Page 1

ERV

ENERGY RECOVERY VENTILATOR

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

This publication contains the installation, operation

and maintenance instructions for standard units of the

ERV-Energy Recovery Ventilators .

For ERV with coils refer to DX & Fluid Supplements.

For cooling coil units, refer to Page 8 of this manual

for guidelines on the installation of condensate drain

traps.

Carefully read this publication prior to any installation or maintenance procedure.

Loren Cook catalog, ERV , provides additional information describing the equipment, fan performance, available

accessories, and specification data.

For additional safety information, refer to AMCA Publication 410-96, Safety Practices for Users and Installers of

Industrial and Commercial Fans .

All of the publications listed above can be obtained from

Loren Cook Company by phoning (417)869-6474, extension 166; by FAX at (417)832-9431; or by e-mail at

info@lorencook.com.

For information on special equipment, contact Loren

Cook Company Customer Service Department at

(417)869-6474.

Receiving and Inspection

Carefully inspect the ERV and ERV accessories for any

damage and any shortage of accessories immediately

upon receipt of the fan.

• Turn each blower wheel by hand to ensure it turns

freely and does not bind.

• Inspect dampers (if supplied) for free operation of all

moving parts.

• Record on the Delivery Receipt any visible sign of

damage.

Storage

If the ERV is stored for any length of time prior to installation, store the ERV in its original crate and protect it from

dust, debris and the weather.

WARNING

This unit has rotating parts. Safety precautions

should be exercised at all times during installation,

operation, and maintenance.

Unit must be grounded to electrical service panel.

ALWAYS disconnect power prior to working on fan.

Failure to comply with these safety precautions could

result in property damage, serious injury or death.

ERV Installation

Before installing, turn the energy wheel by hand in the

direction of rotation to insure that the wheel alignment was

not altered in shipping. If severe binding occurs, it could be

due to excessive seal contact. In this case, adjust the seals

according to the instructions given in the seal adjustment

procedure on page 9.

The ERV seals were preadjusted before leaving the factory. If upon inspection excessive clearance between seals

and sealing surfaces is found, adjust the seals according to

the procedure.

Inspect the drive belt and make sure that it is around the

drive sheaves and wheel. If possible, test run the wheel

before installation.

