Greenheck M Maintenance Manual

®

Document 472786

Model M

®

Utility Distribution System

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

UL Listed to UL 891

General Safety Information

Only qualified personnel should install and service this system. Personnel should have a clear understanding of these

instructions and all applicable local and national building and fire codes.

DANGER

Always disconnect lock and tag power source before

installing or servicing. Failure to disconnect power

source can result in fire, shock or serious injury.

DANGER

Pour écarter les risques d’incendie, de choc électrique

ou de blessure grave, veiller à toujours débrancher,

verrouiller et étiqueter la source de courant avant

l’installation ou l’entretien.

NOTE

Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), and the

latest edition of the National Fire Protection Agency

Standard for Ventilation Control and Fire Protection

of Commercial Cooking Operations (NFPA 96). Follow

the Canadian Electrical Code and ULC-S650 if

installing this product in Canada.

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, injury

or death. Read the installation, operating, and

maintenance instructions thoroughly before installing

or servicing this equipment.

Les poses, réglages, modifications, entretiens et

réparations incorrects peuvent provoquer des dégâts

matériels, des blessures ou la mort. Bien lire les

instructions de pose, d’utilisation et d’entretien avant

l’installation ou l’entretien de ce matériel.

WARNING

AVERTISSEMENT

Utility Distribution System 1

®

Table of Contents

Receiving, Handling and Storage .............. 2

Product Overview .......................... 3

Unit Configuration .......................... 4

Option and Accessory Descriptions ............ 5

Installation

Uncrating ............................... 6

Mounting and Securing .................... 6

Plumbing ................................ 7

Electrical ...............................7-8

Main Incoming Service ..................... 8

Control Power ............................ 8

Fire System Integration ..................... 8

Hose Installation Instructions ................ 9

Start-Up

Testing .................................. 9

Fire Fuel Shut-Off, optional .................. 10

Overcurrent Protection, optional .............. 10

Operation ................................ 11

Troubleshooting ........................... 11

Our Commitment .......................... 12

Receiving

Upon receiving the equipment, check for both obvious

and hidden damage. If damage is found, record all

necessary information on the bill of lading and file a

claim with the final carrier. If any items are missing,

report shortages to your local representative to arrange

for obtaining missing parts. Confirmation of shipment(s)

must be limited to only items on the bill of lading. Any

physical damage to the unit or missing parts found after

acceptance is not the responsibility of the manufacturer.

Handling

Move the unit slowly and carefully using the forklift

pockets on either end. Be sure to completely support

the entire unit length when moving. Do not lay the

crated unit on its side.

Storage

Units are protected against damaged during shipment.

If the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage.

The ideal environment for storage of the UDS and

accessories is indoors, above grade in a clean, dry

atmosphere that is sealed from the elements. Store unit

standing up; do not lay the unit on its side.

