Page 1

Indoor Air Handling Units

IAH Series

MSCF-FC • MSCF-BI • LFC-FC • VFC-FC • VFCD-FC

July

2008

Page 2

Indoor Air

Handling Units

®

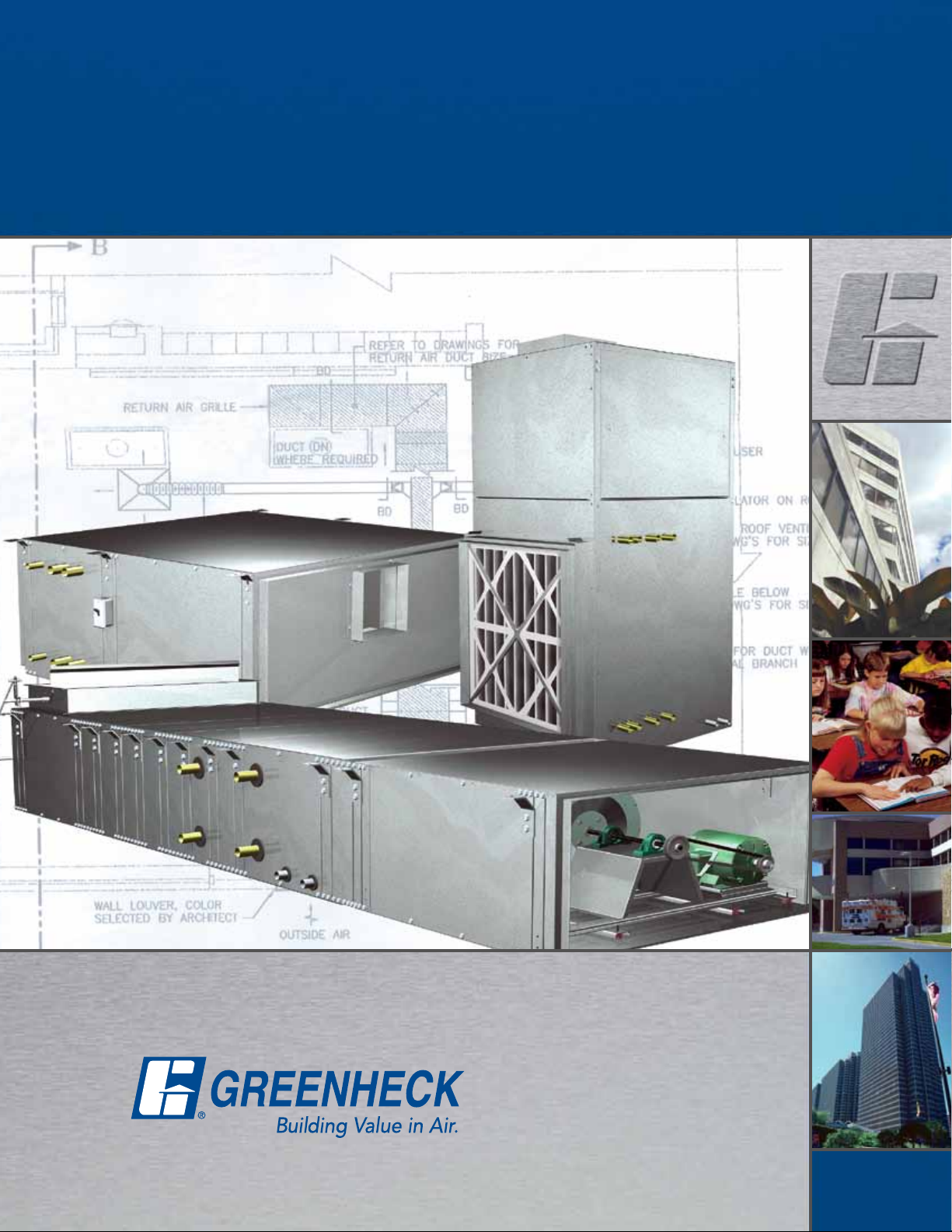

Greenheck’s Indoor Air Handling Series, models MSCF, LFC and VFC, provide air conditioning and/

or heating for buildings and specific spaces. The series was designed with low-profile construction to

fit within tight spaces in applications such as schools, office buildings, apartments, medical facilities

and many other commercial applications. Each model has a variety of sizes and a wide performance

range with quiet, trouble-free operation.

Modular Indoor Air Handler

Model MSCF-FC

Model MSCF-BI

Modular construction allows the

design engineer to configure a unit to

meet their exact requirements. The

modular construction also makes the

MSCF ideal for retrofit applications.

(See pages 5 thru 9 for more

information.)

