Greenheck LFC Installation Manual

Document 464496

Model LFC

®

®

Low-Profile Fan Coil

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with instructions could result in personal injury and/or property damage!

General Safety Information

Only qualified personnel should install this unit.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if high winds

or seismic activity are present. If more information

is needed, contact a licensed professional engineer

before moving forward.

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC), the

National Fire Protection Agency (NFPA), where

applicable. Follow the Canadian Electric Code

(CEC) in Canada.

2. The rotation of the wheel is critical. It must be

free to rotate without striking or rubbing any

stationary objects.

3. Motor must be securely and adequately

grounded.

4. Do not spin fan wheel faster than the maximum

cataloged fan rpm. Adjustments to fan speed

significantly affects motor load. If the fan RPM is

changed, the motor current should be checked

to make sure it is not exceeding the motor

nameplate amps.

5. Do not allow the power cable to kink or come

in contact with oil, grease, hot surfaces,

or chemicals. Replace cord immediately if

damaged.

6. Verify that the power source is compatible with

the equipment.

7. Never open blower access doors while the fan is

running.

DANGER

Always disconnect power before working on or

near a unit. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

CAUTION

When servicing the unit, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

®

Low-Profile Fan Coil

1

Receiving

Upon receiving the product, check to ensure all

items are accounted for by referencing the delivery

receipt or packing list. Inspect each crate or carton

for shipping damage before accepting delivery. Alert

the carrier of any damage detected. The customer will

make a notation of damage (or shortage of items) on

the delivery receipt and all copies of the bill of lading

which is countersigned by the delivering carrier. If

damaged, immediately contact your manufacturer’s

representative. Any physical damage to the unit after

acceptance is not the responsibility of manufacturer.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited to

only items on the bill of lading.

Handling

Units are to be rigged and moved by the lifting

brackets provided or by the skid when a forklift is

used. Location of brackets varies by model and size.

Handle in such a manner as to keep from scratching

or chipping the coating. Damaged finish may reduce

ability of unit to resist corrosion.

Storage

Units are protected against damage during shipment.

If the unit cannot be installed and operated

immediately, precautions need to be taken to prevent

deterioration of the unit during storage. The user

assumes responsibility of the unit and accessories

while in storage. The manufacturer will not be

responsible for damage during storage. These

suggestions are provided solely as a convenience to

the user.

INDOOR — The ideal environment for the storage of

units and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain, or snow. Temperatures

should be evenly maintained between 30°F (-1°C) and

110°F (43°C) (wide temperature swings may cause

condensation and “sweating” of metal parts). All

accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To

avoid “sweating” of metal parts allow cold parts to

reach room temperature. To dry parts and packages

use a portable electric heater to get rid of any

moisture build up. Leave coverings loose to permit air

circulation and to allow for periodic inspection.

The unit should be stored at least 3½ in. (89 mm) off

the floor on wooden blocks covered with moisture

proof paper or polyethylene sheathing. Aisles between

parts and along all walls should be provided to permit

air circulation and space for inspection.

Inspection and Maintenance during Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan wheel by hand ten to fifteen

revolutions to distribute lubricant on motor. Every

three months, the fan motor should be energized. If

paint deterioration begins, consideration should be

given to touch-up or repainting. Fans with special

coatings may require special techniques for touch-up

or repair.

Machined parts coated with rust preventive should

be restored to good condition promptly if signs of

rust occur. Immediately remove the original rust

preventive coating with petroleum solvent and clean

with lint-free cloths. Polish any remaining rust from

surface with crocus cloth or fine emery paper and oil.

Do not destroy the continuity of the surfaces. Wipe

thoroughly clean with Tectyl

®

506 (Ashland Inc.) or

the equivalent. For hard to reach internal surfaces or

for occasional use, consider using Tectyl

®

511M Rust

Preventive or WD-40® or the equivalent.

REMOVING FROM STORAGE — As units are removed

from storage to be installed in their final location,

they should be protected and maintained in a similar

fashion, until the equipment goes into operation.

Prior to installing the unit and system components,

inspect the unit assembly to make sure it is in working

order.

1. Check all fasteners, set screws on the fan,

wheel, bearings, drive, motor base, and

accessories for tightness.

2. Rotate the fan wheel(s) by hand and assure no

parts are rubbing.

Service Clearance

Units require service clearance for:

• Filter replacement

• Coil and drain pan inspection - cleaning, and

replacement

• Motor and drive inspection - maintenance and

replacement

Access panels are provided for inspection and

cleaning of unit components. Allow service clearance

of 26 inches for removal of filters. Allow a service

clearance equal to the unit width for removal of coils

and drain pan.