Utility Distribution System2

®

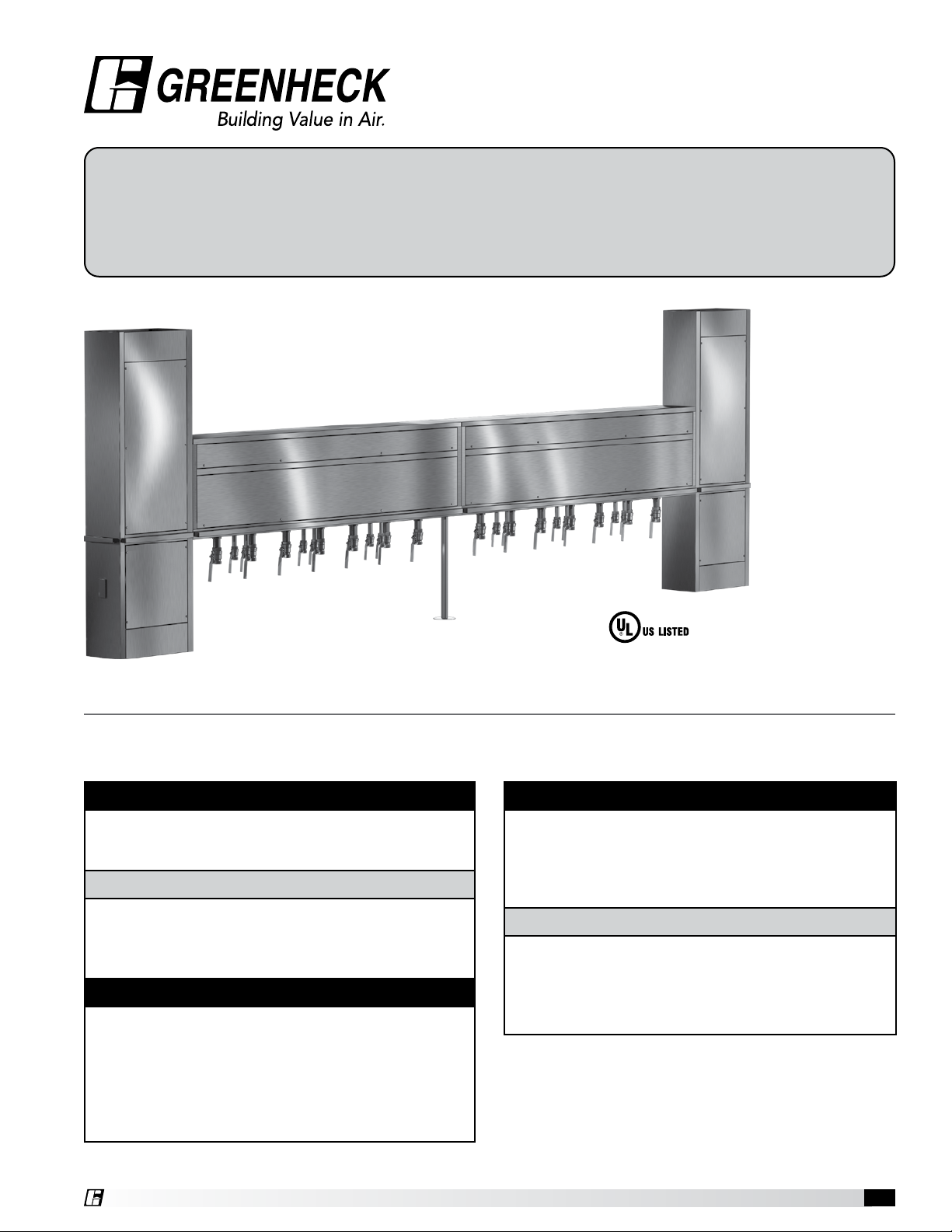

Product Overview

2

Panel Board

Breaker System

4

5

Electrical Option

1

3

6

7

4

NOTE

Utility Distribution System, or UDS, are a highly configurable and customizable product. Some instances in this

manual may make references to features which may or may not be present on your equipment. Please consult

your submittal and electrical drawings which are also provided to determine which portions of this manual apply.

1. Utility Chase – Horizontal component that is

connected between the two (2) vertical risers. This

brings the utilities to the cooking equipment in a

clean convenient way.

2. Utility Riser – Vertical components that house major

utilities, control center, fire fuel shut-off, and field

connections.

3. Pedestal (optional) – Supporting component for the

chase under the field joint(s) at the chase when the

UDS has reached a predetermined length.

4. Access Panels – Doors on the UDS that allow

access for installation or maintenance.

5. Electrical Section of Chase – All electrical (typically

wire bus or bus bar) is fed through this portion of the

utility chase. This portion is intentionally closed off

to the plumbing section of the utility chase. Electrical

sections are accessible through removable panels.

6. Plumbing Section of Chase – All plumbing (typically

includes gas, hot water, and cold water) is fed

through this portion of the utility chase. This portion

is intentionally closed off to the electrical section of

the utility chase. Plumbing sections are accessible

through removable panels.

7. Bumper Strip - Bump out strips mounted about

waist-high on the UDS to prevent cooking equipment

that is not fastened to the floor from hitting and

damaging the UDS.

