Page 1

®

®

Assembly Instructions

Part #458066

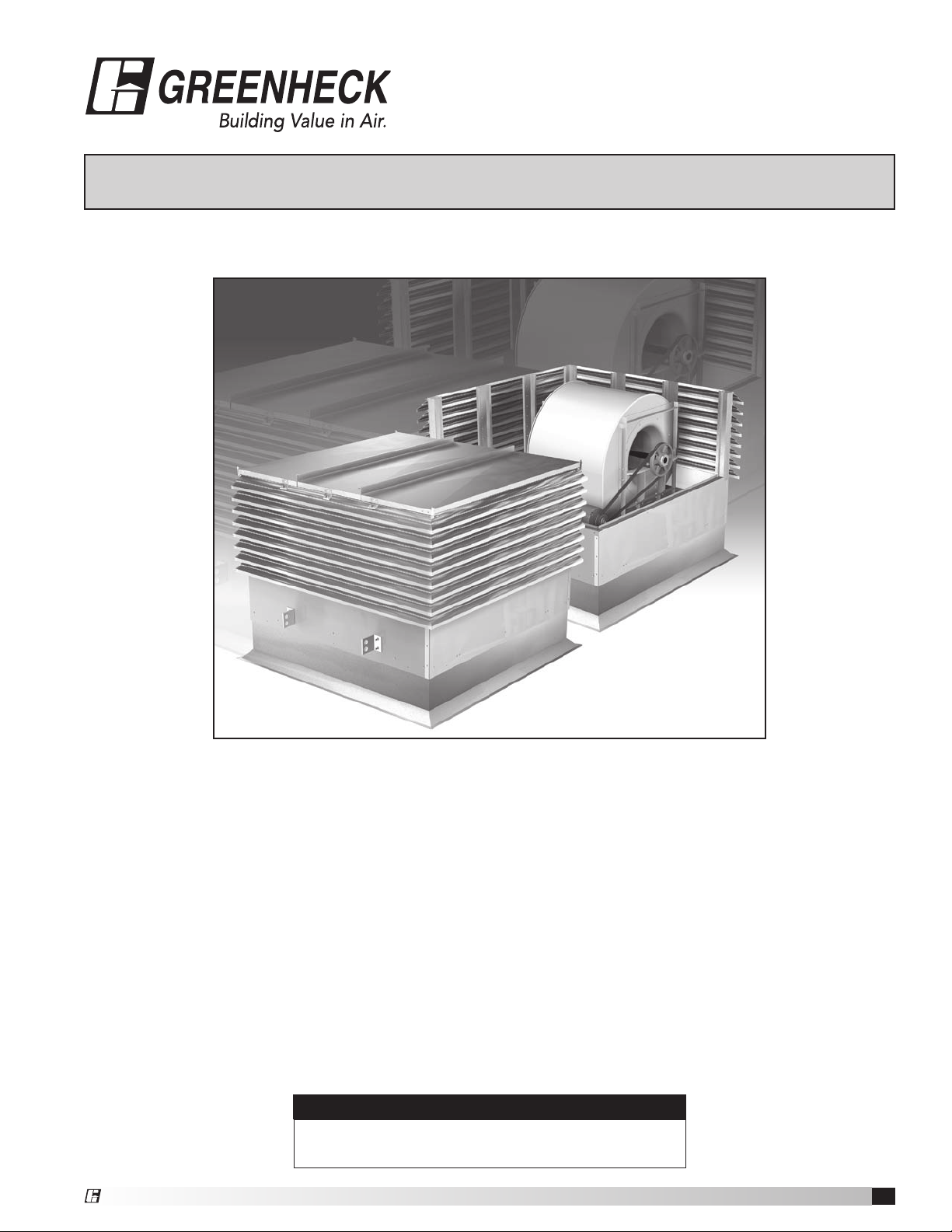

Model LSF Assembly

How to use this manual

Read and save these instructions. This manual is designed to assist with the assembly of Greenheck Model LSF

Louvered Supply Fans. It contains detailed assembly instructions, parts and hardware lists, as well as step-bystep renderings.

