Page 1

READ AND SAVE THESE INSTRUCTIONS

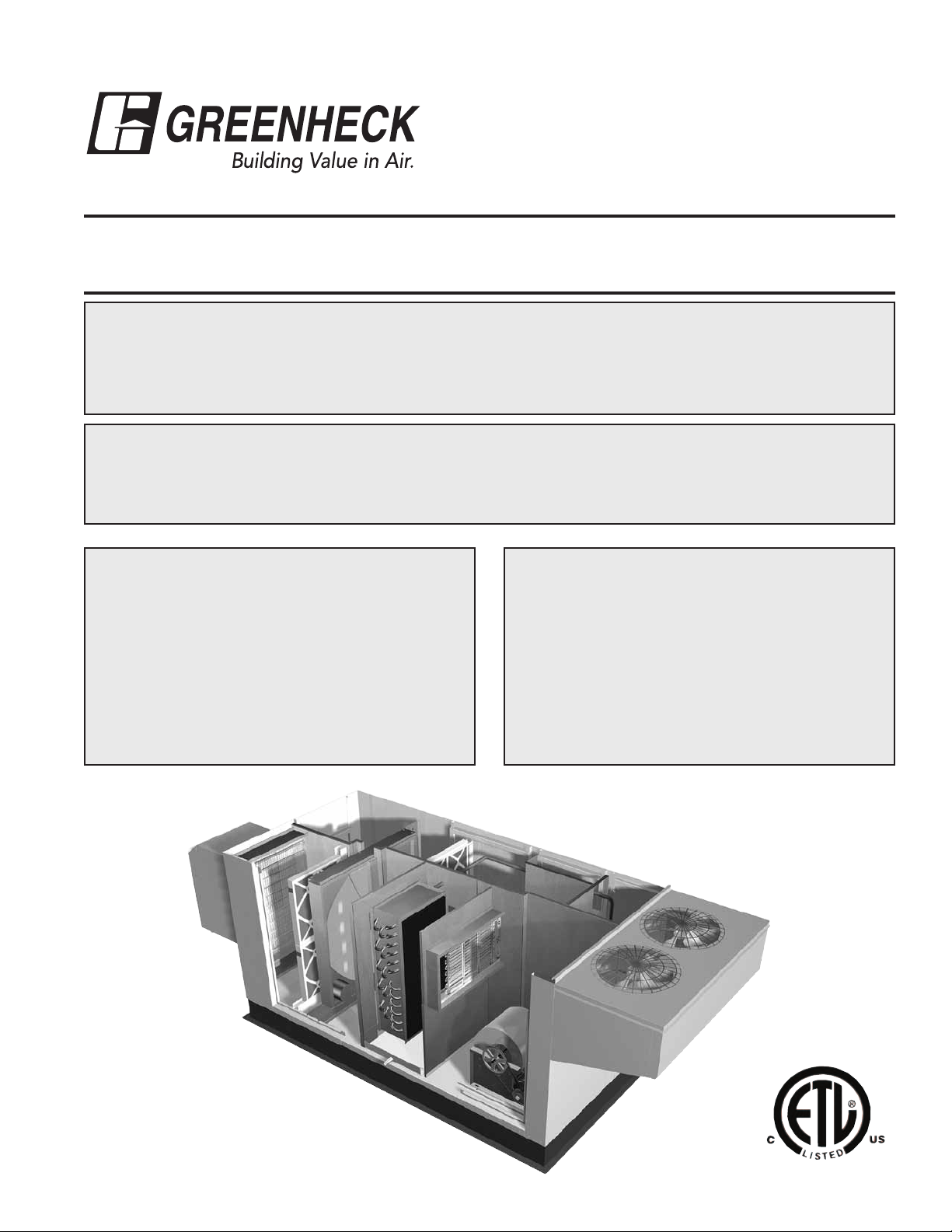

ENERGY RECOVERY UNIT

PART #468151

®

Model ERCH-20, 45, 55 & 90

without DDC Controls

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

RECEIVING AND HANDLING

The ERCH is thoroughly inspected and test run at the factory. However, damage may occur

during shipping and handling. Upon delivery, inspect the unit for both obvious and hidden

damage. If damage is found, record all necessary information on the bill of lading and file a claim

with the final carrier. In addition, ensure all accessory items are present. Some accessory items

are stored inside the unit during shipping.

SAFETY WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read this installation, operation, and maintenance manual thoroughly before

installing or servicing this equipment. Installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

WITH PACKAGED DX

INSTALLATION SUPPLEMENTS

Refer to the following installation supplements

ERCH supplied with Indirect Gas (IG) heating:

Model PVF, Indirect Gas Fired Furnaces

for Energy Recovery Units, Part #461006

ERCH Curb Assembly Instruction, Part #468280

SAVE THIS MANUAL

This manual is the property of the

owner, and is required for future

maintenance. This manual should

remain with each ERCH unit when the

job is complete.

Page 2

TABLE OF CONTENTS

Storage and Owners Information ..........2

Basic Operation..........................3

Installation

Lifting .................................4

Unit Weights & Recommended Roof

Openings ............................4

Installation Concerns .....................5

Roof Curb Mounting ...................5-6

Rail Mounting and Ductwork Connections....6

Electrical Information.................. 7-8

Control Center Components ...............8

Service Clearances ......................9

Dimensional Data/Access Door Description . 10

Coil Applications & Drain Trap Info......11-12

Optional Accessories

Electric Heater Application/Operation ......13

Frost Control Application/Operation........14

Economizer Application/Operation .........15

Variable Frequency Drives ...............16

Typical Wiring Diagram ..................17

Sensors and Lights ..................18-19

Remote Control Panel & Wiring ........20-22

Sensors Mounted by Factory .............23

Energy Recovery Unit with Packaged DX

Start-Up Checklist

Unit ...............................24-26

Optional Accessories....................27

Fan ..................................28

Energy Recovery Wheel .................29

Routine Maintenance Checklist...........33

Belts and Motors .......................34

Blower Wheel and Fasteners .............34

Filters ................................35

Coil Maintenance ......................36

Energy Recovery Wheel Maintenance

Accessing Energy Recovery Wheel ........37

Removing Wheel Segments ..............37

Cleaning Wheel Segments ...............38

Parts List ..............................39

Sequence of Operation ...............40-41

Troubleshooting -Airflow .................42

Troubleshooting -General Unit .........43-44

Troubleshooting -Refrigeration Circuit ..45-50

Notes ..................................51

Warranty ...............................52

STORAGE

When a unit is not going to be in service for an extended amount of time, certain procedures should be followed

to keep the fans in proper operating condition.

•Rotatefanwheelmonthlyandpurgegreasefrombearingsonceeverythreemonths

•Coverunitwithtarptoprotectfromdirtandmoisture

(Note: do not use a black tarp as this will promote condensation)

•Energizefanmotoronceeverythreemonths

•Storebeltsflattokeepthemfromwarpingandstretching

•Storeunitinlocationwhichdoesnothavevibration

•Afterstorageperiod,purgegreasefromfanbearingsbeforeputtingfanintoservice

If storage of unit is in a humid, dusty or corrosive atmosphere, rotate the fan and purge the bearings once a

month. Improper storage which results in damage to the unit or components will void the warranty.

OWNER’S INFORMATION

The following summary highlights some important notes to help avoid premature failure and possible voidance

of warranty.

Product Overview

Greenheck ERCH Models integrated with a complete refrigerant system are designed with the purpose of being

a self-contained source for heating and cooling in both commercial and institutional applications. This is done in

a highly efficient manner through the use of a total enthalpy recovery wheel. The wheel allows the compressors

and cooling equipment to be downsized in the unit, therefore being more cost effective to operate. The DX

system comes fully charged from the factory with refrigerant and is ready for installation upon arrival.

The smaller tonnage units (4-9 tons) contain a single compressor, allowing for one stage of cooling. Larger units

(10-30 tons) come standard with two compressors. This allows for staging of compressors to meet a wider

range of outdoor air loads while reducing the amount of cycles per compressor.

Integral Components

All units are provided with an expansion valve, hermetic scroll compressor(s), liquid line filter drier, high

pressure manual reset cutout, low pressure auto-reset cutout, time delays for compressor protection, service/

charging valves, moisture indicating sight glass, and hot gas bypass. The compressors also come standard with

a crankcase heater for additional protection.

2

Page 3

Energy Recovery Unit with Packaged DX

Shutdown Operation

The scroll compressors in this unit are designed to compress gas refrigerant only. To prevent liquid refrigerant

from migrating into and damaging the compressors, each compressor is supplied with a crankcase heater. Prior

to starting the compressors, the heaters must have power to them for 24 hours. Power should never be cut to

these units unless the complete shutdown procedure is followed.

Proper shutdown procedure:

1) Turn off main power supply to the unit

2) Turn thermostat controls to “off” position

3) Restore main power supply to the unit

4) Wait 24 hours prior to turning the thermostat control to the “on” position

Low Ambient Operation

Low ambient operation can cause damage to the refrigerant system. A factory-installed temperature sensor

in the outdoor air intake prevents refrigerant system operation at ambient conditions below 55ºF. Crankcase

heaters will still be engaged provided the main power has not been disconnected. If cooling is desired at

ambient temperatures below 55ºF, economizer operation (wheel start/stop or wheel modulation) should be

employed.

Reduced Airflow – Pumping oil and liquid refrigerant

Lack of maintenance will lead to filters, condensing coils, and evaporator coils building up with dirt and

debris. As this occurs, the airflow through the unit will decrease. Cooling coils are sized to handle a particular

airflow volume. A reduction in airflow can cause the cooling coils to get too cold and may result in excessive

liquid refrigerant return to the compressors. The liquid refrigerant buildup in the compressors will displace the

necessary oil required for proper lubrication. The combination of these two events will significantly reduce the

life of the compressors.

To maintain the proper airflow and system efficiency, follow all procedures in the Maintenance section.

Safety Listing

The ERCH units are listed per ANSI/UL 1995, Heating and Cooling Equipment, and bear the ETL logo.

Environmental Concerns

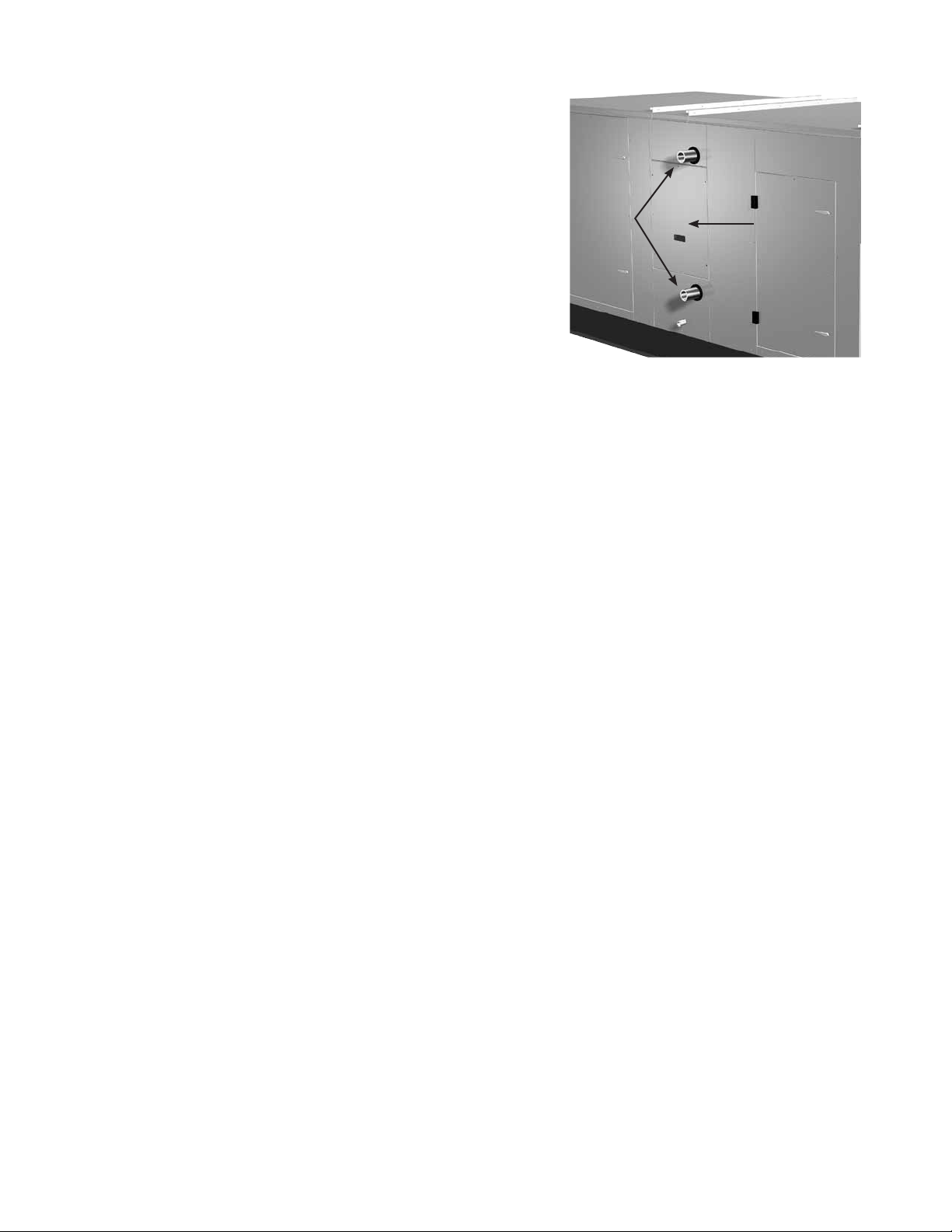

This equipment contains R22 or R-410a refrigerant. Refer to label on

access door identifying the type of refrigerant in the unit.

R22 is a class II refrigerant that contains HCFC’s. If released, HCFC’s

may reduce the amount of ozone in the atmosphere. This ozone

depletion will result in less protection from the sun and therefore it

is critical to use every precaution necessary to minimize the amount

admitted to our environment.

When working with Greenheck’s fully charged refrigerant system, it is

strongly recommended that caution is undertaken during installation,

operation, and routine maintenance. This caution will help ensure

that minimal amounts of refrigerant are leaked into the atmosphere.

To comply to the U.S. Clean Air Act, anytime there is residual

refrigerant, the proper equipment shall be used and methods should be followed to reclaim the refrigerant so

that it can be recycled, reprocessed, or destroyed.

