Page 1

Indoor Air Quality

Air Flow Measuring Control Damper

IAQ-42

April

2006

Page 2

Why is outside air measurement important?

There are many signifi cant benefi ts to monitoring outside air volumes. First, by measuring the amount of

outside air coming into a building you can be assured that the building is complying with all applicable

indoor air quality codes including ASHRAE Standard 62 and California Title 24. Meeting these minimum

requirements reduces indoor airborne viruses and bacteria which can lead to Sick Building Syndrome.

Studies have shown that buildings that are under ventilated suffer from reduced productivity levels.

The second major advantage to monitoring outside air volumes is that it eliminates costly over ventilation. In

addition to increased energy costs associated with heating and cooling of outside air, over ventilation causes

in an increase in humidity that can result in mold development.

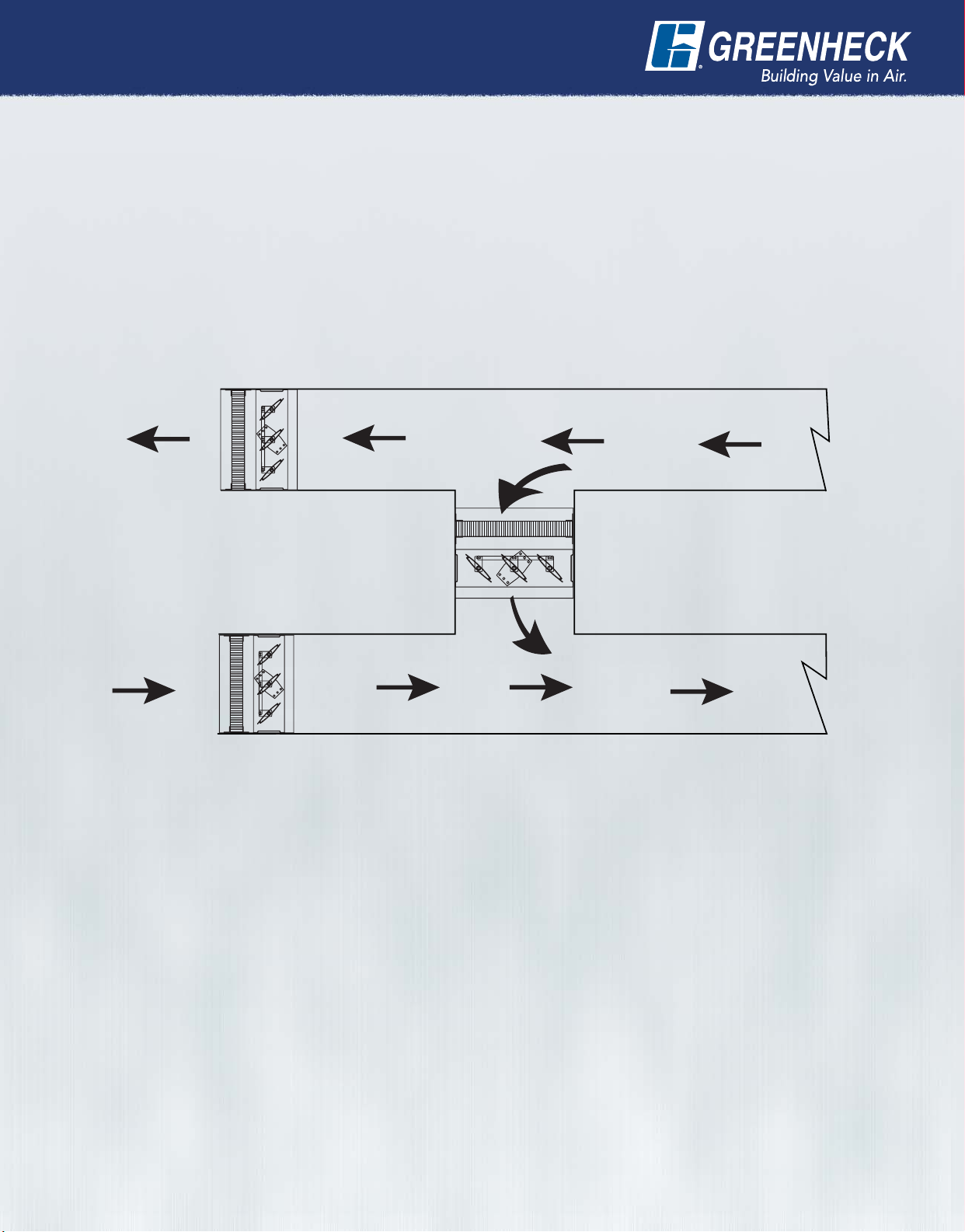

Where should an air measuring damper be used?

