Page 1

Energy Recovery with Cooling & Heating

Model ERCH

• Commercial • Institutional

• 10,000 cfm

• 1.5 in. wg external static pressure

February

2005

Page 2

Product Features

Model ERCH

Energy Recovery Ventilator With Cooling & Heating

The model ERCH combines the benefits of the

total energy wheel with supplemental heating and

cooling. The result is a product that is specifically

designed to process 100% outdoor air to desired

supply conditions. Four housing sizes provide air flow

capacities from 1,000 cfm to 10,000 cfm with external

static pressures up to 1.5 in. wg (for requirements

above this performance, refer to Model ERT or APEX).

Product operation is simple:

• Fresh outdoor air is pre-conditioned by the total

enthalpy wheel, recovering a majority of the energy

from the exhaust air.

• The coil section further conditions the outdoor air to

desired conditions (typically near room conditions).

Standard Construction

Single Point

Wiring is standard.

A disconnect

switch and low

voltage terminal

strip are provided.

Hinged Access

Doors provide

easy access to

blowers, energy

wheel, filters, and

coil section for

inspection and

routine service.

Forward Curved

Blowers are

mounted on neoprene

vibration isolators.

Double Wall Housing is

constructed of heavy gauge

steel with 1-inch insulation.

The supply and exhaust

side are internally lined with

galvanized steel.

A Control Box is furnished

with motor starters for the

supply blower, exhaust

blower and wheel motors.

Also included is a 24 volt

control circuit.

Model ERCH shown with

optional chilled water coil

and indirect gas heater.

The Coil Section

provides supplemental

cooling or heating of

the outdoor air after

pre-conditioning by the

energy wheel. Tempering

options include chilled

water, direct expansion,

hot water, electric heat,

and indirect gas.

Greenheck Fan Corporation certifies

that the ERCH models shown herein

are licensed to bear the AMCA seal.

The ratings shown are based on

tests and procedures performed

in accordance with AMCA

publication 211 and comply with the

requirements of the AMCA Certified

Ratings Program.

Energy recovery wheels certified by the ARI Airto-Air Energy Recovery Ventilation Equipment

Certification Program in accordance with ARI

Standard 1060. Actual performance in packaged

equipment may vary. Certified Ratings are

available in the Certified Product Directory at

http://www.airdirectory.org/ari/erv.php

Benefits

Healthy Buildings: Ventilate buildings adequately

without losing control of indoor humidity levels. The

ERCH is capable of conditioning summer air to room

design conditions. Also, it helps prevent overly dry

winter air that can contribute to respiratory irritation.

System Design Simplicity: The ERCH is designed

specifically to provide outdoor air to the space at

desired conditions. This effectively de-couples the

outdoor air load from the building load, enabling the

traditional VAV system to perform as it was intended

in response to building loads.

2

Load Reduction: The energy wheel saves 3 to 4 tons

of cooling AND 50-60 MBH of heating for every 1,000

cfm of outdoor air for many climates.

Low Maintenance:

Servicing is minimal. All components have a well

established history of reliable operation.

ASHRAE 62 Compliance: By assuring that minimum

outdoor air volumes are delivered to the room spaces,

compliance with the ASHRAE 62 Standard is clearly

demonstrated.

Page 3

50

60

70

80

180

160

140

120

100

80

60

40

20

90%

70%

50%

30%

10%

Reheat

Room Air

Outdoor Air

Wheel

Cooling

Coil

Supply Air

W

e

t

B

u

l

b

T

e

m

p

.

Dry Bulb Te mp.

Specific Humidity

30

40

50

60

70

80

180

160

140

120

100

80

60

40

20

90%

70%

50%

30%

10%

Supply Air

Room Air

Outdoor Air

Wheel

Heating

Coil

10

W

e

t

B

u

l

b

T

e

m

p

.

Dry Bulb Te mp.

