Page 1

Document 476412

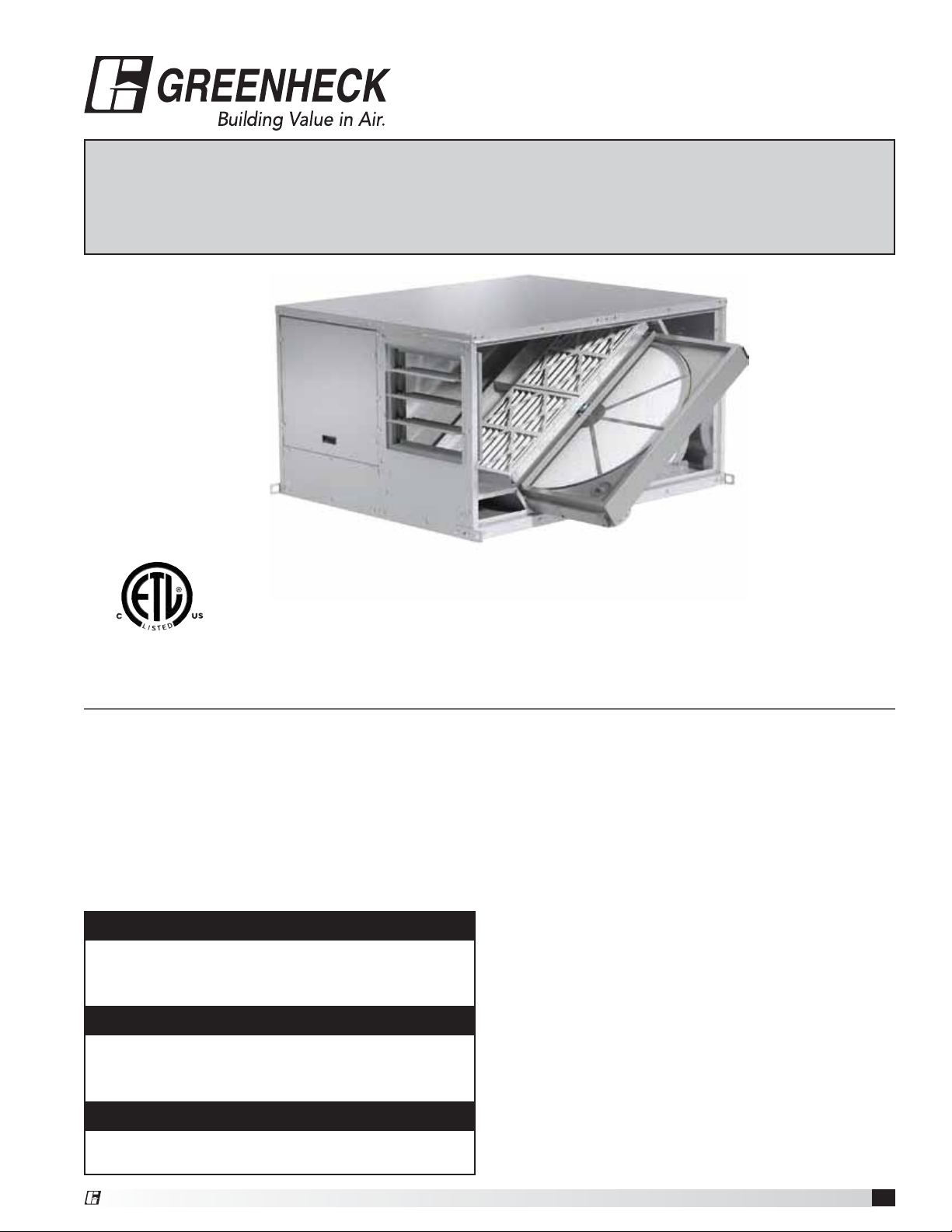

Energy Recovery Ventilators

®

Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

Models:

ERV-10

ERV-20

ERV-45

ERV-55

ERV-90

ERV-120

General Safety Information

Only qualified personnel should install this system.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if high winds

or seismic activity are present. If more information

is needed, contact a licensed professional engineer

before moving forward.

DANGER

Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch

or breaker to prevent accidental power up.

CAUTION

When servicing the unit, the internal components

may be hot enough to cause pain or injury. Allow

time for cooling before servicing.

CAUTION

Precaution should be taken in explosive

atmospheres.

1. Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), the National

Fire Protection Agency (NFPA), where applicable.

Follow the Canadian Electrical Code (CEC) in

Canada.

2. All moving parts must be free to rotate without

striking or rubbing any stationary objects.

3. Unit must be securely and adequately grounded.

4. Do not spin fan wheel faster than maximum

cataloged fan RPM. Adjustments to fan speed

significantly effects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open access doors to the unit while it is

running.

®

Energy Recovery Ventilator

1

Page 2

Receiving

Upon receiving the product, check to make sure

all items are accounted for by referencing the bill

of lading to ensure all items were received. Inspect

each crate for shipping damage before accepting

delivery. Notify the carrier if any damage is noticed.

The carrier will make notification on the delivery

receipt acknowledging any damage to the product.

All damage should be noted on all the copies of

the bill of lading which is countersigned by the

delivering carrier. A Carrier Inspection Report should

be filled out by the carrier upon arrival and the Traffic

Department. If damaged upon arrival, file claim

with carrier. Any physical damage to the unit after

acceptance is not the responsibility of Greenheck Fan

Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited to

only items on the bill of lading.

Machined parts coated with rust preventive should

be restored to good condition promptly if signs of

rust occur. Immediately remove the original rust

preventive coating with petroleum solvent and clean

with lint-free cloths. Polish any remaining rust from

surface with crocus cloth or fine emery paper and oil.

Do not destroy the continuity of the surfaces. Wipe

clean thoroughly with Tectyl

the equivalent. For hard to reach internal surfaces or

for occasional use, consider using Tectyl® 511M Rust

Preventive or WD-40® or the equivalent.

®

506 (Ashland Inc.) or

Handling

Units are to be rigged and moved by the lifting

brackets provided or by the skid when a forklift is

used. Location of brackets varies by model and size.

Handle each piece in such a manner as to keep from

scratching or chipping the coating. Damaged finish

may reduce ability of the unit to resist corrosion.

Storage

Units are protected against damage during shipment.

If the unit cannot be installed and operated

immediately, precautions need to be taken to prevent

deterioration of the unit during storage. The user

assumes responsibility of the unit and accessories

while in storage. The manufacturer will not be

responsible for damage during storage. These

suggestions are provided solely as a convenience to

the user.

Inspection and Maintenance during

Storage

While in storage, inspect units once per month. Keep

a record of inspection and maintenance performed

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate all moving components by hand

ten to fifteen revolutions to distribute lubricant on

motor and bearings. If paint deterioration begins,

consideration should be given to touch-up or

repainting. Units with special coatings may require

special techniques for touch-up or repair.

Energy Recovery Ventilator

2

Page 3

Table of Contents

Product Overview

Product Overview . . . . . . . . . . . . . 3

Supplemental Installation, Operation and

Maintenance Manuals . . . . . . . . . . . 3

Optional Subassemblies . . . . . . . . . . 3

Installation

Dimensional Data . . . . . . . . . . . . 4-5

Recommended Roof Openings & Weights . . . 6

Service Clearances . . . . . . . . . . . . 7

Access Panel Locations . . . . . . . . . 8-9

Handling . . . . . . . . . . . . . . . . . 9

Lifting . . . . . . . . . . . . . . . . . . 9

Roof Curb Mounting . . . . . . . . . . . . 10

Curb Outside Dimensions and Weights . . . . 10

Ductwork Connections . . . . . . . . . . . 10

Rail Mounting / Layout . . . . . . . . . . . 11

Outdoor Air Weatherhood . . . . . . . . . . 11

Exhaust Weatherhood . . . . . . . . . . . 11

Dampers. . . . . . . . . . . . . . . . . 11

Electrical Information

General Electrical Information . . . . . . . . 12

Control Center Components . . . . . . . . . 13

Optional Accessory Wiring Schematics . . . . 14

Unit Overview . . . . . . . . . . . . . . . 15

Optional Component Overview

Economizer . . . . . . . . . . . . . . . 15

Frost Control . . . . . . . . . . . . . . . 16

Variable Frequency Drive . . . . . . . . . . 16

CO

Sensor . . . . . . . . . . . . . . . 16

2

Rotation Sensor . . . . . . . . . . . . . . 16

Dirty Filter Switch . . . . . . . . . . . . . 16

Service Outlet . . . . . . . . . . . . . . 16

Start-Up

General . . . . . . . . . . . . . . . . . 17

Pre Start-Up Checklist . . . . . . . . . . . 17

Special Tools Required . . . . . . . . . . . 17

Start-Up Checklist. . . . . . . . . . . . . 17

Optional Accessories Checklists . . . . . . . 18

Start-Up Components

Fans . . . . . . . . . . . . . . . . . . 19

Vibration . . . . . . . . . . . . . . . . . 20

Energy Recovery Wheel . . . . . . . . . . 20

Drive Belt . . . . . . . . . . . . . . . . 20

Air Seals . . . . . . . . . . . . . . . . . 20

Optional Start-Up Components

Dirty Filter Switch . . . . . . . . . . . . . 20

Economizer . . . . . . . . . . . . . . . 21

Frost Control . . . . . . . . . . . . . . . 22

Variable Frequency Drives . . . . . . . .22-24

Routine Maintenance. . . . . . . . . . 25-28

Troubleshooting

Economizer Alarms . . . . . . . . . . . . 28

Airflow. . . . . . . . . . . . . . . . . . 29

Unit . . . . . . . . . . . . . . . . . 30-31

Maintenance Log . . . . . . . . . Backcover

Our Commitment . . . . . . . . . Backcover

The ERV brings in fresh, outdoor air and removes

stale, exhaust air. Prior to discharging the exhaust

air, the energy recovery wheel transfers energy from

the exhaust air to the outdoor air at an efficiency

of 70-80%. Simply put, this unit preconditions the

outdoor air to save money on heating and cooling

costs.

Supplemental IOMs

Refer to the following Installation, Operation and

Maintenance (IOM) Manuals for additional details:

• ERV-90 and ERV-120 Curbs

• ERV Exhaust Weatherhood

Optional Subassemblies

Electric Heater Application/Operation

Factory installed electric heaters can be provided for

preheat frost control. An electric preheater warms

the outdoor air prior to the energy recovery wheel

to prevent frosting on the wheel. Electric heaters

are available in 208, 230, or 460 VAC (refer to heater

nameplate for voltage).

Preheaters: Preheaters are standard as single-stage

on/off control. Preheaters are single point wired at

the factory. A thermodisc temperature sensor (with

a 5°F set point) is mounted in the outdoor airstream

after the preheater to turn the preheater on. See Frost

Control Application/Operation for typical set points. If

the temperature falls below

the set point and the wheel

pressure drop sensor is

triggered, the preheater will

turn on.

Access to the preheater

control panel is through the

outdoor air filter door.