Exhaust Air

Mixed Air

Outside Air

Exhaust Air

In this application an air measuring control damper is used to measure and control outdoor air intake while a

second air measuring control damper is used to measure and control the exhaust fl ow. The set point for the

exhaust air damper would track the fl ow of the outdoor air damper (minus a differential if positive building

pressure is desired.)

Mixed Air

In this application, an air measuring control damper is used to measure and control outdoor air intake while

a second air measuring control damper is used to control the mixed air temperature. Normally an averaging

sensor is required for mixed-air temperature control because the large temperature differences between

return air and outdoor air cause stratifi cation. The mixed air temperature is calculated from the fl ows and

temperatures measured by each damper eliminating the measurement problem caused by stratifi cation.

Outside Air

In this application, an air measuring control damper provides outdoor air control based on a demand signal.

The demand signal could be determined by a set schedule or by occupancy sensors. Examples of demand

signals are carbon dioxide (CO2) concentration, a binary signal from a motion detector, or a manual switch.

Page 3

What is the IAQ-42?

Greenheck’s IAQ-42 is an air measuring control damper that utilizes patented Specifl ow™ technology. The

IAQ-42 will control air to prevent over-ventilation, provide energy savings during periods of low occupancy,

and prevent under-ventilation not meeting ASHRAE Standard 62. The Specifl ow™ technology built into the

controller measures the pressure, position of the damper blades, and the temperature of the air fl owing

through the damper.

The IAQ-42 can help buildings meet the minimum outdoor air requirements of ASHRAE Standard 62 or

California Title 24 by providing accurate monitoring and control of outside air. You can earn LEED-EB credits

for air monitoring, increased ventilation, and ultra low leakage.

The IAQ-42 meets IECC (International Energy Conservation Code®) requirements with a leakage rating of

3 cfm/sq. ft. @ 1 in. wg (55cmh/m2 @ .25 kPa) or less.

The IAQ-42 is provided

with a factory supplied

honeycomb air straightener.

When ordering an IAQ-42

with an optional 4 inch

(101mm) or 6 inch (152mm)

louver it does not require an

airfl ow straightener.

The air pressure pickups

are designed to be

mounted on the blades.

Temperature sensors

monitor air temperature

to allow the controller to

correct the airfl ow rate

for changes in air density.

Every damper is provided with

a 24 Vac modulating actuator

to control the damper’s blade

position and provide feedback

to the controller. The actuator

can be mounted externally or

internally.

Page 4

Why is Factory Calibration Important?

Every IAQ-42 damper is factory calibrated in

our accredited testing facility before shipping.

Greenheck provides a certifi cation chart with every

damper. By calibrating each damper, you can be

assured of the most accurate airfl ow readings

possible.

The IAQ-42 is available with or without a factory

calibrated controller. The Specifl ow™ technology

built into the controller measures the pressure,

position of the damper blades, and the temperature

of the air fl owing through the damper. From these

readings, the controller computes the airfl ow rate

and adjusts the damper blades accordingly.

What’s the benefi t of the IAQ-42 over the competition?

The IAQ-42 has a number of advantages over the competition:

• By integrating the pressure pickups with the control damper, the pressure signal is increased at low

velocities making the unit more accurate in non-uniform fl ow conditions.

• Locating the pickups on the blade amplifi es the pressure signal which increases the accuracy of

readings.

• The pickups can easily be repaired or replaced.

• The small size of the pickups add minimal pressure drop to the system.

• The controller with Specifl ow™ technology automatically compensates for the effect of air

temperature on air density.

• The controller with Specifl ow™ technology can operate stand alone or integrated with a DDC building

control system.

This table shows the benefi ts of the IAQ-42 versus competitor’s models.

Benefi ts

Low pressure drop

Low velocity

accuracy

Temperature

compensated

Insensitive to

condensation

Integral controller

Factory calibrated

No additional

duct work required

Easily maintainable

Insensitive to

non-uniform fl ow

Greenheck

IAQ-42

99 9

99

99

99 9

99 9

99

99

99

99

Ruskin

IAQ50

Trane Traq™

Damper

Page 5

Why is temperature compensation important?