Complete descriptions and renderings of all parts and hardware items can be found on pages 2-4. Procedures

described in this manual should be followed in the order they appear.

Receiving and Handling

Upon receiving the equipment, check for both obvious and hidden damage. If damage is found, record all

necessary information on the bill of lading and file a claim with the final carrier. Check to be sure that all parts of

the shipment, including accessories and hardware, are present.

NOTE

Rooftop assembly is recommended. Fan should be

assembled on previously mounted roof curb.

Model LSF Assembly

1

Page 2

®

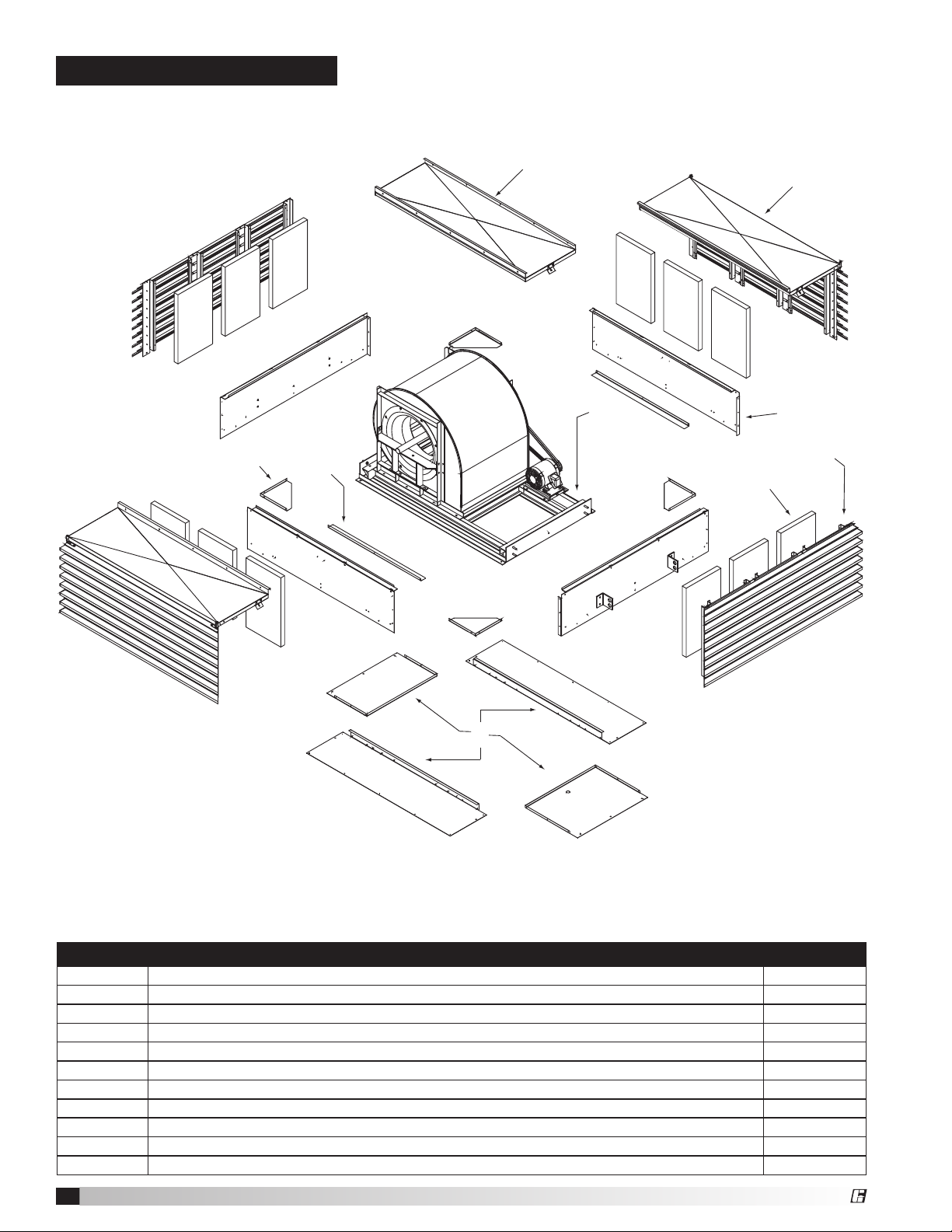

LSF 24, 27 AND 30

6

5

4

1

3

2

7

8

9

PARTS LIST

Item No. Description Quantity

1 Louver Assembly, End 2

2 Louver Assembly, Side 2

3 Base Panel 4

4 Filters See page 12

5 Blower Assembly

6 Curb Adapter Panel (shown upside down) 4

7 Hood Panel, Center 1