Energy Recovery Ventilator

3

Page 4

Installation

g

a

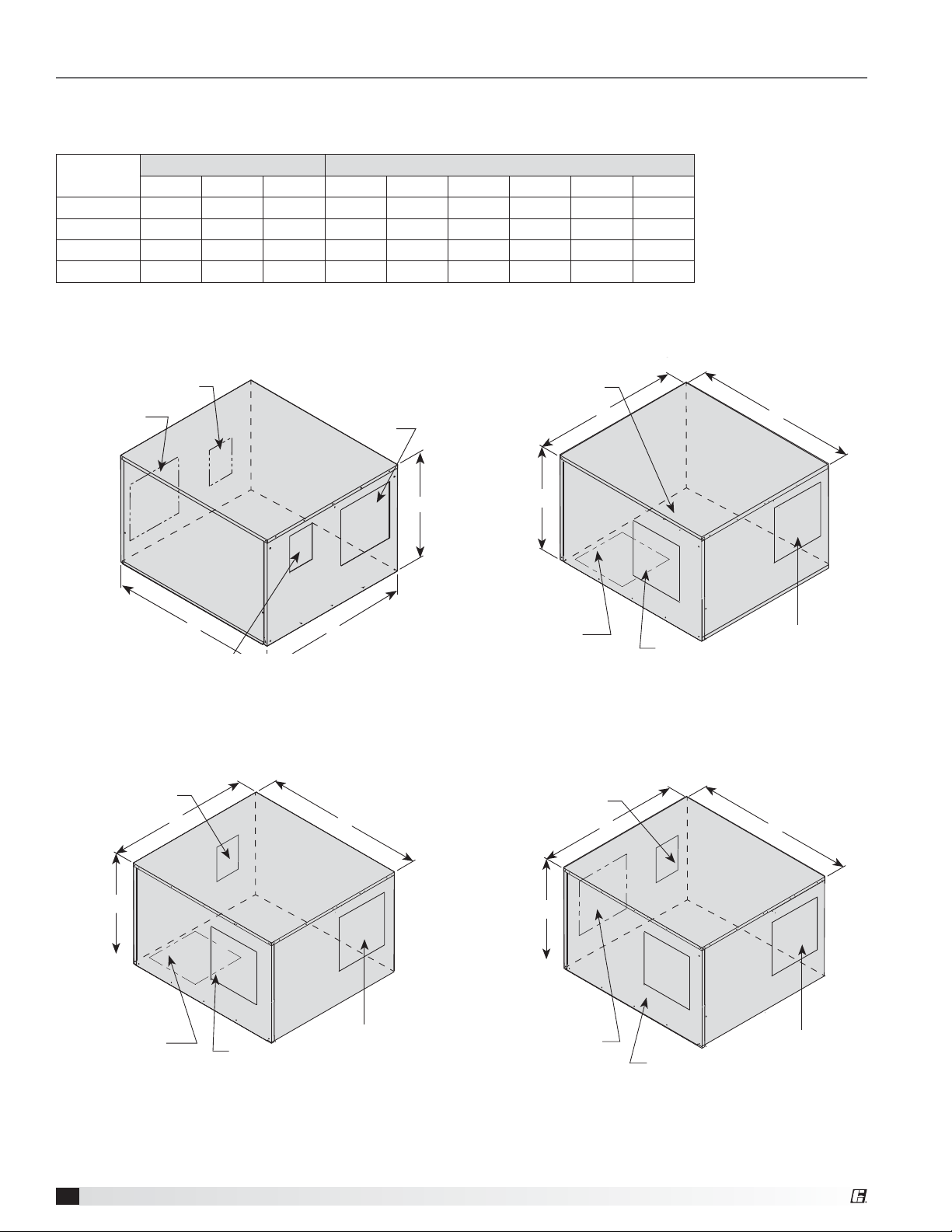

Dimensional Data

ERV-10, 20, 45 and 55

Unit Size

ERV-10 46 34 27 10 16 6

ERV-20 62 51 34 18 18 8

ERV-45 67 67 44 24 24 10

Exterior Dimensions Unit Opening Dimensions

ABCFGKLQP

3

⁄4 71016

3

⁄8 111⁄2 19 18

3

⁄4 131⁄2 26 26

ERV-55 75 70 67 22 27 16 18

All dimensions are in inches.

Outdoor Air Discharge

LxK

Exhaust Air Intake

FxG

Outdoor Air Intake

Q x P

C

3

⁄4 28 48

Outdoor Air Discharge

LxK

B

C

A

A

Exhaust Air Discharge

Outdoor Air Discharge

LxK

B

C

FxG

B

Exhaust Air Intake

FxG

Exhaust Air Discharge

Arrangement A Arrangement B

Outdoor Air Discharge

LxK

Exhaust Air Discharge

A

C

Outdoor Air IntakeExhaust Air Intake

Exhaust Air Intake

B

FxG

Outdoor Air Int

A

Outdoor Air Intake

Energy Recovery Ventilator

4

Arrangement C Arrangement D

Page 5

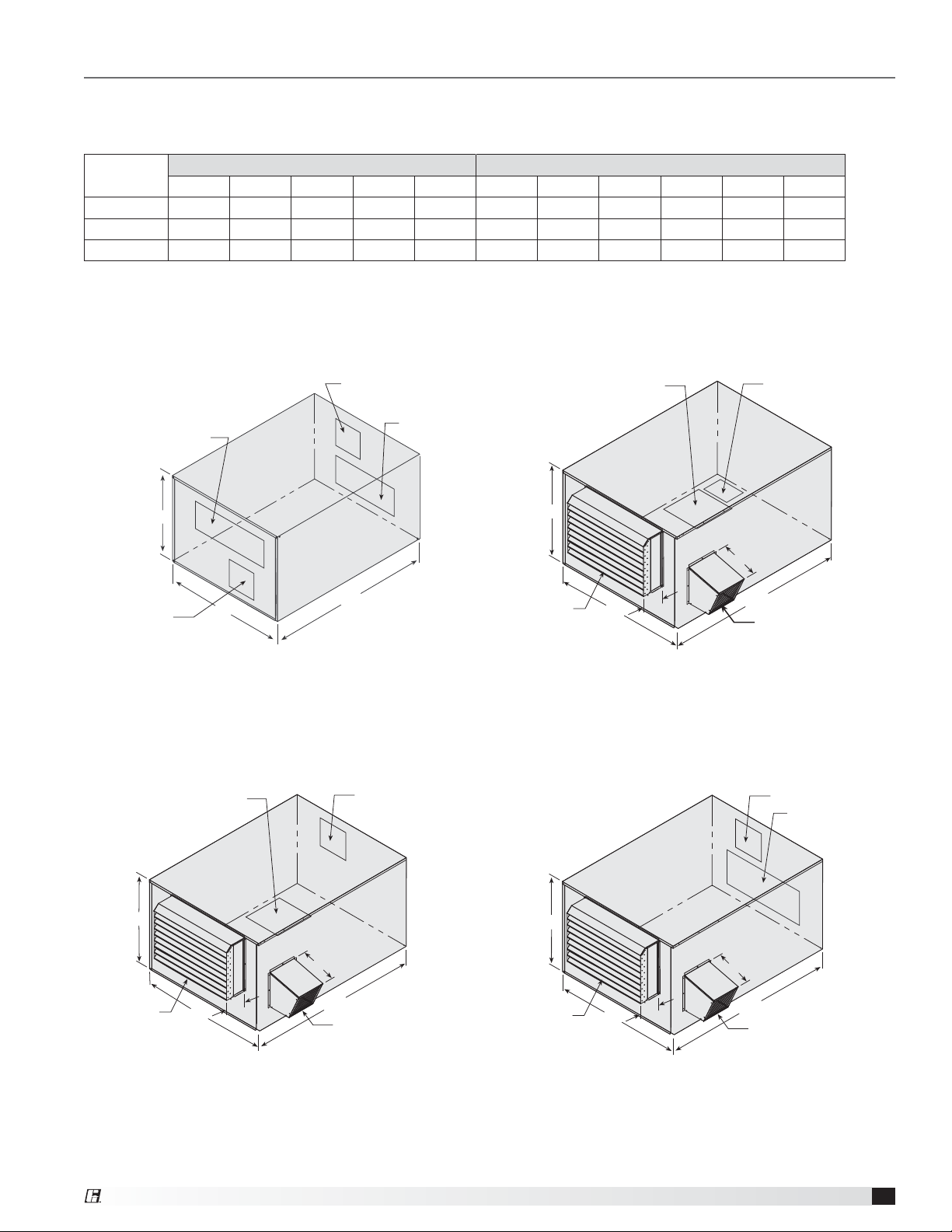

Installation

Dimensional Data

ERV-90 and 120

Unit Size

ABCDEFGK LQP

ERV-90L 124 84 64 16 19 48 25 16 18

Exterior Dimensions Unit Opening Dimensions

5

⁄8 60 25

ERV-90H 124 84 64 16 19 48 25 19 22 60 25

ERV-120H 146 97 77 17

1

⁄2 263⁄4 60 28 23 25 70 30

All dimensions are in inches.

Outdoor Air Discharge

L x K

E

A

Exhaust

Hood

Outdoor Air Inlet

Q x P

C

Exhaust Air Discharge

L x K

Outdoor Air Discharge

L x K

Exhaust Air Inlet

F x G

C

B

A

Intake

Hood

Exhaust Air Inlet

H x J

D

B

C

Intake

Hood

Arrangement A Arrangement B

Exhaust Air Inlet

H x J

D

B

Outdoor Air Discharge

L x K

E

A

Exhaust

Hood

C

Intake

Hood

D

B

Arrangement C Arrangement D

Outdoor Air Discharge

L x K

Exhaust Air Inlet

E

A

Exhaust

Hood

F x G

Energy Recovery Ventilator

5

Page 6

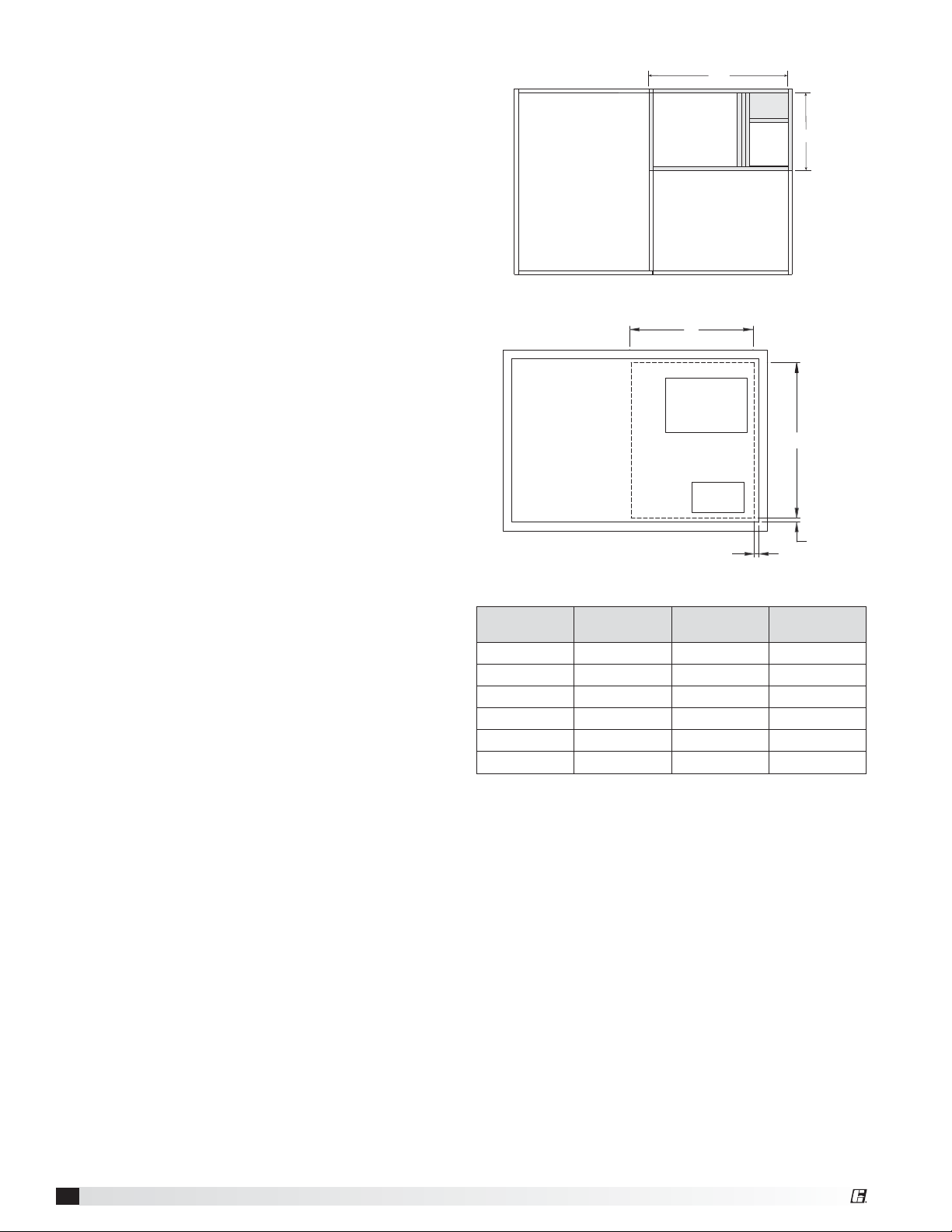

Recommended Roof Openings & Weights

Position the unit roof opening such that the supply

discharge and exhaust inlet of the unit will line up

with the corresponding ductwork. Be sure to allow

for the recommended service clearances when

positioning opening (see Service Clearances).