Airflow measurement accuracy is dependent on the density of the air being measured and in turn air

density is a function of temperature. The IAQ-42 monitors the dry-bulb temperature of the air passing

through it and corrects the air density used to calculate the airflow rate. Airflow measuring devices that do

not compensate for changes in air density must assume a “standard” density to calculate an airflow rate.

As air heats up it gets lighter. If this change in air density is not taken into consideration the monitoring

device will allow too much hot outside air into the building, thus unnecessarily increasing the cooling

load. On a hot summer day outside air temperatures coming off of a black tar roof can easily reach over

120° F (49° C). Without temperature compensation, an airflow-monitoring device would be telling the

system to allow about 5% more air into the building than is desired. For an air-handler with an outside

air design load of 20,000 cfm (101 m/s), this could cost a facility $500 per year. In parts of the country

where dynamic utility rates will be used, the penalty for a 20,000 cfm (101 m/s) outdoor air load would

be $750 per year. In addition to increasing energy costs, over-ventilation in humid climates could cause

excessively high indoor humidity, which could promote the growth of mold.

The opposite is true as air cools down and gets heavier. In cold climates outside air temperatures can

reach –40° F (-40° C). This condition can lead to under-ventilation. An airflow-measuring device that does

not compensate for temperature changes would measure 11% more outside air than is actually coming

into the building. Under-ventilation from lack of temperature compensation will occur at the same time as

cold and flu season.

IAQ-42 can save you space!

In a typical ventilation system, there is a separate damper and airfl ow monitor. The airfl ow monitor needs

to be a certain distance from the damper (formula driven).

The IAQ-42 with a straightener is mounted in a sleeve; the spacing doesn’t change based on the size that

you need. The total space required is 12 inches (305mm)! The IAQ-42 with a 4 inch (101mm) or 6 inch

(152mm) louver needs 16 inches (406mm) of space.

Example:

If the opening is 36 inches W x 36 inches H (914mm x 914mm), the space between the damper and airfl ow

monitor would be 18 inches (457mm). If you add in the damper depth, 5 inches (127mm), and air monitor

depth, 8 inches (203mm), you would need 31 inches (787mm) of space.

The IAQ-42 with straightener takes only 12 inches (305mm) of space and it doesn’t change! That saves 19

inches (483mm) of space!

IAQ-42 with straightener requires a 12 inch

(305mm) sleeve.

IAQ-42 with a 4 or 6 inch (101 or 152mm)

louver requires a 16 inch (406mm) sleeve.

IAQ-42 is available with louver models

ESD-635, ESJ-401LT, or EHV-602.

Page 6

More Energy saving products

from Greenheck!

The following models meet IECC (International Energy Conservation Code)

requirements of damper leakage of 3 cfm/sq. ft @ 1 in. wg or less:

VCD-33

VCD-34

SEVCD-33

VCD-40

VCD-42

VCD-43

ICD-45

The Greenheck Difference

What makes Greenheck different from other damper manufacturers?

Perhaps it’s having the most UL-certified dampers, or the industry-

leading testing capabilities. Most Greenheck dampers meet California

State Fire Marshal and NY MEA requirements. Aggressive research

and development also keeps Greenheck a major player in the damper

industry.

Unparalleled In-house Testing

Capabilities

State-of-the-art testing facilities have always been important to Greenheck’s

continuing business success. We have laboratory facilities devoted to the latest

development and testing of damper products to the latest versions of AMCA,

ASHRAE, UL, and other industry standards of performance.

Every IAQ-42 damper is factory calibrated in our accredited testing facility before

shipping. Greenheck provides a certifi cation chart with every damper.

Leading Edge Technical Support

All Greenheck products are supported by the industry’s best product

literature, electronic media, and Computer Aided Product Selection program

(CAPS). You’ll also find extensive information on the internet.

You can always count on the personal service and expertise of our national

and international representative organizations. To locate your nearest

Greenheck representative, call 715-359-6171, or visit our website at

For more information on energy saving programs:

www.usgbc.com - United States Green Building Council

www.energycodes.gov - U.S. Department of Energy Building Energy Codes Program

www.energystar.gov - Energy Star

www.epa.gov - U.S. Environmental Protection Agency

www.greenseal.org - Green Seal

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year

from the purchase date. Any units or parts which prove defective during the warranty period will be replaced at

our option when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer

for a period of one year. Should motors furnished by Greenheck prove defective during this period, they should

be returned to the nearest authorized motor service station. Greenheck will not be responsible for any removal or

installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Greenheck P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

IAQ Catalog Rev. 1 April 2006 RG Copyright © 2006 Greenheck Fan Corp.

Loading...

Loading...