Page 1

Kitchen Ventilation Systems

Controls and Energy Management

• Relay Box • Temperature Interlock

• Fan Control Center • Variable Volume Systems

September

2009

Page 2

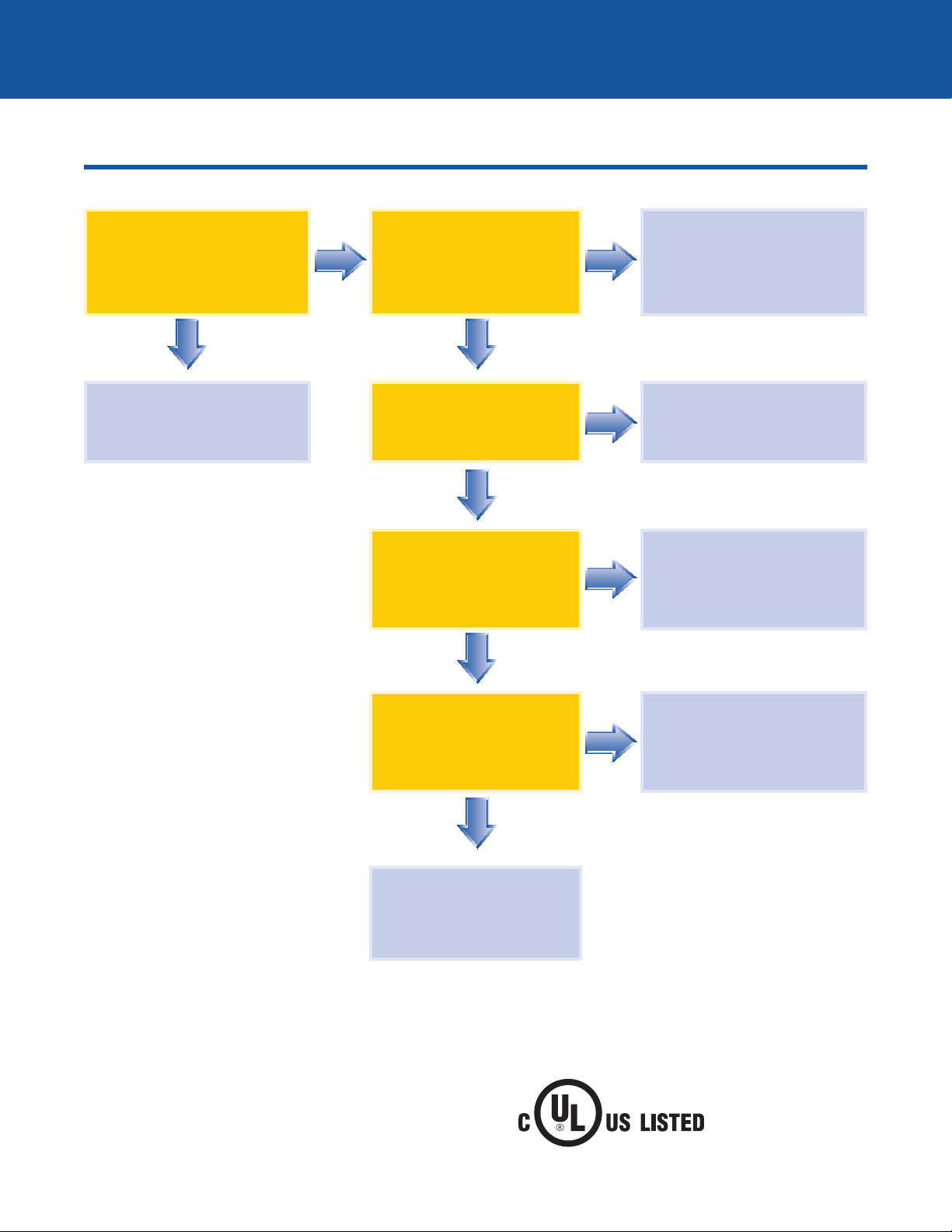

Control Decision Guide

No

No

No

No

No

Which Control is Right For Your Application?

Do you want to start and

stop your fans via a prewired

control package?

No

Field wired or optional

factory mounted switches.

Yes

Do you want the system

to vary the exhaust and

supply rates based on the

cooking load?

No

Do you ONLY require a

temperature interlock

to comply with IMC

507.2.1.1?

No

Do you require factory

prewired options such

as exhaust on in fire,

temperature interlock (IMC

507.2.1.1), etc?

No

Yes

Yes

Yes

Greenheck Vari-Flow System

or Melink Intelli-Hood

System

(Both systems comply with *IMC 507.2.1.1)

Temperature Interlock

Kitchen Fan Control Center

(KFCC)

IMC International Mechanical Code

Do you have:

• More than two fans?

• 3-phase motors?