READ AND SAVE THESE INSTRUCTIONS

®

Installation, Operation and Maintenance Manual

All units are shipped on a skid or packaged to minimize damage

during shipment. The transporting carrier has the responsibility

for delivering all items in their original condition as received from

Greenheck. The individual receiving the equipment is responsible

for inspecting the unit for obvious or hidden damage, recording

any damage on the bill of lading before acceptance and filing a

claim (if required) with the final carrier. Some accessory items

are stored inside the unit during shipping. Care must be taken

during installation to prevent damage to units.

Disconnect and secure all electrical power to the “OFF” position prior to inspection or servicing. Failure

to comply with this safety precaution could result in serious injury or death.

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury

or death. Read the installation, operating, and maintenance instructions thoroughly before installing or

servicing this equipment.

Table of Contents

**WARNING**

Unit Layout & Table of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Lifting & Mounting Instructions

Model Dimensions, Weight & Filter Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hot Water & Steam Coil Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chilled Water & DX Coil Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Airflow Start-up

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

Speed Controls

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Airflow Troubleshooting

Hot Water, Chilled Water & DX Coil Start-Up Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Steam Coil Start-Up Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fan Maintenance Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Coil Maintenance Instructions

Maintenance Documentation & Warranty

Horizontal Fan Coil

Model LFC-FC

A horizontal fan coil unit is ideal for

price sensitive applications. The LFC,

all-in-one construction, results in a

shorter unit which is ideal for space

constrained applications. (See pages

10 and 11 for more information.)

READ AND SAVE THESE INSTRUCTIONS

®

Installation, Operation and Maintenance Manual

MSCF - FC

Disconnect and secure all electrical power to the “OFF” position prior to inspection or servicing. Failure to

comply with this safety precaution could result in serious injury or death.

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or

death. Read the installation, operating, and maintenance instructions thoroughly before installing or

servicing this equipment.

All factory provided lifting lugs should be used when lifting any unit. Failure to comply with this safety

precaution could result in property damage, serious injury or death.

Report any damaged equipment to the shipper immediately!

All units are shipped on a skid or packaged to minimize damage during shipment. The transporting carrier has

the responsibility for delivering all items in their original condition as received from Greenheck. The individual

receiving the equipment is responsible for inspecting the unit for obvious or hidden damage, recording any

damage on the bill of lading before acceptance and filing a claim (if required) with the final carrier. Some

accessory items are stored inside the unit during shipping. Care must be taken during installation to prevent

damage to units.

Model VFCD

Vertical Fan Coil

Report any damaged equipment to the

shipper immediately!

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PN 468361

Vertical Fan Coil

Model VFC-FC

Model VFCD-FC

A vertical fan coil unit, all-inone construction, is ideal for

providing cooling and/or heating

for applications requiring a small

footprint. (See pages 12 thru 15 for

more information.)

Part #462888

MODEL MSCF

Modular Small Cabinet Fan

MSCF - BI

**WARNING**

**IMPORTANT**

Enjoy Greenheck’s extraordinary service, before, during and after the sale.

Greenheck offers added value to our wide selection of top performing, energy-efficient

products by providing several unique Greenheck service programs.

• Our Quick Delivery Program ensures shipment of our in-stock products within 24 hours of

placing your order. Our Quick Build made-to-order products can be produced in 1-3-5-10- or

15-day production cycles, depending upon their complexity.

• Greenheck’s free Computer Aided Product Selection program (CAPS), rated by many as the

best in the industry, helps you conveniently and efficiently select the right products for the

challenge at hand.

• Greenheck has been Green for a long time! Our energy-saving products and ongoing

corporate commitment to sustainability can help you qualify for LEED credits.

• Our 3D service allows you to download, at no charge, easy-to-use AutoDesk™ Revit™ 3D

drawings for many of our ventilation products.

Find out more about these special Greenheck services at greenheck.com

2

Page 3

Standard Features

and Benefits

®

Greenheck’s Indoor Air Handling products have been designed with superior quality and come standard with

premium features that make it ideal for any installation.

