frequency drive use).

High Efficiencies = Lower Operating Costs

Example of Annual Operating Cost Savings

For a system performance requirement of 25,000 cfm at 2.5 inches of static pressure (wg) the corresponding

operating power requirements are 13.97 Bhp with a QEI size 36 and 19.8 Bhp for a size 36 tubular centrifugal fan.

Formulas:

- Kilowatt-Hours = (Operating Power (Bhp) x 0.746 x Hours of Operation) / Motor Efficiency

- Operating Cost = Kilowatt-Hours x Power Cost per kW hour

Assumptions:

- Cost of electricity is $0.09 per kilowatt hour

- 3,120 annual hours of operation (12 hours per day, five days a week, 52 weeks a year)

- 93.0% motor efficiency (equal to NEMA Premium minimum efficiency for 15 and 20 hp, ODP, 1725 RPM motor)

Tubular Centrifugal Fan

kW-Hours = (19.8 Bhp x 0.746 x 3120) / 0.93 = 49,554

Operating Cost = 49,554 x $0.09 = $4,460

Annual Operating Cost Savings = $4,460 - $3,147 = $1,313

QEI - Mixed Flow Fan

kW-Hours = (13.97 Bhp x 0.746 x 3120) / 0.93 = 34,963

Operating Cost = 34,963 x $0.09 = $3,147

11

Page 12

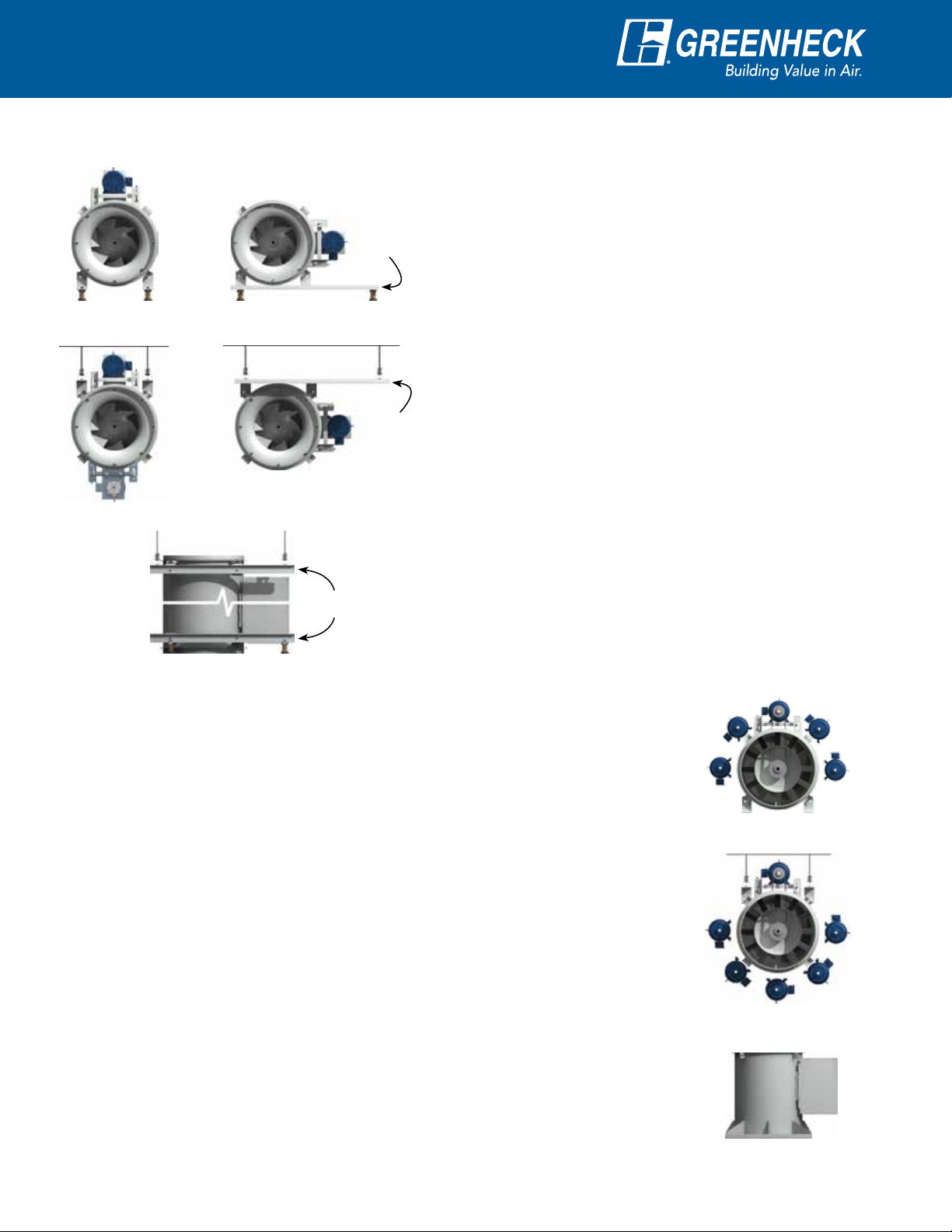

Belt Drive Mounting

Configurations

Sizes 9-27 (Universal Mounting)

Horizontal and Vertical Mounting

Configurations

QEI fans sizes 9-27 can be mounted horizontally or

Optional

Mounting

Rails

Fig. 1

Fig. 3

Vertical Ceiling Hung

Vertical Base Mount

Fig. 5

Fig. 2

Fig. 4

Optional

Mounting Rails

Optional

Mounting

Rails

Sizes 30-60

QEI fans sizes 30-60 are available in horizontal and vertical mounting

configurations. Lifting lugs are provided on horizontal fans for ease of

installation. Vertical units should be lifted by the mounting brackets.

vertically. For ease of installation, eight mounting brackets

are welded on each fan. These eight brackets along with

standard mounting supports provide for Greenheck’s

Universal Mounting System. Motor positions are viewed

from the discharge end.

Fig. 1 Horizontal Base Mount

Each fan is shipped as standard in this arrangement.

Motor at “A” position (12 o’clock) is standard.

Fig. 2 Horizontal Base Mount with motor at “C” or “G”

position (3 or 9 o’clock). A set of optional mounting

rails are recommended for this installation.

Fig. 3 Horizontal Ceiling Hung

In this installation the supports can be positioned for

mounting the motor at “A” or “E” (12 or 6 o’clock).

Fig. 4 Horizontal Ceiling Hung with motor at “C” or “G” (3

or 9 o’clock). A set of optional mounting rails are

recommended for this installation.

Fig. 5 Vertical Mount

Universal QEI fans can be mounted vertically (ceiling

hung or base mount) for either upward or downward

airflow. Optional mounting rails are suggested for

any vertical installation.

A

H

G

B

C

Horizontal Mounting

Horizontal mounting configurations, base mount or ceiling hung, are provided

with an identical support. The mounting configuration can be changed between

base mount or ceiling hung in the field. The motor position can also be field

rotated to any of the shown positions. Motor positions are viewed from the

discharge end.

Base Mount: Rigid steel base provides stable mounting to floor for the housing.

Motor Positions: A, B, C, G and H

Ceiling Hung: Suspend the fan horizontally from the ceiling.

Motor Positions: A, C, D, E, F and G

Mounting rails are recommended for horizontal installations with B, C, D, F, G

and H motor positions.

Vertical Mounting

Vertical mounting configurations, upblast or downblast, are provided with heavy

duty steel brackets welded to both ends. These brackets permit either floor or

ceiling mounting on the same unit. Optional mounting rails are suggested for any

vertical installation for sizes 9-27.