Do not release refrigerant to the

atmosphere! If required service

procedures include the adding or

removing of refrigerant, the service

technician must comply with all

federal, state and local laws. The

procedures discussed in this manual

should only be performed by a

qualified EPA Certified Technician.

IMPORTANT!

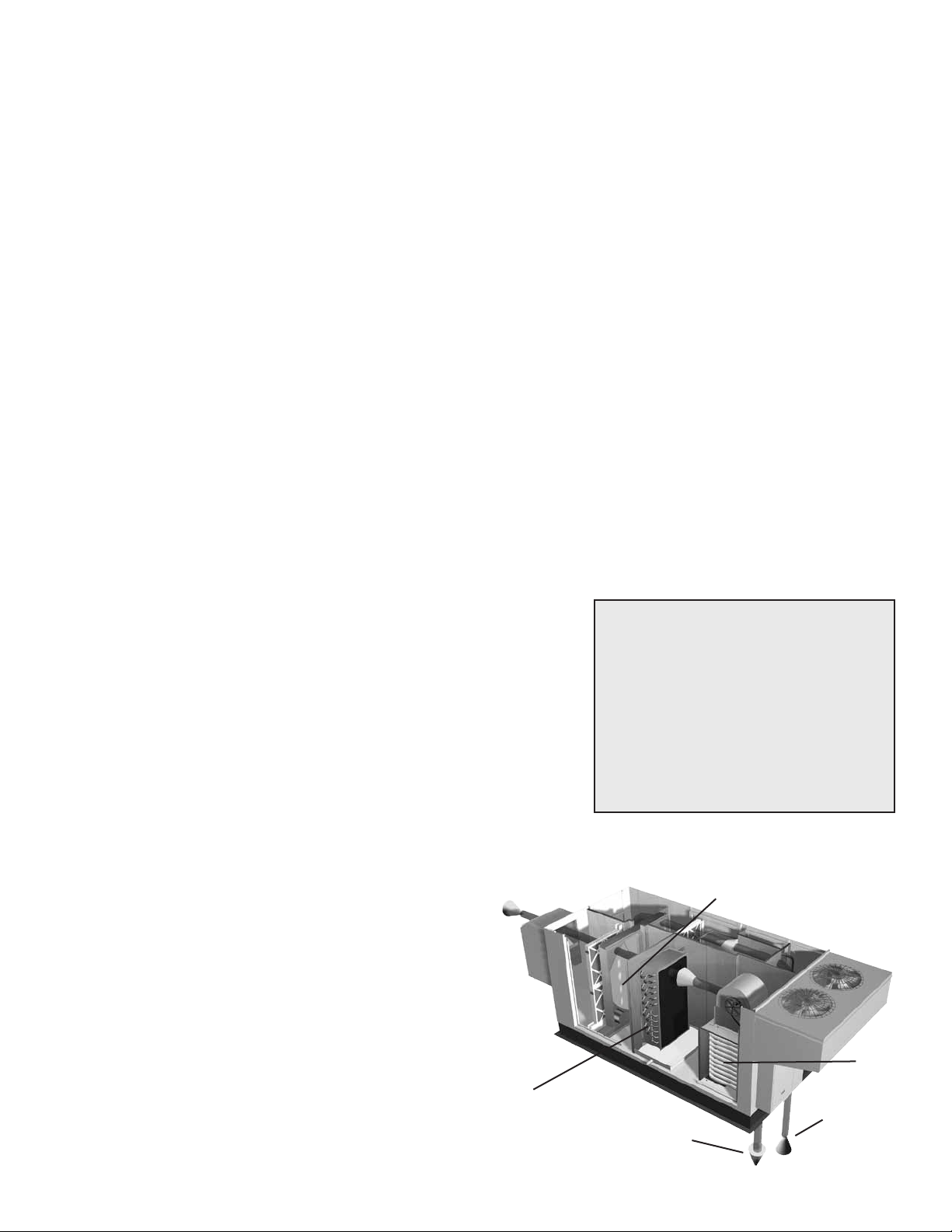

BASIC OPERATION

The ERCH with Packaged DX units bring in

fresh, outdoor air and remove stale, exhaust

air. Prior to discharging the exhaust air, the

energy recovery wheel transfers energy

from the exhaust air to the outdoor air at an

efficiency of 70-80%. Simply put, this unit

preconditions the outdoor air to save money

on heating and cooling costs. These particular

units also have packaged DX cooling and

heating options available after the recovery

wheel to further condition the fresh air.

Outdoor

Air

DX Cooling

Coil

Conditioned Air

sent to space

Energy Recovery Wheel

Optional

Heater

Exhaust Air

from building

3

Page 4

Energy Recovery Unit with Packaged DX

CAUTION!

Unit is designed for Outdoor installation only. Follow all guidelines in this manual for proper installation.

INSTALLATION

The system design and installation should follow accepted industry

practice, such as described in the ASHRAE Handbook.

Adequate space should be left around the unit for piping coils and drains,

filter replacement, and maintenance. Sufficient space should be provided

on the side of the unit for routine service and component removal should

that become necessary.

See Service Clearances/Access Panel Locations section for more details.

SAFETY WARNING

All factory provided lifting

lugs must be used when

lifting the units. Failure to

comply with this safety

precaution could result in

property damage, serious

injury, or death.

HANDLING

While this unit was constructed with quality and dependability in mind, damage still may occur during

handling of the unit for installation. Exercise extreme caution to prevent any damage from occurring to the

refrigerant system. This unit contains a system pressurized with refrigerant that if damaged, could leak into

the atmosphere or cause bodily harm due to the extreme cold nature of expanding refrigerant. Use protective

equipment such as gloves and safety glasses to minimize or prevent injury in case of a system leak during

installation.

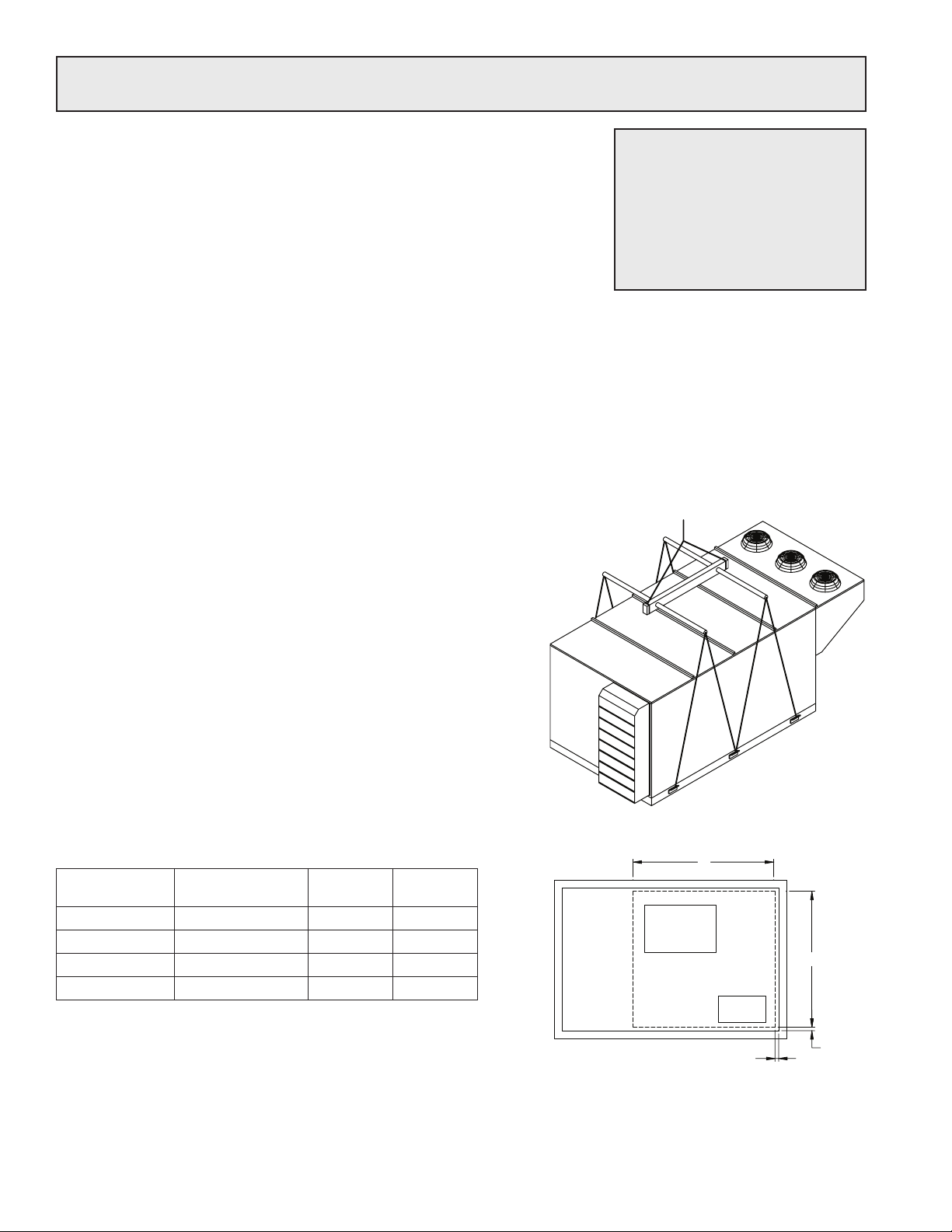

LIFTING

1) Before lifting, be sure that all shipping material has been

removed from unit.

2) To assist in determining rigging requirements, weights are

shown below.

3) Unit must be lifted by all lifting lugs provided on base

structure.

4) Rigger to use suitable mating hardware to attach to unit

lifting lugs.

5) Spreader bar(s) must span the unit to prevent damage to

the cabinet by the lift cables.

6) Always test-lift the unit to check for proper balance and

rigging before hoisting to desired location.

7) Never lift units by weatherhoods.

8) Never lift units in windy conditions.

9) Preparation of curb and roof openings should be completed

prior to lifting unit to the roof.

10) Check to be sure that gasketing (supplied by others) has

been applied to the curb prior to lifting the unit and setting

on curb.

11) Do not use fork lifts for handling unit.

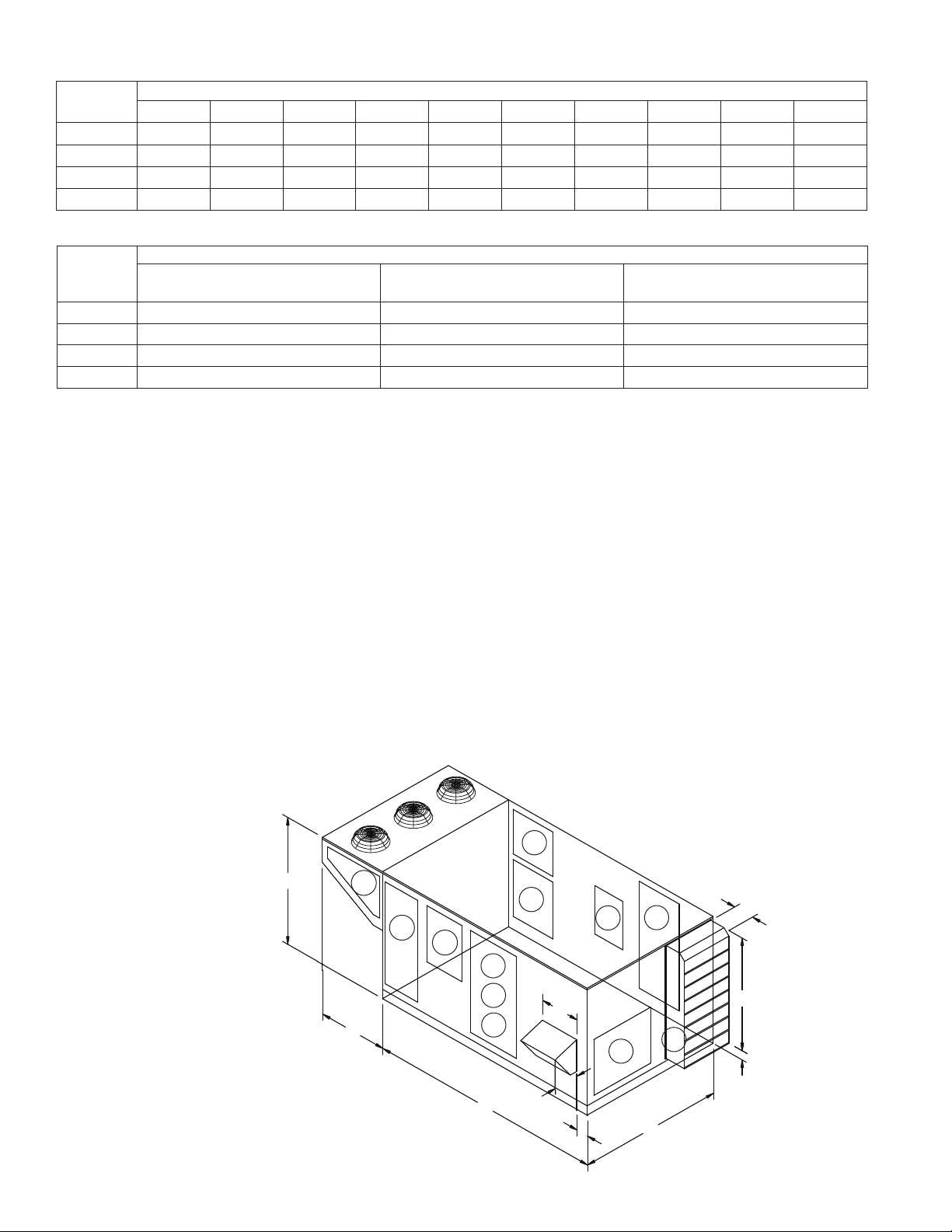

UNIT WEIGHTS & RECOMMENDED ROOF OPENING

Unit

Size

ERCH-20 2150 46 46

ERCH-45 3500 54 48

ERCH-55 4450 65 58

ERCH-90 6200 85 63

Unit weights assume rooftop configuration with weatherhoods, filters,

outdoor air damper, six row DX coil, integral condensing section and

an indirect gas fired furnace.

Approximate

Weight (lbs)

U

(inches)V (inches)

Lift using lifting lugs

and spreader bar

V

EXHAUST

INTAKE

SUPPLY

DISCHARGE

1/2 inch

U

1/2 inch

Position the unit roof opening such that the supply discharge and exhaust inlet of the unit will line up with the

corresponding ductwork. Be sure to allow for the recommended service clearances when positioning opening

(see Service Clearances). Do not face the outdoor air intake of the unit into prevailing wind and keep the intake

away from any other exhaust fans. Likewise, position the exhaust discharge opening away from outdoor air

intakes of any other equipment.