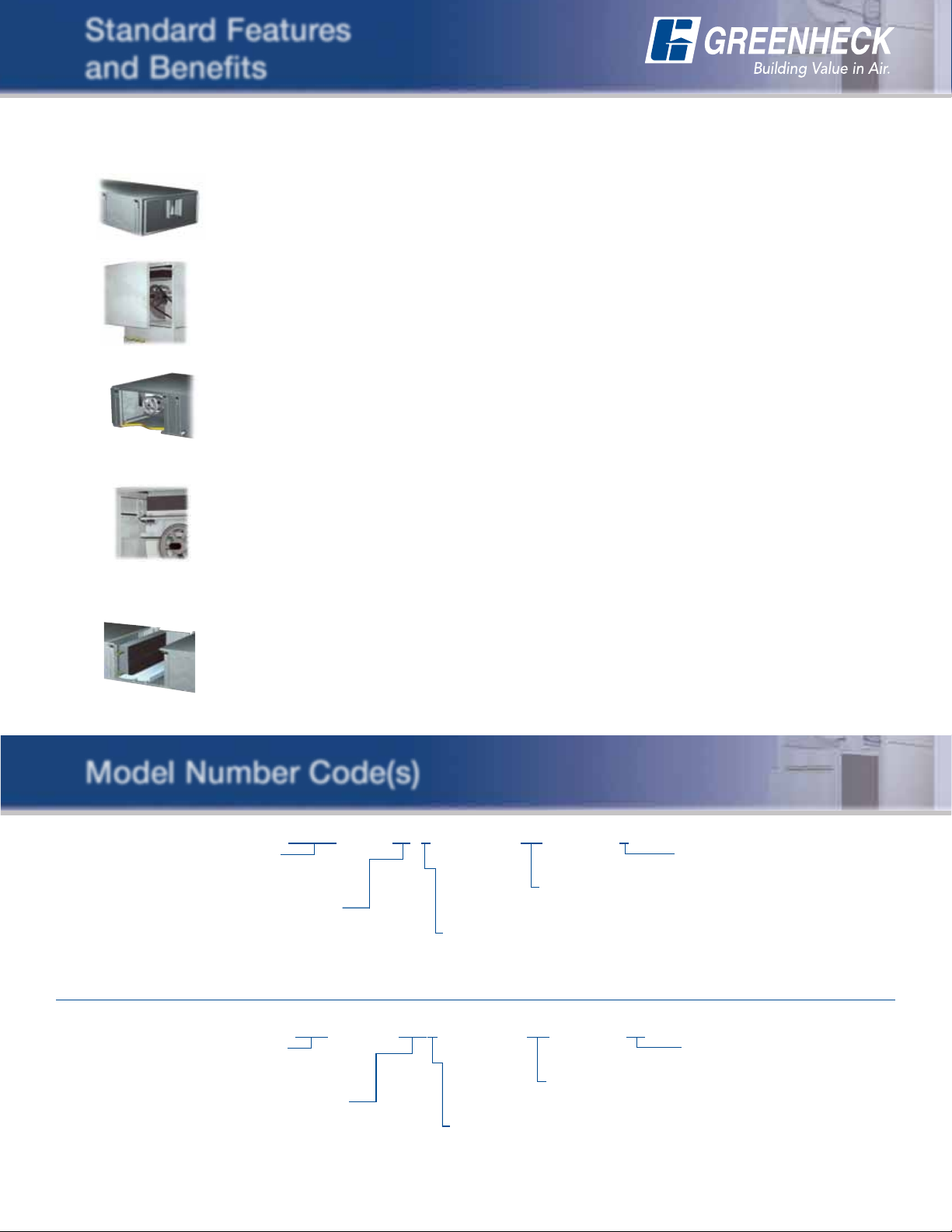

Low-Profile — Every model has been designed as a space saving alternative to other

products on the market. The height of each unit will be 4 to 8 inches less than any competitor

model.

Side Access Panels — Units are constructed with easily removable access panels. Panels are

formed and positioned on both sides of every module or unit to provide extra rigidity and help

maintain cabinet pressure.

One-Inch Double-Wall — Double-wall construction on all units provides excellent indoor air

quality as well as improved radiated sound characteristics over traditional single wall and

exposed insulation models.

Internal Isolation — Internal neoprene isolation and flexible blower to housing connection is

standard on every unit. This isolation improves longevity of the unit and reduces the potential

of noise and vibration generated from fan vibration that could be transmitted to the attaching

ductwork. Internal spring isolation is also available on all VFC sizes and on MSCF and LFC

sizes 20 thru 85.

Drain Pan — The double-wall constructed insulated stainless steel drain pan utilizes a double

pitch slope directing condensation to a main or auxiliary drain connection. The pan improves

indoor air quality by preventing the growth of mold and bacteria. The drain pan removes

easily for coil cleaning.

Model Number Code(s)

MSCF - 15 L - FC - 5

Model

Modular Small Cabinet Fan

Low-Profile Fan Coil

Nominal Face Area

15 - 1.5 sq. ft. 45 - 4.5 sq. ft.

20 - 2.0 sq. ft. 50 - 5.0 sq. ft.

25 - 2.5 sq. ft. 65 - 6.5 sq. ft.

30 - 3.0 sq. ft. 85 - 8.5 sq. ft.