12

Horizontal - Base Mount

A

G

F

E

Horizontal - Ceiling Hung

Vertical

(Upblast shown)

D

C

Page 13

Roof Upblast & Spark Resistant

Construction

Roof Upblast

Model QEI sizes 9 through 54 and model QEID sizes 12

through 54, are available in roof upblast configuration

for Class I and II construction. Roof upblast

configuration is ideal for exhausting contaminants

away from a building to prevent roof damage and reentrainment of exhaust air. The QEI roof upblast has

the high temperature UL rating so it can be used for

emergency smoke exhaust applications.

Standard construction includes a fully-welded heavygauge curb cap to eliminate leaks, a butterfly damper

section for backflow prevention, and a windband

section to protect the butterfly dampers from debris. A

complete line of roof curbs is available for mounting to

a roof deck.

Spark Resistant Construction

Greenheck mixed flow fans are available with spark B

and C resistant designs suitable for applications that

involve flammable particles, fumes or vapors. Spark

resistant construction options adhere to guidelines

defined within AMCA Standard 99-0401-86.

The fan wheel is constructed of a

nonferrous material (aluminum).

Spark B

Spark C

A non-ferrous (aluminum) bearing

cover surrounds the driven bearing,

shielding it from the airstream.

The inlet cone is constructed of

non-ferrous material (aluminum).

A nonferrous (aluminum) bearing

cover surrounds the driven bearing

shielding it from the airstream.

13

Page 14

Accessories

Motor Cover (Belt Drive)

A weatherproof motor cover shields the motor

components from dust, dirt and moisture for indoor

or outdoor installations. Motor covers also serve as a

personnel guards and meet OSHA standards.

Hinged Access Door

Hinged access doors provide an opening through the

fan housing for cleaning or visual inspection of the

wheel. Bolted access door is standard.

Extended Life Bearings (Belt Drive)

Air handling quality, flange mounted bearings meet a

basic rating fatigue life (L

excess of 200,000 hours (L

operating speed.

), per ABMA standards, in

10

at 1,000,000) at maximum

50

Copper Lube Lines

Copper lube lines can be used as a replacement

for standard nylon lube lines. Grease fittings allow

bearing lubrication without disassembling the fan or

while in operation. Fittings are mounted on the outside

of the fan housing. Available on all belt drive units and

direct drive units with NEMA 254T frame size motors

and larger.

Flanges

Inlet and outlet flanges with prepunched holes are

available for all fan sizes. These flanges, welded

to the housing, provide an easy means for bolted

connection to ductwork. Matching bolt-on companion

flanges are also available.

Disconnect Switches

Toggle type and heavy duty disconnect switches are

available for positive electrical shut-off and safety

when servicing fans. The following switches are

available to meet individual electrical requirements

and can be factory mounted or shipped loose for field

mounting.

• NEMA-1 General purpose

• NEMA-3R Rainproof

• NEMA-4 Watertight

• NEMA-7 & 9* Class 1 and 2 hazardous locations

*Greenheck will not factory mount NEMA-7 & 9 disconnect

switches.

Inlet and Outlet Guards

Removable inlet and outlet guards provide protection

for personnel and equipment in ducted or non-ducted

installations.

Extended Wiring (Direct Drive)

Electric leads from motor junction box are brought

out to exterior of unit. This provides an easy means of

connecting the motor to the electrical system.

Belt Tube (Belt Drive)

A totally enclosed belt tube isolates the belts and

drives from the airstream.

Sound Vault Housing

A totally enclosed galvanized enclosure that reduces

radiated noise levels. See page 8 for more details or

Sound Vault Housing brochure available on-line at

www.greenheck.com.

Mounting Rails (Belt Drive)

Mounting rails are used to provide a stable base when

the fan and motor center of gravity is overhung to one

side. They are recommended for horizontal mounting

when the motor is to be located in the 3 or 9 o’clock

position and also for all vertically mounted fans.

Isolators

Both base mount and hanging isolators are available

in either neoprene or spring mounts. The isolators are

sized to match the total weight of each fan.

Special Coatings

Special coatings are available for protective purposes.

Coatings are applied before assembly so that

each manufactured component is coated inside

and out. Painting the exterior a specified color for

appearance is also an option. Consult Greenheck’s

Product Application Guide, Performance Coatings for

Ventilation Products, for a complete list of coatings

available and their chemical resistance. Available online at www.greenheck.com.

Sure-Aire™ Flow Measurement

Sure-Aire™ provides the real-time flow measurement

for use in building automation systems. The

Sure-Aire’s noninvasive design is accurate to within

3% and does not impact fan performance. See page8

or our Sure-Aire Airflow Monitoring System catalog

available on-line at www.greenheck.com for additional

information.

14

Page 15

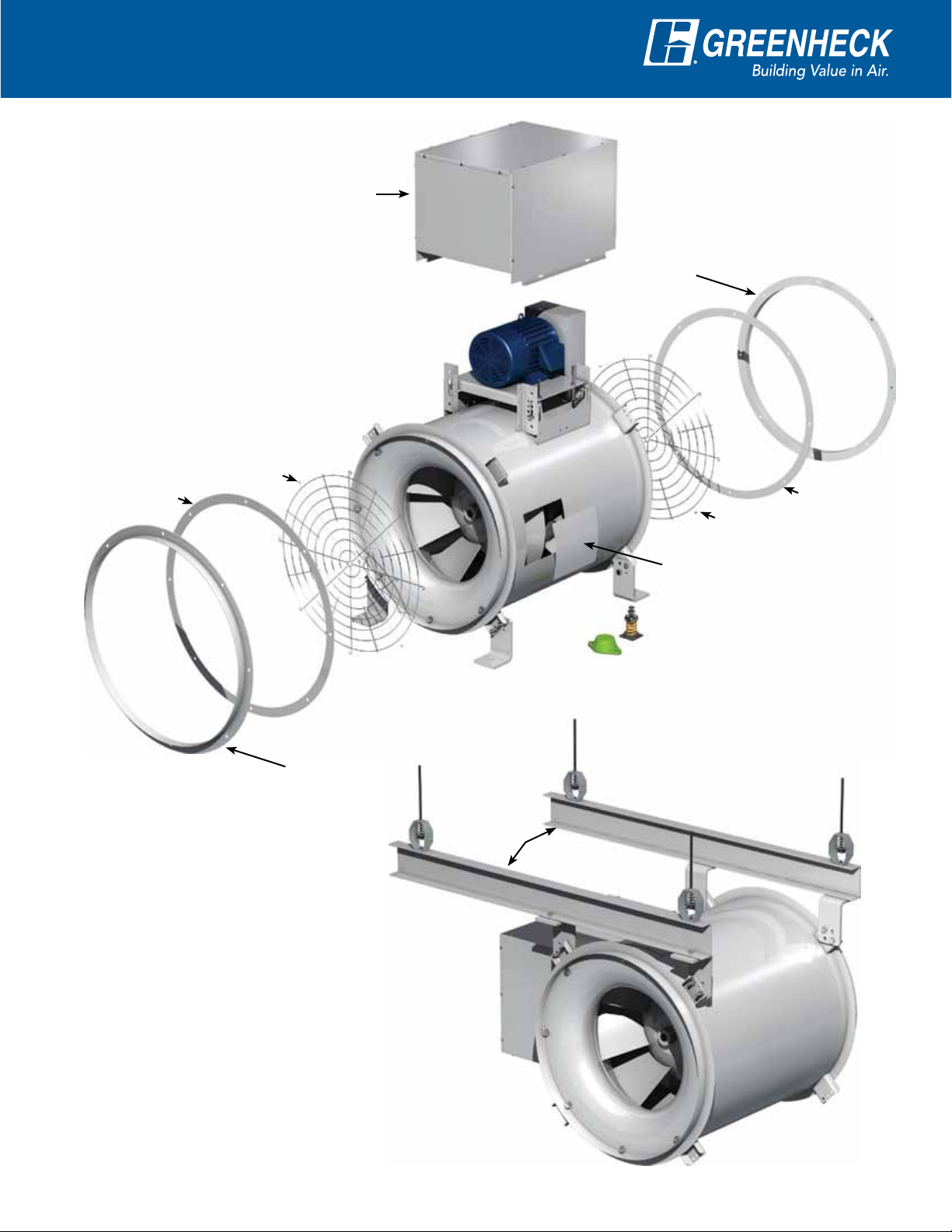

Exploded View

Motor Cover

Inlet Guard

Inlet Flange

Companion Flange

Outlet Flange

Outlet Guard

Companion Flange

Bolted Access Door

(Standard)