Do not face the outdoor air intake of the unit into

prevailing wind and keep the intake away from any

other exhaust fans. Likewise, position the exhaust

discharge opening away from outdoor air intakes of

any other equipment.

When cutting only duct openings, cut opening 1 inch

(25 mm) larger than duct size to allow clearance for

installation. Area enclosed by roof curb must comply

with clearance to combustible materials. If the roof is

constructed of combustible materials, area within the

roof curb must be ventilated, left open, or covered

with non-combustible material which has an “R”

value of at least 5. If area within curb is open, higher

radiated sound levels may result.

Where the supply or warm air duct passes thru a

combustible roof, a clearance of one inch must be

maintained between the outside edges of the duct

and combustible material in accordance with NFPA

Standard 90A.

EXHAUST

INLET

ERV-90 and 120

V

EXHAUST

INTAKE

SUPPLY

DISCHARGE

0.50

U

V

SUPPLY

DISCHARGE

U

0.50

ERV-10, 20, 45 and 55

Unit Size U V

Approx.

Weight (lbs.)

ERV-10 26.5 20 340

ERV-20 43 26 860

ERV-45 58 35 1290

ERV-55 60 30 1470

ERV-90 62 36 3230

ERV-120 77 38 3700

All dimensions are in inches. *Weight assumes outdoor unit

with filters, weatherhoods and outdoor air intake damper.

Energy Recovery Ventilator

6

Page 7

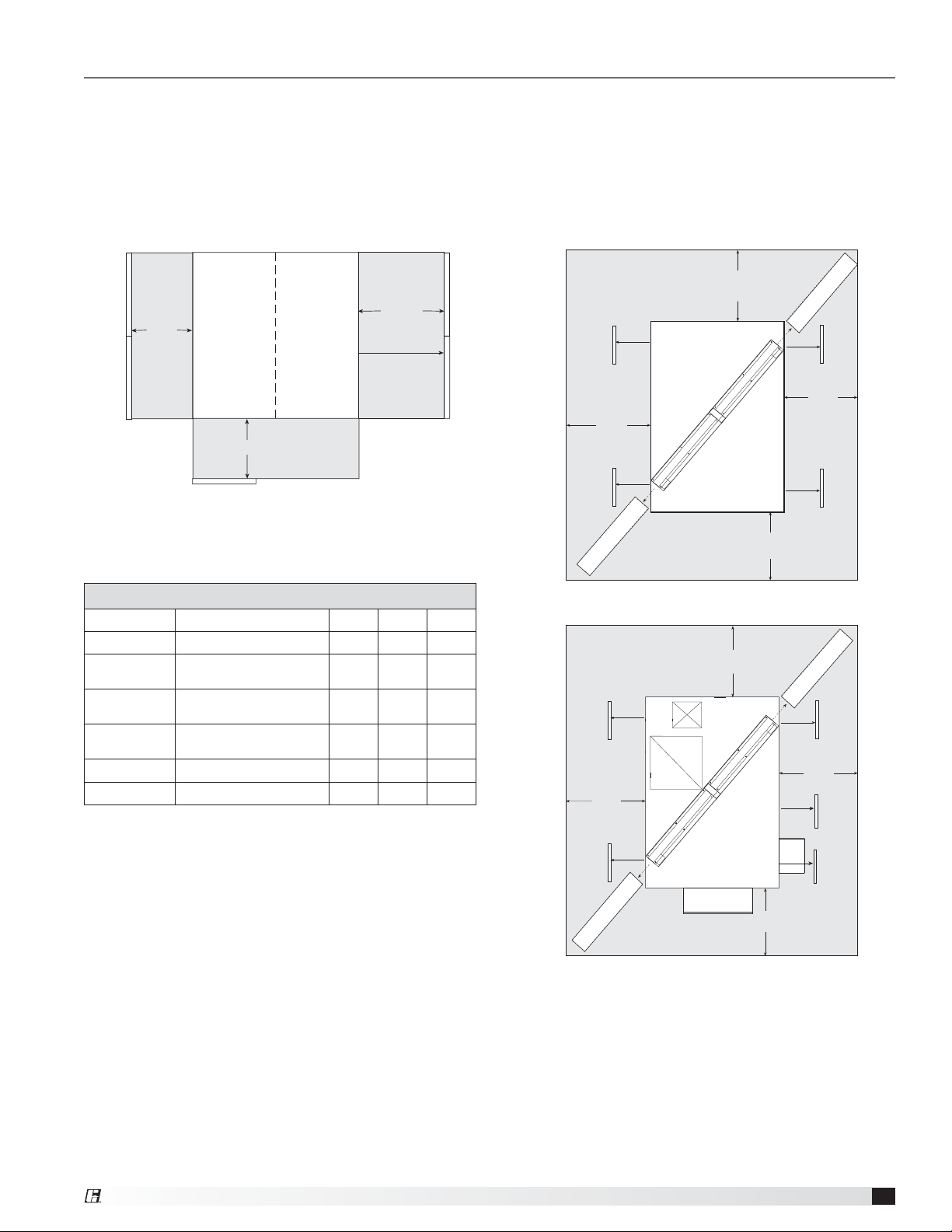

Service Clearances

ERV-10, 20, 45 and 55 units require minimum clearances to perform routine maintenance, such as filter

replacement, energy wheel cassette inspection, and fan belt adjustment. Blower and motor assemblies,

energy recovery wheel cassette and filter sections are always provided with a service door or panel for proper

component access. Clearances for component removal may be greater than the service clearances, refer to

drawings below for these dimensions.

ERV-10, ERV-20, ERV-45, ERV-55 ERV-90, ERV-120

Access Panels

T

Exhaust

Side

Outdoor

Air Side

R

Cassette slides out*

S

*ERV-10, 20, and 45 only.

Arrangement A

Recommended Service Clearances

Unit Size R S T X

ERV-10 32 30 42

ERV-20

ERV-45

ERV-55

(30 for maintenance)

(39 for maintenance)

(32 for maintenance)

44

60

65

ERV-90 42

ERV-120 42

All dimensions are in inches.