2 Low-Profile Fan Coil

®

Table of Contents

Installation

Unit Layout ...............................3

Lifting / Hanging Instructions ................ 3

Dimensions / Weights ...................... 4

Filter Sizes / Quantity ...................... 4

Coil Dimensions .........................5-6

Start-Up

System Start-Up .......................... 7

Troubleshooting

Blower .................................. 8

Motor Overamps .......................... 8

Insufficient / Too Much Airflow ............... 8

Excessive Noise or Vibration ................ 8

Start-Up

Coil Module ............................9-10

Drain Pan / Drain Trap .................... 10

Maintenance

Fan .................................... 11

Coil .................................... 12

Drain Pan ............................... 12

Reference

Start-Up Documentation ................... 12

Optional Ladder Diagrams ...............13-14

Maintenance Log ........................ 15

Our Commitment ...................Backcover

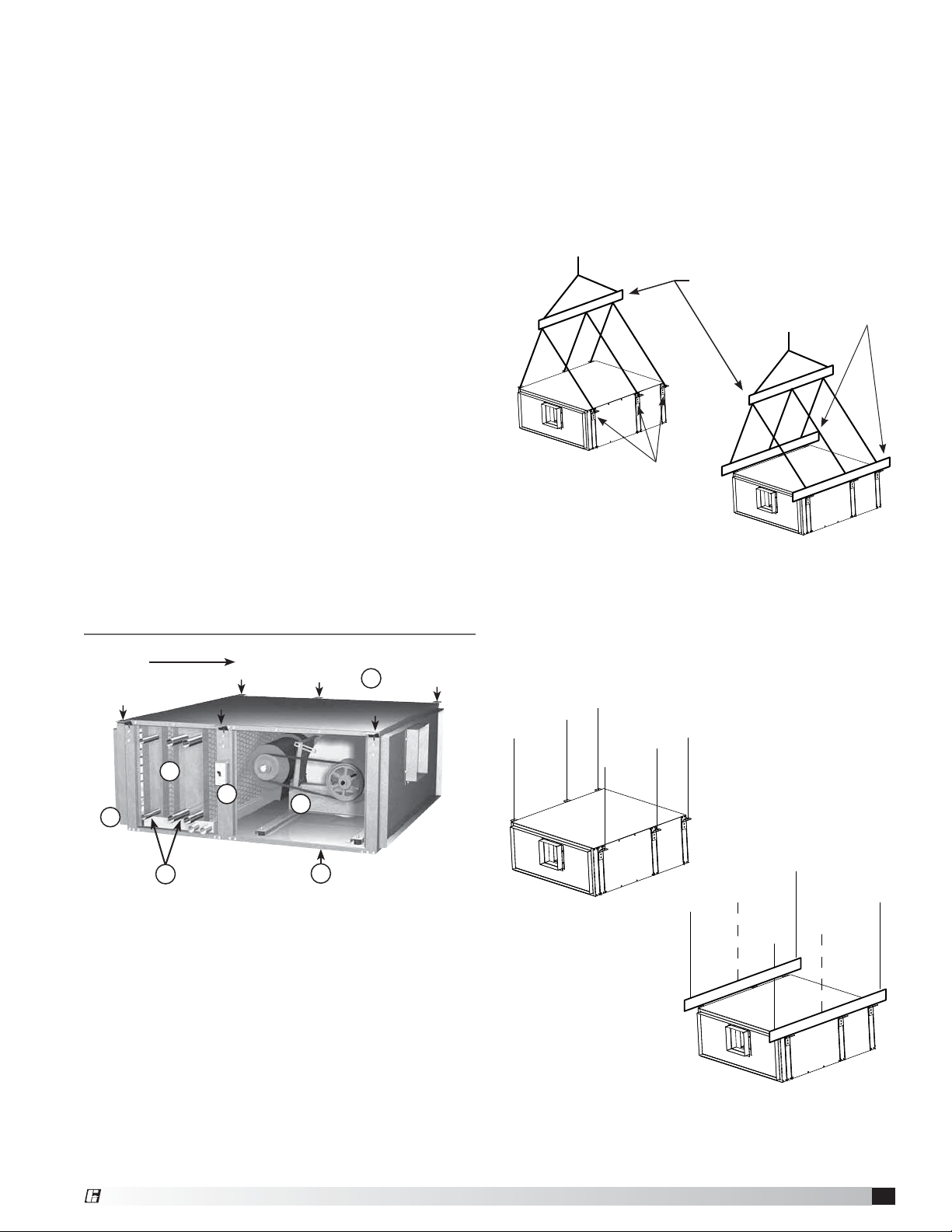

Lifting Instructions

Unit should be lifted by the factory supplied lifting lugs

or frame rails and a spreader bar (by others) to prevent

damage from occurring to the equipment (see Figure

1). Avoid twisting or uneven lifting of equipment. Do

not lift equipment by coil connections or headers.

