Page 1

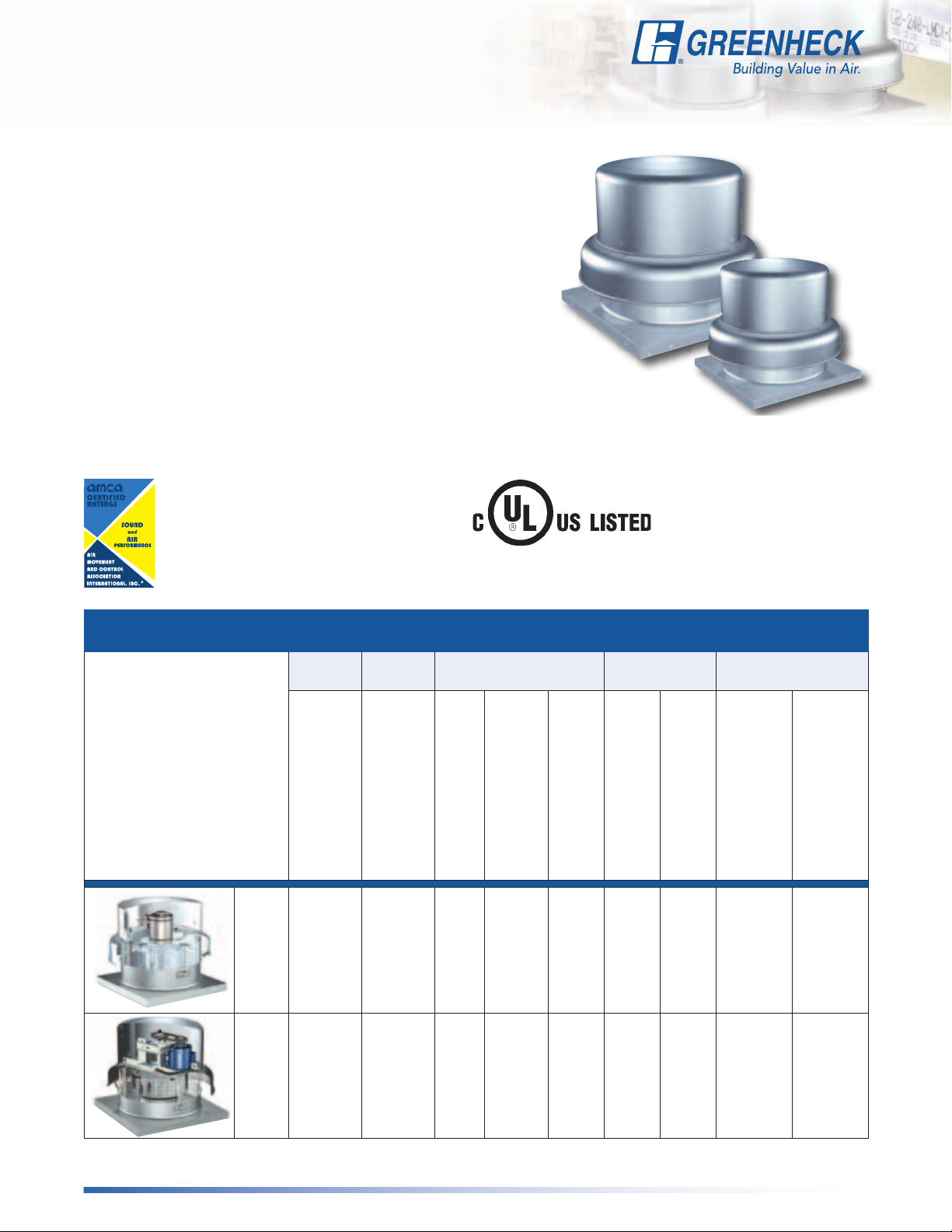

Centrifugal Roof Downblast Exhaust Fans

• General Clean Air • Light Contaminants

• Seismic • High Wind

Models G and GB

July

2009

Page 2

Centrifugal Roof Exhaust Fans

Spun Aluminum • Downblast

Greenheck models G and GB centrifugal roof exhaust fans

provide the industry’s best performance and durability for

general clean air applications.

• Broadest performance in the industry, up to 3.25 in. wg

(810 Pa) and 45,000 cfm (76,500 m3/hr).

• Most advanced motor cooling of any fan in its class.

• Performance as cataloged is assured. All fan sizes are

tested in our AMCA Accredited Laboratory, and all

models are licensed to bear the AMCA sound and air

performance seals.

• UL Listed for electrical.*

• Greenheck subjects these products to extensive life

testing, assuring you that the fans will provide years of

reliable performance.

Greenheck Fan Corporation certifies that the Models G,

and GB fans shown herein are licensed to bear the AMCA

Seal. The ratings shown are based on tests and procedures

performed in accordance with AMCA Publication 211 and

Publication 311 and comply with the requirements of the

AMCA Certified Ratings Program. The certified ratings for

Models G, and GB are shown on pages 17 to 55.

G and GB models are listed for electrical

(UL/cUL 705) File no. E40001

*UL/cUL is optional and must be specified

Model

Model Comparison

Mounting Airfl ow Application Drive Type

G

GB

Roof Curb

Exhaust

General/Clean Air

Maximum Operating

Temperature

130°F

(54°C)

180°F

(82°C)

High Wind (150 mph)

Belt

Direct

Performance

/hr)

3

Maximum Volume

cfm (m

4,300

(7,306)

44,700

(75,946)

Maximum Static

Pressure

in. wg (Pascals)

1.0

(249)

3.25

(810)

2

Page 3

Table of Contents

Model Comparison . . . . . . . . . . . . . . . . . 2

Codes & Certifications . . . . . . . . . . . . . . 4

Applications:

General Clean Air . . . . . . . . . . . . . . . . . 4

Seismic . . . . . . . . . . . . . . . . . . . . . . . . . 5

Vari-Green Motors . . . . . . . . . . . . . . . . 5

High Wind & Hurricane . . . . . . . . . . . . 6

Roof Curbs . . . . . . . . . . . . . . . . . . . . . . 7

Standard Construction Features . . . . .8-9

Options & Accessories . . . . . . . . . . .10-11

Leading Edge Technical Support

When product and IOM (Installation, Operation and Maintenance Manual)

information is needed, our products are supported by the industry’s best product

literature, electronic media, and Computer Aided Product Selection (CAPS)

program. You’ll also fi nd this information on our web site at www.greenheck.com

Typical Installations. . . . . . . . . . . . . .12-13

Severe-Duty Curbs Anchoring . . . . .14-15

Performance and Dimensions:

Model Number Code . . . . . . . . . . . . . 16

Direct Drive (by size). . . . . . . . . . . . .17-26

Belt Drive (by size) . . . . . . . . . . . . . .27-55

Typical Specifications . . . . . . . . . . . .56-59

Quick Build Programs . . . . . . . . . . . . . . 60

Warranty . . . . . . . . . . . . . . . . . . . . . . . . 60

Our national and international representative organizations provide personal service and expertise. To locate

your nearest Greenheck representative, call 715-359-6171 or visit our web site at www.greenheck.com

Outstanding Customer Service

Your local Greenheck representative has a wealth of industry and product

knowledge to answer your questions. Our representatives receive the latest

product information and can have orders processed directly

to our factory. With our direct order processing system, we

can ship orders as fast as the next day. With Greenheck’s

experienced staff, we can answer questions and provide

solutions.

World Class Manufacturing

Greenheck’s skilled production workers use cost-effective

machines and unique dies designed and built by our own engineers

to add innovative features and greater strength to our centrifugal

exhaust fans. Our advanced manufacturing processes and quality

control procedures always ensure the highest product quality. And

just to be sure you get the peace-of-mind you expect when you

specify Greenheck, our assembly inspectors test run and monitor

every fan before it leaves the factory. Results of these tests are

kept in permanent records for future reference.

3

Page 4

Codes and Certifications &

Applications: General Clean Air

Codes and Certifications

UL 705 - Power Ventilators

Intended to assure the buyer of the safety of

electrical components and connections within power

ventilators and duct fans. Limited to fans connected

to permanently installed wiring that meet NFPA 70

and the National Electric Code. Tests under this

standard relate to extremes of current, temperature,

fuses, motor windings, bearing temperatures, and

water that a fan could be subject to.

Clean Air Applications

Models G and GB

These spun aluminum fans are specifically designed

for roof mounted applications. General clean

exhaust air is discharged downward, toward the

roof surface.

• Most advanced motor cooling of any fan in

its class.

• Performance as cataloged is assured. All fan sizes

are tested in our AMCA Accredited Laboratory

and all models are licensed to bear the AMCA

Sound and Air Performance seal.

• Greenheck subjects these products to extensive

life testing, assuring you the fans will provide

many years of reliable performance.

AMCA Certied Ratings Program

Ensures that all data is accurate. The 211 test for air

performance certifies that the fan has been tested

to the appropriate AMCA standards in a licensed

test facility and that the air performance displayed

in catalogues and selection software is accurate.

The 311 test for air and sound performance certifies

that the fan has been tested to the appropriate

AMCA sound standards in a licensed facility and

that the sound performance displayed in catalogues

and selection software is accurate. AMCA Certified

Ratings Program is designed to ensure that the

products perform as stated and that a third party

organization has verified all published data for

accuracy and consistency.

Direct Drive, G

• Typically used for short and/or low

resistance ductwork

Belt Drive, GB

• Typically used for average length and/or average

resistance ductwork

• High volume/average pressure

Belt Drive, GB-HP

• Typically used for long and/or high

resistance ductwork

• Low volume/high pressure

4

Page 5

Applications:

Seismic and Vari-Green Motor

Seismic Applications

Models G and GB

The International Building Code has been adopted

on the state and local level throughout most of the

fi fty states. The adoption of this code has resulted in

the adherence of buildings, along with electrical and

mechanical components, to new previsions in the

code. In particular, there is an emphasis on seismic

compliance. As an industry leader, Greenheck

introduces the fi rst seismic compliant centrifugal

roof exhaust fan available for general clean

air applications.

Greenheck offers products certifi ed for the worst

plausible seismic event that would be found on the

IBC Spectral Response Map. Models G and GB are

rated for seismic design categories A-F, which allows

Greenheck to provide a seismic ventilation solution

regardless of the location in the country.

Rigorous Testing

• Third-party FEA (Finite Element Analysis) by

licensed Professional Engineers

• Tested in Accordance with ICC ES AC-156

acceptance criteria utilizing shake table testing

to simulate the worst case scenario.

Seattle, WA, 03/05/01 -- Damage in Pioneer Square from the

02/28 earthquake. FEMA/Photo by: Liz Roll/FEMA News Photo

State P.E. Calculations

Models have been reviewed by licensed

Professional Engineers to ensure they conform to

the requirements of ASCE 7-05 Minimum Design

Loads for Buildings and Other Structures and the

International Building Code.

How Can Greenheck Provide

a Seismic Solution?

While adhering to rigorous testing standards,

Greenheck Fan Corporation is striving to provide a

comprehensive selection of equipment to address

the HVAC industry’s seismic needs. The offerings

cover all soil site classes. For the simplifi cation of the

submittal process, the consulting engineer simply

needs to specify seismic compliant equipment.

Vari-Green Motor

Applications

Model G available in sizes 080 thru 131

The Greenheck Vari-Green motor blends technology,

controllability and energy-effi ciency into a low

maintenance package changing the way the

industry designs, specifi es and operates air

movement equipment.

The Vari-Green motor is the industry’s fi rst fully

controllable fractional horsepower (hp) motor

available in 1/4 hp, 1/2 hp and 3/4 hp. The VariGreen motor is cost-effective with less than one-year

payback. The motor is available with a potentiometer

speed control dial mounted right on the motor to

make system balancing a breeze. It can also be

provided with 0-10 volt control wire inputs for easy

integration into a Building Automation System (BAS)

or any controller that can output a 0-10 volt signal.

Greenheck is leading the charge in the LEED and

Green Building initiative. Greenheck became one

of the fi rst manufacturers in the Air Movement and

Control industry to join the LEED/green movement

when they joined the United States

Green Building Council (USGBC) in

2005. Greenheck has been actively

researching qualifi cation requirements

for our products to

meet LEED credits

and prerequisites.

The Vari-Green

motor signifi cantly

helps qualifi cation

efforts for the

Energy and

Atmosphere credits

and prerequisites;

specifi cally credit one, Optimize Energy Performance

and prerequisite two, Minimum Energy Performance.

For more detailed information refer to the Vari-Green

Motor brochure.

