Page 1

®

A Global Presence

Marine Products

Dampers, Louvers, and Fans

• Selection • Construction • Performance

November

2004

Page 2

Marine Dampers, Louvers, and

Fan Products

The Greenheck Difference

What makes Greenheck different from other manufacturers? Perhaps its

having the most UL certified dampers or industry leading testing capabilities.

Aggressive research, development and testing keeps Greenheck a leader in

the air movement and control industry. For over 50 years, the Greenheck name

has been synonymous with innovation, product quality and customer service.

Marine Dampers, Louvers, and Fans

A complete line of Fire, Combination Fire/Smoke Dampers,

Louvers, and Fans can be used in marine and offshore ventilation systems

such as:

• Ferries • Ships • Tug boats • Offshore oil rigs • River Boat casinos • Cruise ships

Greenheck is the first US manufacturer with United States Coast Guard Class A-60 division approval on

Combination Fire/Smoke and Fire Dampers. The Marine dampers were tested at Underwriters Laboratories (UL)

in accordance with International Maritime Organization’s (IMO) Fire Test Procedure code. They are also

American Bureau of Shipping (ABS) approved. Performance data testing was conducted in

accordance with AMCA Standard 500-D.

A complete line of Wind-Driven Rain, Drainable and Combination Louvers are available for the

severe and corrosive environments on ships. Wind-Driven Rain models offer excellent rain

resistance while Drainable blade louvers additionally offer outstanding resistance to water

penetration. Combination louver models can be opened or closed as desired.

Greenheck’s high standards of quality and performance provides assurance for fans in

marine environment applications. Greenheck has a versatile line of heavy duty fans

to meet many different performances,configurations, and situation requirements.

Compact designs, efficient performance, and reliable operation are what

Greenheck provides in fans for marine duty environments.

