Page 1

TorqPlus

Electric Valve

Actuators

and Controls

TM

Page 2

Introduction

Advantages

For more than 40 years, Bettis

Corporation has been recognized

worldwide for providing industry

with high performance pneumatic

and hydraulic valve actuators. The

addition of the Bettis line of TorqPlus

electric actuators carries on the

tradition of product quality, innovation and service reliability.

Bettis TorqPlus actuators are specifi-

cally designed for quarter-turn

operating applications — ball, butterfly and plug valves;

dampers; vents and similar uses. TorqPlus actuators are

available in a wide range of output torques and operating speeds to fit your specific requirements.

The Bettis Engineered Solution

Most electric actuators in use today are designed to

meet a range of torque and speed requirements for use

in industrial applications. Controls and optional accessories are often available, added at the factory while

being assembled. Heretofore, not much attention has

been given to field upgrades, inventory modifications or

parts replacement during servicing.

The Bettis TorqPlus actuators, instead, provide its users

with a unique modular approach. The actuators are

manufactured with pre-tapped holes in the base plate

to accommodate a myriad of control and accessory

components, available in more than 200 easy-to-install

kits to fit virtually every requirement imaginable. Kits

are available, depending on the actuator model, to add:

■ Heaters and thermostats

■ Potentiometers

■ Servo controls

■ Motor brakes

■ Positioners and transmitters

■ Control stations

■ Multi-turn operation

■ PLC interface

All of the components can be added inside the CSA type

4/4x weatherproof housing or the CSA type 4/4x, 7 and

9 weatherproof/explosion proof housings.

The Bettis TorqPlus, and the modular concept, offers its

users significant advantages:

■ Compact Design – The actuators provide maxi-

mum torque output relative to its small design

housing.

■ Custom Control Standards – By offering an

almost endless number of control and accessory

combinations, Bettis electric actuators can effectively be designed to virtually any end use.

■ Modular Construction – The modular design

allows the actuators to be easily field modified

and serviced. Accessory kits can be stored for

future use without consuming a large amount of

storage space.

■ High Strength Gearing – We precision-machine

our gears from hardened alloy steel, and run in

needle bearings. The result is efficiency, smooth

energy transfer, quiet operation and, best of all,

long service life.

■ Low Maintenance – Permanent lubrication

reduces the need for scheduled maintenance. The

actuators are supplied with low temperature

lubricant, allowing the units to perform in temperatures to -40°F (-40°C). All operational parts

are fully enclosed in the housing eliminating all

contact with the environment.

■ Guaranteed Minimum Torques – As with other

Bettis actuators, we guarantee that our published

output torque values are minimum values. If any

Bettis TorqPlus actuator fails to meet its specified

torque output under normal use, we will replace it.

■ Duty Cycle – All Bettis actuators are rated for a

duty cycle of at least 30% (one motor-on period

followed by two motor-off periods). Higher duty

cycles (up to 100%), which can allow for up to

1200 starts per hour, at normal ambient temperatures are available.

Page 3

The following information may be used as a guide to

compose specifications for Bettis TorqPlus Electric

Actuators. Bettis supplies Electric Actuators that meet

or exceed all of the specifications stated below except

the Model EM-100 (which is not equipped with a manual

override feature or dual conduit entrances).

1. General

The actuator shall consist of a sand cast CSA* Certified

enclosure complete with an internal high-torque

reversible electric motor, terminal block, heat-treated

alloy steel gearing, a minimum of two (2)1⁄ 2" NPT

conduit connections and a two (2) year original manufacturer’s warranty.

2. Actuator Sizing

All actuator torques must be published and must be guaranteed, by the original manufacturer, as minimum values.

The actuator shall be sized to produce a torque equal

to or greater than the maximum valve torque, including

safety factor, as stated by the valve manufacturer for

the service, operating conditions and ambient

temperature intended.

3. Ambient Temperature Range

The actuator shall be suitable for normal operation in

ambient temperatures ranging from -40 to +140 °F

(-40 to +60°C). For temperatures below 32°F (0°C), highhumidity environments or all outdoor applications the

actuator shall be supplied with an electric heater and

thermostat.

4. Electric Motors

The actuator motor shall be of the reversible, high-torque,

open frame ventilated design with built-in automatic

resetting thermal overload protection, a minimum 30%

duty cycle rating and be UL* and CSA* Certified Motors

of 1⁄4 hp or less with not more than 7 amps of locked

rotor current draw. When single phase motors are

selected, they shall be supplied as a permanent split

capacitor type operating from a 1Ph/60Hz/ 115VAC or

220VAC supply.

5. Reduction Gearing

The actuator shall use exclusively cut alloy gearing. All

power gearing shall be grease lubricated for long life.

6. Limit Switches

All limit switches shall be independently operated by

adjustable cams in each direction of operation. Provisions

shall be made for up to six (6) additional cam operated

switches, each being capable of operation at any point

of travel.

7. Torque Limit Switches

All actuators of 2,000 lb-in (226 Nm) output torque or

greater, shall be supplied with two (2) mechanical

torque limiting switches which shall be responsive to

maximum torque encountered in both directions of

travel.

8. Manual Override

Transfer to manual operation from motor operation

shall not require the use of hand levers, solenoid shifters

or handwheel depression and the transfer shall be positive and reliable.

Actuators of less than 1700 lb-in, except for the model

100, shall be supplied with a disengageable manual

override mechanism. Disengagement of the motor drive

shall permit the use of a wrench on the output shaft

flats and shall by-pass the power gear drive and motor

for manual operation.

Actuators of 2,000 lb-in (226 Nm) or greater output

torque shall be supplied with a handwheel which will

not rotate during motor operation, but must be operational at all times without danger of injury to operator.

The handwheel shall not require more than 50 lbs. of

rim force to operate under the most adverse conditions

and be capable of assisting or opposing the motor

without any form of declutching.

9. Enclosure

The actuator enclosure shall be a high-strength sand

casting and must be certified by CSA*, or equal third

party tester, as acceptable for use in the following

locations:

9.1 Non-hazardous indoor or outdoor location to protect against wind-blown dust and rain, splashing

water and hose-directed water (i.e. CSA Enclosure

4 – Weatherproof, conforms to IP-65).

9.2 Hazardous locations classified as Class I and II,

Groups C, D, E, F and G as defined in the National

Electrical Code plus non-hazardous locations to

protect against wind-blown dust and rain, splashing water and hose-directed water (i.e. CSA

Enclosure 4 and 7 – Explosion-proof and

Weatherproof).

