Page 1

Seismic Solutions

Fan Ratings Information

December

2010

Page 2

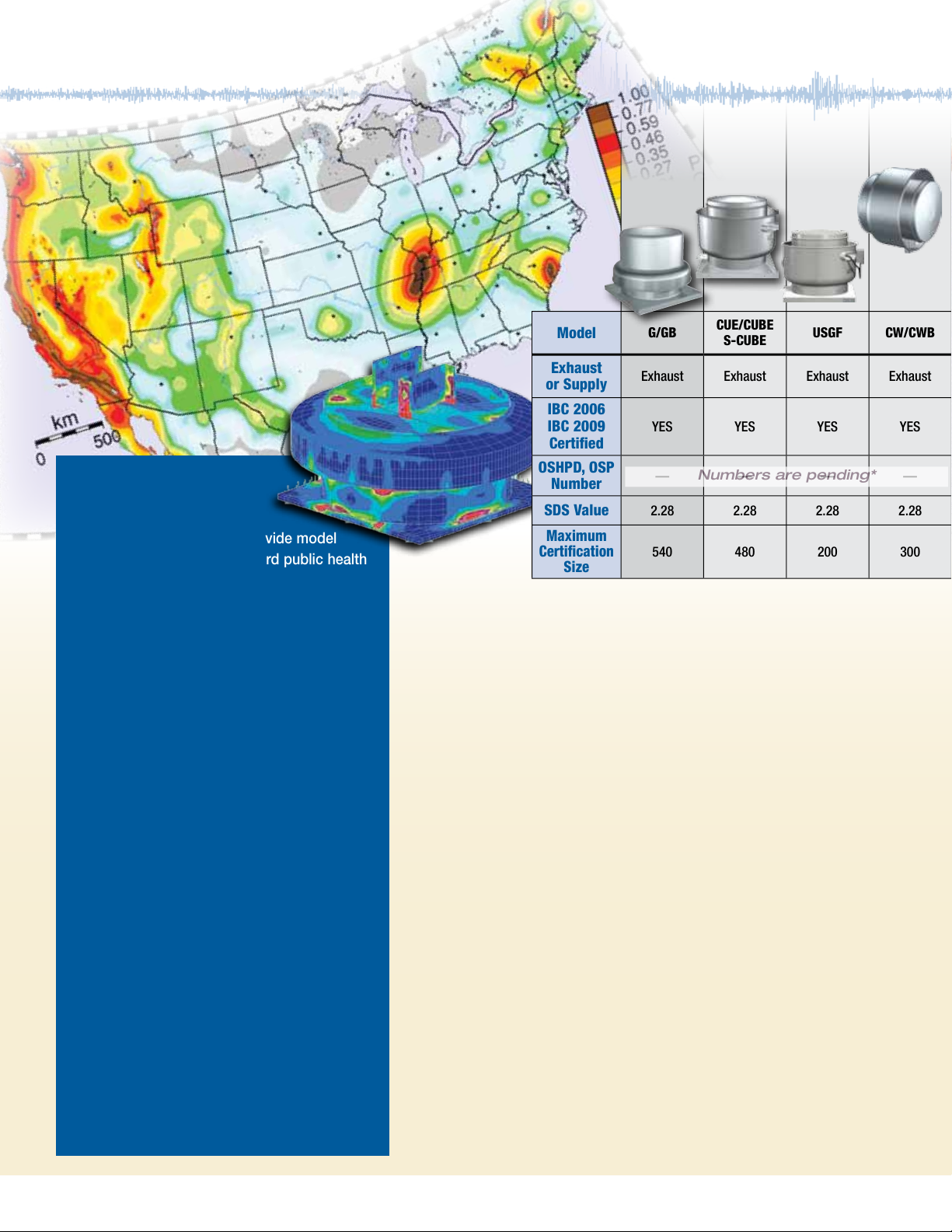

Seismic Rated Fans

Model

G/GB

CUE/CUBE

S-CUBE

USGF CW/CWB SQ/BSQ RSF/RSFP RBUMO R Series

SFD/SFB

SWB

AFSW/BISW AFDW/BIDW QEI/QEID QEM/QEP LFC Vektor-H

Exhaust

or Supply

Exhaust Exhaust Exhaust Exhaust

Exhaust or

Supply

Supply Exhaust

Exhaust or

Supply

Exhaust or

Supply

Exhaust or

Supply

Exhaust or

Supply

IBC 2006

IBC 2009

Certified

YES YES YES YES YES YES YES YES YES YES YES YES YES YES

OSHPD, OSP

Number

— — — —

0113-10 0113-10 0113-10 0113-10 0113-10 0113-10

—

SDS Value

2.28 2.28 2.28 2.28 2.28 2.28 2.28 2.28 2.28 2.28 2.28 2.28 2.28 1.50 2.28

Maximum

Certification

Size

540 480 200 300 420 200 60 72

SWB 236

SFD - 10

SFB - 30

73-AFSW

73-BISW

Class II

73-AFDW

73-BIDW

Class III

Numbers are pending*

Overview

The International Building

Code (IBC) is designed to provide model

code regulations that safeguard public health

and safety in communities across the United

States. The 2006 IBC is the latest version of

outlined standards intended to improve the

performance and design of non-structural

systems subject to seismic events.