Specific Humidity

20 30 40 50 60 70 80 90 100 110

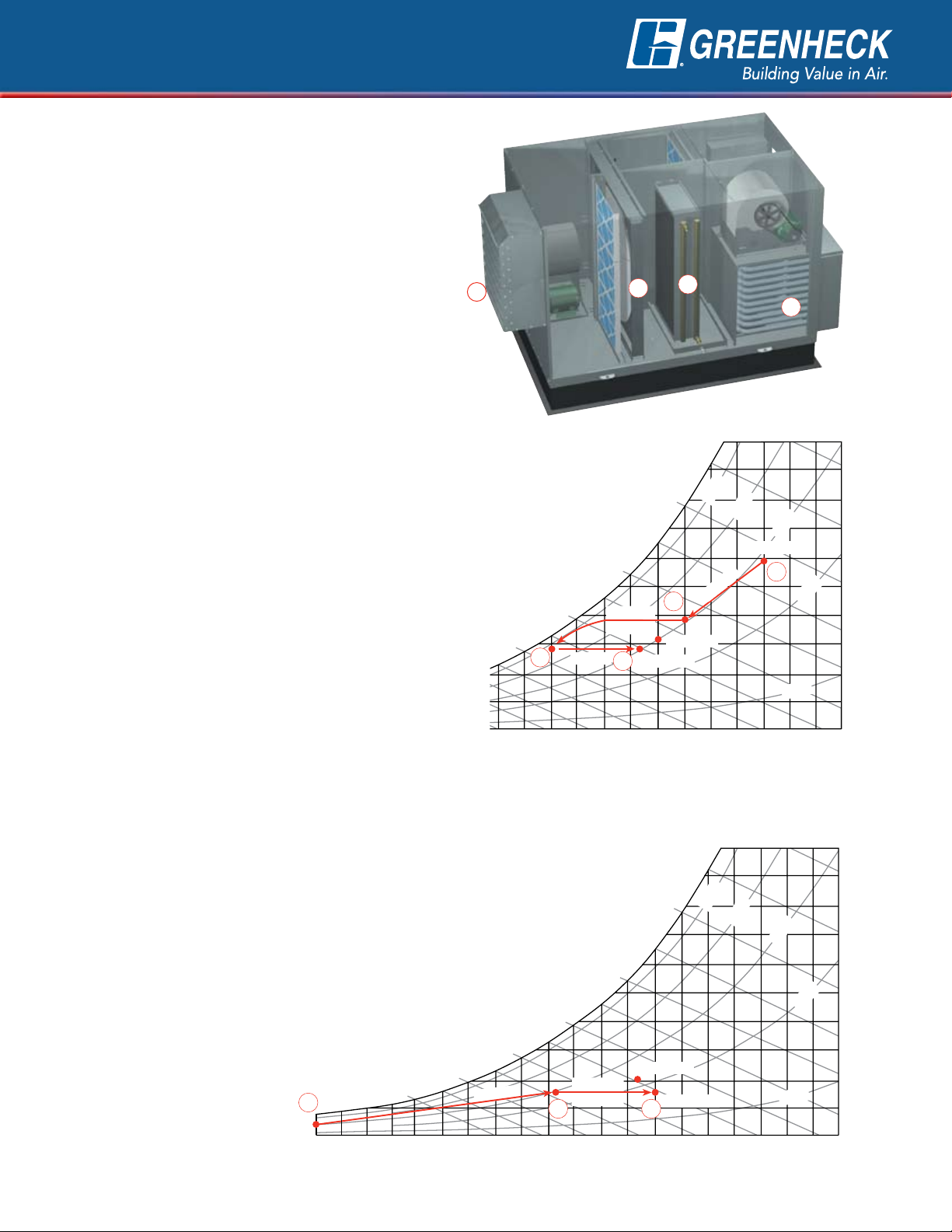

Cooling and Heating

Capabilities

To expand the cooling and heating capabilities

of the energy recovery wheel, a variety of

tempering options are available. The coil

section of the ERCH accommodates a cooling

coil, a heating coil, or both.

A description of the cooling and heating

processes along with a psychrometric

illustration is shown below. Cooling and heating

coil options are also listed.

Consult your Greenheck representative for coil

selections or for tempering options not listed.

COOLING

Supplemental cooling is

recommended when the

air conditions leaving

the energy recovery

wheel have not been

cooled or dehumidified

to the desired leaving

conditions.

Cooling Options

• ChilledWater

• DirectExpansion

Re-heat Options

• Electric

• HotWater

• IndirectGas

1. Outdoor air enters ERCH unit.

2. The energy recovery wheel cools and

dehumidifies outdoor air using energy

from the exhaust airstream. Load is

reduced by 3 to 4 tons per 1,000 cfm

for many climates.

3. The cooling coil provides

supplemental cooling to

further treat the outdoor

air to desired supply

conditions.

4. Optional reheat

available to provide

space neutral air.

1

2

3

4

1

2

3

4

HEATING

Supplemental heating is

recommended when the

air conditions leaving the

energy recovery wheel

have not been heated

to the desired leaving

conditions.