*CSA is Canadian Standards Associations,

Rexdale Ontario, Canada M9W 1R3

*UL is Underwriters Laboratories, Inc.,

Northbrook, IL 60062

*NEMA is National Electrical Manufacturers Association,

Washington, D.C. 20037

TYPICAL SPECIFICATIONS

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #81.20

Page 4

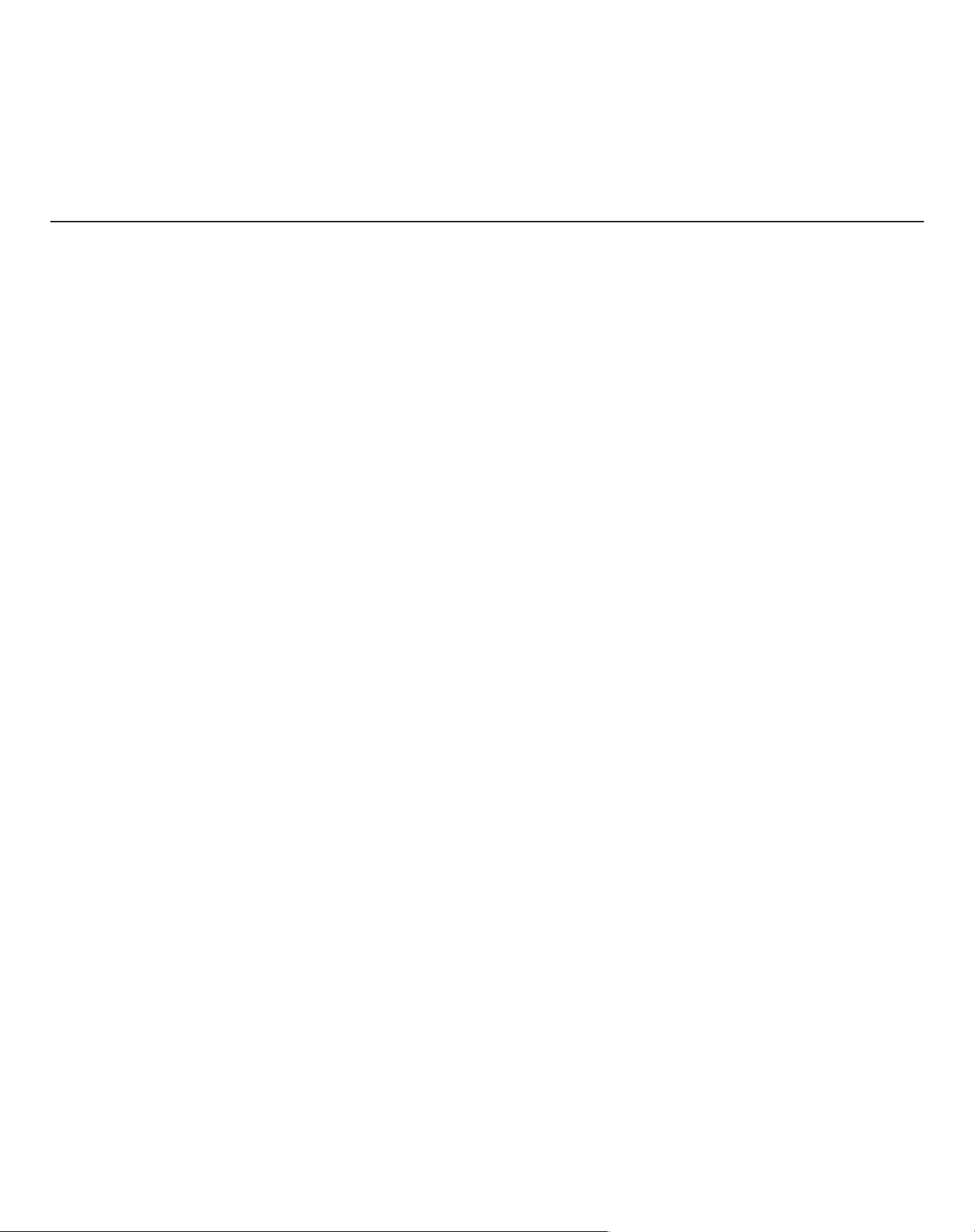

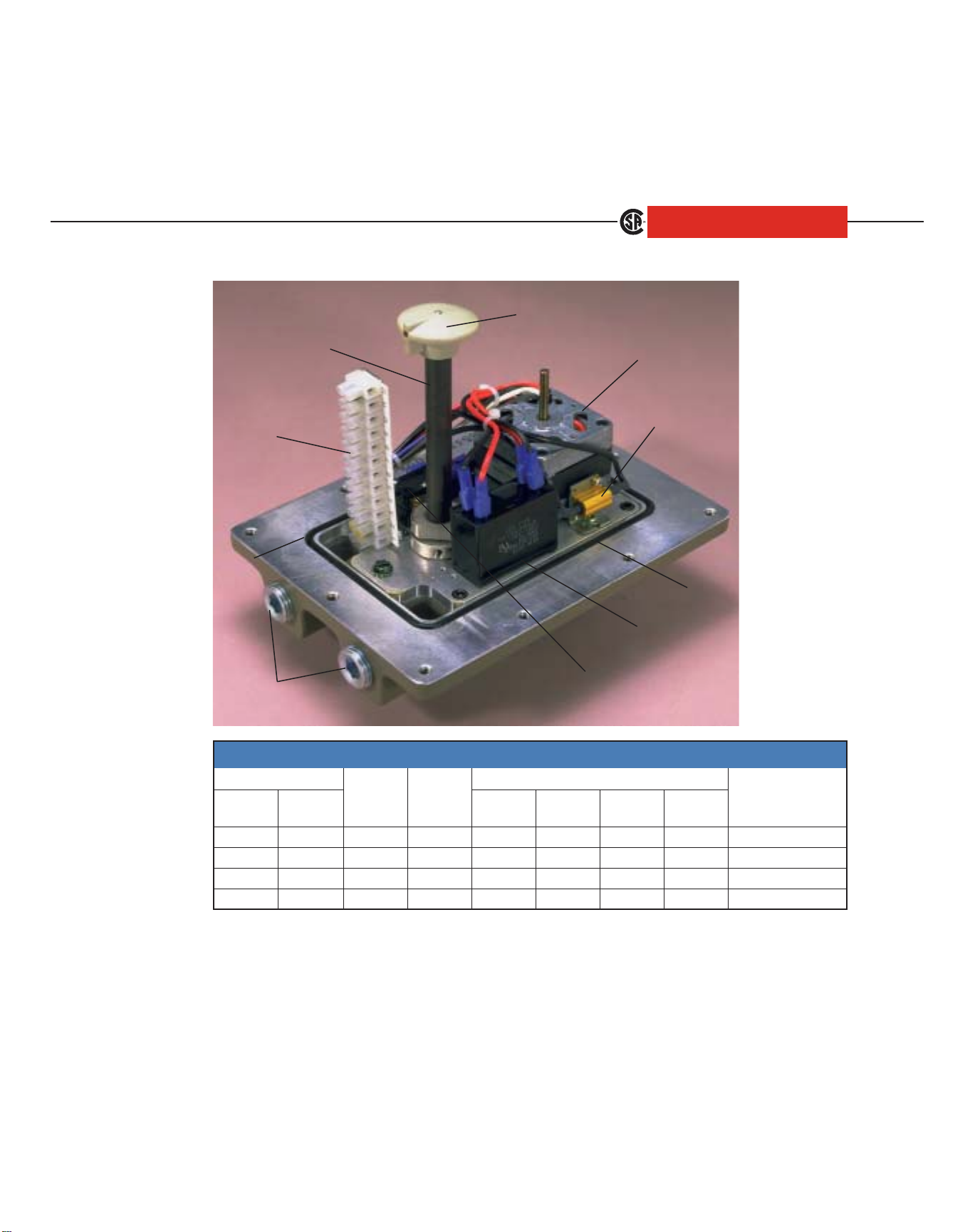

DESIGN AND CONSTRUCTION

2

1

4

5

8

9

These very rugged and versatile electric actuators take

full benefit of precision-machining which allows every

model to provide maximum torque output relative to its

compact design configuration and contains a minimum

of parts to reduce vibration, lessen noise and resist

harsh service. Utilizing a combination of spur, worm and

planetary power gearing reduction systems, the Bettis

TorqPlus actuators incorporate the most efficient, powerful and appropriate drive design for service excellence.

1. Motors. Available in Single Phase, 3 Phase and DC

voltages, all motors are custom built for high-torque,

low current draw and the highest duty cycle ratings

offered. Single phase motors are capacitor run type and

three phase are squirrel cage induction type both having

integral self resetting thermal cut-outs.

2. Brakes. Offered for all AC and DC motors, they are

capable of a holding force equal to the output torque

ratings of each actuator model.

3. Heater and Thermostat. Securely mounted and

appropriately sized to insure ample protection even in

the worst environments (not visible in photo).

4. Terminal Strips. Standard in all models and allow

7

10

6

(EM-500 Series)

easy plus efficient actuator installation.

5. Capacitors. Used on all single phase AC units, each

capacitor is peak voltage rated and of improved design

for maximum service life.

6. Potentiometers. Precision mechanically linked to

actuator output drive for continuous position signaling.

7. Position Indicator. Mechanically driven and easily

viewed at top of actuator to insure or confirm actual

actuator and driven device position at all times (not

available on compact Model EM-100).

8. Dual Conduit Connections. Standard on all models,

except EM-100, allows full electrical code access of all

wiring through two NPT connections.

9. Torque Limit Switches. Standard for the hightorque 800-Series of Bettis TorqPlus actuators. These

mechanical switches eliminate potential driven device

damage due to over torque conditions in either direction of operation.

10.Manual Override. Standard in all models except the

EM-100, manual override capability is offered in two

forms; Declutchable and Direct Acting.

Page 5

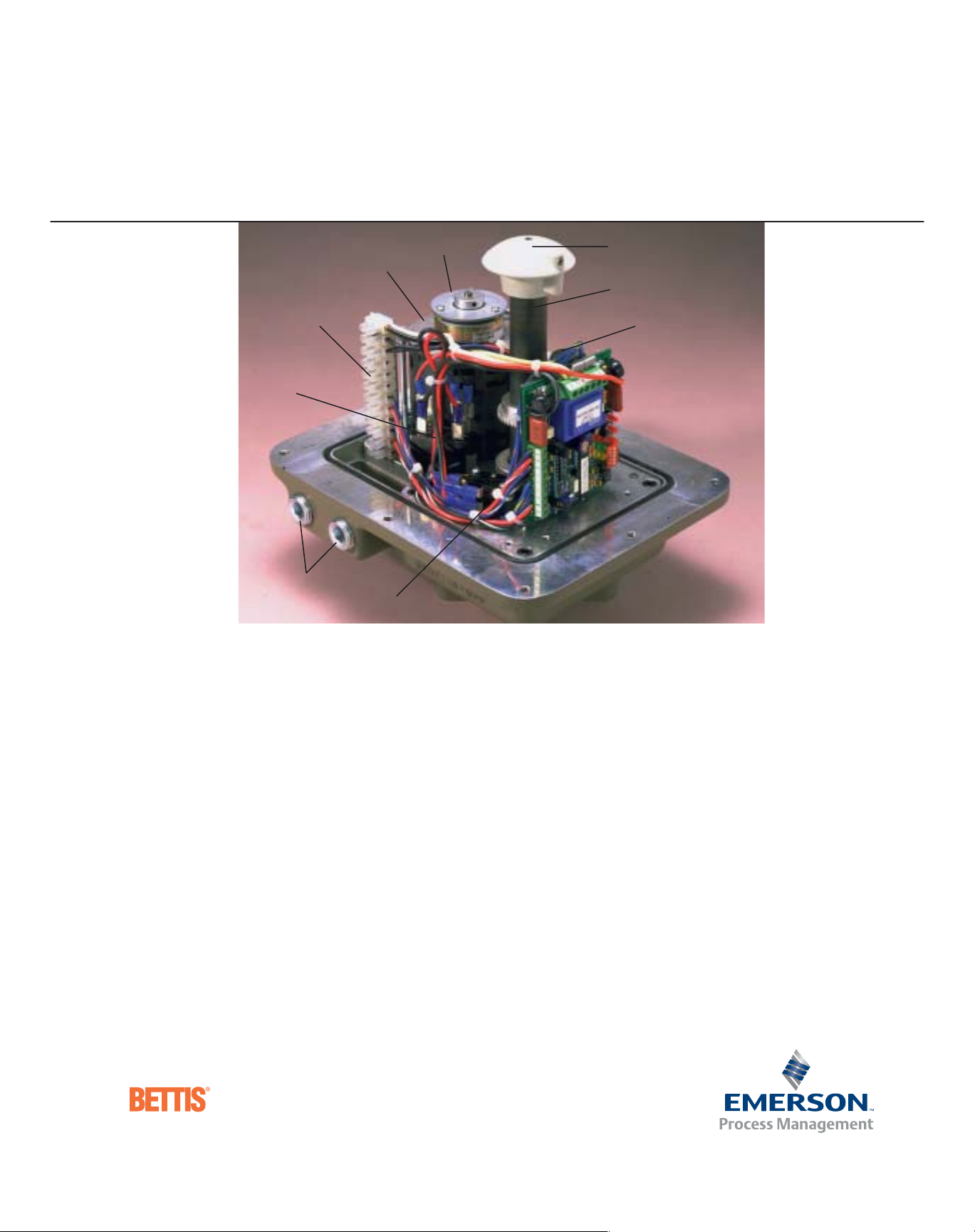

DESIGN AND CONSTRUCTION

7

6

4 2

1

5

9

8

11

12 13

(EM-800 Series)

Model EM-300 and the complete 500-Series

offer a Declutchable design which disengages the power

gear drive from the output shaft. Manual operation is

accomplished by rotating the exposed output shaft

drive flats with an open end wrench after the position

indicator knob is pulled up. Return to full automatic

operation is as easy as removing the wrench and lowering the position indicator knob to allow the mechanism

to re-engage upon application of power. Should power

be applied during manual operation, the declutchable

design will not allow the output shaft to rotate.

The 800-Series offers a Direct Acting handwheel design

which allows completely safe operation at any time and

with never more than 50 pounds of rim pull force.

Operating independent of the motor but directly into

the power gear drive, the handwheel does not rotate

during automatic operation of the actuator, requires no

engagement action for manual operation and may be

rotated with or without power to the unit.

10

11.Enclosures. Made from high strength sand castings,

enclosures are rated for applications in both Non-hazardous and Hazardous locations. As an option, the Bettis

TorqPlus is also available with a CSA Certified combination Hazardous and Non-hazardous enclosure for indoor

and outdoor protection in locations classified Class I and

II, Groups C, D, E, F and G as defined in the National

Electrical Code plus protects against wind-blown dust,

wind-blown rain, splashing water and hose-directed

water.

12.Output Drives are corrosion resistant. Female drives

are available in a variety of DIN/ISO 8-point sizes. Male

drives are also available on models 300 and 500. The

EM-800 series is provided with bored drive sleeve with

double keyways.

13.Powder Coat Finish. A polyester external coating

developed to serve as both a high durability impact and

chemical resistant finish. With up to 160 lb-in ASTM

D2794 impact resistance, over 1000 hours ASTM B117

salt spray rating and 1000+ hours ASTM D2247 humidity resistance, this protective finish will stay in place and

do the job.