4

Page 5

Energy Recovery Unit with Packaged DX

INSTALLATION CONCERNS

Unobstructed airflow to the condensing section must be maintained at all times to ensure proper operating

efficiency and capacity of the cooling system. Unit placement should allow proper airflow over the condensing

section. The unit may not operate properly and damage may occur to the system if there is coil starvation (lack of

air over condenser) or warm air recirculating back through the condensing coil. Recirculating air is caused when

the unit is placed near obstacles that can redirect exhaust air from the condensing fans, back around to the coil

inlet. Overhangs or walls near the condensing section are two examples.

Another consideration when placing the unit is prevailing wind direction. The condensing coil operation can be

significantly affected when winds are blowing continuously and directly at the condensing coil. On hot days, the

wind will help the system by providing extra flow over the coil. But on cooler days, that same wind may overcool

the refrigerant, and cause hot gas bypass to operate more frequently, causing higher operating costs. Therefore,

avoiding direct winds will provide a more stable operation of the system throughout the cooling season.

Lack of air over the coil can reduce efficiencies and affect system operation. Do not allow debris (such as leaves

and trash), to accumulate on or near the unit. Keeping debris clear of the unit will ensure minimal obstruction to

the coils, keeping efficiencies and operation closer to design. The unit typically should not operate when snow

is present. In the event this is possible, make sure all snow is clear of the coil and condensing fans prior to

operating the unit.

If more than one unit is being installed, make provisions so discharge air from either the condensing fans or

exhaust fan of the unit do not discharge towards another unit’s intake. Also, OA intake and condensing sections

should be spaced as too allow proper airflow to each unit helping ensure the units operate as intended.

When cutting only duct openings, cut opening 1 inch (25mm) larger than duct size to allow clearance for

installation. Area enclosed by roof curb must comply with clearance to combustible materials. If the roof is

constructed of combustible materials, area within the roof curb must be ventilated, left open, or covered with

non-combustible material which has an “R” value of at least 5. If area within curb is open, higher radiated sound

levels may result.

Where the supply or warm air duct passes thru a combustible roof, a clearance of one inch must be maintained

between the outside edges of the duct and combustible material in accordance with NFPA Standard 90A.

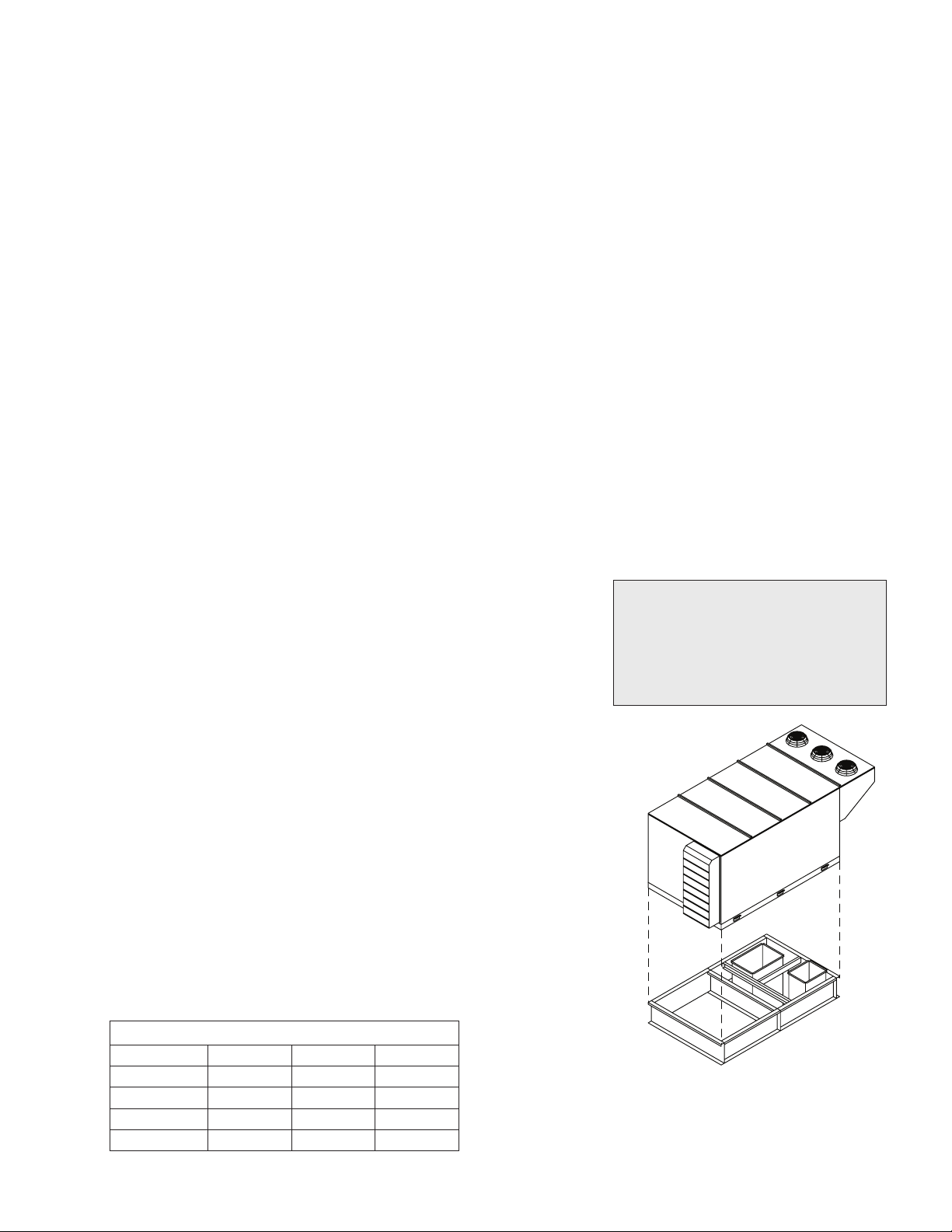

ROOF CURB MOUNTING

Rooftop units require curbs to be mounted first. The duct

connections must be located so they will be clear of structural

members of the building.

1. Factory Supplied Roof Curbs

Roof curbs are Model GKD, which are shipped in a knockdown

kit (includes duct adapter) and require field assembly (by others).

Assembly instructions are included with the curb.

2. Install Curb

Locate curb over roof opening and fasten in place. (Refer

to Recommended Roof Openings). Check that the diagonal

dimensions are within ±1/8 inch of each other and adjust as

necessary. For proper coil drainage and unit operation, it is

important that the installation be level. Shim as required to level.

3. Install Ductwork

Installation of all ducts should be done in accordance with

SMACNA and AMCA guidelines. Duct adapter provided to support

ducts prior to setting the unit.

4. Set the Unit

Lift unit to a point directly above the curb and duct openings.

Guide unit while lowering to align with duct openings. Roof curbs

fit inside the unit base. Make sure the unit is properly seated on

the curb and is level.

Roof curb details, including

duct location dimensions, are

available on ERCH roof curb

assembly instructions,

Part #468280.

Curb Outside Dimensions and Curb Weights (lbs)

Model L W Weight

ERCH-20 104.88 51 310

ERCH-45 115.75 60.63 400

ERCH-55 129.88 71.5 510

ERCH-90 148.13 90.75 720

All dimensions shown are in inches. Weights are for 12 inch high curbs.

Curb Outside Dimensions

5

Page 6

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Length of Straight Duct

GOOD

POOR

GOODPOOR

Tu rning

Vanes

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

GOODPOOR

Tu rning

Vanes

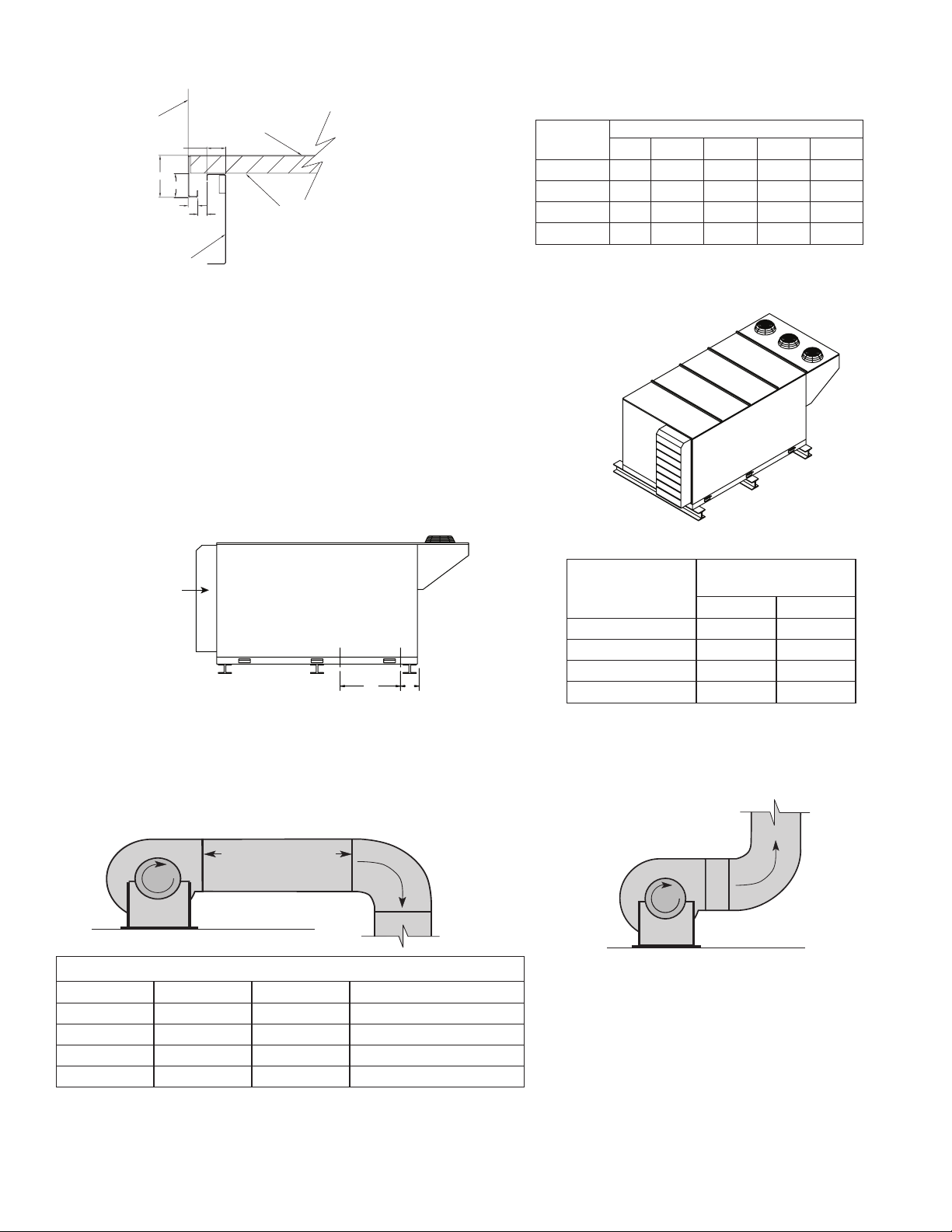

ROOF CURB MOUNTING - CONTINUED

SIDE OF UNIT

BASE

A

B

C

D

E

1 INCH INSULATION

ERCH-20 2.00 2.00 1.00 0.88 0.75

ERCH-45 2.00 4.25 2.00 1.31 0.50

ERCH-55 2.00 4.25 2.00 1.31 0.50

ERCH-90 2.00 4.25 2.00 1.31 0.50

ROOF CURB

All dimensions shown are in inches.

Curb Cap Details for Factory Supplied Roof Curbs

RAIL MOUNTING

Rail Layout

• RailsdesignedtohandletheweightoftheERCHshouldbe

positioned as shown on the diagram (rails by others).

• Makesurethatrailpositioningdoesnotinterferewiththesupply

air discharge opening or the exhaust air intake opening on the

ERCH unit. (Avoid area dimensioned “B” below).

• Railsshouldrunthewidthoftheunitandextendbeyondtheunit

a minimum of 12 inches on each side.

• Setunitonrails.

Model

Energy Recovery Unit with Packaged DX

Curb Cap Dimensions

A B C D E

Isometric view of unit on rails

Rail

OUTDOOR AIR

INTAKE HOOD

Model

Mounting

A B

SUPPLY/EXHAUST

OPENING

B A

Side view of unit on rails

DUCTWORK CONNECTIONS

Examples of good and poor fan-to-duct connections are shown below. Airflow out of the fan should be directed

ERCH-20 5.00 41.00

ERCH-45 7.00 41.90

ERCH-55 5.50 53.00

ERCH-90 6.00 59.00

All dimensions shown are in inches.

straight or curve the same direction as the fan wheel rotates. Poor duct installation will result in low airflow and

other system effects.

n

o

i

Recommended Discharge Duct Size and Length

Model Blower Size Duct Size Straight Duct Length

ERCH-20 9 14 x 14 36

ERCH-45 12 20 x 20 48

ERCH-55 15 28 x 28 60

ERCH-90 18 32 x 32 60

All dimensions shown are in inches.

• Recommendedductsizesarebasedonvelocitiesacrossthecfmrangeofeachmodelatapproximately800feetperminute(FPM)at

minimum airflow and up to 1600 fpm at maximum airflow. Recommended duct sizes are only intended to be a guide and may not satisfy

the requirements of the project. Refer to plans for appropriate job specific duct size and/or velocity limitations.

• Straightductlengthswerecalculatedbasedon100%effectiveductlengthrequirementsasprescribedinAMCAPublication201.

Calculated values have been rounded up to nearest foot.