2

Page 3

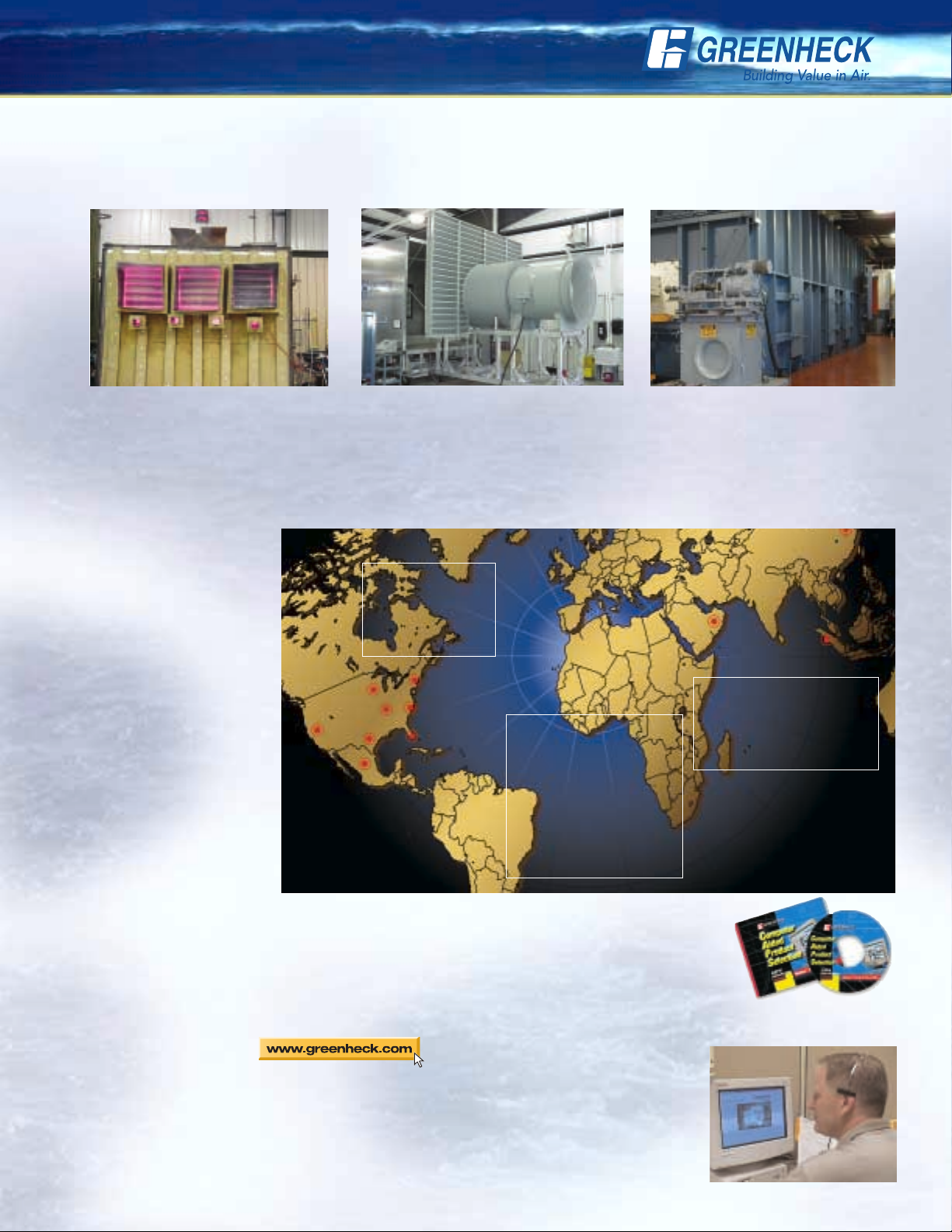

Leading Edge Technical Support and Customer Service

All Greenheck products are supported by the industry’s best product literature,

electronic media, and Computer Aided Product Selection program (CAPS). You’ll also find

extensive information on the internet.

You can always count on the personal service and expertise of our national and

international representative organizations. To locate your nearest Greenheck representative, call 715-359-6171

or visit our website at

With Greenheck’s experienced staff, we can answer questions and provide solutions

to your unique damper, louver, and fan applications. Greenheck’s commitment to our

customers doesn’t end with a finished product. If you have application questions in

the field, we are here to assist you.

Manufacturing

• Rocklin, CA

• Schofield, WI

• Frankfort, KY

• Kunshan, China

International Distribution

•

China

•

Mexico

•

Singapore

•

United Arab Emirates

National Distribution

•

Schofield, WI

•

Rocklin, CA

•

Dallas, TX

•

Miami, FL

•

Greensboro, NC

•

Union, NJ

•

Columbus, OH

•

Las Vegas, NV

IMO Fire Damper Test

Greenheck built a steel bulkhead

to test dampers to the IMO Fire

Test Procedure Code (A.754). The

dampers are tested to 1733ºF

(945ºC) for 60 minutes.

Wind-Driven Rain & Water

Penetration Testing

Our in-house wind-driven rain test

chamber simulates the effects of a

Class II hurricane at 100 mph wind

speeds to test rain rejection while

allowing air passage.

Air Test Chamber

Greenheck has three AMCA

registered air performance test

chambers to measure air

volume and horsepower

requirements at different

pressure levels.

A Global Presence

A Global

Presence

Greenheck operates four

manufacturing locations,

eight national distribution

centers, and four

international distribution

centers.

In-House Testing for Marine Products

Greenheck has invested in state-of-the-art laboratory and testing facilities to help develop new products and

update our existing products to provide you with the highest quality. Greenheck’s laboratory facilities test

products to the latest versions of AMCA, ANSI, ASHRAE, UL, USCG and other industry standards of

performance.