8 Reinforcing Angle for Base Panel 2

9 Gusset 4

Hardware Package #821385 See page 4

Model LSF Assembly

2

Page 3

®

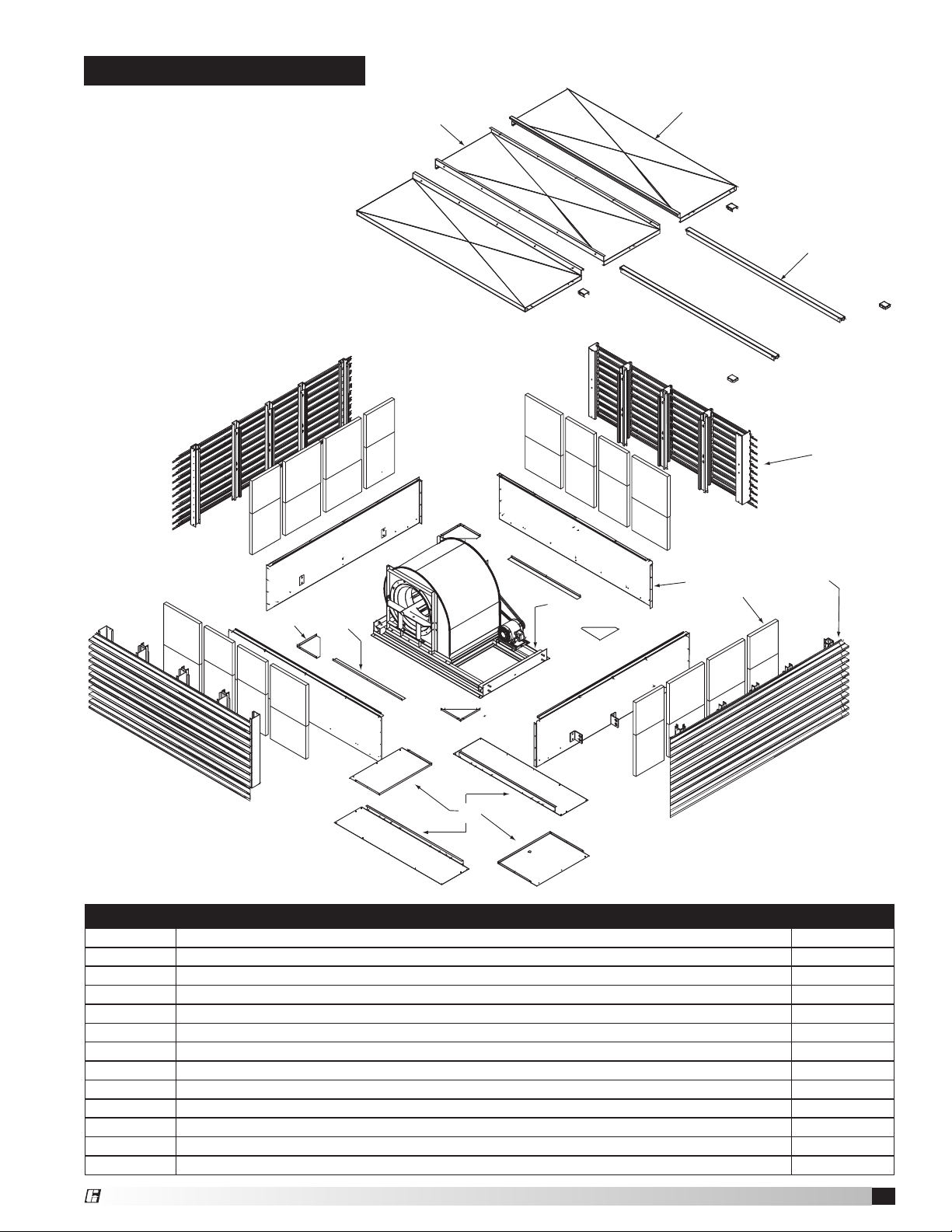

LSF 33 AND 36

6

10

9

5

4

1

3

2

7

8

11

PARTS LIST

Item No. Description Quantity

1 Louver Assembly, End 2

2 Louver Assembly, Side, with Spacer 2

3 Base Panel 4

4 Filters See page 12

5 Blower Assembly

6 Curb Adapter Panel (shown upside down) 4

7 Hood Panel, Center 1

8 Hood Panel, Side 2

9 Reinforcing Angle for Base Panel 2

10 Gusset 4

11 Hood Support Rail 2

Hardware Package #821246 See page 4

Model LSF Assembly

3

Page 4

®

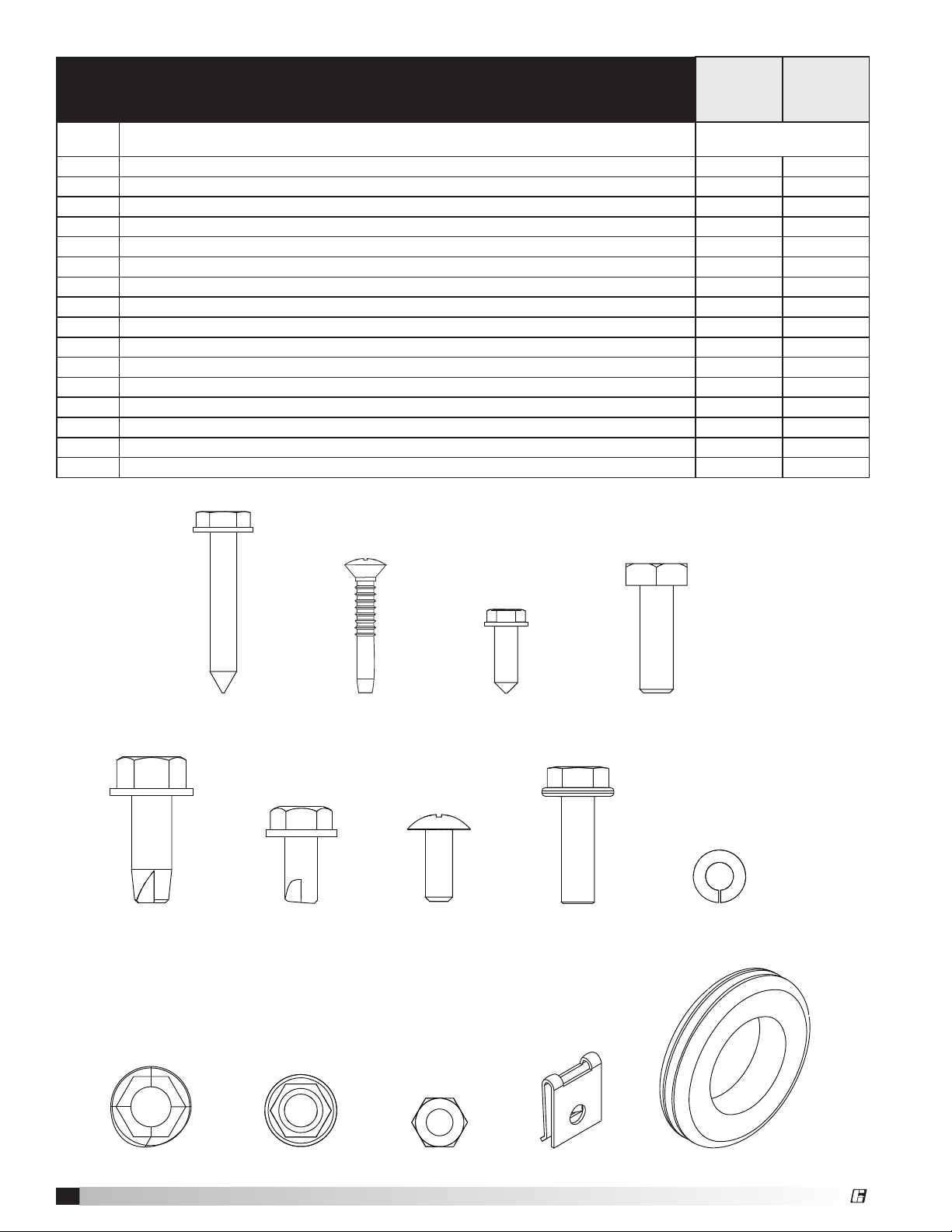

Part

415006 415203 415439 415041

415005 415225 415729 415486 415837

415457 415456 415099 415220 370022

Number

LSF 24 - 30

HARDWARE PACKAGE AND FASTENER DETAILS

Hardware

Package

#821385

Item Description Quantity

LSF 33 - 36

Hardware

Package

#821246

415006 Sheet Metal Screw, Indented Hex Washer, Zinc Plated, #14 x 1-1/2 inch 6 6