The Office of Statewide Health Planning

and Development (OSHPD) is one division

within the California Health and Human

Services Agency assigned to assure the

safety of health care buildings. Though

OSHPD enforces building standards for health

care facilities per the California Building

Code (CBC), this code closely reflects the

standards presented by the IBC.

Standards in the IBC and the CBC expand the

emphasis for position retention of equipment

and emphasize maintaining equipment

functionality following a seismic event.

As an industry leader, Greenheck

manufactures seismic certified products that

maintain structural integrity during and after

a seismic event.

Basic information on seismic certification

and how our products meet these needs are

provided here.

Structural

Finite Element

Analysis of GB Fan

* Final certification due to be completed by March of 2011

Who needs Seismic Certification?

Seismic requirements for a project are made when the

structural engineer assigns a seismic rating to the building.

This rating should be stated on the structural plans. Unless

noted otherwise, non-structural components (which include

mechanical equipment) are assigned the same seismic

requirements as the building. The 2009 IBC states:

Every structure, and portion thereof, including non-structural

components that are permanently attached structures and their

supports and attachments, shall be designed and constructed to

resist the effects of earthquake motions in accordance with ASCE-7.

This includes components required to function for life-safety

purposes or components in essential facilities where failure

could impair continued operation of the facility after a seismic

event (Importance Factor of 1.5).

How are Greenheck products

seismically certified?

Section 1708.4.1 of the 2009 IBC, Seismic certification of

non-structural components, states:

Certification shall be based on an actual test on a shake table,

by three-dimensional shock tests, by an analytical method using

dynamic characteristics and forces, by the use of experience data

(i.e., historical data demonstrating acceptable seismic performance)

or by more rigorous analysis providing for equivalent safety.

