Page 1

Modular Heating & Ventilating Unit

Model IGX-HV

• Indirect Gas-Fired Heating

• Evaporative • Chilled Water • DX Cooling

October

2008

Page 2

PRODUCT FEATURES

Model IGX-HV

Indirect Gas-Fired

Heating and Ventilating Unit

Indoor/Outdoor Installations

All Greenheck model IGX-HV units feature 80%

efficient indirect gas-fired furnace(s), filtered

mixing box section, fan section, and are ETL listed

to the UL-1995 test standard. Heating capacities

range from 100,000 to 1,200,000 BTU/Hr and air

flow volumes are available up to 15,000 cfm.

A modular design concept enables the flexibility

to customize each product for its application. Modules

are then factory assembled and wired to minimize field

installation labor. The result is a semi-custom product at

an attractive cost.

IGX-HV shown with horizontal discharge.

Reliable Fan Performance

Air performance ratings from Greenheck’s AMCA

registered test chamber ensure accurate data.

Indirect Gas-Fired Furnaces

The Greenheck furnace is designed for top-notch

performance and long life, combining quality

components with expert craftsmanship. Unique to

our furnace is a post purge cycle, which runs the

combustion fan after the unit is shut down to vent

hot air and moisture out of

the heat exchanger. The

elimination of these corrosion

catalysts adds years to the

life of the heat exchanger.

Other key features of our

furnace are listed below:

• Power vented

• 80% thermal efficiency

• Seamless tubes

• Electronic staged gas controls

• Electronic modulating gas controls

• Aluminized steel or stainless steel heat exchanger

• Direct spark ignition system

• Easy access burner controls

• ETL listed to ANSI Standard Z83.8

• Solid state automatic ignition module

Fans are constructed of heavy gauge steel and

designed for high efficiency

and low sound levels.

Wheels are statically and

dynamically balanced

to ensure vibration free

operation.

Control Center

The control center includes

the following standard components:

• Magnetic motor starter with solid state overload

protection

• Control transformer

• Disconnect switch

• Separately fused motor

• Distribution terminal strip

Premium grade control

components are selected for reliable operation. All

electrical components are UL Listed, recognized or

classified. Control centers are factory prewired for

single point power connection.

Vibration Isolators

The entire fan and

motor assembly is

mounted on vibration

isolators to minimize

noise transmission into

the building. Neoprene

isolators are standard on

all units, spring isolators

are optional.

2

Factory Wired

and Tested

All units are tested

prior to shipment.

Units are checked for

vibration and proper

operation.