3

Page 4

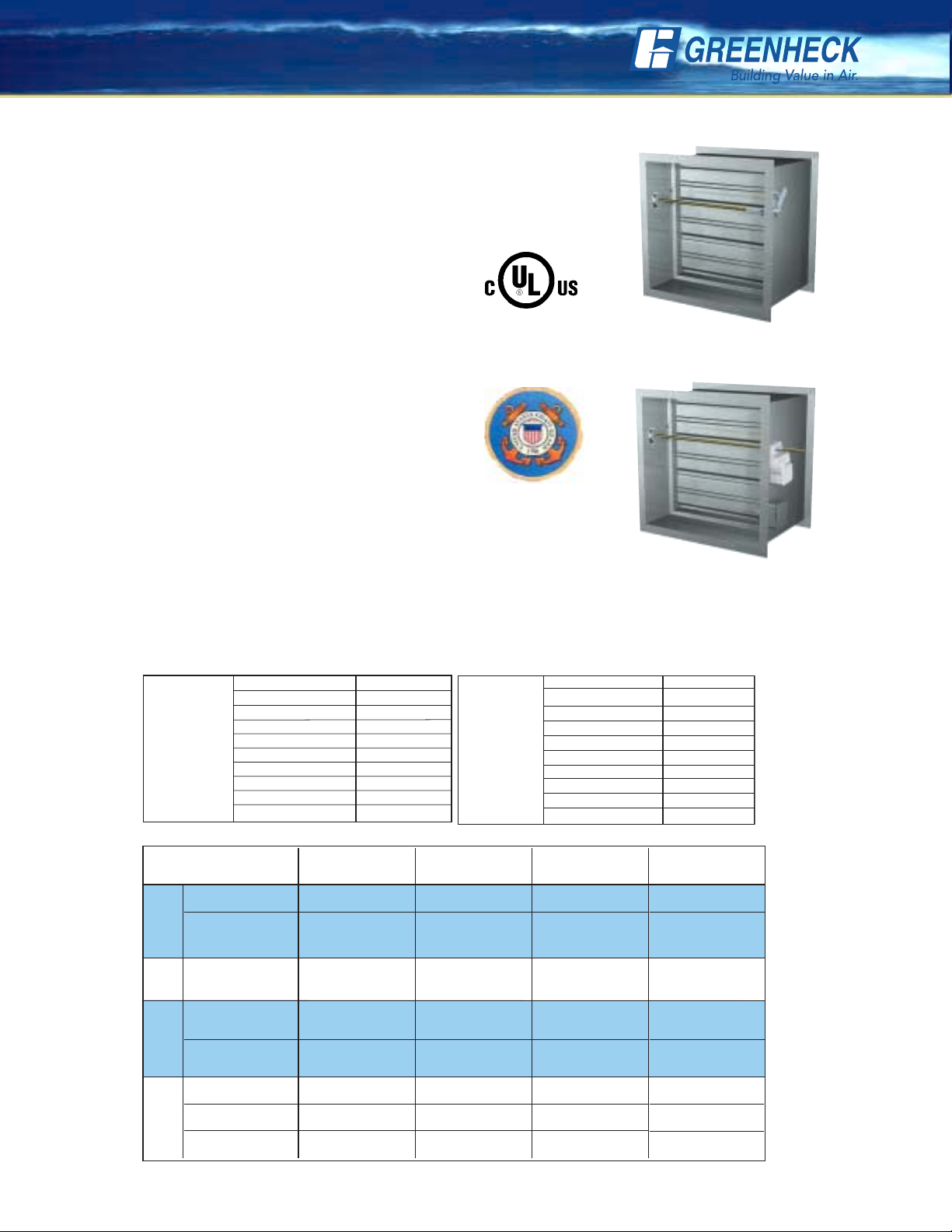

Marine Dampers

Marine Dampers

Greenheck marine dampers are United States Coast Guard approved (Approval

no. 164.139/7/0) and UL approved* (R13317). Compared to the competition our

dampers are 50% lighter, which helps lower the weight of your ship.

IMO-310 Fire Damper

• USCG approved

• UL555 approved*

- 1 1/2 hour fire rating

• Velocity up to 2000 fpm (10.2m/s)

• Pressure up to 4 in. wg (1kPa)

SSIMO-310 Stainless Steel Fire Damper

• USCG approved

• Velocity up to 2000 fpm (10.2m/s)

• Pressure up to 4 in. wg (1kPa)

IMO-311 Combination Fire Smoke Damper

• USCG approved

• UL 555 & UL555S approved*

- 1 1/2 hour fire rating

- Leakage class I

• Velocity up to 3000 fpm (15.2m/s)

• Pressure up to 4 in. wg (1kPa)

SSIMO-311 Stainless Steel Combination Fire Smoke Damper

• USCG approved

• Velocity up to 3000 fpm (15.2 m/s)

• Pressure up to 4 in. wg (1kPa)

IMO-310 / SSIMO-310

Marine Fire Damper

IMO-311 / SSIMO-311

Marine Combination

Fire/Smoke Damper

Quick Reference Chart

Weight Charts

*Consult factory for UL approved sizes.

4

Actual Size - in. (mm) Weight- lb (kg)

8 x 8 (203x203) 11 (5)

10 x 10 (254x254) 14 (6.4)

12 x 12 (305x305) 17 (7.7)

IMO-310/

SSIMO-310

18 x 18 (457x457) 28 (12.7)

20 x 20 (508x508) 31 (14)

24 x 24 (610x610) 39 (17.7)

30 x 30 (762x762) 52 (23.6)

32 x 32 (813x813) 58 (26.3)

64 x 32 (1626x813) 96 (43.5)

STD = Standard

OPT = Optional

Galvanized steel

channel frame

304 stainless steel

channel frame

Construction

Airfoil

Blade

Profile

165º F (74º C) STD

Closure

212º F (100º C) OPT

Temperature

Minimum size

Maximum section

size

Sizing

Maximum multisection size

(1626mm x 813mm)

IMO-310

STD

STD

8 in. x 6 in.

(203mm x 813mm)

32 in. x 32 in.

(813mm x 813mm)

64 in. x 32 in.

Actual Size - in. (mm) Weight- lb (kg)

8 x 8 (203x203) 16 (7.3)

10 x 10 (254x254) 19 (8.6)

12 x 12 (305x305) 22 (10)

IMO-311/

SSIMO-311

SSIMO-310 IMO-311 SSIMO-311

STD STD

STD STD STD

STD STD STD

OPT OPT OPT

8 in. x 6 in.

(203mm x 813mm)

32 in. x 32 in.

(813mm x 813mm)

64 in. x 32 in.

(1626mm x 813mm)

18 x 18 (457x457) 33 (15)

20 x 20 (508x508) 36 (16.3)

24 x 24 (610x610) 44 (20)

30 x 30 (762x762) 57 (26)

32 x 32 (813x813) 63 (28.5)

64 x 32 (1626x813)

STD

8 in. x 6 in.