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #81.30

Page 6

TorqPlus Electric Actuators

TM

Torque 100 IN/LB

The Engineered Solution

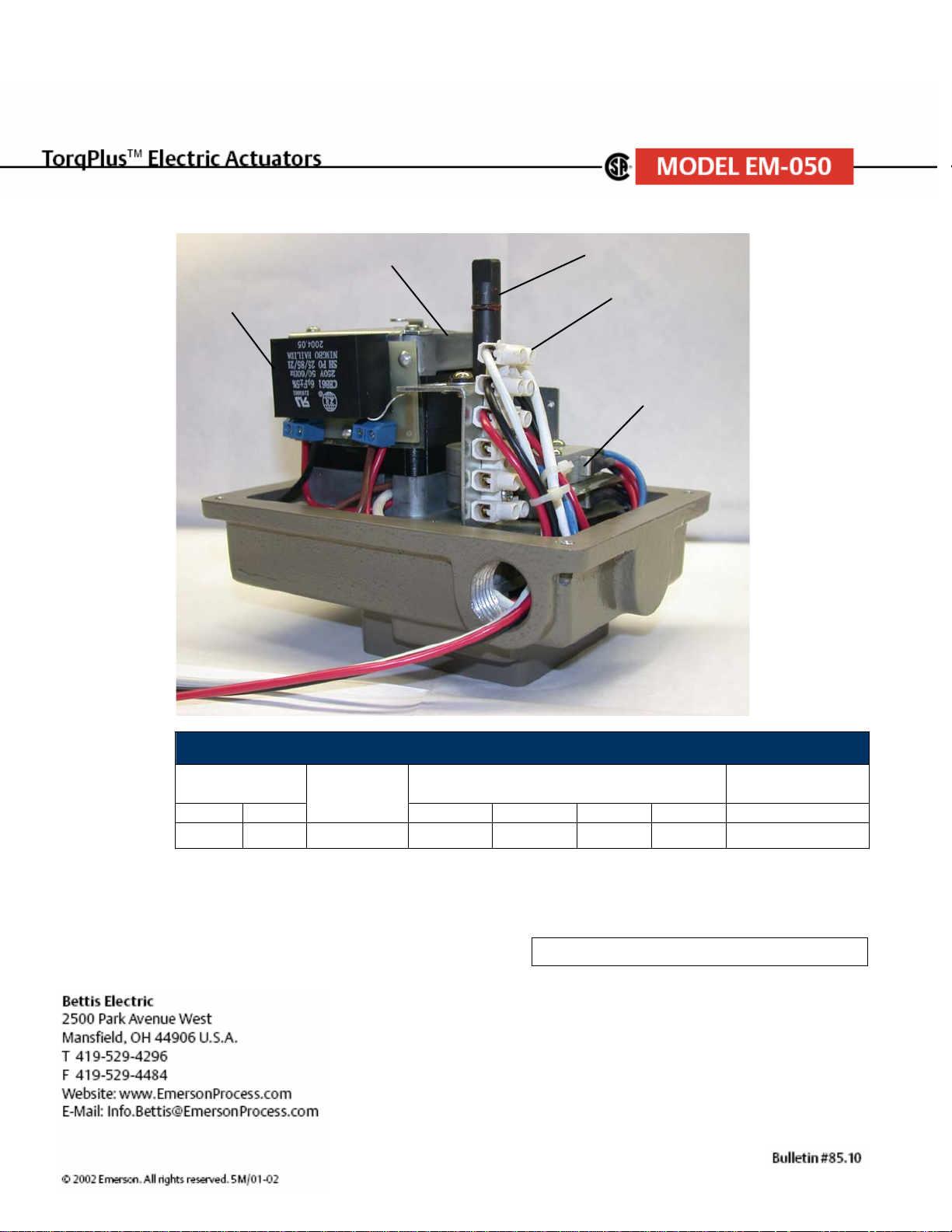

MODEL EM-050

Bettis TorqPlus quality line of electric actuators are

designed for quarter turn applications — ball, butterfly

and plug valves; dampers; vents and similar uses.

TorqPlus actuators are manufactured in a wide range of

guaranteed output torques and operating speeds to fit

your specific requirements.

The Model EM-050 actuators offer compactness with a

rugged design to develop maximum torque in a small

package.

■ Single phase capacitor run motor with thermal

overload protection and internal motor brake

■ Enclosure designed to meet C.S.A.

specifications that conform to Nema type 1, 2, 3,

3R, 4, 4X, & 12

■ Two single pole double throw travel-stop limit

switches with adjustable cams

■ Female DIN/ISO F03 output drive sleeve and

DIN/ISO F03 bolt pattern

■ Operational in any mounting orientation

■ Weight: 5.7 lbs

■ Single 1/2-inch NPT conduit entrance

OPTIONAL FEATURES

■ Maximum of two additional single pole double

throw auxiliary limit switches

■ Heater and thermostat

■ Canadian Standards Association general purpose

for electrical certification available under file

#LR90062

STANDARD FEATURES

■ Two year warranty

■ Permanently lubricated gear train

■ Stainless steel output drive sleeve

■ Operating temperatures:

-40°F with heater activated, to +140° F

Page 7

Torque 100 IN/LBS

Capacitor

Motor

Output Drive

Shaft

Terminal Strip

Female DIN-ISO Mounting

MODEL EM-050 SERIES

TORQUE LOCKED ROTOR AMP

IN/LB NM

100 11 2 1/2 SEC 0.51 N/A N/A N/A 50% N/A

SPEED

90º

115VAC 220VAC 12VDC 24VDC AC DC

Full Load Amps Per CSA Tag on Actuator 0.45

MOTOR DUTY

CYCLE @ 75 º F

Page 8

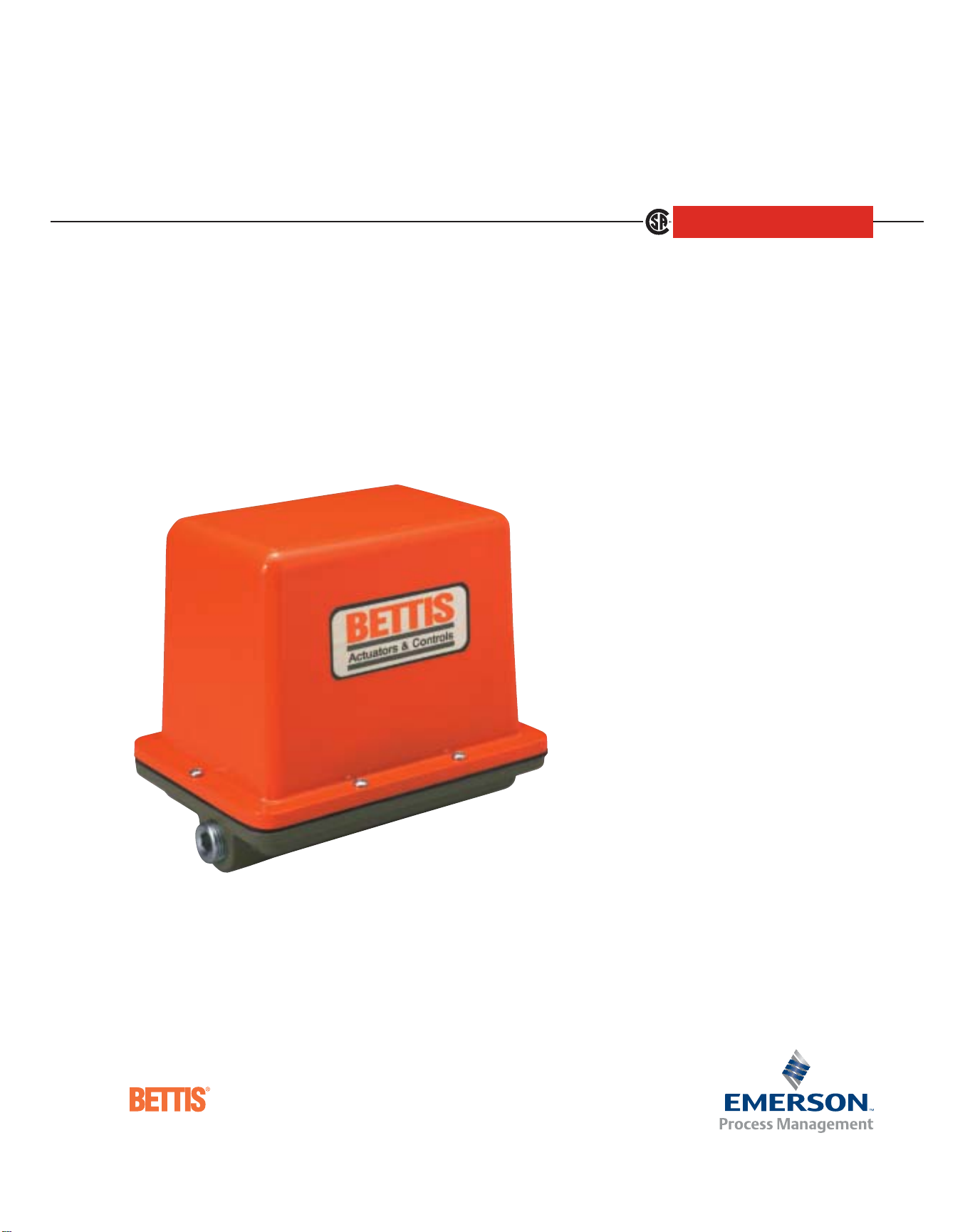

TorqPlusTMElectric Actuators

Torque 100 IN/LB – 350 IN/LB

The Engineered Solution

MODEL EM-100

Bettis TorqPlus quality line of electric actuators are

designed for quarter turn applications — ball, butterfly

and plug valves; dampers; vents and similar uses.

TorqPlus actuators are manufactured in a wide range of

guaranteed output torques and operating speeds to fit

your specific requirements.

The Model EM-100 actuators offer compactness with a

rugged design to develop maximum torque in a small

package.

■ Single phase capacitor run motor with thermal

overload protection and internal motor brake for

250 in/lb and 350 in/lb models

■ Enclosure certified to weatherproof C.S.A.

specifications that conform to Nema type 1, 2, 3,

3R, 4, 4X, & 12

■ Two single pole double throw travel-stop limit

switches with adjustable cams

■ Female DIN/ISO output drive sleeve and DIN/ISO

bolt pattern

■ Operational in any mounting orientation

■ Weight: 5 lbs

■ Single 1/2-inch NPT conduit entrance

OPTIONAL FEATURES

■ Maximum of two additional single pole double

throw auxiliary limit switches

■ Heater and thermostat

■ Canadian Standards Association general purpose

for electrical certification available under file

#LR90062

■ Standard 1KΩ potentiometer. Other ranges

provided upon request.