Pressure Rating

L - Pressure up to 3.3 in. wg

H - Pressure up to 4.5 in. wg (MSCF only)

Motor HP

4 = 1/4 7 = 3/4 20 = 2

Wheel Type

FC - Forward Curved

BI - Backward Inclined (MSCF only)

3 = 1/3 10 = 1 30 = 3

5 = 1/2 15 = 1½

VFC - 600 L - FC - 15

Model

Vertical Fan Coil Direct Drive

Vertical Fan Coil

Nominal CFM

600 2000

800 2400

1300 3000

1600

Wheel Type

FC - Forward Curved

Pressure Rating

L - Pressure up to 3.3 in. wg

Motor HP

4 = 1/4 7 = 3/4 20 = 2

3 = 1/3 10 = 1 30 = 3

5 = 1/2 15 = 1½

3

Page 4

More Options

and Accessories

®

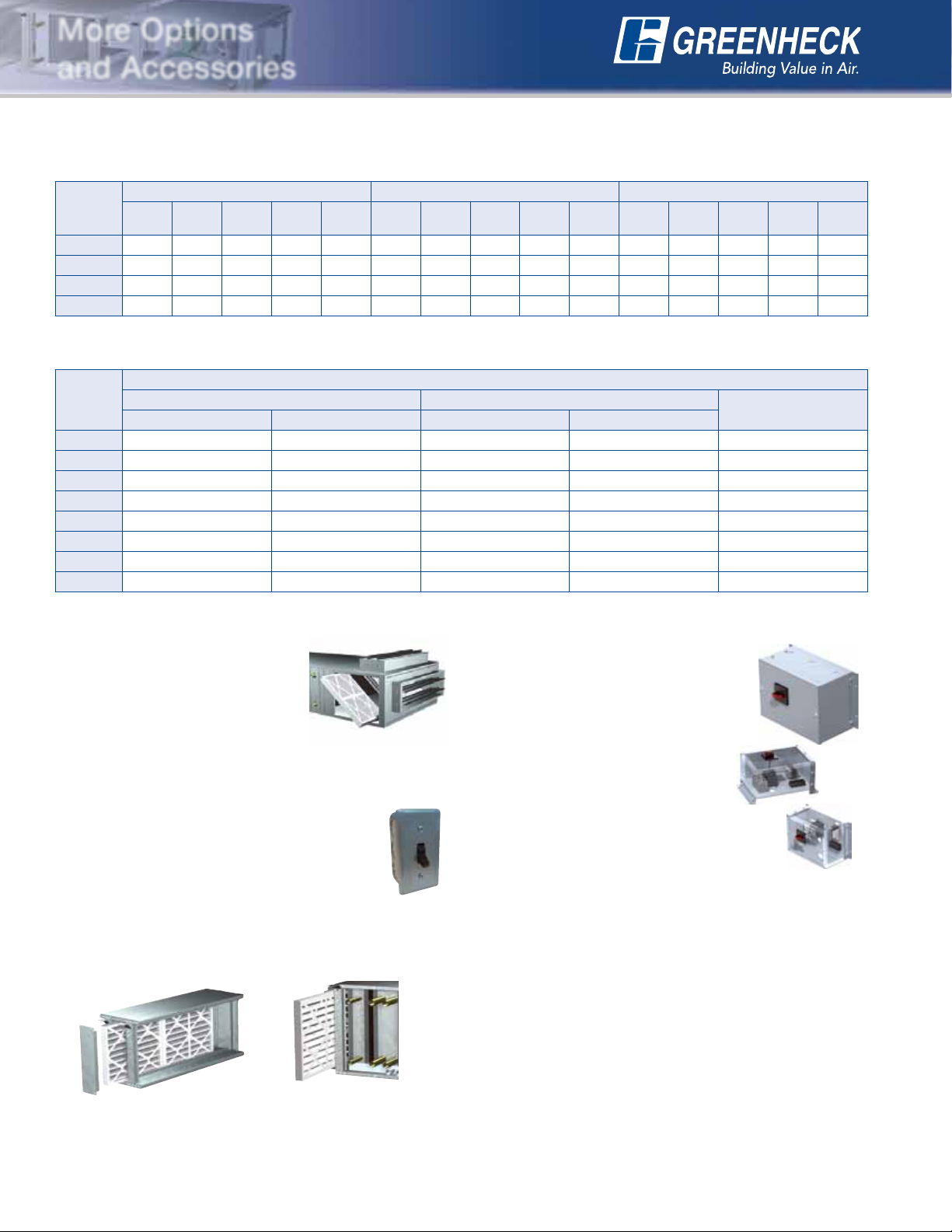

Heating and Cooling Coils — Heating and reheating selections include hot water, steam, or electric. Cooling

selections include chilled water or direct expansion. All cooling coils are supplied with a standard insulated doublewall stainless steel drain pan.

