Page 1

Modular Make-Up Air Unit

with Integral Packaged DX Cooling

for Models DGX, IGX and MSX

• KitchenVentilation

Applications

• 1,000to7,500cfm

• 3-16NominalCoolingTons

• DirectorIndirectGas,Hot

Water,orElectricHeating

• OptionalVariableAirVolume

(VAV)

Providing unconditioned make-up air through

ceiling diffusers or perforated kitchen hood

plenums can create an uncomfortable work

environment during summer months in

commercial kitchens. Although conditioned

make-up air can increase comfort levels, the

need to cool and dehumidify this air to a 55°F

supply air temperature can be detrimental

to the food preparation process and can

significantly increase equipment first cost.

The packaged DX cooling option for the

DGX, IGX, and MSX models is designed to

cool the kitchen make-up air to a 70-75°F

supply air condition to improve space comfort

and enhance employee productivity…at an

economical first cost.

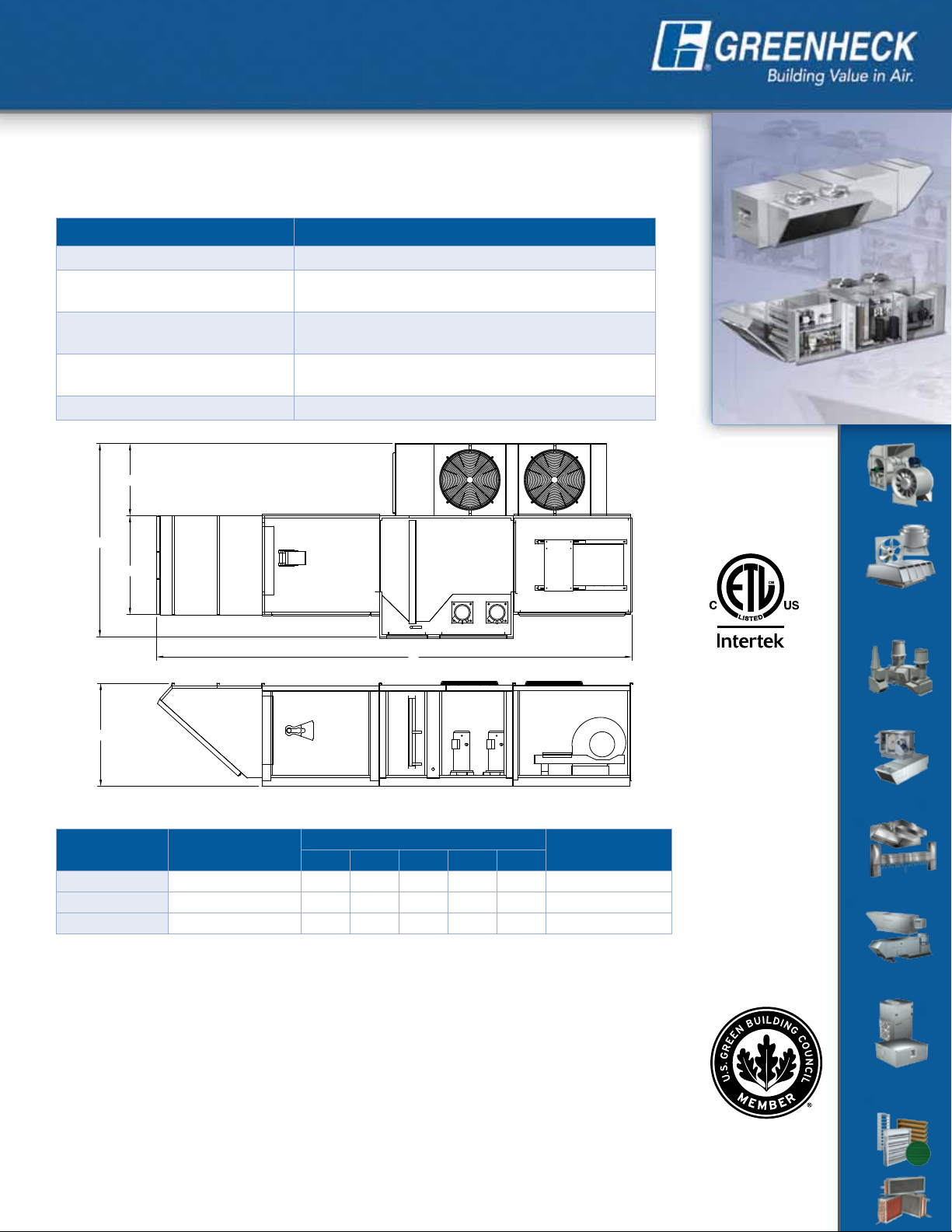

Direct Gas-Fired unit with

Integral Packaged DX Cooling

Condenser fans

are efficient, directdrive, statically and

dynamically balanced.

Condenser and Evaporator

Coils have copper tubes

with permanently expanded

aluminum fins. Evaporator coils

are mounted on a stainless

steel drain pan.

Thermal Expansion Valves

provide refrigerant control.

Head pressure control provides

further control at low–load

conditions.

Compressors are quiet-

running, hermetic scroll-type.

They are mounted in an isolated

compartment to be serviceable

without affecting airflow, and

are mounted on neoprene

isolators to minimize vibration

transmission and noise.

April

2011

Page 2

Features and Benefits

The packaged DX systems available with DGX, IGX and MSX products are designed

specifically for providing comfortable supply air conditions for commercial kitchen

applications. The pre-engineered package is piped and charged at the factory,

providing single-source responsibility and reduced installation costs.

Standard Feature Benefit

R-410A refrigerant Environmentally friendly.

High pressure manual reset

Low pressure automatic reset

Liquid line filter-dryer

Service / charging valves

Sight glass / moisture indicator Provides a view into the system.

C

Ensures the refrigeration system will operate in a safe

performance range.

Removes water, debris and other contaminants from

the refrigerant.

Simplified maintenance resulting in lower maintenance

costs.

D

B

A

E

Dimensional Data

HousingSize NominalTons

Dimensions(inches)

A B C D E

DGX-H12 3, 5, 6, 7 156 33.75 25.5 70 39 1400

DGX-H22 7, 9, 10 212 45 32 87 45 2200

DGX-H32 10, 12, 16 237 52 35.5 99 49 2800

The dimensional data shown is for a standard direct gas-fired unit with a filtered intake hood. Additional

configurations are available through Greenheck’s Computer Aided Product Selection program.

Approximate

Weight(lbs)

The ETL Listed

Mark is accepted

as a product’s mark

of compliance

to applicable

electrical, gas

and other safety

standards.

Intertek is an

OSHA recognized

NRTL (Nationally

Recognized

Testing Laboratory)

and accredited

as a Testing

Organization and

Certification Body

by the Standards

Council of Canada.

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of

one year from the shipment date. Any units or parts which prove defective during the warranty period will

be replaced at our option when returned to our factory, transportation prepaid. Motors are warranted by

the motor manufacturer for a period of one year. Should motors furnished by Greenheck prove defective

during this period, they should be returned to the nearest authorized motor service station. Greenheck will

not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

Greenheck Fan Corp. • P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • www.greenheck.com

00.TAP.NB006 R1 4-2011 RG • Copyright © 2011 Greenheck Fan Corp.

Prepared to Support

Green Building Efforts

Loading...

Loading...