5

Page 6

Applications:

High Wind and Hurricane

High Wind and Hurricane

Models G and GB

Greenheck is leading the High Wind Standard for roof top fans and ventilators.

Forceful winds and wind-borne debris are the cause of most hurricane damage.

Hurricane winds start at 75mph. At speeds over 150mph, wind can exert a

force of 75poundspersquarefoot of pressure or over 900pounds on a fan and

curb. Forceful winds are not the only problem, wind-borne debris can also cause

detrimental effects to objects and structures. High winds and extreme forces are

the cause of most storm damage. By analyzing calculations, computer simulations,

actual testing, and other standards—Greenheck developed the High Wind Standard.

Protocols designed to protect against wind-borne debris and severe wind loads:

Structural

Performance Load

Miami-Dade

County Test

Protocols

Miami-Dade NOA

Numbers

Texas Department

of Insurance

State Licensed

P.E. Calculations

Certified

Independent

Third-Party

Testing

A static load that is 1.5times the design load (91.5 pounds per square foot of pressure)

is applied both positively and negatively to simulate wind force loads in each direction.

Structural Performance per Dade County Protocol TAS-202 (ASTM-E330).

Greenheck has gone the extra mile and worked with Miami-Dade County to design

a High Velocity Hurricane Zone standard for rooftop fans. The model USGF has

become the first rooftop fan certified and approved by the Miami-Dade Building Code

Compliance office and Texas Department of Insurance for use in hurricane zones.

The certifications can be viewed on the Miami-Dade County Web site under the NOA

numbers listed below. Models G and GB are the first downblast aluminum fans in the

industry that have received a Miami-Dade NOA for high wind (150 mph) and hurricane

zones. Miami-Dade NOA 08-0519.02 for models G and GB.

The certifications can be viewed on the Texas Department of Insurance Windstorm

Web site under TDInumberRV-42.

Structural calculations performed by a licensed Professional Engineer (P.E.) on models

G and GB include Finite Element Analysis (FEA) and a stamped P.E. report of the fans

compliance to ASCE 7-02 Minimum Design Loads for Buildings and Other Structures

Standard and the Florida Building Code. The ASCE 7-02 Standard meets the IBC,

Florida and Miami-Dade codes. The models have been proven to withstand winds in

excess of 150 mph (61 psf).

Each of the Greenheck models have been subjected to extensive testing procedures.

The G and GB have been certified by an independent third party to the ASTM E-330

Static Pressure Difference Standard, Florida Building Code Test Protocol

TAS-201 (large missile impact), 202 (static pressure difference) and 203 (cyclic

pressure) Static Pressure Difference.

Computational

Fluid Dynamics

(CFD)

Finite Element

Analysis (FEA)

6

All Greenheck high wind models have been analyzed using Computational Fluid

Dynamics (CFD). CFD is computer software designed to simulate the flow of high

speed (150 mph) winds over the surface of objects. The software records the force

profile exerted on the fan so it can be utilized in Finite Element Analysis (FEA).

Utilizing the results from CFD analysis Greenheck can

accurately predict the stress, strain, and deflection resulting

from high wind loads. Greenheck high wind units have been

proven to withstand 150 mph winds through Finite Element

Analysis utilizing CFD results.

Page 7

Applications: Severe-Duty Roof Curbs

for High Wind and Hurricane

High-wind and severe-duty roof curbs are provided

as standard with models G and GB. The severe-duty

roof curb models can ship separately to allow

for final finishing of the roof prior to the fan

arrival and installation.

Model GPF — This roof curb is specifically

designed for high wind applications up to 150 mph

(61 psf), used on fan models G and GB. Standard

height is 12inches (305mm), fully-welded straight

sides with a 5-inch flashing flange. GPF is available

up to 24inches (460mm) in height to meet greater

height requirements.

Models SD and SDP — The severe-duty curbs

are specifically designed for high wind applications

up to 150mph and used on models G and GB fans.

Model SD is for use on flat roofs and model SDP

for pitched roofs. They are attached directly to the

building structure with extremely high structural

design load requirements. Maximum design load is

130psf. The severe-duty curbs are 12gauge

coated steel with a 13⁄4-inch lip on the top and a

4-inch flange on the bottom. Available heights

include 12–24inches. Heights greater than

18inches are reinforced in the interior with

12gauge x 2-inch angles.

Mounting details for the roof curb to the roof

substrate and the fan to the curb are illustrated

on the following pages and are included with each

model G and GB installation manual.

7

Page 8

Standard Construction

Features

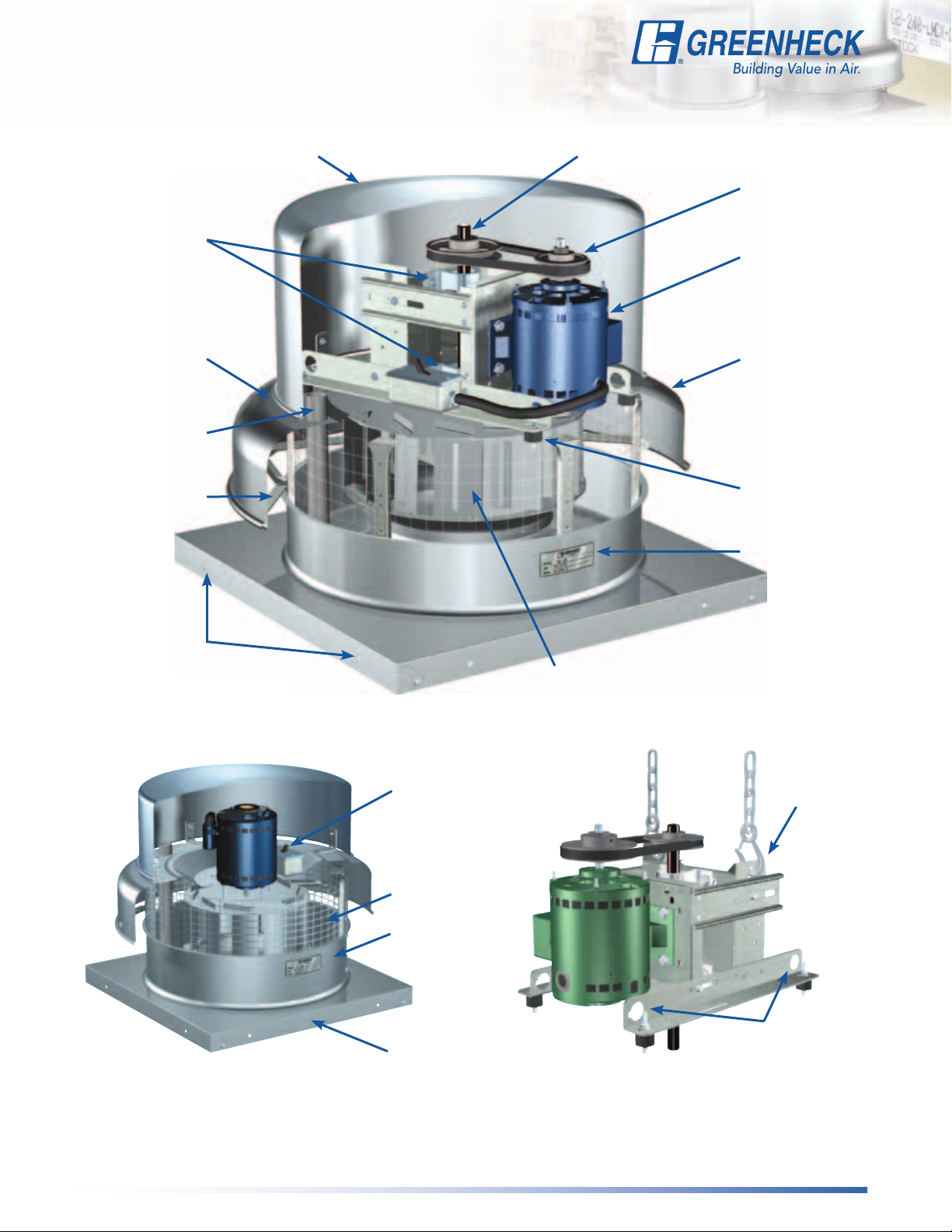

Standard Construction Features

An aluminum, backward-inclined, non-overloading centrifugal wheel is utilized to generate

Wheel

Disconnect

Switch

Fan Shaft

Bearings

Motor Carefully matched to the fan load and is mounted out of the airstream.

Motor Cover

Motor Cooling

Lifting Points Various lifting points are located on the drive frame and bearing plate (on select sizes).

True Vibration

Isolation

Drive Assembly

high-efficiency and minimal sound. Wheel cones are carefully matched to the venturi

for maximum efficiency. Each wheel is robotically welded and statically and dynamically

balanced for long life and quiet operation.

NEMA-1 switch is factory mounted and wiring is provided from the motor as standard

(other switches are available). All wiring and electrical components comply with the

National Electric Code (NEC) and are either UL Listed or Recognized.

Precisely sized, ground and polished so the first critical speed is at least 25% over

the maximum operating speed. Where the shaft makes contact with bearings, close

tolerances result in longer bearing life.

100% factory tested and designed specifically for air handling applications with a

minimum L

Constructed of aluminum, machine-punched, and attached with stainless steel hardware

for easy removal and access to motor compartment and drive assembly.

Cooling fins located on top of the fan wheel draw outside air through a large space

between the fan shroud and the motor cover directly into the motor compartment.

Positive motor cooling with fresh air results in maximum motor life.

Vibration isolators, with no metal-to-metal contact, support the drive assembly and wheel

for long life and quiet operation.

Belts, pulleys, and keys are oversized 150% of driven horsepower. Machined cast pulleys

are adjustable for final system balancing. Belts are static-free and oil-resistant.

life in excess of 100,000 hours (L 50 life of 500,000 hours).

10

G and GB

Lower Windband

Curb Cap

Internal Conduit

Chase

Nameplate Permanent stamped aluminum plate for exact model and serial number identification.

Galvanized

Birdscreen

Fan Shroud

Mounting Holes Curb cap has prepunched mounting holes to ensure correct attachment to the roof.

Internal Supports

Roof Curb

Applicable to fans with high wind option only.

*

Heavy-gauge aluminum with formed edges for added strength and provides

weather resistance.

Curb cap (with integral deep spun venturi) is constructed of aluminum and is one-piece for a

weather-tight fit.

A large diameter conduit for installing electrical wiring through the curb cap into the

motor compartment.

Rigid wire protects the fan discharge from birds and small objects.

One-piece, heavy-gauge aluminum with a rolled bead for extra strength directs exhaust

air downward.

Heavy-gauge supports and bracing are added for additional strength to withstand

a wind of 150 mph (61 psf

High-wind load fans are certified with one of two Greenheck high-wind roof curbs.

Standard 12-inch (305 mm) in height GPF curb has a 5-inch (127 mm) flashing flange. Roof

curbs ship separate for field installation with attachment details provided.

).