22

Page 3

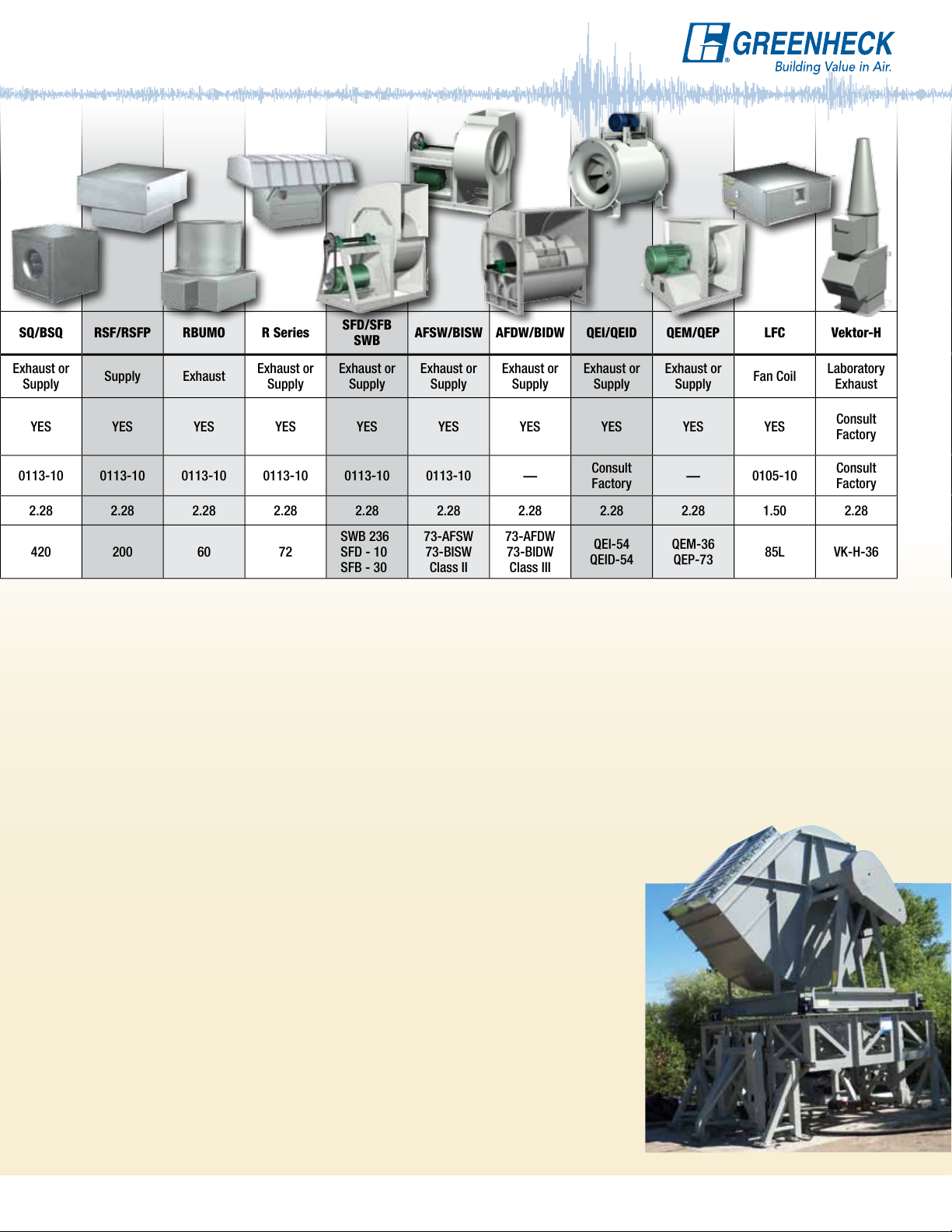

Seismic Certifications

SFD/SFB

SWB

AFSW/BISW AFDW/BIDW QEI/QEID QEM/QEP LFC Vektor-H

Exhaust or

Supply

Supply Exhaust

Exhaust or

Supply

Exhaust or

Supply

Exhaust or

Supply

Exhaust or

Supply

Exhaust or

Supply

Exhaust or

Supply

Fan Coil

Laboratory

Exhaust

Consult

Factory

0113-10 0113-10 0113-10 0113-10 0113-10 0113-10

—

Consult

Factory

—

0105-10

Consult

Factory

SWB 236

SFD - 10

SFB - 30

73-AFSW

73-BISW

Class II

73-AFDW

73-BIDW

Class III

QEI-54

QEID-54

QEM-36

QEP-73

85L VK-H-36

To meet the 2006 IBC, 2009 IBC and OSHPD

requirements, Greenheck’s seismic certified fans

have been shake table tested at an independent test

facility. This is in accordance with ICC-ES AC 156

and under the responsible charge and review of a

California Structural Engineer. The tests simulate the

most severe seismic conditions anywhere in the United

States and include the most severe spectral response

accelerations, an Importance Factor of 1.5, all Site

Classes, all Occupancy Categories, and all Seismic

Design Categories.

Because these units are physically subjected to the

same forces produced during an earthquake, you’re

assured they will operate after a seismic event without

problems—thus allowing Greenheck Seismically

certified fans to be used anywhere in the United States.

While OSHPD standards were originally developed

for health care facilities, they are also being required

on projects outside of health care when specifying

engineers and building owners want to ensure certified

equipment is received. Equipment that’s passed

OSHPD Special Seismic Certification Pre-approval

(OSP), is listed on the OSHPD website providing

engineers with a convenient source for seismic

certified equipment.

Note: Greenheck’s seismically certified equipment is

summarized above.

Fan mounting packages

Seismically rated GPF and severe duty (SD) curbs are

offered on all curb mounted models to provide you with

a complete seismic solution. On non-curb mounted

models, individually sized and seismically certified

isolators can be provided for each individual fan based

on weight and size requirements.

Seismic Solutions

Greenheck Fan Corporation adheres to rigorous

testing standards and strives to

provide the most

comprehensive

selection

of equipment

available to

address the

HVAC industry’s

seismic needs.

The submittal

process is simple—

the consulting

engineer just

needs to specify

IBC or OSHPD

seismic compliant

equipment.

333

PHOTO BY ANCO ENGINEERS, INC.

73-AFSW fan being shake table tested..