Heating Options

• Electric

• HotWater

• IndirectGas

1. Outdoor air enters ERCH unit.

2. The energy recovery wheel heats and humidifies

winter outdoor air using energy from the

exhaust airstream. Heating bills are

significantly reduced and overly dry

indoor conditions are eliminated.

3. The heating coil or furnace

1

provides supplemental heating

to further treat the outdoor

air to desired supply

conditions.

2

3

3

Page 4

Air Performance

ERCH-20M

CFM OV

1000 1142

1300 1485

1600 1828

ERCH-20H

CFM OV

1600 1828

1900 2171

2200 2514

ERCH-45L

CFM OV

2200 2109

2700 2588

3200 3068

ERCH-45H

CFM OV

3200 2184

3800 2593

4400 3003

ERCH-55H

CFM OV

4200 1989

5100 2415

6000 2842

ERCH-90H

CFM OV

6000 2066

8000 2755

10000 3444

Gross supply air performance ratings (airflow, pressure,

and power) are at port 2 with port 1, port 3 and port 4 at

0.0 in. wg. Gross exhaust air performance ratings (airflow,

pressure, and power) are to port 3 with port 1, port 2 and

port 4 at 0.0 in. wg. Power rating (bhp) does not include drive

losses. Performance ratings do not include the effects of

appurtenances in the airstream.

4

RPM 1141 1344 1498

BHP 0.36 0.51 0.53

RPM 1265 1426 1578 1857

BHP 0.55 0.72 0.90 1.05

RPM 1418 1553 1684 1934 2189

BHP 0.87 1.03 1.21 1.67 2.17

RPM 1308 1446 1575 1816

BHP 0.74 0.89 1.04 1.37

RPM 1453 1574 1691 1907 2108 2306

BHP 1.10 1.27 1.45 1.80 2.19 2.65

RPM 1608 1717 1820 2020 2205 2375

BHP 1.57 1.77 1.96 2.39 2.79 3.20

RPM 797 892 986 1166 1329

BHP 0.68 0.81 0.96 1.29 1.65

RPM 900 977 1053 1209 1359 1494 1628

BHP 1.10 1.25 1.40 1.77 2.18 2.58 3.03

RPM 1010 1079 1143 1274 1406 1533 1655 1768

BHP 1.67 1.87 2.04 2.41 2.86 3.33 3.82 4.29

RPM 900 989 1071 1220 1360 1495

BHP 1.17 1.34 1.53 1.92 2.35 2.83

RPM 1004 1083 1157 1297 1422 1542 1654 1769

BHP 1.79 1.99 2.20 2.64 3.11 3.61 4.12 4.70

RPM 1114 1185 1252 1380 1499 1609 1713 1815

BHP 2.60 2.85 3.08 3.57 4.09 4.64 5.18 5.78

RPM 749 832 906 1038 1155

BHP 1.54 1.82 2.10 2.65 3.21

RPM 839 913 982 1107 1216 1318 1412 1520

BHP 2.43 2.77 3.11 3.80 4.45 5.15 5.81 6.73

RPM 940 1003 1065 1181 1287 1382 1472 1558

BHP 3.67 4.05 4.45 5.26 6.06 6.84 7.64 8.44

RPM 612 682 746 862 962 1058

BHP 1.99 2.37 2.75 3.52 4.33 5.21

RPM 723 783 841 941 1036 1122 1202 1275

BHP 3.91 4.41 495 5.94 6.97 7.98 9.08 10.14

RPM 845 897 946 1040 1124 1201 1277 1348

BHP 7.00 7.56 8.18 9.50 10.78 12.00 13.29 14.52

External Static Pressure in inches of wg.

0.50 0.75 1.00 1.50 2.00 2.50 3.00 3.50

External Static Pressure in inches of wg.

0.50 0.75 1.00 1.50 2.00 2.50 3.00 3.50

External Static Pressure in inches of wg.

0.50 0.75 1.00 1.50 2.00 2.50 3.00 3.50

External Static Pressure in inches of wg.

0.50 0.75 1.00 1.50 2.00 2.50 3.00 3.50

External Static Pressure in inches of wg.

0.50 0.75 1.00 1.50 2.00 2.50 3.00 3.50

External Static Pressure in inches of wg.

0.50 0.75 1.00 1.50 2.00 2.50 3.00 3.50

Greenheck Fan Corporation certifies that the

ERCH models shown herein are licensed to

bear the AMCA seal. The ratings shown are

based on tests and procedures performed in

accordance with AMCA publication 211 and

comply with the requirements of the AMCA

Certified Ratings Program.