*

*

8

Page 9

Standard Construction Features

Models G and GB

Bearings

Motor Cooling

Space

Conduit Chase

Shroud Brace

Motor Cover

Fan Shaft

Drive Assembly

Motor

Fan Shroud

True Vibration

Isolators

Nameplate

Mounting Holes

Disconnect

Switch

Birdscreen

Lower

Windband

Curb Cap

Wheel

Bearing Plate

Lifting Points

Drive Frame

Lifting Points

9

Page 10

Options and

Accessories

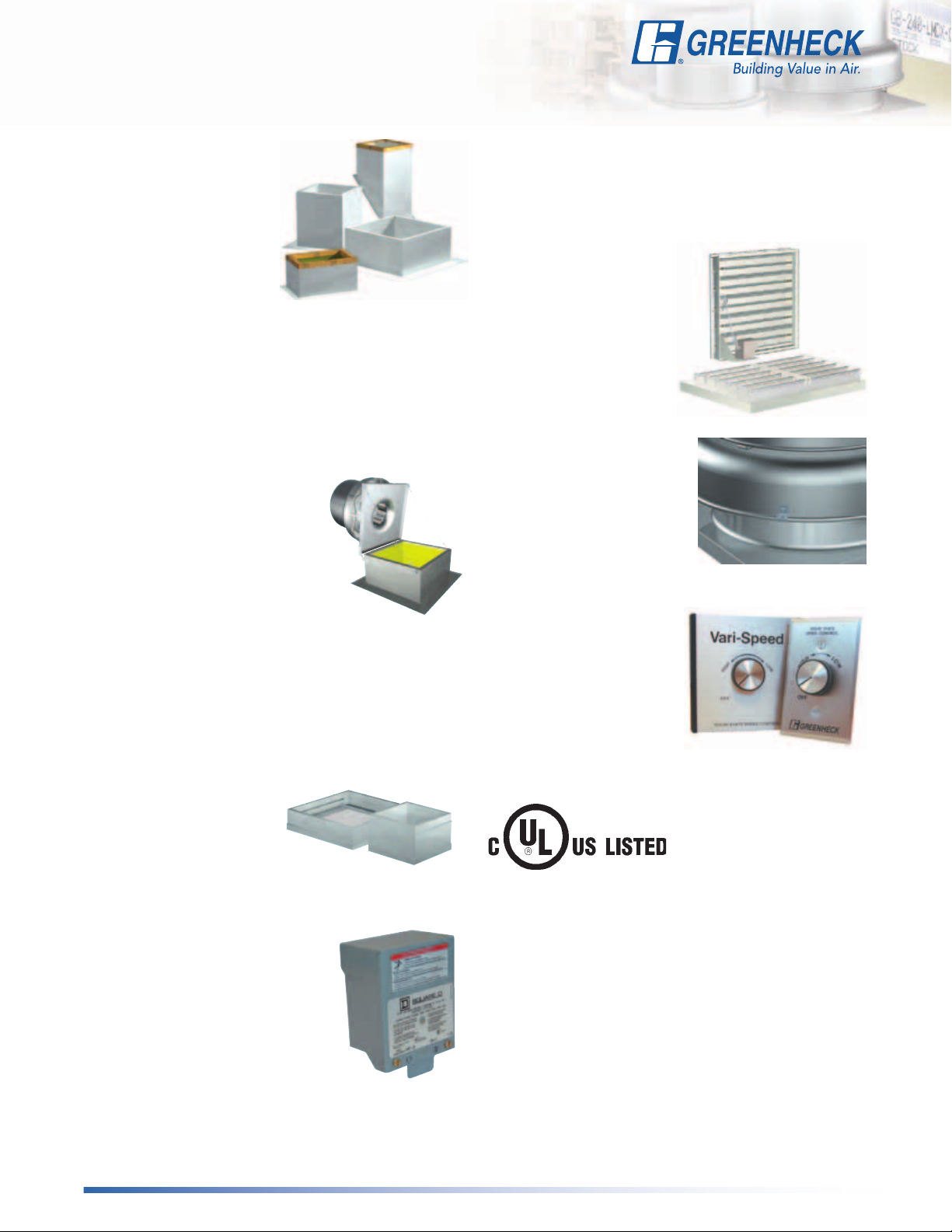

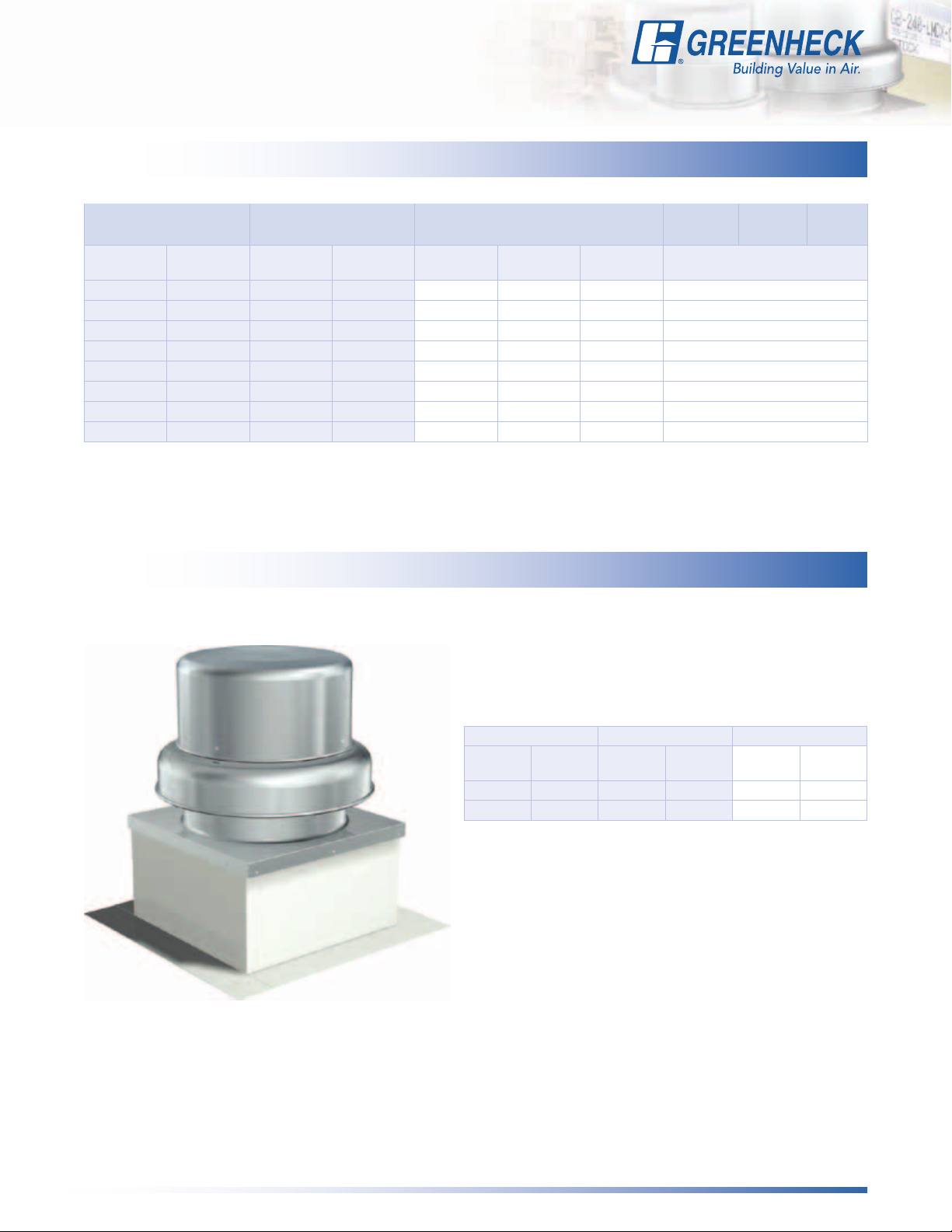

Roof Curbs

Prefabricated roof curbs

reduce installation time

and costs by ensuring

compatibility between

the fan, the curb and roof

opening. All curbs are

insulated with fiberglass.

A wide variety of roof

curbs are available, including: flanged, pitched and

sound-absorbing. For more information on severeduty curbs refer to the information on page 7.

Hinged Curb Cap with Cables (Field Installed)

Mounted to the curb cap, allows entire fan to tilt

away from curb for access to wheel and ductwork.

Includes restraint cables.

Hinged Base (Factory Mounted)

Allows for easy maintenance.

Hinge and restraining cables are

factory mounted to a subbase

attached directly to curb without

additional height added.

Curb Seal

Rubber seal between fan and curb to assure proper

sealing when attached to a curb.

Curb Extensions

Extensions raise the fan discharge above the roofline

and provide an accessible mounting location for

dampers. Insect screen

bases, constructed with

a removable fine mesh,

are recommended for

applications where insect

entry must be prevented.

Disconnect Switches

A wide selection of NEMA rated

switches are available for positive

electrical shutoff and safety,

including: dust-tight, rainproof,

and corrosion-resistant.

Switches may be internally

or externally mounted.

Birdscreen

Galvanized mesh is standard,

optional aluminum or stainless steel rigid wire

are also available.

Dampers

Designed to prevent

outside air from entering

back into the building

when fan is off. Includes

gravity and motorized

dampers. Damper sizes

are shown on each

performance data page.

Tie-Down Points

Four brackets located on

the shroud for securing

the fan in high wind

applications. Cables and

anchors by others.

Speed Controllers

Available for use with

shaded pole and

permanent split capacitor

(PSC) open motors on

model G fans. They provide

an economical means of

system balancing with

direct drive fans.

UL/cUL 705

G and GB models are listed for electrical

(UL/cUL 705) File no. E40001

*UL/cUL is optional and must be specified

10

Page 11

Options and

Accessories

Coatings

A wide variety of coatings and colors are available. Greenheck

coatings and resistance charts can be found in the Performance

Coatings Commercial and Industrial Fans catalog and in our Product

Application Guide—Performance Coatings for Ventilation Products.

PRIMER

PERMATECTOR

HI-PRO

POLYESTER

The chart below shows which options and accessories are available on

Greenheck’s centrifugal roof exhaust fans.

Primer is applied at the factory to allow for final finish

in the field.

Permatector™ is our standard coating. Typically used for

TM

applications that require corrosion resistance in indoor

and outdoor environments.

Hi-Pro Polyester is resistant to salt water, chemical fumes

and moisture in more corrosive atmospheres. Typically

used for applications that require superior chemical

resistance, excellent abrasion and outdoor UV protection.

This coating exceeds protective qualities of Air Dried

Heresite and Air Dry Phenolic.

Baked Enamel Decorative Coatings are heat cured

enamels applied either as wet paints or electrostatic

powders. Customers can choose from 16 standard

decorative colors or color match any color.

Options and Accessories

Roof Curbs

Hinged Curb Cap

Hinged Base

Curb Seal

Curb Extensions

Disconnect Switches

Birdscreen

Dampers

Tie-Down Points

Speed Controllers

UL 705

Coatings

Not available on units with high wind resistant construction.

*

G GB

* *

11

Page 12

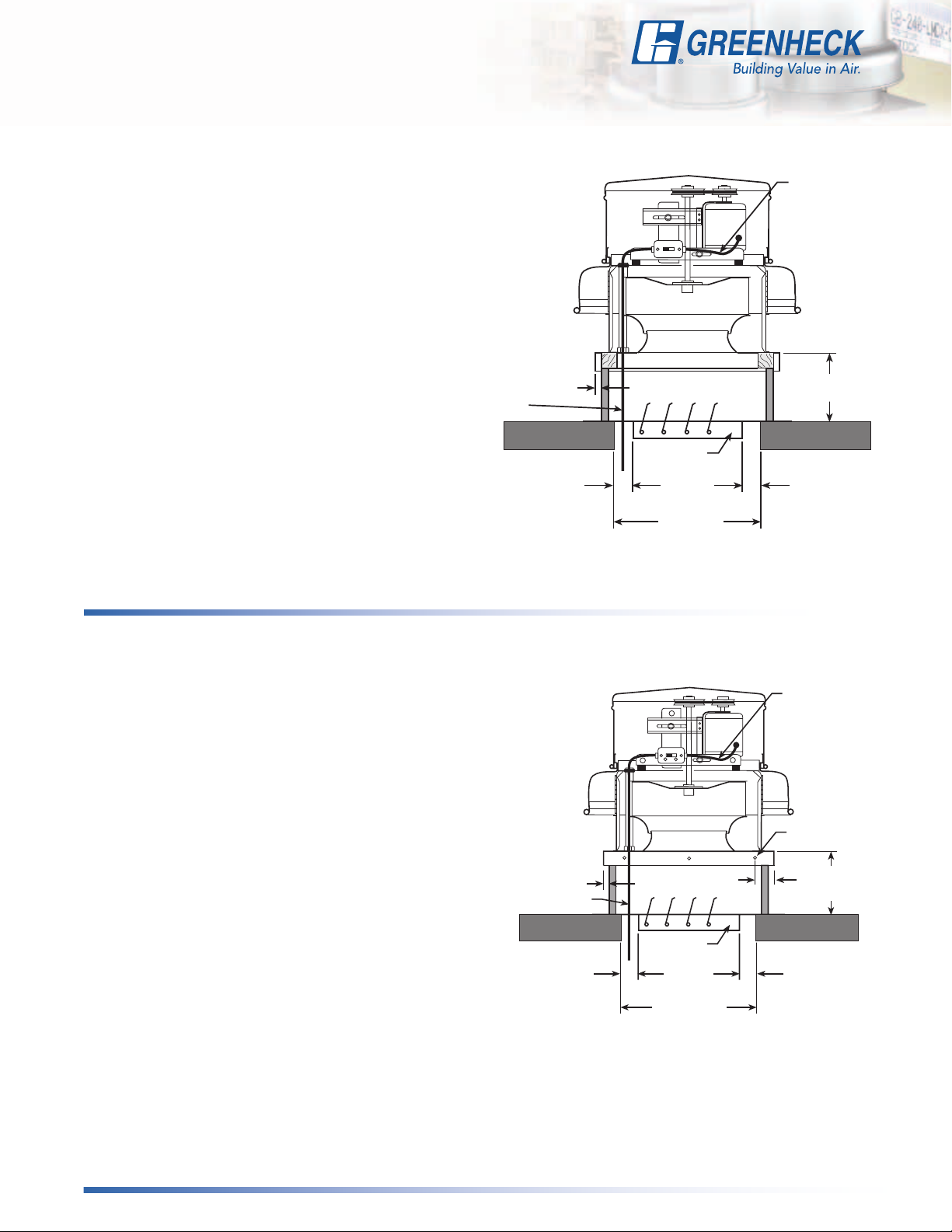

Typical

Installations

General Clean Air

Models G and GB exhaust fans are designed to meet

the needs of general clean air applications. Tests were

conducted to assure safe, rugged and reliable fans.