(203mm x 813mm)

32 in. x 32 in.

(813mm x 813mm)

64 in. x 32 in.

(1626mm x 813mm)

(203mm x 813mm)

(813mm x 813mm)

(1626mm x 813mm)

103 (46.7)

8 in. x 6 in.

32 in. x 32 in.

64 in. x 32 in.

Page 5

VCD-23 & SEVCD-23 and Design

Models VCD-23 and SEVCD-23 have 3-V style blades for application as an

automatic control or manual balancing damper. A wide range of electric or

pneumatic actuators are available for these models.

FEATURES

• Temperature 180ºF (82ºC)

• Velocity up to 3000 fpm (15.2 m/s)

• Pressure rating up to 5 in. wg (1.25 kPa)

• Leakage 10 cfm/sq. ft. @ 4 in. wg

(183 cmh/m2 @ 1 kPa)

VCD-33 & SEVCD-33

Models VCD-33 and SEVCD-33 dampers have an airfoil style blade designed

to meet the highest standards established for commercial control dampers. A

wide range of electric and pneumatic actuators are available for these models.

FEATURES

• Temperature 180ºF (82ºC)

• Velocity up to 4000 fpm (20.3 m/s)

• Pressure rating up to 8 in. wg (2 kPa)

• Leakage 6 cfm/sq. ft. @ 4 in. wg

(110 cmh/m2 @ 1 kPa)

Volume Control

Dampers

5

The AMCA Certified

Ratings Seal applies to

Model VCD-23.

STD = Standard

OPT = Optional

Blade

Profile

304 stainless steel OPT OPT

Material

Frame

inches

Gauge

Blade

Seals

Jamb

Seals

Bearings

Axles

Linkage

Material

(mm)

Sizing

inches

316 stainless steel STD STD

(mm)

304 stainless steel STD STD

316 stainless steel STD STD

304 stainless steel OPT OPT

316 stainless steel STD STD

304 stainless steel OPT OPT

316 stainless steel STD STD

304 stainless steel

316 stainless steel

Minimum size

Maximum single section size

Maximum multi section size Unlimited Unlimited Unlimited Unlimited

3V STD STD

Airfoil STD STD

Galvanized STD STD

Aluminum OPT

16 (1.5) STD STD STD STD

14 (2) OPT OPT

12 (2.8) OPT OPT

Vinyl STD STD

Silicone OPT OPT OPT OPT

EPDM OPT STD STD

Synthetic STD STD

Bronze OPT OPT

Steel STD STD

steel

VCD-23

STD STD

OPT OPT

6x6

(152x152)

48x74

(1219x1880)

VCD-33

6x6

(152x152)

60x74

(1524x1880)

SEVCD-23

STD STD

6x6

(152x152)

48x74

(1219x1880)

(152x152)

60x74

(1524x1880)

SEVCD-33

6x6

Page 6

Industrial Control

Dampers

6

FEATURES

• 316 stainless steel option

• Pressure rating up to 45 in. wg

(11,209 Pa)

• Velocity up to 6000 fpm (30.5 m/s)

• Models HCD series & HCDR series

dampers

(

)

(

)

HCD series

HCDR series

Industrial control dampers are heavy duty flanged style dampers with various blade styles. They are designed

to control airflow and provide shut off in HVAC or industrial process control systems.

HCD-120 HCD-130 HCD-135 HCD-140 HCD-220 HCD-230 HCD-240 HCD-330 HCD-430 HCD-530

Pressure

in. wg (Pascal)

Velocity fpm

Temperature

Blade Profile

Maximum 8.5 (2 117) 8.5 (2117) 8.5 (2 117) 6 (1494) 15 (3736) 15 (3736) 15 (3736) 25 (6227) 35 (8718) 45 (11209)

Maximum 3000 (15.2) 4000 (20.3) 4000 (20.3) 6000 (30.5) 4000 (20.3) 5000 (25.4) 5000 (25.4) 5000 (25.4) 6000 (30.5)

m/s

Standard

Maximum

Optional

Galvanized Standard Standard Standard Standard Standard Standard Standard Standard Standard Standard

304SS Optional Optional Optional Optional Optional Optional Optional Optional Optional Optional

Frame

316SS N/A N/A N/A N/A Optional Optional Optional Optional Optional Optional

Galvanized 3V Standard N/A N/A N/A Standard N/A N/A N/A N/A N/A

304SS 3V Optional N/A N/A N/A Optional N/A N/A N/A N/A N/A

Galvanized Airfoil N/A Standard Standard N/A N/A Standard N/A Standard Standard Standard

Aluminum Airfoil N/A N/A N/A Standard N/A N/A Standard N/A N/A N/A

304SS Airfoil N/A Optional Optional Optional N/A Optional N/A Optional Optional Optional