Page 5

Air Performance

The air performance data on page 4 accounts for the pressure drop across the energy recovery wheel and the

internal housing losses, but does not include pressure drop for filters or tempering options. Add filter and/or

tempering option pressure drop (from tables below) to external static pressure to determine correct rpm and

horsepower.

Filter Pressure Drop (30% eff.)

Model CFM

ERCH-20

ERCH-45

ERCH-55

ERCH-90

1000 0.04

2200 0.22

2200 0.06

4400 0.24

4200 0.09

6000 0.18

6000 0.10

10000 0.27

Pressure Drop

(in. wg)

Intake & Discharge

Options

WiththeERCH,youhavemanyairintake

and discharge options available to simplify

duct layout for rooftop and equipment room

installations. Refer to the table below for the

intake and discharge locations available for

outdoor air (OA) and exhaust air (EA).

Tempering Options Pressure Drop

Model CFM

ERCH-20

ERCH-45

ERCH-55

ERCH-90

NOTE: Coil data assumes 6 row cooling coils and 1 row heating coils.

1000 0.17 0.02 0.03

2200 0.62 0.08 0.13

2200 0.31 0.04 0.09

4400 0.66 0.08 0.34

4200 0.38 0.04 0.10

6000 0.64 0.08 0.26

6000 0.28 0.03 0.24

10000 0.66 0.08 0.55

Outdoor Air

Intake

End

Cooling Coil

(in. wg)

Top

Heating Coil

(in. wg)

Top

Bottom

Indirect Gas

(in. wg)

Outdoor Air

Discharge

End

Side

Bottom Top Side End

OA Intake X X

OK Discharge X X X

EA Intake X X X

EA Discharge X X X

1

Side OA Discharge is ONLY available with

1

the Indirect Gas (IG) heater.

2

End OA Discharge is NOT available with

the Indirect Gas (IG) heater.

2

X

Top

Exhaust

Discharge

Side

Top

Exhaust

Intake

End

End

Bottom

5

Page 6

Accessories

Weather Hoods

A louvered intake hood

with 2-inch aluminum

mesh filters, and an

exhaust hood with an

integral backdraft damper

are available.

Dampers — Internally Mounted

A variety of motorized control

dampers are available. Intake

and exhaust dampers are

internally mounted at the

outdoor and exhaust air inlets.

Dampers are factory wired to a

single point power disconnect.

Filters

Standard size 2-inch, MERV 8, pleated, medium

efficiency filters and filter racks are available for

outdoor air and/or exhaust air streams.

Frost Control

In cold climates, the recovery wheel may develop

frost, which will decrease airflow. Three factory

mounted options are available to address frosting:

• Timed Exhaust Frost Control

The timed exhaust frost control turns the supply

blower off and on intermittently. Control is

triggered by an outdoor air temperature set point in

conjunction with an increased pressure drop across

the energy wheel.

• Modulating Wheel Frost Control

The modulating wheel frost control enables

continuous unit operation. A variable frequency

drive (VFD) reduces wheel speed when the outdoor

air temperature falls below the frost threshold

set point and upon an increase in the differential

pressure across the energy wheel. The temperature

and pressure differential set points are set at the

factory, but are field-adjustable. The VFD will be

fully programmed and wired at the factory.

• Preheat Frost Control

The preheat frost control enables continuous unit

operation. An electric heater warms the outdoor air

above the frost threshold before it enters the energy

recovery wheel. Control is triggered by the outdoor

air temperature set point in conjunction with

increased pressure drop across the energy wheel.

Rotation Sensor

Senses when a wheel rotation failure occurs and

sends a signal to an indicator light. The light is

available on a remote control panel from the factory.

Microprocessor Discharge

Temperature

Control

The microprocessor

controller is specifically designed and programmed

to optimize the performance of an ERCH unit with

supplemental heating and cooling. This option

ensures that the outdoor air is conditioned to

the desired discharge conditions. The controller

and accompanying sensors are factory mounted,

wired and programmed. Default settings are preprogrammed, but are easily field adjustable. The

microprocessor controller can be interfaced with

a Building Management System (BMS) through

LonWorks,BACNET,orModBus.

Economizer Control (Free Cooling)

Whencooloutdoorairisavailable,theenergywheel

may be controlled to provide free cooling. Economizer

operation can be initiated by the unit sensors alone or

in conjunction with a call for cooling (field wired). Two

factory installed options are available.