Due to the varying types of airstreams encountered

in commercial ventilation, system designers must

be aware of national, state, and local codes and

guidelines governing these installations. Local code

authorities should be consulted before proceeding

with any ventilation project.

• When roofing materials extend to the top of the

curb, roof curbs should be 1½ inches (3/4 inch on

each side) less than the unit curb cap to allow for

roofing and flashing.

• For recommended duct size, damper size, and

roof opening dimensions, refer to the performance

data pages.

• Installation must include a means for inspecting,

cleaning and servicing the exhaust fan.

Wiring by

Others

3/4 in.

(19 mm)

1

1

/4 in.

(32 mm)

Damper

Recommended

Duct and

Damper Size

Recommended

Roof Opening

Factory Wired

from Motor to

Disconnect

8 or 12 in.

(203 or 305 mm)

1

1

/4 in.

(32 mm)

High Wind and Hurricane Option

Models G and GB exhaust fans are designed to meet

the needs of general clean air applications. Tests were

conducted to assure safe, rugged and reliable fans.

Due to the varying airstreams encountered in commercial

ventilation, system designers must be aware of national,

state, and local codes and guidelines governing these

installations. Local code authorities should be consulted

before proceeding with any ventilation project.

• Roofing materials can extend to the top of the curb,

roof curbs should be 1-inch (25 mm) total, or 1/2inch

(13 mm) on each side, less than the unit curb cap to

allow for roofing and flashing.

• For recommended duct size, damper size and roof

opening dimensions, refer to the performance

data pages.

• Installation must include a means for inspecting,

cleaning and servicing the exhaust fan.

• See pages 14 and 15 for specific mounting instructions

1/2 in. (13 mm)

Wiring by

Others

1

1

/4 in. (32 mm)

Models G & GB

4 in. (102 mm)

From Curb Edge

Damper

Recommended

Duct and

Damper Size

Recommended

Roof Opening

Factory Wired

from Motor to

Disconnect

1/4 in. (6 mm)

Fastener

8 - 24 in.

(203 - 610 mm)

H-GPF or SD Curb

1

1

/4 in. (32 mm)

Models G & GB

Note: The typical installations shown above are recommendations based on national codes. Local authority may supersede these recommendations.

12

Page 13

Typical

Good

Poor

Counterclockwise

Airflow

Installations

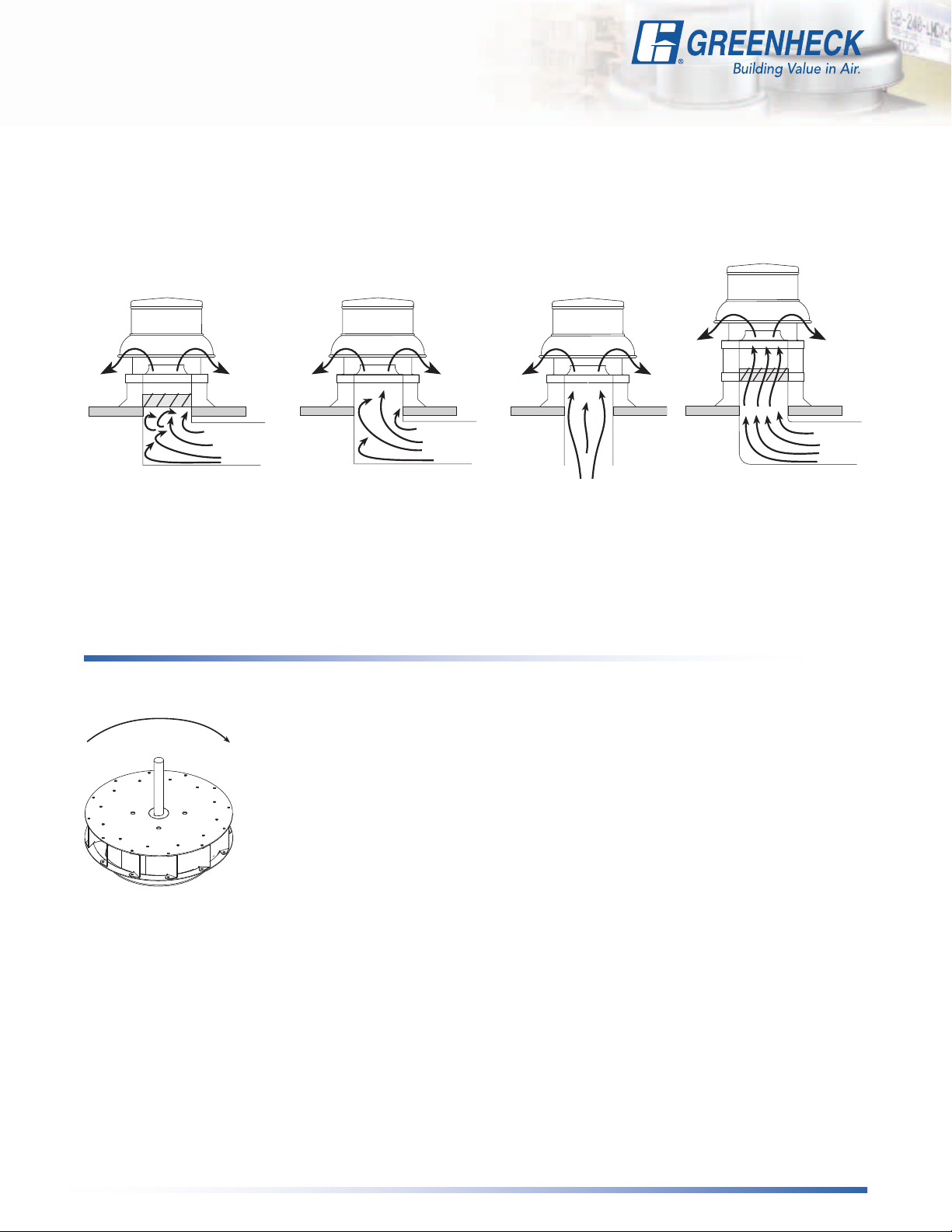

Fan Inlet Connections

In order to assure proper fan performance, caution must be exercised in fan placement and connection to

the ventilation system. Obstructions, transitions, poorly designed elbows, improperly selected dampers, etc.,

can cause reduced performance, excessive noise, and increased mechanical stress. For performance to be

as published, the system must provide uniform and stable airflow into the fan.

Good

Poor

Dampers must open

fully. Use motorized

dampers in low

airflow applications

to reduce losses.

Wheel Rotation

Direction of rotation is very critical. Rotation in the wrong

direction will result in excessive horsepower, possible motor

burnout, and increased noise levels. Check rotation by

energizing the unit only momentarily. The rotation should

be the same as the rotation decals affixed to the unit and is

clockwise when viewed from the top of the unit.

Poor

Avoid sharp turns or

entrance conditions

which cause uneven

flow. Use turning vanes

in elbows to reduce

adverse effects.

Good

Provide uniform

airflow at fan inlet

to assure optimum

performance.

Provide uniform airflow

at fan inlet and through

the damper to assure

optimum performance.

Clockwise

13

Page 14

Severe-Duty Curbs Anchoring:

Hurricane and Seismic Fans

Concrete Deck Anchoring

Outside of Roof Curb

1 inch (25 mm) less

than Fan Curb Cap

8 to 24 inches (203 to 610 mm)

GPF, SD, or SDP curb or

equivalent by others.

Minimum concrete

strength of 2000 PSI

Minimum 5 inches

(127 mm) edge distance

1-inch (25 mm) insulation

Roof opening

5 inches (127 mm)

Mounting flange

Outside flange

Use 3/8 inch (10 mm) expansion anchor or

equal into concrete.

Fasteners one on each corner as detailed.

Each side at center of unit as required.

1

2

⁄2 inches (64 mm)

Minimum embedment

Center fasteners

on flange

1¼ inch

(32 mm)

1¼ inch

(32 mm)

Wood support member

nominal 4 x 4, 6, 8

14

Metal Building/Steel Deck Anchoring

Outside of Roof Curb

1 inch (25 mm) less

than Fan Curb Cap

8 to 24 inches (203 to 610 mm)

GPF, SD, or SDP curb or

equivalent by others.

Roof Truss

1-inch (25 mm) insulation

Roof opening

Minimum 12 gauge steel

5 inches (127 mm)

Mounting flange

Outside flange

Wood Deck Anchoring

Outside of Roof Curb

1 inch (25 mm) less than

Fan Curb Cap

8 to 24 inches (203 to 610 mm)

GPF, SD, or SDP curb or

equivalent by others.

Wood decking

1-inch (25 mm) insulation

Roof opening

5 inches (127 mm)

Mounting flange

Outside flange

Use 1/4-14 self-drilling screws or equal.

Fasteners one on each corner as detailed.

Each side at center of unit as required.

Corrugated roof deck

Center fasteners

on flange

Use 3/8 inch lag screws or equal into

minimum No. 1/No. 2 southern pine

wood support.

Fasteners one on each corner as detailed.

Each side at center of unit as required.

3 inches (76 mm)

Minimum embedment

Center fasteners

on flange

Corner Detail for

all Severe Duty

Deck Anchoring

Page 15

Severe-Duty Curbs Anchoring:

Hurricane and Seismic Fans

Required Severe Duty Curb to Roof Anchoring

Seismic Hurricane Square Dimensions Concrete

G

Size

060 - 075 060 - 075 17

080 - 095 080 - 095 17(432) 12 (318) 26 (660) 2

101 - 121 071 - 131 101 - 121 071 - 131 19 (483) 14 (368) 28 (711) 2

131 - 141 141 - 161 131 - 141 141 - 161 22 (559) 18 (470) 31 (787) 3

150 150 26 (660) 18 (470) 35 (889) 3

160 - 180 180 - 200 160 - 180 180 - 200 30 (762) 20 (521) 39 (991) 3

All dimensions in inches (millimeters). *The outside ange dimension above is for the GPF curbs. Subtract 2 inches (51 mm) if the SD or SDP Curb is being used.

GB

Size

220 - 240 220 - 240 34 (864) 26 (673) 43 (1092) 3

260 - 540 260 - 300 40 (1016) 32 (826) 49 (1245) 3

G

Size

GB

Size

Fan

Curb Cap

(432) 10 (267) 26 (660) 2

Roof

Opening

Outside

Flange

Metal/

Steel

Fasteners Per Side

Required Severe Duty Fan to Curb Mounting

Models G & GB

Wood

5/16 inch (8 mm) recommended 1/4-inch fastener minimum.

Fastener quantities listed below.

Seismic Hurricane Fasteners

G

Size

060 - 141 071 - 161 060 - 141 071 - 161 3 12

150 - 180 180 - 540 150-180 180 - 300 5 20

Fasteners on each side of the fan are to be installed with one fastener

4 inches

remaining fasteners are to be equally spaced.