MSCF-FC/BI LFC VFC, VFCD

Coils

HW x x x x x x x x x

Steam x x x x x x

CW x x x x x x x x x

DX x x x x x x x x x

Maximum kW Available in Electrical Heat

Unit

Size

15 13 14 14 14 14

20 13 19 19 19 19

25 13 40 26.5 40 40

30 13 47.5 26.5 56 56

45 13 47.5 26.5 65 65

50 13 47.5 26.5 65 65

65 13 47.5 26.5 65 65

85 13 47.5 26.5 65 65

1

Row2 Row4 Row6 Row8 Row1 Row2 Row4 Row6 Row8 Row1 Row2 Row4 Row6 Row8 Row

Model MSCF-FC/BI

1 Stage 2 Stage

1 Phase 3 Phase 1 Phase 3 Phase

SCR

Mixing Box — The mixing box

module can be configured using

any of the three inlet connections

(top, bottom and inline or

inline, right and left) and three

damper styles (“V” blades, low

leakage, and airfoil low leakage).

MSCF-FC/BI, LFC-FC

The mixing box can also be

configured with a filter to reduce overall unit length.

Disconnect Switch — An optional NEMA-1

disconnect switch is available. The J-box is

mounted and wired at the factory. The switch

is installed in the field.

Filters — Vertical or sloped filters are available

depending on model. Filter efficiency selections include:

30% MERV 8, 65% MERV 11, 95% MERV 15.

MSCF-FC/BI LFC, VFC, VFCD

Control Center — This control center

is equipped with a 24-volt starter,

transformer, and terminal strip all

mounted in a NEMA-1 enclosure.

Standard features include an

interlocking door disconnect switch

and an adjustable electronic thermal

overload. This reliable control center

reduces installation time, ensures

safety and decreases demand on

panel space. The control center is

UL Listed for Safety for Industrial Control

Panels, UL 508A.

Dimensions are 14 x 8.5 x 6.5 inches

(355.6 x 215.9 x 165.1 mm) (L x W x H)

Fan Types —

• Forward-Curved — Double-width, double-inlet

forward-curved blowers are designed to efficiently

move high volumes of air with low sound levels.

Available on all models and sizes.

• Backward-Inclined — A backward-inclined plenum

fan is available on the MSCF. Backward-inclined

fans are ideal for high-pressure applications across

the entire CFM range. Available on MSCF sizes 25

thru 85.