30 42

40 42

40 42

Access Panels

X

Access PanelAccess Panel

Cassette

X

Access PanelAccess Panel

X

Cassette

Access Panel

X

Access Panel

X

Arrangement A

X

Cassette

Access PanelAccess Panel

X

Cassette

Supply

Weatherhood

Arrangement B, C or D

Energy Recovery Ventilator

Access Panel

Exhaust

Weatherhood

X

7

Page 8

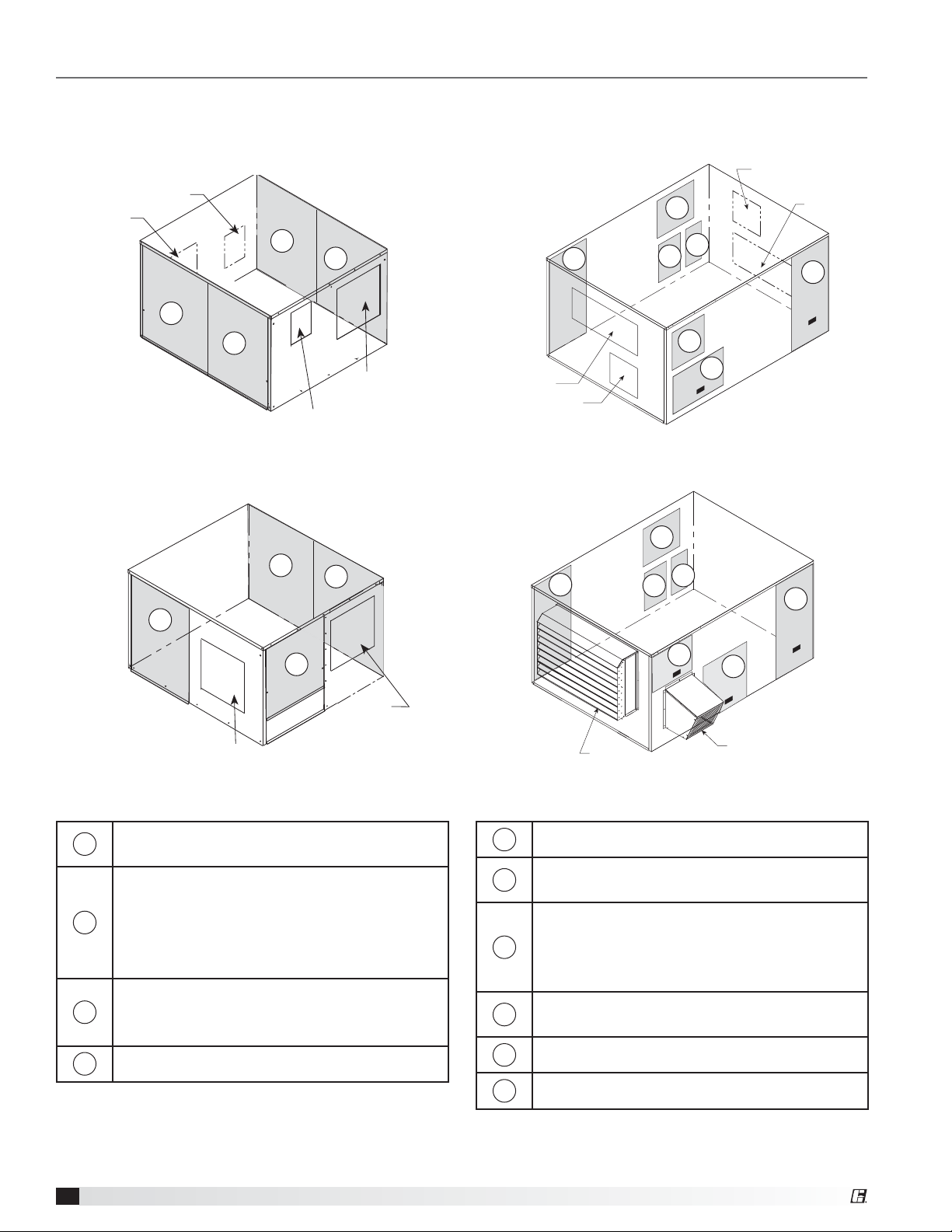

Access Panel Locations

g

ERV-10, ERV-20, ERV-45, ERV-55 ERV-90

Outdoor Air

Discharge

Exhaust Air

Inlet

3

1

2

Interior

3

Outdoor Air

Discharge

5

2

6

Exhaust Air

Inlet

3

4

Arrangement A

1

3

Exhaust Air

Dischar

e

Arrangement B, C or D

Exhaust Air

Discharge

4

Outdoor Ai

2

Intake

Outdoor Air

Intake

Outdoor Air Inlet

Exhaust Air Discharge

Rooftop

3

4

1

Arrangement A

5

2

6

4

Intake Hood

1

Exhaust Hood

Arrangement B, C or D

3

1

Outdoor air blower and motor

Energy wheel cassette

Energy wheel cassette

Internal filters

2

Outdoor air intake damper

Frost control

Outdoor air sensors

Main disconnect

3

Electrical control center

Internal filters

4

Energy Recovery Ventilator

8

Exhaust air blower and motor

1

2

Exhaust blower and motor

Electric control center

Main Disconnect

Energy wheel cassette

3

Internal filters

Frost control

Outdoor air sensors

4

5

6

Preheater controls

Outdoor air intake damper

Supply blower and motor

Exhaust air intake damper

Page 9

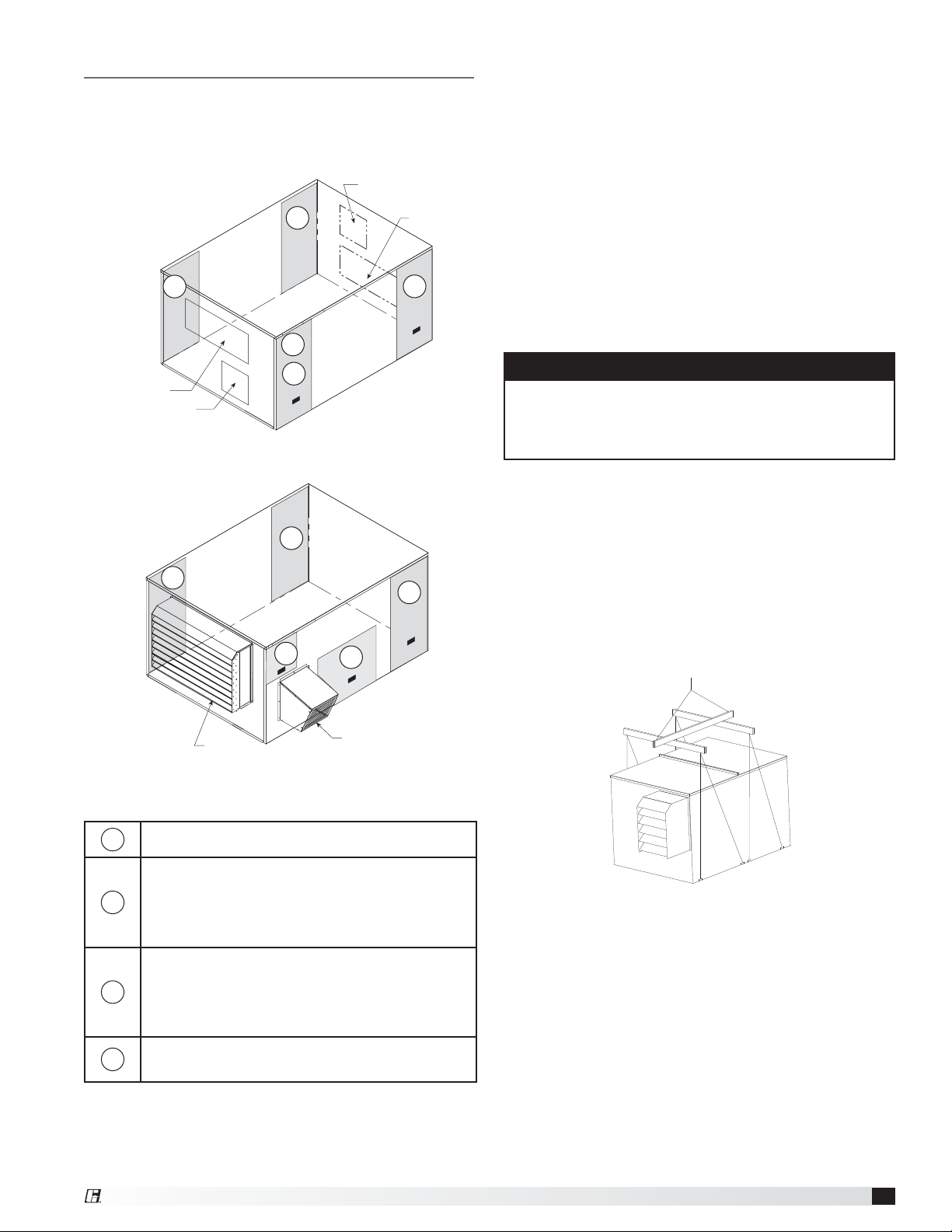

Access Panel Locations continued

ERV-120

Outdoor Air

Discharge

2

3

Exhaust Air

Intake

3

Handling

While this unit was constructed with quality and

dependability in mind, damage still may occur during

handling of the unit for installation. Exercise extreme

caution to prevent any damage from occurring to the

refrigerant system.

The system design and installation should follow

accepted industry practice, such as described in

the ASHRAE Handbook. Adequate space should

be left around the unit for filter replacement and

maintenance. Sufficient space should be provided on

the side of the unit for routine service and component

removal should that become necessary.

Outdoor Air Intake

Exhaust Air Discharge

3

4

1

Arrangement A

2

4

Outdoor

Weatherhood

Arrangement B, C or D

Exhaust Hood

Lifting

WARNING

All factory provided lifting lugs must be used when

lifting the unit. Failure to comply with this safety

precaution could result in property damage, serious

injury or death.

1. Before lifting, be sure that all shipping material

has been removed from unit.

2. To assist in determining rigging requirements,

weights are shown below.

3. Unit must be lifted by all lifting lugs provided on

3

1

base structure.

4. Rigger to use suitable mating hardware to attach

to unit lifting lugs.

5. Spreader bar(s) must span the unit to prevent

damage to the cabinet by the lift cables.

1

2

3

4

Exhaust blower and motor

Electric control center

Main disconnect

Supply blower and motor

Exhaust air intake damper

Energy wheel cassette

Internal filters

Frost control

Outdoor air sensor

Preheater controls

Outdoor air intake damper

6. Always test-lift the unit to check for proper

balance and rigging before hoisting to desired

location.

7. Never lift units by weatherhoods.

8. Never lift units in windy conditions.

9. Preparation of curb and roof openings should be

completed prior to lifting unit to the roof.

10. Check to be sure that gasketing (supplied by

others) has been applied to the curb prior to

lifting the unit and setting on curb.

11. Do not use fork lifts for handling unit.

Energy Recovery Ventilator

9

Page 10

Roof Curb Mounting

R

o

t

a

t

i

o

n

POOR

Roof curb details including duct location dimensions,

are available on ERV-90 & 120 Roof Curb Assembly

Instructions.

Rooftop units require curbs to be mounted first. The

duct connections must be located so they will be

clear of structural members of the building.

1. Factory Supplied Roof Curbs: Roof curbs are

Model GPI or GPNS for the ERV-10, 20, 45, 55.

The GPI or GPNS ships assembled and includes a

duct adapter.

Roof curbs are Model GKD for the ERV-90 and

120. The GKD ships in a knockdown kit (includes

duct adapter) and requires field assembly (by

others). Assembly instructions are included with

the GKD curbs.

2. Install Curb: Locate curb over roof opening and

fasten in place. (Refer to Recommended Roof

Openings). Check that the diagonal dimensions

are within ±1/8 inch of each other and adjust

as necessary. For proper unit operation, it is

important that the installation be level. Shim as

required to level.

3. Install Ductwork: Installation of all ducts should

be done in accordance with SMACNA and AMCA

guidelines. Duct adapter provided to support

ducts prior to setting the unit.

4. Set the Unit: Lift unit to a point directly above

the curb and duct openings. Guide unit while

lowering to align with duct openings. Roof curbs

fit inside the unit base. Make sure the unit is

properly seated on the curb and is level.

Curb Outside Dimensions and Weights

Side of Unit

B

C

D

Roof Curb

E

Base

A

1-inch Insulation

Curb Cap Details for Factory Supplied Roof Curbs

Unit Size A

BCDE

ERV-10 1.75 2.00 1.00 1.125 0.750

ERV-20 1.75 2.00 1.00 1.200 0.875

ERV-45 1.75 2.00 1.00 0.813 0.875

ERV-55 1.75 2.00 1.00 0.813 0.750

ERV-90 1.813 4.00 1.75 1.000 0.750

ERV-120 1.938 4.125 1.938 1.125 0.625

All dimensions are in inches.

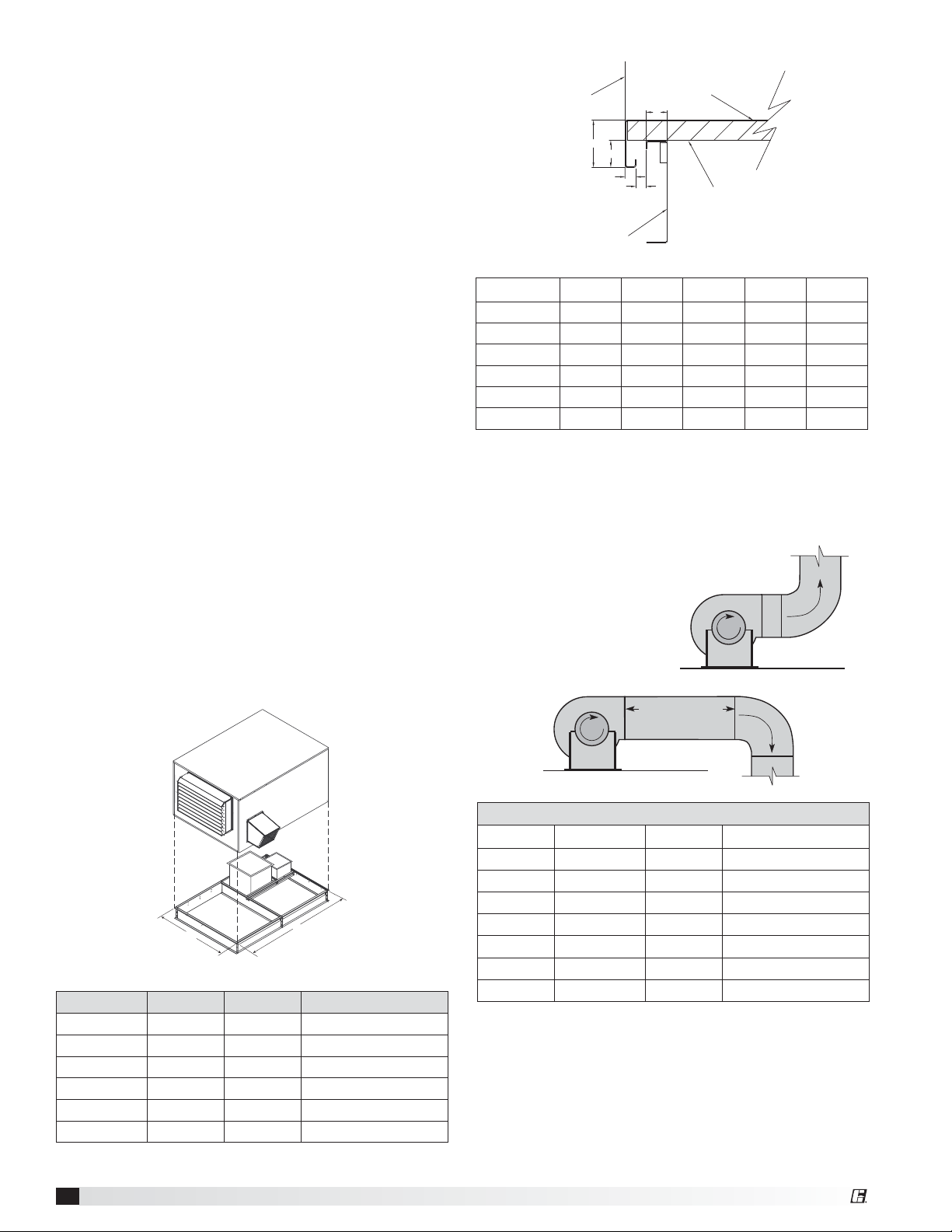

Ductwork Connections

Examples of poor and good fan-to-duct connections

are shown. Airflow out of the fan should

be directed straight or curve the

same direction as the

fan wheel rotates. Poor

duct installation will

result in low airflow and

other system effects.

n

o

i

t

a

t

o

R

Length of Straight Duct

W

L

ERV-90 and 120

Unit Size L W Curb Weight (lbs.)