ERV 1500 - 10,000 ERV 500 - 1,000

Page 2

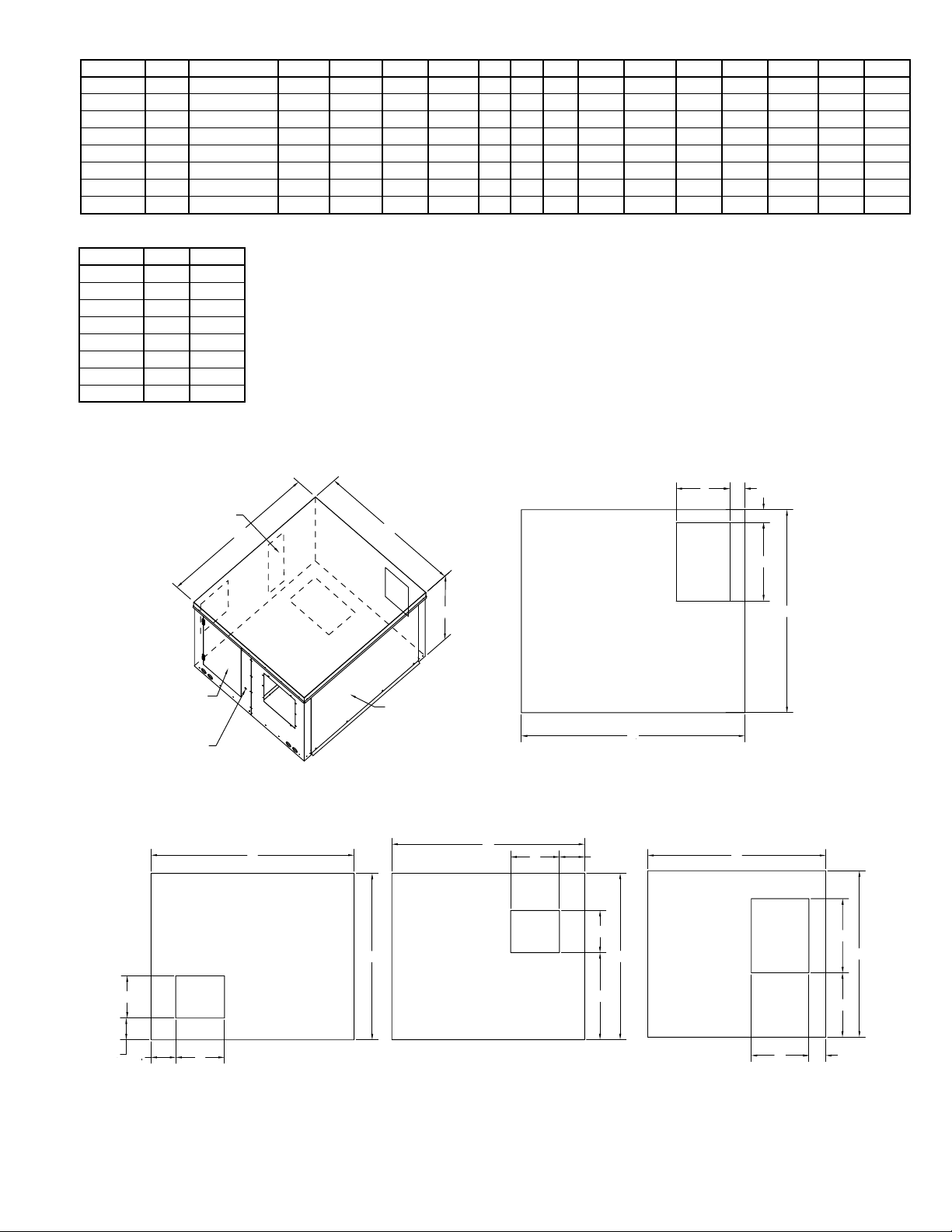

Dimensions - Arrangement V

Unit A A (Coil Units) B C D E F G H J K L M N P Q

ERV 1500 54-3/16 90-3/16 40-13/32 49-9/32 10-1/4 11-13/16 18 14 19 13 6-1/8 21-1/8 6-1/16 6-11/16 3-5/8 3-1/8

ERV 2500 52-1/8 88-1/8 50-1/8 52-1/8 11-3/8 13-1/8 28 20 22 12-3/4 5-1/16 29-5/16 7-5/16 7-1/16 3-1/2 3-3/8

ERV 3500 64-1/2 100-1/2 59 60-1/2 13-7/16 15-5/8 34 20 23 16-1/2 5-7/8 33-13/16 8-13/16 7-13/16 2-9/16 4-1/8

ERV 4500 69-1/2 105-1/2 64-1/2 66-1/2 13-7/16 15-5/8 34 24 26 18-3/4 7-5/16 38-5/8 10 8-1/8 2-9/16 4-1/8

ERV 5500 69-1/2 105-1/2 71 66-1/2 15-7/8 18-5/8 44 24 26 18-3/4 5-7/16 41 8-13/16 9-3/8 2-9/16 4-1/8

ERV 7000 79-1/2 115-1/2 76-1/2 80 18-7/8 21-7/8 44 29 32 24 6-3/16 14-3/16 8-15/16 11-1/8 4-3/4 4-1/8

ERV 8500 79-1/2 115-1/2 83 80 18-7/8 21-7/8 53 29 32 24 6-3/16 14-3/16 8-15/16 11-1/8 4-3/4 4-1/8

ERV 10000 100 136 90 84-1/2 24-3/4 24-3/4 50 37 34-1/2 33 9-1/8 15-1/4 8 12-3/4 4-3/4 3-5/8

All dimensions in inches.

Unit R S

ERV 1500 4-1/16 15-5/8

ERV 2500 2-7/8 18-1/4

ERV 3500 6-1/4 18-1/16

ERV 4500 5-1/4 23-7/8

ERV 5500 5-1/4 20-1/8

ERV 7000 6-15/16 25-15/16

ERV 8500 6-15/16 22-15/16

ERV 10000 3-1/4 31-15/16

All dimensions in inches.