Page 4

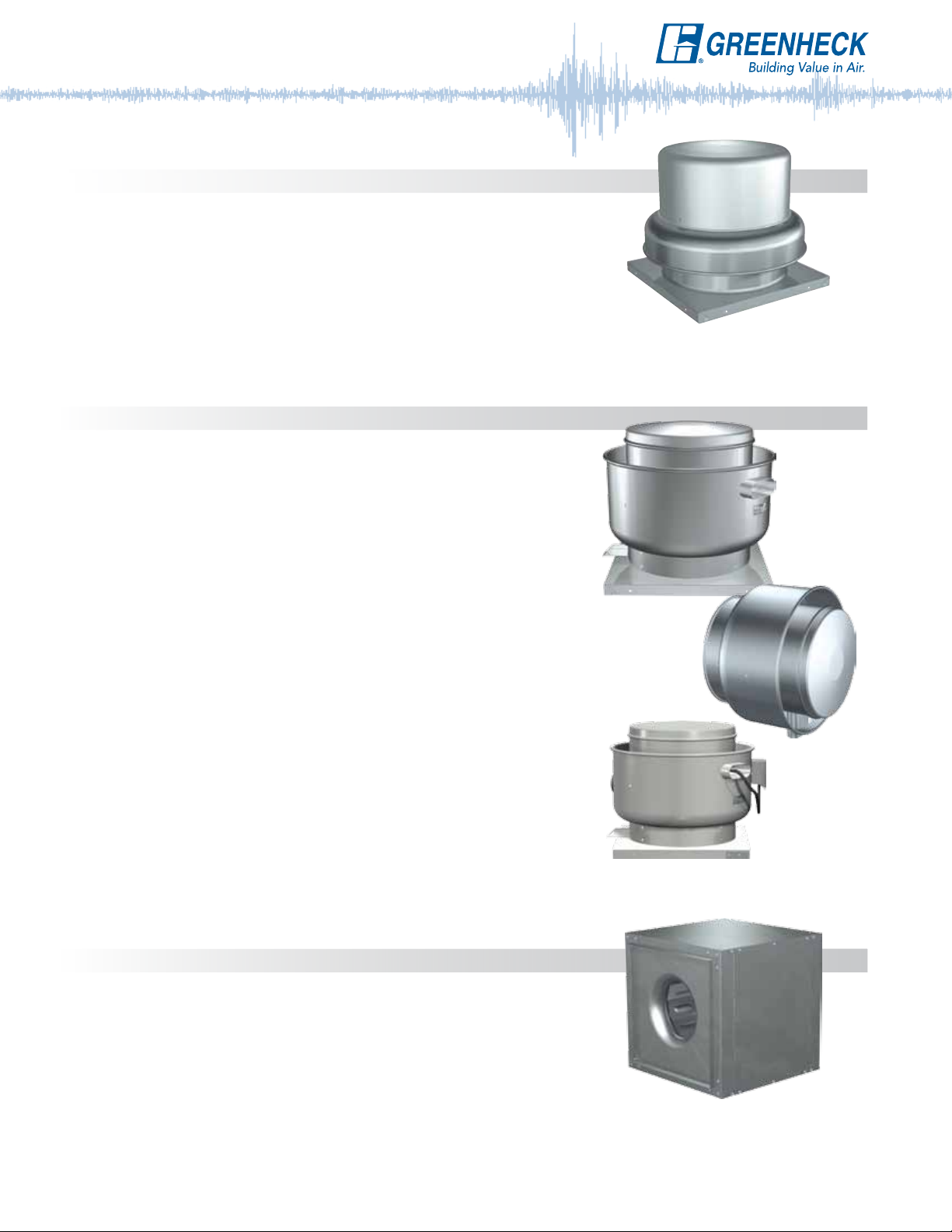

Fan Models

Model G and GB

Centrifugal Roof Exhaust

G (direct drive) and GB (belt drive) are centrifugal roof exhaust fans

designed specifically for seismic applications. The downblast design is

ideal for general clean air applications where air is discharged directly onto

the roof surface. Certified to IBC 2006 and 2009, ASCE 7-05 and California

OSHPD certification standards for all seismic design categories.

Model CUE, CUBE, S-CUBE, USGF, CW and CWB

Centrifugal Upblast Exhaust

CUE (direct drive), CUBE and S-CUBE (belt drives)

Upblast roof exhaust fans designed specifically for seismic applications.

The upblast design is ideal for restaurant (grease laden), general clean air,

smoke and mild contaminates (fume hood) where air is discharged away

from the mounting surface. Certified to IBC 2006 and 2009, ASCE 7-05

and California OSHPD certification standards for all seismic

design categories.

CW/CWB

These spun aluminum fans are specifically designed for sidewall mounted

applications. General clean or lightly contaminated exhaust air can be

discharged directly away from the mounting surface. Certified through

analysis to IBC 2006 and 2009 and ASCE 7-05 certification standards

for all seismic design categories.