GB

Size

(102 mm) from each edge and one fastener centered. The

G

Size

GB

Size

Fasteners

Per Side

Total

Fasteners

15

Page 16

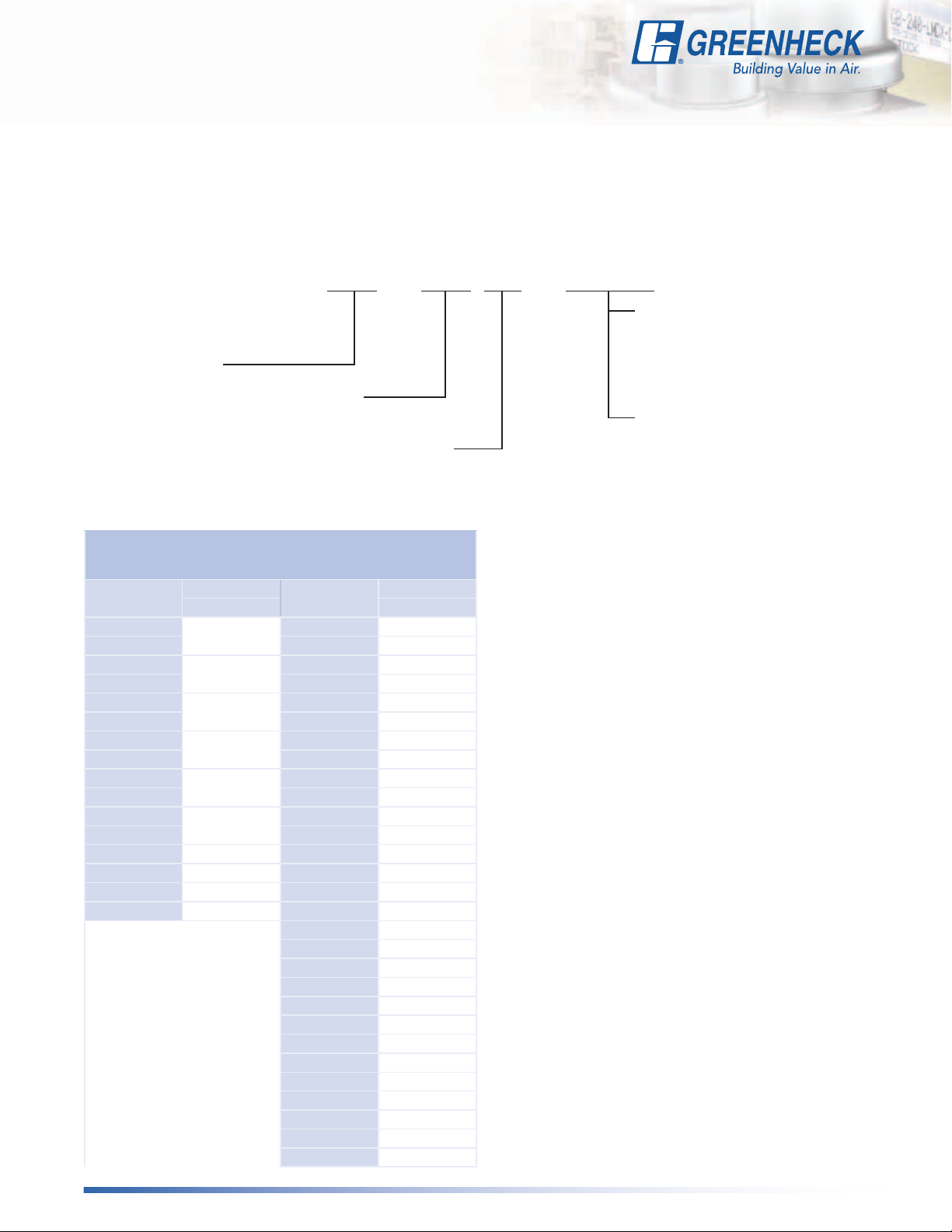

Model Number Code

The model number code system is designed to completely identify the fan. The correct code letters

must be specified to designate belt or direct drive. The remainder of the model code is determined by

the size and performance.

GB - 240 HP - 5 or A

Motor HP (Belt Drive only)

6 = 1/6 10 = 1 50 = 5

4 = 1/4 15 = 1½ 75 = 7½

Configuration

G - Direct Drive

GB - Belt Drive

Fan Size

060 through 540

Wheel Pressure Level

HP - High Pressure

3 = 1/3 20 = 2 100 = 10

5 = 1/2 30 = 3 150 = 15

7 = 3/4

Motor RPM (Direct Drive only)

A = 1725 D = 1550

B = 1140 E = 1050

C = 860 G = 1300

Performance & Dimension

Page Number by Model Size

Size

060

065 081 p. 28

070

075 101 p. 30

080

085 121 p. 32

090

095 141 p. 34

101

121 161 p. 36

131

141 180 p. 38

150 p. 23 180HP p. 39

160 p. 24 200 p. 40

170 p. 25 200HP p. 41

180 p. 26 220 p. 42

Direct Drive

G GB

p. 17

p. 18

p. 19

p. 20

p. 21

p. 22

Size

071 p. 27

091 p. 29

101HP p. 31

131 p. 33

141HP p. 35

161HP p. 37

220HP p. 43

240 p. 44

240HP p. 45

260 p. 46

300 p. 47

300HP p. 48

330 p. 49

360 p. 50

360HP p. 51

420 p. 52

480 p. 53

500 p. 54

540 p. 55

Belt Drive

16

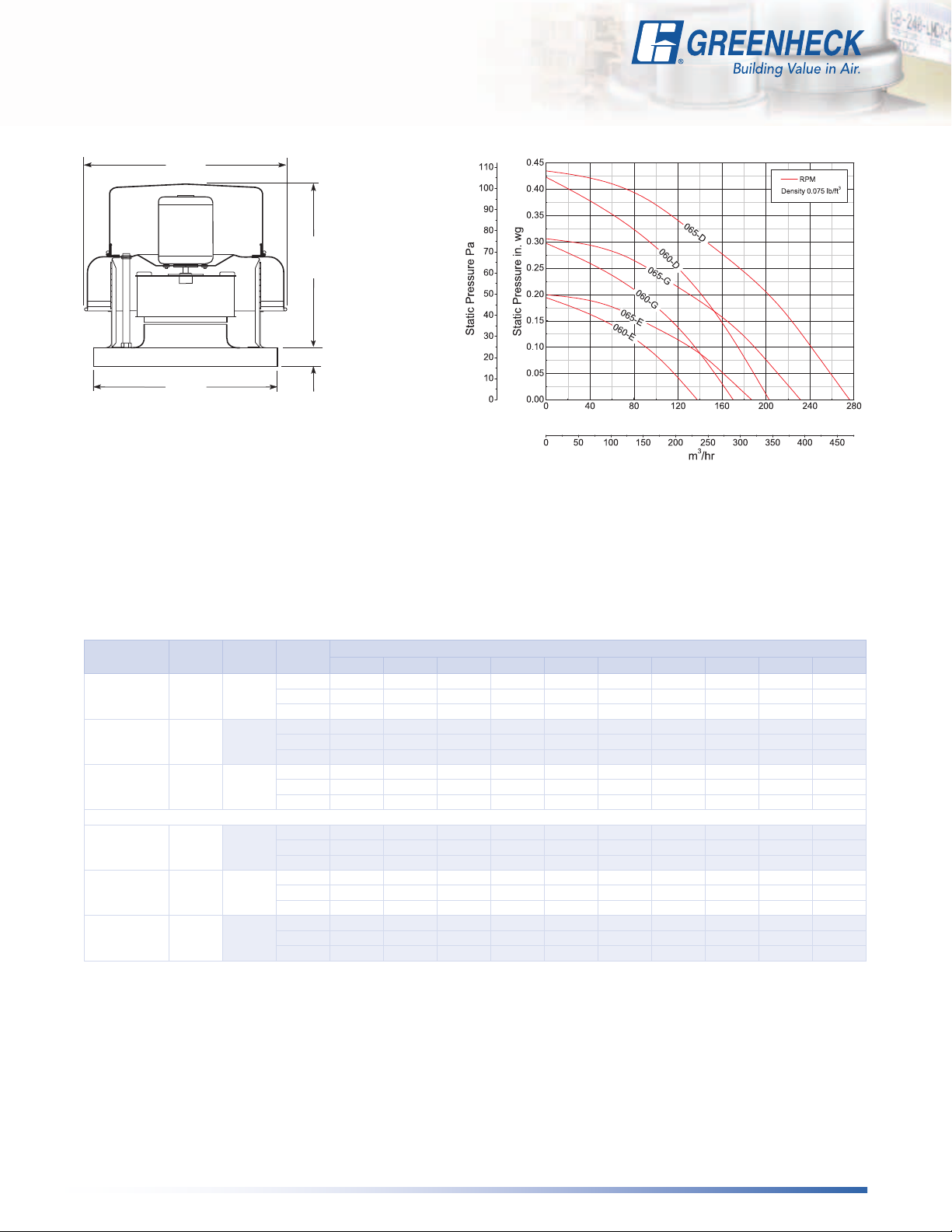

Page 17

Roof Downblast - Direct Drive

G-060 and G-065

193⁄8

(492)

*121⁄8

(308)

13⁄4 (44)

17

(432)

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 20 x 20 (521 x 521)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

cfm

Model

Number

060-E 1/200 1050

060-G 1/100 1300

060-D 1/60 1550

065-E 1/100 1050

065-G 1/60 1300

065-D 1/30 1550

Motor HPFan

RPM

Static Pressure in Inches wg

0 0.05 0.1 0.125 0.15 0.2 0.25 0.3 0.375 0.4

CFM 138 116 90 73 53

BHP 0.00 0.00 0.01 0.01 0.01

Sones 1.7 1.7 1.7 1.7 1.7

CFM 170 153 135 125 113 85

BHP 0.01 0.01 0.01 0.01 0.01 0.01

Sones 2.9 2.8 2.8 2.7 2.7 2.6

CFM 203 188 173 166 158 140 120 92

BHP 0.01 0.01 0.01 0.01 0.02 0.02 0.02 0.2

Sones 4.2 3.9 3.8 3.8 3.8 3.7 3.7 3.6

CFM 187 161 130 110 87

BHP 0.01 0.01 0.01 0.01 0.01

Sones 2.2 2.1 1.9 1.8 1.7

CFM 231 211 189 178 163 130 92

BHP 0.01 0.01 0.01 0.01 0.01 0.01 0.01

Sones 3.2 3.1 3.0 2.9 2.9 2.8 2.7

CFM 276 259 241 232 223 201 176 145 96

BHP 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02

Sones 4.9 4.6 4.5 4.5 4.4 4.3 4.3 4.1 4.0

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

17

Page 18

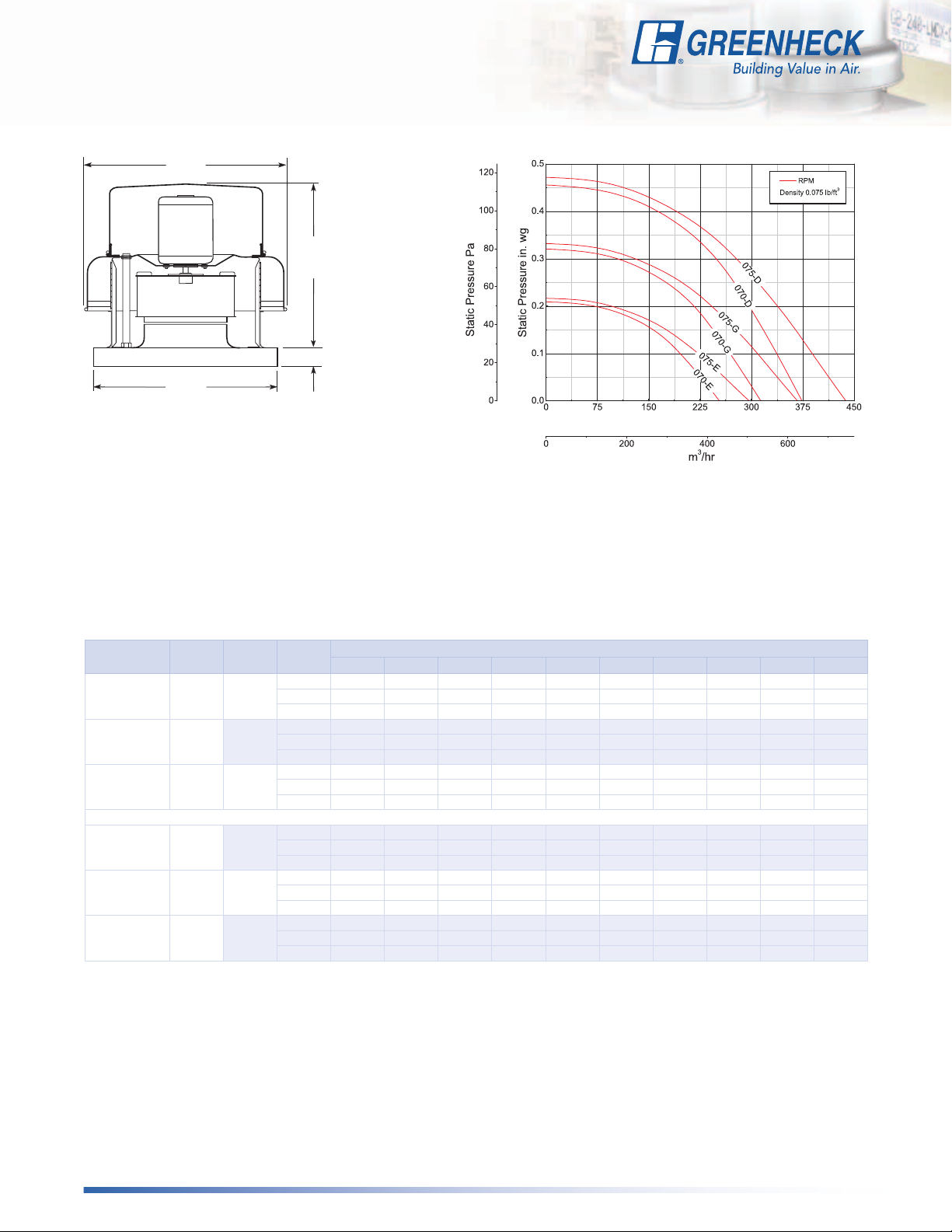

Roof Downblast - Direct Drive

G-070 and G-075

193⁄8

(492)