6

t

a

t

o

R

POOR

Page 7

Energy Recovery Unit with Packaged DX

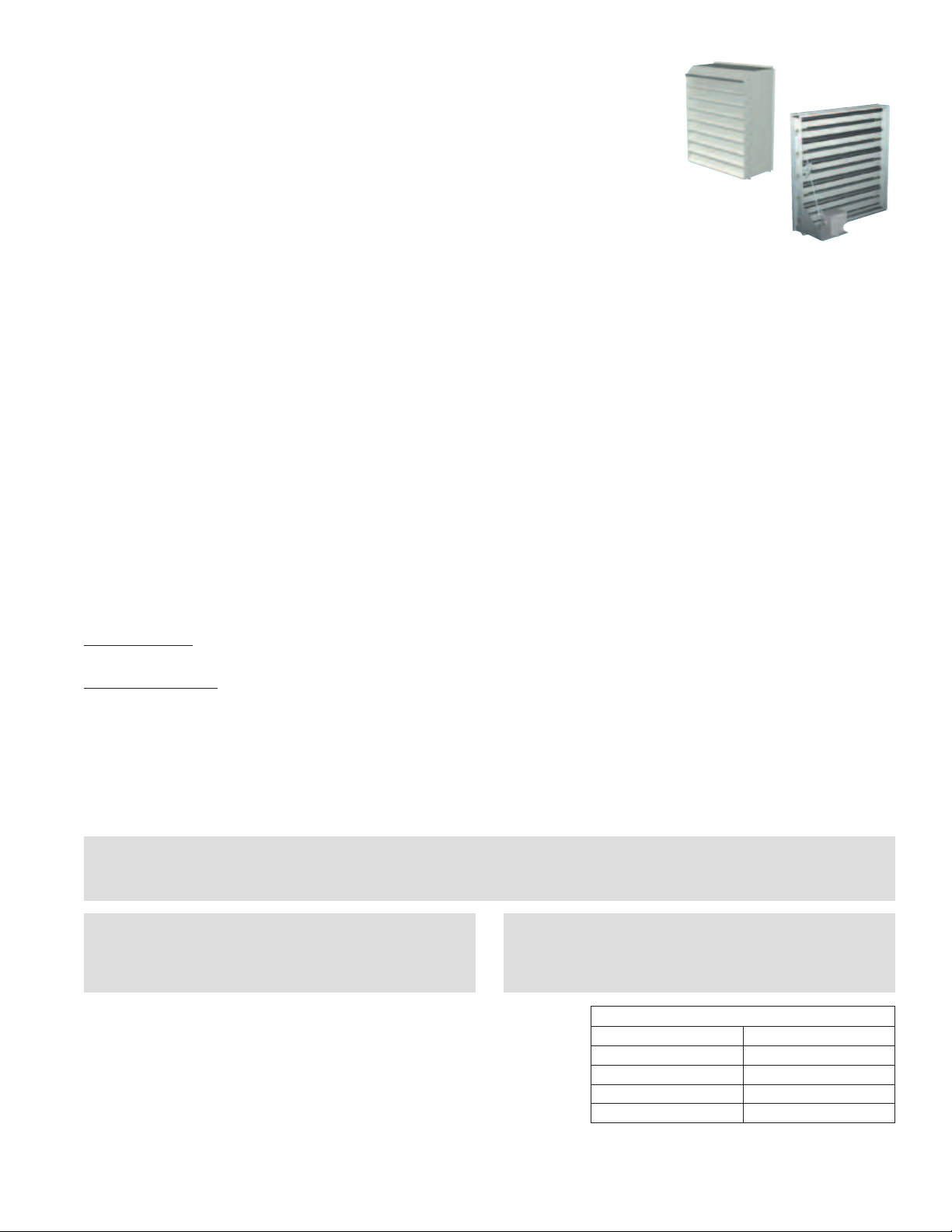

OUTDOOR AIR WEATHERHOOD

Outdoor air weatherhood will be factory mounted.

EXHAUST WEATHERHOOD

The exhaust weatherhood is shipped separately as a kit with its own instructions.

DAMPERS

Backdraft dampers are always included as an integral part of the exhaust hood

assemblies. Motorized outdoor air and exhaust air dampers are optional and are

factory mounted (and wired) at the intake.

ELECTRICAL INFORMATION

The unit must be electrically grounded in accordance with the current National Electrical Code, ANSI/NFPA 70.

In Canada, use current CSA Standard C22.1, Canadian Electrical Code, Part 1. In addition, the installer should

be aware of any local ordinances or electrical company requirements that might apply. System power wiring

must be properly fused and conform to the local and national electrical codes. System power wiring is to the

unit main disconnect (door interlocking disconnect switch standard on most units) or distribution block and

must be compatible with the ratings on the nameplate: supply power voltage, phase, and amperage (Minimum

Circuit Amps - MCA, Maximum Overcurrent Protection - MOP). All wiring beyond this point has been done by

the manufacturer and cannot be modified without affecting the unit’s agency / safety certification.

If field installing an additional disconnect switch, it is recommended that there is at least four feet of service

room between the switch and system access panels. When providing or replacing fuses in a fusible disconnect,

use dual element time delay fuses and size according to the rating plate.

Field Power Connection: Electronic wiring is run through the roof of the unit. All power and control

connections should be run through the floor or side panel.

If power supply is desired through bottom of unit, run the wiring through the curb, cut a hole in the cabinet

bottom, and wire to the disconnect switch. Seal penetration in cabinet bottom to prevent leakage.

The electric supply to the unit must meet stringent requirements for the system to operate properly. Voltage

supply and voltage imbalance between phases should be within the following tolerances. If the power is not

within these voltage tolerances, contact the power company prior to operating the system.

Voltage Supply - See voltage use range on the rating plate. Measure and record each supply leg voltage at all

line disconnect switches. Readings must fall within the allowable range on the rating plate.

Voltage Imbalance - In a 3-phase system, excessive voltage imbalance between phases will cause motors

to overheat and eventually fail. Maximum allowable imbalance is 2%. To determine voltage imbalance, use

recorded voltage measurements in this formula.

Key: V1, V2, V3 = line voltages as measured

VA (average) = (V1 + V2 + V3) / 3

VD = Line voltage (V1, V2 or V3) that deviates farthest from average (VA)

Formula: % Voltage Imbalance = [100 x (VA-VD)] / VA

CAUTION

If any of the original wire as supplied with the appliance must be replaced, it must be

replaced with wiring material having a temperature rating of at least 105ºC.

WARNING

To prevent injury or death due to electrocution or

contact with moving parts, lock disconnect switch

open.

Most factory supplied electrical components are pre-wired. To

determine what electrical accessories require additional field wiring,

refer to the unit specific wiring diagram located on the inside of the

unit control center access door. The low voltage control circuit is

24 Vac and control wiring should not exceed 0.75 ohms. Refer to

Field Control Wiring Length/Gauge table for wire length maximums

for a given wire gauge. Control wires should not be run inside the

same conduit as that carrying the supply power. Make sure that field supplied conduit does not interfere with

access panel operation.

For units with a gas furnace, if you turn off the

power supply, turn off the gas.

WARNING

Field Control Wiring Length/Gauge

Total Wire Length Minimum Wire Gauge

125 ft. 18

200 ft. 16

300 ft. 14

450 ft. 12

7

Page 8

Energy Recovery Unit with Packaged DX

If wire resistance exceeds 0.75 ohms, an industrial-style, plug-in relay should be added to the unit control

center and wired in place of the remote switch (typically between terminal blocks R and G on the terminal strip

(refer to Typical Control Center Components). The relay must be rated for at least 5 amps and have a 24 Vac

coil. Failure to comply with these guidelines may cause motor starters to “chatter” or not pull in which can

cause contactor failures and/or motor failures.

Note: Standard factory installed electric post-heaters have their own disconnect separate from the unit

disconnect. Thus, each electric post-heater requires its own separate power connection.

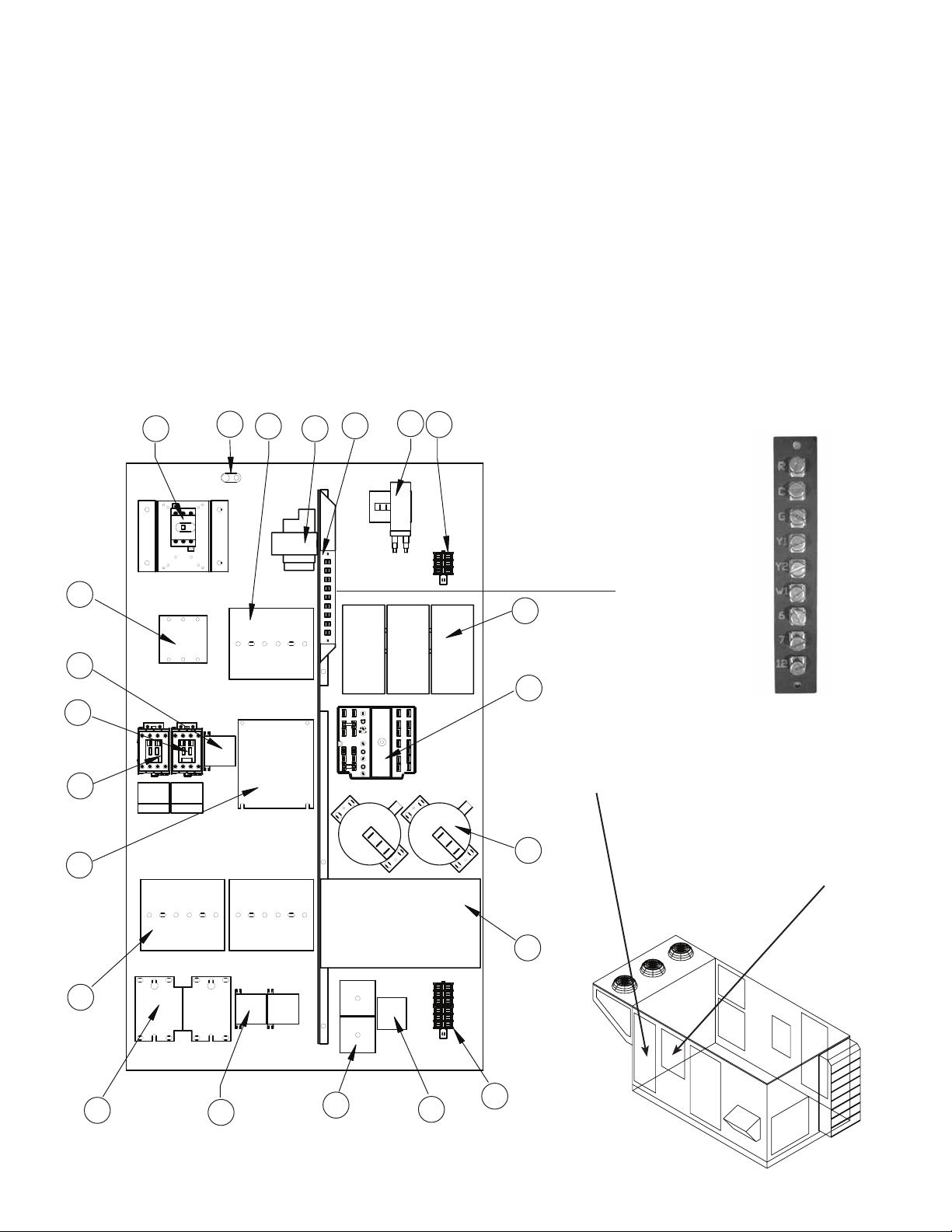

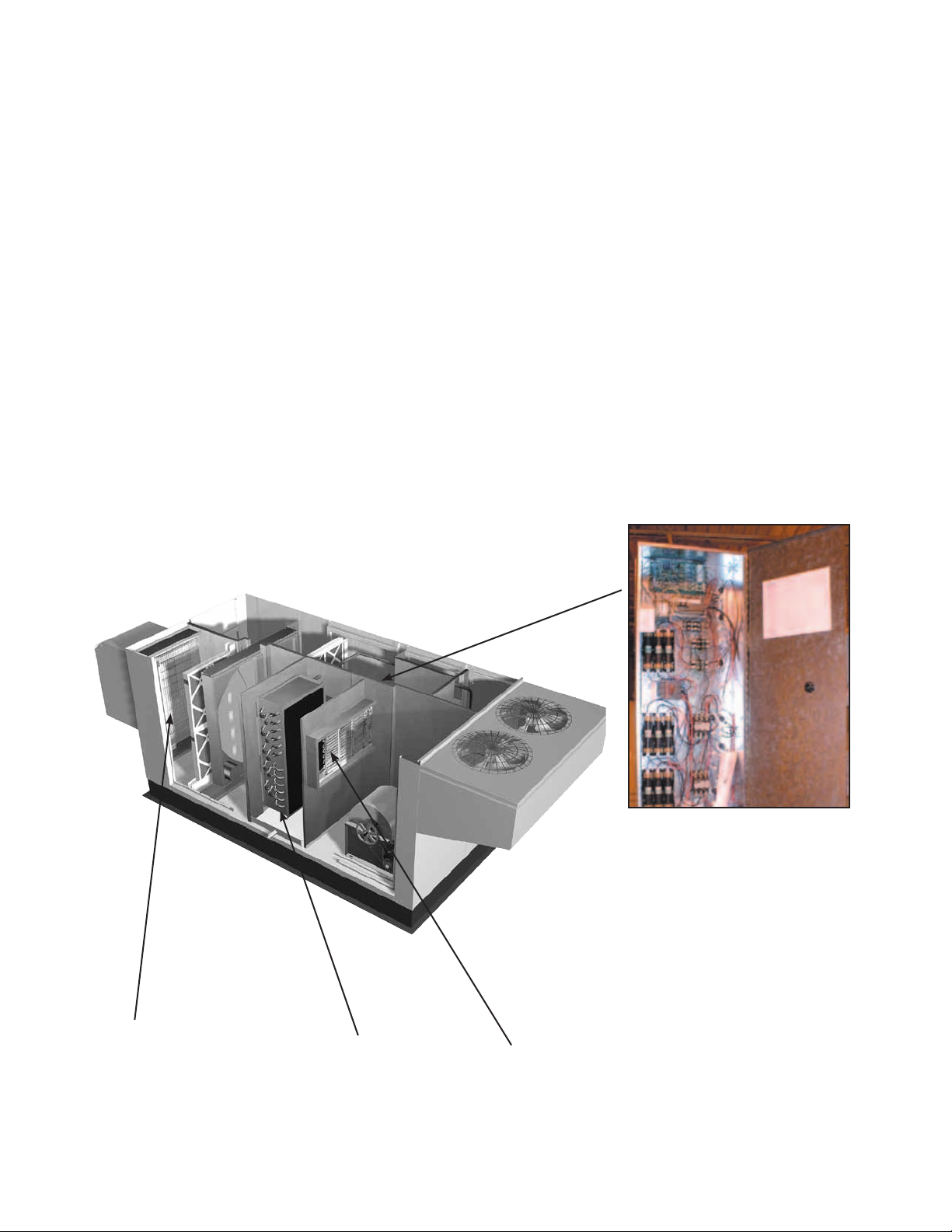

CONTROL CENTER COMPONENTS

1. Main Disconnect (non-fusible,

lockable)

2. Motor Starter - Exhaust Air Fan

3. Motor Starter - Outdoor Air Fan

4. Motor Contactor - Energy Wheel

5. 24 Vac Control Transformer

6. 24 Vac Terminal strip

7. Fuses for blower motors

8. Grounding lug

9. Distributor block

10. Compressor fuse blocks

11. Compressor contactors

12. Condensing fan contactors

13. Compressor cycle timers

14. Compressor relay

15. Terminal block

Optional Control Center Components

16. DDC controller

17. Dirty filter pressure switches

18. Economizer module

19. Thermostats for:

- Economizer module

- Energy Recovery wheel frost

control

- Compressor lock out

20. Terminal block

21. Frost control pressure switch

22. Energy recovery wheel VFD

3

22

8

1 5

7

9

6

21

20

Component #6

19

Exploded Detail

of Terminal Strip

4

18

Refer to “Refrigeration

System” section for

components in compressor

2

compartment

Access to Control Center

17

Components is gained through

the access panel indicated.