The unit must remain upright during lifting. All access

doors and panels must be closed during lifting to

avoid damage.

Spreader Bar

Frame Rails

Lifting Lugs

Figure 1

Unit Layout

Airflow

4

5

6

3

2

1. Fan Section

2. Coil Section

• Chilled Water • Hot Water

• DX Coils • Steam Coils

3. Inlet Filter

Vertical inlet filter with quarter-turn fasteners

4. Lifting Lugs/Hanging Brackets

Six (6) lifting lugs for each unit

5. Side Access Panels

Right and left access to each unit. (Image shows

panels removed).

1

6. 1

⁄4 inch knockout is provided for the recommended

electrical wiring penetration or disconnect switch.

5

1

Hanging Instructions

The LFC should be hung by the factory supplied

lifting lugs or field supplied frame rails as shown

respectively in Figures 2 and 3. All hanging brackets

must be used to mount the unit. The LFC is available

with both external neoprene and spring isolation

options.

Figure 2

Figure 3

®

3Low-Profile Fan Coil

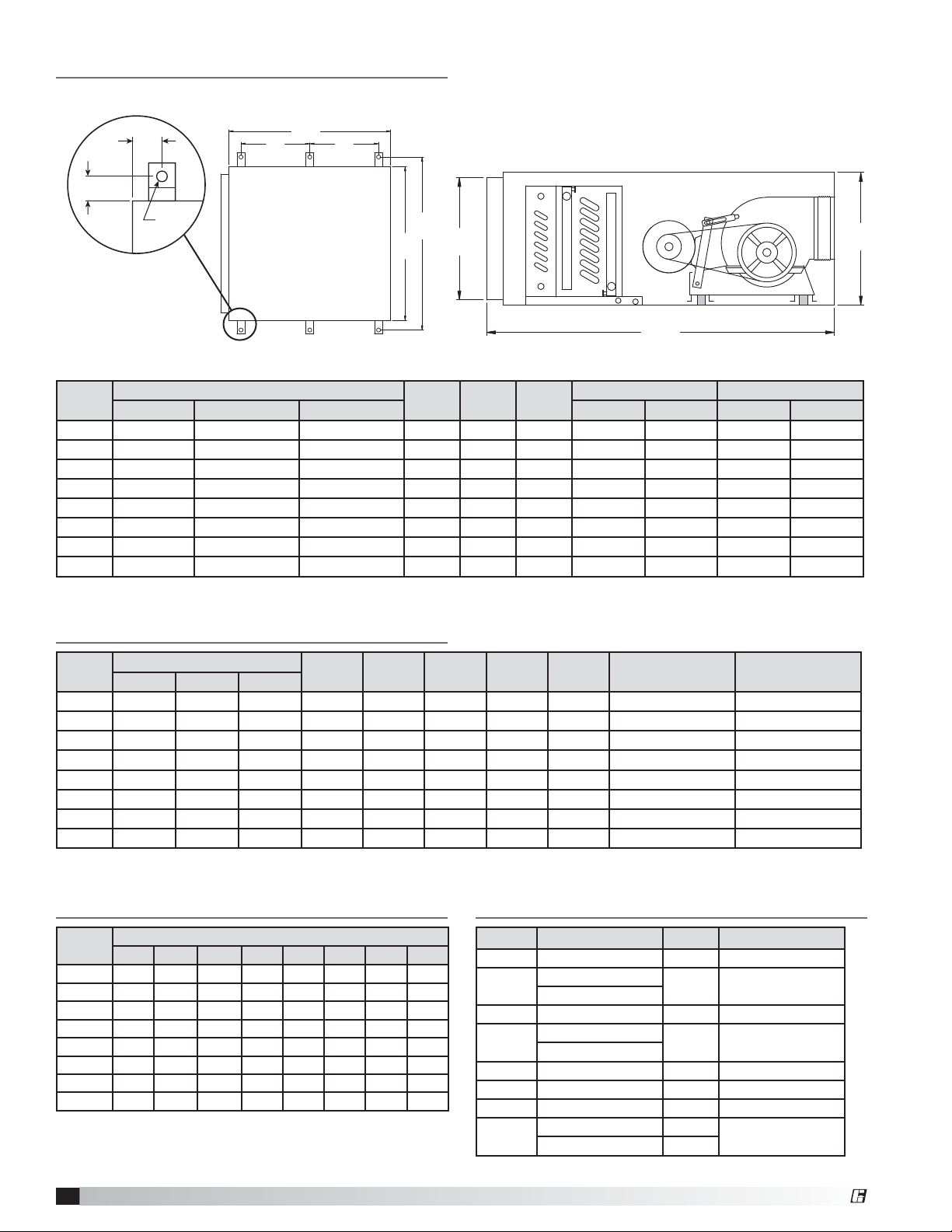

Unit Dimensions

F

H

G

Unit

Size

All dimensions are in inches.

w/o Filter w/ 2 in. Filter w/ 4 in. Filter Height Width Height Width

15 40 42 44 8.0 11.0 38 9.0 36 4.0 6.75

20 40 42 44 11.0 14.0 38 12.0 36 6.5 6.75

25 40 42 44 13.0 16.0 38 14.0 36 8.0 8.5