USGF (belt drive)

The only spun steel fan in the industry for heavy-grease applications (as

stated in NFPA96 Vapor Removal from Cooking Equipment). Specifically

designed for severe grease applications, to remove high amounts of grease

and/or solid fuels and to discharge air directly away from the mounting

surface. Seismic certified through analysis to IBC 2006 and 2009 and

ASCE 7-05 certification standards for all seismic design categories.

Model SQ and BSQ

Centrifugal Inline Fans

SQ (direct drive) and BSQ (belt drive) are backward inclined centrifugal

fans designed for clean air applications (intake, exhaust, return or make-up

air systems) where space is a prime consideration. Multiple mounting and

discharge options allow for flexibility in design and installation. Certified

to IBC 2006 and 2009, ASCE 7-05 and California OSHPD certification

standards for all seismic design categories.

44

Page 5

Fan Models

Model RSF and RSFP

Centrifugal Roof Supply Penthouse Style

Models RSF and RSFP are untempered filtered centrifugal supply fans.

RSF and RSFP are designed to provide unrestricted clean air airflow and

maximum weather protection. Certified to IBC 2006 and 2009, ASCE 7-05

and California OSHPD certification standards for all seismic

design categories.

Models RBUMO

Propeller Upblast Roof Fan

This upblast propeller fan is designed to discharge contaminants up and

away from the building for most commercial jobs and many industrial

applications. The RBUMO has the motor out of the airstream, which allows

for high temperature air to be exhausted. Certified to IBC 2006 and 2009,

ASCE 7-05 and California OSHPD certification standards for all seismic

design categories.

Models R and RB

Hooded Propeller Roof Fans

Hooded propeller roof fans include both belt and direct drive fans with

fabricated steel, fabricated aluminum or cast aluminum blades. A variety

of model configurations are available to handle exhaust and supply

requirements. Belt drive fans offer the ability to adjust fan speed for system

balancing if necessary. Direct drive fans are often preferred for jobs where

maintenance access is difficult. They can operate from general ventilation

up to industrial duty applications with airstream temperatures up to

130°F (54˚C). Certified to IBC 2006 and 2009, ASCE 7-05 and California

OSHPD certification standards for all seismic design categories.

Models SWB, SFB, and SFD

Centrifugal Blowers

SWB is a backward inclined centrifugal fan designed to handle a variety

of applications that include clean air, high temperatures, restaurant

grease, lab exhaust and high temperature smoke.

SFB and SFD are belt and direct driven forward curved utility set fans.

Designed for clean air applications where high efficiency is needed.

Certified to IBC 2006 and 2009, ASCE 7-05 and California OSHPD

certification standards for all seismic design categories.

555

Page 6

Fan Models

Models BISW and AFSW

Centrifugal Blowers

Greenheck’s airfoil (AFSW) and backward inclined (BISW) centrifugal fans

are designed to handle a variety of commercial and industrial applications

including: general supply, return or exhaust systems, emergency smoke

exhaust, restaurant grease exhaust, process heat exhaust, filtration, dust

collectors, built up or custom air handlers, grain drying, and corrosive

fume exhaust.

Seismic certified single wide centrifugal blowers for sizes 7-73, series 21

and 41, arrangements 9 and 10, class I and II.

Certified to IBC 2006 and 2009, ASCE 7-05 and California OSHPD

certification standards for all seismic design categories.

Models AFDW and BIDW

Double Width Centrifugal Blowers

Greenheck’s double inlet, double width airfoil (AFDW) and backward

inclined (BIDW) centrifugal fans are designed to handle a variety of

commercial and industrial applications including: general supply, return or

exhaust systems, and built up or custom air handlers.

Models AFDW and BIDW are seismic certified for sizes 07 to 73

arrangements # 3, classes I through III.

Model AFDW and BIDW fans were certified compliant per IBC 2006 and

2009 and ASCE 7-05 via analysis

Models QEI and QEID

Mixed Flow Fans

Mixed flow inline fans are more efficient than comparably sized tubular

centrifugal and vane axial fans, thus reducing the required motor

horsepower and lowering operating costs.

Greenheck’s mixed flow fans are recommended for any ventilation

application (supply, exhaust, or return) that requires low sound and high

efficiency including: office buildings, parking garages, concert halls,

libraries, educational facilities, emergency smoke exhaust, restaurant grease

exhaust, and much more.

Models QEI and QEID are seismic certified for sizes 15 to 54 in

arrangements # 4 and # 9 and roof upblast configuration.

Model QEI and QEID fans are currently certified compliant per IBC 2006

and 2009 and ASCE 7-05 via analysis. Consult factory for certification per

shake table testing.