Return Air

Filter

Access Door

A

Back

Right

C

B

Supply

Air

Discharge

JQ

Return

Air

Intake

P

H

C

E

Control Panel

Access Door,

Exhaust Blower

Access Door

Removable Plug

for Field

Electrical

Connections

Left

Arrangement V

A

Exhaust

Discharge

Back View

Air

Front

M

Supply Blower,

Rotary Wheel,

And Filter

Access Door

E

K

D

B

L

A

Top View

C

Left View

D

Outdoor

Air

Intake

G

N

F

B

S

R

2

Page 3

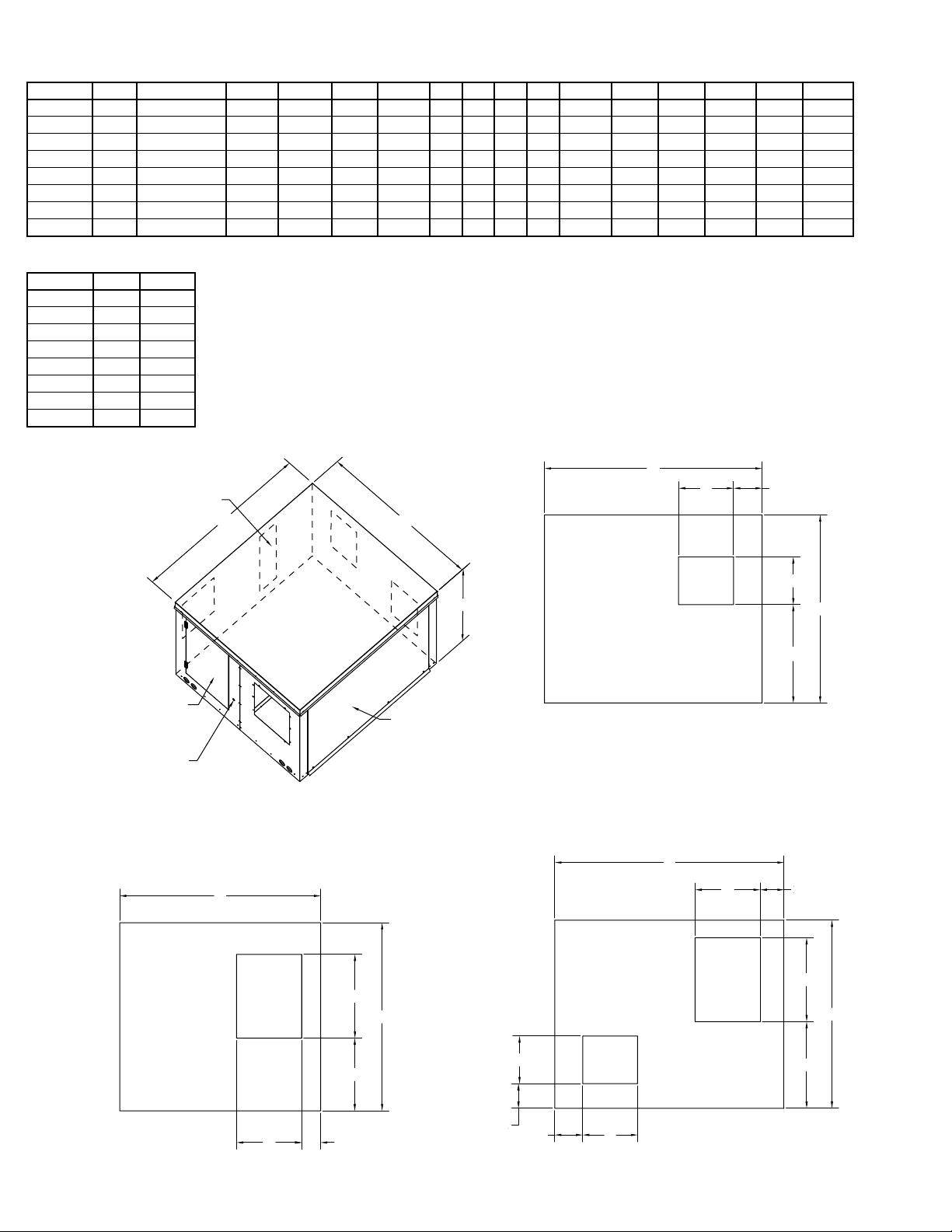

Dimensions - Arrangement C

Unit A A (Coil Units) B C D E F G H J K L M N P Q

ERV 1500 54-3/16 90-3/16 40-13/32 49-9/32 10-1/4 11-13/16 18 14 19 13 5-9/32 6 6-1/8 21-1/8 3-5/8 3-1/8

ERV 2500 52-1/8 88-1/8 50-1/8 52-1/8 11-3/8 13-1/8 28 20 22 12-3/4 9-7/8 7-3/8 5-1/16 29-5/16 3-1/2 3-3/8

ERV 3500 64-1/2 100-1/2 59 60-1/2 13-7/16 15-5/8 34 20 23 16-1/2 10-7/8 8-13/16 5-7/8 33-13/16 2-9/16 4-1/8

ERV 4500 69-1/2 105-1/2 64-1/2 66-1/2 13-7/16 15-5/8 34 24 26 18-3/4 10-13/16 7-3/16 7-5/16 38-9/16 2-9/16 4-1/8

ERV 5500 69-1/2 105-1/2 71 66-1/2 15-7/8 18-5/8 44 24 26 18-3/4 12-1/4 8-7/8 5-7/16 41 2-9/16 4-1/8

ERV 7000 79-1/2 115-1/2 76-1/2 80 18-7/8 21-7/8 44 29 32 24 14-1/4 9-1/16 6-3/16 14-3/16 4-3/4 4-1/8

ERV 8500 79-1/2 115-1/2 83 80 18-7/8 21-7/8 53 29 32 24 14-1/4 9-3/16 6-3/16 14-3/16 4-3/4 4-1/8

ERV 10000 100 136 90 84-1/2 24-3/4 24-3/4 50 37 34-1/2 33 15-7/16 8-1/4 9-1/8 15-1/4 4-3/4 3-5/8

All dimensions in inches.

Unit R S

ERV 1500 4-1/16 15-5/8

ERV 2500 2-7/8 18-1/4

ERV 3500 6-1/4 18-1/16

ERV 4500 5-1/4 23-7/8

ERV 5500 5-1/4 20-1/8

ERV 7000 6-15/16 25-15/16

ERV 8500 6-15/16 22-15/16

ERV 10000 3-1/4 31-15/16

All dimensions in inches.

Return Air

Access Door

Control Panel

Access Door,

Exhaust Blower

Access Door

Removable Plug

for Field

Electrical

Connections

Filter

A

Back

Left

C

C

Right

Front

Supply Blower,

Rotary Wheel,

Access Door

Arrangement C

B

B

And Filter

A

E

Exhaust

Air

Discharge

A

Top View

M

D

B

J

Return

Air

Intake

Q

C

P

H

C

Outdoor

Air

Intake

F

B

Supply

D

K

L

Air

Discharge

E

Right View

Back View

N

Left View

G

S

R

3

Page 4

Dimensions - Arrangement H

Unit A A (Coil Units) B C D E F G H J K L M N P Q

ERV 1500 54-3/16 90-3/16 40-13/32 49-9/32 10-1/4 11-13/16 18 14 14 18 5-9/32 6 5-1/8 18-5/8 6-1/8 21-1/8

ERV 2500 52-1/8 88-1/8 50-1/8 52-1/8 11-3/8 13-1/8 28 20 20 28 9-7/8 7-3/8 5-9/16 13-1/4 5-1/16 29-5/16

ERV 3500 64-1/2 100-1/2 59 60-1/2 13-7/16 15-5/8 34 20 20 34 10-7/8 8-13/16 5-5/16 18 5-7/8 33-13/16

ERV 4500 69-1/2 105-1/2 64-1/2 66-1/2 13-7/16 15-5/8 34 24 24 34 10-13/16 7-3/16 4-5/16 23-13/16 7-5/16 38-5/8

ERV 5500 69-1/2 105-1/2 71 66-1/2 15-7/8 18-5/8 44 24 23 42 12-1/4 8-7/8 4-5/16 22 5-7/16 41

ERV 7000 79-1/2 115-1/2 76-1/2 80 18-7/8 21-7/8 44 29 27 42 14-1/4 9-1/16 7-1/8 27-7/8 6-3/16 14-3/16

ERV 8500 79-1/2 115-1/2 83 80 18-7/8 21-7/8 53 29 27 46 14-1/4 9-3/16 7-1/8 29-7/8 6-3/16 14-3/16

ERV 10000 100 136 90 84-1/2 24-3/4 24-3/4 50 37 32 48 15-7/16 8-1/4 4-3/8 33-7/8 9-1/8 15-1/4

All dimensions in inches.

Unit R S

ERV 1500 4-1/16 15-5/8

ERV 2500 2-7/8 18-1/4

ERV 3500 6-1/4 18-1/16

ERV 4500 5-1/4 23-7/8

ERV 5500 5-1/4 20-1/8

ERV 7000 6-15/16 25-15/16

ERV 8500 6-15/16 22-15/16

ERV 10000 3-1/4 31-15/16

All dimensions in inches.