Page 3

CONTROL OPTIONS

Suppl

y

Return Ai

r

70% - 100

%

Outdoor Air

0% - 30%

Suppl

y

Return Ai

r

70% - 100

%

Outdoor Air

0% - 30%

Suppl

y

Return Ai

r

25% - 100

%

Outdoor Air

30% - 75%

Suppl

y

Return Ai

r

70% - 100

%

Suppl

y

Return Ai

r

25% - 100

%

Suppl

y

Return Ai

r

100

%

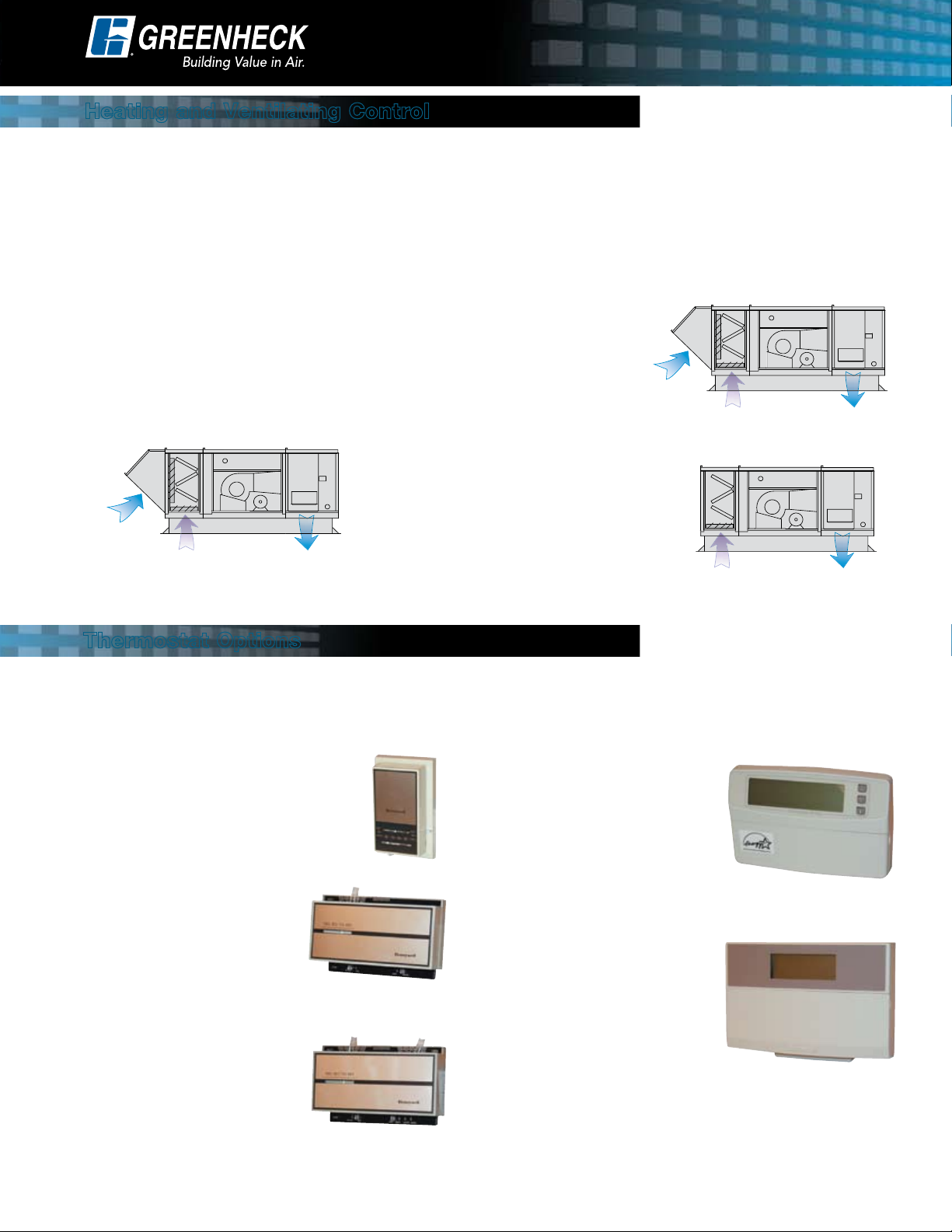

Heating and Ventilating Control

Three heating and ventilating options are available to provide proper tempering and fulfill varying requirements for

fresh outdoor air. In all cases, heating and cooling functions are controlled by a Greenheck room thermostat or a

DDC system (by others).

HV1: 0%-30% Minimum Outdoor Air

HV1 is the most common among

heating and ventilating units, allowing

you to set the minimum outdoor air

volume between 0 and 30% of the total

supply air volume. With the relatively

low percentage of outdoor air, mixed

air temperatures are mild and stable.

1-stage heating and/or cooling is

recommended. (2-stage or electronic

modulation is optional).

Thermostat Options

HV2: 30%-75% Minimum Outdoor Air

The HV2 option is required when the minimum outdoor air volume

exceeds 30% of the total supply air volume. With higher outdoor air

volumes, mixed air temperatures

can vary greatly. Accordingly,

2-stage heating and/or cooling is

recommended. Also, an airstream

override thermostat is standard

with HV2 to prevent cold air

discharge (below 55˚ F) when the

thermostat is satisfied. (electronic

modulation is optional).

HV3: 100% Return Air

The HV3 option is available when no

outdoor air is needed. With relatively

stable return air conditions, 1-stage

heating and/or cooling is strongly

recommended. (2-stage or electronic

modulation is optional).

Basic bimetal thermostats with mercury switches or fully programmable electronic thermostats are available as

part of your IGX-HV system. Match your heating, cooling, staging, and operational requirements to the appropriate

thermostat.

TC1: 1-Stage Heating / Cooling

TC1 is a coiled bimetal thermostat

used for single-stage heating, cooling

or heating-cooling systems.

TC4: Programmable

TC4 has full seven-day program

capability. The thermostat can

be set for four times and eight

temperature settings each day of

the week. It can control up to two

stages of heating and two stages

TC2: 2-Stage Heating

of cooling.

TC2 is a coiled bimetal

thermostat used for 2-stage

heating systems.