4

Page 5

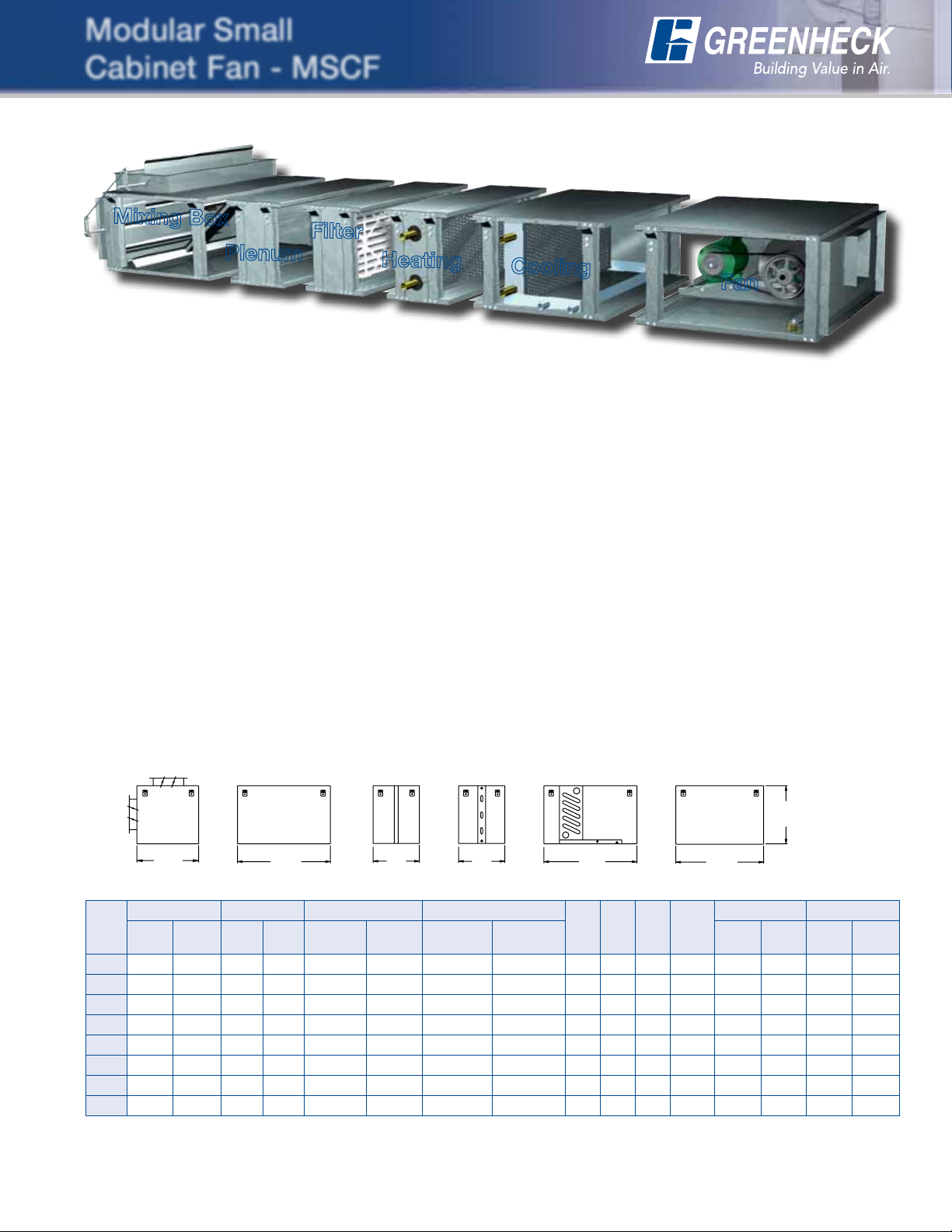

Modular Small

Cabinet Fan - MSCF

®

Mixing Box

Filter

Plenum

Heating

Standard Construction

Model MSCF-FC (Modular Small Cabinet Fan,

Forward Curved) and Model MSCF-BI (Modular

Small Cabinet Fan, Backward-Inclined) are lowprofile, modular constructed small cabinet fans,

essentially small air handling units.

• Performance range 300 - 4,700 cfm at 4.5 in. wg

• 1-inch double-wall construction

• Low profile

• Internal isolation (neoprene or spring)

• Internal flex connection

• Side access panels (standard on

all modules)

• Stainless steel drain pan (insulated

double-wall)

Cooling

Fan

Available Modules

• Pre and/or post filters (vertical and sloped)

• Mixing box

• Mixing box with filter

• Pre and/or post access plenums

(12 or 24 inch lengths)

• Heating coils (hot water, steam or electric)

• Cooling coils (chilled water or direct expansion)

• Re-heating coils (hot water or steam)

• Vertical inlet filter

• Inlet damper

Dimensional Data

G

A

Unit

Size

15 11 24 12¾ 24 12¾ 24 12¾ 15½ 24 25 11 38 9 36 4 6¾

20 14 24 12¾ 24 12¾ 24 12¾ 15½ 24 25 14 38 12 36 6½ 6¾

25 16 27 12¾ 24 12¾ 27 12¾ 15½ 24 29 16 38 14 36 8 8

30 18 31 12¾ 24 12¾ 31 12¾ 15½ 24 32 18 38 16½ 36 9 9

45 18 32 12¾ 24 12¾ 32 12¾ 15½ 24 32 18 50 16½ 48 9 10

50 21 32 12¾ 24 12¾ 32 12¾ 15½ 24 38 21 50 19 48 10 10¼

65 26 38 12¾ 24 12¾ 38 12¾ 15½ 24 42 26 50 24 48 12 12¾

85 26 38 12¾ 24 12¾ 38 12¾ 15½ 24 42 26 62 24 60 12 15

All dimensions are in inches. For complete dimensional information, see CAPS submittal drawings.

Also available as the first module only, is a vertical inlet filter that will add 2 or 4 inches in length to the unit.

A B C D

No

With

Filter

Filter

12 in. 24 in.