• The need for thermal

overloads?

No

Relay Box

Yes

Kitchen Fan Control Center

(KFCC)

All Greenheck controls are UL Listed to

Standard 891 or 710 as it applies.

2

Page 3

3

Greenheck’s relay box is compact, prewired and offers a low-cost method of starting one or several single-

phase fan motors. The relay box can be used in place of larger, more expensive starters.

All

Greenheck Controls

When switches are moved to the on position, lights turn

Relay Box

Standard Construction Features

Requirements:

Limitations:

Temperature Interlock

Standard Construction Features

Page 4

Volt or 120Volt.

Greenheck Controls

When switches are moved to the on position, motor

Kitchen Fan Control Center (KFCC)

Standard Construction Features

Kitchen Fan Control Center Options

Exhaust on in Fire Mode —

Trim Ring —

Removal of Starter When Supplied in Unit —

Up To 2 Status Lights —

Up To 2 Extra Fire Relays —

Lights Out in Fire —

Supply Fan Failure Indicator Light —

Exhaust Fan Failure Indicator Light —

Single Light/Fan Switch —

Power For Shunt Trip —

Automatic Damper Switch —

Temperature Interlock —

Page 5

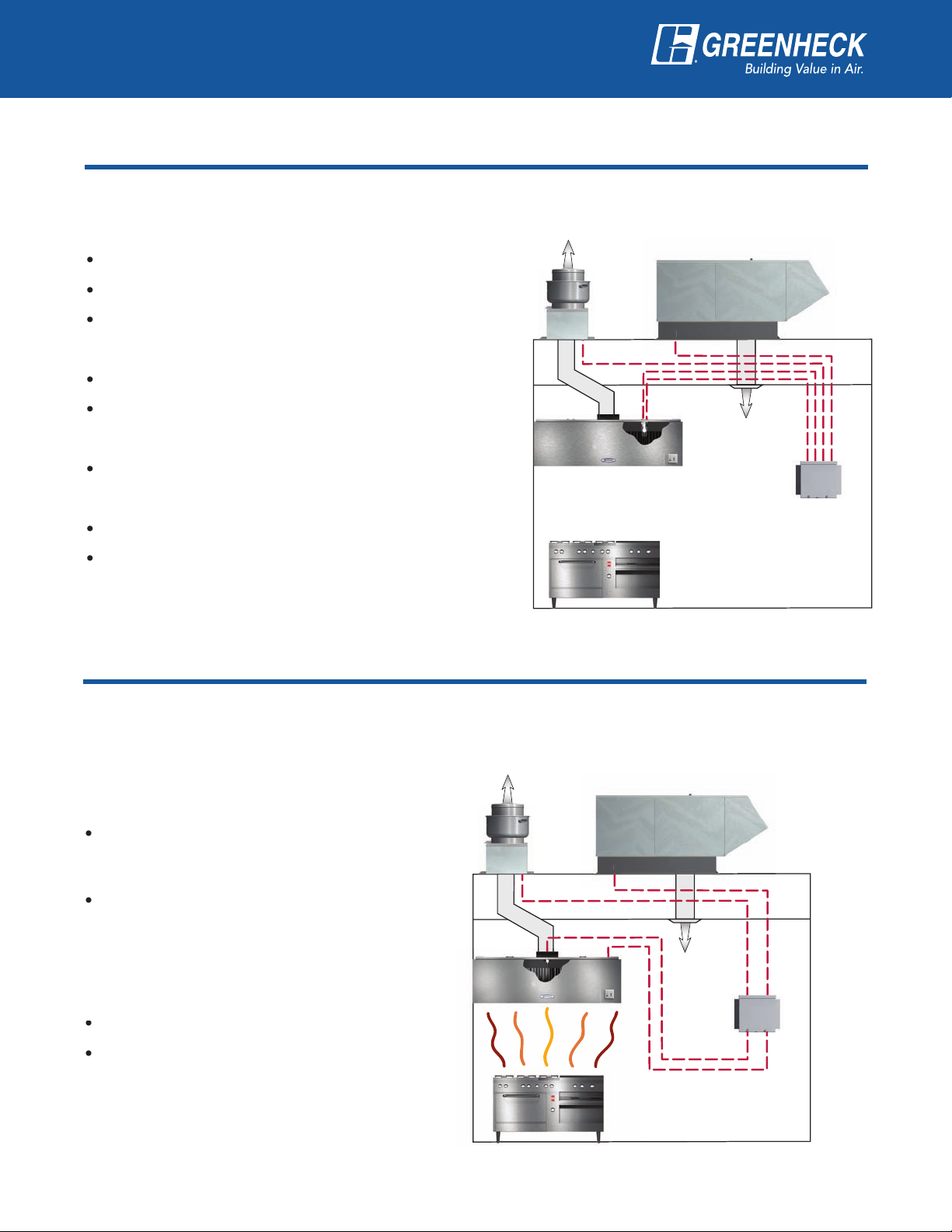

Greenheck Controls

Variable Volume

Greenheck offers variable volume ventilation systems that track the cooking load and vary the exhaust

and supply ventilation based on demand. Since the cooking load varies throughout the day, your exhaust

system doesn’t need to run at the maximum exhaust air volume all day. Greenheck understands that by

varying the speed of the fans based on the cooking load, you will save money by reducing power and

heating and cooling costs. See figures 1 and 2 below.