666

Page 7

Fan Models

Models QEM and QEP

Plenum Fans

Plenum fans are designed for unhoused operation in commercial or

industrial applications. Typical applications include: parking garages,

packaged air handlers, built-up air handlers, custom air handlers, general

supply and return systems.

Model QEM is seismic certified for sizes 12 to 36 arrangements # 4 and # 9.

Model QEP is certified for sizes 12 to 73, classes I through III in horizontal

arrangements # 3 and # 4.

Model QEM and QEP fans were certified compliant per IBC 2006 and 2009

and ASCE 7-05 via analysis.

Model LFC

Low Profile Fan Coil

Model LFC is a low-profile fan coil unit that provides an effective, low-cost

method to air conditioning and heating. Product features include forwardcurved fans with internal flexible connection, double wall construction, and

up to 8 row cooling coils. The LFC is designed for commercial applications

including schools, medical facilities, and office buildings.

Models LFC-20 though LFC-85 are certified to IBC 2006 and 2009, ASCE

7-05 and California OSHPD certification standards for suspended mounting

arrangements for all seismic design categories.

Consult factory for mounting arrangements.

Model Vektor-H

Laboratory Exhaust Fans

Model Vektor-H uses a tapered outlet nozzle to accelerate the exhaust to

a high velocity. This provides the exhaust with additional momentum for

displacement high above the roof. Because the Vektor-H is a curb-mounted

unit, installation time is reduced by eliminating costly field fabricated

inlet and outlet duct. The bypass air plenum and damper accommodates

constant anmd variable volume laboratories.

The Vektor-H and roof curb has been designed to withstand 125 mph wind

loads without the use of guy wires. Capacities range from 500 to 24,000

cfm (850 to 40,766 m3/hr) and 3.5 in. wg (868 PA). UL 762 listed. AMCA

Licensed for Sound and Air Performance.

Consult Factory for seismic certification.

777

Page 8

Anchoring

Roof Curb to Roof Deck

Anchoring Requirements

Corner Detail

Wood, Metal or Concrete

Roof Curb to Roof Deck Anchoring Requirements

Fan Model Fan Size Curb Cap Size

G, GB 060 to 300

G, GB 330 to 540

CUE, CUBE, S-CUBE,

USGF

CUE, CUBE, S-CUBE,

USGF

CUE, CUBE, S-CUBE,

USGF

060 to 240

300 to 360

420 to 480

R/RB 18 to 24

R/RB 30 to 36

R/RB 42

R/RB 48 to 54

R/RB 60 to 72

RSF/RSFP 90 to 120

RSF/RSFP 150

RSF/RSFP 180 to 200

RBUMO 20 to 30

RBUMO 36 to 42

RBUMO 48 to 60

Note: Fasteners required only on two opposite sides of curb. Fasten on longer sides of curb if rectangular.

*

17 x 17 to 40 x 40

(432 x 432 to 1016 x 1016 mm)

46 x 46 to 64 x 64

(1168 x 1168 to 1626 x 1626 mm)

17 x 17 to 34 x 34

(

432 x 432

to 864 x 864)

40 x 40 to 46 x 46

(1016 x 1016 to

1168

x

1168

)

52 x 52 to 58 x 58

(1321 x 1321 to 1473 x 1473)

1

⁄4 x 28 1⁄4 to 34 1⁄4 x 34 1⁄4

28

(718 x 718 to 870 x 870 mm)

1

⁄4 x 40 1⁄4

to 46 1⁄4

⁄4

x 52 1⁄4

to 64 1⁄4

to 82 1⁄2

x 46 1⁄4

x 64 1⁄4

x 82 1⁄2

40

(1022 x 1022 to 1175 x 1175 mm)

58

(1480 x 1480 to 1632 x 1632 mm)

70

(1784 x 1784 to 2095 x 2096 mm)

1

52

(1327 x 1327 mm)

1

⁄4 x 58 1⁄4

1

⁄4 x 70 1⁄4

26 x 26 to 34 x 34

(660 x 660 to 864 x 864 mm)

40 x 40

(1016 x 1016 mm)

46 x 46 to 52 x 52

(1168 x 1168 to 1321 x 1321 mm)

1

⁄2

x 291⁄2

to 39 1⁄2

to 51 1⁄2

to 72 x 72

x 39 1⁄2

x 51 1⁄2

29

(749 x 749 to 1003 x 1003 mm)

1

⁄2

x 45 1⁄2

45

(1156 x 1156 to 1308 x 1308 mm)

1

⁄2

x 57 1⁄2

57

(1461 x 1461 to 1829 x 1829 mm)