TC5: Deluxe Programmable

TC5 has full seven-day program

capability. The thermostat can

be set for two occupied and two

TC3: 2-Stage Heating / 2-Stage Cooling

TC3 is a coiled bimetal

thermostat used for 2-stage

heating, cooling or heatingcooling systems. It includes

an adjustable heat anticipator,

stops, and a locking cover.

unoccupied times with adjustable

temperature settings for each day

of the week. It can control up to

three stages of heating and two

stages of cooling. The Intelligent Fan™ feature energizes the

fan continuously during occupied mode and intermittently

with a call for heating or cooling in unoccupied mode.

3

Page 4

MIXING BOX CONTROLS

Suppl

y

Return Ai

r

Outdoor Air

The mixing box (shown at right) includes

outdoor air and return air low leakage

control dampers in a face and bypass

configuration. Either two inch pleated

or aluminum mesh filters are available

within the mixing box section. Double wall

construction is optional.

A mixing box control option must be

specified for every IGX-HV unit. Greenheck

offers eight mixing box control options

that accommodate a wide variety of

applications. The four EC and four MB

options are described below. Specify only

one control box option per unit.

Mixing Box Controls with Economizer Cooling

The economizer controls package enables free cooling using outdoor air. All EC options include a modulating

actuator for controlling outdoor and return air dampers, and a minimum outdoor air positioner. During a call for

heating the economizer is locked out and the outdoor air damper holds at the minimum position.

EC1: Outdoor Temperature Reference

The economizer controller positions the mixing box

dampers to achieve 55° F mixed temperature when

the thermostat calls for cooling AND the outdoor air

temperature is below the economizer

setpoint. If outdoor air temperature is

between 55° F and the economizer

setpoint, the dampers will modulate

to the 100% outdoor air position.

Above the setpoint, the outdoor

air damper is held at the minimum

position. The setpoint is field

adjustable and the outdoor air sensor

is factory mounted.

EC3: Airstream Temperature Reference

The economizer controller compares the temperatures

of the outdoor air and return air when the thermostat

calls for cooling. The mixing box dampers are then

positioned to maximize the

airflow of the cooler airstream.

When outdoor air temperature

is sufficiently cool, the mixing

box dampers will modulate to

provide 55° F mixed air. The

outdoor air sensor is factory

mounted. The return air sensors

are field installed.

EC2: Outdoor Enthalpy Reference

Same as EC1, except economizer setpoint is based on

outdoor air enthalpy.

EC4: Airstream Enthalpy Reference

Same as EC3, except airstream enthalpy values are

compared.

Mixing Box Controls (no economizer)

In addition to the EC options described above, Greenheck offers four MB mixing box control options for

applications where a factory provided economizer package is not desired.

MB1: Minimum Outdoor Air Positioner

The MB1 option includes a modulating

actuator and potentiometer that control

the outdoor air and return air damper

positions. When the unit is energized,

the dampers will travel to the position

corresponding to the potentiometer

setting, providing the desired amount of outdoor air.

When the unit is powered off, the outdoor air damper

closes to prevent backdrafting. To adjust the damper

settings, simply dial the potentiometer (shown above) to

desired operating position of the outdoor air damper.

MB2: 2-10 Volt External Signal

The MB2 option includes a modulating actuator that is

controlled by an external 2-10 volt signal. This option

is appropriate for applications that call for a building

4

automation system that will control the mixing box

dampers.

MB3: 4-20 mA External Signal

The MB3 option includes a modulating actuator that is

controlled by an external 4-20 mA signal. Like the MB2

option, this option is appropriate for applications that

call for a building automation system that will control the

mixing box dampers.

MB4: Manual Quadrant

The MB4 option consists of a manual

quadrant that enables the outdoor air

and return air dampers to be secured

into a single position. The primary

function is to introduce the specified minimum outdoor

air volume during operation. Dampers remain in the

same position when the unit is powered off.

Page 5

Evaporative Cooling

COOLING OPTIONS

An evaporative cooling section includes a galvanized

steel housing with a louvered intake, two inch aluminum

mesh filters and a stainless steel evaporative cooling

media housing. The evaporative cooling media is

Munters CELdek or GLASdek and has a depth of

12 inches for 90% cooling effectiveness.

Drain and overflow lines are conveniently stubbed

through the side of the cooling section. The supply line

connection is field located where convenient.