30 45 47 49 15.5 18.5 38 16.5 36 9.0 9.0

45 45 47 49 14.25 18.5 50 16.5 48 9.0 10.0

50 48 50 52 16.75 21.0 50 19.0 48 10.25 10.0

65 52 54 56 21.75 26.0 50 24.0 48 12.0 12.75

85 52 54 56 21.75 26.0 62 24.0 60 12.0 15.0

A

B

I

C

E

D

J

J K Width

I

Elevation ViewTop View

Inlet Outlet

K

Weights

Unit

Size

15 128 50 178 25 31 44 60 75 5 8

20 151 50 201 32 41 61 83 105 6 10

25 175 60 235 38 51 77 106 135 8 13

30 199 60 259 45 61 94 129 165 9 15

45 250 75 325 51 70 110 152 195 11 17

50 316 75 391 58 80 127 175 225 12 19

65 405 75 480 64 90 143 198 255 14 22

85 450 100 550 71 100 160 221 285 15 24

All weights are shown in pounds (lbs.) Motor weights may vary depending on enclosure type and horsepower.

Mounting Dimensions

Unit

Size

15 40 18.25 19.75 38 43 1 0.5 2.5

20 40 19 19 38 43 1 0.5 2.5

25 40 19 19 38 43 1 0.5 2.5

30 45 19 24 38 43 1 0.5 2.5

45 45 19 24 50 55 1 0.5 2.5

50 48 19 27 50 55 1 0.5 2.5

65 52 19 31 50 55 1 0.5 2.5

85 52 19 31 62 67 1 0.5 2.5

All dimensions are in inches.

Fan w/ Drain Pan

Fan Motor Total

Horizontal Hanging

ABCDEFGH

1 Row 2 Row 4 Row 6 Row 8 Row

Filter Sizes and Quantity

Size Filter Size Qty Face Area (ft 2)

15 9 x 18 2 1.8

20

25 14 x 18 2 3.0

30

45 16 x 24 2 4.8

50 18 x 24 2 5.4

65 24 x 24 2 7.2

85

All dimensions are in inches.