B

Per/Post

Vertical

C

Pre/Post

Sloped

Hot Water

1 & 2 Row

D

4 Row HW

and Steam

E

E F G

F

Unit

Width

Inlet Outlet

Height Width Height Width

5

Page 6

MSCF

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

ur

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

is

s

y

s

t

e

m

c

u

r

v

e

Performance

MSCF-L-FC

MSCF-20L-FC MSCF-25L-FC

®

MSCF-15L-FC

MSCF-30L-FC MSCF-45L-FC

6

Page 7

MSCF

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

Performance

®

MSCF-50L-FC

MSCF-65L-FC

t

o

t

t

c

e

l

e

s

t

o

n

o

D

MSCF-H-FC

MSCF-25H-FC

e

rv

u

c

m

e

t

s

y

s

s

i

h

t

o

f

t

f

e

l

e

h

o

n

o

D

e

l

e

h

t

o

t

t

c

e

l

e

s

t

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

o

f

t

f

MSCF-85L-FC MSCF-30H-FC

e

v

r

u

c

m

e

t

t

c

e

l

e

s

t

o

n

o

D

s

y

s

s

i

h

t

o

f

t

f

e

l

e

h

t

o

t

7

Page 8

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

hi

s

s

y

s

t

e

m

c

u

r

v

e

MSCF

Performance

®

MSCF-45H-FC

MSCF-50H-FC

MSCF-65H-FC MSCF-85H-FC

MSCF-BI

8

MSCF-25-BI

Page 9

D

o

n

o

t

s

e

l

e

c

t

to

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

is

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

ur

v

e

MSCF

Performance

®

MSCF-45-BIMSCF-30-BI

MSCF-50-BI

MSCF-85-BI

MSCF-65-BI

What's This…

Each MSCF modular section maintains

its own access panel providing excellent

accessibility to all components. All panels

have formed edges, which provide additional

rigidity and enables the MSCF to maintain

cabinet pressure.

9

Page 10

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

Low-Profile

Fan Coil - LFC

Standard Construction

Model LFC (Low-Profile Fan Coil) is a low-profile unit available in eight sizes.

Specially designed for a low cost method of air conditioning and/or heating

featuring a forward-curved wheel and an option of up to 8 rows of heating

and cooling coils.

• Performance range 300 4,700 cfm at 3.5 in. wg

• 1-inch double-wall

construction

• Low-profile

• Internal isolation (neoprene

or spring)

®

• Internal flex connection

• Side access panels

(standard on all models)

• Pre-filter (vertical)

• Heating coils (hot water or

steam)

• Cooling coils (chilled water

or direct expansion)

• Stainless steel drain pan

(insulated double wall)

• Mixing box with filter

B

Unit

Width

A

Inlet Outlet

Dimensional Data

Unit

Size

No Filter With 2 in. Filter With 4 in. Filter With Mixing Box Height Width Height Width

15 40 42 44 22½ 8 11 38 9 36 4 6¾

20 40 42 44 22½ 11 14 38 12 36 6½ 6¾

25 40 42 44 25 13 16 38 14 36 8 8

30 45 47 49 29 15½ 18 38 16½ 36 9 9

45 45 47 49 31 14 18 50 16½ 48 9 10

50 48 50 52 31 16¾ 21 50 19 48 10 10¼

65 52 54 56 37 21¾ 26 50 24 48 12 12¾

85 52 54 56 37 21¾ 26 62 24 60 12 15

All dimensions are in inches. For complete dimensional information, see CAPS submittal drawings.

A

B C

C

Performance

LFC-15L-FC LFC-20L-FC

10

Page 11

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

se

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

LFC

Performance

®

LFC-30L-FCLFC-25L-FC

LFC-50L-FCLFC-45L-FC

LFC-65L-FC LFC-85L-FC

11

Page 12

Belt Drive

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

ve

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

Vertical Fan Coil - VFC

®

Standard Construction

Model VFC (Vertical Fan Coil) is a vertical, low cost, forward-curved fan coil unit available in seven sizes. Up to

8 rows of heating and cooling coils for sizes 600-800 and up to 10 rows for sizes 1300-3000 are available.

• Performance range 300 4,000cfm at 3.5 in. wg

• 1-inch double-wall construction

• Internal isolation (neoprene or

spring)

• Internal flex connection

• Side access panels (standard on

all models)

• Hinged access to blower

Dimensional Data

Unit

Size

600 40 24 24 18 22 6¾ 4

800 40 24 24 18 22 6¾ 6½

1300 44 24 28 18 22 8 8

1600 44 30 28 22 22 9 9

2000 52 34 28 29 23 10 9

2400 52 34 28 29 23 10¼ 10

3000 52 50 32 45 22 12¾ 12

All dimensions are in inches. For complete dimensional information, see CAPS submittal drawings.

A B C

Inlet Outlet

D E F G

• Pre-filter (vertical)

• Heating coils (hot water or

steam)

• Cooling coils (chilled water or

direct expansion)

• Stainless steel drain pan

(insulated double wall)

Outlet

Vetrtical Air Flow

Option

G

F

G

Outlet

Horizontal Opposed

Air Flow Option

Inlet

Air Flow

F

Projection

2 or 4 in.

