Page 1

®

Document Number 468391

ES, EM & GM series

Installation, Operation, and Maintenance Instructions

This manual is the property of the owner, and is required for future maintenance. Please leave it with the

owner when the job is complete.

RECEIVING AND HANDLING

Upon receiving dampers, check for both obvious

and hidden damage. If damage is found, record all

necessary information on the bill of lading and file

a claim with the final carrier. Check to be sure that

all parts of the shipment, including accessories, are

accounted for.

Dampers must be kept dry and clean. Indoor

storage and protection from dirt, dust and the

weather is highly recommended. Do not store at

temperatures in excess of 100°F(37ºC).

Due to continuing research, Greenheck reserves the right to change specifications without notice.

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating, and maintenance instructions

thoroughly before installing or servicing this

equipment.

SAFETY WARNING:

Pre-Installation Guidelines

The basic intent of a proper installation is to secure the damper into the opening in such a manner as to prevent distortion

and disruption of damper operation. The following items will aid in completing the damper installation in a timely and

effective manner.

1) Check the schedules for proper damper locations within the building. Visually inspect the damper for damage.

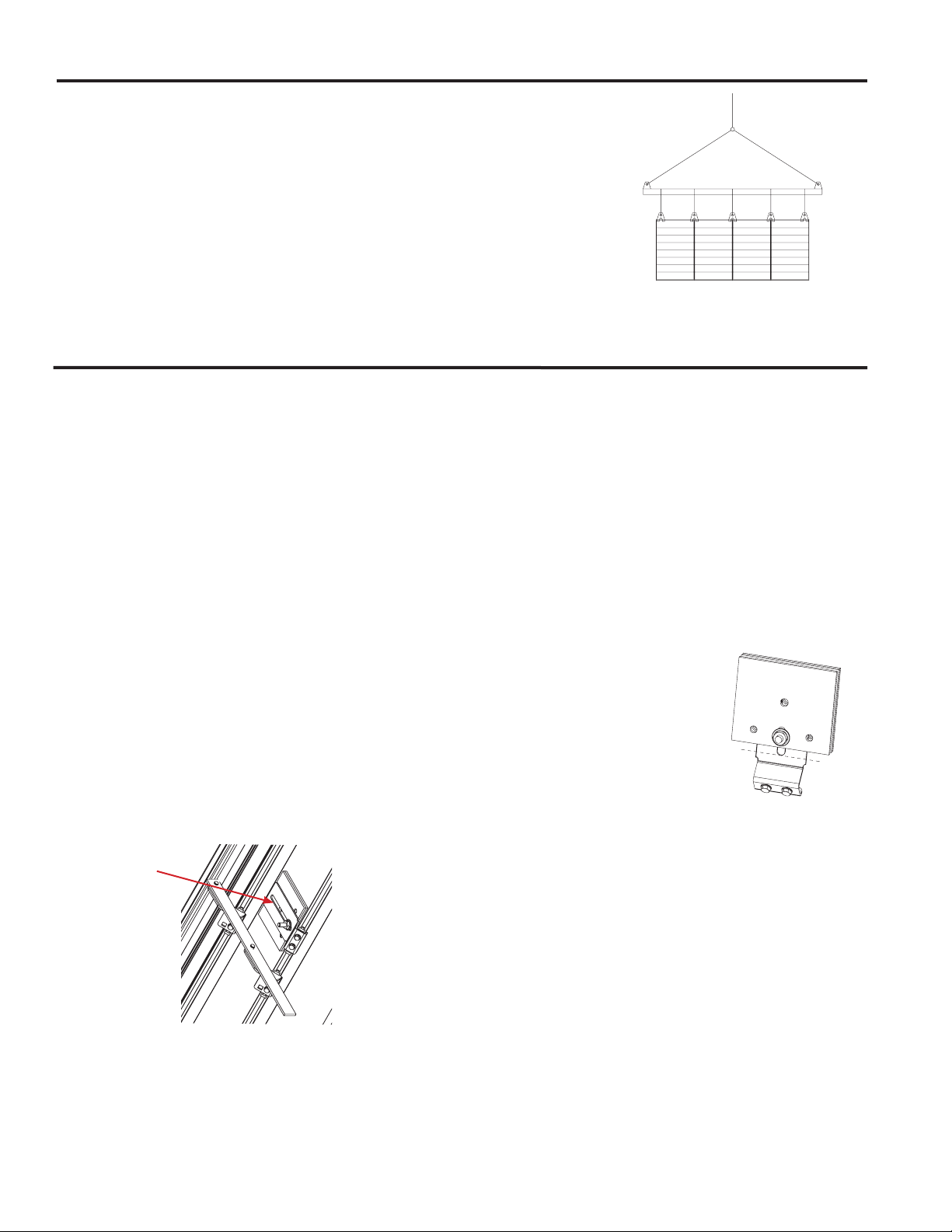

2) Lift or handle damper using sleeve or frame. Do not lift damper using blades or linkage. When handling multiple sections

assemblies, use sufficient support to evenly lift at each section mullion (see drawing). Do not drag, step on, apply

excessive bending, twisting, or racking. (See Figure 1)

3) Do not install screws in damper frame that will interfere with damper blades and prevent them from opening and/or

closing.