Return Air

Access Door

Control Panel

Access Door,

Exhaust Blower

Access Door

Removable Plug

for Field

Electrical

Connections

Filter

A

C

Back

Left

C

Right

Front

Supply Blower,

Rotary Wheel,

Access Door

Arrangement H

B

And Filter

A

Discharge

Back View

C

E

Exhaust

Air

P

D

B

Q

H

M

Left View

Outdoor

Air

Intake

G

Return

Air

F

B

Supply

S

R

D

K

L

Air

Discharge

E

Intake

Right View

J

B

N

4

Page 5

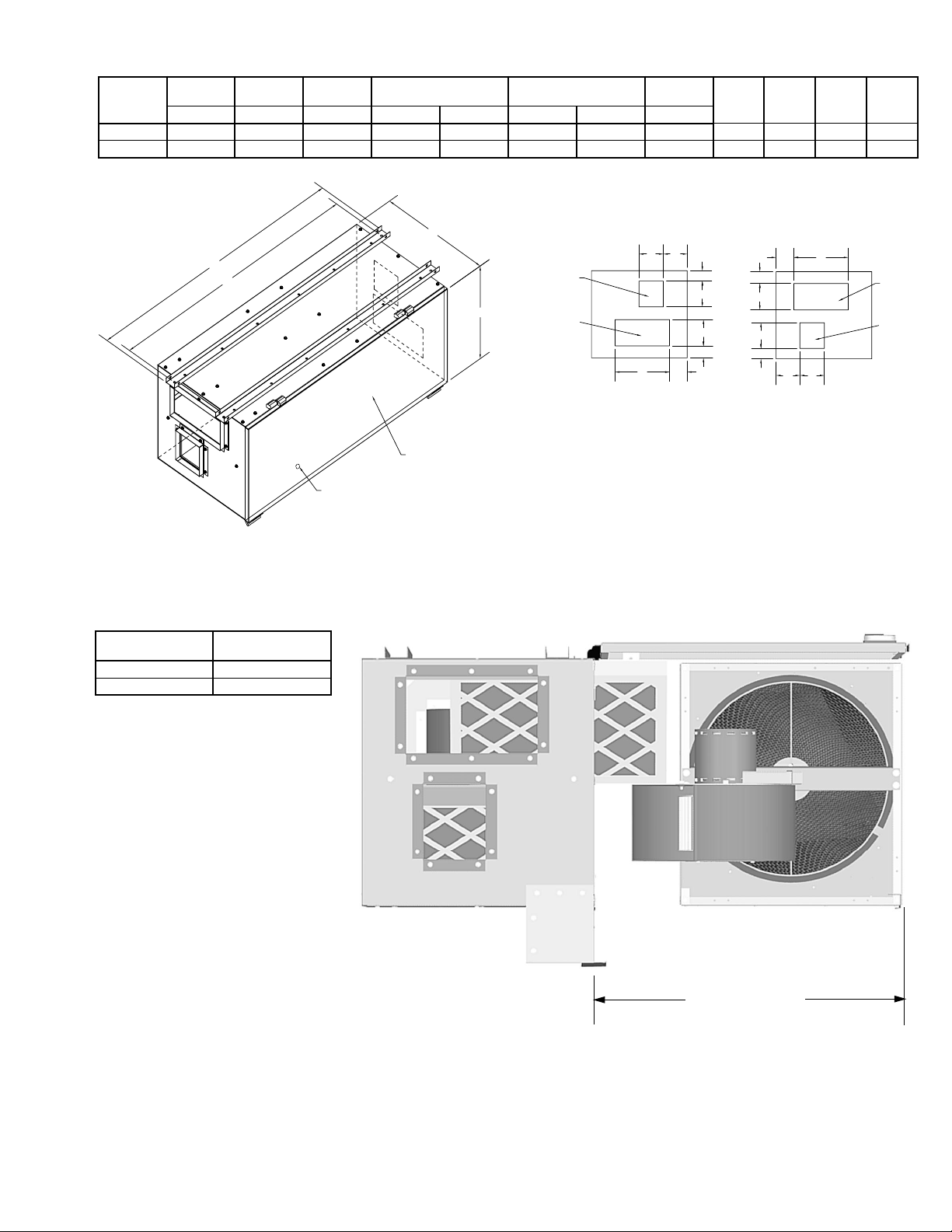

Dimensions - Direct Drive

Unit

Mounting

Rail Length

Housing

Width

Housing

Height

Exhaust Opening Intake Opening

Mounting

Holes

JKLM

ABCDEFGH

ERV 500 52 22 23-13/16 7 5-11/16 7 12 50 4 5-5/16 1-1/2 4

ERV 1000 52 26 28-13/16 10-3/8 6-7/8 7 20 50 6-11/16 11-7/16 1-1/2 4

All dimensions in inches.

B

E

A

H

Right

Back

C

Exhaust Air

Discharge

Outdoor Air

Intake

K

J

D

F

L

G

M

Right View

Front

Hinged Access to

All Internal Components

Left

Removable Plug

For Field

Electrical

Connections

(Bottom Panel)

L

F

D

J

M

K

E

Left View

G

Return Air

Intake

Supply Air

Discharge

Service Clearance- Direct Drive

Unit

500 30

1000 35

All dimensions in inches.

Service

Clearance

Service Clearance

5

Page 6

Service Clearance - Belt Drive

Unit Size Filter Clearance Blower Clearance Cassette Clearance

1500 30 29 61

2500 31 31 64

3500 31 35 73

4500 26 41 79

5500 26 47 79

7000 30 52 92

8500 30 60 92

10000 30 60 96

All dimensions in inches.

Filter

Clearance

Blower

Clearance

Handling

Lift the ERV by the

base lifting holes.

Never lift by the weath-

Cleavis

Pins

erhood. To avoid structural damage, only lift

the unit with all service

Lifting Holes

panels installed.

After installing cleavis pins through all lifting holes, lift unit

a few feet off the ground and check to make sure the unit is

not tilted or twisted.

Cassette

Access

Clearance

Spreader Bars

To protect unit from damage when lifting, the lifting straps

and spreader bars should be utilized as shown in figure

below. To prevent scratching of the exterior surface, pads

should be placed between the cabinet and the cables.

Spreader Bar

6

Page 7

Energy Recovery Ventilator Definitions

Bearing, external - Flanged or pillow block bearing used with rotating shaft models.

Bearing, internal - Sealed ball bearing used with fixed shaft models.

Bulb seal - The seal used for both the circumferential seal and the inner seal in the cassettes. They are constructed of

neoprene and configured to seal against the wheel band in the case of the circumferential seal, and against the wheel

face in the case of the inner seal. These seals are noncontact in that there is a slight gap between seal and sealing

face to allow the wheel to turn at high RPMs without overtorquing motor or causing seal damage. These seals have an

integral clip and are clipped to the cassette face panel cutout (circumferential) or to the post (inner).

Cassette - The steel structure that houses the wheel. Typically ERV cassettes are of punched sheet metal panelized

construction.

Energy Enthalpy Wheel - A generic name for an energy conservation wheel. The term enthalpy refers to an air

stream’s total energy (temperature and humidity level).

Exhaust Air - The air stream leaving an ERV that is exhausted to the outside. Exhaust air is building return air that has

been run through the wheel.

Heat Wheel - Synonymous with enthalpy wheel, energy conservation wheel, or total energy recovery wheel. Some

heat wheels are sensible only wheels and should not be confused with total energy recovery wheels.

Latent Energy - Latent energy in the context of wheel discussions is the work done by the wheel to transfer moisture

from one air stream to another. Latent work is accompanied by humidity changes in the air streams.

Media - The chemical composite part of the wheel which actually performs the latent and sensible exchange.

Outdoor Air - The air stream entering an ERV that is brought in from outside. Outdoor air becomes supply air after

going through the wheel.

Purge - A small segment of supply air defined by the gap between the inner seal on the outdoor air edge of the center

post and the supply air edge of the center post. The purge angle is adjustable. The purge captures the small amount of

supply air captive in the wheel when the wheel moves from return to supply and routes it to return to minimize cross

contamination.

Return Air - The air stream entering an ERV that is returned from the building. Return air becomes exhaust air after

going through the wheel.

Sensible Heat - Sensible energy in the context of wheel discussions is the work done by the wheel to transfer heat

from one air stream to another. Sensible work is accompanied by temperature changes in the air streams.

Sensible Wheel - A wheel that does only sensible work, i.e., where only heat is transferred from one air stream to

another and the resultant moisture level remains unchanged.

Supply Air - The air stream leaving an ERV that is supplied to the building space. Supply air is outdoor air that has

been run through the wheel.