16

10

11

12

13

14

15

8

Page 9

Energy Recovery Unit with Packaged DX

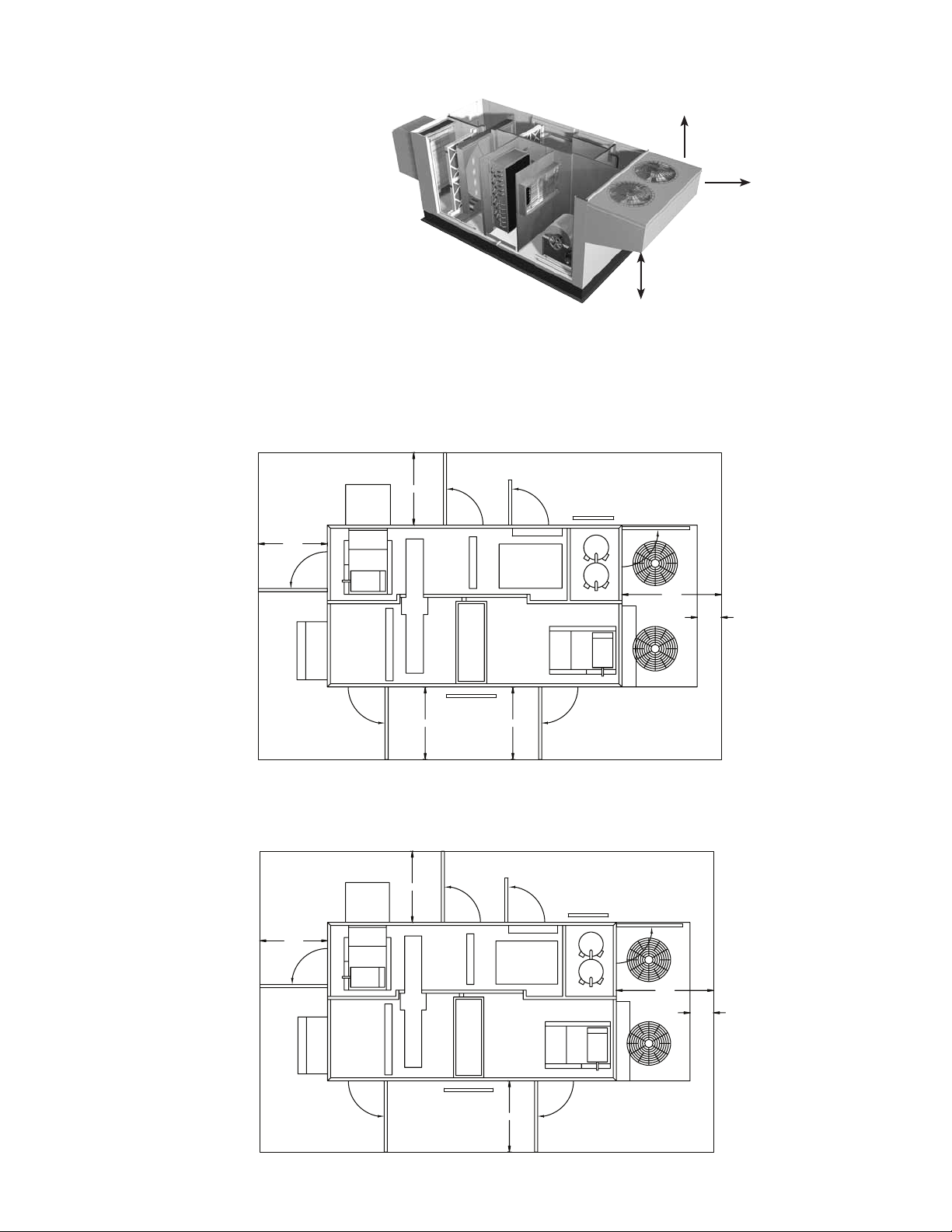

SERVICE CLEARANCES / ACCESS PANEL LOCATIONS FOR MODEL ERCH

Clearances must be maintained on all

sides of this unit. This especially is true

with the top of this unit. Hot air is being

discharged through the condensing

fans during operation, and the more

clearance available, the better the

chance of avoiding recirculation or coil

starvation. This unit should never be

placed under an overhang or inside a

building. A minimum of 48 inches over

the condensing fans is recommended.

ERCH-20, 45, 55, and 90 units require

minimum clearances for access on all sides for routine maintenance. Filter replacement, drain pan inspection

and cleaning, energy wheel cassette inspection, fan bearing lubrication and belt adjustment are examples of

routine maintenance that must be performed. Blower and motor assemblies, energy recovery wheel cassette,

coil and filter sections are always provided with a service door or panel for proper component access.

Clearances for component removal may be greater than the service clearances, refer to drawings for these

dimensions.

ERCH-20

ERCH-45

36 IN

ACCESS PANEL

EXHAUST

HOOD

HOOD

OUTDOOR AIR

FILTERS

36 IN

WHEEL CASSETTE

ACCESS PANEL

FILTERS

COIL

SECTION

ACCESS PANEL

ELECTRICAL BOX

EXHAUST AIR

INTAKE

ACCESS PANEL

ACCESS PANEL

IG HEATER

Minimum 48 inches

clearance

Minimum 12 inches

clearance

Condensing Coil Intake

Keep this area clear

52 IN

CLEARANCE

WITH IG HEATER

12 IN

MINIMUM

ERCH-55

ERCH-90

ACCESS PANEL

*48 IN

ACCESS PANEL

**64 IN

ACCESS PANEL

Clearances for service and component removal on ERCH-20 and ERCH-45

* Clearance for energy wheel removal on ERCH-20

** Clearance for energy wheel removal on ERCH-45

FILTERS

42 IN

ACCESS PANEL

ACCESS PANEL

WHEEL CASSETTE

FILTERS

COIL

SECTION

ACCESS PANEL

ACCESS PANEL

ELECTRICAL BOX

EXHAUST AIR

INTAKE

42 IN

ACCESS PANEL

ACCESS PANEL

ACCESS PANEL

WITH IG HEATER

IG HEATER

52 IN

CLEARANCE

42 IN

ACCESS PANEL

EXHAUST

HOOD

HOOD

OUTDOOR AIR

12 IN

MINIMUM

Clearances for service and component removal on ERCH-55 and ERCH-90

9

Page 10

Energy Recovery Unit with Packaged DX

A

J

E

B

H

C

I

G

F

D

DIMENSIONAL DATA / ACCESS DOOR DESCRIPTIONS AND LOCATIONS

Model

A B C D E F G H I J

Exterior Dimensions

ERCH-20 108 50 56 27 28.5 17 6 14.25 18 18

ERCH-45 119 69 66 38 41 23.375 10.5 13.375 20 16

ERCH-55 133.5 70 76 39 59.5 5.875 7.125 21.25 25 16

ERCH-90 151.5 85 96 46 78 2.875 10 24.5 27 16

All dimensions shown are in inches.

Overall Exterior Dimensions

Model

(including Lifting Lugs)

Width

Overall Width

(with Exhaust Hood)

Overall Length

(with Outdoor Air Hood)

ERCH-20 59.5 75 116

ERCH-45 69.5 86 122

ERCH-55 79.5 101 134

ERCH-90 99.5 123 147

All dimensions shown are in inches.

Following is a list of items accessible through the access doors shown on the diagrams. Some items are

optional and may not have been provided.

1. Exhaust blower, motor, and drives

2. Aluminum mesh filters (intake hood)

3. Energy recovery wheel, motor, belt, and seals

Outdoor air filters

Outdoor air intake damper (optional)

Electric preheater (optional)

Frost control sensors (optional)

Economizer sensors (optional)

4. Coil access / Drain pan

5a. Outdoor air blower, motor, and drives

(with indirect gas furnace)

6. Control center

All electrical controls

VFD for energy recovery wheel (optional)

7. Exhaust air filters

Exhaust air intake damper (optional)

8. Electric post-heater control center (optional)

9. Bypass damper (optional)

10. Condensing fan motors

11. Compressor(s) - refer to Refrigeration System

section for components in compressor

compartment

Drain Pan

5b. Outdoor air blower, motor, and drives

(without indirect gas furnace)

Coil access / Drain pan (w/o Electric Heat)

Model ERCH with Packaged DX

10

5a

10

5b

11

6

7

8

9

4

3

1

2

Page 11

Energy Recovery Unit with Packaged DX

COIL APPLICATION RECOMMENDATIONS

Factory installed cooling and heating components are mounted

in the coil section of the unit. The coil section is downstream

of the energy wheel on the supply air side of the unit.

Note the coil connection locations on the picture. Coil

connections are located external to the unit as shown. Coil

connections that are not external have been ordered from the

factory with interior or exhaust airstream coil connections.

Hot

water coil

connections

Coil access door

Note: DX coil liquid connection is internal to units.

WATER COILS

1. Piping should be in accordance with accepted industry

standards. Pipework should be supported independently

of the coils. Water connections are male NPT iron pipe.

When installing couplings, do not apply undue stress to the

connection extending through the unit. Use a backup pipe wrench to avoid breaking the weld between coil

connection and header.

2. Connect the WATER SUPPLY TO THE BOTTOM CONNECTION on the air leaving side and the WATER

RETURN TO THE TOP CONNECTION on the air entering side. To insure proper venting, an external air vent

in the piping is recommended. Connecting the supply and/or return in any other manner will result in very

poor performance. Be sure to replace factory installed grommets around coil connections if removed for

piping. Failure to replace grommets will result in water leakage into the unit and altered performance.

3. The air vent at the uppermost point should be temporarily opened during system start-up to release all of the

air from the coil. To maintain heat transfer capacity, periodically vent any air in coil.

4. Water coils are not normally recommended for use with entering air temperatures below 40ºF; however,

the energy recovery wheel maintains a pre-coil temperature higher than 40ºF. No control system can be

depended on to be 100% safe against freeze-up with water coils. Glycol solutions or brines are the only safe

media for operation of water coils with low entering air conditions.

CONTINUOUS WATER CIRCULATION THROUGH THE COIL AT ALL TIMES IS HIGHLY RECOMMENDED.

5. Pipe sizes for the system must be selected on the basis of the head (pressure) available from the circulation

pump. The velocity should not exceed 6 feet per second and the friction loss should be approximately 3 feet

of water column per 100 feet of pipe.

DIRECT EXPANSION (DX) COILS WITH INTEGRAL CONDENSING SECTION

1. The condensate drain pipe should be sized adequately to ensure the condensate drains properly. Refer to

Drain Trap section.

11

Page 12

Energy Recovery Unit with Packaged DX

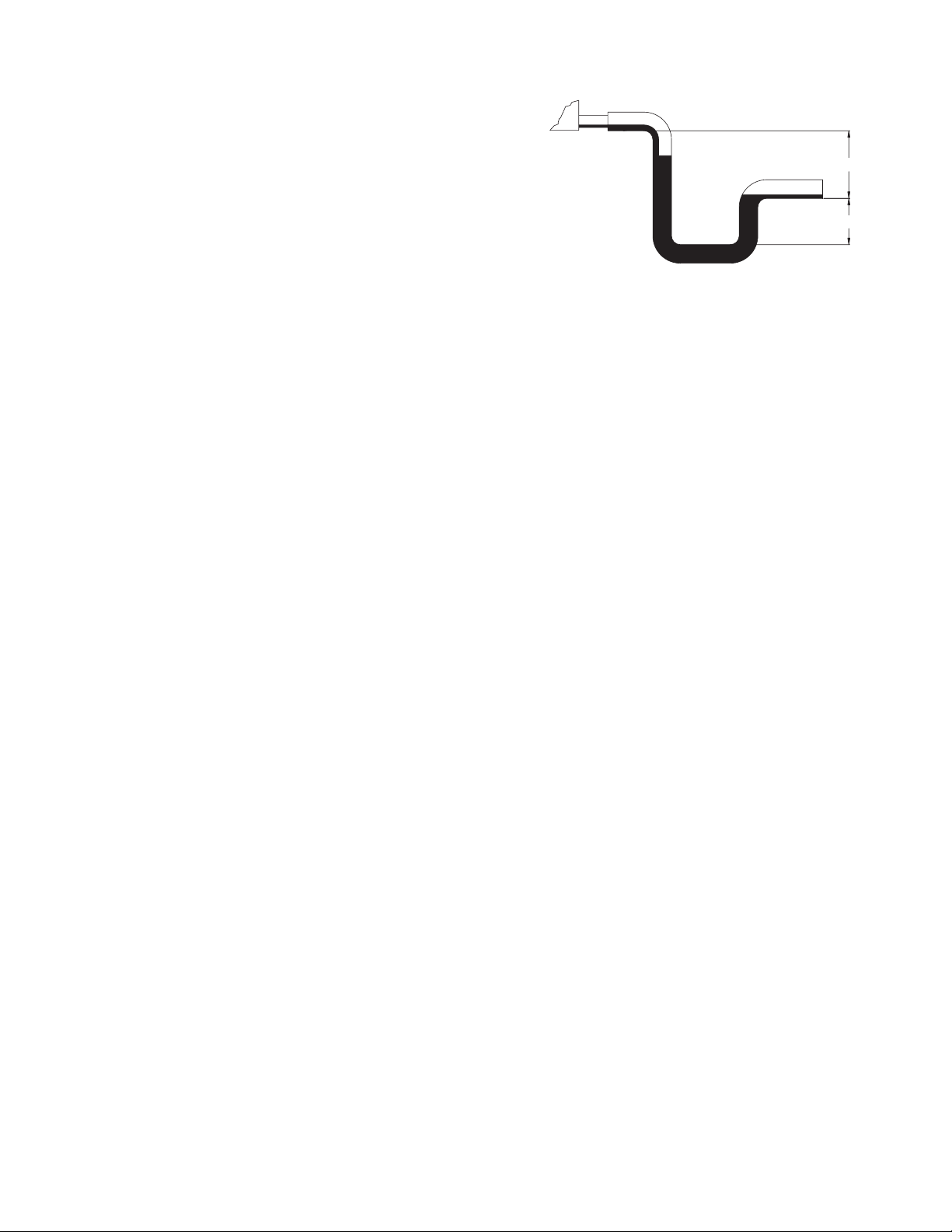

DRAIN TRAP

Cooling coils are provided with a stainless steel drain pan

with 1-inch male NPT drain connection. A drain trap must be

connected to the drain connection to allow excess water to

flow out of the drain pan. More importantly, though, due to the

negative internal static of the cooling coil compartment, installing

the drain trap prevents outdoor air from being pulled into the

drain pan and consequently forcing water out of the pan and into

the unit.