Spring Base Isolator

Neoprene Base Isolator

Spring Hanging Isolator

Mounting

Rails

15

Page 16

Direct Drive Selection Charts

The quick select charts below and on the following page are a convenient method for sizing the fan required for a

specific performance. Colored bands for a given size in each chart represent the entire operating range available

for that size and speed.

For QEID performance pages showing AMCA licensed data for sound and air performance please refer to the

Model QEID Sound and Air Performance Supplement found at www.greenheck.com

12

10

1770 RPM

(60 Hz)

Model QEID

12—33

Static

Pressure

(in. wg)

8

6

4

1170 RPM

(60 Hz)

Model QEID

15—49

Static

Pressure

(in. wg)

2

0

1 5 10 50 100

12

10

8

6

4

181615 3322 3027242012

Volume (cfm x 1000)

16

16

2

0

1 5 10 50 100

Volume (cfm x 1000)

49444036333027242220181615

Page 17

QEID Dimensional Data

8

6

870 RPM

(60 Hz)

Static

Pressure

(in. wg)

Model QEID

36—54

Slip Fit

O.D.

Length

* Length varies with motor frame size.

Refer to Length table shown.

** Weight is for unit only and does not

include motor.

4

2

0

444036 49 54

10 20 30 40 50 100

Volume (cfm x 1000)

Size

12 17.13 435 25.0 635 100 45

15 20.88 530 25.0 635 140 65

16 23.00 584 26.0 660 170 80

18 25.38 645 29.0 737 200 95

20 27.81 706 34.0 864 250 115

22 30.88 784 35.5 902 370 170

24 34.00 864 41.5 1054 480 220

27 37.44 951 45.0 1143 570 260

30 41.63 1057

33 45.75 1162 1140 520

36 50.56 1284 1360 620

40 55.75 1416 1650 750

44 61.63 1565 2190 995

49 67.75 1721 2700 1225

54 75.00 1905 3130 1420

Slip Fit O.D. Length* Weight**

inches mm inches mm lbs. kg.

860 390

Refer to

table below.

Length — inches (millimeters)

Size

30 45.5 (1156) 50.0 (1156) 50.0 (1156)

33 46.5 (1181) 54.0 (1372) 54.0 (1372) 54.0 (1372)

36 50.5 (1283) 58.0 (1473) 58.0 (1372) 58.0 (1372)

40 56.5 (1435) 61.0 (1549) 61.0 (1549)

44 64.0 (1626) 64.0 (1626) 70.0 (1778)

49 74.5 (1892) 74.5 (1892) 80.5 (2045)

54 77.0 (1956) 77.0 (1956) 83.0 (2108)

254/6 T 284/6 T 324/6 T 364/5 T 404/5 T 444/5 T

17

Page 18

QEI Class I and II

Dimensional Data

Slip Fit

O.D.

Airflow

Height

Length

QEI Class I QEI Class II

Size

9

12

15

16

18

20

22

24

27

30

33

36

40

Slip-Fit O.D. Length Height Length Height

inches mm inches mm inches mm inches mm inches mm

17.13 435 NA NA NA NA 28.5 724 36.25 921

17.13 435 28.5 724 36.25 921 30.13 765 36.25 921

20.88 530 31.0 787 41.0 1041 31.0 787 41.0 1041

23.00 584 33.0 838 44.0 1118 34.0 864 44.0 1118

25.38 645 35.0 889 46.5 1181 39.5 1003 47.5 1207

27.81 706 37.5 953 50.5 1283 41.5 1054 50.5 1283

30.88 784 41.0 1041 53.5 1359 44.0 1118 53.5 1359

34.00 864 44.5 1130 57.5 1461 49.0 1245 59.5 1511

37.44 951 47.0 1194 61.0 1549 53.0 1346 63.0 1600

41.62 1057 54.0 1372 65.0 1651 60.5 1537 72.0 1829

45.75 1162 58.5 1486 69.0 1753 64.5 1638 76.5 1943

50.56 1284 64.0 1626 75.0 1905 69.0 1753 82.5 2096

55.75 1416 68.5 1740 83.0 2108 75.5 1918 90.5 2299

18

44

49

54

60

61.62 1565 74.0 1880 89.5 2273 80.5 2045 97.0 2464

67.75 1721 80.5 2045 96.5 2451 86.5 2197 104 2642

75.00 1905 87.0 2210 105 2667 93.5 2375 111 2419

82.88 2105 91.5 2324 113 2870 102.4 2601 119 3023

Page 19

QEI-9 Class II

Performance Data

Maximum Fan RPM 4000

Specification Data

Maximum Motor

Frame Size

Minimum Motor

Starting hp

184T

1/3 hp .25 kW

Wheel Diameter 15 in. 381 mm

Approximate Weight

(Less Motor & Drives)

Maximum Bhp = (Fan RPM / 2671)

170 lbs. 77 kg.

3

Outlet Velocity (FPM) = CFM / 1.56

Tip Speed (FPM) = Fan RPM x 3.93

% WOV = (CFM x 100) / (Fan RPM x 0.73)

Imperial data — Metric data

20

15

10

Static Pressure (Pa x 100)

5

0

10

3

8

2

6

1½

1

4

¾

Static Pressure (in. wg)

½

3

2

0

0 5 10 15 20 25 30

0 1 2 3 4 5

E

L

E

S

T

O

N

O

D

O

T

F

E

L

E

H

T

O

T

2200

T

C

1600

H

T

F

Volume (cfm x 100)

Volume (m /hr x 1000)

5

50% W OV

60% W OV

E

V

R

U

C

M

E

T

S

Y

S

S

I

2800

4000

3400

3

RPM

BHP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

70% W OV

80% W OV

90% W OV

Performance Data

STATIC PRESSURE (inches wg)

CFM OV

850 541 1325 0.09 1463 0.14 1709 0.25 1937 0.38 2148 0.52 2341 0.67

1000 636 1511 0.13 1633 0.18 1854 0.31 2056 0.44 2252 0.59 2432 0.75 2606 0.93 2767 1.11

1150 732 1700 0.17 1811 0.23 2013 0.37 2198 0.52 2371 0.68 2542 0.85 2700 1.03 2858 1.22 3007 1.42

1300 828 1893 0.23 1994 0.29 2177 0.44 2349 0.61 2511 0.78 2661 0.96 2817 1.15 2961 1.35 3098 1.56

1450 923 2088 0.31 2181 0.37 2351 0.53 2510 0.71 2658 0.89 2804 1.08 2940 1.28 3079 1.49 3212 1.71

1600 1019 2285 0.40 2371 0.47 2530 0.63 2674 0.82 2818 1.02 2951 1.23 3083 1.44 3207 1.66 3331 1.88