4) Damper must be installed into duct or opening square and free of twist or other misalignment. Damper must not be

squeezed or stretched into duct or opening. Out of square, racked, twisted or misaligned installations can cause

excessive leakage and/or torque requirements to exceed damper/actuator design.

Page 2

Pre-Installation Guidelines continued...

5) Damper must be kept clean, dry and protected from dirt, dust and other foreign

materials prior to and after installation. Examples of such foreign materials include

but are not limited to:

a) Drywall/mortar dust

b) Firesafing materials

c) Wall texture

d) Paint overspray

6) Damper should be sufficiently covered as to prevent overspray if wall texturing or

Spreader Bar

Attachments

spray painting will be performed within 5 feet (1.50m) of the damper. Excessive dirt

or foreign material deposits on damper can cause excessive leakage and/or torque

requirements to exceed damper/actuator design.

7) ACCESS: Suitable access (actuators maintenance, etc.) must be provided for damper

inspection and servicing. Where it is not possible to achieve sufficient size access, it

will be necessary to install a removable section of duct.

Multi section dampers

Figure 1

EM/ES/GM Damper Counterbalance Adjustment Procedure

The following instructions should be followed when attempting to maximize the counterbalance effect on the EM or

GM model dampers. Be aware that when the balance setting is highly sensitive, friction wear and contamination will

have an adverse effect to the operation of the damper. The sensitivity of the counterbalance should only be set to meet

the application requirements. The damper must be mounted square and plumb and operate freely before any weight

adjustments are performed.

Counterbalance adjustment for EM/ES/GM-30, 31 & 32 Models: Vertical Mount – Horizontal Airflow

Adjustment #1 will effect the balance of the blades in the open position. Adjustment #2 will effect the balance of the blades

in the closed position along with a small change to the open position balance.

If the damper blades do not achieve full open position under airflow and you want them to open further or all the way,

then adjustment #1 will need to be performed. If the damper blades do not open completely and adjustment #1 has been

addressed, then more weight is required.

If the airflow through the damper is light and the blades only slightly move from the closed position, then adjustment #2 and

#1 are required.

Adjustment #1:

Moving the weight stack along the length of the

mounting bracket slot will effect the full open balance

of the blade assembly. Moving the weights further

away from the blade pivot point will cause the blades

to become more balanced so that at some point, and

with enough weight, the blades would remain open.

Care must be taken to ensure that when the weights are

moved outward from the blade pivot point they will not

interfere with the adjacent blade when the blades close.

Moving the weights back towards the blade pivot point

will allow the blades to close.

blade surface. Bending the

counterweight mounting

brackets will move the

counterweight stack behind the

blade pivot point and therefore

allow the blades to start

opening at lower airflow rates.

This adjustment should be

performed in small increments

Bend Here

since the blades will not fully

close if the brackets are bent

to far. Performing adjustment #2

will have a small effect on adjustment #1 therefore, if

adjustment #1 is critical, then adjustment #1 may need

to be repeated.

Adjustment #2:

The damper is assembled with the counterbalance

weights and bracket installed such that, when the

blades are closed, the counterbalance weights and

bracket are positioned directly inline with the blade

pivot points. This position of the weights will provide

a slight load that will hold the blades in the closed

position. To reduce this load, the counterweightmounting brackets can be bent away from the adjacent

2

Counterbalance Adjustment for EM/ES-10, 11 &

12 Models: Horizontal Mount - Vertical Airflow Up

Adjustment #1 will effect the balance of the blades in the

closed position. Adjustment #2 will effect the balance of the

blades in the open position along with a small change to

the balance in the closed position balance.

If the damper blades are partially opening under airflow

and you want them to open further or all the way, then

adjustment #1 will need to be performed. If the blades

remain in the full open position then adjustment #2 is

required.