Blade Seals Optional Optional Standard Standard Optional Optional Standard Optional Optional Optional

Special

Jamb Seals Optional Optional Standard Standard Optional Optional Standard Optional Optional Optional

Features

180º F

(82º C)

400º F

(204º C)

250º F

(121º C)

400º F

(204º C)

250º F

(121º C)

400º F

(204º C)

250º F

(121º C)

N/A

250º F

(121º C)

400º F

(204º C)

250º F

(121º C)

400º F

(204º C)

250º F

(121º C)

400º F

(204º C)

250º F

(121º C)

400º F

(204º C)

250º F

(121º C)

400º F

(204º C)

6000

30.5

250º F

(121º C)

400º F

(204º C)

HCDR-351

15 in. wg (3736) 37 in. - 60 in.

(939mm - 1524mm)

6500 (33)

250º F (121º C)

400º F (204º C)

Standard

Optional

Optional

Optional

Standard

External Standard

Pressure

in. wg (Pascal)

Velocity

fpm(m/s)

Maximum

Temperature

(Celsius)

Frame

Special Features

HCDR-150 HCDR-250 HCDR-350

Maximum 5 (1245) 8.5 (2117) 15 (3736)

Maximum 4000 (20.3)

Standard

Optional

Painted Steel

Painted steel

Hi Temp

Aluminum

304SS

316SS

Blade Seals

Bar Stops

250º F

(121º C)

400º F

(204º C)

Standard Standard Standard

N/A N/A N/A

Optional Optional Optional

Optional Optional Optional

Optional Optional Optional

Optional Optional Optional

5500

(27.9)

250º F

(121º C)

400º F

(204º C)

6500 (33)

250º F

(121º C)

400º F

(204º C)

20 in. wg (4982) up to 37 in. (939mm)

Page 7

7

FSDR-511 & SSFSDR-511 are true round combination fire smoke dampers. They are supplied with sleeves from

the factory.

FEATURES

• UL555S Leakage Class I

• UL555 1 1/2 hour fire resistance rating

• Velocity up to 2000 fpm (10.2 m/s)

• Pressure rating up to 4 in. wg (1 kPa)

FSD-311 is a high performance combination fire smoke damper with extremely low leakage. High strength airfoil

blades ensure the lowest resistance to airflow in HVAC systems. FSD-311 may be installed vertically (with

blades running horizontally) or horizontally and is rated for airflow and leakage in either direction.

FEATURES

• UL555S Leakage Class I

• UL555 1 1/2 hour fire resistance rating

• Velocity up to 3000 fpm (15.2 m/s)

• Pressure rating up to 4 in. wg (1 kPa)

SSFSD-211 & SEFSD-211 are combination fire smoke dampers made out of stainless steel with 3-V style

blades. They may be installed vertically (with blades running horizontally) or horizontally and are rated for

airflow and leakage in either direction.

FEATURES

• UL555S Leakage Class I

• UL555 1 1/2 hour fire resistance rating

• Velocity up to 3000 fpm (15.2 m/s)

• Pressure rating up to 4 in. wg (1 kPa)

Combination Fire

Smoke Dampers

STD = Standard

OPT = Optional

Frame

Blade Profile

Closure

Temperature

Closure

Device

Sizing

Galvanized steel STD STD

304SS

316SS

3-V

Airfoil STD

Round STD STD

165ºF (74ºC) STD STD

212ºF (100ºC) OPT OPT

250ºF (121ºC) OPT OPT

286ºF (141ºC) OPT OPT

350ºF (177ºC) OPT OPT

Fusible link STD STD

RRL STD OPT

TOR OPT OPT

PRV OPT OPT

Min. size

Maximum single

section size

Maximum multi

section size

FSD-311 SDR-511

8 in. x 6 in

(203mm x 152mm)

32 in. x 36 in

(813mm x 914mm)

96 in. x 50 in. V

(2438mm x 1270mm)

128 in. x 100 in. H

(3251mm x 2540mm)

6 in.

152mm)

24 in.

610mm)

NA

SEFSD-211 SSFSD-211

STD

STD STD

STD STD

OPT OPT

OPT OPT

OPT OPT

STD STD

OPT OPT

OPT OPT

8 in. x 6 in

(203mm x 152mm)

24 in. x 30 in

(610mm x 762mm)

48 in. X 30 in.

(1219mm x 762mm)

8 in. x 6 in

(203mm x 152mm)

24 in. x 30 in

(610mm x 762mm)

48 in. X 30 in.

(1219mm x 762mm)

STD

SSFSDR-511

STD

STD

OPT

OPT

OPT

OPT

OPT

OPT

6 in.

(152mm)

24 in.

(610mm)

NA

Page 8

For the extreme conditions of maritime applications, Greenheck offers a complete line of Wind-Driven Rain

Louvers to meet your requirements. Wind-Driven Rain louvers offer the best resistance to water penetration.