1750 1114 2483 0.50 2563 0.58 2711 0.75 2849 0.95 2981 1.16 3109 1.38 3230 1.61 3351 1.84 3466 2.08

1900 1210 2682 0.63 2757 0.72 2897 0.89 3027 1.10 3149 1.32 3271 1.56 3387 1.80 3498 2.04 3611 2.29

2050 1305 2883 0.77 2952 0.87 3084 1.06 3207 1.26 3324 1.50 3435 1.75 3549 2.00 3656 2.26 3758 2.53

2200 1401 3083 0.94 3149 1.04 3274 1.25 3390 1.45 3502 1.70 3609 1.96 3713 2.22 3818 2.50 3918 2.78

2350 1496 3285 1.13 3347 1.24 3465 1.46 3576 1.68 3683 1.92 3785 2.19 3883 2.47 3981 2.76

2500 1592 3487 1.34 3545 1.46 3657 1.69 3764 1.93 3865 2.16 3964 2.44

0.25 0.5 1 1.5 2 2.5 3 3.5 4

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3

3

Inlet Sound Power, L

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

RPM % WOV 1 2 3 4 5 6 7 8 L

100 69 71 74 70 71 67 65 57 75

1600

80 71 69 72 68 68 66 62 56 73 80 77 80 77 67 68 63 58 56 74

60 70 70 71 66 63 65 61 55 71 60 80 78 76 66 66 62 58 56 73

[dB ref 10

A RPM % WOV 1 2 3 4 5 6 7 8 LWoA

Wi

Wo

100 76 78 78 70 71 65 63 56 76

1600

-12

watts]

50 72 70 71 65 63 65 61 55 71 50 82 78 77 66 66 62 58 56 73

2200

100 74 75 78 75 75 74 71 65 80

80 72 71 73 72 72 71 66 60 77 80 86 85 84 73 74 70 65 61 80

60 73 72 74 70 69 70 66 60 76 60 87 85 82 73 73 69 65 61 79

2200

100 86 86 84 77 78 74 69 64 82

50 75 73 74 70 69 70 66 61 76 50 88 86 82 74 73 69 65 61 79

2800

100 77 78 82 78 80 79 75 74 85

80 77 78 77 74 75 75 71 66 81 80 87 88 85 77 79 76 71 66 84

60 78 79 78 74 74 74 70 65 80 60 91 85 86 78 78 75 70 67 84

2800

100 88 85 87 81 83 80 75 72 87

50 78 79 79 75 74 74 70 65 80 50 92 86 86 79 79 75 70 67 84

3400

100 78 80 84 80 83 83 79 79 89

80 78 81 81 77 79 79 75 71 84 80 90 88 89 80 83 81 76 71 88

60 80 82 81 77 78 78 74 70 84 60 94 87 89 82 83 80 76 72 88

3400

100 88 88 91 84 87 85 80 78 92

50 80 82 82 79 78 78 74 70 84 50 94 88 89 83 84 81 76 72 89

4000

100 78 82 85 82 87 87 83 83 92

80 79 83 84 81 83 83 79 76 88 80 94

60 82 85 84 80 82 81 78 76 87 60 95 89 92 85 86 85 81 76 92

4000

100 88 93 96 87 91 90 85 83 96

86 92 82 87 86 81 75 92

50 82 84 85 83 82 82 78 75 88 50 95 90 92 86 88 85 81 77 92

Performance certified is for installation type B: Free inlet, Ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

L

A sound power levels for installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the effects of duct end correction. Ratings for outlet

Wo

sound include the effects of duct end correction. The A-weighted sound power ratings shown have been calculated per AMCA Standard 301. The AMCA Certified

Ratings Seal applies to L

A and L

Wi

A values only.

Wo

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi , L

A and outlet L

Wi

Wo

,

19

Page 20

QEI-12 Class I

Performance Data

Maximum Fan RPM 3800

Specification Data

Maximum Motor

Frame Size

Minimum Motor

Starting hp

184T

1/3 hp .25 kW

Wheel Diameter 15 in. 381 mm

Approximate Weight

(Less Motor & Drives)

Maximum Bhp = (Fan RPM / 2301)

160 lbs. 73 kg.

3

Outlet Velocity (FPM) = CFM / 1.56

Tip Speed (FPM) = Fan RPM x 3.93

% WOV = (CFM x 100) / (Fan RPM x 1.34)

Imperial data — Metric data

20

15

10

Static Pressure (Pa x 100)

5

0

10

8

6

4

Static Pressure (in. wg)

2

0

5

3

2

1½

F

E

L

1

¾

½

3

N

O

D

0 1 2 3 4 5 6

0 2 4 6 8 10

E

H

T

O

T

T

C

E

L

200 0

E

S

T

O

1400

7½

50% W OV

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

2600

Volume (cfm x 1000)

Volume (m /hr x 1000)

3200

3

3800

60% W OV

70% W OV

RPM

BHP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

80% W OV

90% W OV

Performance Data

STATIC PRESSURE (inches wg)

CFM OV

1200 764 1070 0.09 1241 0.15 1549 0.30 1823 0.49

1500 955 1257 0.13 1399 0.20 1661 0.37 1907 0.57 2137 0.79 2341 1.03

1800 1146 1461 0.19 1575 0.27 1807 0.46 2020 0.67 2228 0.91 2423 1.16 2607 1.43 2776 1.72

2100 1337 1669 0.27 1763 0.36 1967 0.56 2162 0.80 2341 1.04 2523 1.31 2690 1.60 2858 1.90 3016 2.22

2400 1528 1881 0.38 1966 0.48 2139 0.69 2317 0.94 2484 1.21 2640 1.49 2801 1.79 2954 2.11 3099 2.44

2700 1719 2095 0.51 2172 0.62 2323 0.85 2479 1.11 2636 1.40 2785 1.71 2926 2.02 3067 2.35 3208 2.70

3000 1910 2310 0.68 2382 0.79 2514 1.04 2657 1.31 2799 1.62 2938 1.94 3072 2.28 3201 2.63 3322 2.98

3300 2101 2527 0.88 2593 1.00 2716 1.26 2840 1.55 2969 1.86 3100 2.21 3226 2.57 3348 2.94 3467 3.32

3600 2292 2745 1.11 2806 1.25 2922 1.53 3029 1.82 3150 2.16 3265 2.50 3387 2.88 3503 3.28 3615 3.68

3900 2484 2964 1.39 3021 1.54 3129 1.84 3231 2.15 3335 2.49 3446 2.86 3551 3.23 3665 3.65 3772 4.08

4200 2675 3184 1.71 3237 1.87 3338 2.19 3435 2.53 3527 2.87 3630 3.25 3731 3.65

4500 2866 3404 2.08 3453 2.25 3549 2.59 3641 2.95 3729 3.31

0.25 0.5 1 1.5 2 2.5 3 3.5 4

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3

3

Inlet Sound Power, L

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

RPM % WOV 1 2 3 4 5 6 7 8 L

100 77 78 71 73 67 68 61 52 75

1400

80 77 78 69 68 65 64 60 52 72 80 87 81 74 71 70 68 62 58 76

60 78 78 68 65 62 61 60 52 70 60 88 82 74 70 68 67 62 59 75

[dB ref 10

A RPM % WOV 1 2 3 4 5 6 7 8 LWoA

Wi

Wo

100 87 83 75 74 72 71 63 59 78

1400

-12

watts]