■ Relay control

■ Electronic proportional positioner for 4-20 mA,

1-5 VDC, or 0-10 VDC control input and 4-20mA

output signal

■ Optional voltages

230 VAC 50/60 Hz single phase

12/24 VDC

24 VAC

STANDARD FEATURES

■ Two year warranty

■ Permanently lubricated gear train

■ Stainless steel output drive sleeve

■ Operating temperatures:

-40°F with heater activated, to +140° F

■ Unidirectional motor with thermal overload pro-

tection and mechanical brake for 100 in/lb model

Page 9

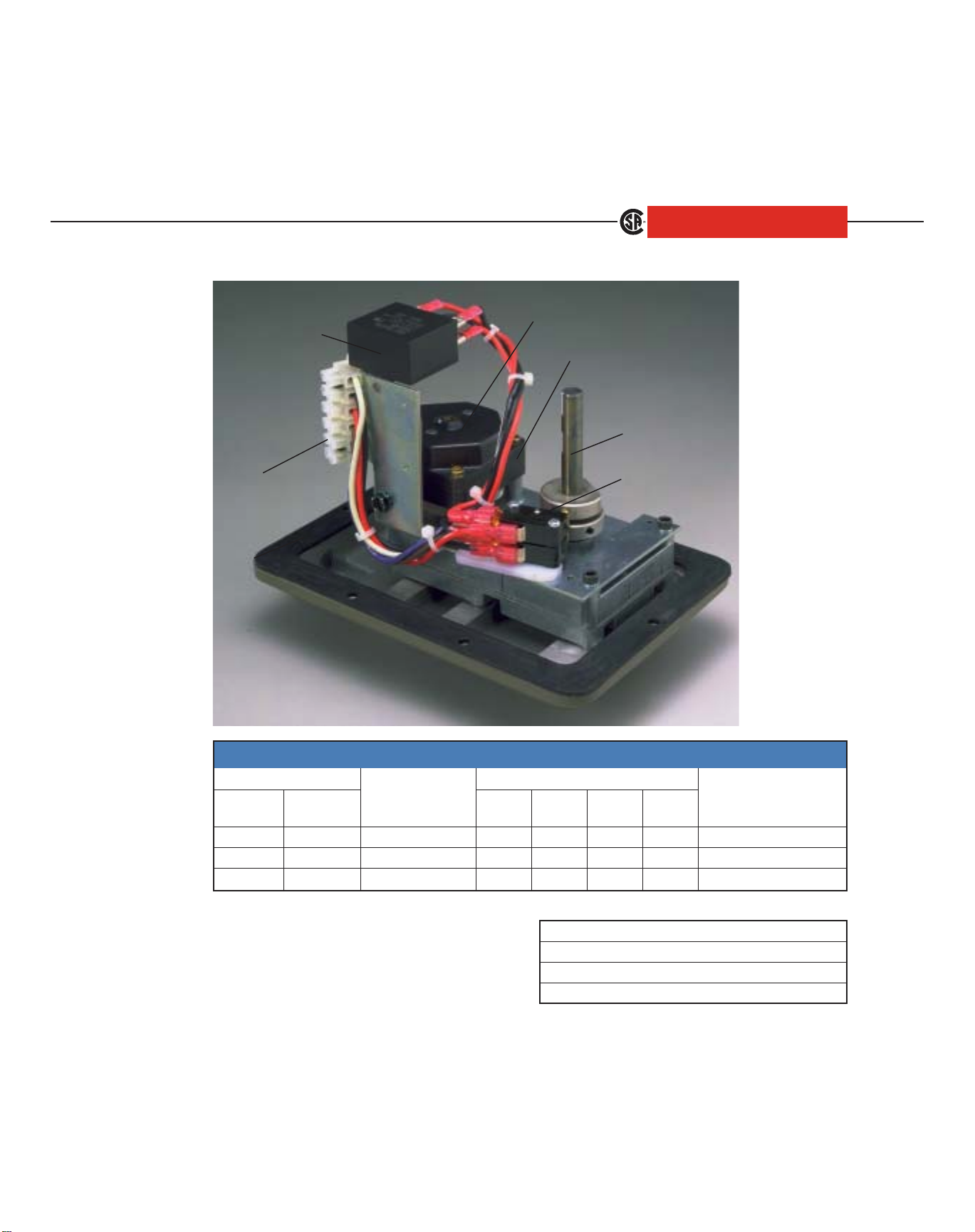

TorqPlusTMElectric Actuators

Torque 100 IN/LB – 350 IN/LB

Capacitor

MODEL EM-100

Brake

Motor

Output Drive

Shaft

Terminal

Limit Switch

Strip

Female DIN-ISO Mounting

MODEL EM-100 SERIES

TORQU E

IN/lB NM 90° 115VAC 220VAC 12VDC 24VDC

100 11 2 SEC 1.30 CF* N/A N/A 30% N/A

250 28 10 SEC 0.70 CF* .70 1.40 30% 100%

350 39 13 SEC 0.70 CF* N/A N/A 30% N/A

* Consult factory for 230VAC locked rotor current.

SPEED

LOCKED ROTOR AMP

MOTOR DUTY

CYCLE @ 75°F

AC DC

Model # Mounting Bolt Circle Drive Sleeve

133 F03 F03

144 F04 F04

Bettis Electric

2500 Park Avenue West

Mansfield, OH 44906 U.S.A.

T 419-529-4296

F 419-529-4484

Website: www.EmersonProcess.com/Bettis

E-Mail: Info.Bettis.Electric@EmersonProcess.com

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #85.10

155 F05 F05

Page 10

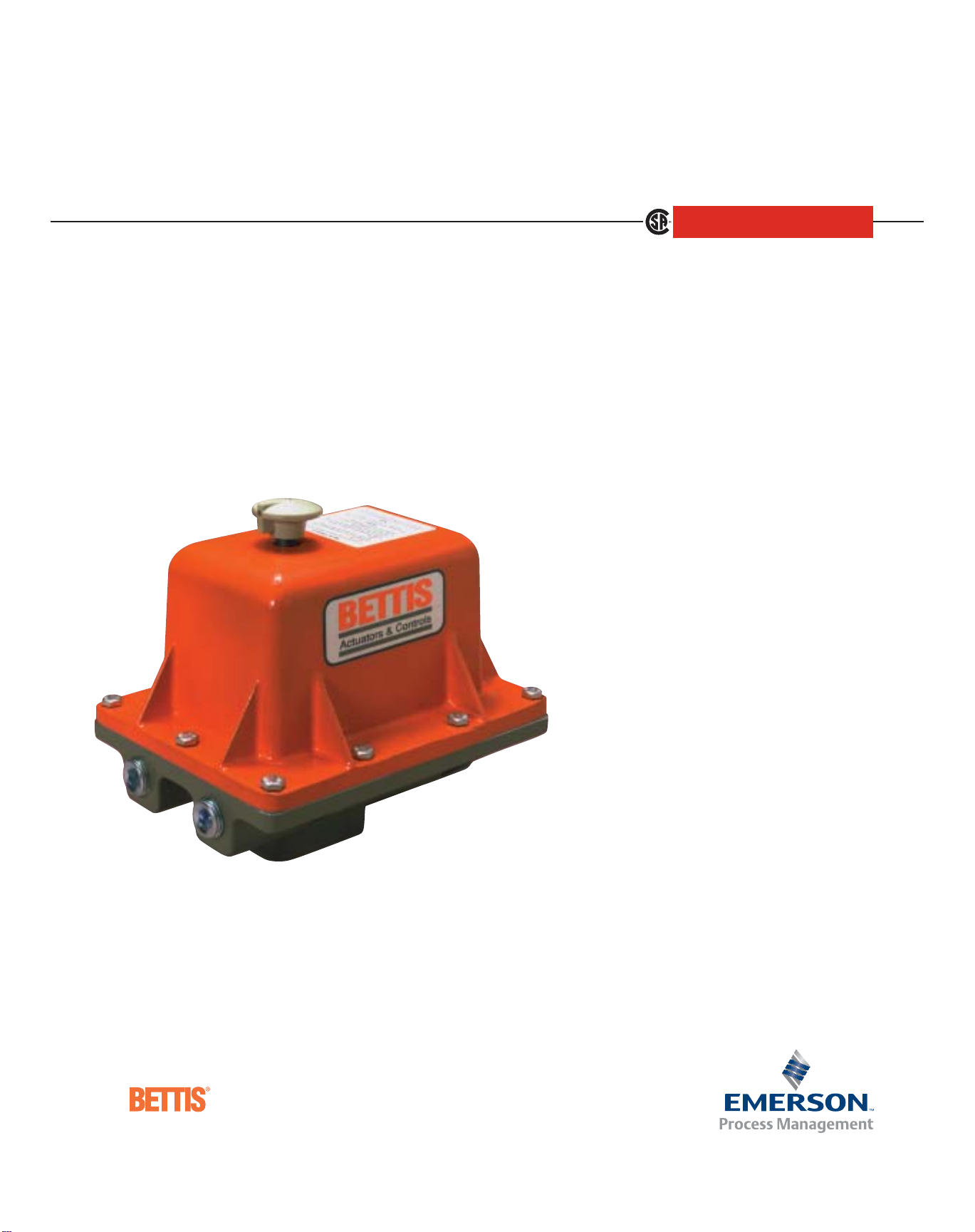

TorqPlusTMElectric Actuators

Torque 150 IN/LB – 600 IN/LB

The Engineered Solution

MODEL EM-300

Bettis TorqPlus quality line of electric actuators are

designed for quarter turn applications — ball, butterfly

and plug valves; dampers; vents and similar uses.

TorqPlus actuators are manufactured in a wide range of

guaranteed output torques and operating speeds to fit

your specific requirements.

The Model EM-300 actuators combine compactness

with manual override capability and an extensive array

of available options for a broad spectrum of applications.

STANDARD FEATURES

■ Two year warranty

■ Heater and thermostat installed in all actuators

■ Case hardened steel spur gear train is permanently

lubricated

■ Hardened steel drive shaft

■ Female DIN/ISO F04 output drive and bolt pattern

or male output drive

■ Operating temperatures:

-40° F with standard heater activated to +140° F

■ Single phase capacitor run motor with thermal

overload protection

■ Internal motor brake on 4 and 10 second units

■ Enclosure certified to weatherproof C.S.A. specifi-

cations that conform to NEMA type 1, 2, 3,

3R, 4, 4X & 12

■ Two single pole double throw travel-stop limit

switches with adjustable cams

■ Declutchable manual override with position

indicator

■ Dual 1/2-inch NPT conduit entrance

■ Operational in any mounting orientation.

■ Weight: 11 to 12 lbs

OPTIONAL FEATURES

■ 75% or 100% extended duty cycle motors

■ Electromechanical brake for 15 second and 30

second units

■ Standard 1KΩ potentiometer. Other ranges pro-

vided upon request.

■ Relay control

■ Electronic proportional positioner for 4-20 mA,

1-5 VDC, or 0-10 VDC control input and 4-20mA

output signal

■ Optional voltages

230 VAC 50/60 Hz single phase

12/24 VDC

24 VAC

■ Maximum of four additional auxiliary single

pole double throw auxiliary limit switches with

adjustable cams.

■ Handwheel

■ Canadian Standards Association general purpose

for electrical certification available under file

#LR90062

■ Dual purpose weatherproof and explosion-proof

enclosures are certified by Canadian Standards

Association for services: Class I Groups C,D,

Division I; Class II Groups E,F,G Division I that

conform to NEMA type 7 and 9

Page 11

TorqPlusTMElectric Actuators

Torque 150 IN/LB – 600 IN/LB

Output

Drive shaft

MODEL EM-300

Position Indicator

Motor and Brake

Terminal

Strip

Heater

O-Ring Seal

Capacitor

Tra vel -St op

Dual Conduit

Limit Switches

Connection

MODEL EM-300 SERIES

TORQU E

IN/IB NM 90° 115VAC 230VAC 12VDC 24VDC

150 17 4 SEC 300-04 0.57* 0.29 1.2A 2.5A **30% 100%

300 34 10 SEC 300-10 0.57* 0.29 1.2A 2.5A **30% 100%

400 45 15 SEC 300-15 0.56* 0.25 1.2A 2.5A **30% 100%

600 68 30 SEC 300-30 0.56* 0.25 1.2A 2.5A **30% 100%

* Locked rotor current for all 75% and 100% duty cycle motors is 0.50 amp

SPEED MODEL

LOCKED ROTOR AMP MOTOR DUTY

CYCLE @ 75°F

AC DC

**75% and 100% duty cycle motors are available for 115 VAC service

Bettis Electric

2500 Park Avenue West

Mansfield, OH 44906 U.S.A.