Standard Construction Features

• The system monitors the cooking operation and adjusts the exhaust and supply unit fans so that when the

cooking load is reduced, the fans operate at a reduced level providing energy savings

• Satisfies International Mechanical Code 507.2.1.1 requirement to start fans when cooking

operationsoccur

• System is prewired, UL Listed and includes wiring diagrams

Payback:

• Typical payback of 1 to 3 years

• Improved efficiency by reducing fan speed

Additional Benefits:

• Ventilation equipment life is extended by soft-starting starting fans, therefore reducing stress on belts

and bearings

• Reduced sound levels to improve customer and employee comfort

The charts below are an example of how the cooking load in a typical restaurant varies

throughout the day and how the variable volume system can generate money savings.

Variable Volume Matches Airflow to Cooking Load

100%

100%

$ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $

$ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $

$ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $

80%

80%

$ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $

$ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $

$

$ $ $ $ $

60%

60%

$ $ $ $ $

CFM

40%

40%

20%

20%

0%

0%

Breakfast

Lunch

Dinner

11109876543211211109876

11109876543211211109876

Operating Hours

= Variable Volume

100%

80%

60%

CFM

40%

20%

0%

Constant Volume Design Airflow

Breakfast

Lunch

Dinner

Operating Hours

= Constant Volume

11109876543211211109876

Figure 1 — The cooking load throughout the day varies

significantly. However, the kitchen only requires maximum

ventilation for a small percentage of the day. The shaded

area represents the savings potential for a variable volume

system. The dashed red line is showing fan operation at

100% regardless of cooking load.

Figure 2 — A variable volume system will track the

cooking load (dashed red line) and vary the exhaust

and supply ventilation. The area above the red line

represents energy savings.

5

Page 6

Greenheck Controls

When as little as seven percent of the optics infrared beam is blocked the exhaust

Greenheck Vari-Flow Air Management System

Standard Construction Features

• ExceptionalValue—

• SpacePressureControl—

• 5TimesQuickerResponse—

• FullyModulatingTurndownupto50%—

Melink Intelli-hood System

Standard Construction Features

HOOD

LIGHTS

FAN

ON/OFF

FAN

100%

SYSTEM

FAULT

472621

• SecondaryOpticSensors—

• ProfessionalStart-upintheField—

• Easily Accommodates Larger Systems —

• FullyModulatingTurndownupto50%—

Page 7

Greenheck Controls

Which Variable Volume System is best for your application?

Greenheck

System Decision Matrix

Factory Installed System

IMC 507.2.1.1 Compliant

Full Fan Speed Override

Supply Controlled by Space Static Pressure

Supply Controlled Proportionally Optional

Professional Start-up by Factory Representative

Lower Cost

Secondary Optic Sensors for

smoke and steam

Small to Medium Size Applications

Large or Steam Intensive Applications

Vari-Flow

System

n n

n n

n n

n

n

n

Looking to Decrease the Payback Period?

Melink

Intelli-hood

System

n

n

n

n

Fully

Modulating

Turndown up

to 50%

Many state and local governments offer rebate and credit programs that the Vari-Flow Air Management

System and Melink Intelli-hood system may qualify for. Rebates can decrease the upfront cost of

thesystems.

Going for LEED™ Certification?

The Vari-Flow Air Management System and the Melink Intelli-hood system align with the following

LEEDcredits and may contribute toward earning up to two LEED credits.

Innovation and Design Process

• ID Credit 1 – Innovation in Design

Energy and Atmosphere

• EA Credit 1 – Optimize Energy Performance.

7

Page 8

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

Prepared to Support

to mechanical engineers by

their clients face with a

top quality, innovative air-

And building owners and

they experience long after the

Copyright © 2009 Greenheck Fan Corp.

September

2009

Kitchen Ventilation Systems

Controls and Energy Management

• Relay Box • Temperature Interlock

• Fan Control Center • Variable Volume Systems

Kitchen Ventilation Systems

• ExhaustHoods&GreaseExtraction

• FireSuppressionSystems

• Accessories

September

2009

Kitchen Ventilation Systems

Kitchen Ventilation Systems

Utility Distribution Systems

October

2009

Building Value in Air

Our Warranty

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Loading...

Loading...