415203 Sheet Metal Screw, Phillips Oval Head, Stainless Steel, #10 x 1-1/4 inch 96 96

415439 Sheet Metal Screw, Indented Hex Washer, Stainless Steel, #12 x 5/8 inch 70 70

415041 Thread Cutting Screw, Indented Hex Washer Head, Zinc Plated, 5/16 inch - 18 x 1 inch 21 33

415005 Thread Cutting Screw, Indented Hex Washer Head, Zinc Plated, 3/8 inch - 16 x 1 inch 2 2

415225 Thread Cutting Screw, Indented Hex Washer Head, Zinc Plated, 5/16 inch - 18 x 5/8 inch 0 8

415729 Machine Screw, Phillips Truss Head, Stainless Steel, 1/4 inch - 20 x 5/8 inch 10 0

415486 Serrated Flange Fastener (Whiz Lock Screw), Zinc Plated, 5/16 inch - 18 x 1 inch 8 8

415837 Lock Washer, Stainless Steel, 1/4 inch 10 0

415457 Nut, Serrated, Zinc Plated, 3/8 inch - 16 2 2

415456 Nut, Zinc Plated, 5/16 inch - 18 8 8

415099 Nut, Stainless Steel, 1/4 inch - 20 10 0

415220 Tinnerman Clip, 5/16 inch - 18 21 21

370022 Grommet, Neoprene 1 1

450023 Rod, Retainer Pin (not shown) 4 0

506023 Louver Bracket (not shown) 4 0

Note: Depending on unit size, all hardware may not be used. Drawing is not to scale.

Model LSF Assembly

4

Page 5

®

Step 1

Locate and identify parts as listed on Parts List

and Hardware Package and Fastener Details

List on pages 2 and 3. See exploded view for

assistance in identifying parts.

Step 2

Place duct adapter panels upside down so that

the screws can be inserted into the predrilled

holes in the flanges. Fasten the panels together

as shown using the #12 x 5/8 inch stainless sheet

metal screws.

Step 3

Install the neoprene grommet in wiring hole.

Step 4

Flip over the duct adapter panels and apply 3/4 x

3/4 inch gray adhesive-backed foam tape to top

of duct adapter around the edge of the opening

at the proper location; noting the size of the unit.

(The roll of foam tape will be attached to the

blower assembly).