To ensure the drain trap works properly, the trap height must

account for the difference in static pressure between ambient

conditions outside the unit and the internal negative pressure of the cooling coil compartment. For energy

recovery units, an assumption of 3.0 in. wg differential will be sufficient. This would require a trap design as

shown. If the internal static is believed to be higher, consult factory.

Refer to local codes to determine drainage requirements. If draining onto to roof, place a drip pad below drain

to protect roof. If draining onto roof is not acceptable, a drain line must be attached to the trap. The drain line

must be pitched away from the unit at least 1/8-in. per foot. On longer runs, an air break should be used to

ensure proper drainage. Local codes may require drainage into a waste water system.

Drainage problems not only occur from improper drain trap design, but also from lack of maintenance of the

cooling coil compartment. Algae can form in the drain pan and trap and cause reduced water flow, which can in

turn result in backup into the system. Regular maintenance will prevent this from occurring. If the drains have a

cleanout opening, be sure to close the opening after cleaning.

4 in.

2 in.

12

Page 13

Energy Recovery Unit with Packaged DX

OPTIONAL ACCESSORIES

Electric Heater Application/Operation

Factory installed electric heaters can be provided for preheat and/or post-heat. An electric preheater warms

the outdoor air prior to the energy recovery wheel to prevent frosting on the wheel. An electric post-heater

warms the air leaving the energy recovery wheel to a user specified discharge temperature. Electric heaters are

available in 208, 230, or 460 Vac (refer to heater nameplate for voltage).

Preheaters: Preheaters are standard as 2-stage, step control. Step control heaters are designed with

multiple stages made up of equal increments of heating capability. For example, a 10 kW

heater with two stages will be composed of two 5-kW stages. Preheaters are single point

wired at the factory. A temperature sensor (with field adjustable set point) is mounted in the

outdoor airstream after the preheater to turn the preheater on. See Frost Control Application

/Operation for typical set points. If the temperature falls below the set point and the wheel

pressure drop sensor is triggered, the first stage of the preheater will turn on. If the first stage

does not satisfy the set point, the second stage will also turn on.

Post-heaters: Post-heaters are standard as SCR control. Post-heaters are not single point wired (see

Electrical Connections). A temperature sensor (with field adjustable set point) is mounted in

the outdoor airstream after the post-heater to turn the post-heater on. A SCR heater provides

an infinitely modulating control of the heat to provide an accurate discharge temperature. A

call for heat is required.

Electric Preheater

The pre-heater is single

point wired to the ERCH

control center. Access

to the preheater control

panel is through the

supply filter door.

DX

Cooling Coil

Post-Heater Control Panel

The post-heater is not single point

wired to the ERCH control center.

Separate power must be supplied to

the post-heater disconnect (located

in unit control center).

See ’Access Door Descriptions and

Locations’ for access to post-heater

control panel. For Model ERCH, the

exhaust filters must be removed

from the unit to access.

Electric

Post-Heater

13

Page 14

Energy Recovery Unit with Packaged DX

OPTIONAL ACCESSORIES

Frost Control Application/Operation

Extremely cold outdoor air temperatures can cause moisture condensation and frosting on the energy recovery

wheel. Frost control is an optional feature that will prevent/control wheel frosting. Three options are available:

1) Timed Exhaust frost control

2) Electric preheat frost control

3) Modulating wheel frost control

All of these options are provided with a thermostat (with

probe) mounted in the outdoor air intake compartment and

a pressure sensor to monitor pressure drop across the

wheel. The typical temperature setting corresponds to the

indoor air relative humidity as shown in the Frost Threshold Temperatures Table and represents when frost can

occur. An increase in pressure drop would indicate that frost is occurring. Both the pressure sensor AND the

outdoor air temperature sensor must trigger in order to initiate frost control. The two sensors together ensure

that frost control is only initiated during a real frost condition. Field wiring of a light (or other alarm) between

6 & C in the control center will notify personnel when unit is in frost control mode (refer to Remote Panel Wiring

schematics section for wiring details). The following explains the three options in more detail.

Timed exhaust frost control includes a timer in addition to the thermostat and

wheel pressure sensor. When timed exhaust frost control is initiated, the timer

will turn the supply blower on and off to allow the warm exhaust air to defrost

the energy recovery wheel. Default factory settings are 5 minutes off and 30

minutes on. Use the following test procedure for troubleshooting.

Testing (refer to diagram at right)

• Jumperthewheelpressureswitchintheunitcontrolcenter.Setthe

Timer Scale for T1 and T2 to 1 minute. Set the Timer Settings for T1 and

T2 to 1.0. Set the dip switch to the down position. (normal position)

• Turnthetemperaturesensorupashighaspossible.Thesupplyblower

should cycle on for one minute, then turn off for one minute.

• Aftertesting,settheTimer Scale as follows: T1 = 10 minutes, T2 =

1 hour

• SettheTimer Settings as follows: T1 = 0.5, T2 = 0.5. The timer is now

set for 5 minutes off and 30 minutes on. Remember to remove the jumper.

Electric preheat frost control includes an electric heater (at outdoor air intake) and an airflow pressure switch

(located at the preheater) in addition to the thermostat and pressure sensor on wheel. (Refer to Electric Heater

Application/Operation for electric preheater location). When electric preheat frost control is initiated, the electric

preheater will turn on and warm the air entering the energy wheel to avoid frosting. Use the following test

procedure for troubleshooting.

Testing

• Turnthethermostatashighasitwillgoandjumperthewheelpressuresensor.Theheater

should turn on.

• Ifitdoesn’t,eitherputtheoutdoorairsidedoorsonortemporarilyjumpertheairflowpressure

switch in the preheater control center to avoid nuisance tripping of the pressure switch. Also

check the airflow switch pressure tap located at the supply discharge blower to ensure the

tubing is connected and the tap is not blocked. Remember to remove the jumpers.

Modulating wheel frost control includes a variable frequency drive in addition to the thermostat and pressure

sensor. When modulating wheel frost control is initiated, the variable frequency drive will reduce the speed

of the wheel. Reducing the speed of the energy wheel reduces its effectiveness, which keeps the exhaust air

condition from reaching saturation, thus, eliminating condensation and frosting. If the outdoor air temperature is

greater than the frost threshold temperature OR the pressure differential is less than the set point, the wheel will

run at full speed. If the outdoor air temperature is less than the frost threshold temperature AND the pressure

differential is greater than the set point, the wheel will run at reduced speed until the pressure differential falls

below the set point. The temperature and pressure differential set points are set at the factory, but are fieldadjustable (refer to VFD section for more information). The variable frequency drive will be fully programmed at

the factory.

14

Indoor RH @ 70°F Frost Threshold Temp

20% -10º F

30% -5º F

40% 0º F

Frost Threshold Temperatures

A1 B1 15

0.60.8

0.41.0

T2

Timer

Scale

T1

0.20

T21 MIN

T11 MIN

0.60.8

0.41.0

0.20

16 18 A2

Timer

Dip

Switch

Page 15

Energy Recovery Unit with Packaged DX

OPTIONAL ACCESSORIES

Economizer Application/Operation

The energy recovery wheel operation can be altered to take advantage of economizer operation (free cooling).

Two modes are available: 1) De-energizing the wheel or 2) Modulating the wheel. A field supplied call for cool

(Y1) is required.

De-energizing the wheel is accomplished with a signal from a Temperature or Enthalpy sensor mounted

in the air intake compartment. This Primary sensor will de-energize the energy wheel when the outdoor air

temperature (factory default is 65ºF) or enthalpy (factory default is the ‘D’ setting) is below the field adjustable

set point. An Override temperature sensor is also furnished in the outdoor air intake compartment to deactivate

economizer mode. The Override (with field adjustable set point) is set at some temperature lower than the

Primary sensor (factory default is 50ºF). Effectively, the two sensors create a deadband where the energy

recovery wheel will not operate and free cooling from outside can be brought into the building unconditioned.

Testing

Temperature Sensor with Override

• TurnbothTemperatureandOverridethermostatsdownaslowastheygo.The

wheel should be rotating.

• TurntheTemperaturesensorupashighasitgoes,andkeeptheOverride

sensor as low as it will go. The wheel should stop rotating.

• Turnbothsensorsashighastheywillgo.Thewheelshouldstartrotating.

• SettheTemperaturesensoratdesiredpointforeconomizeroperationtobegin.

Set the Override sensor at desired point for economizer operation to end

(factory default is 65ºF and 50ºF, respectively).

Enthalpy Sensor with Override

• Turnunitpoweroff.DisconnectC7400solidstateenthalpysensorfromterminal

So on the enthalpy controller. Also, disconnect the 620 ohm resistor from

terminal Sr on the enthalpy controller. Turn unit power on. The LED on the

enthalpy controller should light and the energy recovery wheel should not rotate.

• Turnunitpoweroff.Reconnect620ohmresistortoterminalSrontheenthalpy

controller. Turn unit power on. The LED on the enthalpy controller should not

light and the energy recovery wheel should energize and rotate.

If the steps above provide the results described, the enthalpy economizer is

working properly.

• Turnunitpoweroff.ReconnectC7400solidstateenthalpysensor

to terminal So.

Temperature Sensor

with Override

Enthalpy Sensor

with Override

Modulating the Wheel

In applications in which an internal heat gain is present in the space,

the rotational speed of the energy wheel may be modulated (via

variable frequency drive) to avoid overheating the space during the

Enthalpy

Controller

winter. The speed of the energy wheel will be controlled in response to

the discharge temperature set point.

Sequence of Operation:

The variable frequency drive is fully programmed at the factory (refer to VFD section

for more information). A “call for cool” must be field wired to the unit (terminals provided in unit - refer to wiring

diagram in unit control center) to allow for initiation of economizer mode. When the space calls for cooling,

factory supplied controls will drive the following wheel operations:

TOA > T

RA

TOA < TRA and TOA > T

TOA < TRA and TOA < T

: Wheel runs at full speed (maximum energy recovery)

: Wheel is stopped (no energy recovery)

SA

: Wheel will modulate to maintain discharge temperature

SA

where (TOA) is the outdoor air temperature set point, (TRA) is the return air temperature set point, and (TSA) is the

supply air discharge thermostat set point.

15

Page 16

Energy Recovery Unit with Packaged DX

OPTIONAL ACCESSORIES

Variable Frequency Drives for Energy Recovery Wheel

Factory installed VFD for the energy recovery wheel are programmed at the factory per the settings shown

below. Refer to the instruction manual that ships with the unit when making adjustments. A copy of the manual

can be found online at www.drives.com. For technical support, contact Yaskawa direct at 1-800-927-5292.

Yaskawa GPD-305 Drive

Parameter Setting

n01 Access Level 1

n30 Ref Upper Limit 100% or 66%*

n32 Motor Rated FLA Motor FLA

n33 Elect Thermal Overload 1

n36 Multi-Function input (terminal S2) 10

n40 Multi-Function output (MA,MB,MC) 4

n41 Analog Freq. Reference Gain 0

n42 Analog Freq. Reference Bias 99

n46 Carrier Frequency 2

n58 Frequency Detection Level 20

n01 Access Level 0

*36 inch wheel is 66% (40Hz). All other wheels are 100% (60Hz).

16

Page 17

Energy Recovery Unit with Packaged DX

6C

OPTIONAL ACCESSORIES

Wiring Diagram

Following is an example of a typical wiring diagram located in the unit control center. This wiring diagram

includes a legend highlighting which accessories were provided with the unit. Factory wiring and field wiring

are also indicated. This particular example includes 1) variable frequency drives on the blowers requiring a

modulating input, 2) modulating energy recovery wheel with factory controls for economizer, 3) energy recovery

wheel rotation sensor, 4) outdoor air and exhaust air dirty filter switches, 5) motorized outdoor air and exhaust

air intake dampers, and 6) timed exhaust frost control. Many other factory installed and wired accessories are

available.

MAIN POWER

TO UNIT

GROUND

CONDENSING FAN 2

CONDENSING FAN 1

COMPRESSOR 2

COMPRESSOR 1

R

S1

ST1

13 14

S6

S7

ST2-NO

CC1-NO

CC2-NO

DS1

L1

L2

L3

CF2

CF1

CC2

CC1

G

620 OHM RESISTOR OR

RETURN AIR SENSOR

OUTDOOR AIR

SENSOR

MIXED AIR

SENSOR

Y1

Y2

51

COM NC

DB1

CH1 CH2

T1

16

15

PS1

NO C COM NO

SR

TR1

EC

SR+

SO

+

SO+

T

T1

1

TR

3

TS6

52

FCS

55

FR

2-10V

-

FC

5

2

4

LPS HPS

56

ST1 O.L.

96 95

ST2 O.L.

96 95

TO MA AND MC

MA

ON VFD-W

MC

24 VAC

THERMOSTAT(S) TS1, TS6

TS1

TO FR AND FC

ON VFD-W

R7

1

R7

86

(LOCATED IN CONDENSING FAN)

(LOCATED IN CONDENSING FAN)

3

3

3

53

CF1 O.L.

1P1

1P2

CF2 O.L.

2P22P1

TR1

4

S2

R14

24

6

T6

1

T7

1

54

MULTI-VOLTAGE PRIMARY

24 SECONDARY

A2 A1

A2 A1

A2 A1

A2

OA-SENSOR

SENSOR

A1T1A2

CC2

2

A1A1A2

ST1

ST2

CC1

CF1

CF2

ST1

O.L.

LEGEND

EXHAUST FAN

O.L.