T 419-529-4296

F 419-529-4484

Website: www.EmersonProcess.com/Bettis

E-Mail: Info.Bettis.Electric@EmersonProcess.com

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #82.10

Page 12

TorqPlusTMElectric Actuators

Torque 350 IN/LB – 1600 IN/LB

The Engineered Solution

MODEL EM-500

Bettis TorqPlus quality line of electric actuators are

designed for quarter turn applications — ball, butterfly

and plug valves; dampers; vents and similar uses.

TorqPlus actuators are manufactured in a wide range

of guaranteed output torques and operating speeds to

fit your specific requirements.

The Model EM-500 Series are designed for the entire

mid-range of torques and operating speeds, with a

rugged versatility that is hard to beat.

STANDARD FEATURES

■ Two year warranty

■ Heater and thermostat installed in all actuators

■ Hardened steel spur gear train is permanently

lubricated

■ Hardened steel drive shaft

■ Female DIN/ISO F07 output drive and F07/F10

bolt pattern or male output drive

■ Operating temperatures:

-40° F with standard heater activated, to +140° F

■ Single phase capacitor run motor with thermal

overload protection

■ Enclosure certified to weatherproof C.S.A.

specifications that conform to NEMA type 1, 2, 3,

3R, 4, 4X and 12

■ Declutchable manual override with position

indicator

■ Dual 1/2-inch NPT machined conduit entrances

■ Captive hex bolts on enclosure

■ Operational in any mounting orientation

■ Two single pole double throw end of travel stop

limit switches with adjustable cams

■ Weight: 17 to 18 lbs

OPTIONAL FEATURES

■ Electromechanical brake

■ Standard 1KΩ potentiometer, other ranges pro-

vided upon request

■ Electronic proportional positioner for 4-20mA, 1-

5 VDC, or 0-10 VDC control input, and

4-20mA output signal

■ Relay control

■ Optional voltages

220 VAC 50/60 Hz single phase

12/24 VDC

24 VAC

■ Maximum of four additional single pole double

throw auxiliary limit switches with adjustable cams

■ Handwheel

■ Dual purpose weatherproof and explosion-proof

enclosures are certified by Canadian Standards

Association for services: Class I Groups C,D,

Division I; Class II Groups E,F,G Division I that

conform to NEMA type 7 and 9

■ Canadian Standards Association general purpose

for electrical certification available under file

#LR90062

Page 13

TorqPlusTMElectric Actuators

Torque 350 IN/LB – 1600 IN/LB

MODEL EM-500

Motor

Terminal

Strips

Capacitor

Dual Conduit

Connections

Brake

Tra vel -St op

Limit Switch

Position Indicator

Output

Drive Shaft

Potentionmeter

Electronic

Proportional

Positioner

O-Ring Seal

*Heater and Thermostat not shown.

MODEL EM-500 SERIES

TORQU E

IN/IB NM 90° 115VAC 230VAC 12VDC 24VDC

350 39 5 SEC 500-05 0.69 0.36 4.3 5.0 100% 100%

700 79 10 SEC 500-10 0.69 0.36 4.3 5.0 100% 100%

1000 113 15 SEC 500-15 0.69 0.36 4.3 5.0 100% 100%

1600 181 30 SEC 500-30 0.35 0.45 4.3 5.0 100% 100%

325 36 2 SEC 510-02 1.57 0.80 4.3 8.5 100% 100%

600 68 5 SEC 510-05 1.57 0.80 4.3 8.5 100% 100%

1000 113 7 SEC 510-07 1.57 0.80 4.3 8.5 100% 100%

180 20 5 SEC 520-05 0.57 0.29 1.2 2.5 30% 100%

450 51 10 SEC 520-10 0.57 0.29 1.2 2.5 30% 100%

600 68 15 SEC 520-15 0.57 0.29 1.2 2.5 30% 100%

1000 113 30 SEC 520-30 0.57 0.29 1.2 2.5 30% 100%

Bettis Electric Mansfield, OH U.S.A. T 419-529-4296 Website: www.EmersonProcess.com/Bettis

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #86.10

SPEED MODEL

LOCKED ROTOR AMP MOTOR DUTY

CYCLE @ 75°F

AC DC

Page 14

TorqPlusTMElectric Actuators

Torque 2,000 IN/LB – 20,000 IN/LB

The Engineered Solution

MODEL EM-800

Bettis TorqPlus quality line of electric actuators are

designed for quarter turn applications — ball, butterfly

and plug valves; dampers; vents and similar uses.

TorqPlus actuators are manufactured in a wide range of

guaranteed output torques and operating speeds to fit

your specific requirements.

The EM-800 Series utilizes a highly effective planetary

gearing system and a handwheel manual override to

produce maximum torques in a compact package.

STANDARD FEATURES

■ Two year warranty

■ Heater and thermostat installed in all actuators

■ Case hardened steel spur gear train is permanent-

ly lubricated

■ Operating temperatures:

-40° F with standard heater activated, to +140° F

■ Single phase capacitor run motor with thermal

overload protection

■ Enclosure certified to weatherproof C.S.A.

specifications that conform to NEMA type 1, 2,

3,3R, 4 and 12

■ Handwheel manual operation

■ Mechanical position indicator

■ Captive hex bolts on enclosure

■ Dual 3/4-inch NPT machined conduit entrances

■ Two single pole double throw travel-stop limit

switches with adjustable cams and 2 aux S.P.D.T.

■ Female drive

■ Weight: 65-70 lbs (type 4), 150-160 lbs

(explosion-proof)

■ Two mechanical torque limit switches

OPTIONAL FEATURES

■ Dual purpose weatherproof and explosion-proof

enclosures are certified by Canadian Standards

Association for services: Class I Groups C,D,

Division I; Class II Groups E,F,G Division I that

conform to NEMA type 7 and 9

■ Standard 1K potentiometer, other ranges provid-

ed upon request

■ Electronic proportional positioner for 4-20 mA,

1-5 vDC, or 0-10 vDC control input and 4-20mA

output signal

■ Optional voltages

220 VAC 50/60 Hz single phase

220 VAC 50/60 Hz 3 phase

■ Relay control

■ Maximum of four additional single pole double

throw auxiliary limit switches with adjustable cams

■ Electromechanical brake

■ Canadian Standards Association general purpose

for electrical certification available under file

#LR90062

Page 15

TorqPlusTMElectric Actuators

Torque 2,000 IN/LB – 20,000 IN/LB

MODEL EM-800

Position Indicator

Terminal Strips

Tra vel -St op

Limit

Switches

Dual Conduit

Connections

Planetary

Gearing System

BrakeHeater

Motor

Capacitor

To rqu e

Limit Switches

O-Ring Seal

Direct

Acting

Manual

Override

Electronic

Proportional

Positioner

MODEL EM-800 SERIES

TORQUE SPEED MODEL LOCKED ROTOR AMP MOTOR DUTY

IN/IB NM 90° 115VAC 230VAC CYCLE @ 75°F

2000 226 12 SEC 810-12 3.15 1.3 100%

2500 282 18 SEC 810-18 3.15 1.3 100%

3500 395 30 SEC 810-30 3.15 1.3 100%

4000 452 60 SEC 810-60 3.15 1.3 100%

3000 338 12 SEC 820-12 3.15 1.3 100%

4000 452 18 SEC 820-18 3.15 1.3 100%

6000 678 30 SEC 820-30 3.15 1.3 100%

7000 791 60 SEC 820-60 3.15 1.3 100%

5000 565 12 SEC 830-12 5.97 2.81 100%

7000 791 18 SEC 830-18 5.97 2.81 100%

10000 1130 30 SEC 830-30 5.97 2.81 100%

10000 1130 60 SEC 830-60 5.97 2.81 100%

15000 1695 48 SEC 840-48 5.97 2.81 100%

20000 2260 72 SEC 840-72 5.97 2.81 100%

Bettis Electric Mansfield, OH U.S.A. T 419-529-4296 Website: www.EmersonProcess.com/Bettis

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #84.10

Page 16

TorqPlusTMElectric Actuators

Torque 300 IN/LB – 1,600 IN/LB

MODEL EM-SR5

The Engineered Solution

Bettis TorqPlus has taken the lead in offering compact,

cost effective Spring Return Electric Actuator Packages.

Three models offer a variety of solutions when one needs

to protect a system upon loss of power. These actuators

have been designed for dampers, small

butterfly, ball and plug valves.

The Model EM-SR5 Series

is designed for use in

environments where auto-

matic closing/opening

is required upon loss of

power, with a rugged

versatility that is hard

to beat.

When power is

available, the

device operates like

a normal quarter turn,

open/close or modulating

actuator. Under powered operation, the spring pack travels with

the movement of the actuator.

Under powered stopped

conditions, the actuator and

spring are held in position

via the electric mechanical

brake. Upon loss of power, the

spring is released and drives

actuator to the predesignated

failsafe position. The failsafe

positioning can be provided for

either the CCW limit or to the

CW limit.

the

STANDARD FEATURES

■ Two year warranty

■ Heater and thermostat

■ Case hardened steel spur gear train is

permanently lubricated

■ Operating temperatures:

-40° F, with standard heater activated, to +140° F

■

Thermally protected permanent split capacitor motor

■ Electromechanical brake

■ CW or CCW spring return

■ Dual 1/2-inch NPT conduit entrances

■ Captive hex bolts on enclosure

■ Operational in any mounting orientation

■

Limit switches with independent end of travel cams

■ Male output drive on all models or female

DIN/ISO F04 or F05 output drive on 10, 15 and 30

second models

■

Adjustable mechanical stop at the fail safe position

■ Visual position indicator

■ Enclosure certified to weatherproof C.S.A. specifi-

cations that conform to NEMA type 1, 2, 3, 3R, 4,

4X and 12

OPTIONAL FEATURES

■ Modulating service (separate enclosure)

■ Standard 1KΩ potentiometer, other ranges

provided upon request

■ Optional 220 VAC 50/60 Hz motor

■ Up to four auxiliary switches with adjustable cams

■

Canadian Standard Association general purpose for

electrical certification available under file #LR90062

■ Dual purpose weatherproof and explosion-proof

enclosures are certified by Canadian Standards

Association for services: Class I Groups C,D,

Division I; Class II Groups E,F,G Division I that

conform to NEMA type 7 and 9

MODEL EM-SR5 SERIES

To rq ue To rq ue

(against spring) (with spring) Speed (sec/90°) Motor Ratings

Model in/lb nm in/lb nm Motor Spring LRA FLA

Duty Cycle

SR5-10 300 34 350 40 10 4 0.69 0.34 100% 28-30

SR5-15 400 45 450 51 15 5 0.69 0.34 100% 28-30

SR5-30 600 68 700 79 30 6 0.35 0.30 100% 36-38

SR5-90 1600 181 1400 158 90 25 0.35 0.30 100% 138

Weight

(lbs)

Page 17

TorqPlusTMElectric Actuators

Torque 300 IN/LB – 1,400 IN/LB

MODEL EM-SR5

Brake

Motor

Terminal

Strip

Capacitor

Dual Conduit

Connections

DIN-ISO Mounting/

Female Drive

Position Indicator

Output

Drive Shaft

Heater &

Thermostat

O-Ring Seal

Limit Switch

Adjustable

Spring Stop

EM-SR5-90 with

Gear Reduction Box

Bettis Electric Mansfield, OH U.S.A. T 419-529-4296 Website: www.EmersonProcess.com/Bettis

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #88.10

Page 18

Assembly Layout Drawings

7 1/2

TALL COVER

MODEL EM-050

5.00 CLEARANCE

FOR COVER REMOVAL

6 3/4

1.002

5 1/2

2 3/16

501

F03 MOUNTING WITH

F03 DRIVE SLEEVE

.359

X .44 DEEP (TYP.)