Sizes 24, 27, 30 – flush with edge, all around

Size 33 – flush with edge on long sides, 3/4 inch

away from edge on short sides

Size 36 – flush with edge on long sides, 1-1/4 inch

away on short sides

Step 5

Mount assembled duct adapter onto preexisting

roof curb. Align the adapter squarely on the curb

and nail through the prepunched mounting holes

(nails not provided).

Step 6

Place and align the blower assembly on the duct

adapter—being sure to place the motor near the

wiring hole in the duct adapter. NOTE: Blower

frame will extend 3/4 inch over each end of the

curb. Make sure the frame is centered on the curb.

Step 7

Using the 1/4 inch x 1-1/2 inch lag bolts, fasten

the blower assembly to the curb aligning the

prepunched holes in the blower assembly and

duct adapter.

Step 8

Locate the two (2) wood shipping blocks between

blower assembly frame and isolation base.

Remove and discard the hardware and the blocks.

Step 9

To begin installation of the base panels, remove

the lifting lugs. Save the lifting lugs and mounting

hardware. They will be reused in Step 10.

Model LSF Assembly

5

Page 6

®

Step 10

Set one (1) end panel in place on the end of the

support frame.

Replace the lifting lugs, reusing the hardware

to fasten the panel in place. Do not tighten the

hardware completely until instructed to do so. Use

a 3/8 inch-16x1 inch thread cutting screw in the

center of the end base panel between the lifting

lugs. Do not tighten completely Repeat Step 10 for

the other end base panel.

Step 11

Install reinforcing angle on the two (2) side base

panels. Use #12 x 5/8 inch stainless sheet metal

screws for each reinforcing angle.

Step 12

Place the side base panel with reinforcing angle

on the duct adapter and fasten at both ends using

#12 x 5/8 inch stainless metal screws along both

vertical edges. Repeat Step 12 for the other side

base panel.

Step 13

Install corner gussets on the surface of the duct

adapter and fasten to the bottom corners of the

base panels, using four (4) #12 x 5/8 inch stainless

sheet metal screws in each gusset.

Step 14

Tighten the two (2) bolts in each lifting lug as well

as the one in the center of the base panel that

were not tightened in Step 10.

Model LSF Assembly

6

Page 7

®

Step 15

STOP

Install Tinnerman clips in the slots preprunched at

the top of the base panels.

Step 16

Set one (1) section of the end louver assemblies

(without a cover) in place on an end base panel

(panels with lifting lugs). Fasten posts on louver

assemblies with 5/16 inch-18x1 inch thread

cutting screws, using the prepunched holes in the

posts and Tinnerman clips already installed in the

base panels. Repeat Step 16 for opposite louver

end assembly.

LSF Sizes 24–30 continue on page 8

LSF Sizes 33–36 continue on page 10

Model LSF Assembly

7

Page 8

®

LSF Sizes 24, 27 and 30

Step 17

Set in place one (1) side louver assembly (with

hood panel). Use 5/16 inch -18 x 1 inch thread

cutting screws to fasten posts to base panels as

in Step 16. Using #12 x 5/8 inch stainless sheet

metal screws, fasten the corner posts of the

adjoining sides together at the top and bottom.

Use four (4) screws per louver assembly. Repeat

Step 17 for opposite side louver assembly.

Step 19

Slide the filters into their racks using the diagram

on page 12 as a guide for proper size, location and

orientation of the filters.

Step 18

Fasten mitered louver corners with #10 x 1-1/4 inch

sheet metal screws.

Model LSF Assembly

8

Page 9

®

LSF Sizes 24, 27 and 30

Fasten

Here

Step 20

Set center hood cover on top of louver

assemblies. Slowly close the side hood panels,

one at a time, adjusting the center section

slightly—if necessary—to attain a proper

alignment of all three hood panels.

Step 21

To secure the center hood, locate the center hood

latch. Mark where the slot meets the top louver.

Drill a 9/64 inch hole and insert one (1) sheet metal

screw through center hood latch and top louver.

Repeat Step 21 for opposite side of center hood.