50 78 77 68 64 62 60 60 52 69 50 89 81 73 70 67 66 62 59 74

2000

100 78 78 78 79 75 75 73 59 82

80 74 77 76 75 71 72 66 58 78 80 84 84 77 77 77 75 69 64 81

60 74 76 75 71 68 68 64 58 75 60 85 84 76 75 74 71 67 64 79

2000

100 84 84 80 80 80 77 75 64 84

50 76 77 75 70 67 67 63 58 74 50 87 84 76 75 73 70 66 64 79

2600

100 83 82 80 80 78 77 83 68 86

80 80 82 81 78 75 76 74 65 82 80 92 90 81 79 82 79 75 69 86

60 79 81 79 76 73 74 70 65 80 60 90 89 81 79 79 77 73 69 84

2600

100 90 93 83 82 83 80 82 72 89

50 81 81 79 75 72 73 69 65 79 50 91 90 81 78 78 76 71 70 84

3200

100 85 85 82 82 81 80 87 79 90

80 82 85 83 81 79 78 79 70 86 80 94 92 85 82 85 82 80 74 89

60 83 85 82 81 77 77 74 70 84 60 93 92 85 82 83 81 77 74 88

3200

100 93 95 88 85 86 83 86 81 92

50 83 84 82 81 77 77 74 70 84 50 95 93 86 81 83 80 76 74 88

3800

100 86 87 85 86 86 84 88 91 95

80 80 87 83 83 82 80 80 74 88 80

60 85 88 85 85 80 79 77 74 87 60 96 93 89 85 87 84 81 77 91

3800

100 93 94 93 90 90 88 87 92 97

93 92 89 85 87 84 83 77 92

50 84 87 84 86 81 80 78 74 88 50 97 94 90 85 87 84 81 77 92

Performance certified is for installation type B: Free inlet, Ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

L

A sound power levels for installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the effects of duct end correction. Ratings for outlet

Wo

sound include the effects of duct end correction. The A-weighted sound power ratings shown have been calculated per AMCA Standard 301. The AMCA Certified

Ratings Seal applies to L

A and L

Wi

A values only.

Wo

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi , L

A and outlet L

Wi

20

Wo

,

Page 21

QEI-12 Class II

Performance Data

Maximum Fan RPM 4000

Specification Data

Maximum Motor

Frame Size

Minimum Motor

Starting hp

184T

1/3 hp .25 kW

Wheel Diameter 15 in. 381 mm

Approximate Weight

(Less Motor & Drives)

Maximum Bhp = (Fan RPM / 2345)

180 lbs. 82 kg.

3

Outlet Velocity (FPM) = CFM / 1.56

Tip Speed (FPM) = Fan RPM x 3.93

% WOV = (CFM x 100) / (Fan RPM x 1.16)

Imperial data — Metric data

25

20

15

10

Static Pressure (Pa x 100)

5

0

12

7

5

½

10

8

3

T

S

Y

S

6

2

1½

4

1

Static Pressure (in. wg)

¾

½

2

D

0

0 1 2 3 4 5

T

C

E

L

E

S

T

O

1600

N

O

S

I

H

T

F

O

T

F

E

L

E

H

2800

T

O

T

2200

50% WOV

60% WOV

E

V

R

U

C

M

E

3400

4000

Volume (cfm x 1000)

RPM

BHP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

70% WOV

80% WOV

90% WOV

3

3

0 2 4 6 8

Volume (m /hr x 1000)

3

Performance Data

STATIC PRESSURE (inches wg)

CFM OV

1400 891 1203 0.08 1460 0.21 1696 0.37 2131 0.75 2510 1.21

1600 1019 1375 0.12 1604 0.26 1812 0.43 2213 0.84 2574 1.31 2894 1.84

1800 1146 1547 0.17 1752 0.33 1943 0.51 2301 0.93 2641 1.43 2957 1.98 3239 2.59

2000 1273 1719 0.24 1906 0.41 2080 0.60 2410 1.05 2728 1.56 3021 2.13 3302 2.76 3557 3.43

2200 1401 1891 0.32 2062 0.50 2223 0.71 2522 1.17 2817 1.71 3102 2.30 3366 2.95 3620 3.64 3854 4.37

2400 1528 2062 0.41 2221 0.61 2370 0.83 2653 1.32 2924 1.88 3190 2.49 3443 3.15 3684 3.86 3917 4.62

2600 1656 2234 0.52 2381 0.74 2519 0.97 2785 1.48 3035 2.06 3283 2.70 3530 3.38 3759 4.11 3981 4.88

2800 1783 2406 0.65 2543 0.88 2673 1.13 2921 1.66 3157 2.27 3393 2.92 3618 3.63 3846 4.38

3000 1910 2578 0.80 2706 1.05 2829 1.31 3064 1.87 3289 2.49 3504 3.17 3722 3.90 3934 4.67

3200 2038 2750 0.98 2871 1.24 2987 1.51 3209 2.10 3421 2.74 3624 3.44 3831 4.19

3400 2165 2922 1.17 3036 1.45 3145 1.74 3356 2.35 3556 3.01 3755 3.74 3943 4.50

3600 2292 3094 1.39 3202 1.68 3305 1.99 3504 2.62 3699 3.32 3887 4.06

Shaded values show where Class I fan selections are more efficient than Class II.

RPM % WOV 1 2 3 4 5 6 7 8 L

1600

2200

2800

3400

4000

Performance certified is for installation type B: Free inlet, Ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

L

A sound power levels for installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the effects of duct end correction. Ratings for outlet

Wo

sound include the effects of duct end correction. The A-weighted sound power ratings shown have been calculated per AMCA Standard 301. The AMCA Certified

Ratings Seal applies to L

0 0.5 1 2 3 4 5 6 7

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Inlet Sound Power, L

[dB ref 10

Wi

100 72 77 77 74 70 69 69 56 77

80 74 79 75 69 66 67 61 55 73 80 84 85 73 70 71 69 63 58 76

60 73 80 75 66 64 64 58 55 72 60 85 84 73 68 68 66 61 58 75

-12

watts] Outlet Sound Power, L

A RPM % WOV 1 2 3 4 5 6 7 8 LWoA

Wi

100 87 83 78 75 74 71 69 58 79

1600

[dB ref 10

Wo

-12

watts]

50 74 80 76 65 63 63 57 54 72 50 87 84 73 68 68 65 60 59 74

100 76 77 78 78 76 75 76 67 82

80 76 78 76 74 72 72 68 63 78 80 87 84 77 76 77 74 70 66 81

60 76 79 75 71 70 70 66 62 76 60 88 82 77 74 74 72 67 66 79

2200

100 89 85 80 80 80 77 75 67 84

50 77 79 75 71 69 68 64 62 76 50 89 83 77 74 74 71 67 66 79

100 83 82 83 80 80 78 78 79 86

80 86 86 81 77 76 75 73 68 82 80 91 90 83 80 82 79 75 71 86

60 85 91 79 76 75 75 72 67 82 60 91 87 83 79 80 77 73 71 85

2800

100 97 89 86 83 84 81 78 78 89

50 86 89 80 76 74 74 70 67 81 50 93 88 83 79 79 76 73 70 84

100 83 86 85 83 83 82 80 85 90

80 87 86 83 80 80 79 76 72 85 80 93 90 86 83 85 82 79 75 89

60 87 90 82 79 79 78 76 71 85 60 93 89 86 83 84 81 78 75 89

3400

100 98 91 88 86 88 85 81 84 92

50 87 89 83 80 78 78 75 71 85 50 95 89 86 83 83 81 77 74 88

100 80 89 86 86 87 86 84 89 93

80 82 83 83 81 83 82 79 76 88 80 94

60 84 82 85 81 82 81 79 75 87 60 94 89 89 85 88 85 82 78 92

4000

100 95 90 90 89 91 89 85 87 96

88 87 85 88 86 82 78 92

50 84 83 85 83 82 81 79 75 88 50 94 89 88 86 87 84 82 78 91

-12

A and L

Wi

A values only.