.354

.561

X .63 DEEP (TYP.)

.556

SHORT COVER

#10-24 TAP - .35 DEEP

(4) HOLES ON 1.42 DIA. BOLT CIRCLE

ACROSS CORNERS MIN.

.476

2 1/4

5 1/4

1.169

.585

#10-24 TAP - .35 DEEP

(4) HOLES ON 1.65 DIA. BOLT CIRCLE

7/8

1 5/8

.443

X .51 DEEP (TYP.)

.438

.554

ACROSS CORNERS MIN.

F04 MOUNTING WITH

F04 DRIVE SLEEVE

#8-32 PHIL.

PAN HEAD

(6) PLACES

1/2-14 NPT

CONDU T ENTRY

I

SUPPLIED WITH

PLUG

1.392

.696

F05 MOUNTING WITH

F05 DRIVE SLEEVE

1/4-20 TAP - .35 DEEP

(4) HOLES ON 1.97 DIA. BOLT CIRCLE

.713

ACROSS CORNERS MIN.

Page 19

Assembly Layout Drawings

7 1/2

TALL COVER

MODEL EM-100

5.00 CLEARANCE

FOR COVER REMOVAL

6 3/4

1.002

5 1/2

2 3/16

501

F03 MOUNTING WITH

F03 DRIVE SLEEVE

.359

X .44 DEEP (TYP.)

.354

.561

X .63 DEEP (TYP.)

.556

SHORT COVER

#10-24 TAP - .35 DEEP

(4) HOLES ON 1.42 DIA. BOLT CIRCLE

ACROSS CORNERS MIN.

.476

2 1/4

5 1/4

1.169

.585

#10-24 TAP - .35 DEEP

(4) HOLES ON 1.65 DIA. BOLT CIRCLE

7/8

1 5/8

.443

X .51 DEEP (TYP.)

.438

.554

ACROSS CORNERS MIN.

F04 MOUNTING WITH

F04 DRIVE SLEEVE

#8-32 PHIL.

PAN HEAD

(6) PLACES

1/2-14 NPT

CONDUIT ENTRY

SUPPLIED WITH

PLUG

1.392

.696

F05 MOUNTING WITH

F05 DRIVE SLEEVE

1/4-20 TAP - .35 DEEP

(4) HOLES ON 1.97 DIA. BOLT CIRCLE

.713

ACROSS CORNERS MIN.

Page 20

TorqPlusTMElectric Actuators

MODEL EM-300

EM-310

EM-320

8 1/4

5" MIN. CLEARANCE FOR

COVER REMOVAL

1/2-14 NPT

CONDUIT ENTRY

WITH (2) PIPE

PLUGS SUPPLIED

7 1/2

6 13/32

1 1/2

3

1 1/4

3 1/8

6 1/4

OPEN/CLOSE INDICATOR

.461 ACROSS FLATS

1/2

.44

OPTIONAL MALE OUTPUT

1.168

DIN/ISO F04 FLANGE

F04 DIN/ISO FEMALE DRIVE

TYP.

.584

TYP.

10-24 TAP X 1/2 DEEP

(4) HOLES ON 1.65 DIA. BOLT CIRCLE

45°

.437

SQ. X .50 DEEP (TYP.)

.433

.585 ACROSS CORNERS MIN.

1.500

.750

SQ.

FLANGE DIMENSIONS

WITH MALE OUTPUT

.281

.279

10-24 TAP - .50 DEEP

(4) HOLES

45°

CENTERED

FLATS

DIA.

.456

Bettis Electric

2500 Park Avenue West, Mansfield, OH 44906 U.S.A. T 419-529-4296 F 419-529-4484

Website: www.EmersonProcess.com/Bettis E-Mail: Info.Bettis.Electric@EmersonProcess.com

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #85.15

Page 21

Assembly Layout Drawings

1/2-14 NPT

CONDU IT

ITH

ENTRY W

(2) PIPE

PLUGS

SUPPLIED

2 7/16

1 5/8

6" MIN. CLEARANCE FOR

COVER REMOVAL

1/4-20 S.S. CAPTIVE HEX

SLOTTED SCREW (8 TOTAL)

8

9 7/16

MODEL EM-500

EM-510

EM-520

OPEN/CLOSE

INDICATOR

1 5/8 2 1/2 3 3/4

9 3/4

F07/F10 DIN/ISO FLANGE

F07 DIN/ISO FEMALE DRIVE

5/16-18 TAP .50 DEEP

(4) HOLES EQ. SPACED

ON A 2.76 DIA. B.C.

(F07 FLANGE MOUNTING

PER DIN/ISO)

2.839 TYP

1.419 TYP

3/8-16 TAP - .60 DEEP

(4) HOLES EQ. SPACED

ON A 4.02 DIA. B.C.

(F10 FLANGE MOUNTING PER DIN/ISO)

1.943

.969

.90

OPTIONAL

MALE OUTPUT

45

°

TYP

.669

SQ. TYP.

.673

.75 DEEP

.920

ACROSS CORNERS

MIN.

5/16-18 TAP - .50 DEEP

(4) HOLES

2.250 TYP

1.125 TYP

#10-24 TAP - .50 DEEP

(4) HOLES

.626

.624

7 3/4

FLANGE DIMENSIONS

WITH MALE OUTPUTS

3 7/8

.750 TYP

1.500 TYP

1.03

.875 DIA

Page 22

TorqPlusTMElectric Actuators

13 5/16

15 3/8

MODEL EM-810

EM-820

EM-830

8" CLEARANCE FOR

COVER REMOVAL

14

2 11/16

4 1/2

3/4-14 NPT

STANDARD

CONDUIT ENTRY

3/8-16 TAP X 3/4 DEEP

4-HOLES AS SHOWN

ON 3.250 DIA. B.C.

1.385/1.378 DIA.

X 1-3/4 DEEP

2 3/4

5 1/2

.254

X 1-1/2 DEEP

.250

2-PLACES

1/2-13 TAP X 7/8 DEEP

4-HOLES AS SHOWN

ON 5.000 DIA. B.C.

1.503

1.498

2-PLACES

Bettis Electric

2500 Park Avenue West, Mansfield, OH 44906 U.S.A. T 419-529-4296 F 419-529-4484

Website: www.EmersonProcess.com/Bettis E-Mail: Info.Bettis.Electric@EmersonProcess.com

3 7/8

9 11/16

14

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #84.15

Page 23

Assembly Layout Drawings

13 5/16

7 5/8

BEVEL GEAR ACTUATOR

MODEL EM-840

3/4 NPT CONDUIT

ENTRANCES

DYNATORQ UE

BG4

31 3/8

25 7/8

POSITION

INDICATOR

7 1/2

1/2-13 TAPPED 3/4 DEEP

8 HOLES ON 7.625 DIA. B.C.

14

SHAFT NOTE: STANDARD OR MACHINED

TO CUSTOMER REQUIREMENTS.

Page 24

TorqPlusTMElectric Actuators

MODEL EM-SR5-10

EM-SR5-15

15 3/8

8 3/8

4 1/8 3 3/4

1 5/8

1 5/8

2.75 DIA.

1.170

.585

9 3/4

SEE NOTE 1

1/2 NPT

CONDUIT

ENTRANCES

SPRING RETURN

PACK

F04 OUTPUT ADAPTER

F04 FEMALE OUTPUT

DRIVE

1/4-20 X .50 TAP

(4) HOLES ON 1.650 DIA. BOLT CIRCLE

13 13/16

.79

7 3/4

POSITION

INDICATOR

CLOCKWISE SPRING

RETURN MECHANICAL STOP

COUNTER CLOCKWISE SPRING

RETURN MECHANICAL STOP

MALE OUTPUT DRIVE

.630 SQUARE

2.50 DIA.

1.414

.585

1.170

FEMALE F04 OUTPUT MOUNTING

.556 ACROSS CORNERS MIN.

.437

SQUARE X .50 DEEP

.433

F04 OUTPUT DRIVE VIEW

.746 DIA.

.707

1.414

MALE OUTPUT MOUNTING

NOTE:

1) ADD 4.75 TO OVERALL DIMENSION FOR COVER REMOVAL

.707

5/16-24 X .63 TAP

(4) HOLES ON 2.000 DIA. BOLT CIRCLE

Bettis Electric

2500 Park Avenue West, Mansfield, OH 44906 U.S.A. T 419-529-4296 F 419-529-4484

Website: www.EmersonProcess.com/Bettis E-Mail: Info.Bettis.Electric@EmersonProcess.com

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #85.15

Page 25

Assembly Layout Drawings

MODEL EM-SR5-30

6 1/8

9 1/8

1 15/16

1.63

1.392

9 3/4

3.50 DIA.

.696

.696

1.392

FEMALE F05 OUTPUT MOUNTING

3 3/44 1/8

1/2 NPT

CONDUI T

ENTRANCES

SPRING RETURN

PACK

F05 OUTPUT ADAPTER

F05 FEMALE OUTPUT

DRIVE

1/4-20 X .50 TAP

(4) HOLES ON 1.968 DIA. BOLT CIRCLE

.713 ACROSS CORNERS MIN.

SEE NOTE 1

14 3/16

1.02

7 15/16

.958 DIA.

MALE OUTPUT MOUNTING

1.810

.905

CLOCKWISE SPRING

RETURN MECHANICAL STOP

COUNTER CLOCKWISE SPRING

RETURN MECHANICAL STOP

MALE OUTPUT DRIVE

.748 SQUARE

3.25 DIA.

1.810

.905

3/8-24 X .79 TAP

(4) HOLES ON 2.556 DIA. BOLT CIRCLE

POSITION

INDICATOR

F05 OUTPUT DRIVE

.561

SQUARE .63 DEEP

.556

NOTE:

1) ADD 4.75 TO OVERALL DIMENSION FOR COVER REMOVAL

Page 26

TorqPlusTMElectric Actuators

10 3/16

MODEL EM-SR5-90

DT BG3

1/2-20 TAPPED .87 DEEP

4 HOLES ON 3.06 DIA. B.C.

2 5/32

1 5/64

.984

SQ

1/2 NPT CONDUIT

ENTRANCES

1 1/4

1 5/64

2 5/32

MALE OUTPUT

DRIVE

SPRING RETURN

MECHANICAL STOP

SPRING RETURN PACK

12 9/16

POSITION INDICATOR

17

22 1/2

NOTE:

1) ADD 4.75 TO OVERALL

FOR COVER REMOVAL

BEVEL GEAR ACTUATOR

Bettis Electric

2500 Park Avenue West, Mansfield, OH 44906 U.S.A. T 419-529-4296 F 419-529-4484

Website: www.EmersonProcess.com/Bettis E-Mail: Info.Bettis.Electric@EmersonProcess.com

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #85.15

Page 27

INQUIRIES

Your inquiries for Bettis electric actuators can be processed efficiently when supplied with the information requested on this page.