ERV-10 42.5 30.5 60

ERV-20 58.5 47.5 115

ERV-45 63.5 63.5 160

ERV-55 71.8 66 185

ERV-90 120.5 80.5 520

ERV-120 142.25 93 700

All dimensions are in inches. Weights are for 12-inch high

GPI type curbs.

Energy Recovery Ventilator

10

GOOD

Recommended Discharge Duct Size and Length

Model Blower Size Duct Size Straight Duct Length

ERV-10 10 9 x 9 36

ERV-20 10 14 x 14 36

ERV-45 12 20 x 20 36

ERV-55 15 28 x 28 60

ERV-90L 15 28 x 28 60

ERV-90H 18 32 x 32 60

ERV-120 20 34 x 34 72

All dimensions shown in inches.

• Recommended duct sizes are based on velocities across the

cfm range of each model at approximately 800 feet per minute

(FPM) at minimum airflow and up to 1600 fpm at maximum

airflow. Recommended duct sizes are only intended to be a

guide and may not satisfy the requirements of the project.

Refer to plans for appropriate job specific duct size and/or

velocity limitations.

• Straight duct lengths were calculated based on 100% effective

duct length requirements as prescribed in AMCA Publication

201. Calculated values have been rounded up to nearest foot.

Page 11

Rail Mounting / Layout

• Rails designed to handle the weight of the ERV should be positioned as shown on the diagram (rails by

others).

• Make sure that rail positioning does not interfere with the supply air discharge opening or the exhaust air

intake opening on the ERV unit. Avoid area dimensioned “B” below.

• Rails should extend beyond the unit a minimum of 12 inches on each side.

• Set unit on rails.

ERV-10

ERV-20

ERV-45

ERV-55

ERV-90

ERV-120

OUTDOOR AIR SIDE

Isometric view of

ERV on rails

OUTDOOR AIR SIDE

Side view of

ERV on rails

Unit Size A

ERV-10 4.50 16

ERV-20 4.75 18

ERV-45 5.75 24

ERV-55 4.875 22

All dimensions are in inches.

SUPPLY/EXHAUST

OPENING

B

OUTDOOR AIR INTAKE END

Isometric view of

ERV on rails

OUTDOOR AIR INTAKE HOOD

Side view of

AB

ERV on rails

SUPPLY/EXHAUST

A

Unit Size A

OUTDOOR AIR INTAKE END

OPENING

B

B

ERV-90 4.625 32

ERV-120 4.875 33.25

All dimensions are in inches.

Outdoor Air Weatherhood

Outdoor air weatherhood will be factory

mounted.

Exhaust Weatherhood

The exhaust weatherhood is shipped

separately as a kit with its own

instructions.

Dampers

Backdraft dampers are always

included as an integral part of the

exhaust hood assemblies. Motorized

outdoor air and exhaust air dampers

are optional and are factory mounted

(and wired) at the intake.

Energy Recovery Ventilator

11

Page 12

Electrical Information

The unit must be electrically grounded in accordance

with the current National Electrical Code, ANSI/NFPA

70. In Canada, use current CSA Standard C22.1,

Canadian Electrical Code, Part 1. In addition, the

installer should be aware of any local ordinances or

electrical company requirements that might apply.

System power wiring must be properly fused and

conform to the local and national electrical codes.

System power wiring is to the unit main disconnect

(door interlocking disconnect switch standard

on most units) or distribution block and must be

compatible with the ratings on the nameplate: supply

power voltage, phase, and amperage (Minimum

Circuit Amps - MCA, Maximum Overcurrent Protection

- MOP). All wiring beyond this point has been done

by the manufacturer and cannot be modified without

affecting the unit’s agency / safety certification.

If field installing an additional disconnect switch, it

is recommended that there is at least four feet of

service room between the switch and system access

panels. When providing or replacing fuses in a fusible

disconnect, use dual element time delay fuses and

size according to the rating plate.

If power supply is desired through bottom of unit, run

the wiring through the curb, cut a hole in the cabinet

bottom, and wire to the disconnect switch. Seal

penetration in cabinet bottom to prevent leakage.

The electric supply to the unit must meet stringent

requirements for the system to operate properly.

Voltage supply and voltage imbalance between

phases should be within the following tolerances.

If the power is not within these voltage tolerances,

contact the power company prior to operating the

system.

Voltage Supply: See voltage use range on the rating

plate. Measure and record each supply leg voltage at

all line disconnect switches. Readings must fall within

the allowable range on the rating plate.

Voltage Imbalance: In a 3-phase system, excessive

voltage imbalance between phases will cause motors

to overheat and eventually fail. Maximum allowable

imbalance is 2%. To determine voltage imbalance,

use recorded voltage measurements in this formula.

Key: V1, V2, V3 = line voltages as measured

VA (average) = (V1 + V2 + V3) / 3

VD = Line voltage (V1, V2 or V3) that

deviates farthest from average (VA)

Formula: % Voltage Imbalance = [100 x (VA-VD)] / VA

WARNING

To prevent injury or death due to electrocution or

contact with moving parts, lock disconnect switch

open.

Most factory supplied electrical components are

prewired. To determine what electrical accessories

require additional field wiring, refer to the unit specific

wiring diagram located on the inside of the unit

control center access door. The low voltage control

circuit is 24 VAC and control wiring should not exceed

0.75ohms.

Refer to Field Control Wiring Length/Gauge table for

wire length maximums for a given wire gauge.

Field Control Wiring Length/Gauge

Total

Wire Length

125 ft. 18

200 ft. 16

300 ft. 14

450 ft. 12

Minimum

Wire Gauge

Control wires should not be run inside the same

conduit as that carrying the supply power. Make sure

that field supplied conduit does not interfere with

access panel operation.

If wire resistance exceeds 0.75 ohms, an industrialstyle, plug-in relay should be added to the unit

control center and wired in place of the remote

switch (typically between terminal blocks R and G

on the terminal strip (refer to Typical Control Center

Components). The relay must be rated for at least

5 amps and have a 24 VAC coil. Failure to comply

with these guidelines may cause motor starters to

“chatter” or not pull in which can cause contactor

failures and/or motor failures.

CAUTION

If any of the original wire as supplied with the

appliance must be replaced, it must be replaced

with wiring material having a temperature rating of

at least 105ºC.

Energy Recovery Ventilator

12

Page 13

Typical Control Center Components

g

1. Main Disconnect (non-fusible, lockable)

2. Motor Starter – Exhaust Air Fan

3. Motor Starter – Outdoor Air Fan

4. Motor Contactor – Energy Wheel

5. 24 VAC Control Transformer

6. 24 VAC Terminal strip

7. Fuses for blower motors

5

1

6

7

2 3 4

Exploded Detail

of Terminal Strip

ERV-10, 20, 45, 55

Outdoor Air

Intake

Exhaust Air

Dischar

e

Access to Control Center Components

is gained through the access panel indicated.

ERV-90

ERV-120

Intake

Hood

Exhaust Hood

Outdoor

Weatherhood

Exhaust Hood

Energy Recovery Ventilator

13

Page 14

Optional Accessory Wiring Schematics

Remote Panel

The remote panel is available with a number of

different alarm lights and switches to control the unit.

The remote panel ships loose and requires mounting

and wiring in the field. The remote panel is available

with the following options:

• Unit on/off switch

• Unit on/off light

• 7-day time clock

• Hand/off/auto switch

• Dirty filter light

• Economizer light

• Frost control light

• Wheel rotation sensor light

Unit Interfacing Terminals

Heating/Cooling Switches & Night Setback

Switch/Timer

TERMINAL BLOCKS IN

UNIT CONTROL CENTER

R

UNIT ON/OFF

S1

COOL STAGE 1 / ECONOMIZER

S6

COOL STAGE 2

S7

HEAT

S4

C

G

Y1

Y2

W1

6

7

12

7-Day Timer

TERMINAL BLOCKS IN

UNIT CONTROL CENTER

R

BLACK BLUE

RED

(CAPPED)

TIMER

C

G

Y1

Y2

W1

6

7

12

On/Off/Auto Switch & Indictor Light Wiring

TERMINAL BLOCKS IN

UNIT CONTROL CENTER

UNIT ON/OFF

FROST CONTROL

ECONOMIZER

WHEEL ROTATION

ON

OFF

AUTO

* -- BMS, TIMECLOCK,

TSTAT, RTU, ETC.

*

R

C

G

Y1

Y2

W1

6

7

12

UNOCCUPIED RECIRCULATION

S5

Dirty Filter Indicator

(powered by others)

HOT COMMON

SUPPLY DIRTY

FILTER SWITCH

EXHAUST DIRTY

FILTER SWITCH

NC

NC

A

C

NO

C

NO

DIRTY FILTER

C

SUPPLY DIRTY

FILTER SWITCH

EXHAUST DIRTY

FILTER SWITCH

ON/OFF/AUTO SWITCH ALLOWS THREE MODES OF OPERATION

"ON" - UNIT IS TURNED ON MANUALLY

"OFF" - UNIT IS TURNED OFF MANUALLY

"AUTO" - UNIT IS CONTROLLED VIA SCHEDULER OF BMS, TIMECLOCK, TSAT, ETC.

Energy Recovery Ventilator

14

NC

NC

NO

C

NO

DIRTY FILTER

Page 15

Unit Overview

Optional Component Overview

Basic Unit

The unit is pre-wired such that when a call for outside

air is made (via field-supplied 24 VAC control signal

wired to unit control center), the supply fan, exhaust

fan, and energy wheel are energized and optional

motorized dampers open.

The unit can be supplied with or without heating

and cooling coils. For units with coils, controls can

be supplied by manufacturer or by the controls

contractor. If supplied by the controls contractor,

they would provide, mount, and wire any temperature

controllers and temperature or relative humidity

sensors required for the unit to discharge air at the

desired conditions. However, temperature, pressure,

and current sensors can be provided by manufacturer

for purposes of monitoring via the BMS.

Summer Operation

Outdoor air is preconditioned (temperature and

moisture levels are decreased) by the transfer of

energy from the cooler, drier exhaust air via the

energy recovery wheel. The preconditioned air is

typically mixed with return air going back to the air

handler for final conditioning.

Room Air

75° F

50% RH

Exhaust Air

Supply Air

Outdoor Air

95° F

117 grains/lb.

79° F

75 grains/lb.

Winter Operation

Outdoor air is preconditioned (temperature and

moisture levels are increased) by the transfer of

energy from the warmer, more humid exhaust air via

the energy recovery wheel. The preconditioned air is

typically mixed with return air going back to the air

handler for final conditioning.

Economizer

The energy wheel operation can be altered to take

advantage of economizer operation (free cooling).

Two modes are available:

1. Stopping the wheel

2. Modulating the wheel

Stopping the wheel: A field-supplied call for

cool (Y1) is required. De-energizing the wheel is

accomplished one of three ways:

1. The outdoor air temperature is less than the

outdoor drybulb set point (DRYBLB SET)

2. The outdoor air temperature is less than the

return air temperature

3. The outdoor air enthalpy is within the preset

enthalpy curve

A low temperature lock out (LOW T LOCK) is also set

to deactivate mechanical cooling when it exceeds

the outdoor air temperature (factory default 32ºF).

Effectively, the two sensors create a deadband where

the energy recovery wheel will not operate and free

cooling from outside can be brought into the building

unconditioned.

Modulating the wheel (factory): A variable

frequency drive is fully programmed at the factory.

A “call for cool” must be field wired to the unit

(terminals provided in unit-refer to wiring diagram

in unit control center) to allow for initiation of

economizer mode. The unit recognizes economizer

conditions based one of the previously mention

sensors and set points. The unit will then modulate

the wheel speed to maintain the mixed air

temperature set point (MAT SET).