Recommended Roof Openings

E

B

A

D

C

F

Recommended Roof Openings Arrangement V & C

Unit Size

1500 1-5/8 41 29 18 1-1/2 45-3/4 50-3/4 86-3/4

2500 1-3/4 43 29 20 1-5/8 48-1/2 48-1/2 84-1/2

3500 2-1/2 49 33 22 2 57 61 97

4500 2-1/2 49 35 22 2 63 66 102

5500 2-1/2 55 35 26 2 63 66 102

7000 2-1/2 68 42 31 2 76-1/2 76 112

8500 2-1/2 68 42 31 2 76-1/2 76 112

10000 2-1/2 74 45 38 2 81 96 132

All dimensions in inches.

A

B

(Arr. V)B (Arr. C)

CDE F

(Coil Units)

F

7

Page 8

Mounting

Foundation Mounting for Arrangement H

The ERV requires a

strong, level foundation

of reinforced poured

concrete. A correctly

designed concrete

foundation provides the

best means for mounting floor units. The size

of the foundation is

determined by unit size

and the specific location

of the installation. The

Foundation Mounting for Arr. H

use of rubber isolation

pads between the unit

base and the foundation

is recommended.

Use the following

guidelines to calculate

foundation size:

• The overall dimensions of the foundation

should extend at least

six inches beyond the

outline of the unit.

• The weight of the

foundation should be

two to three times the

weight of the unit and its

motor.

Curb Mounting

Rail Mounting

Use the following recommendations when designing for rail mounting:

• Rails should be positioned six to twelve

inches in from sides of

the unit.

• Rails should extend a

minimum of six inches

beyond the sides of the

unit.

Rail Mounting

Ductwork Connections

Discharge Duct Turns

Where possible, allow 3 duct

diameters between duct turns

or elbows and the fan outlet.

Refer to the figure below.

Free Discharge

Avoid a free discharge into

the plenum. This will result in

lost efficiency because it

doesn’t allow for a static

regain. Refer to figure below.

Correct

Incorrect

Correct

MIN

3 DIA

Incorrect

Ductwork

Mounting

Rails

Installation of Condensate Drain Pan Traps

All drain and trap piping should be sized to match the

condensate drain pan pipe connection supplied on cooling

coil equipped ERV’s. The below figure shows the correct

layout of a low maintenance, trouble-free condensate drain

pan trap. Finger tight plugs allow easy access for inspection and cleaning. To prevent an air leak into the unit

through the trap, dimensions “A” and “B” should be double

the total static pressure “head” found in the drain pan compartment.

Finger-Tight Plug

Clean Out

Finger-Tight Plug

ERV Condensate

Drain Pipe

Drain Trap

B

(6” Min)

Clean Out

Slope To Drain

A

(6” Min)

Motor Installation

To prevent damage to the unit during shipping, extremely

heavy motors (cast iron or severe duty) are shipped loose

and must be field mounted by bolting the motor on the

motor mounting plate in the existing mounting slots.

The motor has been prewired to turn the proper direction.

Follow the directions on the motor schematic accompanying the motor. Some motors can accommodate either 220V

or 440V operation. Once the motors are wired, test run the

ERV and check for proper rotation.

Wiring Installation

All wiring should be in accordance with local ordinances

and the National Electrical Code, NFPA 70. Ensure the

power supply (voltage, frequency, and current carrying

capacity of wires) is in accordance with the motor nameplate.

Lock off all power sources before unit is wired to

power source.

Leave enough slack in the wiring to allow for motor movement when adjusting belt tension. Some fractional motors

have to be removed in order to make the connection with

the terminal box at the end of the motor. To remove motor,

remove bolts securing motor base to power assembly. Do

not remove motor mounting bolts.

Follow the wiring diagram in the disconnect switch

and the wiring diagram provided with the motor. Correctly label the circuit on the main power box and

always identify a closed switch to promote safety (i.e.,

red tape over a closed switch).

Do not allow the fan to run in the wrong direction.

This will overheat the motor and cause serious damage. For 3-phase motors, if the fan is running in the

wrong direction, check the control switch. It is possible

to interchange two leads at this location so that the fan

is operating in the correct direction.

8

Page 9

1/4 inch

1 foot

Figure 1

Belt and Pulley Installation

Belt tension is determined by the sound the belts make

when the fan is first started. Belts will produce a loud

squeal which dissipates after the fan is operating at full

capacity. If the belt tension is too tight or too loose, lost efficiency and possible damage can occur.

Do not change the pulley pitch diameter to change ten-

sion. This will result in a different fan speed than desired.

Correct

Incorrect Incorrect

Figure 2

Incorrect

a. Loosen motor plate adjustment screw and move

motor plate in order that the belts can easily slip into

the grooves on the pulleys. Never pry, roll, or force the

belts over the rim of the pulley.

b. Slide the motor plate back until

proper tension is reached. For

proper tension a deflection of

approximately 1/4” per foot of center

distance should be obtained by

firmly pressing the belt. Refer to Figure 1.

c. Lock the motor plate adjustment

nuts in place.

d. Ensure pulleys are properly aligned.

Refer to Figure 2.

Figure 3

Pulley Alignment

Pulley alignment is adjusted by loosening the motor pulley setscrew and by moving the motor pulley on the motor

shaft or by moving the entire motor along the motor mounting bracket.

Figure 2 illustrates correct and incorrect pulley alignment.

A recommended method of inspecting the pulley alignment is

shown in Figure 3. With the shorter leg of a carpenter’s

square or other straight edge lying along the case of the

motor, adjust the position of the motor pulley (or the motor

until the longer leg of the square is parallel to the belt.

Final Installation Steps

a. Inspect fasteners and setscrews, particularly fan mount-

ing and bearing fasteners, and tighten according to the

recommended torque shown in the table Recom-

mended Torque for Setscrews/Bolts .

b. Inspect for correct voltage with voltmeter.

c. Ensure all accessories are installed.

d. If applicable, ensure fan is secured to ductwork.

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power sources.

b. Ensure fasteners and setscrews, particularly those

used for mounting the fan, are tightened.

c. Inspect belt tension and pulley alignment on blowers.

d. Inspect belt tension on energy wheel drive belt.

e. Inspect motor wiring.

f. Ensure belt touches only the pulleys.

g. Ensure fan and ductwork are clean and free of debris.

h.Ensure rotor moves freely by hand. If not, recheck the

seal to determine whether or not it is binding and if so

adjust seals following the sealcheck instructions.

i. Ensure motor rotation is correct by detaching the belts

from the drive sheave and bumping the motor. The

sheave should be rotating in the direction such that the

belt will result in rotation per the exterior markings. If

not, rewire the motor.

j. Ensure the air flow orientation matches up to design by

looking at the identification markings on the cassette

and/or refer to the general arrangement drawing to

check the four duct connections to the unit.

k. Close and secure all access doors.

l. Restore power to the fan.