Models EVH, EHH

FEATURES AND BENEFITS

• All Greenheck Wind-Driven Rain Louvers are subjected to the more

stringent 50 mph wind/8 inches rain per hour test

• Greenheck’s Wind-Driven Rain Louvers are available in both vertical and

horizontal blade configurations

• Vertical blade models are the most effective in minimizing water penetration

through openings that are sensitive to wind-driven rain in a building’s

exterior wall

• Horizontal blade models offer excellent performance against wind-driven

rain, along with the aesthetically pleasing look of a horizontal blade

• Horizontal (EHH) and vertical (EVH) blade models available include:

• EHH-201, EVH-201 (Two inch frame depth)

• EHH-401, EVH-401 (Four inch frame depth)

• EHH-501 (Five inch frame depth)

• EHH-601, EVH-602 (Six inch frame depth)

• EHH-701 (Seven inch frame depth)

• EVH-801 (Eight inch frame depth)

Wind-Driven Rain Louvers

EVH-602

8

3

Wind Driven Rain

Penetration Classes

Class Effectiveness

A 100%-99%

B 98.9%-95%

C 94.9%-80%

D Below 80%

NOTES: Based on louver

size 48 in. x 48 in.

1

Core

area is the open area of the

louver face (face area less

louver frames). Core area

velocity is the airflow

velocity through the core

area of the louver.

Wind Velocity - 29 mph Wind Velocity - 50 mph

Rainfall - 3 in./hr.

3

Rainfall - 8 in./hr.

3

Free Area Core Area

Airflow (cfm) Velocity (fpm) Velocity (fpm)1Effectiveness Classification Effectiveness Classification

EVH-201

9798 1716 689 100% A

9798 1716 689 99.9 A

EVH-401

9715 1523 689 100% A

8333 1306 591 99.7% A

EVH-602

9157 1557 689 99.4% A

7854 1336 591 99.1% A

EVH-801 9157 1813 689 99.6% A 99.7% A

EHH-201

2817 454 197 99.9% A

1401 226 98 99.5% A

EHH-401

8380 1247 591 99.2% A - -

1390 207 98 99.1% A

EHH-501

9550 1404 689 99.1% A

9550 1404 689 97.2% B

EHH-601

9577 1263 689 100% A

4101 541 295 99.1% A

EHH-701

9577 1336 689 99.9% A

5477 764 394 99.1% A

FEATURES & PERFORMANCE

Blade Style RR RR RR RR RR RR RR RR RR

Blade Thickness (inches) .062 .081 .081 .081 .062 .081 .081 .081 .081

Frame Thickness (inches) .062 .081 .081 .081 .062 .081 .081 .081 .081

Free Area (48 x 48) Square Feet 5.71 6.38 5.88 5.05 6.20 6.72 6.80 7.58 7.17

Free Area (48 x 48) % 36 40 37 32 39 42 43 47 45

Free Area Intake Velocity @ Beginning

1250 1250 1250 1250 914 1250 1250 1250 1250

Point of Water Penetration (Ft/Min)

Pressure Drop @ Maximum

– .370 .161 .100 – .296 .224 .324 .491

Intake Velocity (in. wg)

Maximum Intake Volume

– 7975 7350 6313 – 8400 8500 9475 8962

Flow Rate 48 x 48 unit (cfm)

Exhaust Volume Flow Rate

– 5895 7832 8625 – 5820 5998 6094 4015

@ 0.15 in. wg (cfm)

RAIN RESISTANT

EXTRUDED LOUVERS

EVH-201

EVH-401

EVH-602

EVH-801

EHH-201

EHH-401

EHH-501

EHH-601

EHH-701

RR = Rain Resistant

EHH-601

Greenheck certifies that the models shown

herein are licensed to bear the AMCA seal.

The ratings shown are based on tests and

procedures performed in accordance with

AMCA Publication 511 and comply with the

requirements of the AMCA Certified Ratings

Program.

The AMCA Certified Ratings Seal applies to

air performance, water penetration, and

wind-driven rain ratings for models:

EHH-501 and 701. The AMCA Certified

Ratings Seal applies to air performance and

wind-driven rain for models EVH-602 and

EVH-801.

Page 9

Greenheck offers the most AMCA-licensed louvers in the industry. For more information on Greenheck’s

complete line of louvers and architectural products, please see contact information on back cover.

Drainable, Combination Louvers

9

Combination louvers incorporate both stationary and adjustable blades, allowing the louver to be opened or

closed as desired. The louver appearance does not change when the adjustable damper blade is closed as

stationary blades maintain their position.