Modulating the wheel (by others): A variable

frequency drive is fully programmed at the factory.

A field-supplied 0-10 VDC signal will be required

for operation of the energy wheel. The field will be

required to have full control of the energy wheel

speed at all times. If no 0-10 VDC signal is provided,

the energy wheel will run at the factory default of 3 Hz

and no energy transfer will be captured.

Exhaust Air

Outdoor Air

10° F

5 grains/lb.

Room Air

72° F

40% RH

Supply Air

60° F

39 grains/lb.

Energy Recovery Ventilator

15

Page 16

Frost Control

Extremely cold outdoor air temperatures can cause

moisture condensation and frosting on the energy

recovery wheel. Frost control is an optional feature

that will prevent/control wheel frosting. Three options

are available:

1. Timed exhaust frost control

2. Electric preheat frost control

3. Modulating wheel frost control

All of these options are provided with a thermodisc

mounted in the outdoor air intake compartment and a

pressure sensor to monitor pressure drop across the

energy wheel.

An outdoor air temperature of below 5ºF and an

increase in pressure drop would indicate that frost is

occurring. Both the pressure sensor and the outdoor

air thermodisc must trigger in order to initiate frost

control. The two sensors together ensure that frost

control is only initiated during a real frost condition.

Timed exhaust frost control includes a timer

in addition to the thermodisc and wheel pressure

sensor. When timed exhaust frost control is initiated,

the timer will turn the supply blower off. Time exhaust

using default timer setting will shut down the supply

fan for 5 minutes every 30 minutes to allow exhaust

to defrost energy wheel. Use the test procedure

in the Optional Start-Up Accessories section for

troubleshooting.

Electric preheat frost control includes an electric

heater (at outdoor air intake) in addition to the

thermodisc and pressure sensor on wheel. When

electric preheat frost control is initiated, the electric

preheater will turn on and warm the air entering

the energy wheel to avoid frosting. Use the test

procedure in the Optional Start-Up Accessories

section for troubleshooting.

Modulating wheel frost control includes a variable

frequency drive (VFD) in addition to the thermodisc

and pressure sensor. When modulating wheel frost

control is initiated, the VFD will reduce the speed

of the wheel. Reducing the speed of the energy

wheel reduces its effectiveness, which keeps the

exhaust air condition from reaching saturation, thus,

eliminating condensation and frosting. If the outdoor

air temperature is greater than the frost threshold

temperature OR the pressure differential is less than

the set point, the wheel will run at full speed. If the

outdoor air temperature is less than 5ºF AND the

pressure differential is greater than the set point, the

wheel will run at reduced speed until the pressure

differential falls below the set point. The VFD will be

fully programmed at the factory.

Variable Frequency Drives (VFD)

VFDs are used to control the speed of the fan as

either multi-speed or modulating control. Multispeed VFDs reference a contact which can be made

by a switch or a sensor with a satisfied set point.

Modulating control references a 2-10 VDC signal

to the VFD which will vary the fan speed from a

minimum 50% to full 100% rpm. An optional CO

sensor is available to provide both a set point contact

or a modulating 2-10 VDC signal.

2

CO2 Sensor

This accessory is often used in Demand Control

Ventilation (VDC) applications. The factory provided

sensors can either be set to reference a set point for

multi-speed operation, or output a 2-10 VDC signal to

modulate the fan speed. These can either be shipped

loose to mount in the ductwork, or can be factory

mounted in the return air intake. Follow instructions

supplied with sensor for installation and wiring

details.

Rotation Sensor

The rotation sensor monitors energy wheel rotation. If

the wheel should stop rotating, the sensor will close a

set of contacts in the unit control center. Field-wiring

of a light (or other alarm) between terminals R and

12 in the unit control center will notify maintenance

personnel when a failure has occurred.

Dirty Filter Sensor

Dirty filter sensors monitor pressure drop across the

outdoor air filters, exhaust air filters, or both. If the

pressure drop across the filters exceeds the set point,

the sensor will close a set of contacts in the unit

control center. Field-wiring of a light (or other alarm)

to these contacts will notify maintenance personnel

when filters need to be replaced. The switch has not

been set at the factory due to external system losses

that will affect the switch. This switch will need minor

field adjustments after the unit has been installed

with all ductwork complete. The dirty filter switch is

mounted in the exhaust inlet compartment next to the

unit control center or in unit control center.

Service Outlet

120 VAC GFCI service outlet ships loose for field

installation. Requires separate power source so

power is available when unit main disconnect is

turned off for servicing.

Energy Recovery Ventilator

16

Page 17

Start-Up

DANGER

Electric shock hazard. Can cause injury or death.

Before attempting to perform any service or

maintenance, turn the electrical power to unit

to OFF at disconnect switch(es). Unit may have

multiple power supplies.

WARNING

Use caution when removing access panels or other

unit components, especially while standing on a

ladder or other potentially unsteady base. Access

panels and unit components can be heavy and

serious injury may occur.

Do not operate energy recovery ventilator without

the filters and birdscreens installed. They prevent

the entry of foreign objects such as leaves, birds,

etc.

CAUTION

Do not run unit during construction phase. Damage

to internal components may result and void

warranty.

General Start-Up Information

Every installation requires a comprehensive startup to ensure proper operation of the unit. As part

of that process, the following checklist must be

completed and information recorded. Starting up

the unit in accordance with this checklist will not

only ensure proper operation, but will also provide

valuable information to personnel performing future

maintenance. Should an issue arise which requires

factory assistance, this completed document

will allow unit experts to provide quicker resolve.

Qualified personnel should perform start-up to ensure

safe and proper practices are followed.

Unit Model Number _______________________________

Unit Serial Number _______________________________

Energy Wheel Date Code __________________________

Start-Up Date _______________________________

Start-Up Personnel Name __________________________

Start-Up Company _______________________________

Phone Number _______________________________

Pre Start-Up Checklist – check as items are

completed.

Disconnect and lock-out all power switches

Remove any foreign objects that are located in the

energy recovery unit.

Check all fasteners, set-screws, and locking collars

on the fans, bearings, drives, motor bases and

accessories for tightness.

(e.g. ERV-20)

(e.g. 04C99999 or 10111000)

(e.g. 0450)

Rotate the fan wheels and energy recovery wheels

by hand and ensure no parts are rubbing. If

rubbing occurs, refer to Start-Up section for more

information.

Check the fan belt drives for proper alignment

and tension (refer to Start-Up section for more

information).

Filters can load up with dirt during building

construction. Replace any dirty pleated filters and

clean the aluminum mesh filters in the intake hood

(refer to Routine Maintenance section).

Verify that non-motorized dampers open and close

properly.

Check the tightness of all factory wiring

connections.

Verify control wire gauge (refer to the Electrical

Connections section).

Verify diameter seal settings on the energy

recovery wheel (refer to Start-Up section for more

information).

SPECIAL TOOLS REQUIRED

• Voltage Meter (with wire probes)

• Amperage Meter

• Thermometer

• Tachometer

• Incline manometer or equivalent

Start-Up Checklist

The unit will be in operational mode during start-up.

Use necessary precautions to avoid injury. All data

must be collected while the unit is running. In order to

measure volts & amps, the control center door must

be open, and the unit energized using a crescent

wrench to turn the disconnect handle.

Check line voltage at unit disconnect

_______ L1-L2 volts

_______ L2-L3 volts

_______ L1-L3 volts

Motor Amp Draw

• Supply Fan • Exhaust Fan

_______ L1 amps ______ L1 amps

_______ L2 amps ______ L2 amps

_______ L3 amps ______ L3 amps

• Energy Wheel

_______ L1 amps

_______ L2 amps

_______ L3 amps

Fan RPM

_______ Supply Fan ______ Exhaust Fan

Correct fan rotation direction

Supply Fan Yes / No

Exhaust Fan Yes / No

Energy Recovery Ventilator

17

Page 18

Optional Accessories Checklist

Refer to the respective sections in this Installation, Operation and Maintenance Manual for detailed information.

Refer to wiring diagram in unit control center to determine what electrical accessories were provided.

Provided with Unit?

Frost Control Application / Operation section: Setting Factory Default

Yes No Frost Control set point 5ºF

Differential 2ºF

Timer Refer to IOM

Yes No Frost Control Modulating Refer to IOM

Economizer Application / Operation section:

Yes No Economizer (temperature)

Set point 65ºF

Offset 20ºF

Differential 2ºF

Yes No Economizer (enthalpy)

Set point D

Yes No Economizer (modulating) Refer to IOM

Optional Accessories section: Operational

Yes No Wheel Rotation Sensor Yes No N/A

Yes No OA Dirty Filter Sensor Yes No N/A

Yes No EA Dirty Filter Sensor Yes No N/A

Yes No CO

Sensor Yes No N/A

2

Yes No Service Outlet Yes No N/A

Yes No Remote Control Panel Yes No N/A

Variable Frequency Drives section: Operational

Yes No Blower VFDs Yes No N/A

Yes No Wheel VFD Yes No N/A

Damper section: Operational

Yes No Outdoor Air Damper Yes No N/A

Yes No Exhaust Air Damper Yes No N/A

Energy Recovery Ventilator

18

Page 19

Start-Up Components

Fans

The ERV models contain two forward curved (supply

ans exhaust) fans. These

forward curved fans should

be checked for free rotation.

If any binding occurs, check

for concealed damage and

foreign objects in the fan

housing. Be sure to check

the belt drives per the startup recommendations in the

following section.

CAUTION

When operating conditions of the fan are to be

changed (speed, pressure, temperature, etc.),

consult Greenheck to determine if the unit can

operate safely at the new conditions.

Fan Performance Modifications

Due to job specification revisions, it may be

necessary to adjust or change the sheave or pulley to

obtain the desired airflow at the time of installation.

Start-up technician must check blower amperage

to ensure that the amperage listed on the motor

nameplate is not exceeded. Amperage to be tested

with access doors closed and ductwork installed.

Fan Belt Drives

The fan belt drive components, when supplied by

Greenheck, have been carefully selected for the

unit’s specific operating condition. Utilizing different

components than those supplied could result in

unsafe operating conditions which may cause

personal injury or failure of the following components:

• Fan Shaft • Bearings • Motor

• Fan Wheel • Belt

Tighten all fasteners and set screws securely and

realign drive pulleys after adjustment. Check pulleys

and belts for proper alignment to avoid unnecessary

belt wear, noise, vibration and power loss. Motor and

drive shafts must be parallel and pulleys in line (see

diagrams in this section).

Belt Drive Installation

1. Remove the protective coating from the end of

the fan shaft and assure that it is free of nicks and

burrs.

2. Check fan and motor shafts for

parallel and angular alignment.

3. Slide sheaves on shafts. Do

not drive sheaves on as

this may result in bearing

damage.

Forward Curved

Exhaust Fan

4. Align fan and motor sheaves with a straight-edge

or string and tighten.

5. Place belts over sheaves. Do not pry or force

belts, as this could result in damage to the cords

in the belts.

6. With the fan off, adjust the belt tension by moving

the motor base. (See belt tensioning procedures in

the Routine Maintenance section of this manual).

When in operation, the tight side of the belts

should be in a straight line from sheave to sheave

with a slight bow on the slack side.

WRONG WRONG

WRONG CORRECT

Direction of Fan Wheel Rotation

Blower access is labeled on unit. Check for proper

wheel rotation by momentarily energizing the fan.

Rotation is determined by viewing the wheel from the

drive side and should match the rotation decal affixed

to the fan housing (see Rotation Direction figures).

If the wheel is rotating the wrong way, direction can

be reversed by interchanging any two of the three

electrical leads.

