Page 1

Untempered Make-Up Air

for Kitchen Systems

Models KSFB and KSFD

June

2006

Page 2

PRODUCT FEATURES

Models KSFB and KSFD

Untempered Make-Up Air Unit

Greenheck’s series KSF is available in a belt drive

(KSFB) and direct drive (KSFD). Both have a compact

design providing untempered make-up air for

commercial and institutional kitchen applications.

Eight available blower sizes provide airflow

capacities up to 10,500 cfm and static pressure

capabilities up to 2.0 in. wg.

Installation may be stand alone or on a combination

curb with exhaust fan. See page 3 for details.

Features

Weatherhood and Filters

A weatherhood is standard and meets NFPA 96

requirements when used with a combination package.

See page 3 for details. All weatherhoods come

standard with UL Class 2 rated, 1 in. washable

aluminum mesh filters.

Vibration Isolators

The motor and wheel assembly is

mounted on vibration isolators to

minimize noise transmission into the

building.

Accessories

Kitchen Fan Control Center (KFCC)

Prewired in compliance to the National

Electrical Code, the KFCC simplifies

field wiring, thereby reducing

installation time and mistakes. The

control center is a UL Listed NEMA 1

panel for mounting indoors. It is

designed to interlock with the fir

suppression system.

Remote Starter Control Panel (RSCP)

The Remote Starter Control Panel (RSCP) offers

safety and reliability for remote operation of up to

four fans. Standard NEMA 3R housing allows panel to

be mounted outdoors.

• Multiple supply voltages

Wide range of horsepowers

•

• Disconnect switch(es)

• Control transformer for low

voltage remote switching

• Terminal strips

• Fuse blocks

•

onic motor overload pr

Electr

otection

e

Reliable Fan Performance

Air performance ratings from Greenheck’s third party

accredited test chamber

ensure accurate data.

Double width, double inlet,

forward curved wheels for

high efficiency and low

sound levels are

constructed of heavy

gauge steel. Wheels are

statically and dynamically

balanced to ensure vibration free operation.

Speed Controller

Available on the KSFD, the

speed controller provides an

economical means of system

balancing.

Roof Curbs

Prefabricated roof curbs are available to reduce

installation time and costs by ensuring compatibility

between the fan and the roof opening. All curbs are

lined with fiberglass insulation to prevent

condensation and reduce sound levels. See

Greenheck’s roof curb catalog for complete details.

Special Coatings

Special coatings ar

protective purposes. Consult your Greenheck

representative or the factory for more information.

e available for decorative or

2

Page 3

10 ft.

3 ft.