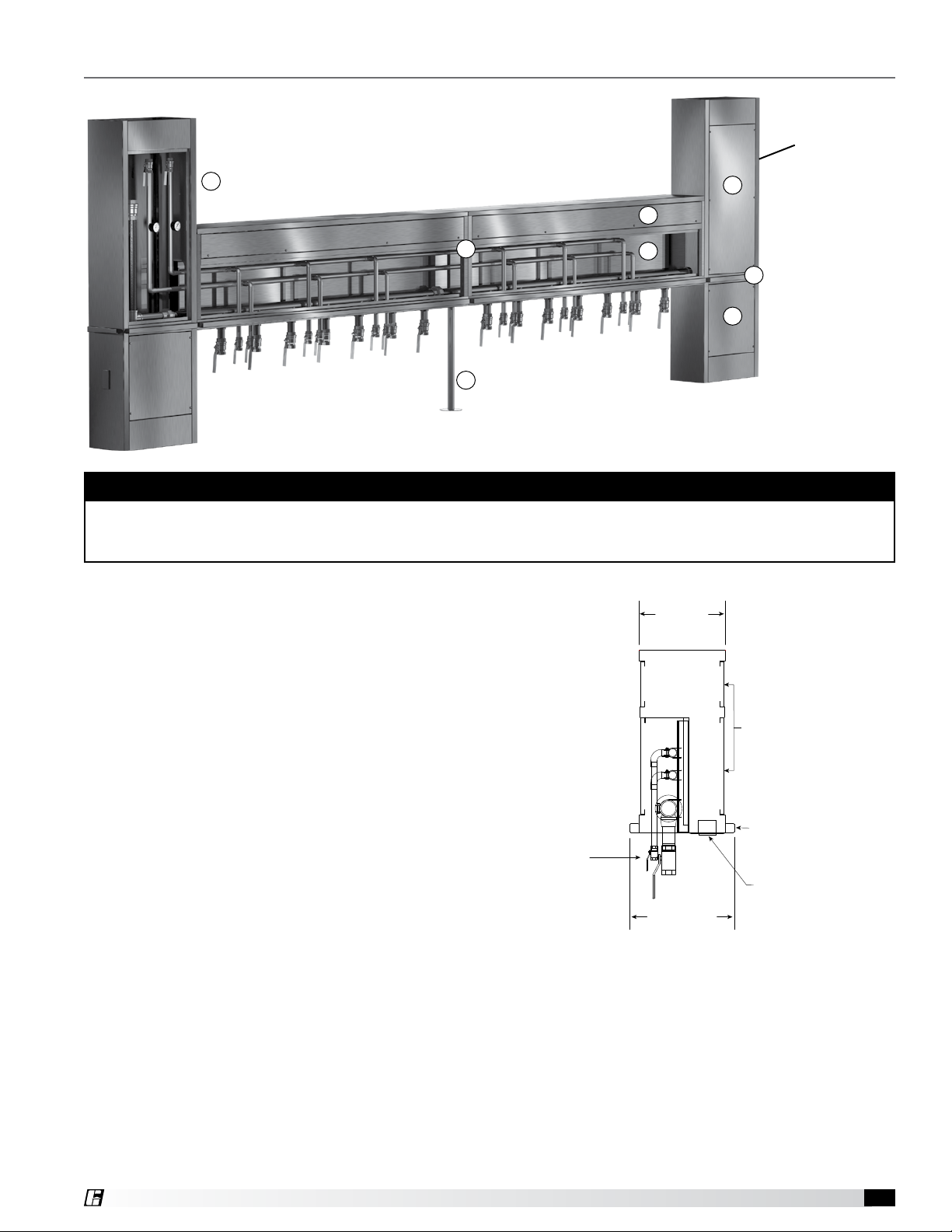

Gas and Water

Plumbing Drops with

Equipment Shutoff

Per Customer Request

Typical Section View Through

Typically

12 inches

16 Gauge Stainless Steel

Removable Panels

(Both Sides on Island UDS)

Full-Length

Bumper Guards

(Both Sides on Island UDS)

Receptacle Plates

Typically

14.6 inches

Utility Distribution System 3

®

Unit Configuration

Utility Distribution System

M W V - GHC - 132

UDS Style

C - Chase

I - Island

O - Overhead

P - Electric Pole

U - Utility Column

W - Wall

Electrical Services

B - Buss Bar

H - Point of Use with Receptacles

N - None

R - Receptacle(s) Only

V - Panelboard with Receptacles

1. Manufacturer

a. Model M, Modular FlexConnect™ Utility

Distribution System Series

2. Style

a. (W) Wall – Mounted up against a wall with

appliances on one side only; no bumper or

electrical outlets on opposite side of utility chase (if

provided with electrical service).

b. (I) Island – Appliances on both sides; bumper and

electrical outlets on both sides of utility chase (if

provided with electrical service).

3. Electrical

a. (V) Panelboard – Electrical service panelboard

in either the right or left most riser. Typically,

this includes a shunt trip or under-voltage main

breaker and individual branch breaker(s) for

each equipment receptacle. Breakers, wiring,

and receptacles are all provided by the factory.

20A convenience outlets are provided on both

left and right riser ends. Equipment receptacles

are fastened in the specified location under the

horizontal chase.

b. (H) Point-of-Use – Incoming electrical service riser

is located on the left or right most riser. Typically,

this includes a shunt trip or under-voltage main

breaker in the riser. Individual branch breakers

for each piece of equipment are located in the

horizontal chase directly inline with the equipment

receptacle. 20A convenience outlets are provided

on both left and right riser ends.

c. (R) Receptacles Only – Unit shall include

equipment receptacles fastened in the specified

location under the horizontal chase. 20A

convenience outlets are provided on both left

and right riser ends. All wiring and/or conduit is

provided by others in the field.

Unit Length

Overall unit length in inches

Piped Services

1 to 4 characters depending upon plumbing services

A - Compressed Air

C - Cold Water

D - Drain and Vent

F - Filtered Water

G - Gas

H - Hot Water

L - Chilled Water

S - Steam/Condensate Return

4. Gas

a. (G) Gas Manifold – Either a single service through

one riser, or a looped service through both risers

is provided. Gas line is fed through the plumbing

section of the utility chase by the factory, with

gas drops every 12 inches. Typically, these are

provided with quarter turn ball valve disconnects if

used for specific appliances.

5. Water

a. (H) Hot Water – Either 3/4 or 1 inch hot water

manifold is fed through the plumbing section of

the utility chase by the factory with drops every

24inches. Typically, these are provided with

quarter turn ball valve disconnects if used for

specific appliances.

b. (C) Cold Water – Either 3/4 or 1 inch cold water

manifold is fed through the plumbing section of

the utility chase by the factory with drops every

24inches. Typically, these are provided with

quarter turn ball valve disconnects if used for

specific appliances.

6. Length

a. Length – Total length of the UDS, including risers

and utility chase by the factory.

Utility Distribution System4

Loading...

Loading...