If the airflow through the damper is light and the blades

only slightly move from the closed position, then adjustment

#1 is required. If the airflow through the damper is light and

the blades do not reach full open position then adjustment

#2 may be excessive or adjustment #1 may need to be

Page 3

increased or both adjustments may need to be addressed.

Adjustment #1:

Moving the weight stack along the length of the

mounting bracket slot will effect the full closed balance

of the blade assembly. Moving the weights further

away from the blade pivot point will cause the blades

to become more balanced so that at some point, and

with enough weight, the blades would remain open

without air pressure being applied. Care must be taken

to ensure that when the weights are moved away from

the blade pivot point the weights will not interfere with

the adjacent blade when the blades close. Moving some

of the weights back towards the blade pivot point will

allow the blades to return to the closed position.

remain in the full open position then adjustment #2 is

required.

If the airflow through the damper is light and the blades

only slightly move from the closed position, then adjustment

#1 is required.

Adjustment #1:

Moving the weight stack along the length of the

mounting bracket slot will effect the full closed balance

of the blade assembly. Moving the weights closer to

the blade pivot point will cause the blades to become

less balanced so that at some point, the blades would

fall open. Care must be taken to ensure that when the

weights are moved outward from the blade pivot point

the weights will not interfere with the adjacent blade

when the blades close. Moving the weights away from

the blade pivot point will force the blades to close

properly. Care must be taken to ensure that when the

weights are moved outward from the blade pivot point

the weights will not interfere with the adjacent blade

when the blades close. Performing adjustment #1

will have a small effect on adjustment #2 therefore, if

adjustment #2 is critical, then adjustment #2 may need

to be repeated.

Adjustment #2:

The damper is factory assembled with the

counterbalance assembly installed such that, the

counterbalance weights and bracket are positioned at

a slight angle to the surface

of the blade. This angle will

position the weights such

that they will provide a slight

load that will cause the blades

to rotate from the full open

position toward the closed

position. If for some reason

the blades remain in the open

Bend Here

position then you will need to

increase this load. To do this

the counterweight-mounting

brackets should be bent further away from the blade

surface. Bending the counterweight mounting brackets

will move the counterweight stack away from the blade

surface and therefore the torsion effect will force the

blades to start closing. This adjustment should be

performed in small increments to each weight bracket.

Performing adjustment #2 will have a small effect on

adjustment #1 therefore, if adjustment #1 is critical,

then adjustment #1 may need to be repeated.

Counterbalance Adjustment for EM/ES-40, 41 &

42: Horizontal Mount – Vertical Airflow Down

Adjustment #1 will effect the balance of the blades in the

closed position. Adjustment #2 will effect the balance of the

blades in the open position along with a small change to

the balance in the closed position.

If the damper blades are only opening partially under airflow

and you want them to open further or all the way, then

adjustment #1 will need to be performed. If the damper

blades do not close completely and adjustment #1 has

been addressed, then more weight is required. If the blades

Adjustment #2:

The damper is factory assembled with the

counterbalance weights and bracket installed such

that, when the blades are closed, the counterbalance

weights and bracket are

positioned directly inline or

slightly ahead of the blade

pivot points. The position

of the weights will provide

a slight load that will cause

the blades to rotate from the

full open position toward the

closed position. To increase

this load, the counterweightmounting brackets can be

bent toward the adjacent blade surface. Bending

the counterweight mounting brackets will move the

counterweight stack which will force the blades to

start closing. This adjustment should be performed in

small increments to each weight bracket since bending

the brackets two much will cause the weight stack to

interfere with the adjacent blade surface. Performing

adjustment #2 will have a small effect on adjustment #1

therefore, if adjustment #1 is critical, then adjustment

#1 may need to be repeated.

Bend Here

3

Page 4

Multi-section Assembly

When the finished damper assembly is made up of multiple sections, the sections will require field assembly. Frame clips are

provided for this purpose. The frame clips are a snap fit component that fit over the joint between adjoining sections. The

clips will require the use of a rubber hammer or similar tool to install as shown below. Install frame clips on the front side and

backside of the assembly. For added strength, screws may be used on the backside of the frames in lieu of or in addition to

the frame clip. Do not install screws on the front side of the frame where they could interfere with the operation of the blades.

Note: Used only on EM series dampers.

Blade

Frame clip

Frame clip

Vertical joint shown. Horizontal joint is similar.

Front side of damper blade

overlaps the frame.

Use screws here if

necessary

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specications without notice.

Specic Greenheck product warranties are located on greenheck.com within the product area tabs and in

the Library under Warranties.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

468391• EM & GM Series Rev. 4, April 2013 Copyright 2013 © Greenheck Fan Corporation

4

Loading...

Loading...