Step 22

Set in place hasp bracket through hood latch.

Hold hasp bracket in place and swing hood panel

open. Mark hasp hole locations on top louver and

drill 1/4 inch holes at each mark. Insert one (1) 1/4

inch - 20 x 1/2 inch machine screw through the

hasp bracket and top louver. Fasten by attaching

one (1) 1/4 inch lock washer and one (1) 1/4 inch

x 20 hex nut to each screw. Follow the same

procedure for the other end of the hood. Repeat

Step 22 for the opposite side hood.

Step 23

Close side hood panels and insert rod retainer pin

through louver bracket to secure side hood panel.

Join side hoods to center hood along hood seams

using four (4) 5/16 inch - 18 x 1 inch serrated

flange fasteners and four (4) 5/16 inch - 18 nuts on

each flange.

Step 24

Using prepunched mounting holes in base panels,

fasten unit to roof curb nailer (fasteners not

provided).

Completed LSF

Size 24, 27 or 30

Model LSF Assembly

9

Page 10

®

LSF Sizes 33 and 36

Step 17

Set in place one (1) side louver assembly with

spacer. Use 5/16 inch -18 x 1 inch thread cutting

screws to fasten posts to base panels as in Step

16. Using #12 x 5/8 inch sheet metal screws,

fasten louver spacer to corner post of end

assembly at the top and bottom. Use four (4)

screws per louver assembly. Repeat Step 17 for

opposite side louver assembly.

Step 19

Slide the filters into their racks using the diagram

on page 12 as a guide for proper size, location and

orientation of the filters.

Step 18

Fasten mitered louver corners with #10 x 1-1/4 inch

sheet metal screws.

Model LSF Assembly

10

Page 11

®

LSF Sizes 33 and 26

Fasten

Here

Step 20

Set in place hood support rails over center posts,

leaving one (1) post between for spacing. Use 5/16

inch - 18 x 5/8 inch thread cutting screws to fasten

hood support rails to center posts; four (4) screws

per center post.

Step 21

Set center hood cover on top of hood support

rails. Align slots in center hood to holes in hood

support rails.

Step 22

Set side hood cover panels on top of unit, one

on each side of center hood. Use thread cutting

screws to fasten hood panels to corner mount

brackets and hood support rails. Join side hoods

to center hood along hood seams using four (4)

5/16 inch - 18 x 1 inch serrated flange fasteners

and four (4) 5/16 inch - 18 nuts on each flange.

Step 23

Using prepunched mounting holes in base panels,

fasten unit to roof curb nailer (fasteners not

provided).

Model LSF Assembly

11

Page 12

®

LSF Filter Sizes and Quantities

All sides are identical.

Size 24 Size 27 Size 30

16 x 20 16 x 20 16 x 20 16 x 20 16 x 25 16 x 20 16 x 25 16 x 25 16 x 25

16 x 20 16 x 20 16 x 20 16 x 20 16 x 25 16 x 20 20 x 25 20 x 25 20 x 25

Size 33 Size 36

20 x 20 20 x 20 20 x 20 20 x 20 20 x 20 20 x 25 20 x 25 20 x 20

20 x 20 20 x 20 20 x 20 20 x 20 25 x 20 25 x 25 25 x 25 25 x 20

Unit Size

Filter

Size

16 x 20

20 x 20

20 x 25

16 x 25

25 x 25

24 27 30 33 36

24 16

32 8

12 16

8 12

8

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from

the purchase date. Any units or parts which prove defective during the warranty period will be replaced at our option

when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of

one year. Should motors furnished by Greenheck prove defective during this period, they should be returned to the

nearest authorized motor service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Greenheck Catalog LSF provides additional information

describing the equipment, fan performance, available

accessories, and specification data.

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

458066 • LSF Assembly, Rev. 1, August 1999 Copyright 2008 © Greenheck Fan Corporation

12

AMCA Publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans, provides

additional safety information. This publication can be

obtained from AMCA International, Inc. at: www.amca.org.

Loading...

Loading...