12 x 12

12 x 24

16 x 16

16 x 20

12 x 24 1

24 x 24 2

2 in. Vertical

Filter

1 2.5

1 3.4

4 in. Vertical

Filter

8.9

4 Low-Profile Fan Coil

®

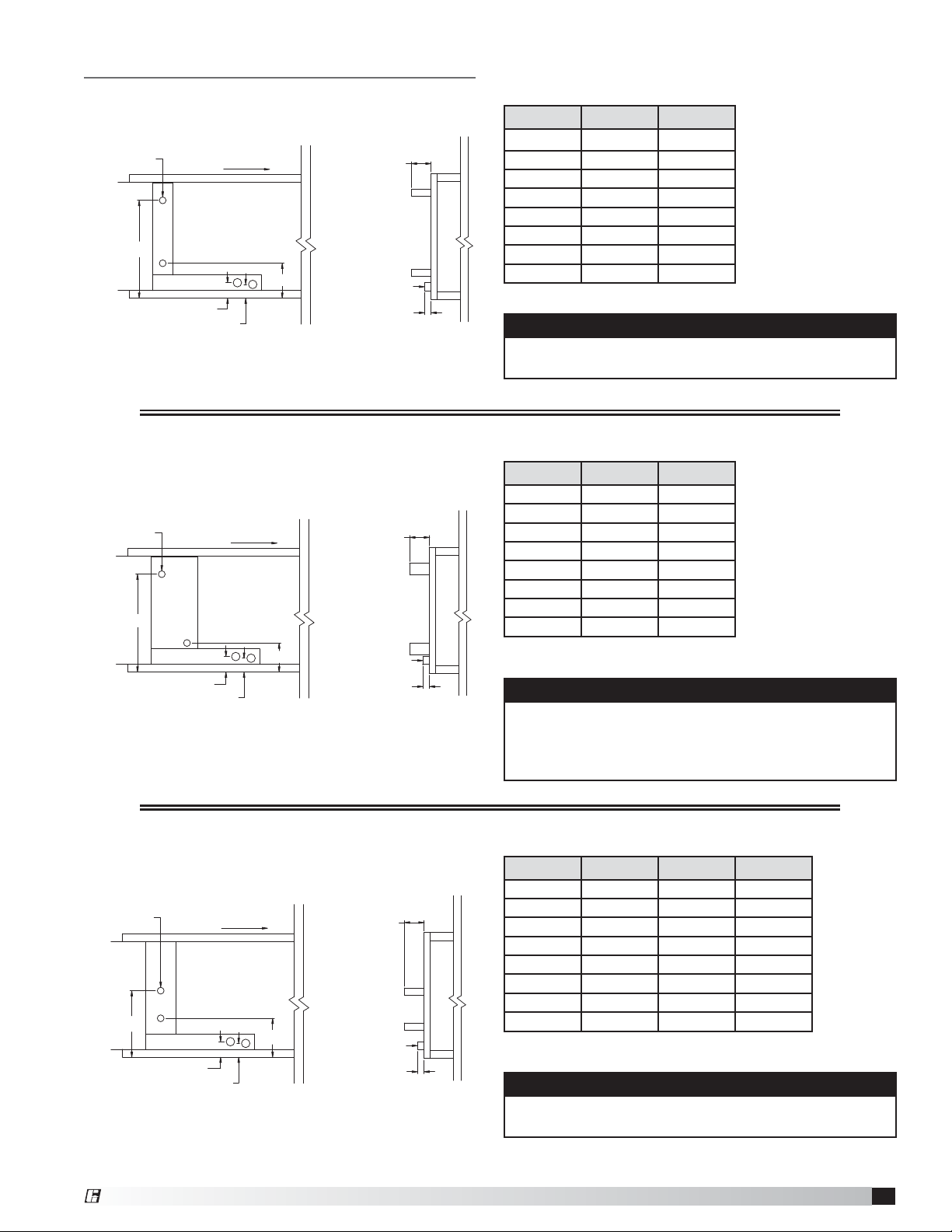

Coil Dimensions

Hot Water • 1 and 2 Row

B

Copper Sweat

A

Airflow

2

1.5

Right side connection shown.

Hot Water • 4 Row

B

Copper Sweat

A

Airflow

2

1.5

Right side connection shown.

3.75

3.75

3

Outlet

0.75

1

Drain Connection

3

Outlet

0.75

1

Drain Connection

Unit Size A B

15

7.63 0.75

20 10.13 0.75

25 12.63 0.875

30 15.13 0.875

45 15.13 0.875

50 17.63 1.125

65 22.63 1.375

85 22.63 1.375

All dimensions are in inches.

NOTE

Fluid enters the coil from the bottom connection

(Inlet) and exits from the top (Outlet).

Unit Size A B

15 7.63 0.75

20 10.13 0.75

25 12.63 0.875

30 15.13 0.875

45 15.13 0.875

50 17.63 1.375

65 22.63 1.375

85 22.63 1.375

All dimensions are in inches.

NOTE

With airflow from left to right, the fluid enters the coil

from the bottom connection (Inlet) and exits from the

top (Outlet). The other two coil connections should

be capped off (Cap).

Steam • 1 and 2 Row

B

Steel MPT

A

®

Airflow

2

1.5

Right side connection shown.

Unit Size A B C

15 7.0 1.5 3.81

20 6.94 1.5 3.56

3

25 8.19 2.5 3.81

30 9.44 2.5 3.56

45 9.44 2.5 3.56

50 10.69 2.5 4.81

Outlet

65 13.19 2.5 3.56

85 13.19 2.5 3.56

C

0.75

1

Drain Connection

All dimensions are in inches.

NOTE

Steam enters the coil from the center connection

(Inlet) and exits from the bottom (Outlet).

5Low-Profile Fan Coil

Loading...

Loading...