Changing Fan Speed

The motor/blower combinations on ERV sizes 1500 and up

are equipped with variable pitch pulleys. To change the fan

speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

b. Turn the pulley rim to open or close the groove facing. If

the pulley has multiple grooves, all must be adjusted to

the same width.

c. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in the

groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in the

groove (larger pitch diameter). Ensure that the RPM limits of

the fan and the horsepower limits of the motor are maintained.

9

Page 10

Recommended Torque for Setscrews/Bolts (IN/Lb)

Setscrews

Size

No.10 3/32” 28 33 3/8”-16 240

1/4” 1/8” 66 80 1/2”-13 600

5/16” 5/32” 126 156 5/8”-11 1200

3/8” 3/16” 228 275 3/4”-10 2100

7/16” 7/32” 348 384 7/8”- 9 2040

1/2” 1/4” 504 600 1”- 8 3000

Key Hex

Across

Flats

Recommended

Torque

Min. Max. Size

Hold Down Bolts

Wrench

Torque

System Start-Up

Start Up

Tu rn the fan on, and inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Bearing noise.

• Improper belt alignment or tension (listen for squealing).

• Improper motor amperage or voltage.

If a problem is discovered, immediately shut the fan

off. Lock out all electrical power and check for the

cause of the trouble. See Troubleshooting.

Inspection

Inspection of the fan should be conducted at the first 30

minute, 8 hour and 24 hour intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as per

the Conditions Chart .

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension on both blowers and energy wheel

drive belt. Adjust and tighten as necessary.

Unit Maintenance

Intake Hood Filters

Filter inspection and cleaning intervals can vary from

once a week to twice per year depending on contaminants

present and acceptable pressure drops across the filter.

Under most conditions filters may be cleaned with hot water

and a mild soap solution (such as dish washing liquid) or

steam. Some caustic cleaners will damage the filter. If in

doubt, please consult the factory for a compatibility list.

High pressure spray washers should be limited to 2,000

psi operating pressure. Every attempt should be made to

remove the contaminants from the filter in a “backwash”

flow (note airflow arrow on the filter frame). Once the filter is

dry, it may be returned to the appropriate filter racks in the

same orientation (airflow direction) as they were removed.

Return Air/Intake Air Disposable Filters

If filters are excessively dirty, replace.

Routine Maintenance

Establish a schedule for inspecting all parts of the fan. The

frequency of inspection depends on the operating conditions

and location of the fan.

It is recommended the following inspection be conducted

twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary.

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. Refer to

Belt and Pulley Installation , page 9.

• Bearings should be inspected as recommended in the

Conditions Chart .

• Inspect filters by removing filter access door.

• Inspect springs and rubber isolators for deterioration and

replace as needed.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling. Removing dirt from the wheel and

housing prevent imbalance and damage.

Lubricants

Loren Cook Company uses petroleum lubricant in a lith-

ium base. Other types of grease should not be used unless

the bearings and lines have been flushed clean. If another

type of grease is used, it should be a lithium-based grease

conforming to NLGI grade 2 consistency.

A NLGI grade 2 grease is a light viscosity, low-torque, rustinhibiting lubricant that is water resistant. Its temperature

range is from -30

° F to +200 ° F and capable of intermittent

highs of +250 ° F.

Motor Bearings

Motor bearings are pre-lubricated and sealed. Under normal conditions they will not require further maintenance for a

period of ten years. However, it is advisable to have your

maintenance department remove and disassemble the

motor, and lubricate the bearings after three years of operation in excessive heat and or in a contaminated airstream

consisting of airborne abrasives.

Fan Bearings

Fan bearings are either permanently sealed and lubricated, requiring no maintenance or they are greasable bearings. Greasable fan bearings are lubricated through a

grease fitting on the bearing and should be lubricated by the

schedule, Conditions Chart .

Conditions Chart

RPM Temperature

100 Up to 120˚F Clean 6 to 12 months

500 Up to 150˚F Clean 2 to 6 months

1000 Up to 210˚F Clean 2 weeks to 2 months

1500 Over 210˚F Clean Weekly

Any

Speed

Any

Speed

Any

Speed

Any

Speed

Up to 150˚F Dirty 1 week to 1 month

Over 150˚F Dirty Daily to 2 weeks

Any Temperature Very Dirty Daily to 2 weeks

Any Temperature

Fan

Status

Extreme

Conditions

Greasing

Interval

Daily to 2 weeks

10

Page 11

For best results, lubricate the bearing while the fan is in

operation. Pump grease in slowly until a slight bead forms

around the bearing seals. Excessive grease can burst

seals thus reducing bearing life.

In the event the bearing cannot be seen, use no more

than three injections with a hand-operated grease gun.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative or

your nearest authorized electric motor service representative.

Replacing Fan Pulleys and Belts

a. Remove pulleys from their respective shafts.

b. Clean the motor and fan shafts.

c. Clean bores of pulleys and coat the bores with heavy

oil.

d. Remove grease, rust, or burrs from the pulleys and

shafts.

e. Remove burrs from shaft by sanding.

f. Place fan pulley on fan shaft and motor pulley on its

shaft. Damage to the pulleys can occur when excessive force is used in placing the pulleys on their

respective shafts.

g. Tighten in place.

h. Install belts on pulleys and align as described in the

Belt and Pulley Installation section.

Fan Bearing Replacement

The fan bearings for the ERV - 10000 are pillow block

ball bearings. Bearings should be replaced individually

from each side of fan.

An emery cloth or file may be needed to remove imper-

fections in the shaft left by the setscrews.

a. Remove blower access door.

b. Loosen motor plate adjustment bolts, then move the

motor plate so the belt will easily slip off. Remove

driven pulley by loosening the setscrews.

c. Remove the bearings from shaft.

d. Slide new bearings onto shaft to desired location and

mount bearings loosely onto support base. Bearing

bolts and setscrews should be loose to allow shaft

positioning.

e. Position the wheel properly and tighten the bearing

bolts securely to the support base.

f. Align setscrews bearing to bearing and tighten against

the shaft securely.

Never tighten both pairs of setscrews before

securing bearing mounting bolts. This may dam-

age the shaft.

g. Check wheel position again. If necessary, readjust by

loosening the bearing bolts and setscrew and repeat

step e.

Energy Recovery Wheel Maintenance

Energy Recovery Wheel Bearings

All ERVs (except ERV-10000) are provided with no

maintenance inboard bearings. These bearings should

require no maintenance during the life of the equipment.

ERV-10000 comes equipped with an external flanged bearing which should be greased annually. Use a petroleum

based lubricant.