• Wheel Off: De-energizes the wheel when the

outdoor temperature is below the field adjustable

set point (enthalpy sensor also available). An

automatic economizer override is included to

engage the wheel for winter heating operation.

• Wheel Modulation: Modulates the energy recovery

wheel to maintain a 55°F discharge temperature

during economizer operation.

Note: Control centers in Greenheck energy recovery

ventilators enable the control of the energy wheel and

fans via 24-volt control signals (by others). Controls

by others may be preferred when air handling units

are equipped with an economizer section.

Variable Air Volume

Model ERCH utilizes variable

frequency drives (VFD’s) for

multi-speed or modulating

blower control to vary airflows.

This includes a separate VFD for

each blower.

Additional Accessories:

• Remote Panels

• GFCI Service Outlet (control power by others)

• Service Lights (control power by others)

• SpareWheelSegments

• Roof Curbs

• Painted Exteriors

• Factory Mounted Sensors

6

Page 7

Typical

Specifications

General: Energy Recovery Ventilator shall be as manufactured

by Greenheck or approved equal provided all specifications

are met. Greenheck Model ERCH is used as the basis of

design. Units shall be listed per ANSI/UL 1995, Heating and

Cooling Equipment. Energy transfer ratings of the energy

recovery wheel shall be ARI Certified. Ventilators shall bear the

AMCA Certified Rating seal for Air Performance. Performance

shall be as scheduled on plans. Exhaust discharge and

outside air intake shall not be located on the same side on

roof top units.

Unit Casing and Frames: Unit shall be of internal frame

type construction of galvanized steel. Frame and panels shall

be G90 galvanized steel. All panels exposed to the weather

shall be a minimum of 18 gauge galvanized steel. Unit shall

be internally lined with galvanized sheet metal creating a

double wall. Where top panels are joined there shall be

an overlapping, standing seam to insure positive weather

protection. All metal-to-metal seams shall be factory sealed,

requiring no caulking at job site. Permatector™ exterior

finish is available for outdoor units. Unit base to be designed

for curb mounting. Unit base shall overhang the curb for a

positive seal against water run-off.

Weatherhoods: Weatherhoods shall be the same finish

as the unit. Outdoor air weatherhood shall incorporate a

louvered design and moisture eliminator. Weatherhoods

shall be tested in accordance with AMCA Standard 500-L to

prevent water penetration up to 3 in/hr at 29 mph.

Insulation: Unit casing to be insulated with 1-inch fiberglass.

Insulation shall meet requirements of NFPA 90A and tested to

meet UL 181 erosion requirements. Insulation to be enclosed

in double wall construction.

Energy Recovery Wheel: Wheelshallbeoftheenthalpytype

for both sensible and latent energy recovery and be designed

to insure laminar flow. Energy transfer ratings must be ARI

Certified to Standard 1060 and bear the ARI Certification

symbol for ARI Air-to-Air Energy Recovery Ventilation

Equipment Certification Program based on ARI 1060. Ratings

“in accordance with 1060” without certification are not

acceptable. Desiccant shall be silica gel for maximum latent

energy transfer. Wheel shall be constructed of lightweight

polymer media to minimize shaft and bearing loads. Polymer

media shall be mounted in a stainless steel rotor for corrosion

resistance.

Wheeldesignshall consist of removable segments for ease

of service and/or cleaning. Silica gel desiccant shall be

permanently bonded to wheel media to retain latent heat

capabilityaftercleaning.Wheelswithsprayedondesiccant

coatingsare not acceptable.Wheelswithdesiccantapplied

after wheel formation are not acceptable. Energy recovery

device shall transfer moisture entirely in the vapor phase.

Energy recovery drive belt material shall be high strength

urethane and shall be factory installed in a pre-stretched

state, eliminating the need for field belt tension adjustment.

Link style belts are not acceptable.

Hinged Access Doors: All components shall be easily

accessible through hinged access doors for exhaust, supply,

filter, and damper compartments. Energy recovery wheels

(smaller than 58 inches) shall be mounted in a slide-out track

for ease of inspection, removal, and cleaning.

Roof Curbs: Roof curb to be supplied by unit manufacturer

for field assembly. Curb shall consist of die formed galvanized

steel sections. Curb shall be full perimeter type with gasketing

provided for field installation between curb and unit base.