Model EAC

FEATURES AND BENEFITS

• Linkage is concealed

• Four and six inch frame depths

• Stainless steel jamb seals

• Electric or pneumatic actuators

FEATURES & PERFORMANCE

Blade Style D D D D DD DD DD DD

Blade Thickness (inches) .063 .081 .081 .081 .081 .081 .081 .081

Frame Thickness (inches) .063 .081 .081 .081 .081 .081 .081 .081

Free Area (48 x 48) Square Feet 6.02 8 8.98 8.53 9.4 8.22 8.58 7.91

Free Area (48 x 48) % 38 50 56 53 59 51 54 49

Free Area Intake Velocity @ Beginning

1058 1007 1151 1250 1250 1112 1201 1065

Point of Water Penetration (Ft/Min)

Pressure Drop @ Maximum

.141 .180 .213 .260 .220 .182 .240 .200

Intake Velocity (in. wg)

Maximum Intake Volume

6369 8056 10336 10663 11753 9141 10305 8424

Flow Rate 48 x 48 unit (cfm)

Exhaust Volume Flow Rate

5963 8188 9285 8359 11292 8312 8399 6577

@ 0.15 in. wg (cfm)

ESD-202

ESD-403

ESD-603

EDD-401

EDD-601

EHM-601

ESD-435

STATIONARY DRAINABLE

EXTRUDED LOUVERS

ESD-635

Greenheck offers a complete line of Drainable Blade Louvers that offer outstanding resistance

to water penetration.

Models ESD, EDD, EHM

FEATURES AND BENEFITS

• A drain gutter is located on each blade of ESD models, capturing rain water and channeling

it to louver jamb members, where it then flows down integral downspouts to the sloped sill

and drains away from the louver

• Models ESD-435 and ESD-635 offer 35º blades and increased free area without

compromising water penetration performance

• Model EDD is a dual drainable blade model with a second drain gutter to further catch water

• Model EHM offers a recessed mullion design for continuous blade appearance

EAC-601

EHM-601

ESD-603

EDD-601

FEATURES & PERFORMANCE

Blade Style DA DA

Blade Thickness (inches) .081 .081

Frame Thickness (inches) .125 .125

Free Area (48 x 48) Square Feet 6.34 7.41

Free Area (48 x 48) % 40 46

Free Area Intake Velocity

1192 1020

Point of Water Penetration (Ft/Min)

Pressure Drop @ Maximum

.170 .160

Intake Velocity (in. wg)

Maximum Intake Volume

7557 7558

Flow Rate 48 x 48 unit (cfm)

Exhaust Volume Flow Rate

6050 7212

@ 0.15 in. wg (cfm)

EAC-401

COMBINATION EXTRUDED

LOUVER DAMPERS

DA = Drainable Adjustable

D= Drainable DD= Dual Drainable

Greenheck certifies that the

models shown herein are licensed

to bear the AMCA seal. The

ratings shown are based on tests

and procedures performed in

accordance with AMCA

Publication 511 and comply with

the requirements of the AMCA

Certified Ratings Program.

Greenheck certifies that the

models shown herein are licensed

to bear the AMCA seal. The

ratings shown are based on tests

and procedures performed in

accordance with AMCA

Publication 511 and comply with

the requirements of the AMCA

Certified Ratings Program.

EAC-601

Page 10

Marine Duty Fans

10

Greenheck has a full line of fans that are suitable for use in marine duty environments. Fans are designed and

built for strength, long life, low maintenance, and corrosion resistance. Greenheck provides heavy duty quality

products with a variety of options for construction materials, superior powder coatings for marine environments

and a full line of accessories.

Motors for the most severe applications

Quality from design through manufacturing and inspection

Greenheck has motors that are designed and approved for use in marine

applications. Marine duty construction options that are available on motors from

Greenheck include:

• IEEE 45 and USCG Marine Duty

• Marine Duty API RP14F for Offshore Platforms

• NEMA MG1-1.26.6 Waterproof Specification

• IEEE 841 Standard for Petroleum and Chemical Industry - Severe Duty

• NEMA Premium Efficiency

• Inverter Duty

Using state of the art design, testing and measuring equipment, Greenheck leads the HVAC industry in

providing reliable products with superior performance and construction.

• Finite element analysis, strain gauge testing, computational fluid dynamics, product life testing,

and testing in AMCA registered sound and air performance labs are some of the methods used

to design and verify structural integrity and performance.

• Belt driven fans have shaft bearings with a life in excess of L(10) 80,000 hours (average life of

400,000 hours).

• Electrostatically applied powder coatings provide even coverage on all surfaces of the fan components.

These coatings are developed and tested to withstand the harshest

chemicals and environments.

• All fans are test run at the factory to ensure proper operation. Amp

readings are taken on motors and each assembled fan must pass a

stringent vibration requirement. Electrical test results and vibration test

reports are maintained as a permanent record for each fan.