Please use this page as a guide or submittal. If you need assistance, just ask your Bettis sales representative.

Customer Detail

Co. ________________________________________________ Job ________________________________________________

St. _________________________________________________ ___________________________________________________

City __________________________ State _______________ Item ____________ of ____________ Qty. _______________

Zip ________________________________________________ Mark /Tag ___________________________________________

Attn: _______________________________________________ ___________________________________________________

Valve Information

Mfg.: ____________________ Type: ___________________ Size: ____________________ Fig No. __________________

Rotation to CLOSE Position:

Maximum Sizing Torque, lb-in: ______________________________________________________________ (Safety factor included)

Actuator Information

Application: ■ Open-Close, 2 position, Service ■ Spring Return

■ Jogging Multi-position Service ■ Fail CW

■ Automatic Modulating Service ■ Fail CCW

Ambient Temperature: From ______________________ °F to ______________________ °F (-40°F to +140°F standard)

Nominal Operating Speed: ______________________ seconds per 90° (min-max range)

Motor Voltage: ______________________ Ph/___________ Hz/___________ VAC or VDC ______________________

Control Voltage: 1Ph/ ______________________ Hz/ ______________________ VAC (3-phase motor only)

Motor Duty Cycle:

Total Number of Limit Switches: ______________________

Enclosure:

■ 30% or ■ 100%

■ Type 4 CSA Certified for: non-hazardous indoor and outdoor locations to protect against wind-blown dust and rain,

splashing water and hose-directed water.

■ Type 4 and 7 CSA Certified for: hazardous and non-hazardous indoor and outdoor locations to protect against

wind-blown dust and rain, splashing water and hose-directed water plus locations classified as Class I and II, Groups

C, D, E, F and G as defined in the National Electrical Code.

Integral Control Items (as required)

■ Motor Brake (standard on EM-100 in 1Ph/60Hz/115VAC and all 800-Series with torques of 6,000 lb-in or greater)

■ Multi-Turn Control: Set for ______________________ output turns (maximum of 30)

■ Heater and Thermostat: 1Ph/ ______________________ Hz/ ______________________ VAC

■ Three Position Operation: Set for ______________________ °/ ______________________ °/ ______________________ ° Stops

■ Control Relay for: ■ normally clockwise or ■ normally counterclockwise

operation and operating on

■ Single Feedback Potentiometer: ______________________ Ohm/4 Watt

■ Electronic Positioner: with ■ 4-20mA or ■ 0-10v or ■ 1-5v input and set for minimum output at

■ Electronic Position Transmitter: 4-20 mA output set for minimum output at ■ clockwise or ■ counterclockwise position

Separate Controls (as required)

■ Manual Operating Station: ■ Type 4 or ■ Type 7 enclosure suitable for ■ wall mounting or ■ close coupling

■ 1Ph/ ______________________ Hz/ ______________________ VAC to include:

■ (_________) __________ Position Selector Switch marked __________ / __________ / __________

■ (_________) Push Buttons marked ______________ / ______________ / ______________

■ (_________) Lights marked and colored ___________-___________ /___________-___________ / ___________-___________

■ (_________) Reversing Starter with 1 Ph/ ______________________ Hz/ ______________________ VAC control voltage

■ Other ______________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

■ Clockwise ■ Counterclockwise as viewed from above (Std. is CW)

■ 1Ph/______________________Hz/ ______________ VAC or ■ ______________ VDC

■ clockwise or ■ counterclockwise position

Page 28

All Bettis TorqPlus Electric Actuators are manufactured

with a product descriptive nameplate to insure its proper

application and continuing identification. The following

represents the typical information included on the

nameplate and the meaning.

Model: Model – Operating Speed – Enclosure Type –

Motor Voltage – Configuration

Tor qu e: Rated Output Torque (lb-in)

Speed Sec 90: Seconds Per 90 Degrees Operation

Vol tag e: Motor Voltage (Ph/Hz/V)

LR Amps: Locked Rotor Amp Draw

Duty Cycle %: Effective Motor Run Capability

Serial: Individual Unit Serial Number

Mfg MM-YY: Month & Year of Unit Manufacturer

Enclosure: Rated Enclosure Type

PRODUCT IDENTIFICATION

A.C. – Alternating current/voltage flowing in both

directions alternately.

Amphere (Amp) – The unit of electric current, defined

in terms of the force between a pair of wires.

Auxiliary Switch – A switch used to energize or

de-energize other equipment (such as lights or pumps).

Supplied with its own cam to synchronize other equipment

at any point of travel.

Capacitor – A device having the property of storing an

electrical charge.

CSA – Canadian Standards Association

D.C. – Direct current/voltage which has a constant value rated

to zero. Steady current in one direction.

Duty Cycle – A mathematical calculation, expressed as a

percent, to indicate available motor-on (running) time without endangering an over heating condition which would

terminate actuator operation.

Using an actuator with a 10 seconds/90° operating speed

and rated for a 50% duty cycle as an example, safe, noninterrupting operational periods would be: One 10 second

motor-on period followed by one 10 second motor-off

period. Total calculation time is 20 seconds of which 50% is

motor-on time.

Proper application of the duty cycle rating allows ample

time for the motor to dissipate internal heat and thereby

not cause a thermal overload cutoff.

Enclosure – The housing that surrounds the actuator’s operat-

ing parts. It can either be weatherproof or explosion proof.

The enclosure generally protects the electrical equipment

from the environment and/or prevents an explosion within

the enclosure from causing an external explosion.

Hertz – Unit of frequency. Equal to one cycle per second.

NEMA – Acronym for National Electrical Manufacturers

Association.

NEMA 4 – Rating designation for weatherproof enclosures.

Pliable gaskets are used on all metal-mating parts to prevent

moisture from entering.

NEMA 7 – Rating designation for enclosures suitable for con-

taining internal explosion without rupturing the enclosure

and without igniting surrounding gases in the atmosphere.

Metal-to-metal sealing is required in these rated products.

Ohm – International unit of electrical resistance. The resistance

in ohms between two points is defined by the DC voltage

divided by the DC current flowing between the points.

Reversing Starter – Its purpose is to connect, disconnect

and reverse electricity to the motor. Also called reversing

contractor, reversing controller or integral starter.

Torque Limit Switches –

Switches designed to monitor physical

variables or operating states and to open circuits in the

event of pre-set limits being exceeded.

Vol t – Unit of potential difference or electrical potential. It

represents the amount of work done per unit charge in

moving a charge from one place to another.

DEFINITIONS

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #81.50

Page 29

TorqPlusTMElectric Actuators

Multi-Turn Operation

Option allows for multiple revolution on non-rising

stem devices.

Electrical Mechanical Motor Brake

Available for all actuator models. Brakes are employed

to eliminate motor run-on and to insure that the

actuator and driven device maintain their position.

Recommended applications include; all resilient seated

valves, valves with high flow rates, all modulating

services and any time in which increased position

control is needed.

Three Position Control

Typically used for multiported valves, operation can be

set for 0°-45°-90° or 0°-90°-180° with a stop at mid

position from one extreme or both.

Potentiometers

Mechanically linked to the actuators output to provide

a resistance signal proportional to the actuator’s and

driven device’s position. Used to give continuous feedback to control panels, modulating position control and

other closed loop devices.

CONTROLS AND OPTIONS

Torque/Current Trip Module

(for DC Motors)

■ Protects the valve and actuator from excessive

torque conditions by comparing the motor current with a factory adjustable trip value.

■ Provides dynamic braking, in order to improve

positioning accuracy at both mid and end of travel stop points. (Caution: A mechanical brake

should also be used in conjunction with the

dynamic brake feature, for applications that

require the valve to be held in place after stopping.)

Control Latching Relay

■

Allows the actuator to run full travel upon receiving

a non-maintained control signal, ranging from

0-240VAC or 0-110VDC.

Control Relay

■ Provides a means of opening and closing a valve

with a variety of standard AC or DC maintained

control signals, such as 120 VAC, 24 VAC, 12 or

24 VDC.

■ Can be used for a fail close (or open) application

upon loss of the control signal. An internal coil

(designed to be continuously energized) maintains the open signal to the actuator. When the

signal is removed, the coil de-energizes, causing

the actuator to close.

Additional Control Options

■ Up to 6 SPDT aux. limit switches

■ Electronic Transmitters (4-20mA output from a

DC transmitter or 4-20mA, 0-10V output from

an AC transmitter)

■ Dual 1k ohm potentiometers

■ Two speed operation (pulse timer package)

■ Unidirectional controls (up to 30 rotations)

■ Control stations including buttons, lights, selector

switches

■ 3-phase motor controls

■ Three position operation (such as 0-45-90 or

0-90-180 degrees)

■ Torque seating for multi-turn and quarter turn

■ Torque switch trip indication

Page 30

CONTROL STATIONS

Control Stations are available in a variety of standard

weatherproof wall-mounted and close-coupled configurations using the following 5-digit code system:

Typical Options

Timer packages, control relays, special labeling, LED

lights, pad lockable switches, space heaters and

Canadian Underwriter Laboratory labels.

Additional options for 3-phase wall-mounted CS’s

include starters, control transformers, and overload

relays.

t 2nd 3rd 4th 5th

CS – 1s

1st indicates the number of pushbuttons

2nd indicates the number of lights

3rd indicates the number of positions on the first

selector switch (such as Local-Remote)

4th indicates the number of po

selector switch (such as Open-Stop-Close)

5th indicates close-coupled (C) or wall-mount (W)

CS-0223C would indicate 0-buttons, 2-lights, 2-position

selector switch (usually Local-Remote), 3-position

selector switch (usually Open-Stop-Close), Close-coupled

to the actuator.

Standard configurations include:

CS-0003* CS-0223* and CS-3220*

CS-0023* CS-0203*

(* C for closed-coupled or W for wall-mount)

sitions on a second

The Remote Signal Generator (RSG) (supplied in a wallmounted enclosure) produces a 4-20mA output signal,

by manually rotating the dial. From a remote location,

this output signal can then be used to position or throttle

an actuator equipped with an integral modulating

board.

The RSG can also be used in conjunction with a closedcoupled “CS” control station.

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #81.50

Page 31

TorqPlusTMElectric Actuators

The Bettis Electric C1397 and C1415 Servo Positioners

are proportional motor controllers for actuator modulating applications. The C1397 is for actuators with AC

powered split phase motors. The C1415 is for use with

12 or 24VDC powered actuators. These controls are

designed to proportionally position an actuator and the

driven device by comparison of a varying external input

command and a mechanically linked potentiometer.

Input commands can be 0-10V, 1-5V, or 4-20mA. The

servo also allows for three responses to command signal

loss (1-5V and 4-20mA only); fail in place, fail to full

clockwise (CW) position, or fail to full counterclockwise

(CCW) position.