11

Energy Recovery Wheel Seals

The seals are designed to be durable and require no

maintenance other than adjustment, but if seals become

worn or damaged they may be easily replaced. The seals

are made to clip on the cassette or post metal easily.

Seal Checks

The ERV wheel cassette is provided with a neoprene bulb

seal which provides not only an effective seal in both the

peripheral and side-to-side sealing directions but also one

which is easily adjusted to compensate for seal run-in, shipping misalignment, etc.

The neoprene bulb is attached to a metal reinforced Ushaped neoprene grip. The metal/neoprene grip allows for

an expandable grip range which can be moved closer or further from the sealing face as needed. The peripheral bulb

seals against the wheel outer band and the inner bulb seals

against the wheel face. With the wheel stopped, move seals

as close to the sealing surface as possible but without

exceeding grip range of bulb seal and without pressing the

bulb down against the seal face. Bump the motor. If the

motor will not turn, the seal is too close and should be

nudged back where needed.

The seal will seek its equilibrium position based on the

closest part of the sealing face. Because the seal is meant

to be a noncontact seal, small gaps may be seen between

seal and sealing surface once the equilibrium position is

reached. Seal leakage is meant to be under 5 percent at 1

inch of differential between supply and exhaust.

Some seal run-in is to be expected, so don’t be alarmed

by small amounts of wear in the neoprene.

Energy Recovery Wheel Cleaning

The wheel is designed to last the life of the equipment. It

is important to routinely change the filters to keep dust and

dirt from the heat transfer wheel surface. The wheel is

somewhat self cleaning through its normal action of rotating

in and out of countercurrent air flow streams. If the wheel

becomes dirty, it may be cleaned by blowing out the unit

with compressed air (20 psig maximum). In cases of severe

uncleanliness, the wheel cassette can be washed with

water following removal of the wheel cassette drive motor. It

is also permissible to steam clean the wheel.

1. Remove wheel access door and slide out cassette.

2. Remove wheel drive motor.

3. Wash the media carefully with water, once clean, allow

the media to dry out for several hours or days if necessary.

4. Reinstall using the reverse procedure. Run the unit. It

may take several hours for the desiccant to dry out and

for the wheel to perform normally.

NOTE: A damp wheel must be dried out as soon as pos-

sible. Mold and mildew can and will form on the wet

wheel media. Failure to dry wheel media completely

can ruin the wheel and will void the wheel warranty.

Use of a wheel that has a mold/mildew condition can

result in occupant complaints and sickness.

Energy Wheel Drive Belt

Proper energy wheel operation depends on the tightnes

of the wheel drive belt. For proper tension, a deflection of

approximately 1/4” per foot of belt distance from where belt

contacts energy wheel to the sheave.

Page 12

Troubleshooting

Problem and Potential Cause

Low Capacity or Pressure

•Incorrect direction of rotation. Make sure the blower wheels rotate in

same direction as the arrows on the motor or belt drive assembly.

•Poor fan inlet conditions. There should be a straight clear duct at the inlet.

•Improper wheel alignment.

Overheated Bearings

• Improper bearing lubrication

• Excessive belt tension.

High Pressure Drop

• Check air flow compared to design.

• Check filters and clean/replace as necessary.

• Check energy recovery wheel media for pluggage and clean per cleaning

instructions.

Excessive Vibration and Noise

• Damaged or unbalanced blower wheel.

• Belts too loose; worn or oily belts.

• Speed too high.

• Incorrect direction of rotation. Make sure the blower wheels rotate in

same direction as the arrows on the motor or belt drive assembly.

• Bearings need lubrication or replacement.

• Fan surge.

• Check seals and adjust as necessary.

• Check the bearings for source of noise.

• Check the belts for slippage.

Improper Blower Wheel Rotation

• Check drive belts for engagement with sheave.

• Check drive motor.

• Check drive motor wiring for proper voltage.

Energy Recovery Wheel Is Not Turning — or runs intermittently

• Check for loose or broken wheel drive belt.

• Bulb seals could be too tight against sealing surfaces.

• If unit is equipped with an economizer control, then check temperature

or enthalpy set points and adjust if required.

Inadequate Energy Recovery Wheel Performance

• Check wheel rotation speed.

• Check for wheel integrity and adjust seals or replace worn seals.

• Check entering air conditions and compare design.

• Check ducting for leakage and fix any leaks.

• Check media for dirt and clean per cleaning instructions.

Overheated Motor

• Motor improperly wired.

• Incorrect direction of rotation. Make sure the fan rotates in same direction

as the arrows on the motor or belt drive assembly.

• Cooling air diverted or blocked.

• Improper inlet clearance.

• Incorrect fan RPMs.

• Incorrect voltage.

Supply and/or exhaust blower motors turned off

• Motor overloads could be tripping.

• If the unit is equipped with an on/off or exhaust only frost protection, then

check frost temperature set point and adjust if required.

Dirty Filter Sensor Calibration

Dirty Filter Sensor - Senses fan compartment suction increase, which then actuates a dirty filter warning light. Sensor requires field calibration after initial

system start up. This is accomplished by shutting off the unit, placing a cardboard block-off in front of the filters to simulate dirty air filter condition. The filter sensor is then adjusted until it actuates the warning light after the unit is restarted with block-off in place. The unit is then shut off and the block-off is

removed. Access panels are reinstalled and the unit is restarted. The actuator light should remain off until the filters become dirty.

Link Belt Information

I. HOW TO MEASURE

Pull belt tight around sheaves to check hand tight length,

overlapping the last two tabs with two holes in matching

links as shown at right.

Count the number of links and remove one link for every 24 of O/3L,

A/4L and B/5L Sections, and one link for every 20 of C & D Sections.

This gives the correct installed belt length and will ensure optimum belt

tension when running. NOTE: Every tenth link is designated with

an arrow.

II. DISASSEMBLY

1. Hold belt upside

down. Bend back

as far as possible;

hold with one hand.

Twist one tab 90

parallel with slot.

o

2. Pull end of link

over tab.

3. Rotate belt and with

o

tab 90

.

4. Pull belt end through

two links.

III. ASSEMBLY

1. Hold belt with tabs

pointing outward.

(As shown) To Ensure Easy Assembly and Disassembly

2. Place end tab

through two links

at once.

IMPORTANT - TURN BELT INSIDE OUT

3. Flex belt further and

insert second tab

through end link by

twising tab with thumb.

4. Ensure tab returns

to position across belt.

Reverse belt so tabs

run inside.