Wo

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi , L

A and outlet L

Wi

Wo

,

21

Page 22

QEI-15 Class I

QEI-15I

Performance Data

Maximum Fan RPM 2721

Specification Data

Maximum Motor

Frame Size

Minimum Motor

Starting hp

213T

1/3 hp .25 kW

Wheel Diameter 18.25 in. 464 mm

Approximate Weight

(Less Motor & Drives)

Maximum Bhp = (Fan RPM / 1617)

190 lbs. 86 kg.

3

Outlet Velocity (FPM) = CFM / 2.32

Tip Speed (FPM) = Fan RPM x 4.78

% WOV = (CFM x 100) / (Fan RPM x 2.55)

Imperial data — Metric data

14

12

10

8

6

Static Pressure (Pa x 100)

4

2

0

6

3

5

2

4

3

1

2

Static Pressure (in. wg)

½

1

¼

O

D

0

0 1 2 3 4 5 6 7

O

T

T

C

E

L

SE

T

O

N

T

H

1018

5

50% WOV

60% WOV

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

E

1617

1283

2331

2037

70% WOV

2721

RPM

BHP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

Volume (cfm x 1000)

0 2 4 6 8 10

Volume (m /hr x 1000)

3

80% WOV

90% WOV

Performance Data

STATIC PRESSURE (inches wg)

CFM OV

1700 732 823 0.12 965 0.21 1229 0.44

2100 905 952 0.17 1072 0.28 1301 0.52 1508 0.81

2500 1077 1088 0.24 1194 0.36 1391 0.62 1580 0.93 1753 1.27 1915 1.64

2900 1250 1231 0.33 1323 0.46 1495 0.75 1662 1.07 1827 1.43 1976 1.83 2122 2.24 2257 2.68

3300 1422 1376 0.44 1456 0.59 1615 0.92 1763 1.25 1907 1.62 2054 2.03 2188 2.47 2317 2.94 2443 3.42

3700 1594 1524 0.58 1597 0.74 1740 1.11 1875 1.47 2008 1.86 2135 2.27 2266 2.73 2390 3.22 2505 3.72

4100 1767 1674 0.75 1740 0.93 1870 1.31 1996 1.73 2114 2.13 2236 2.56 2350 3.02 2469 3.52 2583 4.05

4500 1939 1825 0.95 1885 1.14 2003 1.55 2121 2.01 2234 2.45 2339 2.90 2451 3.38 2556 3.88 2663 4.41

4900 2112 1977 1.19 2031 1.40 2141 1.83 2251 2.31 2356 2.82 2458 3.29 2553 3.77 2657 4.30

5300 2284 2130 1.47 2180 1.69 2282 2.16 2383 2.65 2483 3.20 2579 3.73 2672 4.24

5700 2456 2283 1.79 2330 2.03 2426 2.52 2517 3.04 2613 3.61 2704 4.20

6100 2629 2436 2.16 2481 2.41 2570 2.94 2657 3.48

0.25 0.5 1 1.5 2 2.5 3 3.5 4

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3

3

Inlet Sound Power, L

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

RPM % WOV 1 2 3 4 5 6 7 8 L

100 63 61 59 56 57 52 48 35 60

650

80 62 59 59 53 54 51 48 35 59 80 69 64 59 57 57 55 52 40 62

60 60 59 57 52 54 51 47 35 58 60 70 64 58 56 57 54 52 40 61

[dB ref 10

A RPM % WOV 1 2 3 4 5 6 7 8 LWoA

Wi

Wo

100 74 65 60 58 59 54 52 39 63

650

-12

watts]

50 60 59 56 52 53 51 47 35 58 50 71 64 58 56 57 55 52 40 61

1000

100 65 66 68 65 60 63 52 44 68

80 63 63 65 62 58 56 51 42 64 80 75 74 64 66 63 60 56 47 68

60 63 63 63 60 57 55 50 42 63 60 76 73 64 65 62 59 55 47 68

1000

100 73 73 66 68 65 64 55 47 70

50 66 64 63 59 57 55 50 42 62 50 77 74 64 65 62 59 55 47 68

1400

100 69 77 73 72 69 67 69 53 75

80 68 76 70 68 66 63 58 50 71 80 79 74 72 71 71 67 61 55 74

60 67 70 68 66 65 62 57 50 69 60 77 75 73 69 68 66 61 55 73

1400

100 79 79 74 74 73 69 70 56 78

50 68 71 70 65 64 61 56 50 69 50 80 75 72 69 68 65 61 55 73

2000

100 73 73 82 81 78 74 77 65 84

80 68 76 76 78 74 72 67 61 80 80 79 78 77 79 79 75 70 63 82

60 75 77 77 76 72 70 67 62 78 60 83 81 78 77 77 74 69 64 81

2000

100 83 82 81 83 82 78 78 68 86

50 81 80 77 76 72 71 67 61 78 50 86 83 79 77 76 73 69 64 81

2721

100 79 78 86 88 86 83 80 83 91

80 80 73 83 85 81 79 74 69 86 80 88

60 78 75 78 81 79 77 73 69 84 60 87 87 83 82 83 81 77 71 88

2721

100 91 85 87 90 90 86 82 84 94

83 81 84 86 84 78 72 90

50 80 79 80 81 78 76 74 70 83 50 90 89 85 83 83 81 76 72 88

Performance certified is for installation type B: Free inlet, Ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

L

A sound power levels for installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the effects of duct end correction. Ratings for outlet

Wo

sound include the effects of duct end correction. The A-weighted sound power ratings shown have been calculated per AMCA Standard 301. The AMCA Certified

Ratings Seal applies to L

A and L

Wi

A values only.

Wo

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi , L

A and outlet L

Wi

22

Wo

,

Page 23

QEI-15 Class II

QEI-15II

Performance Data

Maximum Fan RPM 3445

Specification Data

Maximum Motor

Frame Size

Minimum Motor

Starting hp

215T

1/3 hp .25 kW

Wheel Diameter 18.25 in. 464 mm

Approximate Weight

(Less Motor & Drives)

Maximum Bhp = (Fan RPM / 1666)

220 lbs. 100 kg.

3

Outlet Velocity (FPM) = CFM / 2.32

Tip Speed (FPM) = Fan RPM x 4.78

% WOV = (CFM x 100) / (Fan RPM x 2.20)

Imperial data — Metric data

20

15

10

Static Pressure (Pa x 100)

5

0

10

9

5

8

7

6

3

5

2

4

Static Pressure (in. wg)

3

1

2

1

O

D

0

0 1 2 3 4 5 6 7 8

7½

S

S

I

H

T

F

O

T

F

E

L

E

H

T

O

T

T

C

E

L

1666

E

S

T

O

N

50% WOV

60% WOV

10

E

V

R

U

C

M

E

T

S

Y

2402

2099

3259

2847

70% WOV

3445

RPM

BHP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

Volume (cfm x 1000)

0 2 4 6 8 10 12

Volume (m /hr x 1000)

3

80% WOV

90% WOV

3

3

Performance Data

STATIC PRESSURE (inches wg)

CFM OV

2500 1077 1315 0.42 1471 0.64 1790 1.23 2082 1.91

2800 1206 1436 0.53 1575 0.77 1864 1.38 2131 2.09 2392 2.88

3100 1336 1559 0.65 1687 0.92 1948 1.54 2201 2.29 2435 3.11 2670 3.99 2884 4.93

3400 1465 1684 0.79 1805 1.10 2034 1.72 2275 2.51 2500 3.36 2713 4.28 2926 5.25 3122 6.28