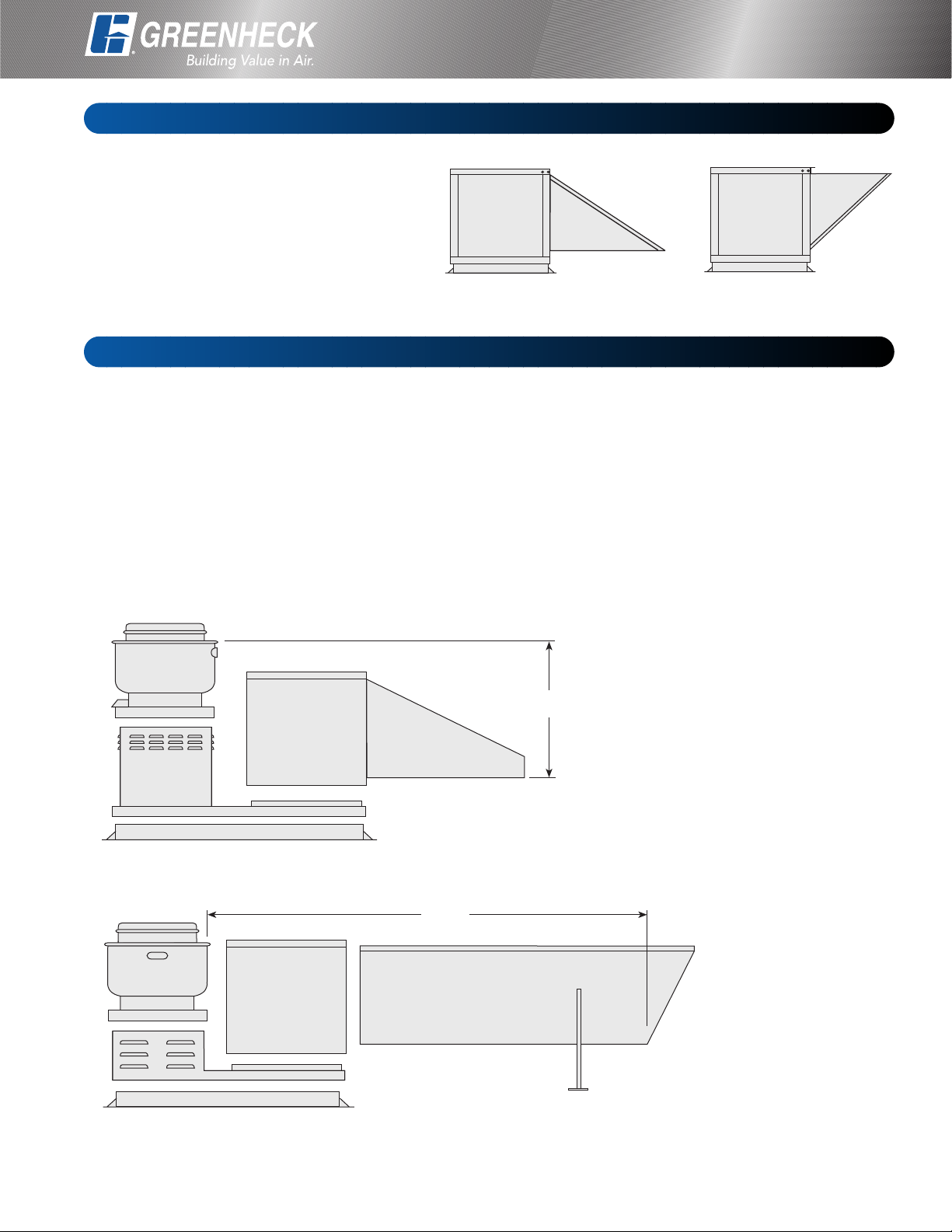

Standard Arrangements

Series KSF has a compact design that is

available in both downblast discharge

(arrangement DB) and horizontal discharge

(arrangement HZ).

Installations may be as stand alone supply

fans as pictured at right or as combination

packages with exhaust and supply fans on a

common curb as shown below.

Combination Packages

INSTALLATION

Arrangement DB Arrangement HZ

With either ten feet of horizontal separation or three

feet of vertical separation, Greenheck has a

combination package for your requirements. The

Greenheck combination package simplifies

installation and reduces field labor costs. This preengineered design offers the benefit of only one roof

penetration for both supply and exhaust ducts, while

ensuring complete compatibility and interface

between the supply fan, exhaust fan, curb and

combination extension.

3 Ft. Vertical Separation - Short Weatherhood

Greenheck combination packages are specifically

designed to comply with NFPA 96, which states:

• Exhaust duct must terminate at least 24 in. above

the roof deck.

• Fan discharge must terminate at least 40 in. above

the roof deck.

• There must be at least 10 ft. of horizontal or 3 ft. of

vertical separation between the intake and exhaust

discharge.

Provides 3 ft. of vertical

separation for

compliance to NFP

A 96.

10 Ft. Horizontal Separation - Extended Weatherhood

Note: Consult local codes and the authority having jurisdiction if ther

questions concer

ning the use of this pr

oduct.

e are

ovides 10 ft. of

Pr

horizontal separation for

compliance to NFPA 96.