IGX-HV airflow capacity for evaporative cooling is up

to 14,000 cfm. Below 9,000 cfm, evaporative cooling

modules ship attached and factory wired. Field

attachment is required for airflow above 9,000 cfm.

Mixing Box Controls:

Mixing box control option EC1 is recommended for use

Cooling Coils

Model IGX-HV boasts the flexibility of Chilled Water or

Direct Expansion (DX) cooling with capacity to 11,000

CFM. The cooling section includes the cooling coil,

stainless steel drain pan and insulated double wall

construction. Drain and coil connections are stubbed

through the wall for convenience.

For proper coil sizing, use Greenheck’s Computer Aided

Product Selection (CAPS) program or contact your local

representative. Four and six row coils are available.

Cooling coil sections are installed downstream of the

mixing box section for a draw through arrangement.

This provides a streamlined transition to adjacent

IGX-HV sections. DX coils require remote condensing

units.

Mixing Box Controls:

All MB and EC mixing box control options are available

with chilled water or DX cooling coils.

with evaporative

cooling. On a call

for cooling when

the outdoor air

temperature is below

the economizer

setpoint, the

dampers modulate

to provide cool

mixed temperatures

down to 55° F. When

the outdoor air is

above the economizer setpoint, the evaporative cooling

section is energized and the dampers travel to the 100%

outdoor air position.

The MB mixing box options are NOT recommended in

conjunction with evaporative cooling.

For economizer

climates, the

EC1 option is

recommended.

Mixing box options

operate as described

on page 4.

Thermostats:

The cooling coil

and MB mixing box

control options may

use a 1-stage (chilled

water or single stage DX) or 2-stage (dual stage DX)

cooling thermostat.

The cooling coil and EC mixing box control options

require a 2-stage cooling thermostat. Economizer

represents the first stage of cooling and a single DX

stage or chilled water coil represents the second stage

of cooling.

Mixing Box Selection Guide

EC Options MB Options

EC1 EC2 EC3 EC4 MB1 MB2 MB3 MB4

No Cooling Yes Yes Yes Yes Yes Yes Yes Yes

Evaporative

Cooling

Chilled Water or

DX Cooling

*Two-stage cooling thermostat required. Boldface type indicates factory recommended options.

Yes

Yes* Yes* Yes* Yes* Yes Yes Yes Yes

Yes

Not

Recommended

Not

Recommended

No No No No

5

Page 6

AIR PERFORMANCE

Housing Size 12

MODEL CFM

800

IGX-HV-108

IGX-HV-109

IGX-HV-110

1,000

1,200

1,500

2,000

2,500

2,000

2,500

3,000

Housing Size 22

MODEL CFM

2,600

IGX-HV-112

IGX-HV-115

3,500

4,400

5,000

6,000

7,000

TOTAL STATIC PRESSURE in inches of WG

0.50 0.75 1.00 1.25 1.50 1.75

RPM 993 1109 1216 1311 1399

BHP .21 .26 .31 .35 .40

RPM 1112 1228 1325 1415 1500 1579

BHP .34 .41 .47 .53 .59 .65

RPM 1238 1347 1445 1530

BHP .51 .59 .68 .75

RPM 880 1014 1140 1255 1361 1460

BHP .36 .45 .54 .63 .73 .84

RPM 1004 1113 1219 1321 1417 1510

BHP .65 .77 .90 1.0 1.1 1.3

RPM 1154 1244 1329 1419 1503 1587

BHP 1.1 1.2 1.4 1.6 1.7 1.9

RPM 805 912 1013 1110 1199

BHP .48 .59 .71 .84 .96

RPM 906 995 1082 1166 1247 1325

BPH .79 .93 1.07 1.21 1.36 1.51

RPM 1014 1097 1172 1244 1315 1386

BHP 1.22 1.39 1.55 1.72 1.88 2.05

TOTAL STATIC PRESSURE in inches of WG

0.50 0.75 1.00 1.25 1.50 1.75

RPM 662 761 853 934 1009

BHP .58 .72 .86 1.0 1.2

RPM 756 839 920 993 1065 1133

BHP 1.0 1.3 1.5 1.7 1.9 2.1

RPM 871 939 1006 1073 1137 1197

BHP 1.8 2.1 2.4 2.6 2.9 3.1

RPM 671 741 808 871 931 986

BHP 1.7 2.0 2.3 2.6 2.9 3.2

RPM 749 812 870 929 982 1035

BHP 2.6 2.9 3.3 3.7 4.0 4.4

RPM 833 889 943 994 1044 1093

BHP 3.7 4.2 4.6 5.0 5.5 5.9

Maximum

Furnace Size

(Input MBH)