Quick Selection

Models AFSW AFDW BISW BIDW IPA AX TBI-CA TBI-FS QEI QEID

Volume Range (cfm)

Max Ps (inch wg) 15 15 22 15 31 5 3.25 4.5 8.5 9.5

AMCA

AMCA Air YES YES YES YES YES YES YES YES YES YES

AMCA Sound YES YES YES YES YES YES YES YES

UL

Electrical (705) OPT OPT OPT OPT OPT OPT OPT OPT OPT

Emergency Smoke OPT OPT OPT OPT

Drive Type

Construction

Coated Steel Casing STD STD STD STD STD STD STD STD STD STD

316 Stainless Steel - Entire OPT OPT OPT

Aluminum Prop/Wheel OPT OPT

Aluminum - Entire OPT OPT OPTOPT OPT

100 -

190,000

Belt Belt

SCROLL TYPE INLINE TYPE

200 -

370,000

OPT

100 -

230,000

Belt /

Direct

OPT OPT OPT STD STD OPT OPT

200 -

360,000

Belt Belt Direct Belt Belt Belt Direct

50 -

140,000

50 -

115,000

1,500 96,000

3,000 77,000

2,000 95,000

1,000 96,000

Page 11

Marine Duty Fans

11

Single Width Single Inlet Centrifugal

Models AFSW and BISW

Versatile airfoil and backward inclined centrifugal models offer a

wide range of configurations and arrangements. Ventilation

applications include clean air, emergency smoke exhaust, or

contaminated process air and high temperature exhaust.

Available in four classes of construction and eight different

discharge positions.

Double Width Double Inlet Centrifugal

Models AFDW and BIDW

Provides high volume capacities and pressure in a compact

housing. Usually used for relatively clean air applications with

unducted inlets such as built-up or custom air handlers.

High Pressure Blower

Model IPA

Radial bladed wheel provides a full range of volume capabilities

with higher pressures than centrifugal wheels. Heavy gauge

materials are used throughout for increased strength and

durability. Used in applications that have clean air, process

exhaust or high temperature ventilation.

High Performance Axial, Direct Drive

Model AX

Compact axial fan with a high efficiency airfoil blade designed to

decrease energy requirements and lower sound levels. Blade

pitch can be adjusted for onsite balancing. Direct drive

construction reduces maintenance. Casing options include

standard length, shorter casing for wall mounting and also a

bolt-on vane section for increased pressure capabilities.

Medium Pressure Axial, Belt Drive

Model TBI

TBI series of fans features two different impeller types; cast

aluminum and fabricated steel. Cast aluminum hub and blades

provide spark resistant construction and manual adjustability for

on-site balancing. Heavy duty fabricated steel impellers are used

for applications that include elevated airstream temperatures or

smoke exhaust.

Mixed Flow, Inline

Model QEI and QEID

Mixed flow fans have the advantage of both high efficiency and

low sound levels in an inline fan. Integral air straightening vanes

and venturi inlet improve the fan performance.

Full line of accessories

All models have as available options:

• Guarding for inlets, outlets and drive components • Inlet bells

• Silencers to reduce noise (AX, TBI, QEI, QEID) • Companion flanges

• Isolators to reduce vibration transmission

Page 12

HVAC Control and

Manual Balancing Dampers

Greenheck warrants this equipment to be free from defects in material and workmanship

for a period of one year from the purchase date. Any units or parts which prove defective

during the warranty period will be replaced at our option when returned to our factory,

transportation prepaid. Motors are warranted by the motor manufacturer for a period of one

year. Should motors furnished by Greenheck prove defective during this period, they should

be returned to the nearest authorized motor service station. Greenheck will not be

responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to

change specifications without notice.

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Copyright © 2004 Greenheck Fan Corp.

Marine Products Rev. 1 November 2004 SP

Our Warranty

The Greenheck Advantage

• Commercial & Industrial Control Dampers

• Fire, Smoke, and Combination Fire Smoke Dampers

• Ceiling Radiation Dampers

• Backdraft Dampers

• Pressure Relief Dampers

• Manual Balancing Dampers

• Access Doors

• Marine Dampers

• Severe Environment Dampers

• Industrial Smoke Damper

• Insulated Thermally Broken Dampers

• Mechanical and Architectural Louvers

• Miami-Dade Louvers

• Wind-Driven Rain Louvers

• Thinline Louvers

• Sightproof Louvers

• Adjustable Louvers

• Acoustical Louvers

• Fabricated Louvers

Complete and Innovative

Dampers & Louvers

Product Offering!

• Combination Louver/Dampers

• Louver Penthouses

• Architectural Sunshades

• Equipment Screens

• Architectural Grilles

• Brick Vents

• Specialty Shapes

• Material Handling

• Industrial Process

• Paint Booths

• Emergency Smoke Exhaust

• Marine Duty

• Tunnel Ventilation

• Grease Exhaust

• Laboratory Fume Exhaust Systems

• Air Handlers

• High Temperature

• General Ventilation

Top Quality Ventilation...

Centrifugal Fan Product Offering!

®

Loading...

Loading...