3

Page 4

AIR PERFORMANCE

KSFD-70-H05

RPM AMPS Watts

1,600 3.77 405 813 783 776 741 707 671 637 603 527

0.000 0.100 0.125 0.250 0.375 0.500 0.625 0.750 1.000

KSFD-80-H08

RPM AMPS Watts

1,610 8.32 830 1672 1617 1604 1542 1484 1427 1367 1306 1171

0.000 0.100 0.125 0.250 0.375 0.500 0.625 0.750 1.000

KSFD-90-H08

RPM AMPS Watts

1,100 7.8 735 2249 2175 2156 2044 1900 1701 1424 1114

0.000 0.100 0.125 0.250 0.375 0.500 0.625 0.750 1.000

KSFB-109-H15

CFM OV

1,300 1,413

1,600 1,739

1,900 2,065

2,200 2,391

2,575 2,798

RPM 593 678 762 842 987 1118 1236

BHP 0.15 0.19 0.23 0.27 0.35 0.43 0.52

RPM 691 764 833 902 1032 1153 1265 1371 1561

BHP 0.26 0.30 0.35 0.40 0.50 0.60 0.69 0.80 1.02

RPM 793 859 918 976 1091 1201 1303 1404 1588

BHP 0.41 0.47 0.52 0.58 0.70 0.82 0.93 1.04 1.28

RPM 899 956 1011 1061 1161 1261 1356 1448

BHP 0.61 0.68 0.74 0.80 0.94 1.08 1.22 1.35

RPM 1034 1082 1132 1178 1265 1349 1435

BHP 0.95 1.03 1.11 1.18 1.33 1.49 1.65

0.125 0.250 0.375 0.500 0.750 1.000 1.250 1.500 2.000

CFM/Static Pressure in inches of WG

CFM/Static Pressure in inches of WG

CFM/Static Pressure in inches of WG

TOTAL STATIC PRESSURE in inches of WG

KSFB-110-H15

CFM OV

2,400 2,123

2,750 2,433

3,100 2,743

3,450 3,053

3,625

3,207

RPM 741 781 834 885 977 1066 1153 1234 1392

RPM 839 871 913 958 1046 1124 1202 1279 1423

RPM 940 967 996 1036 1118 1192 1262 1330

RPM

RPM 1092 1112 1137 1160 1230

KSFB-112-H15

CFM OV

2,700 1,731

3,300 2,115

3,900

4,500 2,885

5,100 3,269

2,500

RPM

RPM

RPM 691 729 766 804 881 956 1027 1093 1221

RPM 787 817 852 884 951 1017 1082 1146

RPM 884 911 940 970 1027

TOTAL STATIC PRESSURE in inches of WG

0.125 0.250 0.375 0.500 0.750 1.000 1.250 1.500 2.000

BHP 0.54 0.59 0.65 0.72 0.85 0.98 1.12 1.27 1.57

BHP 0.80 0.85 0.91 0.99 1.14 1.29 1.44 1.60 1.93

BHP

BHP 1.55 1.60 1.66 1.73 1.92 2.12

BHP 1.80 1.84 1.91 1.97 2.16

BHP

BHP 0.68 0.77 0.87 0.96 1.15 1.33 1.52 1.72 2.09

BHP 1.09 1.19 1.30 1.41 1.63 1.86 2.08 2.28 2.76

BHP 1.64 1.74 1.87 2.00 2.25 2.51 2.77 3.03

BHP

1.13

1041

0.125 0.250 0.375 0.500 0.750 1.000 1.250 1.500 2.000

507

0.40 0.47 0.55 0.63 0.78 0.94 1.09 1.24

596 641 687 733 821 902 979 1052 1183

2.35

1.18 1.24 1.32 1.50 1.67 1.84 2.01

1064

561

2.47

1089

TOT

617

2.60 2.75 3.03

1119

TIC PRESSURE in inches of WG

A

AL ST

671 768 860 941 1014

1191

1264

Power rating (BHP) does not include drive losses. Performance ratings do not include the effects of appurtenances in the airstream.

4

Page 5

AIR PERFORMANCE

KSFB-115-H25

C

FM OV

4,700 2,146

5,400 2,465

6,100 2,785

6,800 3,105

7,500 3,424

RPM 524 567 608 1.31 722 790 856 915 1031

BHP 1.02 1.16 1.31 1.45 1.74 2.03 2.34 2.63 3.29

RPM 589 628 665 700 768 832 891 950 1056

BHP 1.49 1.66 1.83 1.99 2.32 2.65 2.98 3.33 4.01

RPM 656 691 724 757 819 877 934 988 1090

BHP 2.10 2.29 2.47 2.66 3.04 3.40 3.79 4.16 4.94

RPM 723 755 786 815 872 928 979 1031

BHP 2.86 3.07 3.28 3.48 3.91 4.33 4.72 5.15

RPM 792 821 849 876 929 980

BHP 3.78 4.02 4.25 4.47 4.94 5.41

0.125 0.250 0.375 0.500 0.750 1.000 1.250 1.500 2.000

KSFB-118-H25

CFM OV

6,500 2,145

7,500 2,475

8,500 2,805

9,500 3,135

10,500 3,465

Power rating (BHP) does not include drive losses. Performance ratings do not include the effects of appurtenances in the airstream.