100

150

150

200

250

250

250

250

250

Maximum

Furnace Size

(Input MBH)

350

500

600

600

600

600

Housing Size 32

MODEL CFM

TOTAL STATIC PRESSURE in inches of WG

0.50 0.75 1.00 1.25 1.50 1.75

RPM 566 627 685 738 790 839

BHP 2.1 2.5 2.8 3.2 3.6 4.0

RPM 636 690 740 790 836 880

BHP 3.3 3.8 4.2 4.7 5.1 5.6

RPM 712 759 805 849 891 933

BHP 5.0 5.5 6.1 6.6 7.1 7.7

RPM 542 590 634 678 723 765

BHP 3.6 4.0 4.5 5.0 5.6 6.1

RPM 633 672 711 748 784 820

BHP 6.3 6.9 7.5 8.1 8.7 9.3

RPM 731 763 795 829 861 892

BHP 10.2 10.9 11.6 12.3 13.1 13.8

IGX-HV-118

IGX-HV-120

7,000

8,500

10,000

10,000

12,500

15,000

Note: The air performance data shown does not include internal static pressure losses due to items such as

filters, dampers and furnaces. For exact air performance data based on specific unit configuration, use the

Greenheck CAPS selection program.

6

Maximum

Furnace Size

(Input MBH)

1,050

1,200

1,200

1,200

1,200

1,200

Page 7

ACCESSORIES

Air Filter Gauge

Indicates when filters become

dirty. An indicator light may be

wall/beam mounted or provided

with a remote control panel.

Motorized Dampers

Discharge dampers are available

to prevent backdrafts when

the fan is not in operation.

Mixing box dampers are factory

mounted and wired.

Fan Spring Vibration Isolation

Spring vibration isolators are available in lieu of

neoprene isolators for housing sizes H22 and H32

(fan sizes 112 and larger).

115 Volt Service Receptacle

A 115 volt GFCI outlet is mounted externally in a NEMA

3R box for the convenience of field service personnel. A

separate 115 volt power source is required.

Roof Curbs

Factory provided roof

curbs are available to

ensure compatibility

between make-up air

unit and roof curb.

Standard construction is

galvanized steel.

G90

Propane Gas Conversion Kit

Greenheck’s indirect gas furnaces are ETL listed for

both Natural Gas or LP.

Duct Adapter

Duct adapters are optional with factory supplied curbs

and provide an easy method for attaching ductwork to

the curb.

Double Wall Construction

An interior metal liner is available to isolate insulation

from the airstream. One-inch thick insulation is included

with this option.

Gas Pressure Regulator

Required if building gas line pressure

exceeds IGX-HV maximum inlet gas

pressure of 14 in. wg.

Smoke Detector

A 12/24 VDC Photoelectric smoke detector is available

for duct mounting. Typical operating temperature range

is 32°F to 131°F (0°C to 55°C).

Discharge Diffuser

Available as either 3-way

diffuser for horizontal

discharge or 4-way

diffuser for downblast

discharge.

Special Coatings

Greenheck’s Permatector powder paint is available if a

painted look is desired and recommended for outdoor

installations near salt water shorelines. Decorative

baked enamel paints are also available in a variety of

colors to match existing building fixtures. Consult your

Greenheck representative for paint selections.

Weatherhood

A galvanized steel mist eliminating intake hood

is standard on outdoor IGX-HV models. The mist

eliminating intake hood provides a double layer of

protection against moisture entering the mixing box

section.

3-Way Diffuser

Airstream Override

This option prevents the discharge air temperature

from dropping below 55°F after the call for heating has

ended.

Warm-Up Control

Available with the TC5

thermostat. The thermostat

may be programmed to

provide a warm-up cycle prior

to the occupied start time. This

ensures immediate comfort

and proper air quality as people enter the occupied

areas.

7

Page 8

Specifications

General: Heating and Ventilating unit shall be as

manufactured by Greenheck or approved equal provided

all specifications are met. Greenheck Model IGX-HV is

used as the basis of design. Performance shall be as

scheduled on plans.