SERVO POSITIONING SYSTEMS

Features and Benefits

Digital micro-control allows:

■ Pushbutton programming - eliminates Span and

Zero pots

■ 10-bit resolution

■ Off-line calibration - eliminates the need for

loop calibrators

Available in multiple power supply configurations:

AC 120/230V; DC 12/24V

Onboard manual jog buttons

AC controller includes speed control

DC controller includes:

■ Torque trip with relay output

■ Dynamic braking for accurate stopping

Signal Wiring

4-20mA TRANSMITTER 0-10V TRANSMITTER COMMAND POTENTIOMETER

9

8

7

6

5

SIG GND

4

3

4-20mA

2

1-5V

1

-

+

TO 4-20mA

RECEIVER

4-20mA

XMITTER

SIG GND

0-10V

-

+

TO 4-20mA

RECEIVER

4-20mA

XMITTER

9

8

7

6

5

4

3

2

1

9

8

7

6

5

4

3

2

1

GND

+5

-

+

TO 4-20mA

RECEIVER

CCW

COMMAND

POT

Page 32

SPECIFICATIONS

Power Supply

C1397S 115VAC ± 10% 50/60Hz

C1397D 230VAC ± 10% 50/60Hz

C1415 12/24VDC Jumper configurable

Signal Inputs

All signal inputs are digitized to 10 bits of resolution.

0-10 VDC Compound Input: 200kohm input impedance.

1-5 VDC Command Input: 100kohm input impedance.

Loss of signal threshold is 75% of low signal.

4-20 mA Command Input: 250ohm input impedance.

Loss of signal threshold is 75% of low signal.

Feedback Input: 5 VDC excitation voltage. 1Mohm

input impedance. Use with 1000ohm potentiometer.

4-20mA Output

300ohm maximum load impedance. 10-bit A/D.

Function Details

Motor Outputs

C1397 When mounted in accordance with guidelines

below, outputs will supply a maximum locked rotor load

current (LRA) of 5A with less than 5/10mA

(115/230VAC) of leakage current.

C1415 Continuous current 3A; Peak 5A.

External Fuses

C1397 Employ fusing per actuator motor LRA to a

maximum of 5A.

C1415 Employ fusing per actuator motor LRA to a

maximum of 5A. Consult factory for additional application details on DC powered units.

Environmental

Operating temperature: +32°F to +158°F (0°C-70°C)

Storage temperature: -40°F to +185°F (-40°C-85°C)

Relative humidity: 0 to 90% non-condensing

DIP SW 1

DIP SW FUNCTION:

1 - AUTO/MAN

CW LED

G

CCW LED

R

DIP SW FUNCTION:

1 - AUTO/MAN

2 - Torque trip Save/Adjust

5

PB3

PB2

PB1

3 - Direct/Reverse acting

4 -

Loss of Comand Response select

5 -

Store

Manual CW

Manual CCW

C1415

POWER & CONTROL CONNECTIONS

Pot rotation<180

JP2

Pot rotation>180

Configuration pots

1-5V/4-20mA

JP1

0-10V

9

8

7

6

5

4

3

2

1

3

2

1

CONTROL

INTERFACE

2 - Disable/Enable Speed control

3 - Direct/Reverse acting

4 5 -

DIP SW 1

5

PB3

PB2

PB1

Loss of Comand Response select

Y

G

R

C1397

Diagnostic LED

CW LED

CCW LED

Store

Manual CW

Manual CCW

CONNECTIONS

JP3

50/60HZ

POWER

Pot rotation<180

JP2

Pot rotation>180

Configuration pot

1-5V/4-20mA

JP1

0-10V

9

8

7

6

5

4

3

2

1

CONTROL

INTERFACE

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #00.00

Page 33

Performance Data – Open/Close and Modulating Configurations

Available Torques, Operating Speeds, Motor Duty Cycles, Motor Voltages and Locked Rotor Amp Draws

Torque Expression: Inch-Pounds (in-lb) and Newton Meters (Nm).

Speed Expression: Seconds per 90° output rotation.

Operating

Torque Output

in-lb Nm Sec/90° Model Cycle 115VAC 230VAC 230VAC 460VAC 12VDC 24VDC

100 11 2.5 EM-050 30% .51 N/A — — — —

100 11 2 Note 4 EM-100 30% 1.30 CF — — — —

250 28 10

350 39 13

150 17 4 Note 4 EM-300 30% 0.6 0.3 — — 1.25 2.5

300 34 10

400 45 15

600 68 30

180 20 5 Note 4 EM-520 30% 0.6 0.3 — — 1.25 2.5

450 51 10

600 68 15

1,000 113 30

350 39 5 Note 4 EM-500 100% 0.7 0.4 — — 2.5 5.0

700 79 10

1,000 113 15

1,600 181 30

325 36 2 Note 4 EM-510 100% 1.6 0.8 — — 4.3 8.5

600 68 5 Note 4

1,000 113 7 Note 4

2,000 226 12 EM-810 100% 3.2 1.3 CF CF — —

2,500 282 18

3,500 395 30

4,000 452 60

3,000 339 12 EM-820 100% 3.2 1.3 CF CF — —

4,000 452 18

6,000 678 30

7,000 791 60

5,000 565 12 EM-830 100% 6.0 2.8 CF CF — —

7,000 791 18

10,000 1,130 30

10,000 1,130 60

15,000 1,695 48 EM-840 100% 6.0 2.8 CF CF — —

20,000 2,260 72

300 34 10 Note 4 EM-SR5 100% 0.7 0.4 — — — —

400 45 15

600 68 30

1,600 181 90

Notes: 1. Operating speed is nominal at rated torques. Final operating speed may vary depending on actual service.

2. Actuators with 12VDC motors will have an operating speed of approximately 40% longer (slower) than that shown.

3. CF – Consult Factory

4. Bettis does not recommend the use of any actuator for any modulating application with an operating speed of 10 seconds or less.

Speed

Motor

Duty

30% 0.70 CF — — — —

30% 0.70 CF — — — —

30% 0.6 0.3 — — 1.25 2.5

30% 0.6 0.3 — — 1.25 2.5

30% 0.6 0.3 — — 1.25 2.5

30% 0.6 0.3 — — 1.25 2.5

30% 0.6 0.3 — — 1.25 2.5

30% 0.6 0.3 — — 1.25 2.5

100% 0.7 0.4 — — 2.5 5.0

100% 0.7 0.4 — — 2.5 5.0

100% 0.4 0.5 — — 2.5 5.0

100% 1.6 0.8 — — 4.3 8.5

100% 1.6 0.8 — — 4.3 8.5

100% 3.2 1.3 CF CF — —

100% 3.2 1.3 CF CF — —

100% 3.2 1.3 CF CF — —

100% 3.2 1.3 CF CF — —

100% 3.2 1.3 CF CF — —

100% 3.2 1.3 CF CF — —

100% 6.0 2.8 CF CF — —

100% 6.0 2.8 CF CF — —

100% 6.0 2.8 CF CF — —

100% 6.0 2.8 CF CF — —

100% 0.7 0.4 — — — —

100% 0.4 0.5 — — — —

100% 0.4 0.5 — — — —

1 Phase /50 - 60 Hz 3Ph/60Hz Direct Current

Locked Rotor Amp Draw

Page 34

TorqPlus

TM

Product Matrix

Model Model Model EM-500 EM-800 SR5

Feature EM050 EM100 EM300 Series Series Series

Output Torque Range in-lb 100 100 to 350 150 to 600 180 to 1,600 2,000 to 20,000 300 to 1,600

Nm 11 11 to 39 17 to 68 20 to 181 226 to 2,260 34 to 181

Operating Speeds (60Hz) Sec/90°

2 1/2 2 to 13 4 to 30 2 to 30 12 to 72 10 to 90

115VAC / 1Ph / 50-60Hz Motor Voltage Standard Standard Standard Standard Standard Standard

220VAC / 1 Ph / 50-60Hz Motor Voltage N.A. Optional Optional Optional Optional Optional

12 or 24VDC Motor Voltage N.A. Optional Optional Optional N.A. N.A.

CSA Certified Enclosure 4 (NEMA 4) Standard Standard Standard Standard Standard Standard

CSA Certified Enclosure 4&7 (NEMA 4&7) Note 4 N.A. N.A. Optional Optional Optional Optional

CSA General Purpose Electrical Specification Note 3 Optional Optional Optional Optional Optional Optional

Reversible Operation, Adjustable

0 °

0 – 180° 0 – 180° 0 – 180° 0 – 180° 0 – 90°

Multi-Turn Output Control N.A. N.A. N.A. Optional Optional N.A.

Ambient Operating Temperature Standard Standard Standard Standard Standard Standard

-40°F to +140°F (-40°C to +60°C)

Corrosion Resistant Powder Coat Finish Standard Standard Standard Standard Standard Standard

Standard Manual Override Type Direct N.A. Declutching Declutching Direct HW N.A.

Mechanical Position Indicator Standard N.A. Standard Standard Standard Standard

Standard Number of SPDT Switches 2 2 2 2 4 2

Number of Optional SPDT Switches Note 1 2 2 4 4 6 4

Dual Torque Limit Switches N.A. N.A. N.A. N.A. Standard N.A.

Standard Conduit Entry, Number & NPT Size (1) 1/2" (1) 1/2" (2) 1/2" (2) 1/2" (2) 3/4" (2) 1/2"

Standard Output Drive Configuration Female Female Female Female Female Female

DIN/ISO DIN/ISO DIN/ISO DIN/ISO Bore & Key DIN/ISO

or Male or Male or Male

Motor Brake Standard Standard Optional for Optional 6000 in-lb and Standard

Note 2

15 & 30 sec

Standard for

above – std.

All others

4 & 10 optional

Heater & Thermostat All Voltages Standard Optional Standard Standard Standard Standard

Potentiometer 1k Ohm - 1/2% N.A. Optional Optional Optional Optional Optional

Electronic Proportional Positioner and/or N.A. Optional Optional Optional Optional Optional

Electronic Position Transmitter N.A. Optional Optional Optional Optional Optional

(1) When actuator is to be supplied with potentiometer, reduce number of available optional switches by two (2) except for 100 series.

(2) Brake is part of motor rotor

(3) Actuators were subjected to an endurance test of 6000 complete cycles at maximum rated torque.

(4) Hazardous locations classified as Class I and II Groups C,D,E,F and G.

Bettis Electric Mansfield, OH U.S.A. T 419-529-4296 Website: www.EmersonProcess.com/Bettis

© 2002 Emerson. All rights reserved. 5M/01-02 Bulletin #83.10

Page 35

Bettis Electric

2500 Park Avenue West

Mansfield, OH 44906 U.S.A.

T 419-529-4296

F 419-529-4484

Website: www.EmersonProcess.com/Bettis

E-Mail: Info.Bettis.Electric@EmersonProcess.com

Bettis USA

P.O. Box 508

Waller, TX 77484 U.S.A.

T 281-463-5100

F 281-463-5103

Website: www.EmersonProcess.com/Bettis

E-mail: Info.Bettis@EmersonProcess.com

Bettis UK Ltd.

3 Furze Court

114 Wickham Rd.

Fareham, Hampshire PO 16 7SH

T 44-1329-848-900

F 44-1329-848-901

Bettis Canada Ltd.

4112-91 A Street

Edmonton, Alberta T6E 5V2

Canada

T 780-450-3600

F 780-450-1400

Bettis France:

30/36 Allee du Plateau

93250 Villemomble

France

T 331-48-122610

F 331-48-122619

Bettis Int’l Sales Office:

Calgary, Canada

Rheinberg, Germany

New Bombay, India

Singapore

Important: Due to Emerson’s continuing commitment to engineered

product advancement, data presented herein is subject to change.

Certified dimensional drawings and wiring diagrams are available on

request. Consult factory with model designation and serial number.

Bettis Bulletin # 10.10 Rev: 02/02

© 2002 Emerson. All rights reserved. 5M/02/02

Loading...

Loading...