ST2

L1

L2

VFD-W

L3

S1

SC

R1

4

3

C

A1

COM

B1

7

A2

EXHAUST DAMPER

EXHAUST FAN

SUPPLY DAMPER

SUPPLY FAN

ENERGY WHEEL

ROTATION SENSOR

ROTATION SENSOR

THERMOSTAT CONTROLLER(S)

FROST CONTROL

ECONOMIZER CONTROL

COMPRESSOR 1

COMPRESSOR 2

COMPRESSOR INTERLOCKS

CONDENSING FAN 1

CONDENSING FAN 2

D1

D2

R1

R14

12

R7

MOTOR

SUPPLY FAN

MOTOR

T1

T2

ENERGY WHEEL

MCT3MA

FCFR

SEE BELOW FOR

TERMINAL CONNECTIONS

C1 COOLING STAGE 1 RELAY

C2 COOLING STAGE 2 RELAY

CC COMPRESSOR CONTACTOR

*

CF CONDENSING FAN CONTACTOR

*

CH COMPRESSOR SUMP HEATER

*

D DAMPER

**

DB POWER DISTRIBUTION BLOCK

*

DL DAMPER LIMIT SWITCH

DS DISCONNECT SWITCH

*

EC ECONOMIZER CONTROLLER

*

FCS CONDENSOR FAN CYCLE SWITCH

*

FU FUSES

FU5 CONTROL TRANSFORMER FUSES (NOT ON CLASS II)

FZ1 FREEZE PROTECTION

HG HOT GAS REHEAT VALVE

HPS HIGH PRESSURE SWITCH (MANUAL RESET)

*

LPS LOW PRESSURE SWITCH

*

PS1 WHEEL FROST PRESSURE SWITCH

*

PS2 SUPPLY DIRTY FILTER PRESSURE SWITCH

*

PS3 EXHAUST DIRTY FILTER PRESSURE SWITCH

*

R1 ENERGY WHEEL RELAY/CONTACTOR

*

R2 OCCUPIED/UNOCCUPIED RELAY

R3 EXHAUST BLOWER VFD RELAY

R4 SUPPLY BLOWER VFD RELAY

R5 MODULATING WHEEL FROST CONTROL RELAY

R6 ECONOMIZER RELAY

R7 COMPRESSOR INTERLOCK RELAY

*

R8 EVAP RELAY (INDIRECT)

R9 EVAP RELAY (DIRECT)

R10 UNIT RELAY

R11 POST HEAT RELAY

R12 DEHUMIDIFICATION RELAY

R13 ROOM CALL FOR HEAT RELAY

R14 ROTATION SENSOR RELAY

*

R15 ROTATION SENSOR RELAY

o

S1 FAN SWITCH

S2 ROTATION SENSOR (LOCATED BY WHEEL)

*

S3 ROTATION SENSOR (LOCATED BY WHEEL)

S4 CALL FOR HEAT SWITCH

S5 OCC/UNOCC SWITCH - CLOSED=OCCUPIED/OPEN=UNOCCUPIED

S6 CALL FOR COOL SWITCH (FIRST STAGE)

o

o

S7 CALL FOR COOL SWITCH (SECOND STAGE)

S8 CALL FOR DEHUMIDIFICATION SWITCH

ST MOTOR STARTER

*

*

T1 FROST CONTROL TIMER

*

TYPICAL SETTINGS t1(OFF) = 5 MIN., t2(ON) = 30 MIN.

T4 ECONOMIZER WHEEL JOG TIMER

TYPICAL SETTINGS t1(OFF) = 3 HRS., t2(ON) = 10 SEC.

T5 EVAP DELAY OFF TIMER

*

T6 COMPRESSOR MINIMUM OFF TIMER (TYP. 3 MIN.)

T7 COMPRESSOR MINIMUM OFF TIMER (TYP. 3 MIN.)

*

TR TRANSFORMER

*

TS1 FROST CONTROL THERMOSTAT (JUMPER - HEAT)

*

CLOSES ON TEMP. DECREASE TYPICAL SETTING 5° F.

TS2 ECONOMIZER LOW LIMIT THERMOSTAT (JUMPER - HEAT)

OPENS ON TEMP. DECREASE TYP. SETTING 20° OFFSET OR 50°F.

TS3 ECONOMIZER UPPER LIMIT THERMOSTAT (JUMPER - HEAT)

CLOSES ON TEMP. DECREASE TYP. SETTING 65° F./2° DIFF.

TS4 ROOM OVERRIDE SENSOR

TS5 INLET AIR POST HEATER LOCKOUT THERMOSTAT (AFTER WHEEL)

CLOSES ON TEMP. DECREASE TYPICAL SETTING 65° F.

TS6 INLET AIR COMPRESSOR LOCKOUT THERMOSTAT (JUMPER-HEAT )

*

OPENS ON TEMP. DECREASE TYPICAL SETTING 60° F./2° DIFF.

FACTORY SUPPLIED AND WIRED

*

o FIELD WIRED

FIELD CONTROL WIRING RESISTANCE SHOULD NOT EXCEED 0.75 OHM.

IF RESISTANCE EXCEEDS 0.75 OHM THEN CONSULT FACTORY.

USE 14 GAUGE MINIMUM WIRE THICKNESS FOR CONTROL WIRING.

REPLACEMENT FUSES: MUST HAVE A MINIMUM I.R. RATING OF 5 KA

CAUTION:

UNIT SHALL BE GROUND IN ACCORDANCE WITH N.E.C.

POWER MUST BE OFF WHILE SERVICING.

USER INTERFACE CONNECTIONS:

USER TO VERIFY THAT TR1 CAN HANDLE THE VA LOAD OF INDICATOR DEVICES.

DIRTY FILTER INDICATOR SHOWN AS 24V POWER FROM UNIT.

PS2

SUPPLY DIRTY

FILTER SWITCH

PS3

EXHAUST DIRTY

FILTER SWITCH

FROST CONTROL INDICATOR

C

NC NO

C

NC

ROTATION INDICATOR

NO

12 C

CR

CR

17

Page 18

Energy Recovery Unit with Packaged DX

OPTIONAL ACCESSORIES

Rotation Sensor

The rotation sensor monitors energy recovery wheel rotation. If the wheel should stop rotating, the sensor will

close a set of contacts in the unit control center. Field wiring of a light (or other alarm) between terminals R & 12

in the unit control center will notify maintenance personnel when a failure has occurred (refer to Remote Panel

Wiring Schematics section for wiring details).

Dirty Filter Sensor

Dirty filter sensors monitor pressure drop across the outdoor air filters, exhaust air filters, or both. If the

pressure drop across the filters exceeds the set point, the sensor will close a set of contacts in the unit control

center. Field wiring of a light (or other alarm) to these contacts will notify maintenance personnel when filters

need to be replaced.

The switch has not been set at the factory due to external system losses that will affect the switch. This switch

will need minor field adjustments after the unit has been installed with all ductwork complete. The dirty filter

switch is mounted in the exhaust inlet compartment next to the unit control center or in unit control center.

To adjust the switch, the unit must be running

with all of the access doors in place, except

for the compartment where the switch is

located (exhaust intake compartment). The

adjusting screw is located on the top of the

switch. Open the filter compartment and

place a sheet of plastic or cardboard over

50% of the filter media. Replace the filter

compartment door. Check to see if there

is power at the alert signal leads (refer to

electrical diagram). Whether there is power or

not, turn the adjustment screw on the dirty filter

gauge (clockwise if you did not have power,

counterclockwise if you did have power) until

the power comes on or just before the power

goes off. Open the filter compartment and

remove the obstructing material. Replace the door and check to make sure that you do not have power at the

alert signal leads. The unit is now ready for operation.

Positive pressure connection is toward the ‘back or bottom’ of

the switch (senses air inlet side of filters)

Setscrew (on front of switch) must be manually

adjusted after the system is in operation.

Negative pressure connection is toward the

‘front or top’ of the switch (senses blower

side of filters)

DDC Temperature Control Package

Temperature control package allows for stand-alone operation

of energy recovery units provided with supplemental cooling

and heating. Controller can be ordered for discharge or room

control. Room control would require a room thermostat (or

other call for heat or cool) be wired to the controller. A remote

panel option is also available to allow set points and other

controller parameters to be adjusted from a remote location.

For additional information, refer to the controls catalog and

Installation, Operation and Maintenance Manual.

18

Page 19

Energy Recovery Unit with Packaged DX

OPTIONAL ACCESSORIES

CO2 Sensor

This accessory is often used to provide a modulating control signal to a variable frequency drive to raise and

lower airflow in relationship to the CO2 levels in the space. This strategy is often referred to as Demand Control

Ventilation and provides further energy savings to the system. Follow instructions supplied with sensor for

installation and wiring details.

Service Outlet

120 Vac GFCI service outlet ships loose for field installation.

Requires separate power source so power is available when

unit main disconnect is turned off for servicing.

Vapor Tight Lights

Vapor tight lights provide light to each of the compartments

in the energy recovery unit. The lights are wired to a

junction box mounted on the outside of the unit. The switch

to turn the lights on is located in the unit control center.

The switch requires a separate power source to allow for

power to the lights when the unit main disconnect is off for

servicing.

19

Page 20

Energy Recovery Unit with Packaged DX

OPTIONAL ACCESSORIES

Remote Control Panel and Wiring Schematics

The remote panel is available with a number of different

alarm lights and switches to control the unit. The remote

panel ships loose and requires mounting and wiring in

the field.

The remote panel is available with the following options:

• Uniton/offswitch

• Uniton/offlight

• 7-daytimeclock

• Hand/off/autoswitch

• Dirtyfilterlight

• Economizerlight

• Frostcontrollight

• Wheelrotationsensorlight

Refer to Electrical Connections section for Field Control Wiring recommendations.

7-Day Timer or On/Off Switch

7-Day Timer

For 7-Day Timer, use blue and black wires.

Red wires should be capped off.

Hand/Off/Auto Switch

Hand/Off/Auto Switch allows the unit to

“Off” - off

“On” - Manual Operation

“Auto” - Unit is controlled by BMS, RTU, etc.

S1 - Unit On/Off

On

Off

Auto

BMS

R

C

G

R

C

G

Terminal Block

in

Unit Control

Center

Terminal Block

in

Unit Control

Center

NOTE: RTU controllers are by others.

20

Page 21

OPTIONAL ACCESSORIES

Remote Panel Wiring Schematics

Indicator Lights

powered by the ER Unit

Y1

Y2

W1

12

Energy Recovery Unit with Packaged DX

R

C

G

6

7

Unit On/Off

Frost Control

Economizer

Rotation Sensor

Dirty Filter Indicator

(Power by Others)

PS2

C

NC NO

PS3

C

NC NO

PS2

NC

C

NO

Dirty Filter

Dirty Filter

NC

PS3

Hot

L1

Refer to Pressure Switch for voltage and load ratings.

C

NO

21

Page 22

OPTIONAL ACCESSORIES

Remote Panel Wiring Schematics

Heating/Cooling Switches and Night Setback

Switch/Timer

S1

S6

S7

S4

Unit On/Off

Econ/First Stage Cooling

Second Stage Cooling

Heat

Unit On/Off

Econ/First Stage Cooling

Second Stage Cooling

Heat

Energy Recovery Unit with Packaged DX

R

C

G

Y1

Terminal Block

Y2

W1

6

7

in unit

Control Center

Terminal Block

in

Unit Control

Center

S5

Night Setback Timer

Night Setback Timer

Night Setback Switch

Night Setback Switch

12

A

22

Page 23

Energy Recovery Unit with Packaged DX

OPTIONAL ACCESSORIES

Sensors Mounted by Factory

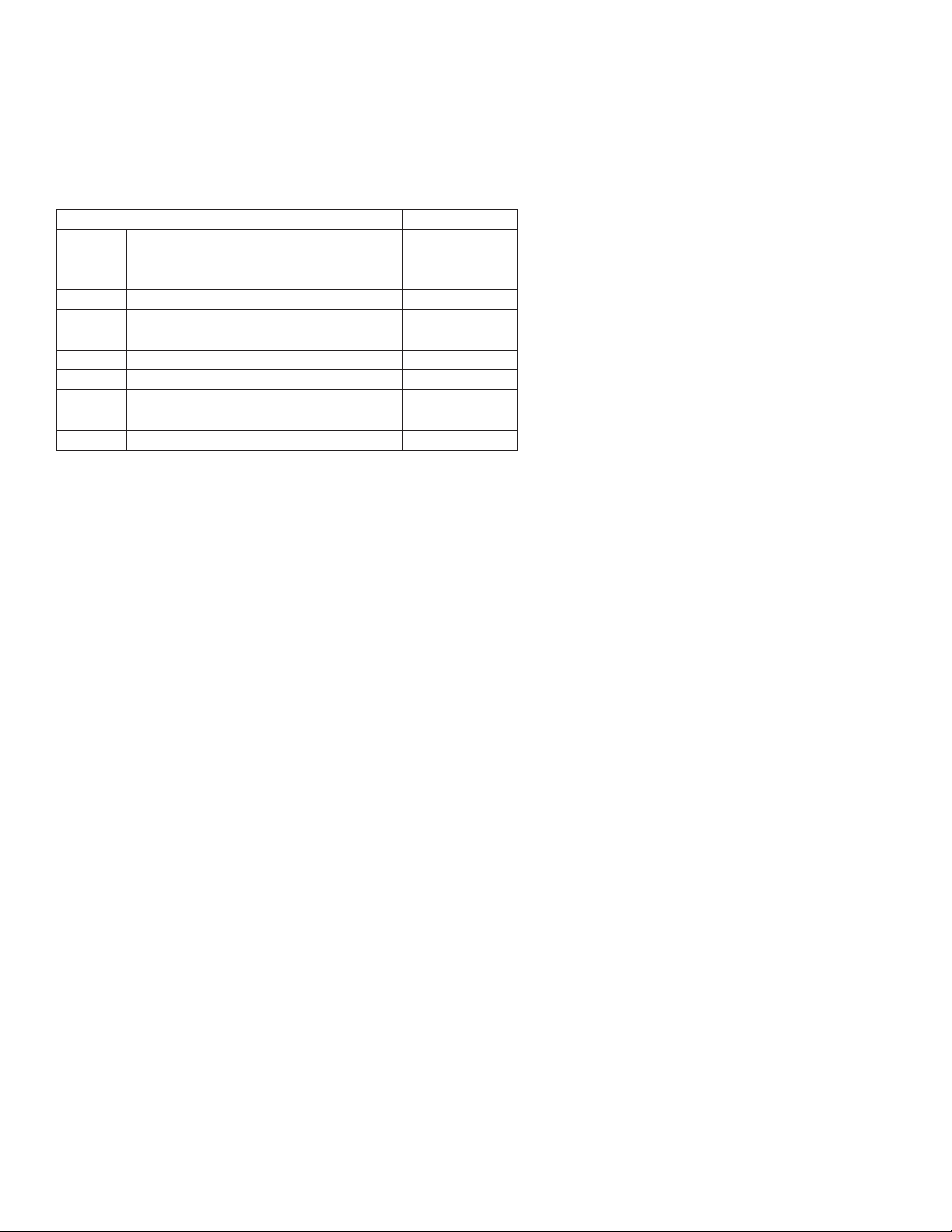

Factory mounted temperature, pressure, and current sensors are available in the locations indicated on the unit

diagram below. A list of available sensors is shown below. The specific sensors provided on a given unit are

labeled in the unit control center on the terminal strip. Sensors are wired to the terminal strip to make it easy for

the controls contractor to connect the Building Management System for monitoring purposes.