Furnace: Indirect gas fired furnace shall be 80% efficient,

ETL Listed and have a blow through fan design. Furnace

shall be capable of operation with Natural or LP gas and

have a power venting system with post purge cycle. The

heat exchanger shall be constructed of aluminized steel

or stainless steel. Standard furnace features shall include

main gas pressure regulator, main gas valve, electronic

staged controls, direct spark ignition system, high limit and

a 24 volt control transformer. Furnace shall be insulated

and have double wall construction.

Temperature Control: Heating and cooling output shall

be controlled by a room thermostat to maintain desired

room temperature. Economizer control shall provide the

first stage of cooling, where specified. Furnaces shall

provide one or two stages of heat output control.

Unit Casing and Frames: All frames and panels shall

be G90 galvanized steel. Where top panels are joined

there shall be a standing seam to insure positive weather

protection. All metal-to-metal surfaces exposed to the

weather shall be sealed, requiring no caulking at job

site. All components shall be easily accessible through

removable doors.

Insulation: Models provided with a mixing box shall be

insulated from the return section through to the supply

discharge. Insulation shall be in accordance with NFPA

90A and tested to meet UL 181 erosion requirements.

Double wall shall be provided if specified.

Fan Section: Centrifugal fans shall be double width,

double inlet. Fan and motor shall be mounted on a

common base and shall be internally isolated. All blower

wheels shall be statically and dynamically balanced.

Ground and polished steel fan shafts shall be mounted in

permanently lubricated ball bearings (up to size 118) or

ball bearing pillow blocks (size 120 and larger). Bearings

shall be selected for a minimum (L10) life in excess of

100,000 hours at maximum cataloged speeds.

Motors and Drives: Motors shall be energy efficient,

complying with EPACT standards, for single speed

ODP and TE enclosures. Motors shall be permanently

lubricated, heavy duty type, matched to the fan load and

furnished at the specified voltage, phase and enclosure.

Drives shall be sized for a minimum of 150% of driven

horsepower. Pulleys shall be cast and have machined

surfaces, 10 horsepower and less shall be supplied with

an adjustable drive pulley.

Electrical: All internal electrical

components shall be prewired for

single point power connection. All

electrical components shall be UL

listed, recognized or classified where

applicable and wired in compliance

with the National Electrical Code.

Control center shall include motor

starter, control circuit fusing, control

transformer for 24 VAC circuit,

integral disconnect switch with

separate motor fusing and terminal

strip. Contactors, Class 20 adjustable

overload protection and single phase

protection shall be standard.

Filter Section: Filters shall be

mounted in a V-bank arrangement

such that velocities across the filters

do not exceed 550 feet per minute. Filters shall be easily

accessible through a removable access panel.

Weatherhood: Weatherhood shall be mist eliminating

type, constructed of G90 galvanized steel. The

weatherhood shall contain drainable blade louvers, backed

by mist eliminating filters to prevent moisture intake.

Mixing Box: Mixing box shall contain outside air and

return air dampers with low leak, pressure activated,

extruded vinyl blade seals, aluminum jamb seals, Belimo

actuator and 30% efficient pleated filters in a V-bank

arrangement. The mixing box shall modulate the amount

of outdoor and return air by use of dampers. Input signal

for return damper shall be from potentiometer, 2-10 volt

signal, 4-20 mA signal or manual quadrant controller.

Evaporative Cooling Section: Evaporative cooling

section shall include a galvanized steel housing with

louvered intake, two inch aluminum mesh filters and a

stainless steel evaporative cooling module all provided

by the make-up air unit manufacturer. The louver shall

be stationary type with drainable blades, designed to

withstand wind loads of 25 PSF and bear the AMCA seal.

Evaporative cooling media shall be Munters CELdek with

a depth of 12 inches for a cooling effectiveness of 90%.

Drain and overflow connections shall be piped through the

side of the evaporative cooling section.

Cooling Coil: Direct expansion (DX) or chilled water

coil shall be factory tested and rated in accordance with

ARI 410. Coils shall have copper tubes with permanently

expanded aluminum fins, 12 fpi or less. DX coils shall be

equipped with distributors to receive expansion valves at

the liquid connections. Drain pans shall extend at least

12 inches downstream of coil and be sloped to drain

connection.

Copyright © 2008 Greenheck Fan Corp. • IGX-HV Rev. 2 October 2008 SN

Loading...

Loading...