Fan Sections: Centrifugal fans to be double width, double

inlet, forward curved type. All blower wheels shall be statically

and dynamically balanced. Ground and polished steel fan

shafts shall be mounted in permanently lubricated, sealed

ball bearing pillow blocks. Bearings shall be selected for a

minimum (L10) life in excess of 100,000 hours at maximum

cataloged operating speeds. Separate motors for exhaust

and supply blowers shall be provided. Adjustable sheaves

on belt-driven fans with motors less than 10 hp shall allow

independent balancing of exhaust and supply airflow. Fan and

motor assemblies are mounted to unit base with neoprene

isolators as standard. Fans shall be located in draw-through

position in reference to the energy recovery wheel.

Motors and Drives: Motors shall be energy efficient,

complying with EPACT standards, for single speed ODP

and TE enclosures. Motors shall be permanently lubricated,

heavy-duty type, matched to the fan load and furnished at

the specified voltage, phase, and enclosure. Drives shall be

sized for a minimum of 150% of driven horsepower. Pulleys

shall be of the fully machined cast type, keyed and securely

attached to the fan wheel and motor shafts; 10 hp and less

shall be supplied with an adjustable drive pulley. Energy

wheel motors shall have integral overload protection.

Filters: Supply and exhaust air filters shall be 2-inch thick

pleated fiberglass, 30% efficient and tested to meet UL

Class 2. Filter racks shall be die-formed galvanized steel.

Electrical: All internal electrical components shall be factory

wired for single point power connection. Units with electric

reheat will be wired with independent power supply. All

electrical components shall be UL Listed, Approved, or

Classified where applicable and wired in compliance with the

National Electrical Code.

Weatherproof, integral doorinterlocking disconnect switch,

motor starters, control circuit fusing, control transformer

for 24 VAC circuit, and terminal strip shall be supplied as

standard components in the control center. Motor starters

consist of a contactor and Class 20 electronic adjustable

overload protection and shall be provided for all fan motors.

Cooling Coil: Direct expansion (DX) and chilled water coils

shall be factory tested and rated in accordance with ARI 410.

Coils shall have copper tubes with permanently expanded

aluminum fins, 12 fpi or less. DX coils shall be equipped

with distributors to receive expansion valves at the liquid

connections. DX coils shall include stainless steel drain pan.

Indirect Gas: Indirect fired gas furnace shall be 80%

efficient, UL Certified and Listed per ANSI Z83.8 - 2002,

C.G.A. approved per 2.6 - 2002 and have a blow through fan

design. Furnace shall be capable of operation with natural

or LP gas and have a power venting system. The burner and

heat exchanger shall be constructed of aluminized steel.

Standard furnace features shall include main gas pressure

regulator, main gas valve, electronic staged or electronic

modulating controls, direct spark ignition system, high limit

and a 24 volt control transformer.

Hot Water Coil: Hot water coil shall be factory tested and rated

in accordance with ARI 410. Coils shall have copper tubes with

permanently expanded aluminum fins, 12 fpi or less.

Electric Heat: Electric heat shall be UL listed and circuit

fused per NEC over 48 amps. Heater shall be multi-step

control, factory wired and installed. Control will be 24 volt

with class 2 transformer. Standard air flow switch to shut

down heater if air ceases to flow across heater.

7

Page 8

Dimensional Data

Outdoor Air

Hood

Outdoor Air

Hood

Exhaust

Hood

2 in. filters

2 in. filters

2 in. filters

Wheel Cassette

Wheel Cassette

Coil

Section

Coil

Section

Optional

IG Heater

Optional

IG Heater

Electrical Box

DA

B

C

E

F

Model A B C D E F

ERCH-20 98 50 56 18 18 9

ERCH-45 106 69 66 16 20 11

ERCH-55 118 70 76 16 25 11

ERCH-90 131 85 96 16 27 11

All dimensions shown are in inches.

Model Approximate Weight (lbs)

ERCH-20 1500

ERCH-45 2300

ERCH-55 3000

ERCH-90 5000

Actual weight is dependent upon unit configuration.

Side

View

Top

View

OurWarranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period

of one year from the purchase date. Any units or parts which prove defective during the warranty

period will be replaced at our option when returned to our factory, transportation prepaid. Motors are

warranted by the motor manufacturer for a period of one year. Should motors furnished by Greenheck

prove defective during this period, they should be returned to the nearest authorized motor service

station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

GreenheckP.O.Box410•Schofield,WI54476-0410•Phone(715)359-6171•greenheck.com

Copyright©2005GreenheckFanCorp.•CatalogERCHSNRev.4February 2005

Prepared to Support

Green Building Efforts

Loading...

Loading...