*121⁄8

(308)

13⁄4 (44)

17

(432)

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 20 x 20 (521 x 521)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

cfm

Model

Number

070-E 1/100 1050

070-G 1/60 1300

070-D 1/30 1550

075-E 1/80 1050

075-G 1/50 1300

075-D 1/25 1550

Motor HPFan

RPM

Static Pressure in Inches wg

0 0.05 0.1 0.125 0.15 0.2 0.25 0.3 0.375 0.4

CFM 253 226 195 179 152

BHP 0.01 0.01 0.01 0.01 0.01

Sones 2.7 2.1 1.7 1.5 1.2

CFM 314 292 269 2557 244 214 171

BHP 0.01 0.1 0.02 0.02 0.02 0.02 0.02

Sones 4.1 3.7 3.4 3.3 3.2 2.9 2.6

CFM 374 356 337 327 317 297 274 244 190

BHP 0.02 0.02 0.02 0.03 0.03 0.03 0.03 0.03 0.03

Sones 5.6 5.4 5.2 5.2 5.1 4.9 4.7 4.5 4.1

CFM 297 260 222 200 176

BHP 0.01 0.01 0.01 0.01 0.01

Sones 3.6 3.1 2.9 2.8 2.6

CFM 367 338 309 293 277 241 195

BHP 0.02 0.02 0.02 0.02 0.02 0.02 0.02

Sones 4.1 3.9 3.7 3.7 3.7 3.6 3.5

CFM 438 413 389 377 364 337 309 277 214

BHP 0.03 0.03 0.3 0.04 0.04 0.04 0.04 0.04 0.03

Sones 6.1 5.8 5.6 5.4 5.3 5.1 4.9 4.9 4.8

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

18

Page 19

Roof Downblast - Direct Drive

G-080 and G-085

213⁄4

(552)

*145⁄8

(371)

13⁄4 (44)

17

(432)

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 20 x 20 (521 x 521)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

cfm

Model

Number

080-E 1/40 1050

080-G 1/30 1300

080-D 1/20 1550

085-E 1/40 1050

085-G 1/30 1300

085-D 1/20 1550

Motor HPFan

RPM

Static Pressure in Inches wg

0 0.1 0.125 0.15 0.2 0.25 0.3 0.375 0.5 0.625

CFM 335 268 249 230 189 134

BHP 0.01 0.02 0.02 0.02 0.02 0.02

Sones 3.8 3.7 3.6 3.7 3.9 4.2

CFM 415 361 348 333 303 272 239 174

BHP 0.02 0.03 0.03 0.03 0.03 0.03 0.03 0.03

Sones 5.4 5.4 5.4 5.4 5.4 5.5 5.6 5.9

CFM 495 450 439 427 404 379 354 314 237

BHP 0.04 0.04 0.04 0.05 0.05 0.05 0.05 0.06 0.6

Sones 7.3 7.3 7.3 7.3 7.3 7.2 7.3 7.3 7.6

CFM 398 326 307 286 240 179

BHP 0.01 0.02 0.02 0.02 0.02 0.02

Sones 4.0 3.9 3.9 3.9 4.1 4.3

CFM 493 436 420 405 375 340 302 233

BHP 0.02 0.03 0.03 0.03 0.03 0.04 0.04 0.04

Sones 5.5 5.3 5.3 5.3 5.3 5.3 5.4 5.5

CFM 588 541 528 515 490 464 439 394 308 168

BHP 0.04 0.04 0.05 0.05 0.05 0.05 0.06 0.06 0.06 0.06

Sones 7.6 7.4 7.4 7.4 7.4 7.4 7.4 7.4 7.6 8.1

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

19

Page 20

Roof Downblast - Direct Drive

G-090 and G-095

213⁄4

(552)

*145⁄8

(371)

13⁄4 (44)

17

(432)

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 20 x 20 (521 x 521)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

cfm

Model

Number

090-E 1/40 1050

090-G 1/25 1300

090-D 1/15 1550

095-E 1/30 1050

095-G 1/12 1300

095-D 1/8 1550

Motor HPFan

RPM

Static Pressure in Inches wg

0 0.1 0.125 0.15 0.2 0.25 0.3 0.375 0.5 0.625

CFM 520 441 420 398 351 293

BHP 0.01 0.02 0.02 0.02 0.02 0.02

Sones 4.0 3.9 3.9 4.0 4.1 4.2

CFM 644 580 565 549 515 478 440 373

BHP 0.03 0.03 0.04 0.04 0.04 0.04 0.04 0.05

Sones 5.4 5.4 5.4 5.4 5.4 5.5 5.5 5.6

CFM 768 714 701 688 662 633 605 557 473 338

BHP 0.05 0.05 0.06 0.06 0.06 0.06 0.07 0.07 0.08 0.07

Sones 7.6 7.5 7.5 7.5 7.5 7.4 7.4 7.4 7.4 7.8

CFM 717 606 570 534 468 389 290

BHP 0.03 0.03 0.04 0.04 0.04 0.04 0.03

Sones 5.4 4.5 4.5 4.5 4.4 4.5 4.6

CFM 888 802 780 754 695 640 586 493 184

BHP 0.06 0.06 0.06 0.06 0.07 0.07 0.07 0.07 0.05

Sones 7.6 6.8 6.7 6.6 6.5 6.4 6.4 6.4 6.8

CFM 1059 987 969 950 912 863 814 745 623 474

BHP 0.10 0.10 0.10 0.11 0.11 0.11 0.11 0.12 0.12 0.11

Sones 9.6 9.4 9.3 9.2 9.0 8.8 8.7 8.7 8.7 8.7

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

20

Page 21

Roof Downblast - Direct Drive

G-101 and G-121

245⁄8

(625)

*20

(508)

13⁄4 (44)

19

(483)

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 20 x 20 (521 x 521)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

cfm

Model

Number

101-C 1/8 860

101-B 1/6 1140

101-A 1/4 1725

121-C 1/8 860

121-B 1/6 1140

121-A 1/4 1725

Motor HPFan

RPM

Static Pressure in Inches wg

0 0.1 0.125 0.25 0.3 0.375 0.5 0.625 0.75 1

CFM 766 625 588

BHP 0.02 0.03 0.03

Sones 4.3 4.2 4.2

CFM 1015 917 893 747 683 569

BHP 0.05 0.06 0.06 0.06 0.06 0.06

Sones 7.1 7.0 7.0 6.8 6.8 6.6

CFM 1536 1470 1454 1374 1340 1277 1181 1086 974

BHP 0.17 0.18 0.19 0.20 0.20 0.20 0.21 0.22 0.22

Sones 12.1 11.9 11.8 11.6 11.5 11.3 11.2 11.3 11.7

CFM 922 767 723 450

BHP 0.03 0.03 0.04 0.04

Sones 5.6 5.2 5.2 5.2

CFM 1222 1107 1078 918 848 734 335

BHP 0.06 0.07 0.07 0.08 0.09 0.09 0.07

Sones 8.1 7.9 7.9 7.8 7.8 8.1 9.8

CFM 1849 1772 1753 1659 1621 1560 1453 1341 1223 911

BHP 0.22 0.23 0.24 0.25 0.26 0.27 0.28 0.29 0.3 0.29

Sones 14.1 14.0 13.9 13.8 13.6 13.4 13.4 13.4 13.4 14.1

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

21

Page 22

Roof Downblast - Direct Drive

G-131 and G-141

287⁄8

(733)

*20

(508)

13⁄4 (44)

22

(559)

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 20 x 20 (521 x 521)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

cfm

Model

Number

131-C 1/8 860

131-B 1/6 1140

131-A 1/2 1725

141-C 1/8 860

141-B 1/6 1140

Motor HPFan

RPM

Static Pressure in Inches wg

0 0.1 0.125 0.25 0.3 0.375 0.5 0.625 0.75 1

CFM 1193 1050 1011 771 626

BHP 0.04 0.049 0.051 0.056 0.055

Sones 6.5 6.1 6.0 5.9 5.9

CFM 1581 1482 1452 1304 1239 1130 889

BHP 0.094 0.105 0.108 0.12 0.123 0.13 0.129

Sones 9.9 9.8 9.7 9.4 9.2 9.0 8.8

CFM 2393 2340 2327 2225 2186 2127 2030 1931 1817 1555

BHP 0.325 0.339 0.342 0.366 0.376 0.389 0.407 0.423 0.426 0.453

Sones 19.2 18.9 18.9 18.4 18.4 18.2 18.1 18.1 17.8 17.4

CFM 1376 1205 1161 919 798 489

BHP 0.055 0.064 0.066 0.074 0.074 0.063

Sones 6.8 6.6 6.5 6.4 6.6 8.0

CFM 1824 1701 1667 1498 1425 1314 1113 794

BHP 0.129 0.141 0.144 0.158 0.163 0.17 0.175 0.158

Sones 10.4 10.4 10.3 9.8 9.5 9.1 8.7 8.4

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

22

Page 23

Roof Downblast - Direct Drive

G-150

351⁄2

(902)

*211⁄8

(537)

13⁄4 (44)

26

(660)

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 20 x 20 (521 x 521)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

cfm

Model

Number

150-C 1/8 860

150-B 1/4 1140

Motor HPFan

RPM

Static Pressure in Inches wg

0 0.1 0.125 0.2 0.25 0.3 0.375 .5 .625 .75

CFM 1772 1598 1553 1415 1304 1194 1005

BHP 0.09 0.09 0.10 0.12 0.12 0.13 0.13

Sones 7.9 7.8 7.8 7.5 7.4 7.5 7.7

CFM 2349 2217 2185 2085 2017 1949 1836 1628 1397 1114

BHP 0.21 0.21 0.21 0.21 0.23 0.25 0.27 0.29 0.29 0.28

Sones 11.7 11.6 11.6 11.3 11.1 11.0 10.9 11.2 11.8 12.8

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

23

Page 24

Roof Downblast - Direct Drive

G-160

351⁄2

(902)

*215⁄8

(549)

13⁄4 (44)

30

(762)

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 20 x 20 (521 x 521)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

cfm

Model

Number

160-C 1/8 860

160-B 1/3 1140

Motor HPFan

RPM

Static Pressure in Inches wg

0 0.1 0.125 0.2 0.25 0.3 0.375 .5 .625 .75

CFM 2008 1828 1784 1637 1535 1421 1230

BHP 0.10 0.11 0.12 0.13 0.13 0.13 0.14

Sones 8.0 7.7 7.7 7.5 7.4 7.3 7.3

CFM 2662 2521 2489 2392 2319 2245 2135 1933 1697 1411

BHP 0.23 0.25 0.25 0.27 0.28 0.28 0.29 0.31 0.32 0.32

Sones 13.6 13.4 13.4 13.3 13.1 13.1 13.1 12.9 12.7 12.6

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

24

Page 25

Roof Downblast - Direct Drive

G-170

351⁄2

(902)

*215⁄8

(549)

13⁄4 (44)

30

(762)

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 20 x 20 (521 x 521)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

cfm

Model

Number

170-C 1/4 860

170-B 1/2 1140

Motor HPFan

RPM

Static Pressure in Inches wg

0 0.1 0.125 0.25 0.3 0.375 0.5 0.625 0.75 1

CFM 2572 2379 2330 2077 1961 1782 1416

BHP 0.172 0.187 0.191 0.208 0.214 0.223 0.228

Sones 9.7 9.6 9.5 9.2 9.1 9.1 9.1

CFM 3409 3263 3227 3043 2969 2857 2647 2428 2181 1457

BHP 0.4 0.421 0.426 0.45 0.46 0.473 0.494 0.514 0.532 0.488

Sones 16.3 16.2 16.2 16.1 16.1 16.1 16.1 16.1 16.1 17.2

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

25

Page 26

Roof Downblast - Direct Drive

G-180

351⁄2

(902)