Check for unusual noise, vibration, or

overheating of bearings. Refer to the Troubleshooting

section of this manual if a problem develops.

t

t

a

i

o

o

n

R

n

o

i

t

a

t

o

R

Airflow

Forward Curved

Fan RPM

Supply fan and exhaust fan will have an adjustable

motor pulley (on 15 HP and below) preset at the

factory to the customer specified RPM. Fan speed

can be increased or decreased by adjusting the pitch

diameter of the motor pulley. Multi-groove variable

pitch pulleys must be adjusted an equal number

of turns open or closed. Any increase in fan speed

represents a substantial increase in load on the

motor. Always check the motor amperage reading

and compare it to the amperage rating shown on the

motor nameplate when changing fan RPM. All access

doors must be installed except the control center

door. Do not operate units with access doors open or

without proper ductwork in place as the fan motors

will overload.

Energy Recovery Ventilator

19

Page 20

Vibration

Excessive vibration may be experienced during initial

start-up. Left unchecked, excessive vibration can

cause a multitude of problems, including structural

and/or component failure. The most common sources

of vibration are listed.

Many of these

Wheel Unbalance

Drive Pulley Misalignment

Incorrect Belt Tension

Bearing Misalignment

Mechanical Looseness

Faulty Belts

Drive Component Unbalance

Poor Inlet/Outlet Conditions

Foundation Stiffness

conditions can be

discovered by careful

observation. Refer to

the Troubleshooting

section of this manual

for corrective actions.

If observation cannot

locate the source of

vibration, a qualified

technician using vibration analysis equipment should

be consulted. If the problem is wheel unbalance,

in-place balancing can be done.

Generally, fan vibration and noise is transmitted

to other parts of the building by the ductwork. To

eliminate this undesirable effect, the use of heavy

canvas connectors is recommended.

Energy Recovery Wheel

The ERV models contain a total energy recovery

wheel. The wheels are inspected for proper

mechanical operation at the factory. However, during

shipping and handling, shifting can occur that may

affect wheel operation. The wheel is accessible

through the access door marked “Energy Wheel

Cassette Access”. For the ERV-10, 20, 45, and 90,

the wheel cassette(s) slide out. Due to the size and

weight of the ERV-55 and 120 wheels, they remain

stationary and all maintenance is performed in place.

There is room inside the unit to perform energy

recovery wheel servicing.

Turn the energy recovery wheels by hand to verify

free operation. The wheel should rotate smoothly and

should not wobble.

Drive Belt

Inspect the drive belt. Make sure the belt rides

smoothly through the pulley and over the wheel rim.

Bearing

Adjustable

Air Seals

Drive Belt

Drive Pulley

Support

Label

showing

cassette

serial #

and date

code

Air Seals

Check that the air seals located around the outside of

the wheel and across the center (both sides of wheel)

are secure and in good condition. Air seal clearance

is determined by placing a sheet of paper, to act as a

feeler gauge, against the wheel face. To access seals,

enter the unit for the ERV-55 and 120, or pull out the

cassette for the ERV-10, 20, 45, and 90, following

the instructions in the Energy Recovery Wheel

Maintenance section. To adjust the air seals, loosen

all eight seal retaining screws. These screws are

located on the bearing support that spans the length

of the cassette through the wheel center. Tighten the

screws so the air seals tug slightly on the sheet of

paper.

Replace cassette into unit, plug in wheel drive,

replace access door and apply power. Observe by

opening door slightly (remove filters if necessary to

view wheel) the wheel should rotate freely at about

50-60 RPM.

Optional Start-Up Components

Dirty Filter Switch

Setscrew (on front of switch) must

be manually adjusted after the

system is in operation.

Negative pressure connection

is toward the ‘front or top’ of

the switch. (Senses pressure on

the blower side of filters)

Positive pressure connection is toward the ‘back or bottom’

of the switch. (Senses pressure at air inlet side of filters)

To adjust the switch, the unit must be running with

all of the access doors in place, except for the

compartment where the switch is located (exhaust

intake compartment). The adjusting screw is located

on the top of the switch.

1. Open the filter compartment and place a sheet of

plastic or cardboard over 50% of the filter media.

2. Replace the filter compartment door.

3. Check to see if there is power at the alert signal

leads (refer to electrical diagram).

4. Whether there is power or not, turn the

adjustment screw on the dirty filter gauge

(clockwise if you did not have power, counterclockwise if you did have power) until the power

comes on or just before the power goes off.

5. Open the filter compartment and remove the

obstructing material.

6. Replace the door and check to make sure that

you do not have power at the alert signal leads.

The unit is now ready for operation.

Energy Recovery Ventilator

20

Page 21

Economizer

Relevant Set Points

1. MAT SET The mixed air temperature set point

after the energy wheel. The control will modulate

the energy wheel to maintain temperature as best

as it can. (Set point menu, default 53°F )

2. LOW T LOCK The set point for the low

temperature mechanical cooling lockout. (Set

point menu, default 32°F)

3. DRYBLB SET The outdoor air set point to call for

economizer. (Set point menu, default 63°F)

4. MIN POS The minimum signal voltage sent to

the energy wheel. This must be set to 2 VDC. (Set

point menu, default 2.8 VDC)

5. AUX1 O The controllers operating sequence

structure. (Set point menu, default ‘None’)

6. ERV OAT SP The set point for low temperature

economizer lockout. This is the low temperature

set point when AUX1 O is set to ERV. (Set point

menu, default 32°F)

7. STG3 DLY Time delay after second cooling stage

is enabled (Advanced setup menu, default 2 hrs.)

Using the Keypad with Settings and Parameters

To use the keypad when working with Set points,

System and Advanced Settings, Checkout tests, and

Alarms:

1. Navigate to the desired menu.

2. Press

currently displayed menu.

3. Use the and buttons to scroll to the desired

parameter.

4. Press

currently displayed item.

5. Press the button to increase (change) the

displayed parameter value.a

6. Press the

displayed parameter value.

7. Press (enter) to accept the displayed value and

store it in non-volatile RAM.

8. CHANGE STORED displays.

9. Press

parameter.

10. Press

parameter.

a

When values are displayed, pressing and

holding the or button causes the display to

automatically increment.

(enter) to display the first item in the

(enter) to display the value of the

button to increase (change) the

a

(enter) to return the current menu

(escape) to return to the current menu

The table shows which set points are relevant to the

given sequences. Refer to the wiring diagram for the

units’s sequence.

MODULATE WHEEL STOP WHEEL

OA

OA

Temp

Enthalpy

DRYBLB SET X X

MAT SET X X X X X X

LOW T LOCK X X X X X X

ERV OAT SP X X X

MIN POS X X X

AUX1 OUT ERV ERV ERV

STG3 DLY X X X X X X

OA/RA

Temp

Differential

OA

Temp

OA

Enthalpy

OA/RA

Temp

Differential

Stop Wheel

1. Navigate to the Checkout menu and press

(enter).

2. The energy wheel and cooling should stop.

3. Navigate to Connect ERV and press

(enter)

twice to run the test.

4. Voltage between AUX1-O and C should be 24

VAC. The energy wheel should activate.

Modulate Wheel

1. Navigate to the Checkout menu and press

(Enter).

2. The cooling should turn off and the wheel should

be rotating at full speed.

3. Navigate to Damper Open and press

twice to run the test.

4. Voltage between terminals ACT 2-10 and ACT

COM should be 10 VDC. This will slow the wheel

down to minimum speed.

5. Press

press

(escape), navigate to Damper Close and

(enter) twice to run the test.

6. Voltage between terminal ACT 2-10 and ACT

COM should be 2 VDC. This will speed the wheel

up to maximum speed.

(enter)

Energy Recovery Ventilator

21

Page 22

Frost Control

Timed Exhaust

1. Remove power from unit.

2. Jumper the frost indicating wheel pressure switch

in the unit control center.

3. Jumper the temperature indicating thermodisc in

the unit control center. Thermodisc has a pre-set

temperature of 5ºF.

4. Set the frost control timer scale for T1 and T2 to

1m. Set the timer settings for T1 and T2 to 10.

5. Add power to the unit. Blower

should cycle on for one minute,

then turn off for one minute.

6. Remove power from unit and

remove jumpers that were

placed. Re-set timer settings.

• T1 timer setting set to 5 and

timer scale set to 10m for 5

minutes of wheel off time.

Timer

Scale

Timer

Settings

Timer

Scale

T1

T2

• T2 timer setting set to 5 and

timer scale set to 1h for 30

minutes of wheel on time.

Electric Preheat

1. Remove power from unit.

2. Jumper the frost indicating wheel pressure switch

in the preheat control center.

3. Jumper the temperature indicating thermodisc in

the preheat control center. Thermodisc has a preset temperature of 5º F.

4. Apply power to unit. Preheater should turn on.

Variable Frequency Drives

Optional factory installed, wired, and programmed

variable frequency drives (VFDs) may have been

provided for modulating or multi-speed control of the

blowers and energy recovery wheel for economizer

and frost control modes. One VFD, either Yaskawa

model V1000 or J1000, is provided for each blower

(supply air and exhaust) and one Yaskawa model

J1000 is provided for the energy recovery wheel.

Refer to the tables in this section for factory settings

and field wiring requirements. Refer to the unit control

center for unit specific wiring diagram. When making

adjustments outside of the factory set points, refer to

Yaskawa VFD instruction manual, which can be found

online at www.drives.com. For technical support,

contact Yaskawa direct at 1-800-927-5292.

IGS-S+R-R+

MPACAMAC+VA2A1PCP2P1

MA MB MCRPH1SCHCS7S6S5S4S3S2S1

V1000

OPTION 1 - 0-10 VDC CONTROL

USER TO PROVIDE ISOLATION AS REQUIRED

A1 AC

SEE VFD INSTALLATION MANUAL FOR MORE DETAIL

FOR CONTINUOUS 60Hz OPERATION JUMPER TERMINALS A1 AND +V.

0-10 VDC CONTROL SIGNAL (BY OTHERS)

WIRED TO A1 (+) AND AC (COMMON)

0 VDC = 30 Hz

10 VDC = 60 Hz

FOR ONE 0-10 SIGNAL, WIRE TO DRIVES IN PARALLEL

J1000

MA MB MCACAMAC+VA1SCS5S4S3S2S1

Energy Recovery Ventilator

22

OPTION 2 - MULTI SPEED CONTROL

USER TO PROVIDE CONTACTS AND ISOLATION AS REQUIRED

S5S4 SC

SEE VFD INSTALLATION MANUAL FOR MORE DETAIL

NEITHER S4 OR S5 CONTACT CLOSED

DRIVE SPEED = 60 Hz.

S4 TO SC CONTACT CLOSED (BY OTHERS)

DRIVE SPEED = 40 Hz.

S5 TO SC CONTACT CLOSED (BY OTHERS)

DRIVE SPEED = 30 Hz.

Page 23

Factory Set Points

Variable frequency drives (VFDs) for the blowers are

factory setup to operate in one of the three following

modes:

• Modulating: 0-10 VDC signal wired in the field by

others varies the speed of the blower between 30

and 60 Hz

• Multi-speed: Digital contact closures by others

command the VFD to run at multiple speed

settings:

ż Open - Drive runs at 60 Hz

ż SC to S4 - Drive runs at 40 Hz

ż SC to S5 - Drive runs at 30 Hz

• CO

Sensor:

2

ż Set Point Control: A carbon dioxide sensor is

provided from the factory for field mounting OR

unit mounting in the space(s) being served by

the energy recovery unit. The CO

sensors are

2

wired to the unit VFD’s with two preset speeds

of 700 PPM or less CO

= 50% fan speed and

2

800 PPM or greater CO2 = 100% fan speed.

ż Proportional Control: A carbon dioxide sensor

is provided from the factory for field mounting

OR unit mounting in the space(s) being served

by the energy recovery unit. The CO

sensors

2

are wired to the unit VFD’s with default factory

settings of 500 PPM or less CO2 = 50% fan

speed and 1000 PPM or greater CO2 = 100% fan

speed. Modulation of VFD occurs proportional

to CO

between 500 and 1000PPM.