12

Page 13

Direct Drive Parts List - ERV-500, ERV-1000

Part Number Description Quantity Part Number Description Quantity

1 Bearing Support 2 14 Outer Housing 1

2 Energy Recovery Wheel 1 15 Insulation Cover 4

3 Cassette Face 1 16 Intake Duct Flange 4

4

5 Wheel Drive Belt 1 18 Discharge Duct Flange 4

6 Energy Recovery Wheel Motor 1 19 Blockoff Panel 2

7 Filter 2 20 End Panel 2

8 Cassette Side Panel 2 21 Optional Low Voltage Control Panel 1

9 Gusset 4 22 Door Latch 2

10 Hinge 2 23 Blower Motor 2

11 Door Latch Keeper 2 24 Blower Housing Mounting Bracket 2

12 Access Door 1 25 Blower Housing 1

13 Hanging Channel 2

Filter Size

Size Quantity

500 2 16 x 20

1000 2 16 x 25

All dimensions in inches.

Cassette Assembly Top/Bottom

Panel

Filter

Size

217Discharge Duct Flange 2

14

13

12

16

17

18

19

21

20

22

15

24

25

11

10

9

8

7

1

2

5

423

3

6

13

Page 14

Belt Drive Parts List - ERV 1500 through ERV- 10000

Part

Number

1 Cassette Access Door 1 16 Filter Access Panel 1

2 Filters See Table Below 17 Lower Cassette Guide 2

3 Filter Rack 2 18 Return Air Cover Arr. H & I 1

4 Base

5 Intake Panel 1 20 Blockoff Panel 2

6 Intake Weather Hood 1 21 Blower Blockoff Arr. H & I 1

7 Blower Mounting Rails 2 22 Intake Blower 1

8 Discharge Blower/Electrical Panel Access Door 1 23 Blower Cover Arr. V 1

9 Electrical Panel Compartment 1 24 Intake Motor 1

10 Discharge Panel 1 25 Upper Door Channel 1

11 Discharge Motor 1 26 Upper Cassette Guide 2

12 Discharge Blower 1 27 *Cassette Assembly 1

13 Discharge Hood 1

14 Filter Access Door 1

15 Base Blockoff Arr. H & I 1

Description Quantity

1 - ERV 1500, ERV 2500

2 - ERV 3500 - 10000

Part

Number

19 Outlet Panel 1

28 Top Cap (Not Shown)

Description Quantity

1 - ERV 1500, ERV 2500

2 - ERV 3500 - 10000

* Parts list for cassette assembly on page 16.

Filter Size

Size

1500 (2) - 12 x 24, (2) - 20 x 24

2500 (4) - 20 x 25

3500 (4) - 14 x 25, (4) - 16 x 25

4500 (10) - 16 x 20

5500 (12) - 16 x 20

7000 (4) - 20 x 20, (8) 20 x 24

8500 (6) - 18 x 24, (6) - 20 x 24

10000

All dimensions in inches.

(6) - 20 x 24, (6) - 18 x 20

Filter

Size

19

20

21

22

23

24

27

25

26

1

15

14

16

17

18

2

3

4

5

6

13

2

12

11

3

10

9

8

7

14

Page 15

Belt Drive with Coil Option Parts List - ERV 1500 through ERV- 10000

Part

Number

1 Supply Blower Access Door 1

2 Coil Cover Panel 1

3 Fluid Coil Cover Varies

4 Fluid Coil Grommet - 1-7/8 I.D. Varies

5 DX Coil Access Door 1

6 Condensate Drain Pipe 1

7 DX Coil Cover Varies

8 DX Coil Grommet - 1-5/8 I.D. Varies

9 Cassette Access Door 1

10 Front Panel (Not Shown) 1

11 Preheater (Optional) 1

12 Filter Access Door 1

13 Cooling Coil (DX or CW) - Optional (1) Size 1500-3500, (2) Size 4500 & Up

14 Heating Coil (HW or Electric) - Optional (1) Size 1500-3500, (2) Size 4500 & Up, (1) Electric

15 Secondary Block Off Panel 1

16 Drain Pan (Not Shown) 1 (Supplied with Cooling Coil)

17 Topcap (Not Shown) 2

Description Quantity

14

13

12

Notes:

Parts List

The ERV and the ERV with Coils

Option share many of the same

parts. If the part is not called out

here, then refer to the Belt Drive

Par ts List on the preceding page.

Filter

s

The ERV and the ERV with Coils

Option use the same filters. For

filter sizes refer to the filter size

table on the preceding page.

15

11

10

15

1

2

3

5

6

7

8

9

4

Page 16

Cassette Assembly Parts List - ERV 1500 through ERV- 10000

Part

Number

1 Energy Recovery Wheel 1

2 Wheel Drive Belt 1

3 Bearing Support 2

4 Cassette Face 1

5 Top and Bottom Panel 2

6 Side Panel 2

7 Wheel Motor 1

8 Drive Sheave 1

9 Bulb Seal

10 Cassette Top Rails 2

11 Cassette Motorplate 1

12 Gusset 7

13 Face Bulb Seal 2

14 Small Cassette Flange 2

15 Large Cassette Flange 2

15

14

Description Quantity

10

7

11

8

2

9

4

1

13

3

5

12

6

ERV Limited Warranty

Loren Cook Company warrants that your Loren Cook Energy Recovery Ventilator (ERV) was manufactured free of defects in materials and workmanship, to the extent stated

herein. For a period of one (1) year after date of shipment, we will replace any parts found to be defective and for a period of seven (7) years after date of shipment, we will

replace the energy recovery wheel if found to be defective. These parts will be replaced without charge, except for shipping costs, which will be paid by you. This warranty is

granted only to the original purchaser placing the fan in service. This warranty is void if the ERV or any part thereof has been altered or modified from its original design or has

been abused, misused, damaged or is in worn condition or if the ERV has been used other than for the uses described in the company manual. This warranty does not cover

defects resulting from normal wear and tear. To make a warranty claim, notify Loren Cook Company, General Offices, 2015 East Dale Street, Springfield, Missouri 658034637, explaining in writing, in detail, your complaint and referring to the specific model and serial numbers of your ERV. Upon receipt by Loren Cook Company of your written

complaint, you will be notified, within thirty (30) days of our receipt of your complaint, in writing, as to the manner in which your claim will be handled. If you are entitled to warranty relief, a warranty adjustment will be completed within sixty (60) business days of the receipt of your written complaint by Loren Cook Company. This warranty gives only

the original purchaser placing the ERV in service specifically the right. You may have other legal rights which vary from state to state.

Corporate Offices: 2015 E. Dale Street Springfield, MO 65803 417.869.6474

lorencook.com

16

ERV IOM- December 2002

Loading...

Loading...