*223⁄4

(578)

13⁄4 (44)

30

(762)

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 20 x 20 (521 x 521)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

cfm

Model

Number

180-C 1/3 860

180-B 3/4 1140

Motor HPFan

RPM

Static Pressure in Inches wg

0 0.1 0.125 0.25 0.3 0.375 0.5 0.625 0.75 1

CFM 3240 3053 3002 2733 2603 2390 1978 1438

BHP 0.24 0.262 0.268 0.296 0.306 0.321 0.332 0.316

Sones 12.1 12.4 12.4 12.5 12.5 12.3 11.9 11.9

CFM 4295 4156 4121 3933 3855 3731 3509 3241 2971 2246

BHP 0.559 0.589 0.596 0.634 0.649 0.671 0.707 0.74 0.771 0.759

Sones 19.5 19.4 19.4 19.3 19.5 19.7 19.8 20 20 21

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

26

Page 27

Roof Downblast - Belt Drive

GB-071

243⁄8

(619)

*233⁄4

(603)

43⁄8 (111)

13⁄4 (44)

19

(483)

Damper Size = 12 x 12 (305 x 305)

Roof Opening = 14 x 14 (368 x 368)

Shroud Thickness = 0.051 (1.3)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 58 lb (26 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

e

v

r

u

c

m

te

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Motor HPFan

RPM

630

738

0 0.125 0.25 0.375 0.5 0.625 0.75 0.875 1 1.125

CFM 137 79

BHP 0.01 0.01

Sones 1.3 1.4

CFM 161 112

BHP 0.01 0.01

Static Pressure in Inches wg

MAXIMUM BHP AT A GIVEN RPM = (RPM/3371)

MAXIMUM RPM = 1710

TIP SPEED (ft/min) = RPM x 2.929

MAXIMUM MOTOR FRAME SIZE = 56

3

Sones 1.9 2.1

CFM 184 144 95

846

BHP 0.02 0.02 0.01

Sones 2.7 2.6 2.6

CFM 208 172 132 76

954

BHP 0.02 0.02 0.02 0.02

Sones 3.5 3.6 3.4 3.2

CFM 231 200 164 127

1062

BHP 0.03 0.03 0.03 0.03

Sones 4.5 4.6 4.4 4.2

071-6

or

071-4

1/6

or

1/4

1170

CFM 255 227 196 162 123

BHP 0.04 0.04 0.04 0.04 0.04

Sones 5.7 5.7 5.5 5.2 5.0

CFM 279 254 226 195 164 124

1278

BHP 0.05 0.05 0.05 0.05 0.05 0.05

Sones 6.7 6.7 6.5 6.2 6.0 5.8

CFM 302 280 253 226 197 169 129

1386

BHP 0.07 0.07 0.07 0.07 0.07 0.07 0.06

Sones 7.6 7.6 7.4 7.2 6.9 6.7 6.5

CFM 326 305 280 257 230 203 177 138

1494

BHP 0.09 0.09 0.09 0.09 0.09 0.08 0.08 0.07

Sones 8.6 8.6 8.4 8.2 7.9 7.6 7.5 7.3

CFM 349 329 308 286 262 237 212 186 150

1602

BHP 0.11 0.11 0.11 0.11 0.11 0.10 0.10 0.10 0.09

Sones 9.8 9.7 9.6 9.3 9.1 8.8 8.5 8.4 8.1

CFM 373 353 335 312 292 269 246 223 198 164

1710

BHP 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.12 0.12 0.11

Sones 11.1 11.0 11.0 10.6 10.3 10.0 9.8 9.5 9.3 9.1

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

27

Page 28

Roof Downblast - Belt Drive

GB-081

243⁄8

(619)

*233⁄4

(603)

43⁄8 (111)

13⁄4 (44)

19

(483)

Damper Size = 12 x 12 (305 x 305)

Roof Opening = 14 x 14 (368 x 368)

Shroud Thickness = 0.051 (1.3)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 58 lb (26 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Motor HPFan

RPM

630

738

0 0.125 0.25 0.375 0.5 0.625 0.75 0.875 1 1.125

CFM 316 207

BHP 0.01 0.01

Sones 2.4 2.1

CFM 370 283

BHP 0.01 0.02

Static Pressure in Inches wg

MAXIMUM BHP AT A GIVEN RPM = (RPM/2985)

MAXIMUM RPM = 1710

TIP SPEED (ft/min) = RPM x 2.929

MAXIMUM MOTOR FRAME SIZE = 56

Sones 3.1 2.8

CFM 433 361 265

864

BHP 0.02 0.02 0.02

Sones 4.0 3.8 3.5

CFM 478 413 341

954

BHP 0.03 0.03 0.03

Sones 4.8 4.6 4.2

CFM 532 474 411 329

1062

BHP 0.04 0.04 0.05 0.04

Sones 5.9 5.7 5.3 5.0

081-6

or

081-4

1/6

or

1/4

1170

CFM 586 533 478 419 317

BHP 0.05 0.06 0.06 0.06 0.06

Sones 6.9 6.7 6.4 6.0 5.7

CFM 640 592 543 490 428 320

1278

BHP 0.07 0.07 0.08 0.08 0.08 0.07

Sones 7.9 7.8 7.4 7.0 6.7 6.6

CFM 694 650 605 557 507 441 334

1386

BHP 0.09 0.09 0.10 0.10 0.10 0.10 0.09

Sones 9.1 8.9 8.6 8.2 7.9 7.6 7.6

CFM 748 708 666 623 577 528 457 357

1494

BHP 0.11 0.12 0.12 0.12 0.12 0.13 0.12 0.11

Sones 10.1 10.0 9.8 9.4 8.9 8.7 8.5 8.4

CFM 802 765 725 686 644 602 552 480 388

1602

BHP 0.14 0.14 0.15 0.15 0.15 0.15 0.16 0.15 0.14

Sones 11.3 11.1 10.9 10.5 10.1 9.9 9.6 9.5 9.3

CFM 856 821 785 748 710 669 630 581 511 424

1710

BHP 0.17 0.17 0.18 0.18 0.19 0.19 0.19 0.19 0.18 0.17

Sones 12.5 12.3 12.1 11.9 11.5 11.2 10.9 10.6 10.5 10.3

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

28

3

Page 29

Roof Downblast - Belt Drive

GB-091

3

⁄8

24

(619)

*233⁄4

(603)

43⁄8 (111)

13⁄4 (44)

19

(483)

Damper Size = 12 x 12 (305 x 305)

Roof Opening = 14 x 14 (368 x 368)

Shroud Thickness = 0.051 (1.3)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 58 lb (26 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Motor HPFan

RPM

630

738

0 0.125 0.25 0.375 0.5 0.625 0.75 0.875 1 1.125

CFM 477 309

BHP 0.01 0.01

Sones 2.9 3.0

CFM 559 421

BHP 0.02 0.02

Static Pressure in Inches wg

MAXIMUM BHP AT A GIVEN RPM = (RPM/2703)

MAXIMUM RPM = 1710

TIP SPEED (ft/min) = RPM x 2.929

MAXIMUM MOTOR FRAME SIZE = 56

3

Sones 3.7 3.6

CFM 655 539 405

864

BHP 0.03 0.03 0.03

Sones 4.9 4.8 4.5

CFM 723 619 506 313

954

BHP 0.04 0.04 0.04 0.04

Sones 5.9 5.7 5.3 5.1

CFM 805 711 613 502

1062

BHP 0.05 0.06 0.06 0.06

Sones 7.2 7.0 6.6 6.2

CFM 886 802 715 621 500

091-4 1/4

1170

BHP 0.07 0.08 0.08 0.08 0.08

Sones 8.7 8.4 8.0 7.5 7.1

CFM 968 891 813 729 639 516

1278

BHP 0.09 0.10 0.10 0.10 0.11 0.10

Sones 9.5 9.3 8.9 8.5 8.1 7.8

CFM 1050 979 907 832 752 666 545

1386

BHP 0.12 0.12 0.13 0.13 0.13 0.14 0.13

Sones 10.3 10.1 9.9 9.5 9.1 8.8 8.5

CFM 1132 1066 999 932 860 785 698 584

1494

BHP 0.15 0.15 0.16 0.16 0.17 0.17 0.17 0.16

Sones 11.2 11.1 10.9 10.6 10.2 9.9 9.6 9.3

CFM 1214 1152 1090 1028 962 894 823 738 631

1602

BHP 0.18 0.19 0.19 0.20 0.20 0.20 0.21 0.21 0.20

Sones 12.3 12.1 12.0 11.8 11.4 11.1 10.8 10.5 10.2

CFM 1296 1238 1180 1122 1062 999 934 867 785 685

1710

BHP 0.22 0.23 0.23 0.24 0.24 0.25 0.25 0.25 0.25 0.24

Sones 13.4 13.3 13.2 13.0 12.7 12.4 12.1 11.8 11.6 11.2

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

29

Page 30

Roof Downblast - Belt Drive

GB-101

3

24

⁄8

(619)

*233⁄4

(603)

43⁄8 (111)

13⁄4 (44)

19

(483)

Damper Size = 12 x 12 (305 x 305)

Roof Opening = 14 x 14 (368 x 368)

Shroud Thickness = 0.051 (1.3)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 63 lb (29 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Motor HPFan

RPM

830

930

0 0.125 0.25 0.375 0.5 0.625 0.75 0.875 1 1.25

CFM 703 594 420

BHP 0.03 0.03 0.03

Sones 4.5 3.5 2.6

CFM 788 688 572

BHP 0.04 0.04 0.05

Static Pressure in Inches wg

MAXIMUM BHP AT A GIVEN RPM = (RPM/2593)

MAXIMUM RPM = 1800

TIP SPEED (ft/min) = RPM x 2.913

MAXIMUM MOTOR FRAME SIZE = 56

Sones 5.1 4.3 3.7

CFM 873 781 688 539

1030

BHP 0.05 0.06 0.06 0.06

Sones 5.7 5.1 4.7 3.8

CFM 958 873 795 690 420

1130

BHP 0.07 0.08 0.08 0.08 0.07

Sones 6.5 5.9 5.6 5 3.6

CFM 1042 965 894 807 693

101-4 1/4

1230

BHP 0.09 0.10 0.11 0.11 0.11

Sones 7.3 6.8 6.5 6.2 5.5

CFM 1127 1055 987 917 827 696

1330

BHP 0.12 0.12 0.13 0.14 0.14 0.13

Sones 8.3 7.8 7.6 7.4 6.9 6.4

CFM 1212 1144 1080 1021 943 851 715

1430

BHP 0.14 0.15 0.16 0.17 0.17 0.17 0.16

Sones 9.1 8.8 8.5 8.2 7.8 7.3 6.6

CFM 1297 1233 1173 1117 1053 975 883 744

1530

BHP 0.18 0.18 0.19 0.20 0.21 0.21 0.21 0.19

Sones 10.0 9.7 9.5 9.1 8.6 8.2 7.8 7.1

CFM 1386 1326 1269 1215 1162 1095 1020 929 793

1635

BHP 0.22 0.22 0.23 0.24 0.25 0.25 0.25 0.25 0.24

Sones 11.1 10.8 10.4 10.2 9.8 9.3 8.9 8.4 7.8

CFM 1456 1399 1345 1291 1244 1185 1118 1043 943

1718

101-3 1/3

1800

BHP 0.25 0.26 0.27 0.28 0.29 0.29 0.29 0.29 0.29

Sones 12.1 11.7 11.3 11.1 10.8 10.2 9.8 9.4 8.9

CFM 1526 1471 1419 1368 1321 1270 1209 1142 1065 793

BHP 0.29 0.30 0.30 0.31 0.33 0.34 0.34 0.34 0.34 0.30

Sones 13.2 12.8 12.5 12.3 12.2 11.3 10.8 10.6 10.1 9.3

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

30

3

Page 31

Roof Downblast - Belt Drive

GB-101HP

243⁄8

(619)

*233⁄4

(603)

43⁄8 (111)

13⁄4 (44)

19

(483)

Damper Size = 12 x 12 (305 x 305)

Roof Opening = 14 x 14 (368 x 368)

Shroud Thickness = 0.051 (1.3)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 63 lb (29 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

e

v

ur

c

m

e

t

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Motor HPFan

RPM

1300

1445

0 0.25 0.5 0.75 1 1.25 1.5 1.75 2 2.25

CFM 571 477 342

BHP 0.06 0.06 0.07

Sones 6.6 5.7 5.3

CFM 635 553 449 243

BHP 0.08 0.09 0.09 0.08

Static Pressure in Inches wg

MAXIMUM BHP AT A GIVEN RPM = (RPM/3165)