2

The terminal locations for modulating and multispeed are shown on the previous page. Most of the

set points in the VFDs are Yaskawa factory defaults.

However, a few set points are changed at Greenheck

and are shown in the tables. These settings are

based on the VFD mode selected.

Change Set Points

To gain access to change set points on the V1000 and

J1000 drives, parameter A1-01 needs to be set at “2”.

To prevent access or tampering with drive settings on

either drive, change parameter A1-01 to “0”.

• Drive Operation

ż SC to S1 contact for On/Off

ż A1 (0-10 VDC) referenced to AC.

Can use +15 VDC from +V.

Resetting the V1000 drive to factory defaults

To reset the V1000 drive back to Greenheck factory

defaults, go to parameter A1-01 and set it to “2”.

Then go to A1-03 and change it to “1110” and press

enter. The drive is now reset back to the settings

programmed at Greenheck. This option is not

available on the J1000.

MODULATING CONTROL FOR FAN SPEED

(0-10 VDC)

Parameter

Setting

V1000 J1000

A1-01 Access Level 2 2

B1-17 VFD Start-Up Setting 1 1

C6-02 Carrier Frequency 1 1

D2-02 Ref Lower Limit 50% 50%

E2-01 Motor Rated FLA

Motor

FLA

Motor

FLA

H2-01 Terminal MA, MC Function 5 5

H3-04 Terminal A1 Bias 50% 50%

L4-01 H2-01 Frequency Detection 15 15

L5-01 Auto Restart Attempt 5 5

A1-01 Access Level 0 0

CO2 SENSOR CONTROL FOR FAN SPEED

(1/2 SPEED WHEN CO2 DROPS BELOW 700 PPM)

(FULL SPEED WHEN CO2 RISES ABOVE 800 PPM)

MULTI-SPEED CONTROL FOR FAN SPEED

(1/3 OR 1/2 SPEED REDUCTION)

Parameter

Setting

V1000 J1000

A1-01 Access Level 2 2

B1-01

Reference Source

(Frequency)

00

B1-17 VFD Start-Up Setting 1 1

C6-02 Carrier Frequency 1 1

D1-01 Frequency Reference 1 60 Hz 60 Hz

D1-02 Frequency Reference 2 40 Hz 40 Hz

D1-03 Frequency Reference 3 30 Hz 30 Hz

D1-04 Frequency Reference 4 60 Hz 60 Hz

D2-02 Ref Lower Limit 50% 50%

E2-01 Motor Rated FLA

H1-04

H1-05

H1-06

Multi-Function Input Sel 4

(Terminal S4)

Multi-Function Input Sel 5

(Terminal S5)

Multi-Function Input Sel 6

(Terminal S6)

Motor

FLA

Motor

FLA

33

44

5NA

H2-01 Terminal MA, MC Function 5 5

H3-10 A2 Not Used F NA

L4-01 H2-01 Frequency Detection 15 15

L5-01 Auto Restart Attempt 5 5

A1-01 Access Level 0 0

Energy Recovery Ventilator

23

Page 24

CO2 PROPORTIONAL CONTROL

Parameter

Setting

V1000 J1000

B1-17 VFD Start-Up Setting 1 1

C6-02 Carrier Frequency 1 1

D2-02 Ref Lower Limit 50% 50%

E2-01 Motor Rated FLA FLA FLA

H3-03

H3-04

Analog Frequency

Reference (Gain)

Analog Frequency

Reference (Bias)

150% 150%

25% 25%

L2-01 Ride Thru Power Loss 2 2

L4-05 Frequency Ref Loss 0 NA

L5-01 Auto Restart Attempt 5 5

A1-01 Access Level 0 0

VARIABLE FREQUENCY DRIVES

FOR ENERGY RECOVERY WHEEL

Parameter Setting – J1000

A1-01 Access Level 2

B1-17 VFD Auto Start 1

C1-04 Decel Time 600

*C4-

01

Torque Gain 0.6

C6-02 Carrier Frequency 2

D2-01 Ref Upper Limit 40 or 50*

D2-02 Ref Lower Limit 5%

E2-01 Motor Rated FLA Motor FLA

E2-03 Motor No-Load Current

H1-02

H2-01

H1-04

Multi-Function Input

(Terminal S2)

Multi-Function Output

(MA, MB, MC)

Multi-Function Input Sel 4

(Terminal S4)

Economizer Signal Source

(0-10 VDC)

H3-03

H3-04

Analog Frequency

Reference (Gain)

Analog Frequency

Reference (Bias)

Must be less

than FLA

6

4

7

Setting

Honeywell

Module

Controller

0

40 or

50**

Carel

40 or

50*

L1-01 Elect Thermal Overload 2

L2-01 Ride Thru Power Loss 2

L4-01 Frequency Detection Level 15

L5-01 Auto Restart Attempt 5

A1-01 Access Level 0

* 208/230 volt only

**36 through 52 inch wheels are 40 (24 Hz)

58 or 74 inch wheel is 50 (30 Hz)

0

Energy Recovery Ventilator

24

Page 25

Routine Maintenance

DANGER

Electric shock hazard. Can cause injury or death.

Before attempting to perform any service or

maintenance, turn the electrical power to unit

to OFF at disconnect switch(es). Unit may have

multiple power supplies.

CAUTION

Use caution when removing access panels or other

unit components, especially while standing on a

ladder or other potentially unsteady base. Access

panels and unit components can be heavy and

serious injury may occur.

Once the unit has been put into operation, a routine

maintenance program should be set up to preserve

reliability and performance. Items to be included in

this program are:

Lubrication

Apply lubrication where required

Dampers

Check for unobstructed operation

Fan Belts

Check for wear, tension, alignment

Motors

Check for cleanliness

Blower Wheel & Fasteners

Check for cleanliness

Check all fasteners for tightness

Check for fatigue, corrosion, wear

Bearings

Check for cleanliness

Check set screws for tightness

Lubricate as required

External Filter

Check for cleanliness - clean if required

Internal Filter

Check for cleanliness - replace if required

Door Seal

Check if intact and pliable

Energy Recovery Wheel

Check for cleanliness - clean if required

Check belt for wear

Check pulley, bearings, and motor

Maintenance Procedures:

Lubrication

Check all moving components for proper lubrication.

Apply lubrication where required. Any components

showing excessive wear should be replaced to

maintain the integrity of the unit and ensure proper

operation.

Dampers

Check all dampers to ensure they open and close

properly and without binding. Backdraft dampers can

be checked by hand to determine if blades open and

close freely. Apply power to motorized dampers to

ensure the actuator opens and closes the damper as

designed.

Fan Belts

Belts must be checked on a regular basis for

wear, tension, alignment, and dirt accumulation.

Premature or frequent belt failures can be caused by

improper belt tension (either too loose or too tight)

or misaligned sheaves. Abnormally high belt tension

or drive misalignment will cause excessive bearing

loads and may result in failure of the fan and/or motor

bearings. Conversely, loose belts will cause squealing

on start-up, excessive belt flutter, slippage, and

overheated sheaves. Both loose and tight belts can

cause fan vibration.

When replacing belts on multiple groove drives, all

belts should be changed to provide uniform drive

loading. Do not pry belts on or off the sheave. Loosen

belt tension until belts can be removed by simply

lifting the belts off the sheaves. After replacing belts,

insure that slack in each belt is on the same side of

the drive. Belt dressing should never be used.

Do not install new belts on worn sheaves. If the

sheaves have grooves worn in them, they must be

replaced before new belts are installed.

The proper belt setting is the lowest tension at which

the belts will not slip under peak load operation. For

initial tensioning, set the belt deflection at

1

⁄64-inch for

each inch of belt span (measured half-way between

sheave centers). For example, if the belt span is

64 inches, the belt deflection should be oneinch

(using moderate thumb

pressure at mid-point

Deflection =

Belt Span

64

of the drive). Check

belt tension two times

during the first 24hours

of operation and

periodically thereafter.

Belt Span

Fan Motors

Motor maintenance is generally limited to cleaning

and lubrication. Cleaning should be limited to exterior

surfaces only. Removing dust and grease buildup

on the motor housing assists proper motor cooling.

Never wash-down motor

with high pressure spray.

Greasing of motors is

only intended when

fittings are provided.

Many fractional motors

are permanently

lubricated for life and

require no further

lubrication.

Energy Recovery Ventilator

25

Page 26

Fan Wheel & Fasteners

Wheels require very little attention when moving clean

air. Occasionally oil and dust may accumulate on the

wheel causing imbalance. When this occurs the wheel

and housing should be cleaned to assure smooth and

safe operation. Inspect fan impeller and housing for

fatigue, corrosion or wear.

Routinely check all fasteners, set screws and locking

collars on the fan, bearings, drive, motor base and

accessories for tightness. A proper maintenance

program will help preserve the performance and

reliability designed into the fan.

Bearings

Most bearings are permanently lubricated and require

no further lubrication under normal use. Normal use

being considered -20ºF to 120ºF and in a relatively

clean environment. Some bearings are relubricatable

and will need to be regreased depending on fan use.

Check your bearings for grease zerk fittings to find

out what type of bearing you have. If your fan is not

being operated under normal use, bearings should be

checked monthly for lubrication.

External Filter Maintenance

Aluminum mesh, 2-inch deep filters are located in the

supply weatherhood (if the weatherhood option was

purchased). Filters should be checked and cleaned

on a regular basis for best efficiency. The frequency

of cleaning depends upon the cleanliness of the

incoming air. These filters should be cleaned prior to

start-up.

To access these filters,

remove bottom bolt in the

access door on the side of

the weatherhood. Slide the

access door up and then pull

bottom out to remove door.

Then, slide the filters out (see

picture at right).

Clean filters by rinsing with

a mild detergent in warm

water.

Outdoor air intake hood

mesh filter access

Internal Filter Maintenance

The ERV units will typically be provided with 2-inch,

pleated filters in the outdoor air and exhaust

airstreams. These filters should be checked per

a routine maintenance schedule and replaced as

necessary to ensure proper airflow through the

unit. See table for pleated filter size and quantity

for each unit. Replacement filters shall be of same

performance and quality as factory installed filters.

Filter type must be pleated design with integral metal

grid. Two acceptable filter replacements are Aerostar

Series 400 or Farr 30/30

®

.

Pleated Filter Size and Quantities

Unit Size Size

ERV-10 16 x 25 1 1

ERV-20 16 x 20 2 2

ERV-45 16 x 25 3 3

ERV-55 16 x 20 6 6

ERV-90 16 x 25 7 7

ERV-120 20 x 25 6 6

All dimensions in inches.

Supply

Qty.

Exhaust

Qty.

Outdoor Air Filters: Access to the outdoor air filters

is through the door labeled as “Filter Access” on the

outdoor air side of the unit.

Exhaust Air Filters: Access to the exhaust air filters

is through the door labeled as “Filter Access” on the

exhaust air side of the unit.

Refer to Access Door Descriptions section for

additional information on filter locations.

Door Seal Maintenance

ERV-10, 20, 45, and 55: Closed cell foam tape is

installed on the perimeter of the door. Inspect at least

annually to ensure that the seal is still intact.

ERV-90 & 120: Slip-on type vinyl

seal is installed on the perimeter of

the door openings. Inspect at least

annually to ensure that seal is still

pliable and intact.

Energy Recovery Wheel Maintenance

Annual inspection of the energy recovery wheel is

recommended. Units ventilating smoking lounges

and other non-clean air spaces should have energy

recovery wheel inspections more often based upon

need. Inspections for smoke ventilation applications

are recommended bimonthly to quarterly until a

regular schedule can be established.

Accessing the Energy Recovery Wheel in

Models ERV-10, 20, 45 and 55

Disconnect power to the ERV. Remove access

panel(s) labeled “Energy Wheel Cassette Access”.

Unplug the wheel drive

motor. The center

channel must be

removed to access the