3700 1594 1810 0.96 1926 1.30 2137 1.95 2358 2.75 2570 3.64 2771 4.59 2968 5.59 3164 6.66 3347 7.76

4000 1724 1938 1.15 2047 1.52 2242 2.21 2443 3.01 2647 3.94 2841 4.92 3023 5.96 3207 7.05 3389 8.20

4300 1853 2067 1.37 2170 1.76 2353 2.50 2538 3.31 2730 4.26 2913 5.29 3093 6.36 3261 7.48 3431 8.65

4600 1982 2197 1.61 2294 2.04 2471 2.84 2641 3.67 2816 4.61 2995 5.67 3164 6.78 3331 7.94

4900 2112 2328 1.89 2420 2.34 2590 3.22 2746 4.05 2908 5.01 3080 6.09 3243 7.24 3402 8.43

5200 2241 2460 2.20 2546 2.67 2710 3.64 2856 4.49 3011 5.47 3165 6.53 3326 7.72

5500 2370 2592 2.55 2673 3.04 2831 4.07 2973 4.99 3115 5.96 3259 7.04 3411 8.23

5800 2500 2724 2.93 2802 3.45 2953 4.53 3092 5.53 3221 6.50 3362 7.61

Shaded values show where Class I fan selections are more efficient than Class II.

RPM % WOV 1 2 3 4 5 6 7 8 L

1000

1400

2000

2700

3445

Performance certified is for installation type B: Free inlet, Ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

L

A sound power levels for installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the effects of duct end correction. Ratings for outlet

Wo

sound include the effects of duct end correction. The A-weighted sound power ratings shown have been calculated per AMCA Standard 301. The AMCA Certified

Ratings Seal applies to L

0.5 1 2 3 4 5 6 7 8

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Inlet Sound Power, L

[dB ref 10

Wi

100 64 70 70 72 66 65 55 48 73

80 62 66 67 66 63 60 52 43 68 80 75 72 67 67 68 62 53 44 71

60 61 62 63 62 61 58 51 42 65 60 75 72 67 64 66 60 53 44 69

-12

watts] Outlet Sound Power, L

A RPM % WOV 1 2 3 4 5 6 7 8 LWoA

Wi

100 76 75 69 72 70 67 55 47 74

1000

[dB ref 10

Wo

-12

watts]

50 62 63 63 62 60 58 51 41 65 50 75 71 67 64 65 60 52 44 68

100 67 69 73 74 71 72 64 56 78

80 66 65 71 72 68 67 61 53 75 80 78 74 71 72 74 69 62 52 77

60 67 66 68 68 66 65 58 51 71 60 79 75 71 70 72 67 60 52 75

1400

100 80 76 74 76 76 73 66 56 80

50 69 67 69 67 65 63 57 52 71 50 79 75 71 70 72 67 60 52 75

100 71 73 78 77 77 75 79 66 84

80 67 69 76 75 74 73 70 62 79 80 88 78 77 79 80 76 72 65 84

60 71 71 74 74 72 71 68 61 77 60 87 82 78 77 78 74 69 63 82

2000

100 90 81 81 83 82 78 79 66 87

50 75 74 76 74 72 71 67 61 77 50 89 83 79 78 78 73 69 64 82

100 78 78 79 85 85 83 87 77 91

80 79 74 76 85 84 80 77 71 88 80 85 85 83 83 88 83 79 72 90

60 81 78 77 82 82 78 75 70 85 60 88 89 87 82 86 81 77 71 89

2700

100 87 85 85 88 90 86 86 78 94

50 81 80 79 82 81 78 74 70 85 50 89 90 87 83 86 80 77 72 89

100 79 82 84 89 90 88 91 87 96

80 75 79 81 85 87 85 83 78 91 80 89

60 79 83 82 82 84 83 81 77 89 60 92 94 93 87 90 87 84 79 94

3445

100 91 90 91 93 95 93 92 89 100

92 91 89 92 89 86 80 96

50 81 85 85 86 85 82 80 77 90 50 93 94 93 89 90 87 83 78 94

-12

A and L

Wi

A values only.

Wo

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi , L

A and outlet L

Wi

Wo

,

23

Page 24

QEI-16 Class I

QEI-16I

Performance Data

Maximum Fan RPM 2483

Specification Data

Maximum Motor

Frame Size

Minimum Motor

Starting hp

213T

1/3 hp .25 kW

Wheel Diameter 20 in. 508 mm

Approximate Weight

(Less Motor & Drives)

Maximum Bhp = (Fan RPM / 1387)

220 lbs. 100 kg.

3

Outlet Velocity (FPM) = CFM / 2.79

Tip Speed (FPM) = Fan RPM x 5.24

% WOV = (CFM x 100) / (Fan RPM x 3.36)

Imperial data — Metric data

16

14

12

10

8

6

Static Pressure (Pa x 100)

4

2

0

7

5

6

5

3

4

3

1½

Static Pressure (in. wg)

2

¾

1

/3

1

D

0

0 1 2 3 4 5 6 7 8 9

T

T

C

E

L

E

S

T

O

N

O

Y

S

S

I

H

T

F

O

T

F

E

L

E

H

T

O

1260

961

7½

T

S

M

E

1587

50% WOV

60% WOV

E

V

R

U

C

2483

2371

2000

70% WOV

RPM

BHP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

Volume (cfm x 1000)

0 2 4 6 8 10 12 14

Volume (m /hr x 1000)

3

80% WOV

90% WOV

Performance Data

STATIC PRESSURE (inches wg)

CFM OV

2400 860 837 0.19 951 0.31 1169 0.59 1362 0.94

2800 1003 939 0.25 1039 0.39 1230 0.69 1411 1.05 1576 1.45

3200 1146 1046 0.33 1134 0.48 1307 0.81 1471 1.18 1625 1.60 1770 2.06 1904 2.54

3600 1290 1155 0.43 1235 0.59 1389 0.95 1538 1.33 1684 1.77 1820 2.25 1950 2.76 2073 3.29 2188 3.85

4000 1433 1266 0.55 1338 0.72 1479 1.11 1616 1.52 1747 1.96 1879 2.46 2002 2.99 2119 3.55 2233 4.13

4400 1577 1378 0.69 1445 0.88 1573 1.29 1700 1.73 1824 2.20 1940 2.69 2062 3.25 2174 3.83 2280 4.43

4800 1720 1492 0.85 1554 1.06 1673 1.50 1789 1.97 1901 2.46 2016 2.98 2121 3.52 2234 4.13 2338 4.76

5200 1863 1607 1.05 1664 1.27 1774 1.74 1880 2.24 1989 2.76 2093 3.30 2198 3.87 2294 4.46 2399 5.11

5600 2007 1722 1.27 1774 1.51 1878 2.01 1979 2.54 2078 3.09 2177 3.65 2274 4.25 2371 4.86 2461 5.49

6000 2150 1837 1.52 1886 1.77 1984 2.31 2080 2.87 2170 3.45 2265 4.04 2355 4.66 2447 5.29

6400 2293 1954 1.81 1999 2.08 2092 2.64 2181 3.23 2269 3.84 2355 4.47 2443 5.11

6800 2437 2070 2.14 2113 2.42 2201 3.01 2284 3.63 2369 4.27 2449 4.93

0.25 0.5 1 1.5 2 2.5 3 3.5 4

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3

3

Inlet Sound Power, L

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

RPM % WOV 1 2 3 4 5 6 7 8 L

100 65 62 60 57 57 52 47 34 61

600

80 64 61 59 55 55 52 47 35 59 80 70 65 60 58 58 55 51 39 62

60 62 60 57 53 54 52 47 35 59 60 71 64 59 57 58 55 51 40 62

[dB ref 10

A RPM % WOV 1 2 3 4 5 6 7 8 LWoA

Wi

Wo

100 75 66 60 59 60 55 51 39 64

600

-12

watts]