Metal Building

Steel Deck

Fasteners

per side

2 4 2 4 2 4

3 6 3 6 3 6

2 4 2 4 2 4

3 6 3 6 3 6

5 10 5 10 5 10

2 4 2 4 2 4

3 6 3 6 3 6

4 8 4 8 4 8

6 12 5 10 4 8

8 16 6 12 5 10

3 6 3 6 3 6

4 8 4 8 4 8

5 10 5 10 5 10

3 6 3 6 2 4

4 8 4 8 3 6

6 12 6 12 5 10

Total

*

Fasteners

11⁄4 inch (32 mm)

Wood Deck Concrete Deck

Fasteners

per side

Total

*

Fasteners

Fasteners

per side

11⁄4 inch

(32 mm)

Fasteners

Total

*

8

Page 9

Anchoring

18 ga. minimum steel

roof curb 8-24 in.

(203-610 mm) height.

Greenheck GPF, SD

or SDP curbs

Roof Truss

5 in. (127 mm)

Mounting Flange

1 in. (25 mm)

Insulation

Minimum

12 Ga. Steel

Roof Opening

Outside Flange

Use 5⁄16 in. (8 mm) self-drilling screws or equal Fasteners

one on each corner as detailed.

Each side at center of unit. Maximum fastener spacing

of 8 in. (203 mm), add additional fasteners to satisfy.

Corrugated

Roof Deck

Center fasteners

on flange

Metal Building Steel Deck

18 ga. minimum steel

roof curb 8-24 in.

(203-610 mm) height.

Greenheck GPF, SD

or SDP curbs

Wood Decking

Wood Support Member

Nominal 4 x 4, 6, 8

18 ga. minimum steel

roof curb 8-24 in.

(203-610 mm) height.

Greenheck GPF, SD

or SDP curbs

Minimum Concrete

Strength of 2000 PSI

5 in. (127 mm) Mounting Flange

1 in. (25 mm)

insulation

5 in. (127 mm)

Mounting Flange

Minimum 1

(44 mm) edge distance

Roof Opening

Outside Flange

Roof Opening

3

⁄4 in.

Outside Flange

Spun aluminum and RSF/RSFP, 3⁄8

−R-Series and RBUMO,

into minimum No. 1/No. 2 southern pine wood support.

Fasteners one on each corner as detailed.

Each side at center of unit. Maximum fastener spacing

of 6 in. (152 mm), add additional fasteners to satisfy.

Center fasteners

on flange

3

⁄8 in. (10 mm) Hilti Kwik Bolt 3 expansion anchors

Use

or equal into concrete.

Fasteners one on each corner as detailed.

Each side at center of unit. Maximum fastener spacing

of 8 in. (203 mm), add additional fasteners to satisfy.

2

Recommended

minimum 1

Center fasteners

on flange

in. (10 mm) lag screws

7

⁄16

in. (83 mm) lag screws or equal

Spun aluminum

(83 mm)−R-Series/RBUMO,

1

⁄2 in. (89 mm) minimum

3

embedment

1

⁄2 in. (64 mm) Embedment

RSF, 31⁄4 in.

5

⁄8 in. (41 mm)

Wood Deck

Concrete Deck

9

9

Page 10

Roof Curbs

Roof Curbs

Greenheck seismically certified fans are designed

for easy mounting to a variety of roof curbs. For your

convenience Greenheck offers the industry’s largest

selection of tested and approved seismic roof curbs.

Greenheck Models GPF, GPFP, GPFV, SD and SDP

curbs offer fully configurable sizes for both flat and

pitched roofs. Selectable in sizes up to 80 x 80 inches

(2032 x 2032 mm) and heights ranging from 8 inches (203

mm)

to 24 inches (610 mm) tall.

For applications where factory supplied curbs are not

an option, the Greenheck seismic certified fans can

be used in conjunction with any previously installed or

customer supplied curbs as long as they meet a series

of minimum requirements. Considerations like

no wood nailers, minimum material gauges and specific

material types may allow field supplied curbs to

be acceptable.

GPFV

The GPFV vented roof curb is typically used for kitchen

applications; the vents allow hot air and gases to

escape between the ductwork and roof curb. This curb

is designed for use with Greenheck fan models CUBE

and CUE to provide the required 40 inch

minimum discharge height above the roof line per

NFPA 96. This curb is to be used on non-insulated flat

roof decks. Model GPFV is mounted directly to the roof

deck structure, roofed to the vertical surface and sealed

to the 5-inch flashing flange. It is available in nine

different sizes.