TO

OUTSIDE

FROM

OUSTIDE

EXHAUST

BLOWER

OAF-P

OA

FILTER

EAWEF-A

OAI

EW-P

ENERGY WHEEL

OAW-P

OAAW

COOL

COIL

RAI

ACC

HEAT

COIL

RAF-P

RA

FILTER

OAF-A

SUPPLY

BLOWER

FROM INSIDE

TO INSIDE

OAD

Temperature Sensors - 1K Ohm RTD

Drawing Labels Terminal Strip Labels

OAI OA/Supply Inlet Temp

OAAW OA After Wheel

ACC After Cooling Coil Temp

OAD Supply Discharge Temp

EAW Exhaust After Wheel Temp

RAI RA/Exhaust Inlet Temp

Pressure Sensors (analog or digital)

Drawing Labels Terminal Strip Labels

OAF-P OA/Supply Filter Pressure

OAW-P Outdoor Air Wheel Pressure

RAF-P RA/Exhaust Filter Pressure

EW-P Exhaust Wheel Pressure

Amp - Current Sensors (analog or digital)

Drawing Labels Terminal Strip Labels

OAF-A Supply Fan Amps

EF-A Exhaust Fan Amps

23

Page 24

START-UP CHECKLIST FOR UNIT

Energy Recovery Unit with Packaged DX

SAFETY DANGER!

Electric shock hazard. Can cause injury or death. Before

attempting to perform any service or maintenance,

turn the electrical power to unit to OFF at disconnect

switch(es). Unit may have multiple power supplies.

SAFETY CAUTION!

Do not operate energy recovery ventilator without the

filters and birdscreens installed. They prevent the entry of

foreign objects such as leaves, birds, etc.

Use caution when removing access panels or other unit

components, especially while standing on a ladder or

other potentially unsteady base. Access panels and unit

components can be heavy and serious injury may occur.

Do not run unit during construction phase. Damage to

internal components may result and void warranty.

SAFETY CAUTION!

CAUTION!

CAUTION! WARNINGS!

• Unitwasfactorytested.Allblowers,fans,andcompressorsareset-uptoruncorrectwhensupplied

power. If any one fan is running backwards or the compressor is making loud noises, immediately turn off

the power. Switch two leads on the incoming power to the disconnect. This will ensure proper operation of

the unit. Failure to comply may damage the compressors and void the warranty.

• Donotjumperanysafetydeviceswhenoperatingtheunit.Thismaydamagecomponentswithinorcause

serious injury or death.

• Donotoperatecompressorwhentheoutdoortemperatureisbelow40ºF.

• Donotshort-cyclethecompressor.Allow5minutesbetween“on”cyclestopreventcompressordamage.

• Priortostartinguptheunit,powermustbeenergizedfor24hourswithoutacallforcooltoallowthe

compressor crankcase heaters time to boil off any liquid refrigerant present in the compressor.

• DXsystemischargedwithrefrigerant.Start-upmustbeperformedbyEPACertifiedTechnician.

Every installation requires a comprehensive start-up to ensure proper operation of the unit. As part of

that process, the following checklist must be completed and information recorded. Starting up the unit in

accordance with this checklist will not only ensure proper operation, but will also provide valuable information

to personnel performing future maintenance. Should an issue arise which requires factory assistance, this

completed document will allow unit experts to provide quicker resolve. Qualified personnel should perform

start-up to ensure safe and proper practices are followed.

Unit Model Number ___________________________ (e.g. ERCH-55)

Unit Serial Number ___________________________ (e.g. 04C99999 or 10111000)

Energy Wheel Date Code ___________________________ (e.g. 0450)

Compressor 1 Model Number ___________________________ (e.g. ZR36-XXXX)

Compressor 2 Model Number ___________________________ (e.g. ZR36-XXXX)

Start-Up Date ___________________________ (MM/DD/YYYY)

Start-Up Personnel Name ___________________________

Start-Up Company ___________________________

Phone Number ___________________________

24

Page 25

Energy Recovery Unit with Packaged DX

START-UP CHECKLIST FOR UNIT

Pre-Start Up Checklist - check boxes as items are completed

o Disconnect and lock-out all power switches

o Remove any foreign objects that are located in the energy recovery unit.

o Check all fasteners, set-screws, and locking collars on the fans, bearings, drives, motor bases and

accessories for tightness.

o Rotate the fan wheels and energy recovery wheels by hand and ensure no parts are rubbing. If rubbing

occurs, refer to Start-Up section for more information.

o Check the fan belt drives for proper alignment and tension (refer to Start-Up section for more

information).

o Filters can load up with dirt during building construction. Replace any dirty pleated filters and clean the

aluminum mesh filters in the intake hood (refer to Routine Maintenance section).

o Verify that non-motorized dampers open and close properly.

o Check the tightness of all factory wiring connections.

o Verify control wire gauge (refer to the Electrical Connections section).

o Verify diameter seal settings on the energy recovery wheel (refer to Start-Up section for more

information).

o Verify proper drain trap installation (refer to Drain Trap section).

o Check condensing fans for any damage or misalignment. Spin the blades and make sure they don’t

contact any parts and are free turning without any resistance.

o Look over the piping system. Inspect for oil at all tubing connections. Oil typically highlights a leak in

the system. If a leak is present, refer to the Maintenance section in this manual.

o Inspect all coils within the unit. Fins may get damaged in transit or during construction. Carefully

straighten fins with a fin comb.

o If there is an indirect gas-fired furnace in this unit, refer to the PVF IOM provided with this unit for __

Pre- Start-Up information.

o This unit contains a crankcase heater for each compressor which needs power supplied to it 24 hours

prior to start-up. If start-up is scheduled in 24 hours, unlock the disconnect power and energize unit.

Special Tools Required

•VoltageMeter(withwireprobes) •Thermometer

•AmperageMeter •PressureGauges

•Inclinemanometerorequivalent •TemperatureGaugescapableofmeasuringpipetemperature

•Tachometer

Start-Up Checklist

The unit will be in operational mode during start-up. Use necessary precautions to avoid injury. All data must be

collected while the unit is running. In order to measure volts & amps, the control center door must be open, and

the unit energized using a crescent wrench to turn the disconnect handle.

Start-Up Procedure

• MakesurePre-Start-Upchecklistiscomplete.

• JumperRtoG,RtoY1,andRtoY2(ifapplicable)onthecontrolboard.

• Turnthedisconnecton.After3minutescompressorswillcomeon.Makesureallfansandcompressorsare

rotating the correct direction.

WARNING!

All motor(s) / compressor(s) have been checked for rotation. If blower rotation is incorrect, wiring must be

changed at the disconnect to ensure all motor(s) / compressors are corrected.

Operation of scroll compressor(s) in this unit are directional and will be damaged if run with the wrong direction.

• Allowtheunittorununtiltherefrigerantsystemstabilizes.Approximately1-2minutes.

• Takethefollowingmeasurementswhiletheunitisrunningtoensureproperoperation.

25

Page 26

Energy Recovery Unit with Packaged DX

START-UP CHECKLIST FOR UNIT

Line Voltage - check at unit disconnect

L1-L2 ________ Volts L2-L3 ________ Volts L1-L3 _______ Volts

Motor Amp Draw:

Supply Motor Amps L1 ________ Amps L2 ________ Amps L3 ________ Amps

Exhaust Motor Amps L1 ________ Amps L2 ________ Amps L3 ________ Amps

Fan RPM: Supply Fan RPM _____________

Exhaust Fan RPM _____________

Correct fan rotation direction: Supply Fan Yes / No

Exhaust Fan Yes / No

Energy Wheel Motor: L1 ________ Amps L2 ________ Amps L3 ________ Amps

Compressor 1: L1 ________ Amps L2 ________ Amps L3 ________ Amps

Crankcase Heater ________ Amps

Compressor 2: L1 ________ Amps L2 ________ Amps L3 ________ Amps

Crankcase Heater ________ Amps

Condensing Fan 1: L1 ________ Amps L2 ________ Amps L3 ________ Amps

Condensing Fan 2: L1 ________ Amps L2 ________ Amps L3 ________ Amps

Condensing Fan 3: L1 ________ Amps L2 ________ Amps L3 ________ Amps

Outdoor Air Temperature ________ Deg F

Return Air Temperature ________ Deg F

Outdoor Air Relative Humidity ________ % RH

Return Air Relative Humidity ________ % RH

Superheat ________ Deg F Should be between 8º and 12ºF

Subcooling ________ Deg F Should be between 12º and 17ºF

Discharge Pressure PSIG Should be between 200 and 280 PSIG for R22

or 300 and 500 PSIG for R410a

Suction Line Pressure PSIG Should be between 60 and 80 PSIG for R22

or 100 and 135 PSIG for R410a

Liquid Line Temp ________ Deg F

Suction Line Temp ________ Deg F

Moisture Indicating Sight Glass Liquid Visible Yes / No Color of Center Dot Green / Yellow

Hot Gas Bypass Operational Yes / No

26

Page 27

Energy Recovery Unit with Packaged DX

OPTIONAL ACCESSORIES CHECKLIST

Refer to the respective sections in this Installation, Operation and Maintenance Manual for detailed information.

Refer to wiring diagram in unit control center to determine what electrical accessories were provided.

Provided with Unit? Frost Control Application / Operation section: Setting Factory Default

Yes No Frost Control set point 5ºF

Differential 2ºF

Timer Refer to IOM

Yes No Frost Control Modulating Refer to IOM

Economizer Application / Operation section:

Yes No Economizer (temperature)

Set point 65ºF

Offset 20ºF

Differential 2ºF

Yes No Economizer (enthalpy)

Set point B

Yes No Economizer (modulating) Refer to IOM

Optional Accessories section: Operational

Yes No Wheel Rotation Sensor Yes No N/A

Yes No OA Dirty Filter Sensor Yes No N/A

Yes No EA Dirty Filter Sensor Yes No N/A

Yes No CO

Yes No Service Outlet Yes No N/A

Yes No Vapor Tight Lights Yes No N/A

Yes No Remote Control Panel Yes No N/A

Variable Frequency Drives section: Operational

Yes No Blower VFDs Yes No N/A

Yes No Wheel VFD Yes No N/A

Damper section: Operational

Yes No Outdoor Air Damper Yes No N/A

Yes No Exhaust Air Damper Yes No N/A

Yes No Night Setback Damper Yes No N/A

Sensor Yes No N/A

2

Yes No Indirect Gas Furnace (refer to the PVF IOM, Part #461006 for start-up information)

27

Page 28

Energy Recovery Unit with Packaged DX

Belt Span

Deflection =

Belt Span

64

Belt Span

Deflection =

Belt Span

64

WRONG WRONG

MOTOR

FAN

MOTOR

UNIT START-UP

Refer to Parts List section for component locations.

Fans

The ERCH models contain a forward curved supply fan and

a forward curved exhaust fan. These forward curved fans

should be checked for free rotation. If any binding occurs,

check for concealed damage and foreign objects in the fan

housing. Be sure to check the belt drives per the start-up

recommendations in the following section.

SAFETY CAUTION!

When operating conditions of the fan are to be changed (speed, pressure, temperature, etc.), consult Greenheck to

determine if the unit can operate safely at the new conditions.

Fan Performance Modifications

Due to job specification revisions, it may be necessary to adjust or change the sheave or pulley to obtain the

desired airflow at the time of installation. Start-up technician must check blower amperage to ensure that the

amperage listed on the motor nameplate is not exceeded. Amperage to be tested with access doors closed and

ductwork installed.

Forward

Curved

Fan

Fan Belt Drives

The fan belt drive components, when supplied by Greenheck, have been carefully selected for the unit’s specific

operating condition. Caution: utilizing different components than those supplied could result in unsafe operating

conditions which may cause personal injury or failure of the following components: 1) Fan Shaft, 2) Fan Wheel,

3) Bearings, 4) Belt, 5) Motor. Tighten all fasteners and set screws securely and realign drive pulleys after

adjustment. Check pulleys and belts for proper alignment to avoid unnecessary belt wear, noise, vibration and

power loss. Motor and drive shafts must be parallel and pulleys in line (see below).

Belt Drive Installation

1. Remove the protective coating from the end of the fan shaft and assure

that it is free of nicks and burrs.

2. Check fan and motor shafts for parallel and angular alignment.

3. Slide sheaves on shafts. Do not drive sheaves on as this may result in

bearing damage.

4. Align fan and motor sheaves with a straight-edge or string and tighten.

5. Place belts over sheaves. Do not pry or force belts, as this could result

in damage to the cords in the belts.

6. With the fan off, adjust the belt tension by moving the motor base. (See

belt tensioning procedures in the Routine Maintenance section of this

manual). When in operation, the tight side of the belts should be in a

straight line from sheave to sheave with a slight bow on the slack side.

28

WRONG WRONG

Proper alignment of motor and drive shaft.

WRONG CORRECT

Page 29

UNIT START-UP

R

o

t

a

t

i

o

n

Backward Inclined

R

o

t

a

t

i

o

n

Backward Inclined

Direction of Fan Wheel Rotation

Blower access is labeled on unit. Check for proper wheel

rotation by momentarily energizing the fan. Rotation is

determined by viewing the wheel from the drive side and

should match the rotation decal affixed to the fan housing

(see Rotation Direction figures). If the wheel is rotating the

wrong way, direction can be reversed by interchanging

any two of the three electrical leads.

noise, vibration, or overheating of bearings. Refer to

the Troubleshooting section of this manual if a problem

develops.

Fan RPM