50 62 60 57 53 54 52 47 35 58 50 72 64 59 57 57 55 51 40 62

900

100 65 67 68 65 61 62 51 43 68

80 64 64 65 62 58 56 50 41 64 80 76 73 65 66 63 60 55 46 68

60 63 63 63 60 57 55 49 41 63 60 76 72 64 65 62 59 54 46 67

900

100 74 73 67 68 65 63 55 46 70

50 66 65 63 60 57 55 49 41 62 50 77 73 65 65 62 59 54 46 67

1250

100 71 78 73 72 69 67 67 51 75

80 69 78 70 68 65 62 57 49 71 80 78 75 72 71 70 66 61 54 74

60 68 71 68 66 65 61 57 50 69 60 77 75 72 69 68 65 60 55 73

1250

100 80 80 74 74 72 70 68 54 77

50 69 73 69 65 64 60 55 50 69 50 79 76 72 69 68 65 60 55 73

1750

100 73 75 81 80 77 75 75 62 83

80 69 76 76 77 73 71 66 59 79 80 79 78 77 79 78 74 69 62 82

60 75 77 77 75 71 70 66 60 77 60 83 80 77 77 76 73 68 62 80

1750

100 82 82 81 83 81 78 76 65 86

50 80 80 77 75 71 70 66 60 77 50 86 82 79 77 75 72 68 63 80

2483

100 80 80 88 88 86 83 81 84 92

80 80 75 84 85 81 79 74 69 87 80 88

60 78 77 80 82 79 77 74 70 84 60 88 88 85 83 84 81 77 72 88

2483

100 91 86 88 90 90 87 83 85 94

84 82 85 87 84 78 72 90

50 81 80 82 81 78 77 74 70 84 50 90 89 86 84 84 81 77 72 88

Performance certified is for installation type B: Free inlet, Ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

L

A sound power levels for installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the effects of duct end correction. Ratings for outlet

Wo

sound include the effects of duct end correction. The A-weighted sound power ratings shown have been calculated per AMCA Standard 301. The AMCA Certified

Ratings Seal applies to L

A and L

Wi

A values only.

Wo

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi , L

A and outlet L

Wi

24

Wo

,

Page 25

Static Pressure (in. wg)

Static Pressure (Pa x 100)

Volume (cfm x 1000)

3

Volume (m /hr x 1000)

0 2 4 6 8 10 12 14 16

0

5

10

15

20

25

D

O

N

O

T

S

E

L

E

C

T

T

O

T

H

E

L

E

F

T

O

F

T

H

I

S

S

Y

S

T

E

M

C

U

R

V

E

0 1 2 3 4 5 6 7 8 9 10

0

1

2

3

4

5

6

7

8

9

10

11

12

QEI-16II

RPM

BHP

% WOV

Density 0.075 lb/ft

3

Density 1.2 kg/m

3

1430

2

3

1801

2062

2444

2797

1

50% WOV

60% WOV

70% WOV

80% WOV

90% WOV

5

3145

7½

10

15

QEI-16 Class II

Performance Data

Maximum Fan RPM 3145

Specification Data

Maximum Motor

Frame Size

Minimum Motor

Starting hp

Wheel Diameter 20 in. 508 mm

Approximate Weight

(Less Motor & Drives)

Maximum Bhp = (Fan RPM / 1430)

Outlet Velocity (FPM) = CFM / 2.79

Tip Speed (FPM) = Fan RPM x 5.24

% WOV = (CFM x 100) / (Fan RPM x 2.89)

Imperial data — Metric data

Performance Data

CFM OV

3000 1075 1199 0.50 1342 0.77 1633 1.48 1900 2.29

3300 1182 1291 0.61 1421 0.89 1688 1.62 1934 2.47 2176 3.41

3600 1290 1384 0.73 1503 1.03 1750 1.78 1987 2.66 2209 3.63 2424 4.68

3900 1397 1478 0.86 1592 1.20 1816 1.95 2041 2.88 2249 3.88 2456 4.96 2650 6.11

4200 1505 1574 1.01 1683 1.39 1887 2.16 2100 3.10 2302 4.14 2488 5.25 2682 6.44 2861 7.68

4500 1612 1670 1.18 1774 1.61 1965 2.39 2163 3.35 2356 4.42 2539 5.57 2715 6.78 2893 8.07 3060 9.40

4800 1720 1767 1.38 1867 1.83 2045 2.65 2229 3.61 2415 4.73 2592 5.91 2758 7.15 2926 8.46 3092 9.84

5100 1827 1865 1.59 1960 2.06 2128 2.94 2299 3.91 2478 5.05 2646 6.27 2811 7.55 2964 8.88 3124 10.3

5400 1935 1964 1.83 2054 2.33 2217 3.27 2377 4.26 2543 5.39 2707 6.65 2865 7.97 3017 9.34

5700 2043 2063 2.10 2149 2.62 2307 3.63 2457 4.63 2608 5.76 2770 7.05 2920 8.41 3071 9.82

6000 2150 2163 2.39 2245 2.93 2398 4.02 2537 5.03 2684 6.19 2835 7.48 2983 8.87 3125 10.3

6300 2258 2263 2.71 2341 3.27 2489 4.45 2623 5.48 2762 6.66 2900 7.93 3046 9.36

Shaded values show where Class I fan selections are more efficient than Class II.

RPM % WOV 1 2 3 4 5 6 7 8 L

900

Performance certified is for installation type B: Free inlet, Ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

L

sound include the effects of duct end correction. The A-weighted sound power ratings shown have been calculated per AMCA Standard 301. The AMCA Certified

Ratings Seal applies to L

1250

1750

2475

3145

A sound power levels for installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the effects of duct end correction. Ratings for outlet

Wo

0.5 1 2 3 4 5 6 7 8

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Inlet Sound Power, L

100 66 71 71 72 66 64 54 47 72

80 63 67 67 66 63 59 51 42 68 80 75 73 67 67 67 61 52 43 71

60 62 63 63 63 61 57 50 41 65 60 75 73 67 65 65 60 52 43 69

50 63 64 63 62 60 57 50 40 65 50 75 72 67 64 65 59 52 43 68

100 68 70 73 74 71 71 63 55 77

80 66 67 71 72 69 67 60 52 74 80 78 74 71 73 73 68 60 51 76

60 67 66 68 68 66 64 57 51 71 60 79 74 71 71 72 66 59 51 75

50 69 68 69 67 65 63 57 51 70 50 78 75 71 70 71 66 59 51 75

100 71 74 78 77 77 76 77 63 83

80 67 70 77 74 73 72 68 61 79 80 86 78 77 79 79 75 70 63 83

60 71 72 74 73 72 70 66 60 77 60 86 81 78 77 77 73 68 62 81

50 74 74 76 74 71 70 65 60 77 50 88 82 79 78 77 72 68 62 81

100 79 79 81 86 86 84 86 77 92

80 80 75 78 86 84 80 77 71 88 80 86 86 84 84 88 83 79 72 91

60 82 79 78 83 82 78 75 70 86 60 89 90 87 83 86 81 77 71 90

50 82 81 80 83 82 78 74 70 86 50 90 91 87 84 86 81 77 72 89

100 81 84 85 91 91 89 92 87 97