(1016 mm)

GPF

The GPF is a straight sided curb constructed of heavy

gauge galvanized steel with a 5-inch (127 mm) flashing

flange. It is designed specifically for use in seismic

applications on flat roofs. Roofing material can be

wrapped up over the top of the curb or can be directly

flashed to the side of the curb for a complete tested and

certified installation.

GPFP

The GPFP is similar in construction to the GPF. It is

constructed of heavy gauge galvanized steel and can be

configured to match the pitch of the roof ensuring that

any fan mounted to the GPFP is going to sit level and

operate properly. The 5-inch (127 mm) flashing flange

can be used to secure the curb to the roof of metal

(steel), concrete or wood frame building and easily

flashed over to ensure weather tightness.

Special Purpose Roof Curbs

SD

The SD curb is Greenheck’s highest strength curb

constructed with a minimum 12 gauge high strength

steel. A 2-inch (51 mm) reinforcement angle is provided

on taller sizes. The fan curb is coated as standard with

our Permatector™ high performance coating (other

coatings available). The SD curb is available in heights

up to 24 inches (610 mm) and is ideal for larger and

heavier units.

SDP

The SDP curb is similar in construction to the SD.

Minimum 12 gauge steel with the 2-inch (51 mm)

reinforcements and a 4-inch (102 mm) flashing flange

make it strong and easy to install. The curb can be

configured to match the pitch of a sloped roof so that

the fans sit level on the curb. This curb is ideal for

supporting heavier, larger equipment.

1010

Page 11

Mounting

Typical Mounting

Fan to Curb - G, GB, CUE,

CUBE, S-CUBE and USGF

G/GB

CUE/CUBE, S-CUBE

and USGF

5/16 inch (8 mm) recommended, 1/4 inch (6mm)

fastener minimum. Table shows fastener requirements.

Fan to Curb Requirements

Seismic

G/GB Size

060 - 161 060 - 161 4 16

180 - 360 180 - 360 6 24

420 - 540 420 - 480 10 40

Fasteners on each side of the fan are to be installed

with one fastener 4 inches (102 mm) from each edge

and the remaining fasteners are to be equally

spaced between.

CUE/CUBE

USGF sizes

Fasteners

Per Side

Total

Fasteners

Spring Isolator

Isolators to be specified

per models below

SQ and BSQ

All mounting configurations are acceptable, however if

a unit is hung, the mounting and restraint system must

be designed by others.

Spring isolators are to be to be Mason RW30, VMC

HRS or equivalent (Certified by others).

SWB, SFB and SFD

Models must be mounted using specified spring

isolators. Isolators must be similar to those tested

and sized appropriately for the weight of the fan.

Spring isolators are to be Mason SLR, VMC AMSR

or equivalent (Certified by others).

BISW and AFSW

Models BISW and AFSW must be mounted on

a Greenheck structural steel base or base with

equivalent strength and stiffness. Fans require a

minimum of 4, seismically approved isolators, one

located at each corner of the structural base. Isolators

are certified by others. Greenheck recommends

connection between the isolators and structural base

to be with grade 8 bolt(s) and for any restraint bolts

located on the isolator to be grade 8.

RSF, RSFP, R, RB and RBUMO

Six fasteners required per side on all sizes. Fasteners

shall be 5⁄16 in. (8 mm) minimum installed one each corner

and one at center per side.

Laboratory Exhaust

For Vektor models, consult factory for mounting

requirements

LFC Fan Coil

Consult factory for mounting requirements.

11

11

Page 12

Other Severe Duty Fans

Hurricane and High Wind Fans

Models: G, GB, CUE, CUBE, S-CUBE, USGF,

R, RB, FGI, FGR, LBP, LDP, RSF, RSFP

SWB, SFB and SFD

March 2010

Hurricane and High Wind Fans

Greenheck is the first fan manufacturer to

certify products to hurricane standards and is

committed to offering the widest selection of

hurricane rated ventilation fans in the industry.

All products are third-party certified and

designed to out-perform the competition.

Greenheck will provide you with what you

need to meet the challenges for high winds

and hurricanes. See the Hurricane and High

Wind Fans brochure for detailed information.

Building Value in Air

Greenheck delivers value

to mechanical engineers by

helping them solve virtually

any air quality challenges

their clients face with a

comprehensive selection of

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

top quality, innovative airrelated equipment. We offer

extra value to contractors

by providing easy-to-install,

competitively priced, reliable

products that arrive on time.

And building owners and

occupants value the energy

efficiency, low maintenance

and quiet dependable operation

they experience long after the

construction project ends.

Seismic Rated Fans December 2010

Copyright © 2010 Greenheck Fan Corp.

Prepared to Support

Green Building Efforts

Loading...

Loading...