D

B

Filter

E

A

C

Performance

VFC-600L-FC VFC-800L-FC

12

Page 13

VFC

D

o

n

o

t

s

e

l

e

c

t

to

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

f

o

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

Performance

®

VFC-1600L-FCVFC-1300L-FC

VFC-2000L-FC

VFC-3000L-FC

VFC-2400L-FC

What's This…

Belt drive fans offer the ability to adjust

fan speed for system balancing if

necessary. They also offer more flexibility

in speed and motor selections than direct

drive fans.

13

Page 14

Direct Drive

Vertical Fan Coil - VFCD

®

Standard Construction

Model VFCD (Vertical Fan Coil - Direct Drive) is a vertical, low cost, forward-curved fan coil unit available in

seven sizes. Up to 8 rows of heating and cooling coils for sizes 600-800 and up to 10 rows for sizes 1300-3000

are available. The motor and scroll assembly can be slid out and easily removed for accessibility.

• Performance range 300 4,000cfm at 2.0 in. wg

• 1-inch double-wall construction

• Side access panels (standard on

all models)

• Pre-filter (vertical)

• Hinged access to blower

Dimensional Data

Unit

Size

600 40 24 24 18 22 5½ 5½

800 40 24 24 18 22 5½ 7¼

1300 44 24 28 18 22 5

1600 44 30 28 22 22 5

2000 52 34 28 29 23 5

2400 52 34 28 29 23 5

3000 52 50 32 45 22 10

All dimensions are in inches. For complete dimensional information, see CAPS submittal drawings.

A B C

Inlet Outlet

D E F G

5

/

8

5

/

8

5

/

8

5

/

8

3

/

8

327/

18

18

26

26

8

Performance

• Heating coils (hot water or

steam)

• Cooling coils (chilled water or

direct expansion)

• Dual pitched stainless steel

drain pan (insulated double wall)

Outlet

Vetrtical Air Flow

Option

Inlet

Air Flow

Projection

2 or 4 in.

D

B

G

Filter

E

F

C

A

14

VFCD-600L-FC VFCD-800L-FC

Page 15

VFCD

Performance

®

VFCD-1600L-FCVFCD-1300L-FC

VFCD-2000L-FC

VFCD-3000L-FC

VFCD-2400L-FC

What's This…

An optional 10 Amp solid state speed control

is available on VFCD sizes 600-FC thru 2400-

FC. Model 10WSSC speed control will ship

with the unit, mounted

in the factory mounted

J-Box.

15

Page 16

Product Characteristic Comparison

Model MSCF LFC VFC/VFCD

Drive

Belt Belt Belt, Direct

®

Fan Type

Typical Application

Cabinet Design

Cabinet Material

Normal SP Range

Filters

Insulation Density

Construction

Ducted/Unducted

Nominal cfm Range

Heating/Cooling

Mounting Brackets

Disconnect Switch

Pre/Post Plenums

Mixing Box

FC, BI FC FC

Space Constrained Space Constrained Small Footprint

Horizontal Horizontal Vertical

Galvanized

18 ga

0 - 4.5 in. wg 0 - 3.5 in. wg 0 - 3.3 in. wg

30%, 65%, 95% 30%, 65% 30%, 65%

1.5 lb., 3 lb. 1.5 lb., 3 lb. 1.5 lb., 3 lb.

Double Wall Double Wall Double Wall

Ducted Ducted Ducted

800 - 4,700 800 - 4,700 600 - 4,000

Either, Both Either, Both Either, Both

Hanging, Base Hanging, Base 6 in. Extended Base

NEMA-1

Control Center

12, 24 inch N/A N/A

Yes Yes No

Galvanized

18 ga

NEMA-1

Control Center

Galvanized

18 ga

NEMA-1

Control Center

Building Value in Air

Greenheck delivers value

to mechanical engineers by

helping them solve virtually

any air quality challenges

their clients face with a

comprehensive selection of

top quality, innovative air-

related equipment. We offer

extra value to contractors

by providing easy-to-install,

competitively priced, reliable

products that arrive on time.

And building owners and

occupants value the energy

efficiency, low maintenance

and quiet dependable operation

they experience long after the

construction project ends.

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period

of one year from the shipment date. Any units or parts which prove defective during the warranty

period will be replaced at our option when returned to our factory, transportation prepaid. Motors are

warranted by the motor manufacturer for a period of one year. Should motors furnished by Greenheck

prove defective during this period, they should be returned to the nearest authorized motor service

station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

Prepared to Support

Green Building Efforts

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Copyright © 2008 Greenheck Fan Corp.

00.TAP.1034 R3 7-2008 SN

Loading...

Loading...