MAXIMUM RPM = 2550

TIP SPEED (ft/min) = RPM x 2.978

MAXIMUM MOTOR FRAME SIZE = 56

3

Sones 8.4 7.5 7.0 6.3

CFM 699 626 537 417

1590

101HP-4 1/4

1735

BHP 0.10 0.11 0.12 0.12

Sones 10.4 9.5 9.1 8.3

CFM 762 697 619 527 376

BHP 0.13 0.15 0.15 0.16 0.15

Sones 11.5 10.8 10.7 10.3 10.2

CFM 826 767 697 618 518 337

1880

BHP 0.17 0.18 0.20 0.20 0.21 0.18

Sones 12.7 12.2 11.9 12 11.4 11.9

CFM 890 836 772 702 622 515 313

2025

BHP 0.21 0.23 0.24 0.24 0.26 0.25 0.22

Sones 14.2 13.6 13.3 13.2 12.6 12 11.4

CFM 939 889 830 765 693 607 474

2137

101HP-3 1/3

2229

BHP 0.25 0.26 0.28 0.28 0.30 0.30 0.28

Sones 15.4 14.8 14.4 14.2 13.4 13.1 12.1

CFM 979 931 875 814 748 674 574 406

BHP 0.29 0.30 0.31 0.32 0.33 0.35 0.33 0.31

Sones 15.8 15.4 14.8 14.5 14.1 13.7 13.2

CFM 1026 981 928 871 809 742 661 543 358

2336

BHP 0.33 0.34 0.36 0.37 0.37 0.39 0.40 0.38 0.34

Sones 16.4 16.0 15.4 14.9 14.7 14.0 14.1 13.5 13.6

CFM 1073 1030 981 927 869 807 739 649 519

101HP-5 1/2

2443

BHP 0.38 0.39 0.41 0.42 0.42 0.44 0.46 0.44 0.42

Sones 17.3 16.9 16.4 16.0 14.9 14.5 14.7 15.0

CFM 1120 1078 1032 982 928 869 807 735 639 497

2550

BHP 0.43 0.44 0.46 0.48 0.48 0.49 0.51 0.52 0.50 0.47

Sones 18.2 17.9 17.4 17.2 16.3 16.1 15.1 15.6 16.2 17.2

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

31

Page 32

Roof Downblast - Belt Drive

GB-121

243⁄8

(619)

*233⁄4

(603)

43⁄8 (111)

13⁄4 (44)

19

(483)

Damper Size = 12 x 12 (305 x 305)

Roof Opening = 14 x 25 (368 x 368)

Shroud Thickness = 0.051 (1.3)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 66 lb (30 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Motor

HP

Fan

RPM

595

728

0 0.125 0.25 0.375 0.5 0.625 0.75 1 1.25 1.5

CFM 722 542

BHP 0.02 0.02

Sones 3.3 3.4

CFM 883 747 543

BHP 0.03 0.04 0.04

Static Pressure in Inches wg

MAXIMUM BHP AT A GIVEN RPM = (RPM/2170)

MAXIMUM RPM = 1725

TIP SPEED (ft/min) = RPM x 3.420

MAXIMUM MOTOR FRAME SIZE = 56

Sones 4.2 4.3 4.2

CFM 1044 933 798 584

861

BHP 0.05 0.06 0.06 0.06

Sones 5.4 5.5 5.2 5.2

CFM 1206 1111 1004 872 673

121-4 1/4

994

BHP 0.08 0.09 0.09 0.10 0.09

Sones 6.7 6.7 6.6 6.4 6.3

CFM 1367 1284 1195 1092 969 799

1127

BHP 0.11 0.12 0.13 0.14 0.14 0.13

Sones 8.2 8.2 8.2 7.9 7.8 7.7

CFM 1528 1454 1377 1292 1196 1084 938

1260

BHP 0.16 0.17 0.18 0.19 0.19 0.19 0.19

Sones 10.1 10.1 10.0 9.9 9.6 9.5 9.3

CFM 1692 1625 1557 1484 1404 1315 1214 907

1395

BHP 0.21 0.23 0.24 0.25 0.26 0.26 0.26 0.25

Sones 12.5 12.4 12.3 12.2 12.0 11.7 11.5 11.3

CFM 1787 1723 1659 1591 1518 1438 1352 1127

1473

121-3 1/3

1550

BHP 0.25 0.27 0.28 0.29 0.30 0.31 0.31 0.30

Sones 13.5 13.4 13.3 13.1 12.9 12.7 12.4 12.0

CFM 1880 1820 1759 1696 1629 1555 1475 1289 974

BHP 0.30 0.31 0.32 0.33 0.34 0.35 0.36 0.36 0.33

Sones 14.6 14.5 14.3 14.2 14.0 13.8 13.5 12.9 12.4

CFM 1987 1930 1872 1814 1751 1684 1613 1452 1238

1638

121-5 1/2

1725

BHP 0.35 0.36 0.38 0.39 0.40 0.41 0.42 0.43 0.42

Sones 16.0 15.8 15.6 15.5 15.3 15.1 14.9 14.0 13.5

CFM 2093 2038 1984 1928 1871 1810 1743 1600 1426 1180

BHP 0.40 0.42 0.44 0.45 0.46 0.47 0.48 0.50 0.50 0.48

Sones 17.4 17.2 17.0 16.8 16.7 16.4 16.2 15.5 14.9 14.0

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

32

3

Page 33

Roof Downblast - Belt Drive

GB-131

3

⁄8

28

(721)

*233⁄4

(603)

4 (102)

13⁄4 (44)

19

(483)

Damper Size = 12 x 12 (305 x 305)

Roof Opening = 14 x 14 (368 x 368)

Shroud Thickness = 0.051 (1.3)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 67 lb (30 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Motor HPFan

RPM

595

700

0 0.125 0.25 0.375 0.5 0.625 0.75 1 1.25 1.5

CFM 844 655

BHP 0.02 0.02

Sones 4.5 4.6

CFM 993 845 585

BHP 0.03 0.04 0.04

Static Pressure in Inches wg

MAXIMUM BHP AT A GIVEN RPM = (RPM/2047)

MAXIMUM RPM = 1685

TIP SPEED (ft/min) = RPM x 3.436

MAXIMUM MOTOR FRAME SIZE = 56

3

Sones 5.2 5.2 5.0

CFM 1135 1012 843

800

BHP 0.05 0.06 0.06

Sones 6.0 6.0 5.7

CFM 1277 1169 1039 845

900

131-4 1/4

1000

BHP 0.07 0.08 0.08 0.08

Sones 7.0 6.9 6.6 6.3

CFM 1419 1223 1213 1075 867

BHP 0.10 0.11 0.11 0.12 0.11

Sones 8.1 8.0 7.7 7.4 7.0

CFM 1516 1475 1381 1268 1124 898

1100

BHP 0.13 0.14 0.15 0.15 0.16 0.15

Sones 9.5 9.2 9.0 8.6 8.3 7.9

CFM 1703 1624 1539 1443 1330 1191 964

1200

BHP 0.17 0.18 0.19 0.20 0.20 0.20 0.19

Sones 11.1 10.8 10.5 10.1 9.7 9.4 8.8

CFM 1866 1794 1718 1637 1545 1435 1305

1315

BHP 0.22 0.23 0.24 0.25 0.26 0.26 0.26

Sones 13.2 12.8 12.5 12.1 11.7 11.2 10.9

CFM 2044 1978 1911 1838 1759 1674 1571 1299

131-3 1/3 1440

BHP 0.294 0.306 0.318 0.327 0.336 0.344 0.347 0.342

Sones 15.0 15.0 15.1 15.1 14.5 13.9 13.4 12.5

CFM 2218 2158 2097 2031 1964 1887 1807 1606 1300

1563

131-5 1/2

1685

BHP 0.375 0.389 0.402 0.413 0.424 0.432 0.44 0.445 0.427

Sones 16.0 15.8 15.6 15.5 15.2 14.8 14.3 13.6 12.8

CFM 2391 2335 2279 2219 2158 2093 2020 1857 1654 1312

BHP 0.47 0.485 0.499 0.512 0.523 0.534 0.543 0.555 0.557 0.522

Sones 16.9 16.6 16.3 16.0 15.7 15.4 15.1 14.5 13.9 13.5

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

33

Page 34

Roof Downblast - Belt Drive

GB-141

3

⁄8

28

(721)

*233⁄4

(603)

4 (102)

13⁄4 (44)

22

(559)

Damper Size = 16 x 16 (406 x 406)

Roof Opening = 18 x 18 (470 x 470)

Shroud Thickness = 0.051 (1.3)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 83 lb (38 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Motor HPFan

RPM

525

663

0 0.125 0.25 0.375 0.5 0.75 1 1.25 1.5 1.75

CFM 974 709

BHP 0.03 0.03

Sones 4.4 4.2

CFM 1230 1046 732

BHP 0.06 0.06 0.06

Static Pressure in Inches wg

MAXIMUM BHP AT A GIVEN RPM = (RPM/1676)

MAXIMUM RPM = 1705

TIP SPEED (ft/min) = RPM x 3.829

MAXIMUM MOTOR FRAME SIZE = 145T

Sones 5.3 5.5 4.4

CFM 1486 1337 1161 850

141-4 1/4

801

BHP 0.10 0.11 0.11 0.10

Sones 6.5 6.6 6.1 5.3

CFM 1742 1614 1482 1313 1040

939

BHP 0.16 0.17 0.17 0.18 0.16

Sones 7.9 7.8 7.5 7.0 6.4

CFM 1994 1882 1771 1647 1490

1075

BHP 0.24 0.25 0.26 0.26 0.26

Sones 10.0 9.9 9.4 8.9 8.4

CFM 2170 2067 1966 1859 1734 1356

141-3 1/3 1170

BHP 0.31 0.32 0.33 0.33 0.34 0.32

Sones 11.4 11.3 10.8 10.3 9.9 8.7

CFM 2347 2250 2158 2062 1955 1677 1048

1265

141-5 1/2

1360

BHP 0.39 0.40 0.41 0.42 0.42 0.42 0.35

Sones 12.9 12.7 12.3 11.9 11.4 10.4 8.8

CFM 2523 2433 2347 2259 2166 1943 1602

BHP 0.48 0.50 0.51 0.52 0.52 0.53 0.51

Sones 14.6 14.3 13.9 13.5 13.1 12.2 11.0

CFM 2695 2612 2530 2449 2365 2173 1914 1513

1453

141-7 3/4

1545

BHP 0.59 0.60 0.62 0.63 0.64 0.64 0.64 0.60

Sones 16.2 15.9 15.6 15.3 14.8 13.9 13.0 11.8

CFM 2866 2787 2710 2634 2556 2384 2177 1890

BHP 0.71 0.72 0.74 0.75 0.76 0.77 0.78 0.75

Sones 17.6 18.0 17.4 17.1 16.8 14.9 14.7 14.7

CFM 3163 3091 3020 2952 2883 2739 2574 2370 2120 1731

141-10 1 1705

BHP 0.95 0.97 0.98 1.00 1.02 1.03 1.03 1.05 1.02 0.96

Sones 20 20 20 19.6 19.2 18.1 16.9 16.7 16.6 16.4

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a

birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown

are for installation type A: free inlet hemispherical sone levels.

34

3

Page 35

Roof Downblast - Belt Drive

GB-141HP

283⁄8

(721)

*233⁄4

(603)

4 (102)

13⁄4 (44)

22

(559)

Damper Size = 16 x 16 (406 x 406)

Roof Opening = 18 x 18 (470 x 470)

Shroud Thickness = 0.051 (1.3)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 83 lb (38 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Motor HPFan

RPM

905

1054

0.5 0.75 1 1.25 1.5 1.75 2 2.25 2.5 2.75

CFM 270

BHP 0.05

Sones 5.5

CFM 537

BHP 0.09

Static Pressure in Inches wg

MAXIMUM BHP AT A GIVEN RPM = (RPM/2351)

MAXIMUM RPM = 2170

TIP SPEED (ft/min) = RPM x 3.829

MAXIMUM MOTOR FRAME SIZE = 145T

3

Sones 6.7

CFM 714 527

141HP-4 1/4

1203

BHP 0.13 0.13

Sones 8.4 8.3

CFM 870 740 547

1352

BHP 0.18 0.19 0.19

Sones 10.9 10.3 10.4

CFM 1009 903 774 592

1500

BHP 0.24 0.26 0.26 0.25

Sones 13.1 12.3 12.2 12.4

CFM 1151 1064 959 833 668