RPM 438 473 510 544 608 667 723 776

BHP 1.26 1.42 1.60 1.78 2.13 2.47 2.83 3.20

RPM 495 526 557 588 646 702 754 802 897

BHP 1.87 2.06 2.26 2.46 2.86 3.27 3.66 4.05 4.92

RPM 554 580 607 636 690 740 790 835 922

BHP 2.66 2.87 3.09 3.32 3.79 4.22 4.69 5.14 6.04

RPM 614 637 661 685 735 783 827 872 954

BHP 3.67 3.86 4.13 4.37 4.90 5.41 5.90 6.43 7.43

RPM 675 695 715 738 783 827 870

BHP 4.91 5.14 5.39 5.66 6.23 6.80 7.37

0.125 0.250 0.375 0.500 0.750 1.000 1.250 1.500 2.000

TOTAL STATIC PRESSURE in inches of WG

TOTAL STATIC PRESSURE in inches of WG

Arrangement HZ - Standard Weatherhood

B

D

A

DIMENSIONAL DATA

STAND ALONE

C

A B C D

Housing 05 183⁄8 315⁄8 20 193⁄8

Housing 08 183⁄8 313⁄4 37 193⁄8

Housing 15 251⁄4 711⁄8 317⁄8 391⁄2

Housing 25 34 813⁄8 401⁄4 473⁄8

All dimensions ar

e in inches

5

Page 6

Extended Weatherhood Option

DIMENSIONAL DATA

STAND ALONE

Arrangement DB - Standard Weatherhood

B

D

A

A B C D

Housing 05 141⁄2 41 20 211⁄4

Housing 08 141⁄2 41 367⁄8 211⁄4

Housing 15 221⁄4 803⁄8 317⁄8 403⁄4

Housing 25 291⁄2 991⁄2 401⁄4 521⁄4

C

All dimensions are in inches

Arrangement DB - Extended Weatherhood

B

D

A

C

A B C D

Housing 05 141⁄2 1711⁄8 20 211⁄4

Housing 08 141⁄2 1653⁄4 367⁄8 211⁄4

Housing 15 221⁄4 1451⁄4 317⁄8 403⁄4

Housing 25 291⁄2 1521⁄2 401⁄4 521⁄4

All dimensions ar

6

e in inches

Page 7

COMBINATION PACKAGE

Arrangement DB3 - Standard Weatherhood

*

Top of

UBE fan

C

op of curb

T

*

B

A

0 in. min.

4

DIMENSIONAL DATA

*

C

6 in. min.

3

Weatherhood

w/Filters

A* B* C*

Housing 05 25 50 701⁄8

Housing 08 353⁄8 527⁄8 821⁄2

Housing 15 427⁄8 55 1313⁄4

Housing 25 583⁄4 661⁄8 1641⁄4

All dimensions are in inches

Arrangement DBC - Extended Weatherhood

A*

Top of

CUBE fan

B*

40 in. min.

Top of curb

* Maximum dimensions

(dependent on CUBE fan)

C*

Adjustable Legs

A* B* C*

Housing 05 25 50 2001⁄4

Housing 08 353⁄8 527⁄8 2071⁄4

Housing 15 427⁄8 55 1965⁄8

Housing 25 583⁄4 661⁄8 2171⁄4

All dimensions are in inches

10 ft. min.

* Maximum dimensions

(dependent on CUBE fan)

7

Page 8

Typical Specifications

General: Make-up air unit shall be as

anufactured by Greenheck or approved equal

m

provided all specifications are met. Greenheck

Model KSFB and KSFD equipment is used as the

basis of design. Performance to be as scheduled

on plans. Make-up air units shall be listed to UL

705. Manufacturer to provide lifting lugs of

adequate strength to allow rigging without

damage.

Unit Casing: Make-up air unit casing shall be

constructed of G-90 galvanized steel. Hinged

panels shall be provided for access to the blower,

motor, and drives. All metal surfaces exposed to

the weather shall be sealed, requiring no caulking

at jobsite.

Fan Section: Centrifugal fans shall be double

width, double inlet. Fan and motor shall be

mounted on a common base and shall be internally

isolated. All blower wheels shall be statically and

dynamically balanced. Ground and polished steel

fan shafts shall be mounted in permanently

lubricated ball bearings. Bearings shall be selected

for a minimum (L10) life in excess of 100,000 hours

at maximum cataloged speeds.

Motors and Drives: Motors shall

e energy efficient, complying

b

with EPACT standards for single

speed ODP and TEFC enclosures.

Motors shall be permanently

lubricated, heavy duty type,

matched to the fan load and

furnished at the specified voltage,

phase and enclosure. The motors

shall be factory wired to a factory

supplied disconnect switch.

Drives shall be sized for a

minimum of 150% of driven

horsepower. Pulleys shall be cast

and have machined surfaces.

Weather Hood: Weather hood

shall be constructed of G90 galvanized steel and

include easily removable 1-inch UL Class 2

aluminum mesh filters. Outdoor air openings shall

be sized so air velocities do not exceed 900 fpm.

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from the

purchase date. Any units or parts which prove defective during the warranty period will be replaced at our option when returned

to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of one year. Should motors

furnished by Greenheck prove defective during this period, they should be returned to the nearest authorized motor service station.

Greenheck will not be responsible for any removal or installation costs.

esult of our commitment to continuous impro

As a r

vement, Greenheck reserves the right to change specifications without notice.

Greenheck P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Copyright © 2006 Greenheck Fan Corp. • KSFB KSFD Catalog SN Rev. 2 June 2006

Loading...

Loading...